* Corresponding author. International Fire Safety Consultant, 9 Lakis Close, Flast Walk, Hampstead,

London NW3 1JX, UK. Tel.: #44-20-7431-5372; fax: #44-20-7431-5374.

E-mail address: gcooke@joinnet.uk.com (G.M.E. Cooke).

Fire Safety Journal 36 (2001) 459}475

Behaviour of precast concrete #oor slabs exposed

to standardised "res

Gordon M.E. Cooke*

Visiting Professor, Department of Civil Engineering, City University, London, UK

Received 2 February 2000; received in revised form 24 October 2000; accepted 10 January 2001

Abstract

This paper quanti"es the thermal movements of 14 simply supported precast reinforced

concrete #oor slabs of 4.5 m span and 900 mm width exposed to two standardised heating

regimes used in "re resistance furnace tests. The tests were designed to show the e!ect of varying

the slab thickness, type of concrete, imposed load, so$t protection and nature of "re exposure

on the mid-span #exural de#ection and axial movements of the slab ends. Measured de#ections

showed that during the 90 min design period of "re resistance thermal bowing was dominant

and the e!ect of the 1.5 kN/m

design imposed load was small. The NPD hydrocarbon

"re

exposure caused a doubling of the #exural de#ections achieved using the standard BS 476: Part

8 (now Part 20) "re exposure in the "rst 20 min of exposure.

2001 Elsevier Science Ltd. All

rights reserved.

Keywords: Floor slabs; Concrete; Standard "re tests; Thermal response; Structural response

1. Introduction

As part of the Building Research Establishment (BRE) Large Panel Structures

research programme, the Fire Research Station (FRS) undertook a full scale natural

"re test in the Ronan Point high rise block of #ats in 1984. The test was terminated

because the "re exposed 4 m long #oor slab spanning onto the external wall exhibited

an unexpected high rate of increase in the mid-span de#ection after only 12 min from

ignition. There was concern that, with further heating, the associated axial expansion

0379-7112/01/$ - see front matter

2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 3 7 9 - 7 1 1 2 ( 0 1 ) 0 0 0 0 5 - 4

of the precast slab could push out the load bearing external wall panels at the

wall/#oor junction causing an eccentric loading condition for the load-bearing ex-

ternal wall panels which might precipitate a &pack of cards' type of progressive

collapse. A search of the literature revealed a paucity of experimental data on axial

de#ections of concrete slabs exposed to "re: while many hundreds of standard "re

resistance tests have been made on #oors there has never been a requirement to

measure axial de#ections and such information was therefore very rare and unpub-

lished.

The interdependence of thermal bowing, axial de#ection and axial restraint was

unclear. It was therefore decided to proceed with a two-part programme of "re tests.

The "rst part, reported herein, would examine the "re behaviour of axially unre-

strained, simply supported, precast concrete #oor slabs. The second part would

examine the e!ect of partial axial restraint on narrow strips of #oor construction. For

the "rst part of the programme, the author, then working at FRS, proposed, designed

and supervised seven "re tests on pairs of precast concrete slabs each nominally 4.7 m

long

;900 mm wide. Six pairs were prepared by the BRE Civil Engineering Laborat-

ory, Cardington. One pair was cut from a large #oor panel taken from the Ronan

point #ats during demolition. The tests were made in a standard "re resistance #oor

test furnace and were designed to determine the unrestrained mid-span de#ection and

axial de#ections of the slab ends at mid depth. The nature of the axial de#ections

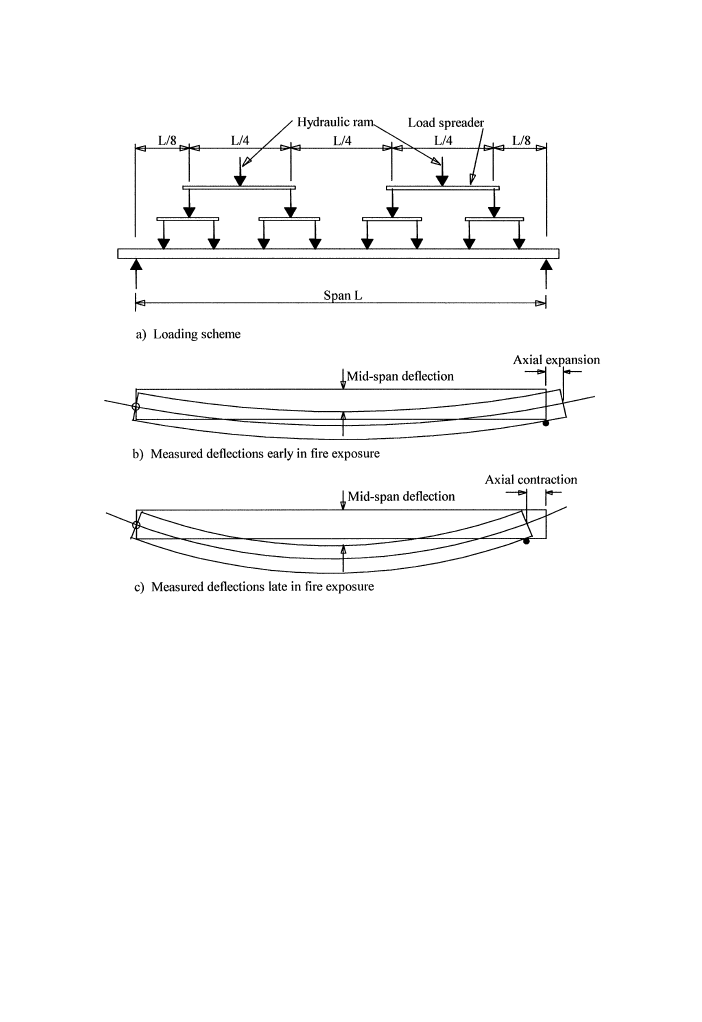

measured as time progressed is shown in Figs. 1(b) and (c).

It was assumed that the bowing behaviour of a large #oor panel which spans in one

direction will be similar to the behaviour of a narrower specimen if edge e!ects are

guarded against so that unidirectional heat #ow was achieved in the narrower

specimen. This assumption allowed two specimens to be tested side by side in the #oor

furnace, unrestrained by each other, in the simply supported condition with a span of

4.5 m. This also meant that the specimens could be easily manufactured, handled and

transported, and the cost of "re testing was reduced by more than 50%.

Precast #oor slabs of the kind tested are not used in modern #oor construction in

multi-storey buildings in UK which typically comprise hollow core prestressed

concrete planks with in situ topping or composite pro"led sheet steel/concrete #oor

decks. In addition, the tested #oor slabs were simply supported which results in

maximum #exural defection representing the worst case scenario in which bene"cial

rotational restraint generated by slab continuity over beams in multi-span #oors is

ignored. Nonetheless, the results have practical application to existing large panel

precast #oor construction which has little continuity at the supports and to new

single-span conventional in situ reinforced concrete construction. The data can also

be used to predict #exural de#ections of reinforced concrete #oor slabs having

rotational restraint but this requires an assessment of the positions of contra-#exure in

the #oor slab and any mitigating e!ect of membrane action arising from two-way

spanning, but this is beyond the scope of this paper. The test results are perhaps most

useful for enabling both qualitative and quantitative comparisons to be made while

changing important parameters such as the type of concrete and "re test severity.

Some of these test results have been presented by Cooke and Morgan in a BRE

Information Paper [1].

460

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 1. Loading scheme and measured de#ections.

Numerical modelling of the thermal and structural response of "re-exposed com-

posite steel and concrete structures has reached an advanced stage in the UK, much of

the impetus coming from the recent full scale test work conducted on an eight-storey

building erected in the BRE large laboratory at Cardington. Universities involved in

modelling include Edinburgh, She$eld and City.

1.1. Fire test parameters

For the BRE slabs the following parameters were varied: slab thickness (150 and

250 mm), type of concrete (normal weight and light weight), live load (zero and

1.5 kN/m

of

#oor slab area), so$t protection (zero and two di!erent gypsum board

systems) and severity of standard "re exposure (ISO 834 and the Norwegian Petro-

leum Directorate (NPD) temperature-time curves). Table 1 lists the chosen combina-

tions.

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

461

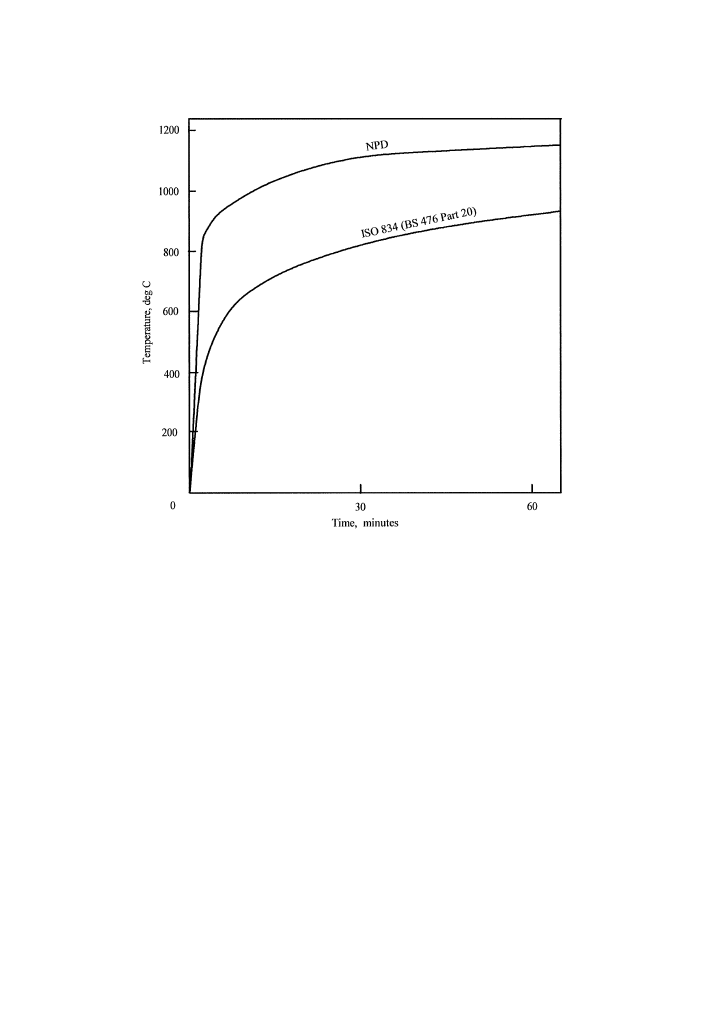

Fig. 2. Comparison of temperature}time curves used in tests.

The BRE slabs were designed to have a 90 min "re resistance assuming a live load of

1.5 kN/m

when exposed to the heating conditions speci

"ed in BS 476 Part 8: 1972

(ISO 834), which is appropriate for structural elements in high rise blocks of residen-

tial #ats in the UK. The time}temperature curve in Part 8 is the same as in the current

standards i.e. BS 476 Part 20, ISO 834 and the corresponding CEN standard. A com-

parison of the NPD and ISO/BS temperature-time curves is given in Fig. 2. The

structural design was based on BS 8110: Part 1: 1985 [2].

1.2. Fire test specimens

All the test specimens were 4.7 m long by 925 mm wide and were simply supported

at 4.5 m centres. The "re exposed length was 4.0 m.

The BRE slabs used concrete mixes designed to have a characteristic cube strength

of 30 N/mm

. The normal weight concrete (NWC) used a siliceous (20 mm

#int gravel)

aggregate with natural sand and had a nominal density of 2400 kg/m

; the light weight

concrete (LWC) contained Lytag ( pulverised fuel ash) coarse aggregate and had

a nominal density of 1800 kg/m

. All the reinforcing steel bars were of high yield

ribbed bar (Deformed Type 2 to BS 4449) having a nominal yield strength of

462

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Table 1

Fire test parameters

Test

Specimen

Thickness

(mm)

No. of

rebars

Concrete Live

load

Heating

Comments

1

1

150

10

NWC

No

BS 476

BRE slab

1

2

150

10

NWC

Yes

BS 476

BRE slab

2

3

150

10

NWC

No

NPD

BRE slab

2

4

150

10

NWC

Yes

NPD

BRE slab

3

5

250

6

NWC

No

BS 476

BRE slab

3

6

250

6

NWC

Yes

BS 476

BRE slab

4

7

150

10

LWC

No

BS 476

BRE slab

4

8

250

6

LWC

No

BS 476

BRE slab

5

9

150

10

NWC

No

NPD

BRE slab

5

10

250

6

NWC

No

NPD

BRE slab

6

11

150

10

NWC

No

BS 476

BRE slab#so$t (1)

6

12

150

10

NWC

No

BS 476

BRE slab#so$t (2)

7

13

185

NWC

No

BS 476

Ronan Point slab

7

14

185

NWC

Yes

BS 476

Ronan Point slab

Notes: Live load " 1.5 kN/m

, So

$t (1)"10 mm thick glass reinforced gypsum board with 37 mm air

gap, So$t (2)"12.5 mm gypsum Fireline board with 37 mm air gap, NWC"Normal weight concrete,

LWC"Light weight concrete, BS 476"BS 476: Part 8:1972 (ISO 834), NPD"Norwegian Petroleum

Directorate (hydrocarbon "re simulation).

460 N/mm

. The primary (longitudinal ) steel was 8 mm diameter. The concrete cover

to the primary steel was 25 and 20 mm for the NWC and LWC slabs, respectively,

being appropriate for 90 min "re resistance according to UK regulatory guidance [3].

The concrete side cover was 25 mm. The moisture content of the slabs varied between

3.5 and 4.5% by weight.

The Ronan point slabs comprised a structural reinforced concrete slab of normal

weight concrete nominally 180 mm thick incorporating circular voids of 110 mm

diameter running longitudinally at 150 mm centres. This slab was overlaid with

a non-composite 12.5 mm thick layer of expanded polystyrene foam and a 65 mm

thick granolithic concrete screed. The screed and foam was present during the "re

tests.

Two kinds of proprietary boarded so$t protection were fabricated and installed at

the "re test laboratory by British Gypsum Ltd. One slab was protected with a 10 mm

thick glass reinforced gypsum (GRG) board. Another slab was protected with a

12.5 mm thick Fireline gypsum-based board. Both board protections were "xed to the

concrete so$t using cold formed steel members which resulted in an air gap of 37 mm.

These protection systems were included in the test programme as they had been used

in remedial work contracts on high rise #ats. Details of the tests are given in Table 1.

For the BRE slabs thermocouples were attached to 50 mm diameter cylindrical

cores of the appropriate concrete mix at a range of heights. The sensing ends were

aligned horizontally so that they would lie on an isotherm and were adhered to the

core with an epoxy resin. The ends of the cores were lightly bonded to the plywood

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

463

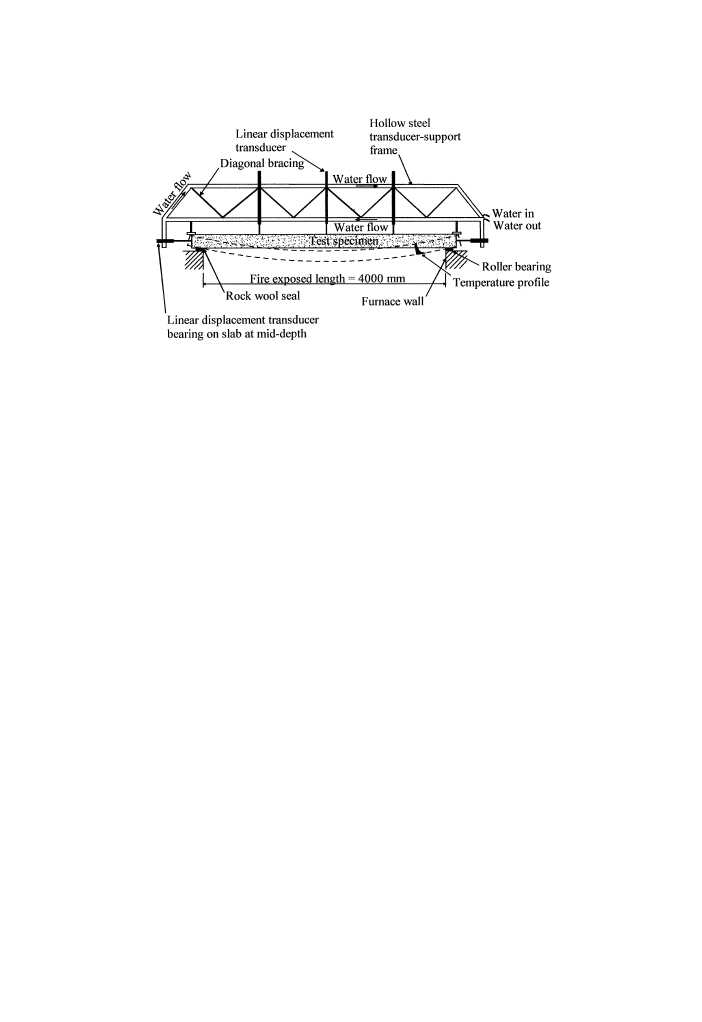

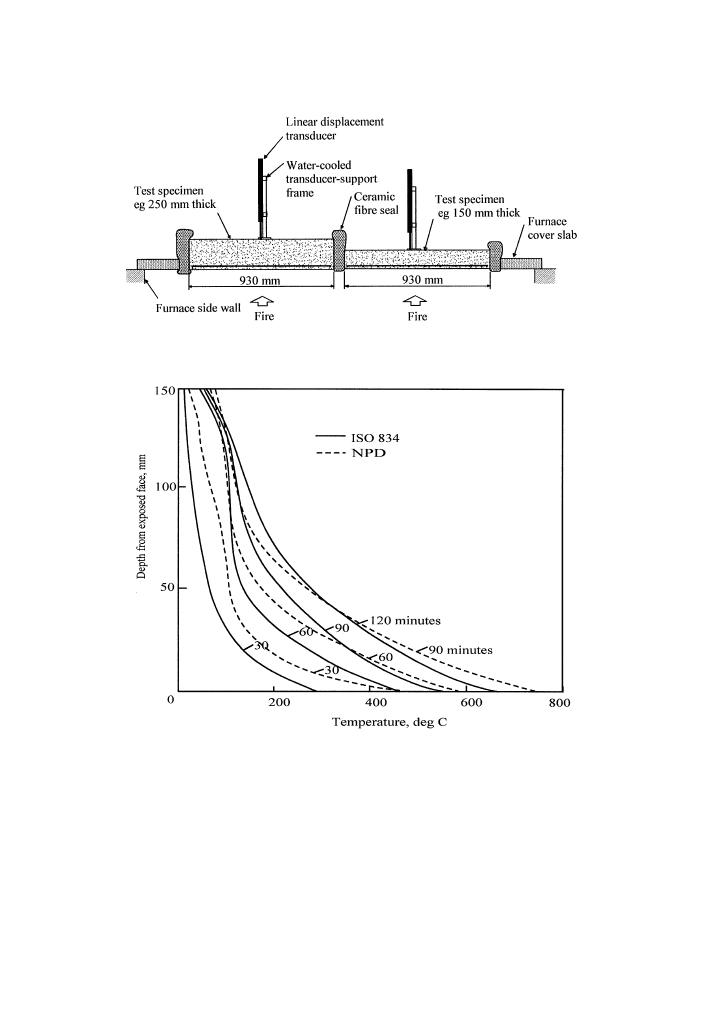

Fig. 3. Longitudinal section through furnace showing transducer-support frame.

formwork before casting the slabs so that the position of all cores and hence

thermocouples from the "re-exposed face were accurately known. The cores were

placed at mid-span and quarter-span positions along the centreline of the slab.

1.3. Test apparatus

The tests were made in the "re resistance #oor furnace at the Warrington Fire

Research Centre. The ends of each slab were simply supported. All de#ection

measurements were made relative to the ends of a slab using two purpose-made

hollow steel frames which rested on the ends of the slab. Each frame was kept cool

during a test using a continuous #ow of water so it would not itself de#ect due to

a change in ambient conditions. Linear displacement transducers (LDT's) were used

to measure vertical de#ections at mid-span and quarter-span positions. An LDT was

also aligned horizontally at either end of the slab at mid depth so as to measure axial

de#ection. The apparatus is shown in Fig. 3. Loads were applied using A-frames, two

hydraulic jacks and a system of load spreaders to approximate uniformly distributed

loading indicated in Fig. 1(a).

In each test, two slabs were laid side by side separated from each other and from the

furnace cover slabs with a #exible ceramic "bre seal so that the edges of the slabs were

protected from "re and were free to de#ect during a test. Fig. 4 shows the arrangement

in which a pair of slabs of di!erent thickness are being tested.

2. Test results

2.1. Temperature proxles in slabs

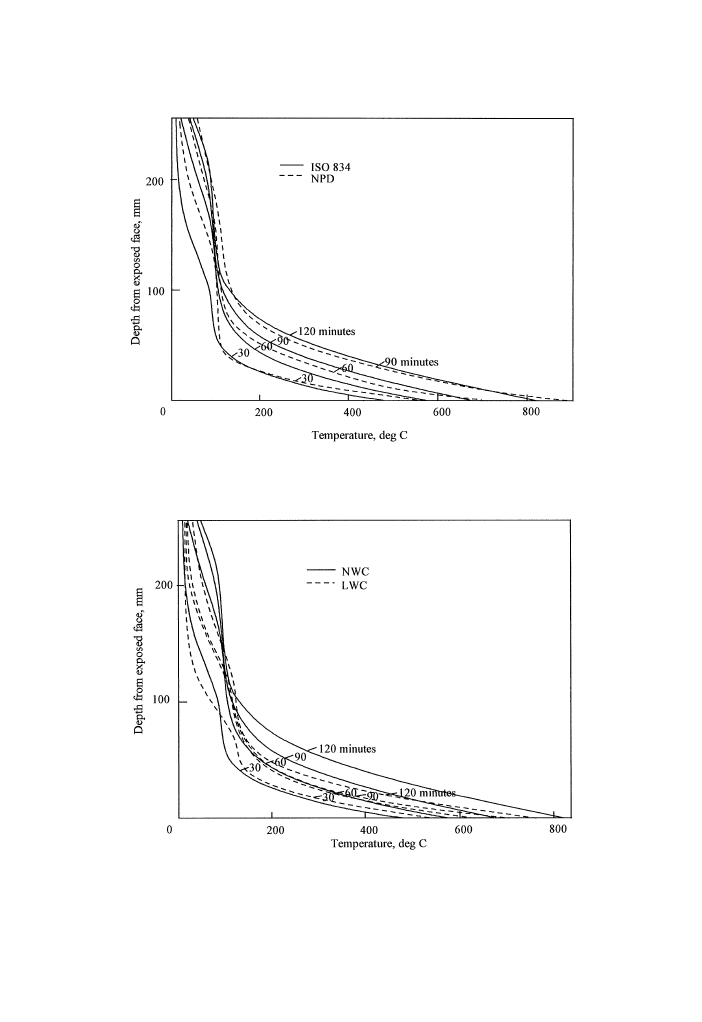

Averaged temperature pro"les within BRE slabs without so$t protection at 30 min

increments are given in Figs. 5}7. The "gures show the e!ect of varying the "re

464

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 4. Cross section of #oor slab specimen assembly.

Fig. 5. Temperature pro"les (150 mm, NWC).

exposure and type of concrete. The pro"les in the 250 mm slabs show a clearly

pronounced moisture plateau at 1003C when steam is driven o! and also exhibit

steeper temperature gradients and higher temperatures near the exposed surface when

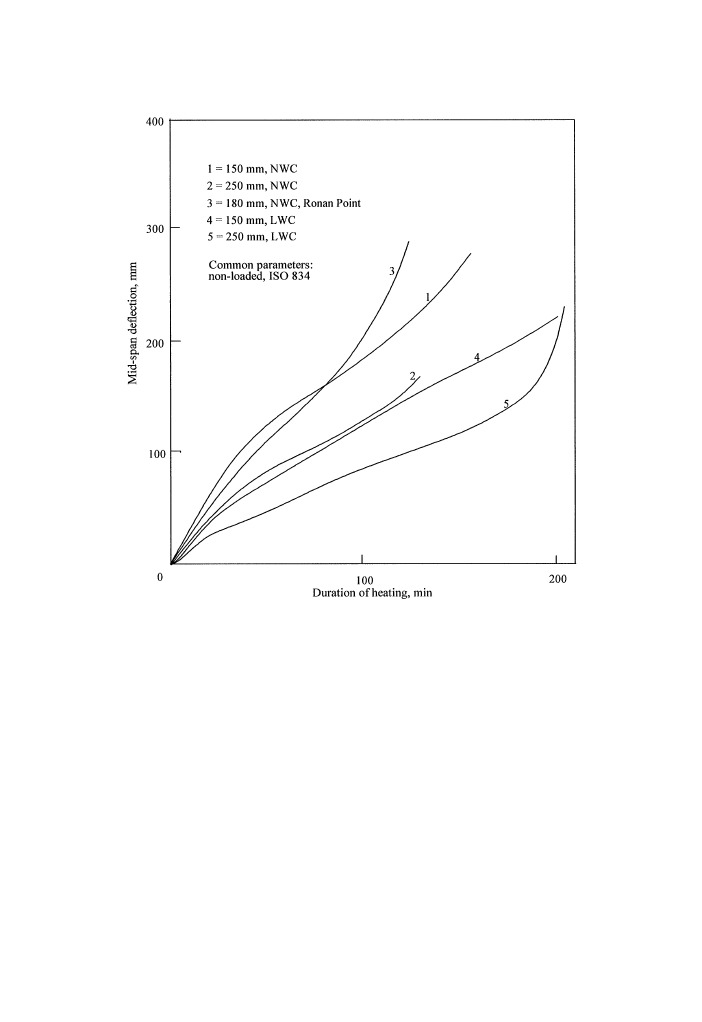

compared with the data for the 150 mm slabs. Fig. 7 shows that the e!ect of the higher

thermal insulation of Lytag LWC made little di!erence to the maximum temperatures

attained in the concrete, but the bene"t of LWC is considerable at the depth where the

reinforcing steel is normally located: the temperature at 20 mm after the 90 min design

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

465

Fig. 6. Temperature pro"les (250 mm, NWC).

Fig. 7. Temperature pro"les (250 mm, ISO 834).

466

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 8. E!ect of slab thickness and concrete type.

exposure to ISO 834 is approximately 3003C for the 250 mm thick slab, and at

this temperature the reinforcing steel would have lost none of its room temperature

ultimate tensile strength [4,5]. The e!ect of the hydrocarbon exposure when

compared to the ISO 834 exposure is, as expected, markedly to increase the temper-

atures near the exposed face as shown in Figs. 5 and 6. It has to be recognised that it is

di$cult accurately to measure the temperature of concrete at the concrete/combus-

tion gas interface because of the large temperature gradient.

All of the slabs tested resisted spalling throughout the full period of "re exposure

and it can therefore be said that any aberrations in the temperature data are not due

to spalling; such aberrations can occur due to moisture removal during the heating

process and this e!ect, as previously mentioned, can and did have an e!ect. It should

not be concluded from this work that spalling is not a problem: it is generally accepted

that spalling can occur where a large hogging moment is present (it was absent in the

present tests because of the simple supports), and there is increasing evidence that high

strength concrete used in prestressed planks is prone to spalling in "re.

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

467

Fig. 9. E!ect of imposed load.

2.2. Mid-span deyections

Here some of the more important comparisons are made of measured mid-span

de#ections. It is assumed that the #exural de#ection of a non-loaded slab is dominated

by thermal bowing, i.e. the self weight of the slab has negligible e!ect upon de#ections

except near ultimate failure. With the exception of a 250 mm NWC slab exposed to the

hydrocarbon "re which su!ered runaway de#ection at 110 min, none of the slabs

collapsed during the exposure period of nominally 2 h so the assumption that thermal

bowing is dominant within the 90 min design period of "re exposure seems reasonable.

2.2.1. Ewect of slab thickness

Fig. 8 shows the e!ect of slab thickness for three NWC and two LWC slabs,

respectively, when exposed to ISO 834. The thicker slab de#ects less which is what one

might expect intuitively and agrees with the theory of thermal bowing [1] which

shows that thermal bowing is inversely proportional to the slab thickness. The

468

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 10. E!ect of heating rate.

de#ection curve for the non-loaded 180 mm thick Ronan point slab suggests that the

relative magnitudes of de#ection agree with the theory of thermal bowing up to

80 min*the curve for 180 mm thickness lies between those for 150 and 250 mm.

2.2.2. Ewect of concrete type

Fig. 8 also shows the e!ect of concrete mix on de#ections of non-loaded slabs of

150 and 250 mm thickness, respectively, when exposed to ISO 834. The lightweight

concrete slabs (incorporating Lytag aggregate made from pulverised fuel ash) de#ect

markedly less than the NWC slabs. This may be attributed to (a) the lower thermal

conductivity of the LWC which may result in lower temperatures and lower thermal

expansion in the "re-exposed structural layer, and (b) the lower coe$cient of linear

thermal expansion of Lytag compared with dense aggregate, but further analysis

would be needed before the relative importance of thermal conductivity and thermal

expansion could be assessed. Certainly the di!erence in de#ections is large*at the

90 min design period of "re resistance the mid-span de#ections of the LWC slabs are

roughly two}thirds those of the NWC slabs, and it should be remembered that these

are di!erences in thermal bowing since the slabs were not loaded.

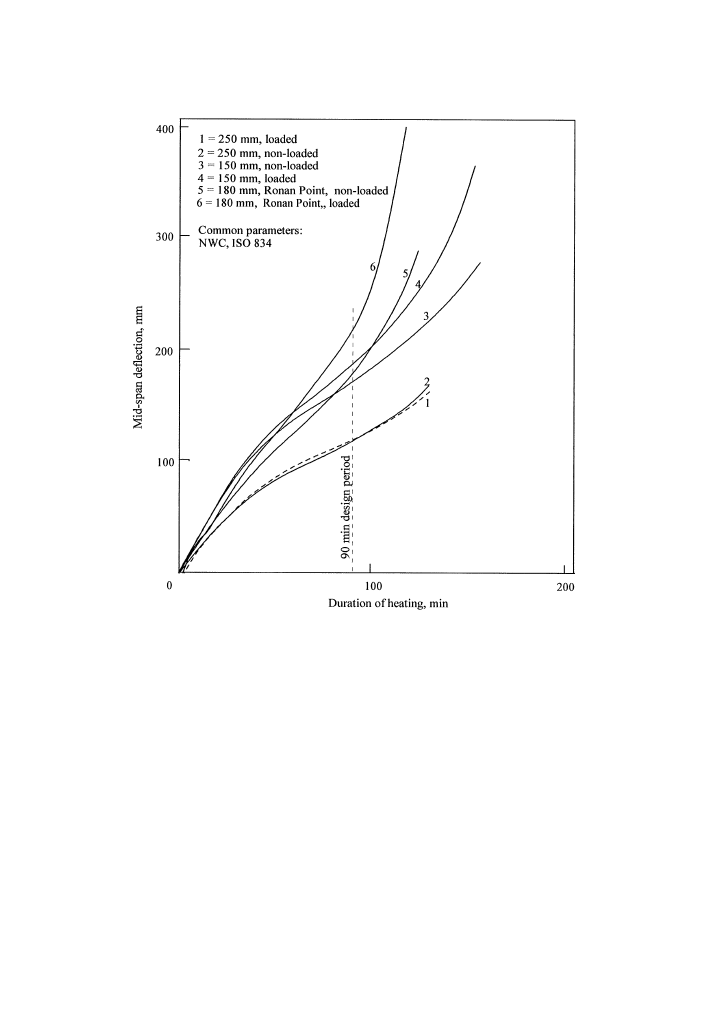

2.2.3. Ewect of imposed load

Fig. 9 shows the e!ect of imposed load on mid-span de#ections for NWC slabs 150

and 250 mm thick, respectively, when exposed to ISO 834. Within the design period of

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

469

Fig. 11. E!ect of so$t protection.

90 min "re resistance it is clear that the mid-span de#ections are a!ected to a negli-

gible e!ect by the imposed load. The mid-span de#ection of the 180 mm thick Ronan

point slabs exposed to ISO 834 also demonstrated the negligible e!ect of the

1.5 kN/m

imposed load although it should be noted that the design imposed load is

not known for the Ronan point building. Hence the de#ections are dominated by

thermal bowing. This is an important "nding as it shows that a calculation of thermal

bowing would su$ce in estimating the likely total de#ections before the onset of

collapse.

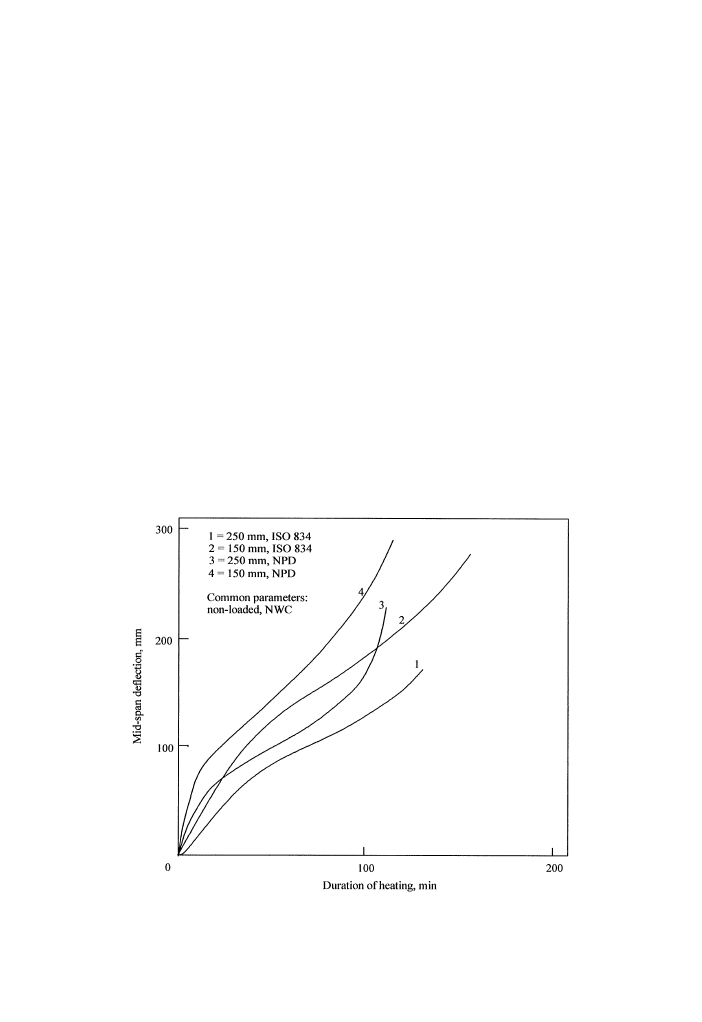

2.2.4. Ewect of heating rate

Fig. 10 shows the e!ect of exposing non-loaded NWC slabs of 150 and 250 mm

thickness, respectively, to the NPD (hydrocarbon) temperature}time curve which has

a higher heating rate than ISO 834. The NPD exposure results in much larger

de#ections, especially in the early stage of exposure: at 20 min the de#ections were

almost doubled in the 250 mm thick slab. Although both slabs were designed to have

a 90 min "re resistance for ISO 834 exposure, the slabs were able to resist collapse

under the more severe NPD exposure for the 90 min period and this suggests that

there is a large measure of safety associated with present UK "re safety design practice

for reinforced concrete slabs.

470

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 12. E!ect of slab thickness.

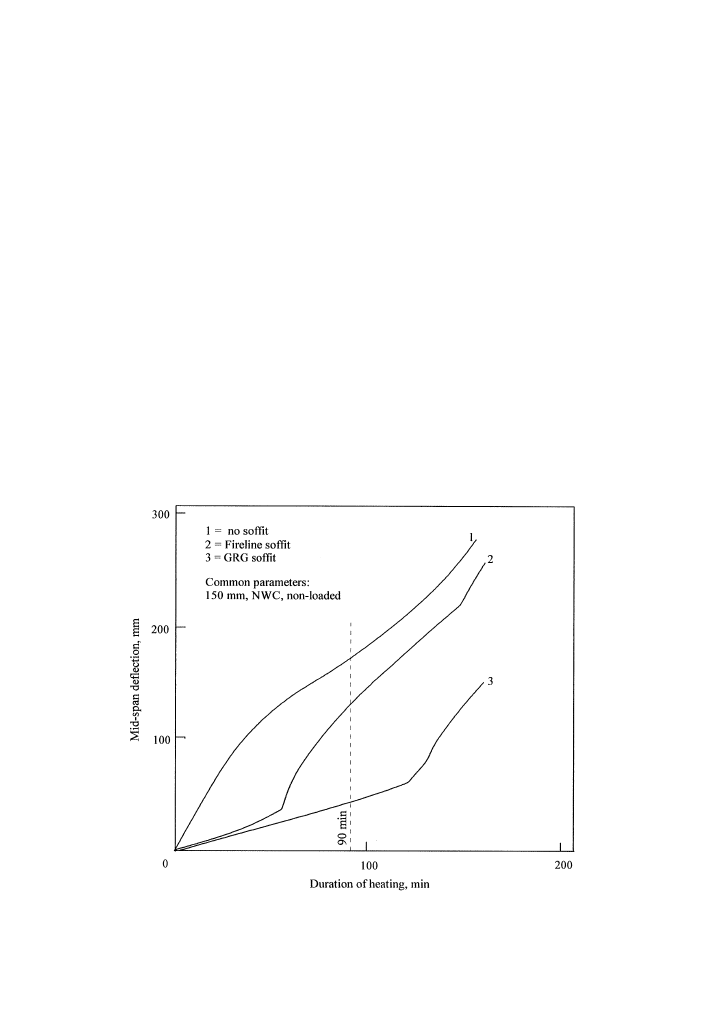

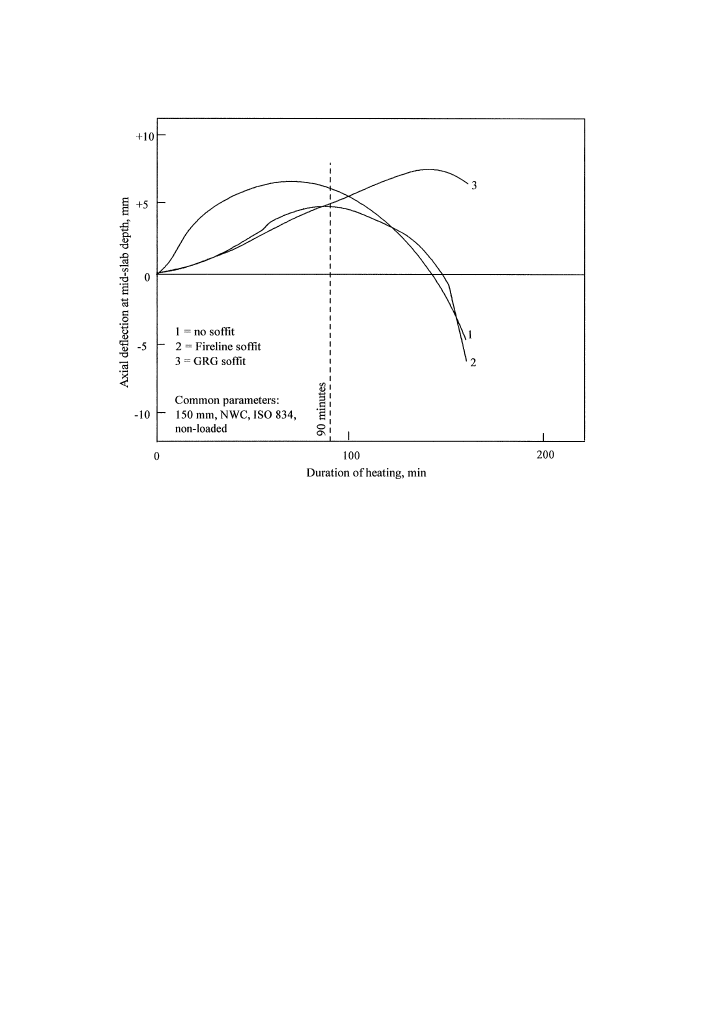

2.2.5. Ewect of sozt protection

Fig. 11 shows de#ections of 150 mm thick non-loaded slabs of NWC exposed to

ISO 834 with and without the two di!erent "re protecting boards. Details of the

protection are given earlier. The curves show that the addition of a plaster-based so$t

gives much smaller de#ections provided the protection remains in place (part of the

Fireline fell down at approximately 55 min). At the 90 min design period of "re

resistance the de#ection of the slab with GRG protection was roughly a quarter of

that of the unprotected slab.

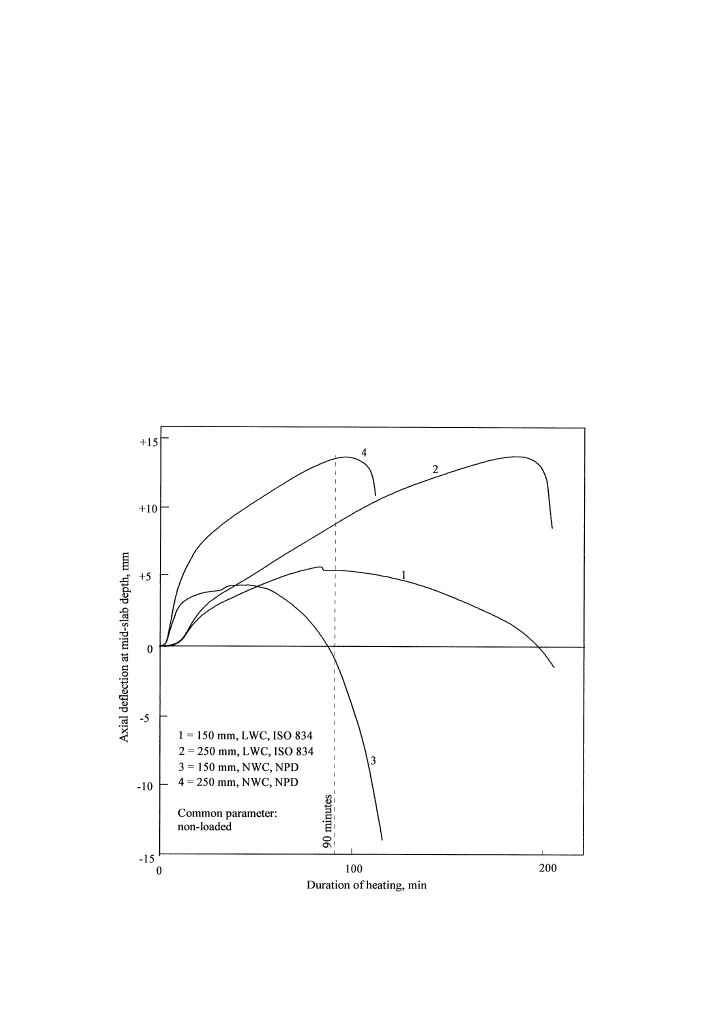

2.3. Axial deyections

Axial de#ection is here de"ned as the horizontal de#ection of one end of a slab

relative to the other end. All the measured de#ections were made at the mid depth of

the slab, Fig. 1. A positive axial de#ection corresponds to an increase in the chord

length as occurs in the early stage of "re exposure due to thermal expansion. Later in

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

471

Fig. 13. E!ect of imposed load.

the "re exposure excessive bowing leads to a shortening of the chord length and

a negative axial de#ection is obtained. Since the axial de#ection depends on the

mid-span de#ection in the later stages of "re exposure, an understanding of the axial

de#ection curves requires reference to the corresponding mid-span de#ection curves.

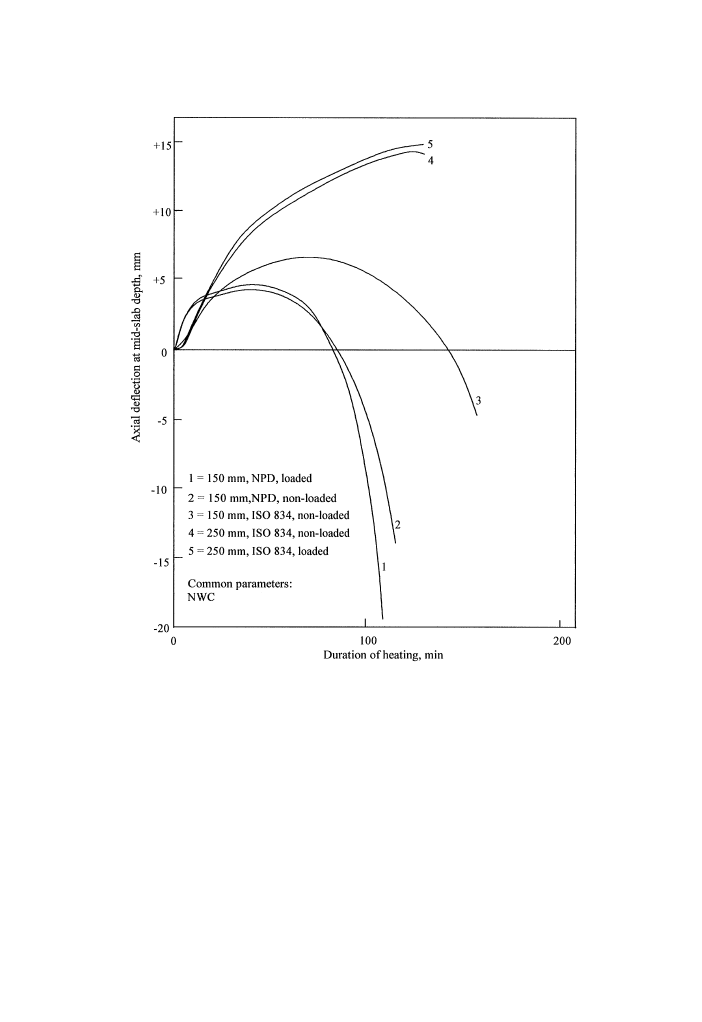

Measured axial de#ections are given in Figs. 12}15. Some general comments on the

results are as follows:

Fig. 12 shows axial de#ections for 150 and 250 mm thick, non-loaded slabs of LWC

exposed to ISO 834. The axial de#ection is larger for the thicker slab, and the time of

maximum de#ection is di!erent, being delayed for the thicker slab. At 90 min the

de#ection was 5.5 and 9 mm for the 150 and 250 mm slabs, respectively. Maximum

de#ections for 150 and 250 mm thick, non-loaded slabs of NWC exposed to NPD

were 5.5 and 14 mm, respectively.

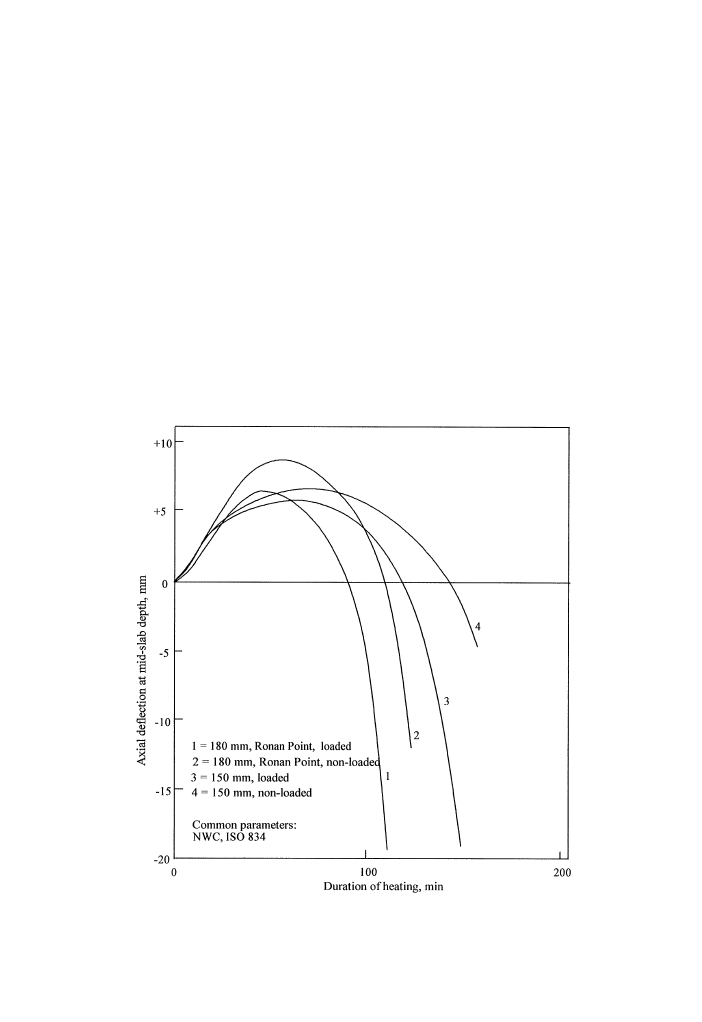

Fig. 13 shows axial de#ections of the non-loaded and loaded 180 mm thick Ronan

point slabs and 150 mm slabs of NWC exposed to ISO 834. The runaway axial

de#ections of the Ronan point slabs are attributed to the runaway mid-span de#ec-

tions. Fig. 14 shows, more than in any other test, the negligible e!ect of imposed load

472

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

Fig. 14. E!ect of imposed load.

on axial de#ection, and this can be attributed to the almost identical mid-span

de#ection curves.

Fig. 14 shows that the largest axial de#ection of all the tests occurred with the

250 mm NWC slab exposed to ISO 834*the maximum positive de#ection was

14 mm. In contrast, the 150 mm NWC slab exposed to NPD exhibited an early

maximum positive axial de#ection of only 4 mm followed by a reversal and large

negative de#ections. The "gure also shows the large e!ect of the rapid heating

achieved in the NPD exposure for 150 mm thick NWC slabs.

Fig. 15 shows that the axial de#ection of the so$t-protected 150 m NWC slab is

approximately three-quarters that of the unprotected slab at the 90 min design period

of ISO 834 "re exposure.

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

473

Fig. 15. E!ect of so$t protection.

3. Conclusions

(1) A series of seven furnace tests has been successfully carried out giving accurate

data on mid-span de#ection and axial de#ection for 14 unrestrained reinforced

concrete #oor slabs having a "re exposed length of 4000 mm. The e!ect of

varying the slab thickness, imposed load, heating rate, concrete type and so$t

protection has been established. These data enable numerical models to be

validated.

(2) The method of test whereby two slabs nominally 900 mm metre wide structurally

independent of each other are exposed to the same heat #ux means that accurate

comparisons can be made. The method also means that specimens can easily be

manufactured, handled and transported, and the cost of testing is halved which is

an important consideration for parametric research studies of the kind reported

in this paper.

(3) Mid-span de#ections were dominated by thermal bowing during the 90 min

design period of "re exposure; the e!ect on de#ections of imposing the design live

load of 1.5 kN/m

, Fig. 9, was very small and this suggests that BS 8110 is

conservative.

(4) The higher rate of heating associated with the NPD hydrocarbon "re exposure

caused almost a doubling of mid-span de#ection obtained using the ISO 834 "re

exposure in the "rst 20 min, Fig. 10.

474

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

(5) The e!ect of using lightweight concrete employing Lytag coarse aggregate is to

reduce the mid-span de#ection associated with normal weight concrete by rough-

ly 30% at the 90 min design period of "re resistance, Fig. 8. The reduced

de#ections are probably due to the lower coe$cient of thermal expansion and

lower thermal conductivity of light weight concrete.

(6) The e!ect of so$t protection is, as one might expect, to reduce the mid-span

de#ection. Fig. 11 shows that the mid-span de#ection of the 150 mm NWC slab

with so$t protection was roughly a quarter that of the unprotected slab. Fig. 15,

however, shows that the slab having a so$t protection which remained in place

su!ers almost the same magnitude of axial de#ection at mid-slab depth as the

same slab with no so$t protection, although the peak de#ection occurred much

later for the so$t-protected slab.

Acknowledgements

The author wishes to thank Professor G. Cox, Fire Research Station, Building

Research Establishment, for permission to publish the test results and Mr. R.L.

Sawford and his team in the Civil Engineering Laboratory, BRE, Cardington for

making the precast concrete test specimens. Thanks are also due to British Gypsum

Ltd for supplying and installing, free of charge, two so$t board protection systems.

Again thanks are due to laboratory sta! of Warrington Fire Research Centre who

worked closely with the author in the preparation for and conduct of the tests. The

provision of funds from the Construction Directorate of the Department of the

Environment is gratefully acknowledged.

References

[1] Cooke GME, Morgan PBE. Thermal bowing in "re and how it a!ects building design. BRE

Information Paper IP 21/88, Building Research Establishment, December 1988.

[2] BS 8110 Structural use of concrete, Part 1 Code of practice for design and construction. British

Standards Institution, 1985.

[3] Morris WA, Read REH, Cooke GME. Guidelines for the construction of "re resisting structural

elements. Building Research Establishment Report BR 128, BRE, Garston, 1988.

[4] Holmes M, Anchor RD, Cooke GME, Crook RN. The e!ects of elevated temperatures on the strength

of reinforcing and prestressing steels. The Structural Engineer 1982;60(1):7}13.

[5] British Standards Institution, ENV 1993: Design of steel structures: DD ENV 1993-1-2: Structural "re

design (including UK NAD). Expected 2001.

G.M.E. Cooke / Fire Safety Journal 36 (2001) 459}475

475

Wyszukiwarka

Podobne podstrony:

Behaviour of precast reinforced concrete pile caps

08 Polak M A Preventing punching shear failures of reinforced concrete slabs, results of static and

Principles of Sigma Delta Conversion for Analog to Digital Converters

FreeNRG Notes from the edge of the dance floor

16 197 208 Material Behaviour of Powder Metall Tool Steels in Tensile

[2006] Application of Magnetic Energy Recovery Switch (MERS) to Improve Output Power of Wind Turbine

Analysis of Gangs Why are Youth drawn to them

36 495 507 Unit Cell Models for Thermomechanical Behaviour of Tool Steels

43 597 609 Comparison of Thermal Fatique Behaviour of Plasma Nitriding

50 707 719 Thermal Fatique and Softening Behaviour of Hot Work Steels

44 611 624 Behaviour of Two New Steels Regarding Dimensional Changes

Electrochemical behavior of exfoliated NiCl2–graphite intercalation compound

Analysis of Reinforced Concrete Structures Using ANSYS Nonlinear Concrete Model

DYNAMIC BEHAVIOUR OF THE SOUTH Nieznany

Management of Adult Patients With Ascites Due to ascites

49 687 706 Tempering Effect on Cyclic Behaviour of a Martensitic Tool Steel

Design Guide 11 Floor Vibrations Due To Human Activity

Ecology and behaviour of the tarantulas

Fatigue Behavior of Polymers

więcej podobnych podstron