The Incorporation of Carboxylate Groups into

Temperature-Responsive Poly(

N-isopropylacrylamide)-Based

Hydrogels Promotes Rapid Gel Shrinking

MITSUHIRO EBARA,

1

TAKAO AOYAGI,

2

KIYOTAKA SAKAI,

1

TERUO OKANO

2

1

Department of Applied Chemistry, Waseda University, 3-4-1 Ohkubo, Shinjuku-ku, Tokyo 169-8555, Japan

2

Institute of Biomedical Engineering, Tokyo Women’s Medical University, 8-1 Kawada-cho, Shinjuku-ku,

Tokyo 162-8666, Japan

Received 4 October 2000; accepted 16 November 2000

ABSTRACT:

Aqueous gel deswelling rates for copolymer hydrogels comprising N-isopro-

pylacrylamide (IPAAm) and 2-carboxyisopropylacrylamide (CIPAAm) in response to

increasing temperatures were investigated. Compared with pure IPAAm-based gels,

IPAAm–CIPAAm gels shrink very rapidly in response to small temperature increases

across their lower critical solution temperature (their volume is reduced by five-sixths

within 60 s). Shrinking rates for these hydrogels increase with increasing CIPAAm

content. In contrast, structurally analogous IPAAm–acrylic acid (AAc) copolymer gels

lose their temperature sensitivity with the introduction of only a few mole percent of

AAc. Additionally, deswelling rates of IPAAm–AAc gels decrease with increasing AAc

content. These results indicate that IPAAm–CIPAAm copolymer gels behave distinctly

from IPAAm–AAc systems even if both comonomers, CIPAAm and AAc, possess car-

boxylic acid groups. Thus, we propose that the sensitive deswelling behavior for

IPAAm–CIPAAm gels results from strong hydrophobic chain aggregation maintained

between network polymer chains due to the similar chemical structures of CIPAAm and

IPAAm. This structural homology facilitates aggregation of chain isopropylamide

groups for both IPAAm and CIPAAm sequences with increasing temperature. The

incorporation of AAc, however, shows no structural homology to IPAAm, inhibiting

chain aggregation and limiting collapse. A functionalized temperature-sensitive

poly(N-isopropylacrylamide) hydrogel containing carboxylic acid groups is possible with

CIPAAm, producing rapid and large volume changes in response to smaller tempera-

ture changes.

© 2000 John Wiley & Sons, Inc. J Polym Sci A: Polym Chem 39: 335–342, 2001

Keywords:

poly(N-isopropylacrylamide);

2-carboxyisopropylacrylamide;

tempera-

ture-responsive hydrogels; volume phase transition; deswelling kinetics; functional

groups; anionic gel

INTRODUCTION

Stimuli-responsive hydrogels that exhibit sub-

stantial property changes in response to temper-

ature,

1,2

pH,

3,4

light,

5

and electric fields

6 – 8

have

been investigated in the context of new devices for

drug delivery systems and biomaterials. Poly(N-

isopropylacrylamide) (PIPAAm) gels are known

for their reversible swelling– deswelling behavior

in response to temperature changes across a

lower critical solution temperature (LCST).

9

PIPAAm gels have been applied to control drug

Correspondence

to:

T.

Aoyagi

(E-mail:

taoyagi@lab.

twmu.ac.jp)

Journal of Polymer Science: Part A: Polymer Chemistry, Vol. 39, 335–342 (2001)

© 2000 John Wiley & Sons, Inc.

335

release rates in temperature-modulated drug de-

livery systems.

1,2,10

We already reported ther-

mally induced on– off drug release by using the

formation of a rate-controlling collapsed polymer-

gel-skin layer impermeable to drug molecules

and water.

11,12

Polymer-gel-skin-layer formation

leads to very slow deswelling of the bulk polymer

network. To avoid rate-limiting skin formation

and facilitate rapid water– drug efflux, we pre-

pared comb-type PIPAAm gels that contained a

large amount of freely mobile PIPAAm graft

chains.

13,14

These comb-type PIPAAm gels shrink

rapidly in response to temperature changes or

solvation changes near the LCST because mobile

PIPAAm graft chains are able to undergo rapid

dehydration in response to small temperature in-

creases.

Another method to accelerate deswelling rates

in PIPAAm-based gels is the introduction of hy-

drophilic groups into PIPAAm gels. Kim et al.

15

reported deswelling kinetics studies of random

copolymer

PIPAAm

gels

containing

small

amounts of acrylic acid (AAc). N-Isopropylacryl-

amide (IPAAm)–AAc gels showed rapid deswell-

ing with increasing temperature because a small

amount of ionized AAc suppressed collapsed poly-

mer-skin-layer formation on the gel surface,

whereas the deswelling volumes for IPAAm–AAc

gel decreased with an increasing AAc content. We

propose that the small content of AAc in the gel

decreases PIPAAm chain hydrophobic aggrega-

tion forces due to both charge– charge repulsion

and excess hydration by AAc proximal to the

IPAAm polymer backbone. In our recent study,

hydrophilic poly(ethylene oxide) (PEO)-grafted

chains were introduced into PIPAAm gel net-

works.

14,16

The deswelling rate of this PEO-

grafted PIPAAm gel was also accelerated over

pure IPAAm gel because hydrophilic PEO chains

plausibly form channels for water through the

IPAAm collapsed skin layer. In contrast to col-

lapsible IPAAm–AAc gels, high PIPAAm thermo-

sensitivity in this case was maintained in the

presence of significant hydrophilic PEO grafting

in the PIPAAm network. This might be due to

significant association of IPAAm chain units in-

dependent of PEO-grafted chains because of the

gel architecture. On the basis of these previous

reports, sensitive gel temperature response might

result from the readily reversible association of

critical lengths of isopropylamide groups as in an

IPAAm homopolymer.

To establish molecular design criteria for func-

tionalized hydrogels with high thermosensitivity,

we newly designed the functional monomer 2-car-

boxyisopropylacrylamide

(CIPAAm).

CIPAAm

shares all the structural features of IPAAm ex-

cept for the terminal carboxyl group.

17,18

Hence,

random copolymers of IPAAm with CIPAAm were

proposed to maintain continuous lengths of asso-

ciating polymer isopropylamide groups similar to

IPAAm homopolymers with similar gel thermo-

sensitivity in the presence of significant amount

of hydrated, electrostatically repulsive carboxy-

late groups in the PIPAAm network. We recently

reported that IPAAm–CIPAAm soluble linear co-

polymers containing less than 20 mol % CIPAAm

exhibit very sensitive phase transitions in re-

sponse to temperature changes with phase-tran-

sition temperatures nearly the same as those of

the IPAAm homopolymer and its gel over a wide

pH range.

17,18

In contrast, the phase-transition

temperature and collapse sensitivity for IPAAm–

AAc analogous copolymers and gels were influ-

enced considerably by small amounts of AAc, so-

lution pH, and ionic strength.

With this study, we sought to clarify the effects

of both gel carboxyl groups and polymer isopro-

pylamide aggregation in IPAAm–CIPAAm gels on

their deswelling kinetics in response to tempera-

ture changes and temperature cycles across the

LCST. From these results, the deswelling mech-

anism for IPAAm–CIPAAm gels versus IPAAm–

AAc gels was contrasted. Preserving the associa-

tion of critical lengths of gel network chain iso-

propylamide

groups

is

shown

to

play

an

important role in the resulting strong hydropho-

bic aggregation that produces thermosensitivity

in the respective gel networks.

EXPERIMENTAL

Materials

IPAAm was kindly provided by Kojin Co. (Tokyo,

Japan) and was purified by recrystallization from

n-hexane. AAc was distilled under reduced pres-

sure. N,N,N

⬘,N⬘-Tetramethylethylenediamine (TE-

MED), ammonium persulfate (APS), and N,N

⬘-

methylenebisacrylamide (MBAAm) were purchased

from Kanto Chemical Co., Ltd. (Tokyo) and were

used as received.

Synthesis of CIPAAm

CIPAAm was synthesized with the same methods

reported in a previous article.

17

In brief,

D

,

L

-3-

336

EBARA ET AL.

aminobutyric acid was esterified with benzyl al-

cohol, and acryloyl chloride was reacted with

D

,

L

-3-aminobutyric acid benzyl ester in the pres-

ence of triethylamine. CIPAAm was obtained by

the hydrolysis of benzyl ester with a sodium hy-

droxide aqueous solution. Protonation of result-

ing carboxyl groups was carried out with an ex-

cess amount of hydrochloric acid.

Gel Synthesis

For each gel composition, appropriate amounts of

IPAAm, CIPAAm, MBAAm, and TEMED were

dissolved in distilled water, and the solution was

transferred to a test tube and bubbled with dry

nitrogen gas for 15 min to remove oxygen. APS

was added to the solution, and then glass capil-

laries (300-

m inner diameter) were set into the

solution. The test tube was kept at 4 °C for 1 day

for polymerization and spontaneous gelation. The

poly(IPAAm-co-CIPAAm) gels were abbreviated

as IPAAm–CIPAAm (X) gel, where X is the molar

percentage of CIPAAm in the feed. Poly(IPAAm-

co-AAc) gels and PIPAAm homopolymer gel were

synthesized with the same methods and were ab-

breviated as IPAAm–AAc (X) gel and PIPAAm

gel, respectively. After the gelation was complete,

the 300-

m diameter gels were removed from the

glass capillaries, cut into small pieces, and im-

mersed in pure cold water to remove unreacted

compounds for 1 day. The gels were set in glass

capillaries 1.34 mm in diameter filled with phos-

phate-buffered saline (pH 7.4, 0.15 M), and the

glass capillaries were sealed.

18

Measurements of Gel Deswelling Kinetics

Gel deswelling kinetics from the equilibrium

swollen state to equilibrium deswollen conditions

were continuously monitored with a charge-cou-

pled device camera connected to a microscope.

The swelling ratio of the gel, (d

t

/d

o

)

3

, during the

deswelling change was calculated from the ratio

of the gel diameter at a certain time to the origi-

nal diameter (300

m).

RESULTS AND DISCUSSION

Molecular Design of the Hydrogels

Random copolymerization of IPAAm with func-

tional monomers such as AAc or other ionizable

comonomers is very conventional, readily intro-

ducing ionizing groups into temperature-respon-

sive PIPAAm gels.

19

In IPAAm–AAc random co-

polymer gels, however, small amounts of AAc

significantly affect the temperature-responsive

behavior. Specifically, gel volume changes are re-

duced, and their transition temperatures shift to

higher temperatures. We hypothesized that reg-

ular aggregations of critical lengths of isopropy-

lacrylamide groups along PIPAAm chains are re-

quired to produce their sensitive dehydration

changes that result in rapid shrinking of gels. Our

inclusion of the new monomer CIPAAm, despite

its content of carboxylic acid functional groups,

was intended to maintain IPAAm chain aggrega-

tion behavior characterized in previous IPAAm–

CIPAAm copolymers

17

and gels.

18

This hypothe-

sis was confirmed: phase-transition temperatures

and transition sensitivity for IPAAm–CIPAAm

linear polymers and its hydrogels were nearly

independent of solution pH and carboxyl group

content.

18

These results are distinctly different

from those of IPAAm–AAc and its gels.

17,18

Spe-

cific evidence supporting this hypothesis is pro-

vided later.

Hydrogel Deswelling Kinetics

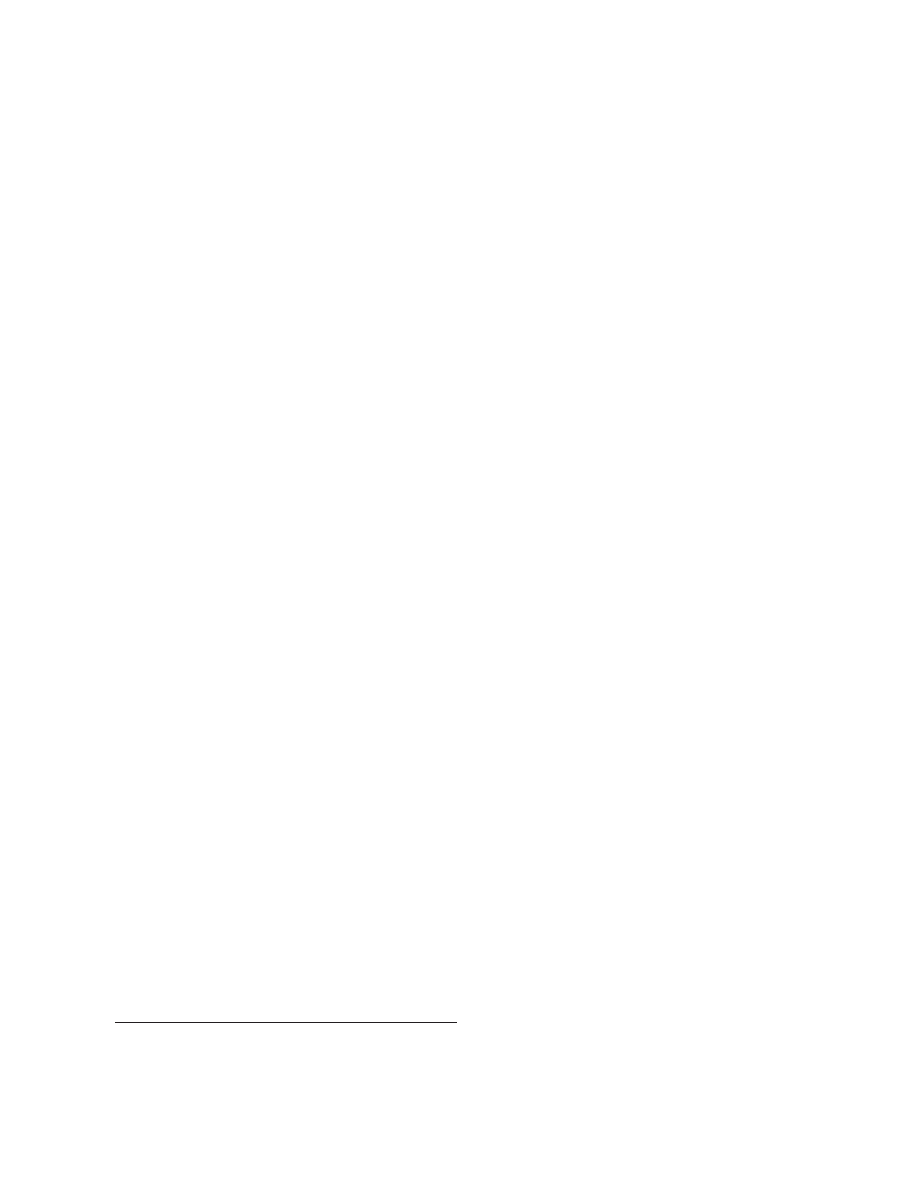

Figure 1 compares the deswelling kinetics data

from PIPAAm and IPAAm–AAc copolymer gels

exposed to stepwise temperature changes from 10

°C under equilibrium swelling conditions to 40 °C

in PBS (pH 7.4). Pure PIPAAm gels behaved as

previously shown.

11,12,19,20

Rapid initial shrink-

ing was observed just after the temperature

change

was

induced.

Deswelling,

however,

abruptly stopped, and volume change rates be-

came very slow for long periods. This phenome-

non, that is, instantaneous shrinking followed by

a slow volume change, has been attributed to a

surface collapsing polymer layer, the so-called

polymer-skin layer.

11,12,20

The gel shrinking be-

havior is demonstrated in Figure 2. The PIPAAm

gel changed from transparent to opaque within

60 s after a temperature change was induced,

suggesting the formation of a heterogeneous gel

structure. Then, this gel shrank gradually from

its surface inward, mediated by cooperative diffu-

sion of the collapsing polymer networks and the

gradual permeating release of entrapped water

from within the gel. As explained previo-

usly,

11,12,20

the shrinking rate of PIPAAm gel is

controlled by hindered water permeation from the

inner gel because of the collapsed polymer skin

POLY(N-ISOPROPYLACRYLAMIDE)-BASED HYDROGELS

337

and the onset of internal hydrostatic pressure

from collapse.

As shown in Figure 2(b), the IPAAm–AAc (3)

gel shrinks rapidly, maintaining a gel transpar-

ence. In contrast to the PIPAAm gel, IPAAm–AAc

gel with a small AAc content shrinks rapidly

without polymer-skin-layer formation because

hydrophilic AAc suppresses the formation of the

collapsed hydrophobic skin layer.

15,19

However,

the gel deswelling magnitudes decrease with in-

creasing AAc content in the series of IPAAm–AAc

copolymer gels. Hydrophobic polymer aggregation

forces in the phase transition are apparently

weakened because hydrated charged AAc units

disrupt regular aggregation of isopropylamide

groups in polymer chains. As a result, water per-

meation from inside these gels increases with in-

creasing AAc content.

16

In particular, volume

changes for the IPAAm–AAc (5) gel were reduced

over time: the collapsed size of IPAAm–AAc (5)

gel at 40 °C was only half that of the equilibrium

swelling state at 10 °C, whereas lower AAc con-

tent gels showed higher swollen/collapsed ratios.

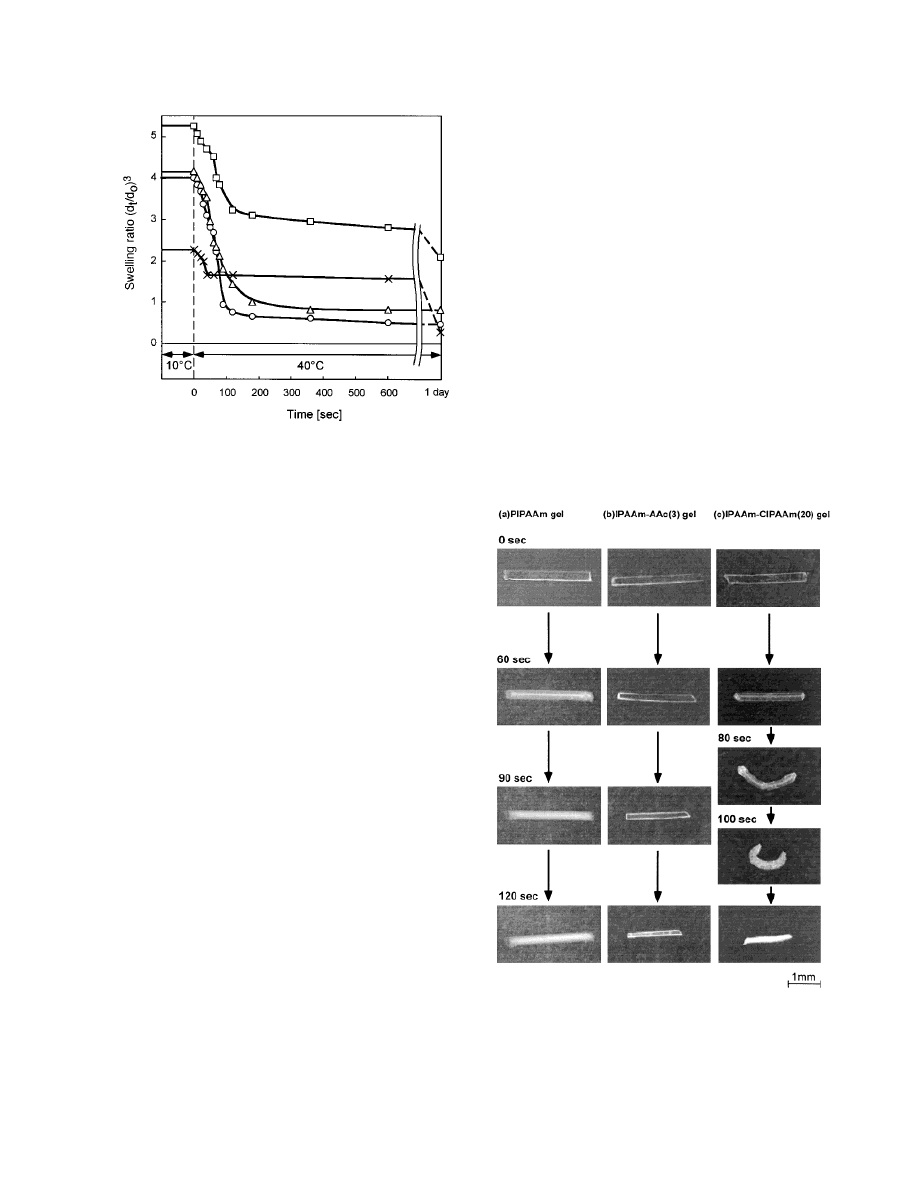

Figure 3 shows deswelling kinetics for the

IPAAm–CIPAAm gels exposed to stepwise tem-

perature changes from 10 (equilibrium swelling

state) to 40 °C (above the LCST), enough to

readily prompt gel collapse in PBS (pH 7.4).

IPAAm–CIPAAm (5) gel shrank rapidly after ini-

tial temperature changes. However, its volume

change stopped after skin-layer formation was

observed on the gel surface after 80 s of temper-

ature change. This indicates that despite its

charged, albeit small, monomer content, IPAAm–

CIPAAm gel maintains strong hydrophobic aggre-

gability, an effect distinct from the analogous

IPAAm–AAc

gels

attributed

to

the

unique

CIPAAm structure. This gel deswelling rate and

collapse magnitude gradually increases with in-

creasing CIPAAm content. Figure 2(c) shows pho-

tographs of the shrinking process for the IPAAm–

CIPAAm (20) gel. The initially transparent

IPAAm–CIPAAm (20) gel became opaque within

80 s after being heated from 10 to 40 °C. The

formation of a heterogeneous polymer network

structure due to polymer chain surface aggrega-

tion was observed. However, the deswelling rate

of IPAAm–CIPAAm (20) gel was not hindered,

Figure 2.

Photographs for deswelling changes ob-

served for (a) PIPAAm gels, (b) IPAAm–AAc (3), and (c)

IPAAm–CIPAAm (20) in response to a temperature

increase from 10 to 40 °C in PBS (initial gel dimen-

sions: 0.3-mm diameter and 2.7-mm length).

Figure 1.

Shrinking kinetics for PIPAAm and

IPAAm–AAc gels at 40 °C under equilibrium swelling

conditions at 10 °C (initial gel dimensions: 0.3-mm

diameter and 5-mm length).

⫻ ⫽ PIPAAm gel; E ⫽

IPAAm–AAc (1) gel; ‚

⫽ IPAAm–AAc (3) gel; 䊐 ⫽

IPAAm–AAc (5) gel.

338

EBARA ET AL.

regardless of the skin-layer formation, because of

sufficient ionic monomer content. These results

indicate that the uniquely structured carboxyl

groups of CIPAAm influence the gel shrinking

process. More specifically, the density of the col-

lapsed polymer-skin layer of IPAAm–CIPAAm

(20) gel must be lower than that of PIPAAm gel to

permit squeezing water efflux and avoid hydro-

static pressure increases, whereas the chain ag-

gregation forces between polymer chains produc-

ing collapse are maintained in comparison with

that in IPAAm–AAc gels. Therefore, water within

the collapsing gel readily permeates out through

its porous skin layer.

These results emphasize the balance of two

factors important for producing rapid shrinking of

IPAAm copolymer gels: (1) maintenance of effec-

tive hydrophobic aggregation forces between col-

lapsing polymer chains and (2) facilitation of wa-

ter channel formation in the gels to readily re-

lease water through the collapsing gel-skin layer.

If the chain aggregation force is too strong and

the gel-skin-layer density is very high, water in-

side the gel cannot permeate, and the gel deswell-

ing change is halted by the resulting hydrostatic

pressure as seen in PIPAAm gels. On the con-

trary, if aggregation forces are weakened by the

introduction of hydrophilic comonomer moieties,

deswelling rates become inordinately slow and

diffuse, and the collapse magnitude becomes

small, as seen in IPAAm–AAc gels. Deswelling

rates and magnitudes in the PIPAAm copolymer

gels are readily controlled with CIPAAm because

the collapsed skin-layer density is altered by

changes in the CIPAAm content. This result is

completely different from that of conventional

IPAAm–AAc hydrogels, where the introduction of

only 1 mol % AAc prevents gel-skin-layer forma-

tion. Moreover, increasing the AAc content re-

duces hydrophobic aggregation forces consider-

ably, and gel deswelling rates are subsequently

reduced.

Gel Deswelling Changes in Response to Small

Temperature Changes

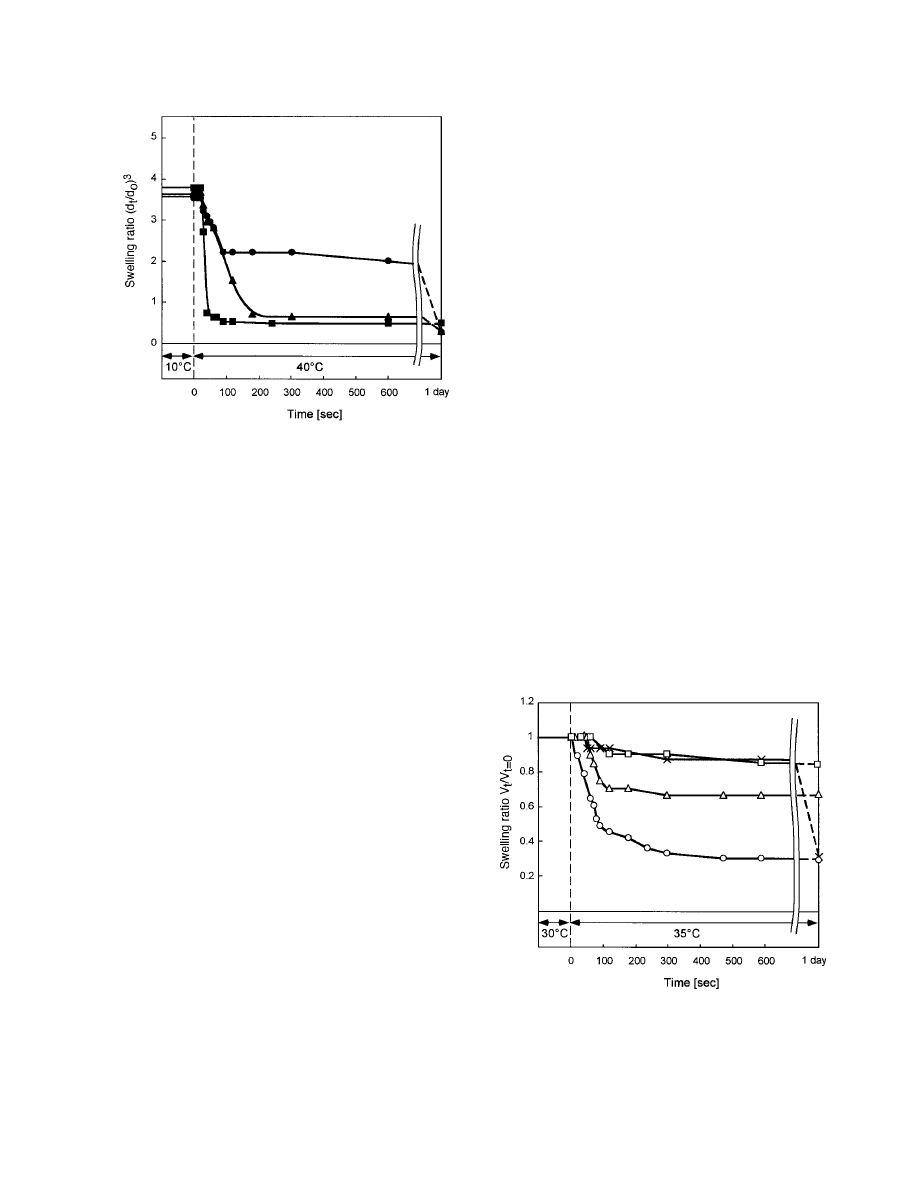

Figure 4 shows deswelling kinetics for pure

PIPAAm gel and IPAAm–AAc gels at 35 °C from

equilibrium swelling states at 30 °C in PBS (pH

7.4). Swelling ratios during the continuous de-

swelling changes are converted to normalized

swelling ratios, V

t

/V

t

⫽0

, calculated from the ratio

of the gel volume at a certain time (V

t

) to the

initial volume at 30 °C (V

t

⫽0

). As seen in Figure 4,

changes in the PIPAAm gel volume after the tem-

perature increased to 35 °C were not observed

over this timescale because of rapid skin-layer

formation. Equilibrium in this case takes weeks

or months.

11,12,19,20

In contrast, the IPAAm–AAc

Figure 4.

Shrinking kinetics for PIPAAm and

IPAAm–AAc gels at 35 °C under equilibrium conditions

at 30 °C (initial gel dimensions: 0.3-mm diameter and

5-mm length).

⫻ ⫽ PIPAAm gel; E ⫽ IPAAm–AAc (1)

gel; ‚

⫽ IPAAm–AAc (3) gel; 䊐 ⫽ IPAAm–AAc (5) gel.

Figure 3.

Shrinking kinetics for IPAAm–CIPAAm

gels at 40 °C under equilibrium swelling conditions at

10 °C (initial gel dimensions: 0.3-mm diameter and

5-mm length). F

⫽ IPAAm–CIPAAm (5) gel; Œ ⫽

IPAAm–CIPAAm (10) gel; ■

⫽ IPAAm–CIPAAm (20)

gel.

POLY(N-ISOPROPYLACRYLAMIDE)-BASED HYDROGELS

339

(1) gel shrinks rapidly because hydrophilic AAc

moieties inhibit the formation of a gel-skin layer

and readily release water from inside to outside,

relieving opposing hydrostatic pressure and facil-

itating collapse. The IPAAm–AAc (3) gel also

shrinks rapidly. However, deswelling changes are

not so large because of repulsive ionic comonomer

content. Additionally, deswelling changes in

those IPAAm–AAc gels become smaller with in-

creasing AAc content. These phenomena are due

to the introduction of hydrophilic AAc into

PIPAAm chains; increased hydrated, charged hy-

drophilic sites, and a decreased tendency to ag-

gregate critical lengths of isopropylacrylamide

chain units. Figure 5 shows deswelling kinetics

for IPAAm–CIPAAm gels at 35 °C from equilib-

rium swelling states at 30 °C in PBS (pH 7.4). The

deswelling behaviors of IPAAm–CIPAAm gels

correspond very well to deswelling kinetics from

heating modes from 10 to 40 °C, as seen in Figure

3. The IPAAm–CIPAAm (10) and IPAAm–

CIPAAm (20) gels exhibit large volume changes

in response to small temperature changes, and

gel shrinking is nearly complete within 1 min

after the temperature change is induced. These

results indicate that the IPAAm–CIPAAm gel

maintains strong hydrophobic chain aggregation

capabilities despite relatively large amounts of

carboxyl groups introduced into the PIPAAm net-

work via CIPAAm.

Reversibility of the Gel Swelling–Deswelling

Kinetics

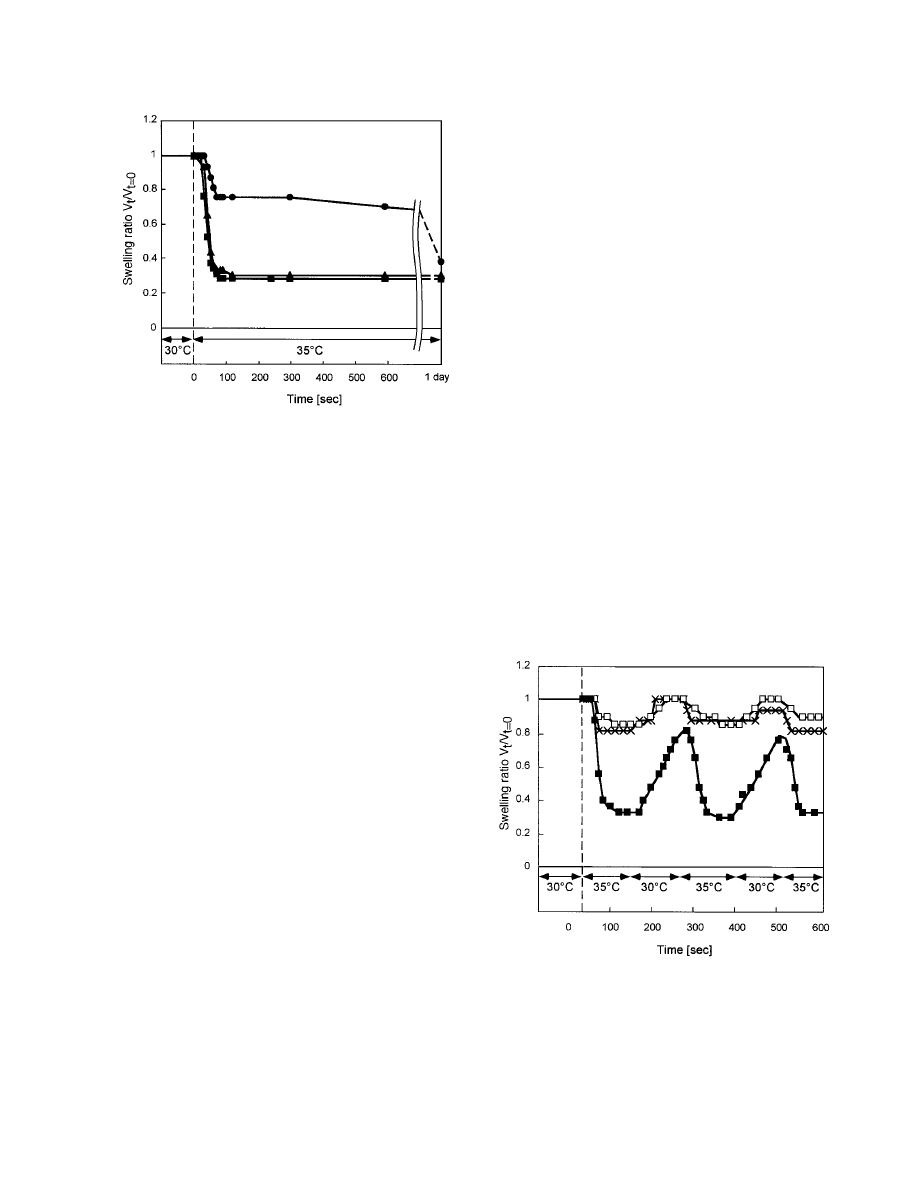

Figure 6 demonstrates the swelling– deswelling ki-

netics for PIPAAm, IPAAm–AAc (5), and IPAAm–

CIPAAm (20) gels over 2-min temperature cycles

between 30 and 35 °C in PBS (pH 7.4). Normalized

swelling ratios calculated from the ratio of the gel

volume at a certain time (V

t

) to the initial volume at

30 °C (V

t

⫽0

) were used to compare the swelling–

deswelling behavior. A small swelling– deswelling

change of the PIPAAm gel was observed.

11,12,19,20

PIPAAm gel showed completely repeatable and re-

producible oscillations between 0.8 and 1.0 swelling

ratios. The PIPAAm gel became opaque with tem-

perature increases from 30 to 35 °C, supporting

heterogeneous collapse. When the temperature was

decreased to 30 °C from 35 °C, PIPAAm gels imme-

diately became transparent again. In contrast, a

large swelling– deswelling change was observed for

the IPAAm–CIPAAm (20) gel, with swelling ratios

oscillating between 0.3 and 0.8. The size of the

IPAAm–CIPAAm (20) gel at 30 °C was more than

twice that of the deswollen state at 35 °C, whereas

those for the PIPAAm and IPAAm–AAc (5) gels

were about 1.2 times those of their deswollen states

at 35 °C. In addition, shrinking behavior differences

between the IPAAm–CIPAAm (20) and IPAAm–

Figure 6.

Swelling– deswelling kinetics for PIPAAm,

IPAAm–AAc (5), and IPAAm–CIPAAm (20) gels in re-

sponse to stepwise temperature changes between 30

and 35 °C for 2-min cycles (initial gel dimensions:

0.3-mm diameter and 5-mm length).

⫻ ⫽ PIPAAm gel;

䊐 ⫽ IPAAm–AAc (5) gel; ■ ⫽ IPAAm–CIPAAm (20)

gel.

Figure 5.

Shrinking kinetics for IPAAm–CIPAAm

gels at 35 °C under equilibrium conditions at 30 °C. F

⫽ IPAAm–CIPAAm (5); Œ ⫽ IPAAm–CIPAAm (10); ■

⫽ IPAAm–CIPAAm (20).

340

EBARA ET AL.

AAc (5) gels are observed. The deswelling rate of the

IPAAm–AAc (5) gel from 30 to 35 °C is nearly iden-

tical to that from 35 to 30 °C because both phenom-

ena are governed by simple diffusion of polymer

chains in water (no skin-layer hindrance). However,

the deswelling rate of IPAAm–CIPAAm (20) gel

from 30 to 35 °C was 2.5 times faster than its swell-

ing rate from 35 to 30 °C. These results suggest that

the shrinking mechanism for the IPAAm–CIPAAm

(20) gel is based on strong chain aggregation medi-

ated by dehydration and hydrophobic interaction,

as well as retention of water pores throughout the

aggregated collapsed polymer chain network. In

other words, the IPAAm–CIPAAm (20) gel main-

tains strong chain aggregation despite a 20 mol %

content of carboxyl groups. The IPAAm–AAc ran-

dom copolymer gel exhibits a lower limit of carboxyl

group content (5 mol %) sufficient to maintain such

a rapid shrinking behavior response to temperature

changes, but it loses its swelling– deswelling mag-

nitude with this content. In contrast, the IPAAm–

CIPAAm gel exhibits a much greater magnitude of

swelling changes in response to small temperature

cycles between 30 and 35 °C with substantial (20

mol %) carboxyl group content.

CONCLUSION

Deswelling kinetics for temperature-responsive

IPAAm copolymer gels containing new functional

CIPAAm monomer were compared to known tem-

perature-sensitive gels. Deswelling kinetics for

IPAAm–CIPAAm gels at 40 °C (above their LCST)

from equilibrium swelling states at 10 °C (below

their LCST) in PBS (pH 7.4) were compared to

those of pure PIPAAm and IPAAm–AAc ionic gels.

The conventional PIPAAm gel becomes opaque just

after this temperature increase, with limited de-

swelling changes for long time periods because of

collapsed skin-layer formation. In contrast, known

IPAAm–AAc gels shrink rapidly without opposing

internal hydrostatic pressure buildup because hy-

drophilic AAc suppresses the formation of the hy-

drophobic collapsed polymer-skin layer.

19

However,

gel deswelling rates and volume changes decrease

with increasing AAc content because network chain

aggregation forces are weakened by AAc ionomer

incorporation. In contrast to IPAAm–AAc gels, the

deswelling rates for ionized IPAAm–CIPAAm gels

gradually increase with increasing CIPAAm con-

tent. Although deswelling changes for the IPAAm–

CIPAAm (5) gel (5 mol % CIPAAm) are limited over

longer periods, IPAAm–CIPAAm (20) gels shrink

rapidly at ionic contents where IPAAm–AAc gels

have lost their phase transition.

19

Despite the large

amount of carboxyl groups, this gel maintains col-

lective IPAAm chain aggregation forces under ther-

mally induced collapse in comparison with IPAAm–

AAc gels. Swelling– deswelling kinetics for gels

compared over 2-min temperature cycles between

30 and 35 °C in PBS (pH 7.4) show that the

PIPAAm and IPAAm–AAc (5) gels exhibit small

swelling– deswelling changes accompanied by a

slight and gradual decrease in gel diameter over

repeated temperature cycles. In contrast, a rapid

and large volume swelling– deswelling change was

observed for the IPAAm–CIPAAm (20) gel. The size

of IPAAm–CIPAAm (20) gel at 30 °C was nearly

three times that of its deswelling gel state at 35 °C

and significantly greater than any IPAAm–AAc

ionic gels under comparable conditions. These be-

haviors are consistent with the proposed hypothesis

that chain aggregation forces in phase transitions

(near the LCST) can be maintained in ionic gels if

chain– chain association is facilitated by careful

monomer design.

The authors are grateful to Professor David Grainger

(Colorado State University) for valuable comments.

This work was supported in part by a Grant-in-Aid for

Scientific Research on Priority Areas (A, No. 1167276)

from the Ministry of Education, Science, Sport and

Culture (Japan) and the Japan Society for the Promo-

tion of Science Research for the Future Program (JSPS-

RFTF96I00201).

REFERENCES AND NOTES

1. Feil, H.; Bae, Y. H.; Heijan, J.; Kim, S. W. Macro-

molecules 1993, 26, 2496 –2500.

2. Yoshida, R.; Kaneko, Y.; Sakai, K.; Okano, T.;

Sakurai, Y.; Bae, Y. H.; Kim, S. W. J Controlled

Release 1994, 32, 97–102.

3. Dong, L. C.; Hoffman, A. S. J Controlled Release

1991, 15, 141–152.

4. Park, S. Y.; Bae, Y. H. Macromol Rapid Commun

1999, 20, 269 –273.

5. Suzuki, A.; Tanaka, T. Nature 1990, 346, 345–347.

6. Takeoka, Y.; Aoki, T.; Sanui, K.; Ogata, N.;

Yokoyama, M.; Okano, T.; Sakurai, Y.; Watanabe,

M. J Controlled Release 1995, 33, 79 – 87.

7. Kwon, I. C.; Bae, Y. H.; Okano, T.; Berner, B.; Kim,

S. W. Makromol Chem Macromol Symp 1990, 33,

265–277.

8. Kwon, I. C.; Bae, Y. H.; Kim, S. W. Nature 1991,

354, 291–293.

9. Bae, Y. H.; Okano, T.; Kim, S. W. J Polym Sci Part

B: Polym Phys 1990, 28, 923–936.

POLY(N-ISOPROPYLACRYLAMIDE)-BASED HYDROGELS

341

10. Yoshida, R.; Kaneko, Y.; Sakai, K.; Okano, T.;

Sakurai, Y.; Bae, Y. H.; Kim, S. W. J Controlled

Release Short Commun 1994, 32, 97–102.

11. Yoshida, R.; Sakai, K.; Okano, T.; Sakurai, Y.; Bae,

Y. H.; Kim, S. W. J Biomater Sci Polym Ed 1991, 3,

155–162.

12. Yoshida, R.; Okano, T.; Sakurai, Y.; Kaneko, Y.;

Sakai, K. Drug Delivery Syst 1995, 10, 31–35.

13. Yoshida, R.; Uchida, K.; Kaneko, Y.; Sakai, K.;

Kikuchi, A.; Sakurai, Y.; Okano, T. Nature 1995,

374, 240 –242.

14. Kaneko, Y.; Nakamura, S.; Sakai, K.; Aoyagi, T.;

Kikuchi, A.; Sakurai, Y.; Okano, T. Polym Gels

Networks 1998, 6, 333–345.

15. Gutowska, A.; Bae, Y. H.; Feijen, J.; Kim, S. W. J

Controlled Release 1992, 22, 95–104.

16. Kaneko, Y.; Nakamura, S.; Sakai, K.; Aoyagi, T.;

Kikuchi, A.; Sakurai, Y.; Okano, T. Macromole-

cules 1998, 31, 6099 – 6105.

17. Aoyagi, T.; Ebara, M.; Sakai, K.; Sakurai, Y.;

Okano, T. J Biomater Sci Polym Ed 2000, 11, 101–

110.

18. Ebara, M.; Aoyagi, T.; Sakai, K.; Sakurai, Y.;

Okano, T. Macromolecules, 2000, 33, 8312– 8316.

19. Yu, H.; Grainger, D. W. J Appl Polym Sci 1993, 49,

1553–1563.

20. Kaneko, Y.; Yoshida, R.; Sakai, K.; Sakurai, Y.;

Okano, T. J Membr Sci 1995, 101, 13–22.

342

EBARA ET AL.

Document Outline

Wyszukiwarka

Podobne podstrony:

The role of BRCA1 in DNA damage response

Trithemius The Arte Of Drawing Spirits Into Crystals

Study of temperature responsibility on the surfaces of a thermo responsive polymer modified stationa

J Slowacki Into the midst of riotous squabblers

Kradin Placebo Response and the Power of Unconscious Healing (Routledge, 2008)

Student Roles and Responsibilities for the Masters of Counsel

A Bite Into the History of the Autopsy

Forstchen, William R Into the Sea of Stars

The effect of temperature on the nucleation of corrosion pit

Bondeson; Aristotle on Responsibility for Ones Character and the Possibility of Character Change

Borovik Mirrors And Reflections The Geometry Of Finite Reflection Groups (2000) [sharethefiles com

Phillip G Zimbardo A Situationist Perspective On The Psychology Of Evil Understanding How Good Peo

social networks and the performance of individualns and groups

S D Houston Into the Minds of Ancients Advances in Maya Glyph Studies

Modification of Intestinal Microbiota and Its Consequences for Innate Immune Response in the Pathoge

William R Forstchen Into the Sea of Stars

British Patent 16,709 Improvements relating to the Conversion of Alternating into Direct Electric Cu

Latin in Legal Writing An Inquiry into the Use of Latin in the M

więcej podobnych podstron