© Raymond Mack 2000 or year indicated on drawing

0

Dimensioned Drawing Package

For

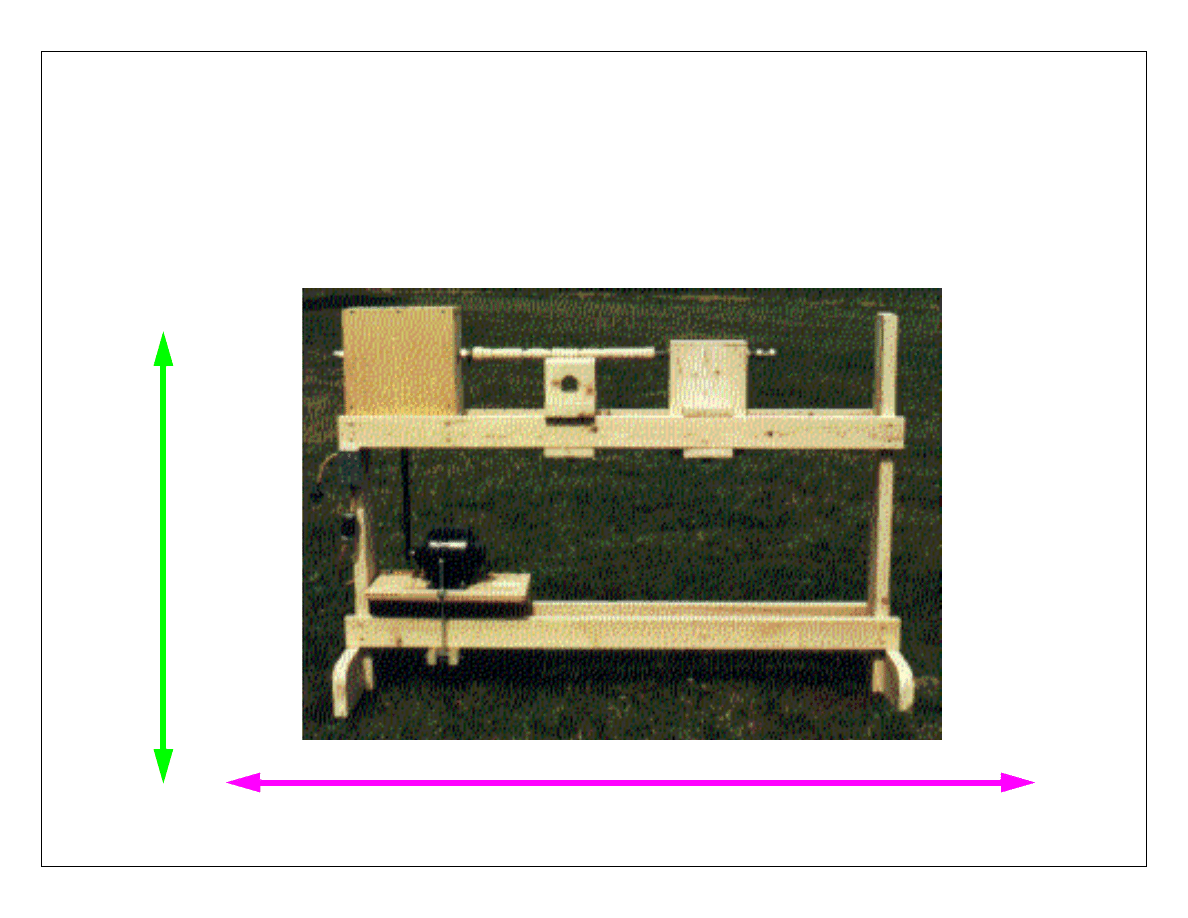

Homemade Wood Lathe

© Raymond Mack 2000 or year indicated on drawing

1

© Raymond Mack 2000

Information contained within is the copyrigthted intellectual property of Raymond Mack, All rights reserved. No part of the

information contained within may be duplicated. Information is provided for personal use by the reader and may not be

incorporated into any commercial publication or venture.

Information within is provided for purposes of entertainment and hobby discussion. Author assumes no responsibility for

safe application of the information which shall be the responsibility of the reader or user of the information.

Note: Because these drawings had to be rendered from multiple conversions of format, various anomalies in line color and

width were unavoidable.

Double click yellow page icons to view drop-down notes

© Raymond Mack 2000 or year indicated on drawing

2

© Raymond Mack 2000 or year indicated on drawing

3

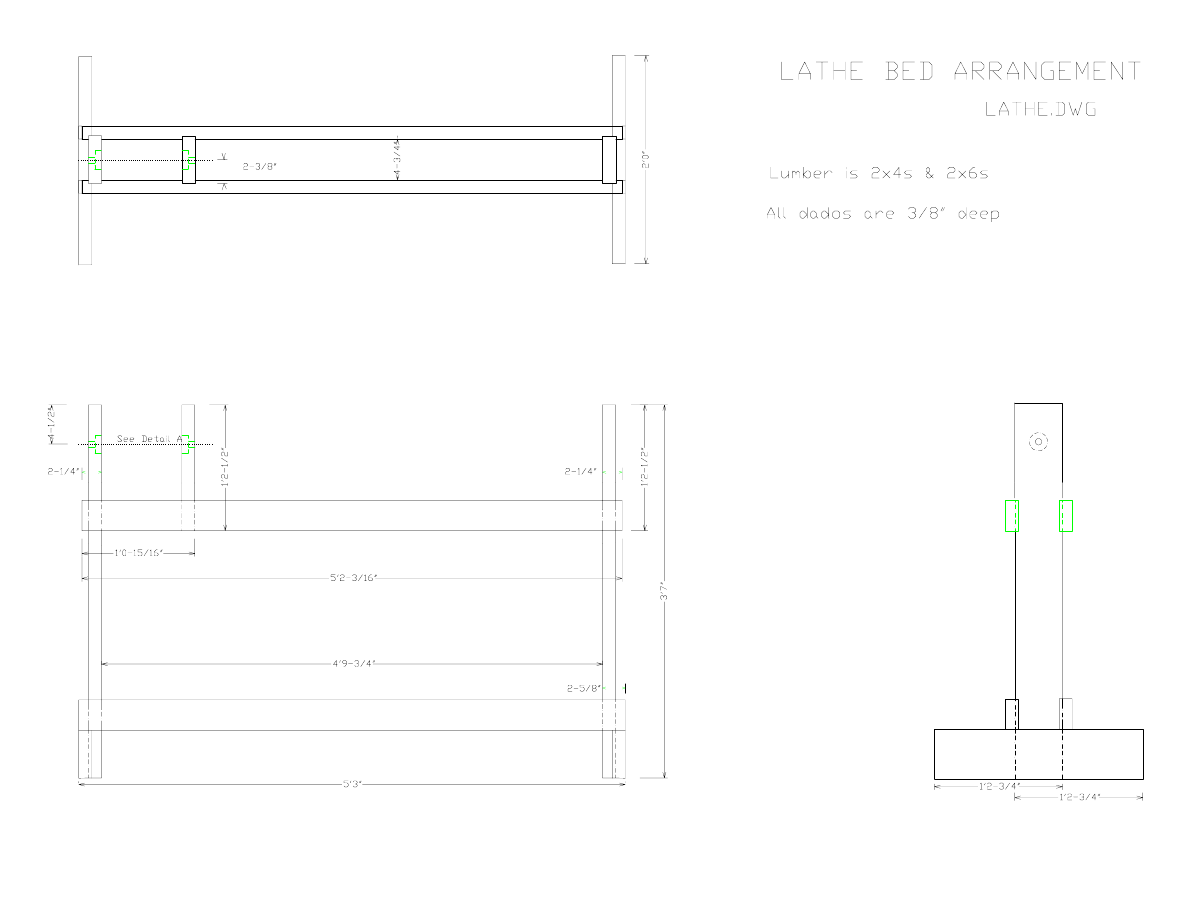

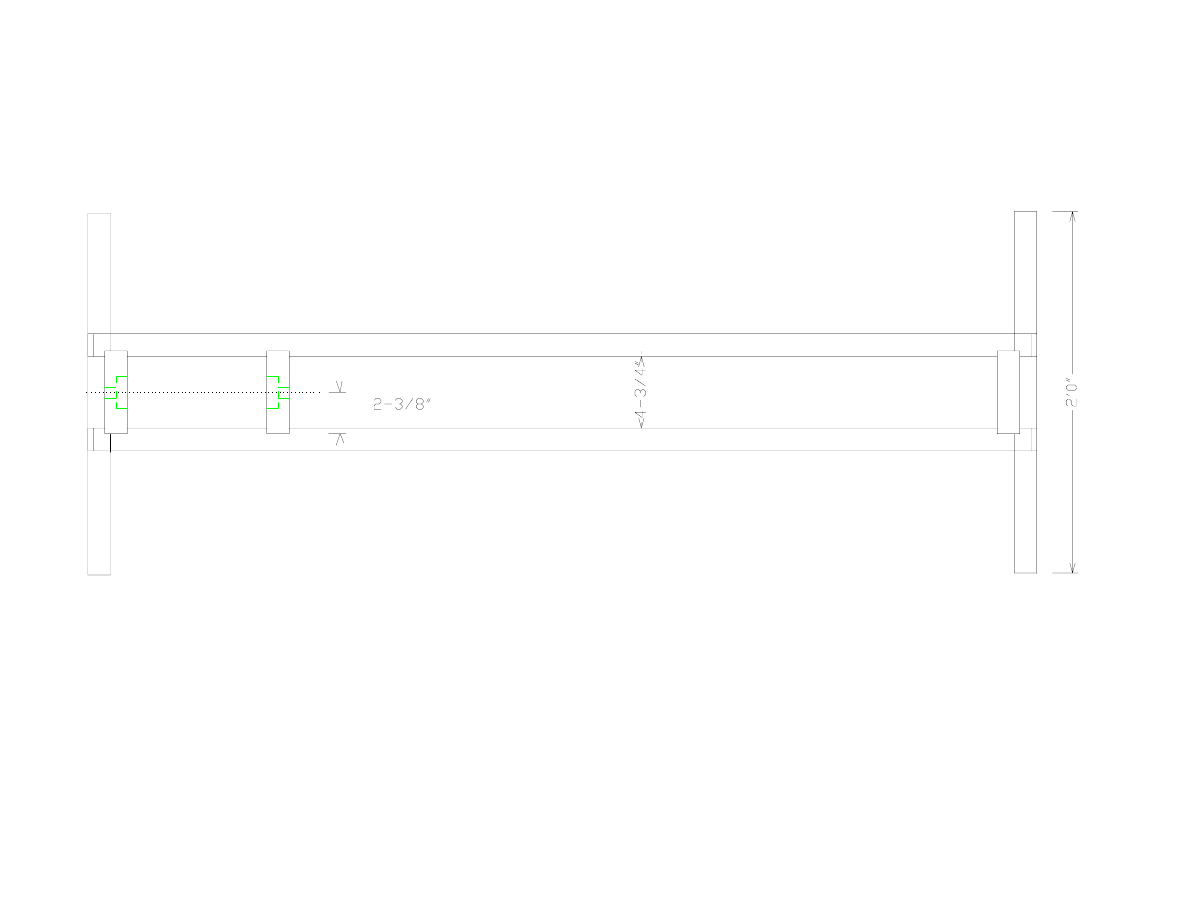

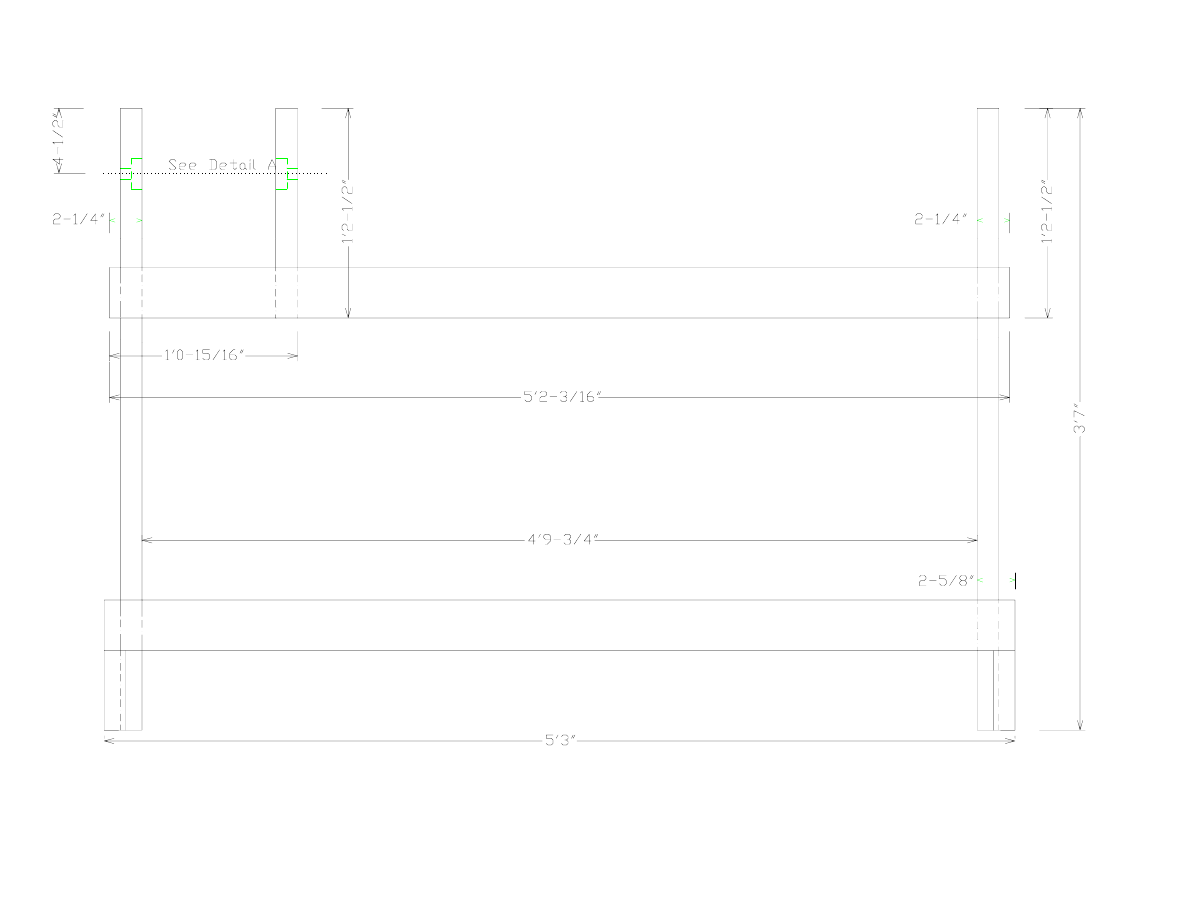

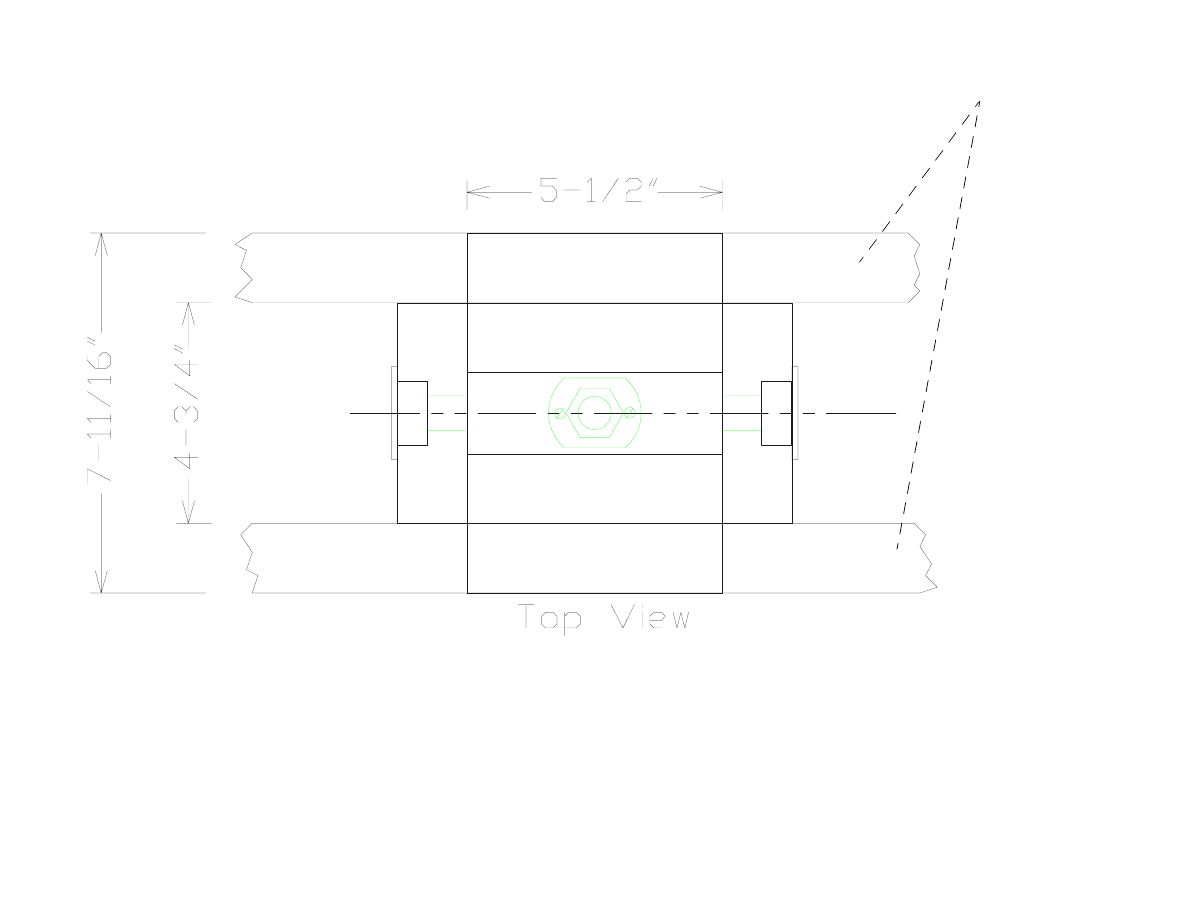

Top View

© Raymond Mack 2000 or year indicated on drawing

4

Front View

© Raymond Mack 2000 or year indicated on drawing

5

Side View

© Raymond Mack 2000 or year indicated on drawing

6

0-

11

/1

6"

2-

1/

16

"

0-11/16"

0-11/16"

4-1/2" c-e

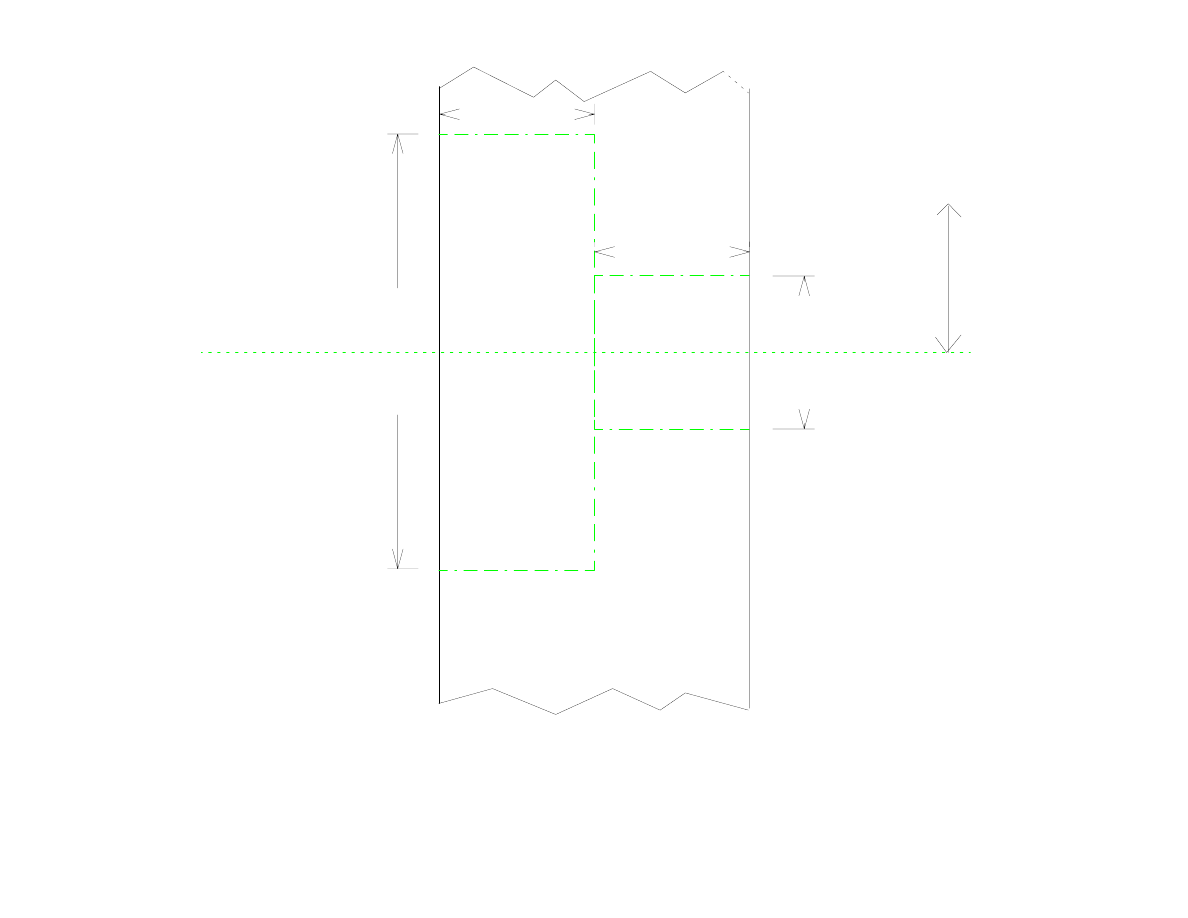

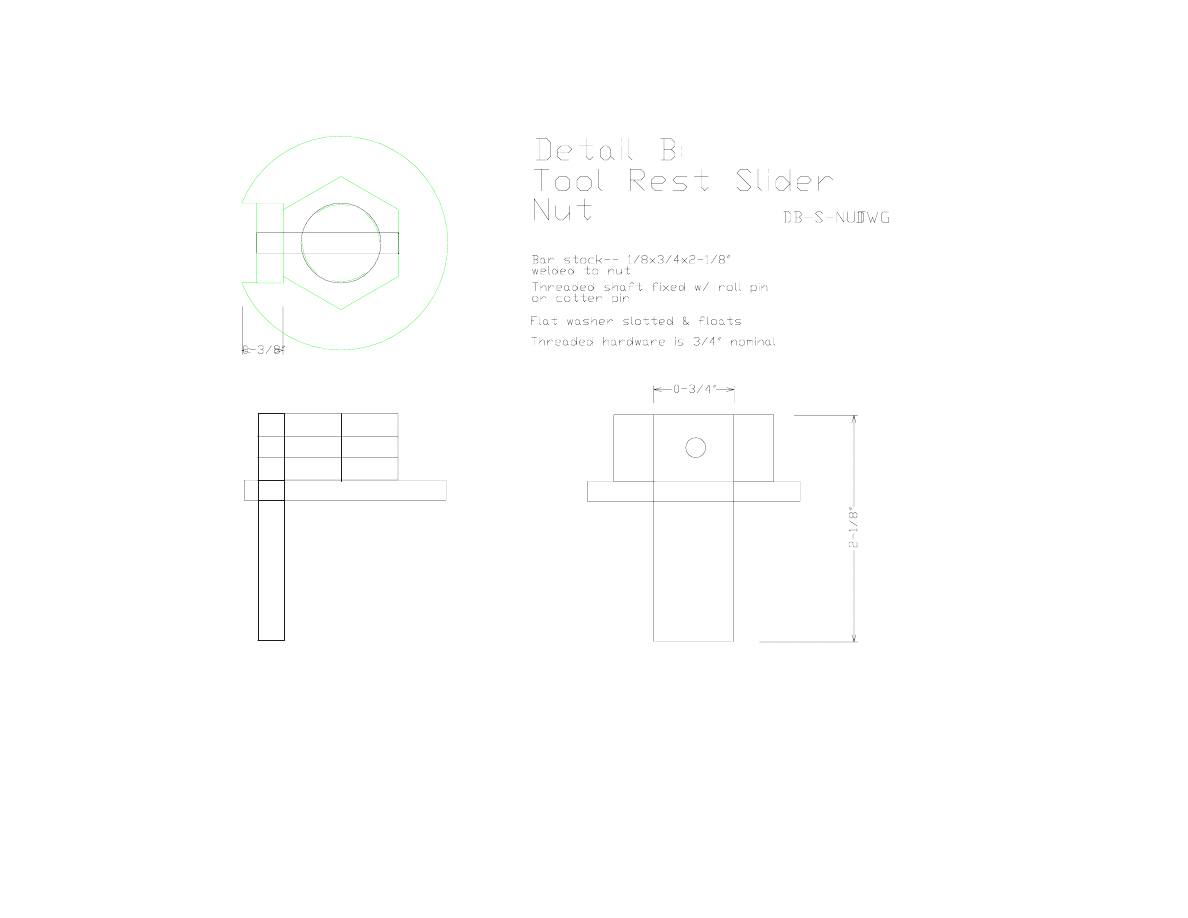

Detail A

Bearing Insets

DA-BRNGI.DWG

Detail A

Bearing Insets

4-1/2” c-e

Rout bearing inset to achieve interfer-

ence fit for the outside diameter of the

particular bearing you have. Dimensions

shown provide fit for front wheel bear-

ings of a 57 Chevy 1/2 too pickup truck.

© Raymond Mack 2000 or year indicated on drawing

7

© Raymond Mack 2000 or year indicated on drawing

8

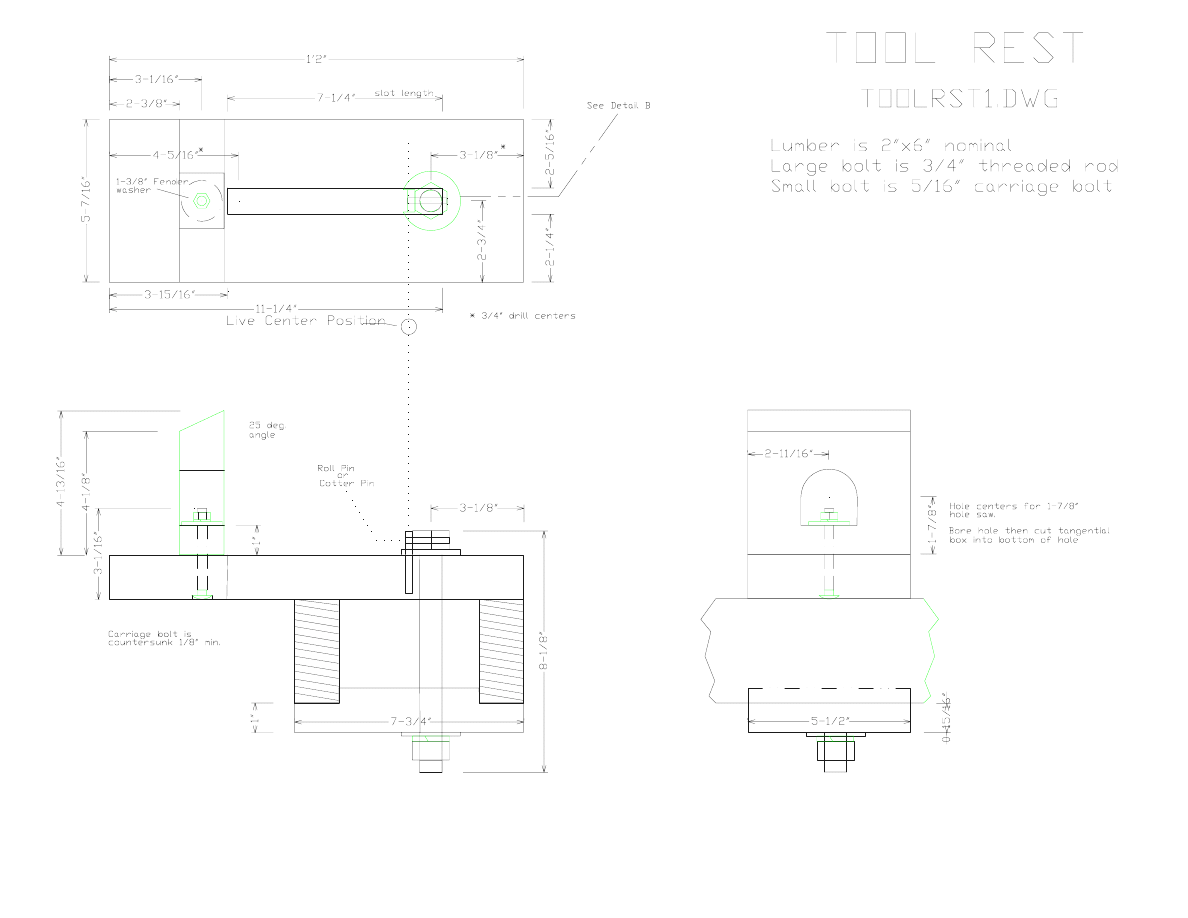

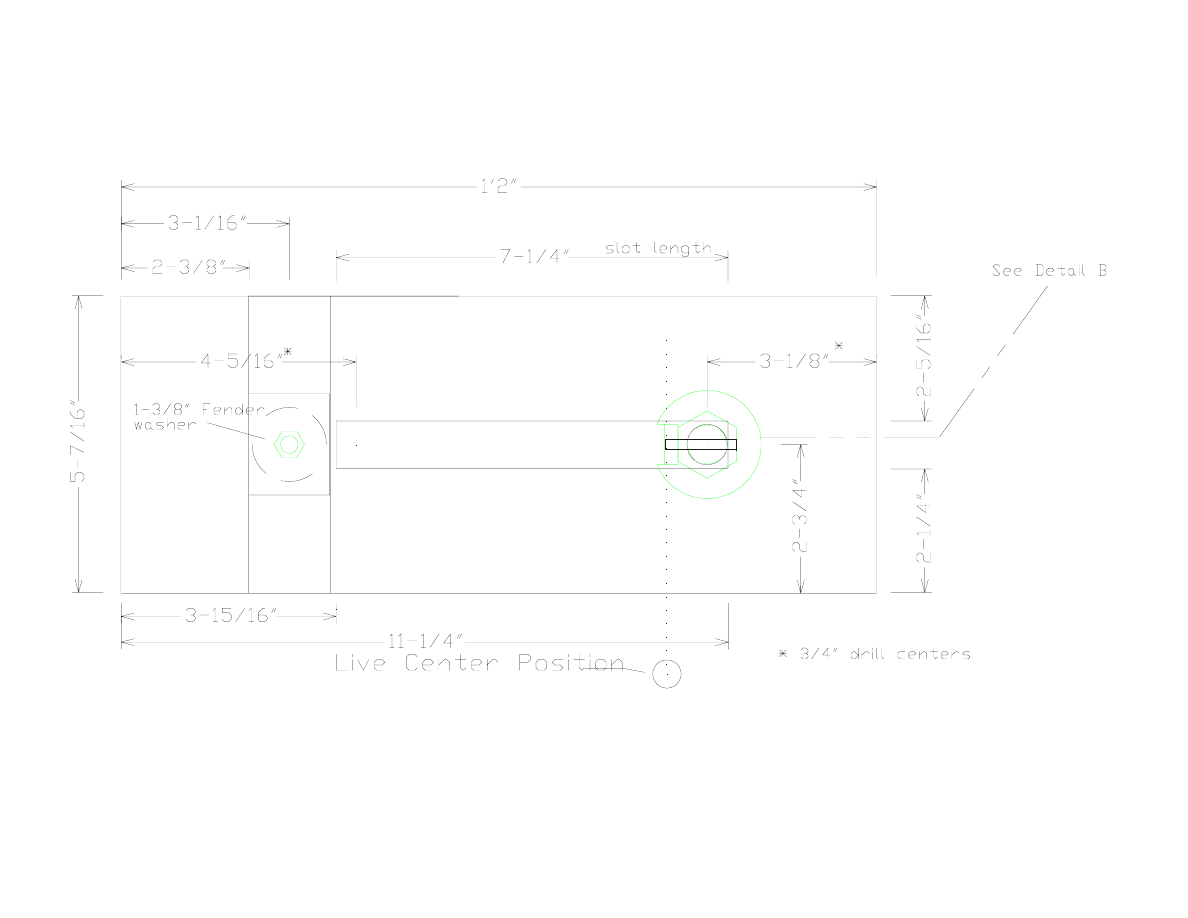

Tool Rest

Top View

© Raymond Mack 2000 or year indicated on drawing

9

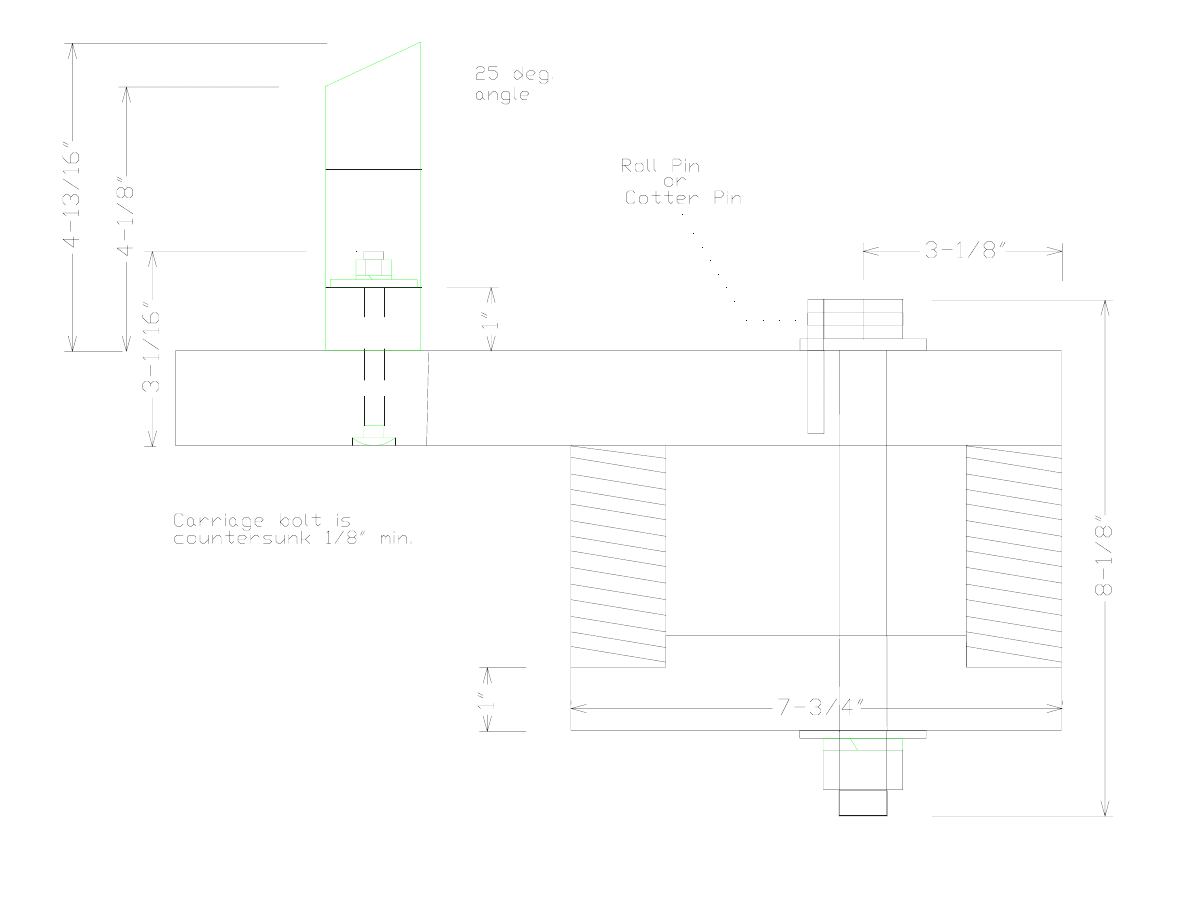

Tool Rest

Side View

© Raymond Mack 2000 or year indicated on drawing

10

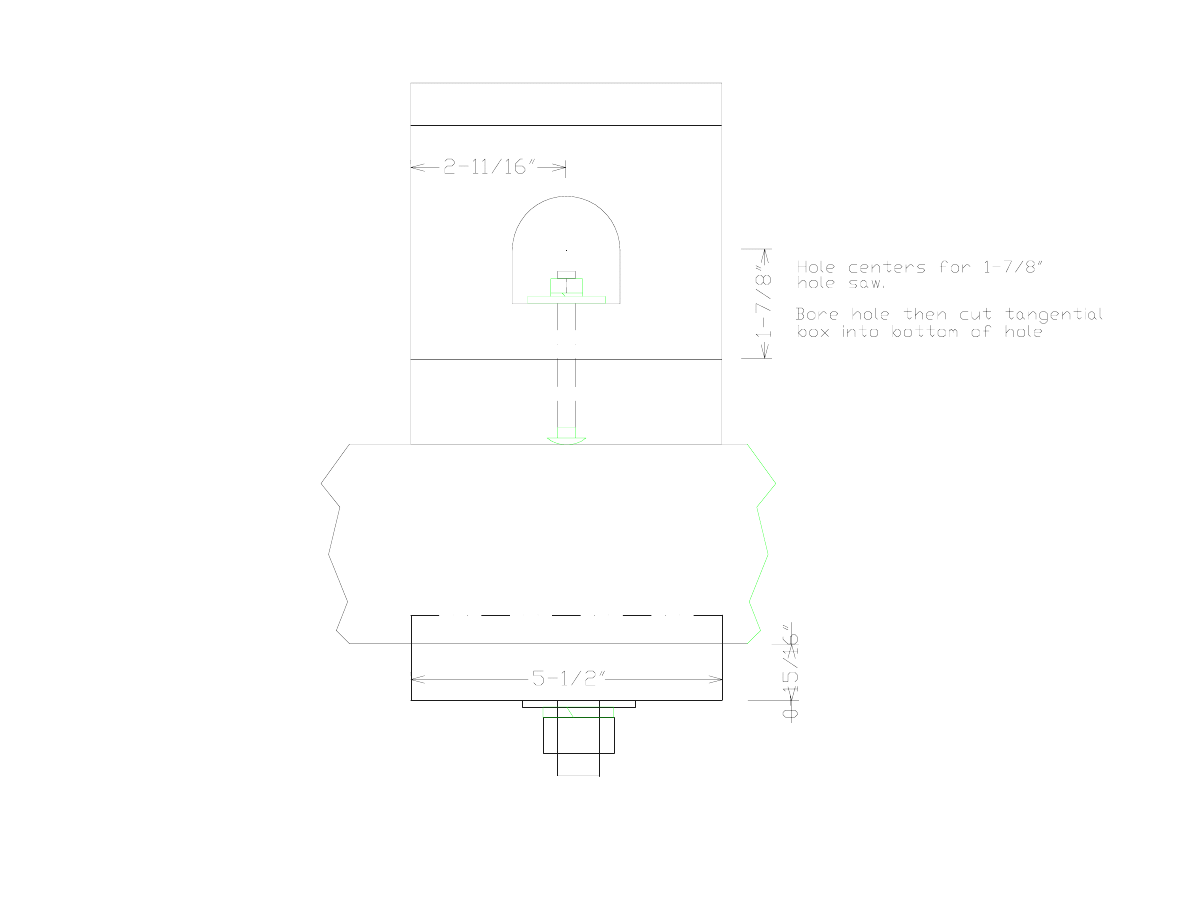

Tool Rest

Front View

© Raymond Mack 2000 or year indicated on drawing

11

© Raymond Mack 2000 or year indicated on drawing

12

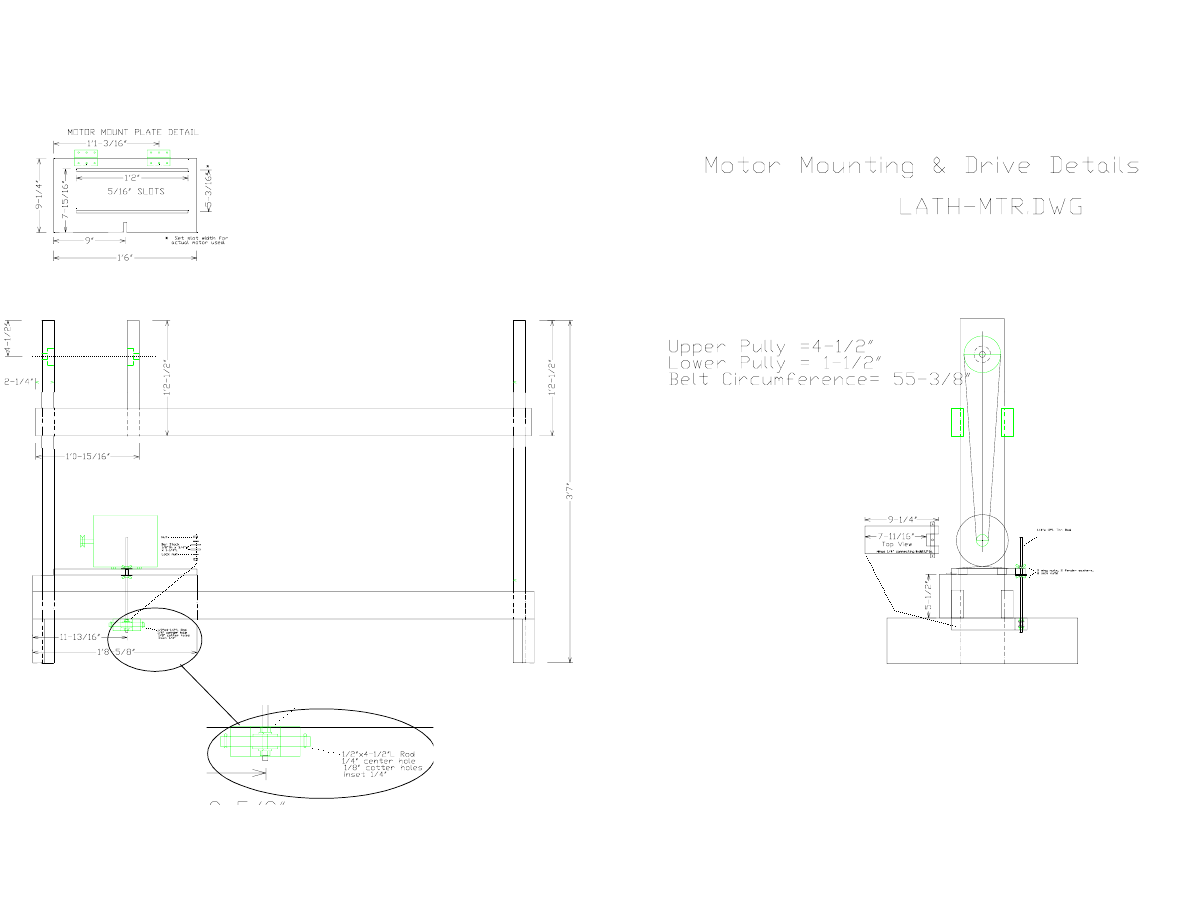

Typical

Modify as needed to match specific

belt - pulley - motor combination.

© Raymond Mack 2000 or year indicated on drawing

13

© Raymond Mack 2000 or year indicated on drawing

14

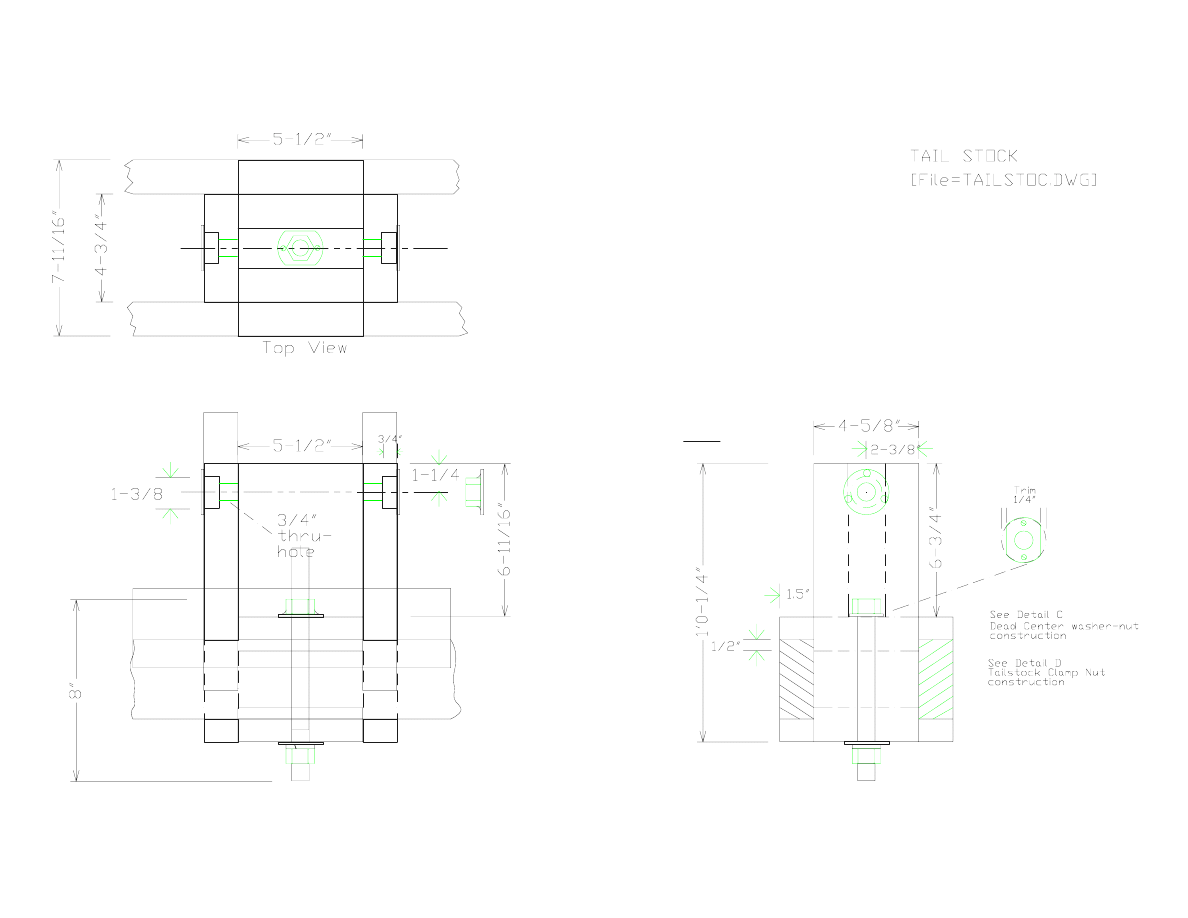

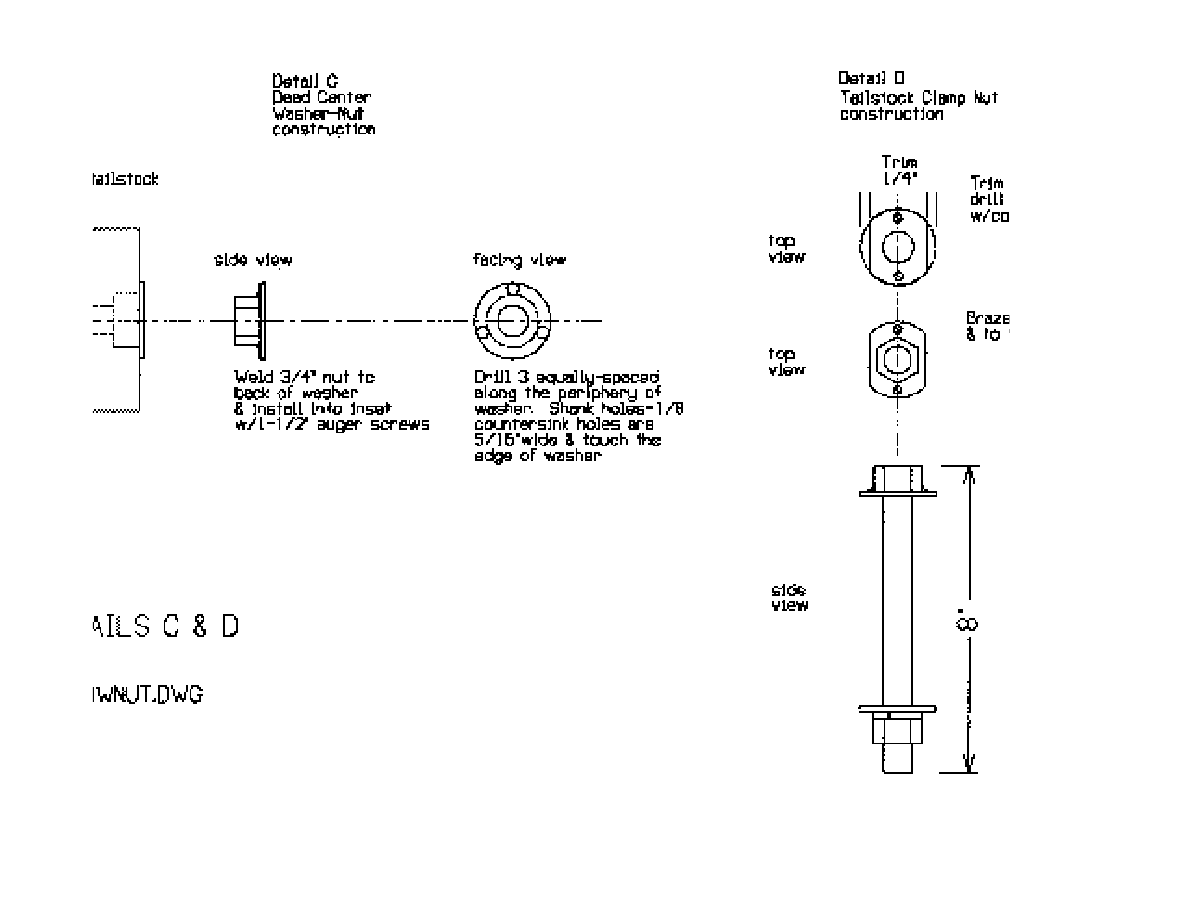

Tail Stock

Lathe Bed Rails

© Raymond Mack 2000 or year indicated on drawing

15

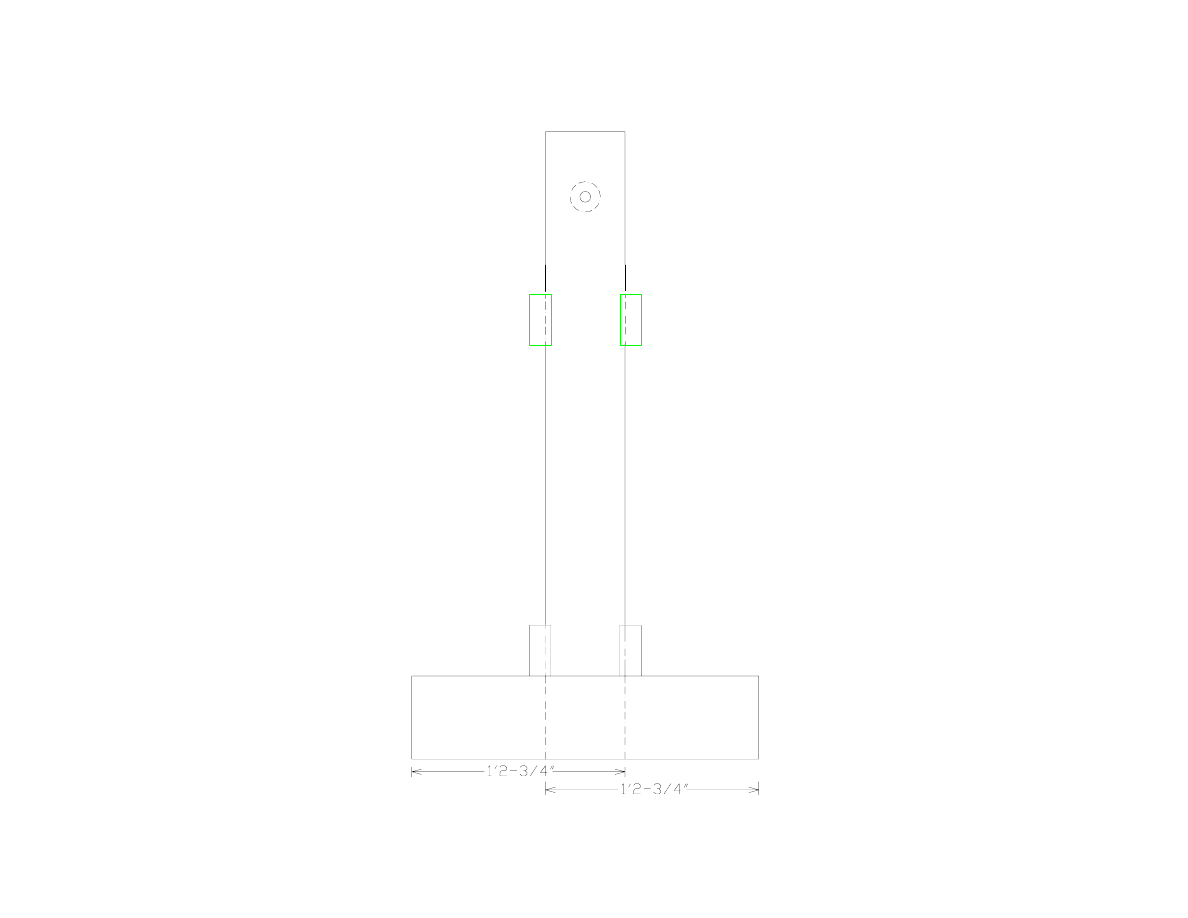

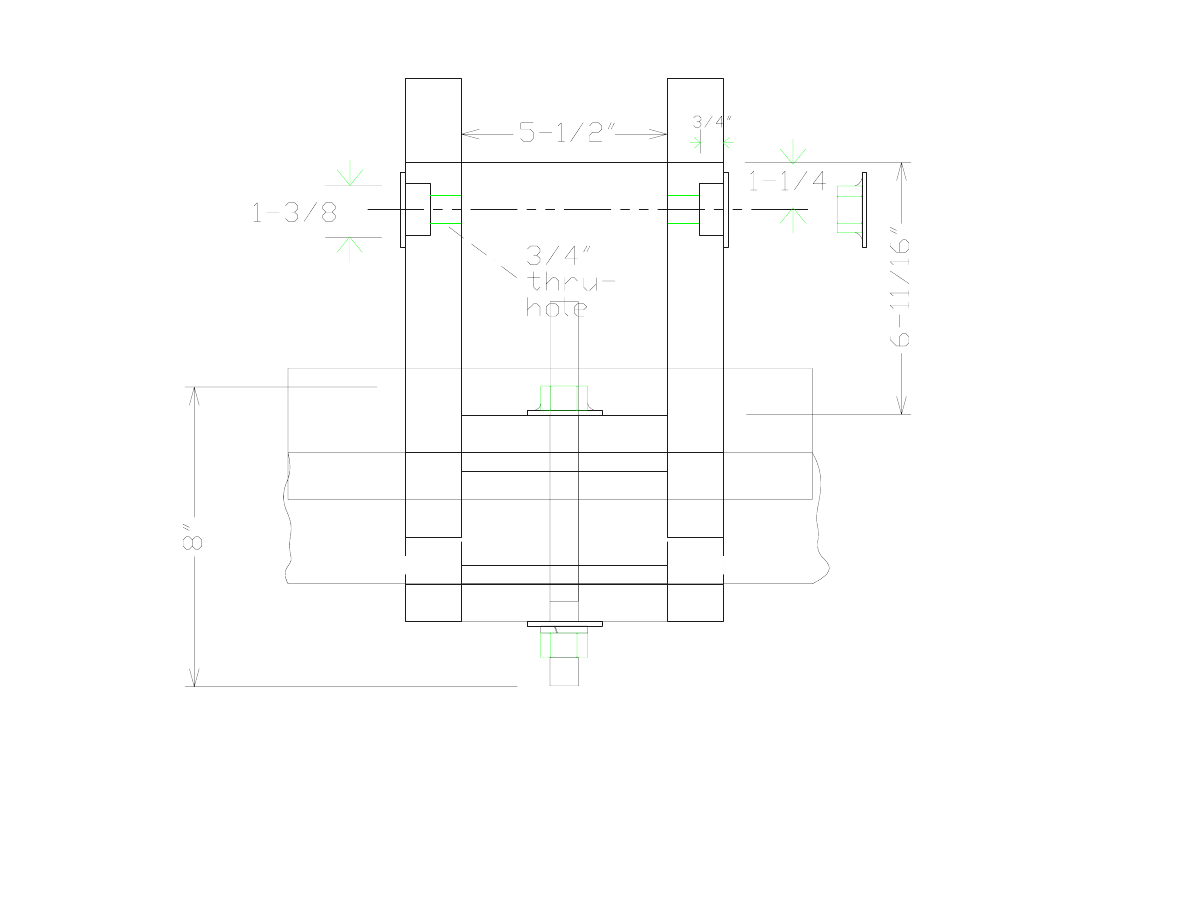

Tail Stock

Front View

© Raymond Mack 2000 or year indicated on drawing

16

Tail Stock

End View

© Raymond Mack 2000 or year indicated on drawing

17

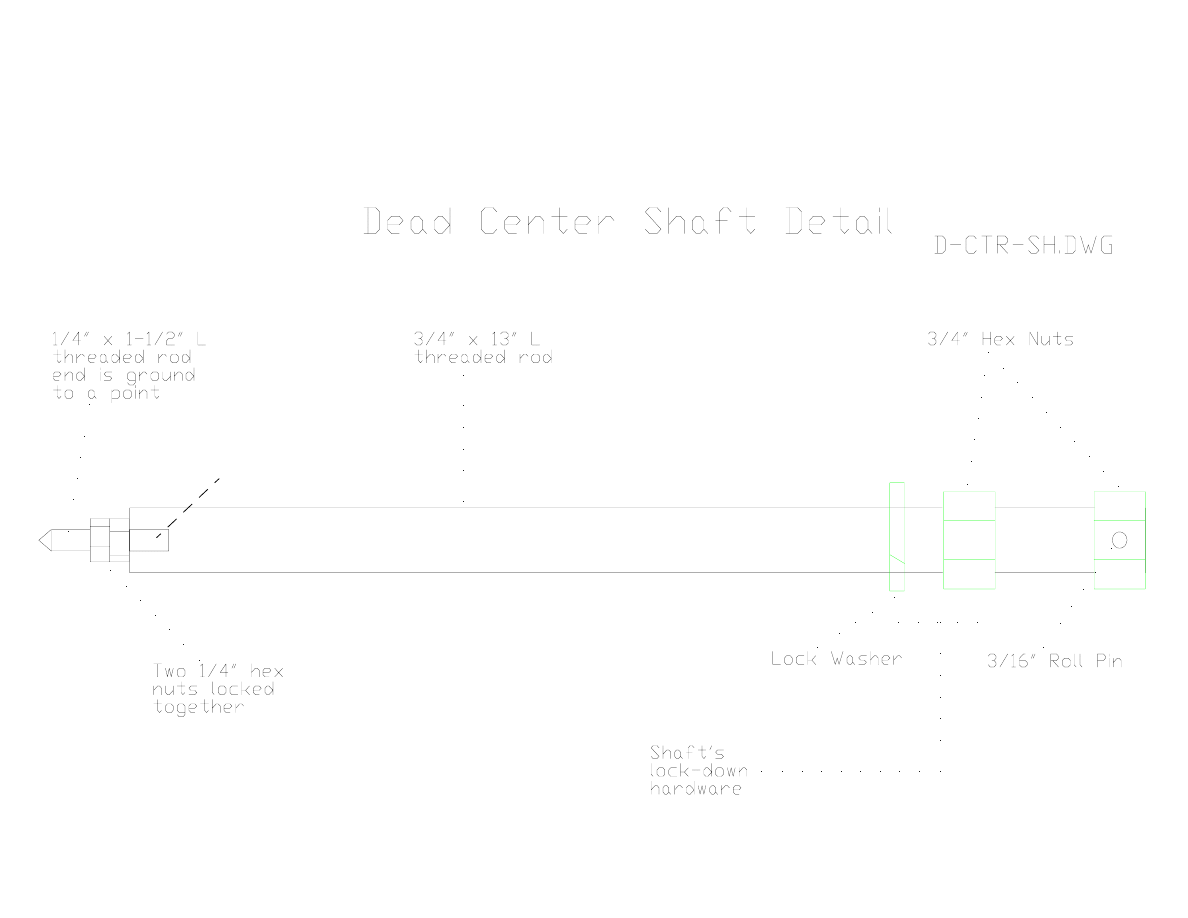

re: Tail Stock

© Raymond Mack 2000 or year indicated on drawing

18

© Raymond Mack 2000 or year indicated on drawing

19

Tap Thread 1/4-20

by 1/2” deep

© Raymond Mack 2000 or year indicated on drawing

20

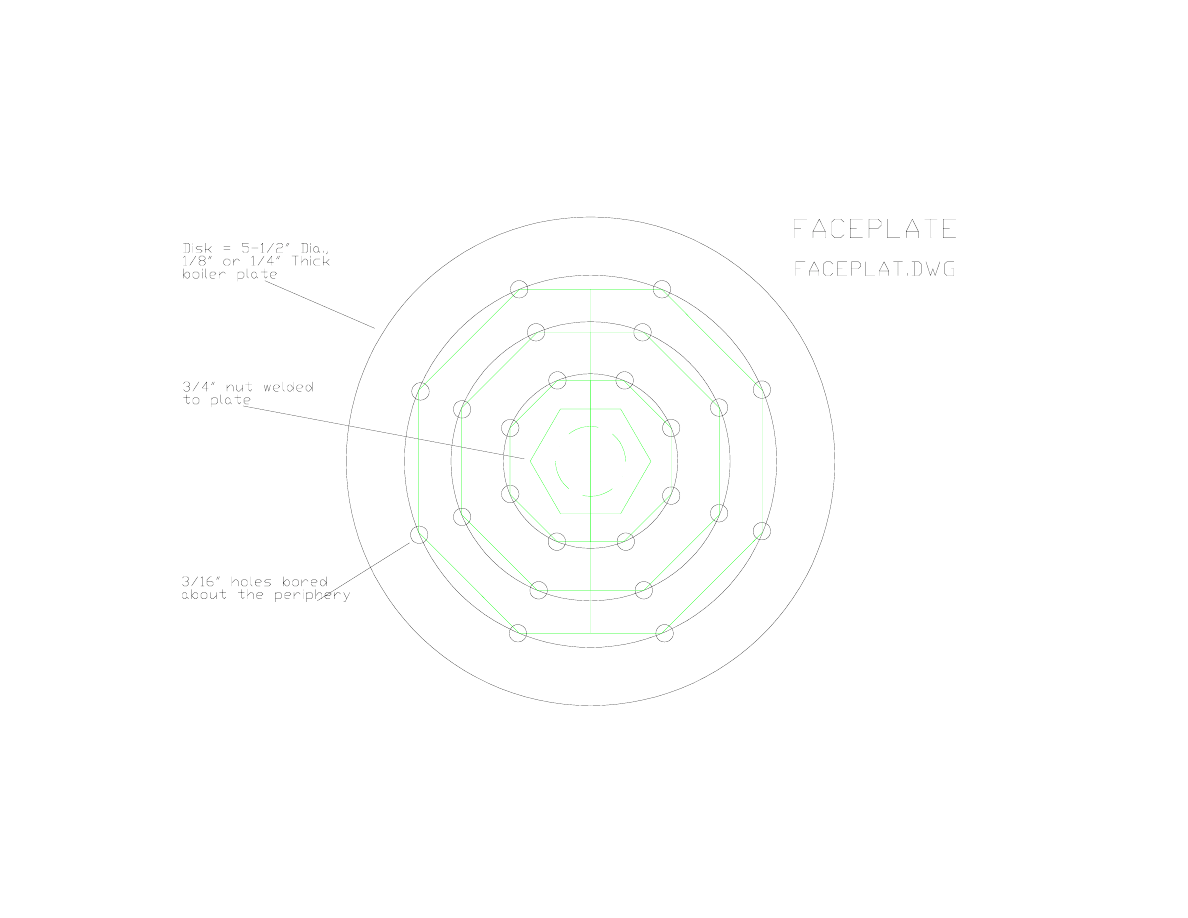

Faceplates are used for

spinning bowls, etc.

Faceplates are typically

used for spinning bowls,

© Raymond Mack 2000 or year indicated on drawing

21

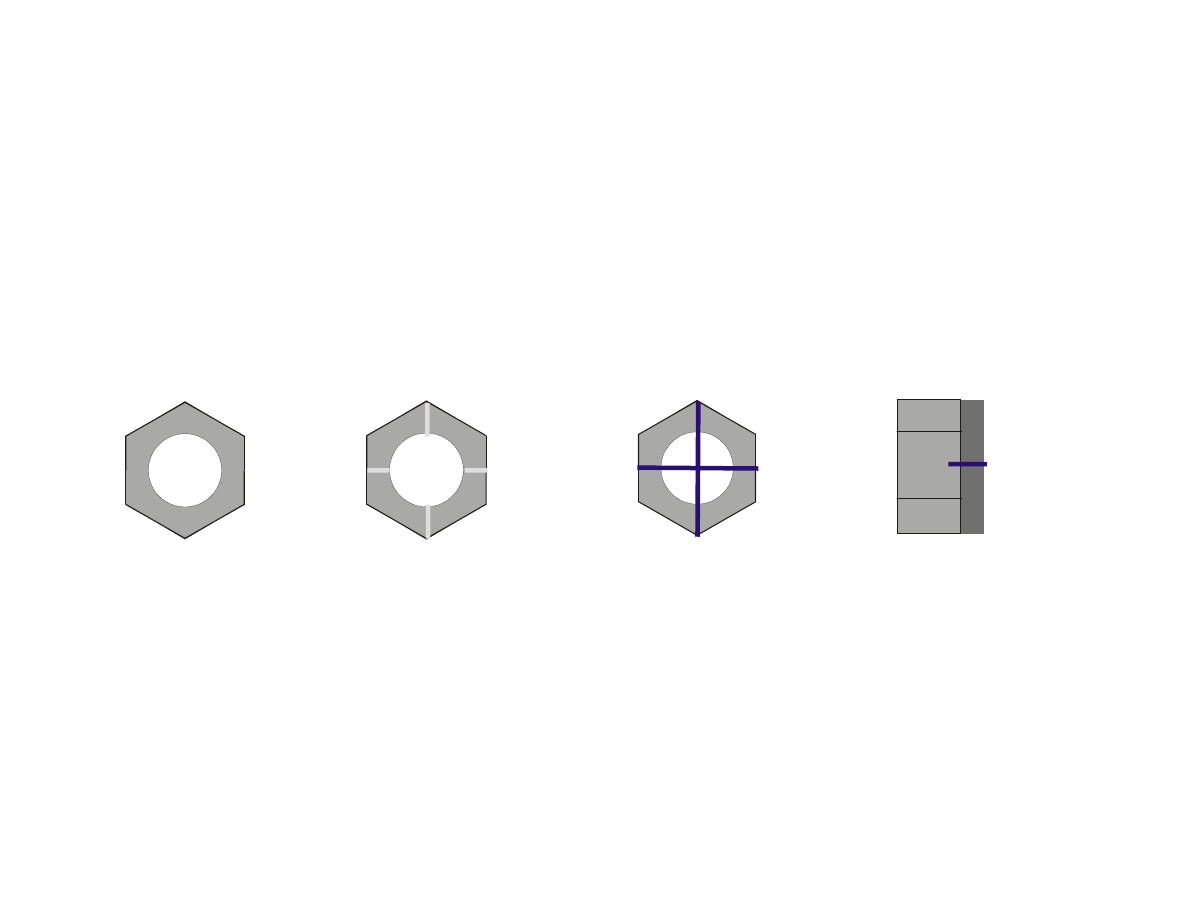

Drive Spur Strategies

Here are a couple of strategies for a drive spur.

1) Slot a cross pattern in a 3/4” hex nut and braze/weld bar stock into the slots as shown below. Note: You can change the width of the slot

(saw kerf) by stacking several hacksaw blades onto the hacksaw.

2) Acquire a standard tapered wood-lathe drive spur. Cut the spur head off from the taper shaft and weld it to a 3/4” hex nut.

3/4” Hex Nut

3/4” Hex Nut

with Slots Cut

into Face

3/4” Hex Nut

with bar stock

welded into

slots

3/4” Hex Nut

with bar stock

spurs. Side View

Hex Nut Spur Example

Wyszukiwarka

Podobne podstrony:

eBook DIY Woodworking Plans Guide To Wood Finishing

(Ebooks) Diy Woodwork Plans Bending Wood

(EBooks) DIY Woodwork Plans 10 Workbench Accessories

Wood Working Plans for 6 inch Turret Lathe

(Ebooks) DIY Woodwork Plans Drill Press Table

(Ebooks) Diy Woodwork Plans Kitchen Cabinets

DIY Woodwork Homemade Woodturning Lathe

(Ebooks) Diy Woodwork Plans Shed 24 Utility Shed

(Ebooks) Diy Woodwork Plans Longer Plank Top Workbench

Woodwork Plans For Hydraulic Press

(Ebooks) Diy Woodwork Plans Shed 10 x10 Gambrel Roof With Loft Plans

(Ebooks) Diy Woodwork Plans Timber Garden Shed Part Ii

DIY Mortis Dreadmought Plans & Templates

Finished drawing for air reservoir,pressure tank,calorifer

DIY Land Speeder Plans & Templates

Drawing for the Absolute and Utter Beginner

(madera) Woodworking plans Workbench Popular Mechanics Hard Maple

DIY Mortis Dreadmought Plans & Templates

więcej podobnych podstron