Biomaterials 22 (2001) 2931}2936

The corrosion resistance of pure titanium in organic acids

Marie Koike*, Hiroyuki Fujii

Department of Removable Prosthodontics, Nagasaki University School of Dentistry, 1-7-1 Sakamoto, Nagasaki 852-8588, Japan

Received 15 September 2000; accepted 22 January 2001

Abstract

The purpose of this study was to assess the corrosive properties of titanium at various pHvalues. Cast pure titanium specimens

were immersed in 128 mmol/l of lactic and formic acids at pH1.0}8.5 for 3 weeks at 373C. The solubility, color, weight and chemical

binding state of specimens were observed. Titanium dissolved in all lactic acid. The amount of dissolved titanium tended to decrease

with a higher pH. In formic acid, the amount of dissolved titanium at pH 1.0 was larger than that in lactic acid at the same pH, but less

than the detectable limit at pH4.0 or higher. Signi"cant discoloration was macroscopically observed only in formic acid at pH2.5 and

4.0. The weight of the titanium samples immersed in lactic acid all decreased, but it was not a!ected by pH. In formic acid, the weight

decreased at pH1.0 and increased at pH2.5}5.5. Thickening of the TiO corresponding to that showing discoloration was observed in

the super"cial oxide "lm of the titanium samples. Our results show that the corrosive properties of titanium are markedly dependent

on pHin formic acid, and relatively less dependent on pHin lactic acid in which titanium is dissolvable at pH1.0}8.5.

2001

Elsevier Science Ltd. All rights reserved.

Keywords: Titanium; Organic acid; PH; Immersion; Corrosion

1. Introduction

Biocompatibility is one of the most important condi-

tions for biological materials, and since titanium is con-

sidered to have high biological a$nity, it is used as

a medical material. In fact, in patients with hypersensitive

reaction to the present dental alloys, pure titanium is one

of the metals that can be used for dental restoration.

However, there have been several studies describing pa-

tients who did not adapt to titanium [1,2] or patients

allergic to titanium [3}6].

We previously reported that titanium has a high resist-

ance to corrosion in physiological saline and arti"cial

saliva by immersion tests, and that it was dissolved and

became discolored when in contact with lactic acid or

formic acid, which are both produced in the mouth [7,8].

However, these results were obtained at pH 2.5 below

128 m

M

of acid solutions.

Based on the electric potential}pH "gure at 253C

[9], titanium is stable around the electric potential equi-

librium (passive state area), irrespective of pH, but it is

* Corresponding author. Tel.: #81-95-849-7693; fax: #81-95-849-

7694.

E-mail address: marie-k@net.nagasaki-u.ac.jp (M. Koike).

likely to corrode at electric potentials lower (strongly

acidic) and higher (strongly alkaline) than the equilib-

rium (corrosive area). The roughness and solidity of the

titanium surface varied by anodic oxidation in physiolo-

gical saline bu!ered at di!erent pHwith phosphate [10],

and titanium ions were more dissolved in culture solu-

tions at a lower pH[11]. Moreover, it has been hy-

pothesized that the dissolution of titanium varied in vivo

with complicated changes in the surrounding pHcaused

by organic and inorganic ions [12].

In the oral cavity, dental plaque, which includes or-

ganic acids such as lactic and formic acids, is more likely

to precipitate on the titanium surface, compared to other

dental metal alloys [13], and the kinds and concentra-

tions of organic acids can vary depending on whether the

environment is aerobic or anaerobic [14]. Furthermore,

the pHaround titanium was reduced in contact with

other metals such as amalgam [15].

The pHof dental plaque after consuming sugar is

about 4.0 [16], but it can range from 2.0 to 11.0 depend-

ing on the foods and beverages consumed [17]. Thus, it is

necessary to investigate the properties of titanium for

clinical use, especially under various conditions in the

mouth [7,8]. The present study investigated the e!ects of

organic acids at various pHon the chemical stability of

titanium.

0142-9612/01/$ - see front matter

2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 0 4 0 - 0

Table 1

Test material and the chemical composition of mass %

Material

Ti

Fe

Others

Pure titanium A

99.49

0.25

0.26

2. Materials and methods

2.1. Preparation of samples

According to the manufacturer's instructions, cast

samples measuring about 15 mm

;20 mm;1 mm or

5 mm

;5 mm;1 mm were made from pure titanium

(equivalent to ASTM grade 2, described simply as tita-

nium hereafter) (Table 1) [18]. The surfaces of the cast

samples were air-abraded using

50 m alumina pow-

der, and then the samples were "nished with ASTM

C600 wet silicon carbide paper.

During the process of abrasion, surface thickness of the

samples was reduced by 250}300

m, and the reduced

thickness was more than the thickness of the reaction layer

[19]. Subsequently, the samples were subjected to ultra-

sonic cleaning in acetone for 15 min to remove any grease,

then stored in a desiccator. Solubility, color, and weight

changes were examined using the large samples, and the

chemical binding states of the surface were examined using

small samples. Experiments were performed in duplicate.

2.2. Immersion of samples

As immersion solutions, lactic acid and formic acid at

pH2.5 were diluted with distilled and deionized water to

128 m

M

(equivalent to lactic acid at 1%), and were ad-

justed to pH1.0, 4.0, 5.5, 7.0, and 8.5 using 1

N

hydrochlo-

ric acid or 1

N

sodium hydroxide. After pHadjustment,

the concentration of hydrochloric acid and sodium hy-

droxide in the immersion solutions was 159 m

M

(0.58%)

and 105 m

M

(0.42%), respectively.

A titanium sample was entirely immersed in 10 ml of the

immersion solution in a 50 ml centrifugal tube, and the

tube was covered with a lid to prevent evaporation. For

each immersion solution, 4 tubes containing a large

sample and 1 tube containing a small sample were pre-

pared. These tubes were shaken at 80 rpm in an isothermal-

shaking bath at 373C. Three weeks later, the amounts of

dissolved metal ions were measured, then the samples were

removed from the tubes, and subjected to ultrasonic clean-

ing in distilled water for 15 min, then in acetone for 15 min.

The samples were dried in a desiccator, and the color,

weight, and properties of the surface were examined.

2.3. Determination of dissolved ion concentration

The amount of ions dissolved in the immersion solu-

tion of each tube was measured 4 times in an Inductively

Coupled

Plasma-Atomic

Emission

Spectrometry

(SPS1700HVR, Seiko Instruments Inc., Chiba, Japan;

ICP-AES hereafter). Measurements below the detectable

limit (0.005 ppm) were regarded as 0 ppb. The standard

reagent was titanium standard solution for atomic ab-

sorption spectrometry diluted to 1 ppm with unused im-

mersion solution.

The amount per unit area of dissolved ions was deter-

mined by dividing the measured amount by the surface

area calculated using the outer size of samples.

2.4. Discoloration of the surface of samples

The color of the surface of the dried samples was

visually examined, the color at 5 randomly chosen sites in

each sample was measured using a spectrophotometer

(CM-503i, MINOLTA Co. Ltd., Tokyo, Japan), and the

mean of measured values were regarded as the color

value of that sample.

Measurements were performed under the conditions of

a light source of D65, a visual "eld angle of 103, and

a diameter of 3 mm. The color di!erence (

E*ab) be-

tween the standard color (color value of the samples

before immersion) and the measured color value

was determined according to the L*a*b* colorimetric

system [20].

2.5. Weight changes of samples

Samples were weighed using an electronic analytical

balance (AEM-5200, Shimadzu Co., Kyoto, Japan, read-

ability"0.001 mg).

The weights of polished, defatted, and dried samples

before immersion and washed and dried samples after

immersion were measured twice, and the mean was deter-

mined. The weight change per unit area was determined

by dividing the di!erence in the mean weight before and

after immersion by the surface area of samples.

2.6. Observations of the chemical binding state

on the titanium surface

To examine the changes in the properties of the tita-

nium surface, the chemical binding state of the sample

surface were observed using an X-ray photoelectron

spectrometer (ESCA-850, Shimadzu Co., Kyoto, Japan,

described simply as ESCA hereafter), and the depth was

measured by repeated etching using argon ions in the

apparatus. Based on the reported binding energy of tita-

nium and measurement of O1s, the binding energies of Ti

and TiO at 2p1/2 and 2p3/2 were calculated to be 459.9

and 464.8 eV, respectively, and 453.8 and 459.1 eV, re-

spectively [21,22].

Mg K

(acceleration voltage, 8 kV; ion current, 30 mA)

was used as the excited X-ray source for ESCA. Etching

was performed in 90 layers at 1 kV, 20 mA for 30 s. The

2932

M. Koike, H. Fujii / Biomaterials 22 (2001) 2931}2936

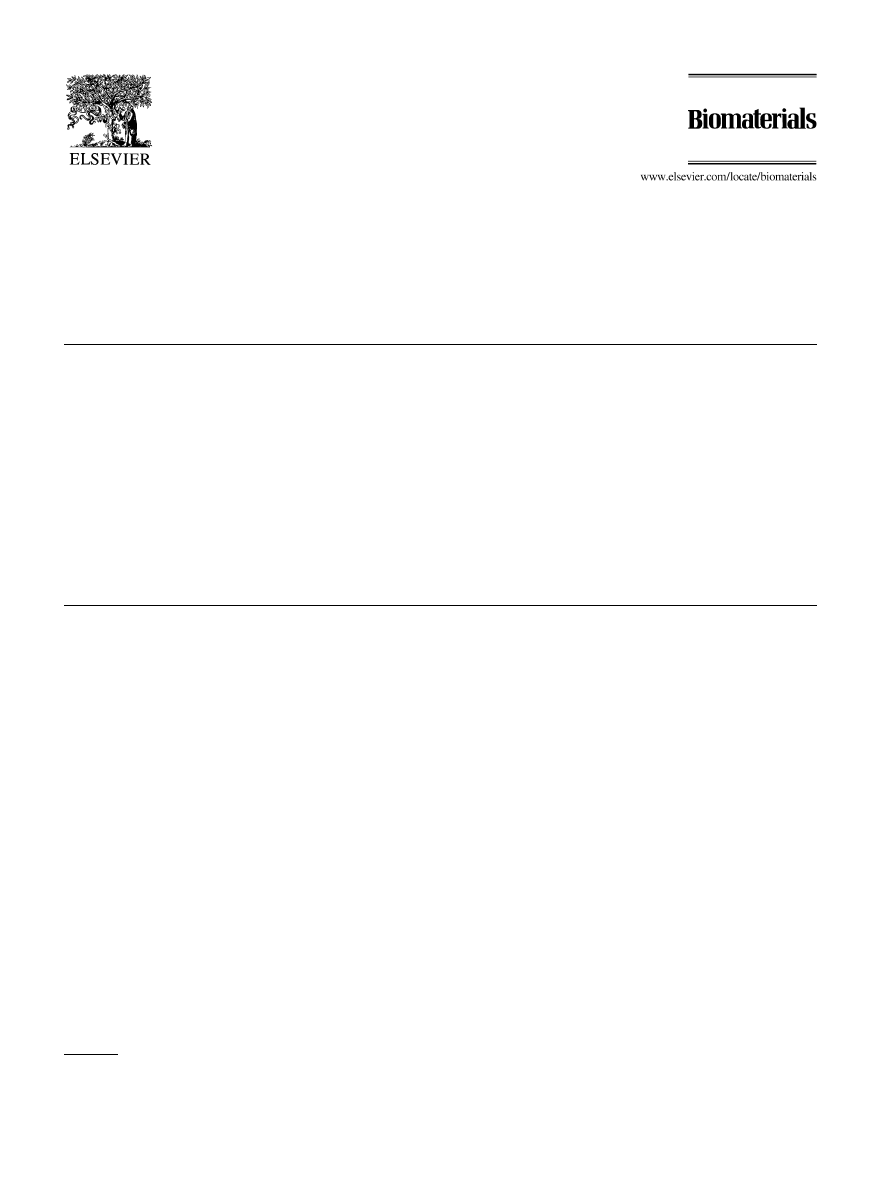

Fig. 1. Dissolution of titanium ion after 3-week immersion test (mean

and SD).

degree of vacuum was about 2

;10\ Pa at the time of

examination

of

the

sample

surface

and

about

6.5

;10\ Pa at the time of etching. By using the formula

for calculation, etching depth per etching was calculated

to be approximately 18 A

s [23].

2.7. Statistical analysis

The amount of dissolved titanium ions, discoloration

of the surface of samples, and changes in the sample

weight were statistically examined by one-way analysis of

variance (ANOVA). If a di!erence appeared to be signi"-

cant, the parameter was further examined by multivariate

variance analysis [24].

3. Results

3.1. Dissolution of titanium ions

The pHof both lactic acid and formic acid signi"cantly

a!ected the dissolution of titanium ions and the e!ect of

pHwas signi"cantly higher in formic acid than in lactic

acid (p(0.001).

Fig. 1 shows the amount of dissolved titanium ions in

immersion solutions. In lactic acid, the amount of dis-

solved titanium ions decreased with a higher pH, within

a range of 1.0

GpHG7.0. The amounts of dissolved ions

at pH1.0 and 2.5 were signi"cantly larger than those at

pH4.0 or higher (p(0.015), but there was no di!erence

among pHvalues greater than pH4.0. The amount of

dissolved ions was slightly larger at pH8.5, but the

di!erence was not signi"cant. In formic acid, the e!ects of

pHon dissolution were very signi"cant. A large amount

of titanium (0.735 ppm/cm

) was dissolved at pH1, and

this was 1.6-fold larger than the amount of ions dissolved

in lactic acid at the same pH. However, the amount of

dissolved ions markedly decreased at a pHhigher than

1.0, and was below the detectable limit at pH4.0 or

higher.

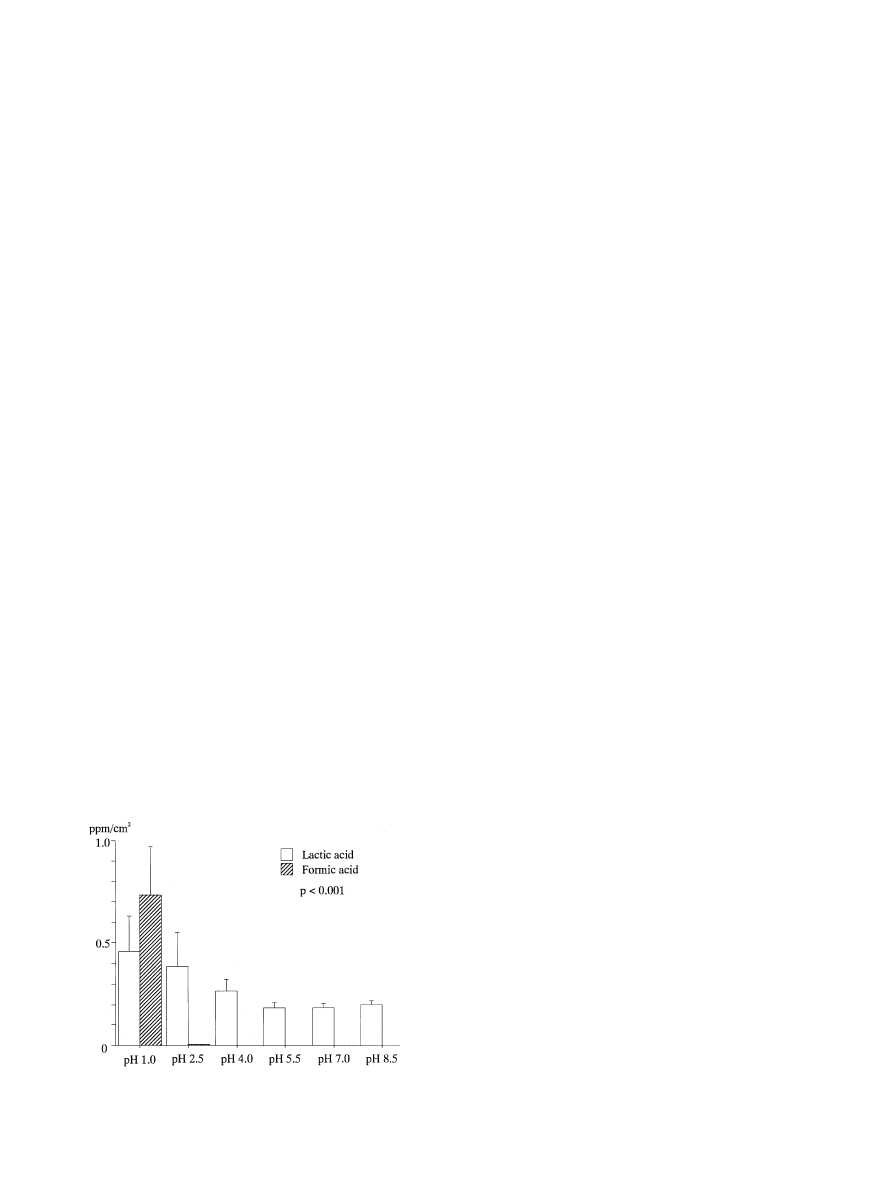

3.2. Discoloration

Fig. 2 shows the characteristic cases of titanium

samples before and after immersion. Analysis of the

color di!erence revealed that the e!ects of pHon dis-

coloration di!ered between lactic acid and formic acid,

and color di!erences between lactic acid and formic acid

were observed only for pH2.5, 4.0 and 5.5 (Fig. 3)

(p(0.0001). In lactic acid, the color di!erences of

samples were considered

`slighta according to the

criteria proposed by the International Lighting Com-

mittee

, but it was not signi

"cant between di!erent pH

(p'0.72).

However, the e!ects of pHin formic acid on discolora-

tion were signi"cant (p(0.001), and marked discolora-

tion of the samples immersed in formic acid at pH2.5 and

pH4.0 was visually observed. The color di!erence value

(

E*ab) was 13.8 at pH2.5 and 8.3 at pH4.0, which were

considered to be

`very mucha and `mucha, respectively,

according to the above criteria.

E*ab of the sample immersed in formic acid at pH

1.0, 7.0 and 8.5 were less than 1.37, which was not

signi"cantly di!erent from those in lactic acid (p'0.44).

3.3. Weight changes

The e!ect of pHon weight varied with the solution

used (Fig. 4, p"0.003). The weight of all samples immer-

sed in lactic acid decreased by 1.2}3.0

g/cm. However,

the di!erences in the decreased weight were not signi"-

cant between di!erent pH(p'0.05).

The changes in the weight of the samples immersed in

formic acid varied with pH(p(0.001); weight decreased

by 8.4

g/cm at pH1.0, while weight slightly increased at

pH2.5}5.5 (1.9}0.9

g/cm). There were no signi

"cant

changes in weight at pH7.0 and 8.5.

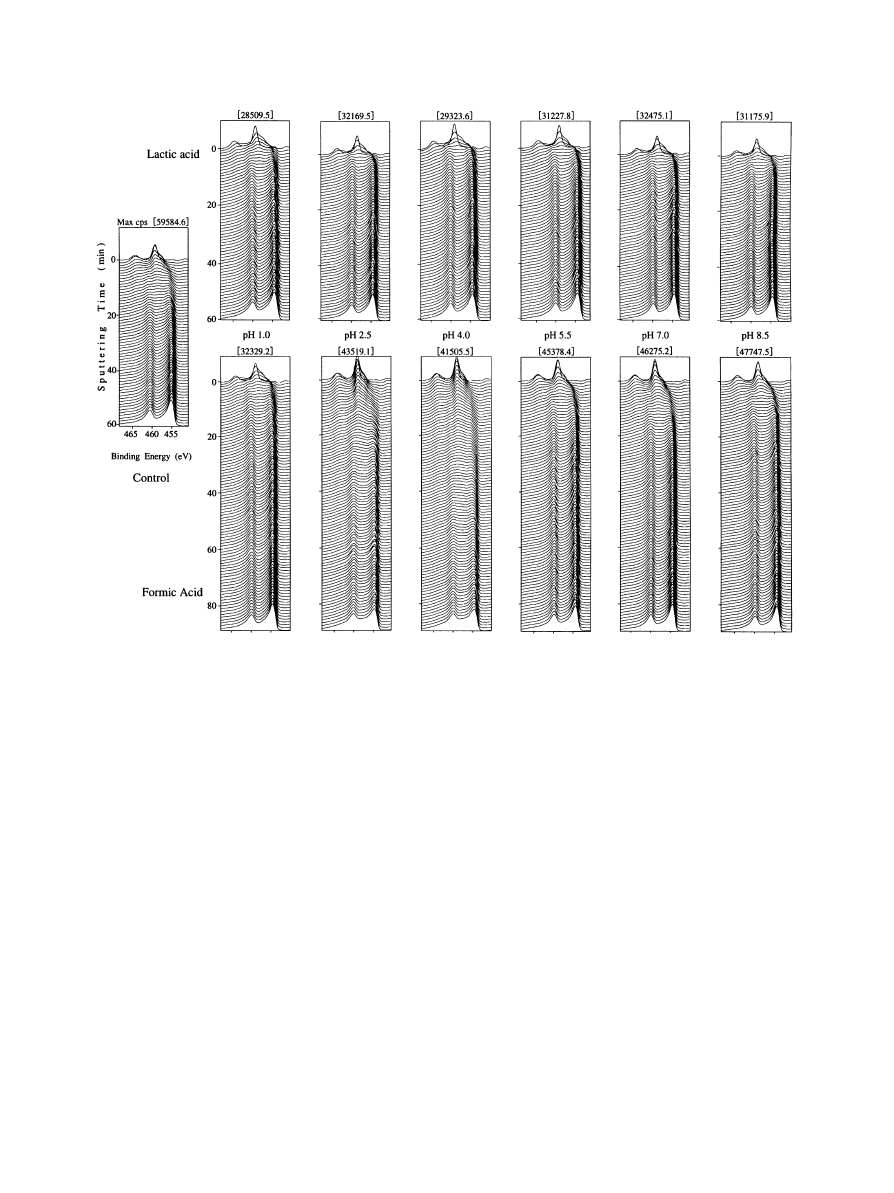

3.4. Changes in chemical binding state of surface

Fig. 5 shows the result of analysis with ESCA. Before

immersion, peaks corresponding to the binding energy of

TiO were observed on the "rst layer (super"cial layer) of

the samples, and the "rst peak corresponding to the

binding energy of Ti (metal titanium) was observed on

the 10th layer (Fig. 5).

All peaks observed on the "rst layer of the samples

after immersion corresponded to those of the binding

energy of TiO. In the samples immersed in lactic acid,

there were no di!erences in the layers showing these

peaks between di!erent pH. However, the TiO layers of

the specimen surface were thinner after immersion than

before immersion.

M. Koike, H. Fujii / Biomaterials 22 (2001) 2931}2936

2933

Fig. 2. Titanium specimens before [control (left)] and after 3-week immersion tests in lactic acid (upper step) and formic acid (lower step). a: pH1.0, b:

pH2.5, c: pH4.0, d: pH5.5, e: pH7.0, f: pH8.5.

Fig. 3. Color di!erence of titanium specimens after 3-week immersion

test (mean and SD).

Fig. 4. Weight changes of titanium specimens after 3-week immersion

test (mean and SD).

In the samples immersed in formic acid at pH1.0, there

were no di!erences in the layer of the "rst peak corre-

sponding to the binding energy of Ti between before and

after immersion (Fig. 5). However, the TiO layer was

thickened in the samples immersed in formic acid at pH

2.5 or higher. Moreover, the peaks of Ti did not appear

until the 35th layer at pH2.5, the 55th layer at pH4.0 and

the 20th layer at pH5.5 or higher.

4. Discussion

The pHin human saliva is reported to be 6.2}7.6

(mean, 6.7), usually 6}7 in plaque deposits 2}2.5 h after

food intake (carbohydrate), and 7}8 with starved plaque

8}12 h after intake of carbohydrate [25]. It has also been

reported that pHdecreases to almost 4 when sucrose is

being eaten [16], and that the pHof foods and beverages

can range from 2.0 to 11.0 [17]. However, the reduction

of oral pHby drinking and eating is not considered to

persist for a prolonged period because of the bu!ering

action of components in saliva and plaque.

Titanium is reported to have corrosion resistance to

hydrochloric acid at 3% or lower and sodium hydroxide

at 40% or lower [26]. In this study, the concentration of

hydrochloric and sodium hydroxide in immersion solu-

tion were 0.58% and 0.42%, respectively. Thus, our re-

sults were considered to re#ect the e!ects of pH, not of

the pH-adjust itself.

In lactic acid, dissolution of titanium ions and weight

loss of the samples were observed at every pHtested,

although they slightly decreased at a higher pH(Figs. 1

and 4). On the other hand, there were no di!erences

in the color di!erences and corrosion depth between

di!erent pH(Figs. 3 and 5). These results reveal that

hydrogen evolution type corrosion occurred on the sur-

face of titanium at every pHtested between 1.0 and 8.5 in

lactic acid.

However, in formic acid, corrosion of the samples

was highly dependent on pH; at pH 1.0, the amount of

dissolved titanium ions and the weight loss were

0.7 ppm/cm

and 8 g/cm, respectively, which were

higher than those of the samples immersed in lactic acid

at the same pH. Nevertheless, discoloration and the

thickness of the super"cial TiO layer were very similar

to those of the samples immersed in lactic acid. These

"ndings

indicate that hydrogen evolution type cor-

rosion also occurred on the surface of titanium samples

2934

M. Koike, H. Fujii / Biomaterials 22 (2001) 2931}2936

Fig. 5. The results of depth analysis with ESCA before (left) and after 3-week immersion test in lactic (upper) and formic (lower) acid (mean and SD).

immersed in formic acid at pH1.0, and that this cor-

rosion was more active in formic acid than in lactic acid

at the same acid concentration.

However, in the samples immersed in formic acid, the

amount of dissolved titanium was low at pH2.5 or

higher. Furthermore, at pH2.5 and pH4.0, a signi"cant

discoloration and weight gain were observed (Figs. 2}4),

and the super"cial TiO layer was thickened 4}4.5-fold

(Fig. 5). These results demonstrate that oxygen pen-

etrated the surface of titanium and di!used (oxygen di!u-

sion type corrosion) at pHranged from 2.5 to 4.0 in

formic acid. The surface color of titanium varies with the

thickness of the super"cial oxide "lm [27]. At a pH

higher than 5.5, corrosion of titanium would be very

low even though corrosion does occur under these

conditions.

In conclusion, the results of the present study reveal

that both hydrogen evolution type corrosion and oxygen

di!usion type corrosion can occur on the surface of

titanium in the oral cavity, and that corrosive properties

were markedly dependent on pHin formic acid, but less

dependent in lactic acid.

Acknowledgements

This study was partly supported by Grant-in-aid for

Scienti"c Research (C) No. 10671837 from The Japanese

Ministry of Education, Science, Sports and Culture.

References

[1] Merritt K, Rodrigo JJ. Immune response to synthetic materials.

Sensitization of patients receiving orthopaedic implants. Clin

Orthop 1996;326:71}9.

[2] Urban RM, Jacobs JJ, Tomlinson MJ, Gavrilovic J, Black J,

Peoch M. Dissemination of wear particles to the liver, spleen, and

abdominal lymph nodes of patients with hip or knee replacement.

J Bone Joint Surg Am 2000;82:457}76.

[3] Lalor PA, Revell PA, Gray AB, Wright S, Railton GT, Freeman

MAR. Sensitivity to titanium, a cause of implant failure? J Bone

Joint Surg Br 1991;73-B:25}8.

[4] Abdallah HI, Balsara RK, O'Riordan AC. Pacemaker contact

sensitivity: clinical recognition and management. Ann Thorac

Surg 1994;57:1017}8.

[5] Yamauchi R, Morita A, Tsuji T. Pacemaker dermatitis from

titanium. Contact Dermatitis 2000;42:52}3.

M. Koike, H. Fujii / Biomaterials 22 (2001) 2931}2936

2935

[6] Basketter DA, Whittle E, Monk B. Possible allergy to complex

titanium salt. Contact Dermatitis 2000;42:310}1.

[7] Koike M, Nakamura S, Fujii H. In vitro assessment of release

from titanium by immersion tests. J Jpn Prosthodont Soc 1997;

41:675}9.

[8] Koike M, Fujii H. In vitro assessment of corrosive properties of

titanium as a biomaterial. J Oral Rehabil, in press.

[9] Pourbaix M. Electrochemical corrosion of metallic biomaterials.

Biomaterials 1984;5:122}34.

[10] Khan MA, Williams RL, Williams DF. In-vitro corrosion and

wear of titanium alloys in the biologic environment. Biomaterials

1996;17:2117}26.

[11] Doi H, Takeda S. In vitro metal dissolution under various extrac-

tion conditions. J J Dent Mater 1990;9:375}86.

[12] Strietzel R, HoKsch A, Kalb#eisch H, Buch D. In vitro corrosion of

titanium. Biomaterials 1998;19:1495}9.

[13] Simonis A, KruKaKmer A, Netuschil L, Schlachta T, Geis-Gerstorfer

J.

In-vivo-Korrosionsuntersuchungen

an

ZahnuKaKrztlichen

Legierungen unter BeruKcksichtigung des Speichel-pH-Wertes.

Dtsch ZahnuKaKrztl Z 1990;45:485}9.

[14] Suga S, editor. Illustrated cariology. Tokyo: Ishiyaku Publishers

Inc., 1990. p. 120}127.

[15] Ravnholt G. Corrosion current and pHrise around titanium

coupled to dental alloys. Scand J Dent Res 1988;96:466}72.

[16] Imfeld Th. Evaluation of the cariogenicity of confectionery by

intra-oral wire-telemetry. Schweiz Monatsschr Zahnheilkd 1977;

87:437}64.

[17] McCabe JF, editor. Applied dental materials. 8th ed. London:

Butler & Tanner Ltd., 1990. p. 1}28.

[18] J. Morita Corp. Instruction manual of pure titanium A.

1989.

[19] Miyakawa O, Watanabe O, Okawa S, Nakano S, Kobayashi M.

Reaction layers of titanium cast in molds containing spinel.

J J Dent Mater 1995;14:560}8.

[20] Commission internationale de l'eclairage. Technical report

COLORIMETRY.

Vienna:

Commission

internationale

de

l'eclairage, 1986.

[21] Ramqvist L, Hamrin K, Johansson G, Fahlman A, Nordling C.

Charge transfer in transition metal carbides and related com-

pounds studied by ESCA. J Phys Chem Solids 1969;30:

1835}47.

[22] Porte LD, Demosthenous M, Duc TM. EEtude ESCA de

l'interaction oxyge`ne-titane*. J Less-common Met 1977;56:

183}91.

[23] Briggs D, Seah MP, editors. Practical surface analysis by auger

and X-ray photoelectron. Sussex: Wiley, 1983.

[24] Erwin K, editor. Introductory mathematical statistics. Principles

and methods. New York: Wiley, 1970.

[25] Edgar WM, Mullane DMO, editors. Saliva and oral health.

London: British Dental Association, 1996.

[26] Ito G, editor. Corrosion science and engineering. Tokyo: Corona

Publishing Co. Ltd., 1979.

[27] Cotton JB, Hay"eld PCS. Decorative "nishes on titanium. Trans

Inst Met Finish 1967;45:48}52.

2936

M. Koike, H. Fujii / Biomaterials 22 (2001) 2931}2936

Wyszukiwarka

Podobne podstrony:

In vitro corrosion resistance of titanium made using differe

5 49 62 The Influence of Tramp Elements on The Spalling Resistance of 1 2343

The corrosion behaviour of Ti

Corrosion behaviour of commercially pure titanium shot blast

72 1031 1039 Influence of Thin Coatings Deposited by PECVD on Wear and Corrosion Resistance

25 339 348 Development Trends of Corrosion Resistant Plastic Mould Steels

Freies Deutschland Guerrilla Warfare in East Prussia, 1944 1945; A Contribution to the History of

the other side of change resistance

Resistance and the background conversations of change

Corrosion behavior of titanium nitride

mapi com The Ayurvedic View of Marijuana

Interruption of the blood supply of femoral head an experimental study on the pathogenesis of Legg C

Ebsco Gross The cognitive control of emotio

37 509 524 Microstructure and Wear Resistance of HSS for Rolling Mill Rolls

Bo Strath A European Identity to the historical limits of the concept

Betsy Powell Bad Seeds, The True Story of Toronto's Galloway Boys Street Gang (2010)

więcej podobnych podstron