A Flywheel Switched Reluctance Motor Drive for Wind Energy Applications

I.J. Iglesias

1

, L.García-Tabarés

1

, M.Lafoz

1

, J.Calero

1

, S.Portillo

1

, I.Cruz

2

, F.Toral

2

, P.Abramian

2

1

Centro de Estudios y Experimentación de Obras Públicas (CEDEX)

Centro de Estudios de Técnicas Aplicadas

AlfonsoXII, 3. 28014 Madrid

phone:+ 34913357320 –fax:+34913357257-e-mail:Jorge.Iglesias@cedex.es

2

Centro de Investigaciones Energéticas MedioAmbientales y Tecnológicas (CIEMAT)

Av Complutense, 22,28040, Madrid

Abstract- This paper describes the design and fabrication of a

switched reluctance Machine (SRM) drive for a flywheel as

part of a wind/diesel stand-alone generator, in order to

minimise the number of start-stop cycles of the diesel engine.

After an explanation of the complete system, the paper

analyses the design and manufacturing of the SRM, followed

by a description of the bi-directional power converter.

1. Introduction

Even nowadays, we tend to forget that there are still

many locations in the world, which do not have an

electrical connection to a central network. Furthermore, in

many remote places, it is unlikely that the connection to

the main grid will never be established. However, the need

for power still exists. At present, the most common way to

supply electricity to remote loads, is with a diesel engine

driving a generator set, but many of those places are in

regions of high wind potential.

In this sense, in 1998 we started the SEDUCTOR

project as part of the Spanish Plan of Electrotechnical

Research. The aim of this project has been to develop an

innovative wind/diesel system [1], including a low price,

high-speed flywheel as short -term energy storage system.

The system is intended for the market of stand-alone

power supply units of 50 kW or more. Four partners co-

operated in the project: CIEMAT, CEDEX, UPM and IIT

on the design and development tasks and several

companies have collaborated in the project at different

levels like: ENERTRON, GRUMADISA, BORNAY

AEROGENERADORES.

Due to the fact that wind power is proportional to the

cube of the speed, the presence of short term wind speed

fluctuations (turbulences in order of seconds to minutes),

and the variability of the electrical load would involve

continuous operation of the diesel with a high fuel

consumption (below 40 per cent of rated power,

consumption can be significant and wasteful).

In order to minimise the frequent start-stop cycles which

would be associated with turning the diesel on and off, it is

convenient to use some kind of short-term energy storage.

There exist several candidates for short-term energy

storage: batteries, flywheels, hydraulic accumulators or

supercapacitors. Flywheels are particularly well suited to

this application because they offer a fairly high energy

density and long lifetime, even under the fast

charge/discharge conditions, which are typical of wind-

diesel applications.

2. System Description

The system works in the following way [2]: when the wind

power exceeds the load by some specified amount, the

diesel generator is disconnected by an electromagnetic

clutch from the engine, which is stopped. The synchronous

generator continues to spin supplying the necessary

reactive power to the network, as the induction generator

of the wind turbine is unable to supply it. At this moment,

the flywheel driven by a high-speed switched reluctance

motor (operating asynchronously through a frequency

converter), follows the power variations, accelerating when

the energy is absorbed and decelerating when the energy is

released to the system. By allowing large speed variations

(from 5,000 rpm to 30,000 rpm) the amount of energy

which can be handled with a 50 kW flywheel, can be

considerably increased.

This 50 kW peak power, 1.25 kWh stored energy,

flywheel system consists of a bi-directional power

converter, a high-speed Switched Reluctance Motor

(SRM), a hybrid composites made rotor and a container.

All the main components of the full facility are depicted in

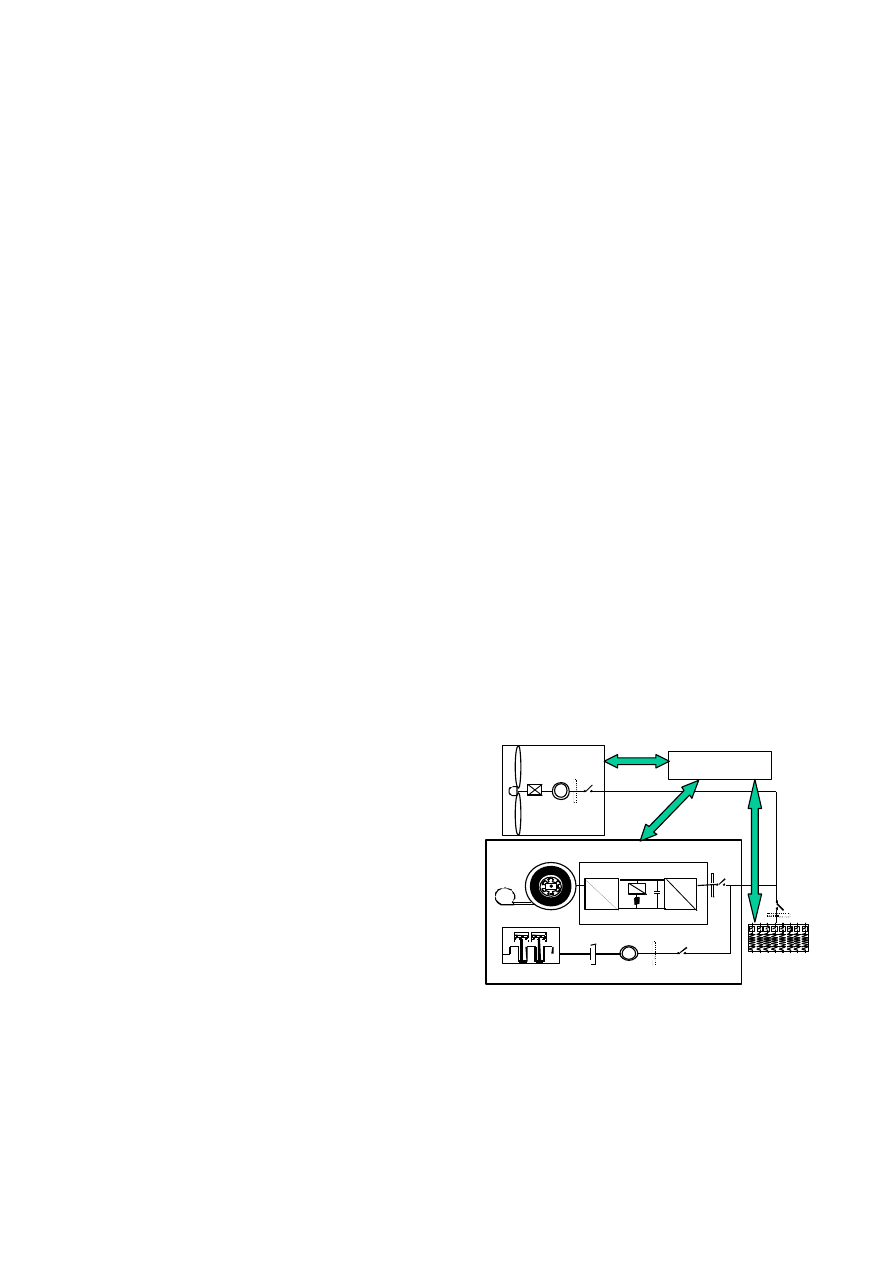

figure 1.

Fig. 1. Main components of the facility

The bi-directional power converter is based on IGBT

technology. It consists of a line-side full bridge three-phase

PWM Converter, a SRM High Frequency Driver and a

DC/DC Chopper connected to the 750 V DC-link in order

to dissipate the surplus wind energy in resistances, if the

flywheel speed reaches the upper allowable limit.

DIESEL ENGINE 62 C.V.

WIND TURBINE

ASYNCHRONOUS

GENERATOR

50 KW 400 V

GEARBOX

.

PROGRAMMABLE LOADS

100 KW

MULTICONVERTERS

& PROTECTIONS

ELECTROMAGNETIC

CLUTCH

50 KW SYNCHRONOUS

GENERATOR

VACUUM

PUMP

50

kW

SWITCHED

RELUCTANCE

MOTOR (SRM)

FLYWHEEL RIM

ROTOR

CONTAINEMENT

AC

DC

DC

AC

DC

DC

50

kW

B I-DIRECTIONAL POWER CONVERTER

VSI CONVERTER

CHOPPER

DISSIPATION LOADS

AS DUMP LOADS

SG

AG

MODULAR SUPERVISORY,

CONTROL AND DATA

ACQUISITION SYSTEM

CONTAINER

MOTOR DRIVE

STALL

REGULATED

The 50 kW high-speed electrical machine is a three-

phase, 6/2 poles SRM very robust and simple. It uses

commercial hybrid bearings (ceramic balls/steel rings)

which are stiff, reliable and low costs devices.

The energy storage rotor is based on concentric thick

rings, wound over an inner steel ring, with an overall mass

of around 70 kg. The set motor-rotor is enclosed in an

evacuated container to reduce aerodynamic losses and to

prevent accidents in the event of a rotor bursting. The

rotor weight can be reduced drastically, because it can

withstand very high rotational speeds and the strength of

its protective container can be minimised due to the very

advantageous destruction mechanism. (no heavy parts can

break apart from the rotor).

One additional advantage of this flywheel system is that

the storage unit can be located far from the rest of the

system, inside a commercial container for instance,

allowing to have a portable system.

3. The Flywheel Driving Machine

To accelerate and to brake the flywheel, an electrical

machine is needed, acting as a motor in the first case and

as a generator in the second one. There are a few types of

machines candidates for this purpose and after an specific

analysis for our application we concluded that the best

choice was to use a Switched Reluctance Machine (SRM),

according to the following criteria:

- Low price and maintenance

- Low losses in the rotor and high overall efficiency

- Good capability for working at high speed

This section describes the design and fabrication of the

SRM as well as some individual tests which were

performed to validate this design.

3.1. SRM Design

Before describing specific aspects , some general remarks

regarding the overall design and manufacturing should be

done. As it is well known the SRM allows a relatively

wide number of configurations concerning the number of

poles and phases [3]. The final choice is basically a trade-

off between torque ripple and maximum electrical

frequency at the driver output. In order to achieve low

ripple and to reduce the frequency to admissible values for

the maximum rotational speed (30,000 rpm), the number of

stator phases was set to 3, while the number of rotor poles

was chosen to be 2, thus leading to 6 stator poles.

From the manufacturing point of view, the design was

focussed on realising a compact and robust machine and

this is basically achieved by using curved coils which fit

very well to the stator geometry, allowing a good thermal

contact and reducing the ext ernal diameter of the machine.

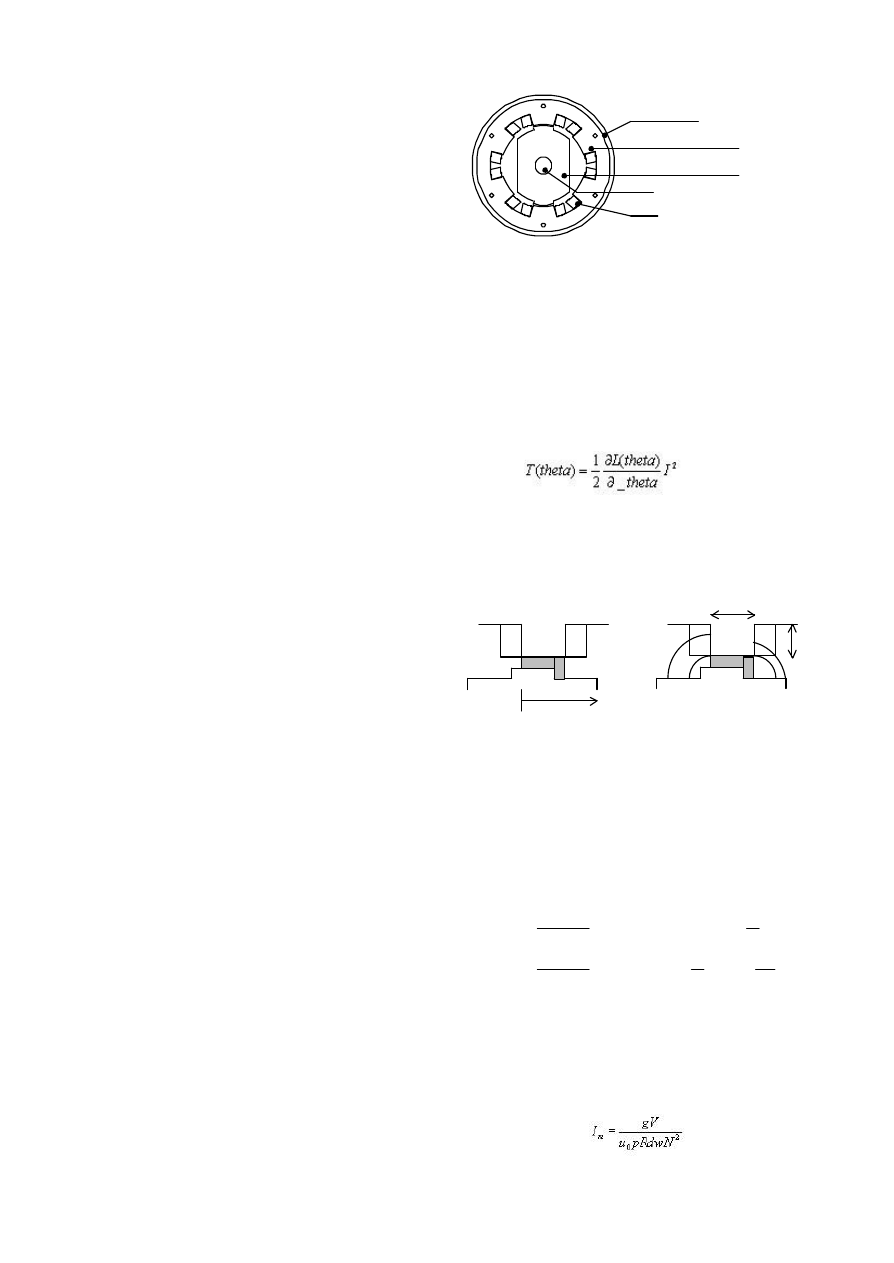

Figure 2 shows a cross section of the SRM indicating its

main components.

Most of the main aspects of the design were based on the

previous experience developed in a 2kW prototype which

was built before according to the same basic principles [2].

Fig. 2.- Cross section of the SRM

3.1.1. Magnetic Design

Magnetic design basically aims to define, from some initial

constraints, the size and geometry of the machine to

achieve the required values of torque at a given speed.

If the machine is considered as a linear magnetic system,

the torque for a constant current I can be derived from the

self-inductance variation of the actives poles, L(theta),

with the rotor position, theta, as:

(1)

A first and simple model to evaluate L(theta) (model a)

can be deduced with the help of figure 3.a, where only the

central flux between the rotor and the stator is considered.

a) b)

Fig. 3.Flux model. a) Only central flux b) Lateral flux included

Simple application of Ampere´s law, allows to find an

expression for the flux density in the air gap and hence,

for the self-inductance L(theta), as a function of the

minimum air gap g, the air gap radius R, the number of

turns per pole N, the number of pole pairs per phase p and

the stator depth, d:

=

?

?

(2)

=

?

?

The SRM converter will normally operate the machine

at the required current value. This model, nevertheless,

establishes a limit, I

m

, to the current, imposed by the d.c.

voltage

V and the rotational frequency

w as

V·theta/wL(theta). From (2), it yields:

(3)

Shrink fit tube

Stator iron laminations

Rotor iron laminations

Shaft

Coils

g

theta

STATOR

STATOR

ROTOR

ROTOR

w

h

3

2

3

for

)

3

/

2

(

)

(

3

0

for

)

(

2

0

2

0

pi

theta

pi

theta

pi

g

pRdN

u

theta

L

pi

theta

theta

g

pRdN

u

theta

L

-

Equations (1) and (2) provide an expression for the

developed torque corresponding to this simple model as:

(4)

The complete determination of the torque during the

active period of each phase, has to consider the overall

evolution of the current, including the switch-on and the

switch-off intervals.

A more precise self-inductance and thus torque

determination can be done if lateral flux through the poles

is also taken into account as it is depicted in figure 3.b,

(model b) ,where the lateral field lines are approximated by

circular wedges [4]. It can be shown that for this model,

the torque for motoring operation is given as:

(5)

Symmetrical expressions with respect to pi/3 are

obtained for generating operation. Equations (2) through

(5) allow a first evaluation of the machine dimensions if

some further constraints are made as the allowable stresses

in the rotor, the maximum flux density in the iron or the

conductor size.

Although the previous models provide a good approach,

a more precise analysis using a F.E.M. method is

mandatory for an accurate computation of L(theta), which

also allows to define the optimum switch-on and switch-

off strategy to achieve the best torque shape for every

condition.

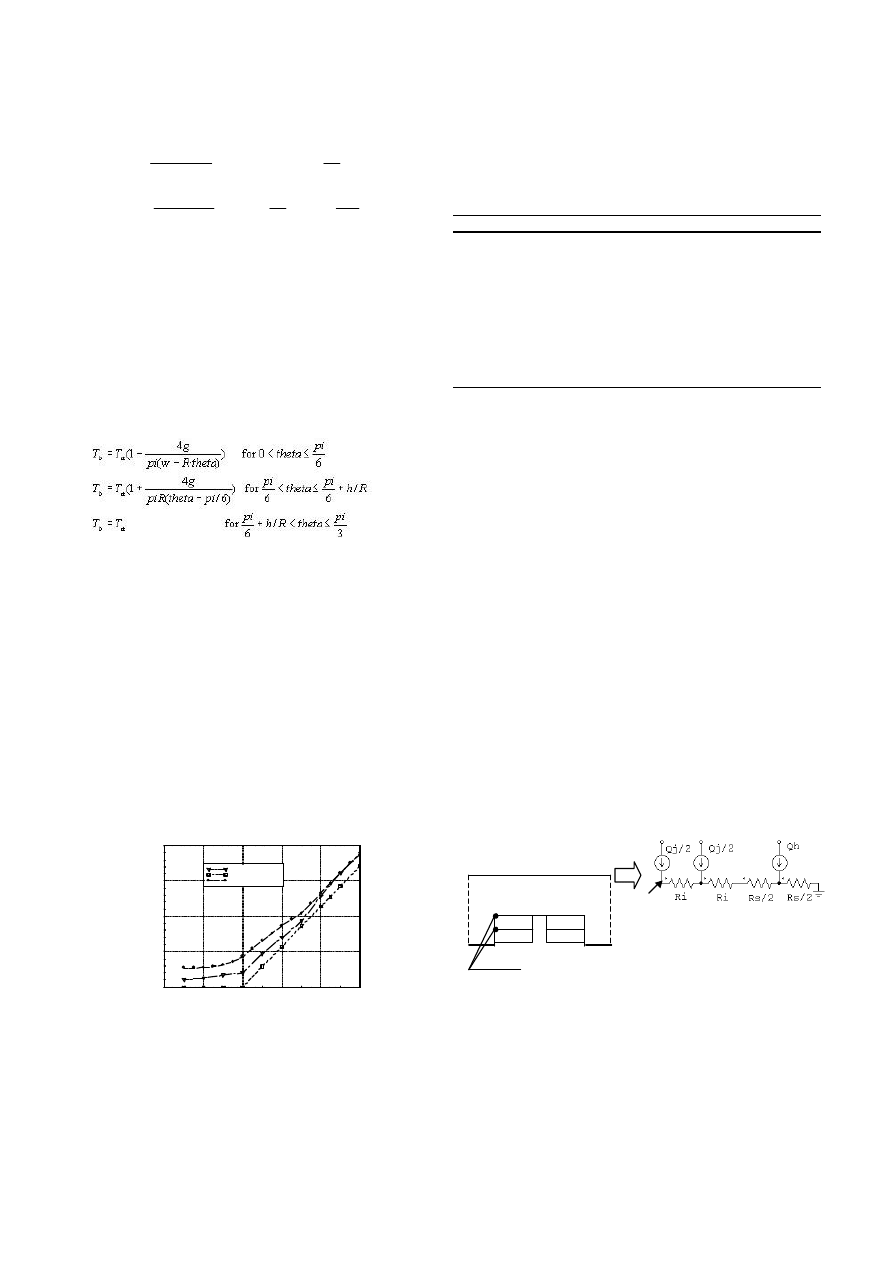

Figure 4 shows the F.E.M. calculated values of L(theta)

(-pi/6 to pi/3 interval and no saturation) for the designed

SRM, compared to those provided by models a) and b).

Fig 4. F.E.M and Analytical computation of L(

?

)

Precise calculation of the torque also need for F.E.M.

simulation as saturation becomes important at high current

levels and the torque can not be derived from simple

expressions as (1). Later on, some results will be

discussed and compared to experimental static torque

measurements.

Table 1 shows a list of the main parameters of the

machine. Some of them can be considered as input

variables, while the rest are derived from the above

described magnetic design.

TABLE I

Main Parameters of the SRMachine

PARAMETER

VALUE

Rotor outer radius

71 mm

Stator outer radius

117 mm

Air gap

2/4 mm

Active length

110 mm

Nº of turns per pole

18 (9+9)

d.c. Voltage

750 V

RMS current per phase at max. torque

70 A

Maximum torque

16 Nm

Maximum speed

30,000 rpm

Maximum power

50 kW

3.1.2. Thermal Design

Thermal design is specially relevant for this application as

the machine will operate under vacuum conditions and

heat evacuation can only be done by conduction to the

outer wall of the stator, where a fan will remove the

conducted heat. There are, basically two sources of heat:

Joule losses in the coils and iron losses in both rotor and

stator laminations. From the current and the coil resistance,

evaluation of the first term is straight forward, while

determination of the second one is more complicated and it

has been done on the basis that every time one phase is

magnetised and demagnetised, one-quarter of the

hysteresis loop is described. From the data sheet of the

magnetic material, hysteresis iron losses per kg have been

expressed as a function of the electrical frequency which

corresponds to six times the rotational frequency. For our

design, iron losses in the stator at maximum r.p.m. and

current can rise up to 215 W.

A simplified model based on the classical conduction

equations has been developed. Figure 5 shows the

corresponding geometry as well as the electrical equivalent

circuit for the thermal analysis.

Fig.5. Thermal model for temperature computation

In the equivalent electrical circuit, heat sources are

replaced by current sources, and thermal resistances by

electrical resistances whose values are calculated from the

thermal conductivity and dimensions of the represented

element. The goal of the model is to evaluate the maximum

temperature, which is achieved at the inner side of the coil

0

0 .000 5

0 .001 0

0 .001 5

0 .002 0

-4 0

-2 0

0

2 0

40

60

A naly tic al ( M odel b)

A naly tic al (Model a)

F. E. M

?

(DEGREES)

L

(

?

)

H

STATOR (Iron losses)

COILS (Joule Losses)

Insulation

Qj=Joule losses

Qh=Iron losses

Ri=Insulation thermal resistance

Rs= Stator thermal resistance

3

2

3

for

2

3

0

for

2

2

2

0

2

2

0

pi

theta

pi

I

g

pRdN

u

T

pi

theta

I

g

pRdN

u

T

a

=

?

?

= -

?

?

and can be calculated as the voltage at the node pointed

with an arrow in figure 5.

The most uncertain parameter for the simulation is R

i

, as

the contact surface of the insulated coil and the stator is far

from being 100% of the maximum value. From

experimental observation during fabrication of the SRM,

R

i

has been chosen as twice the theoretical value for full

contact. Simulations for the worst conditions( maximum

current and speed) predict a peak temperature of 35ºC over

the stator outer wall. Some experimental thermal

measurements will also be discussed later on.

3.2 Machine Fabrication

The most peculiar component of our SRM are the curved

coils which were wound in a “double pancake”

configuration using a special winding machine able to

wind two layer curved coils in one step. The coils are

impregnated afterwards in a mould, to achieve precise

dimensions and mechanical stability.

Iron laminations for both, rotor and stator were cut using

an spark-erosion machine as a classical punching

procedure became too expensive for a prototype. The rotor

laminations were guided into position through the shaft,

while stator ones were placed into position by means of

non-magnetic rods. Once the stator was mounted, the

shrink fit external cylinder (galvanically insulated) was

placed into position to hold the full assembly. The coils

were insulated from the back iron with a relatively high

thermal conductivity tape and once they were placed into

position, the rotor was inserted and the two end plates with

the hybrid bearings (ceramic and steel) were mounted.

External connections are placed radially to achieve a more

compact design and pole interconnections were made by

means of copper rings. The machine includes o-rings at

both ends to guarantee vacuum tightness.

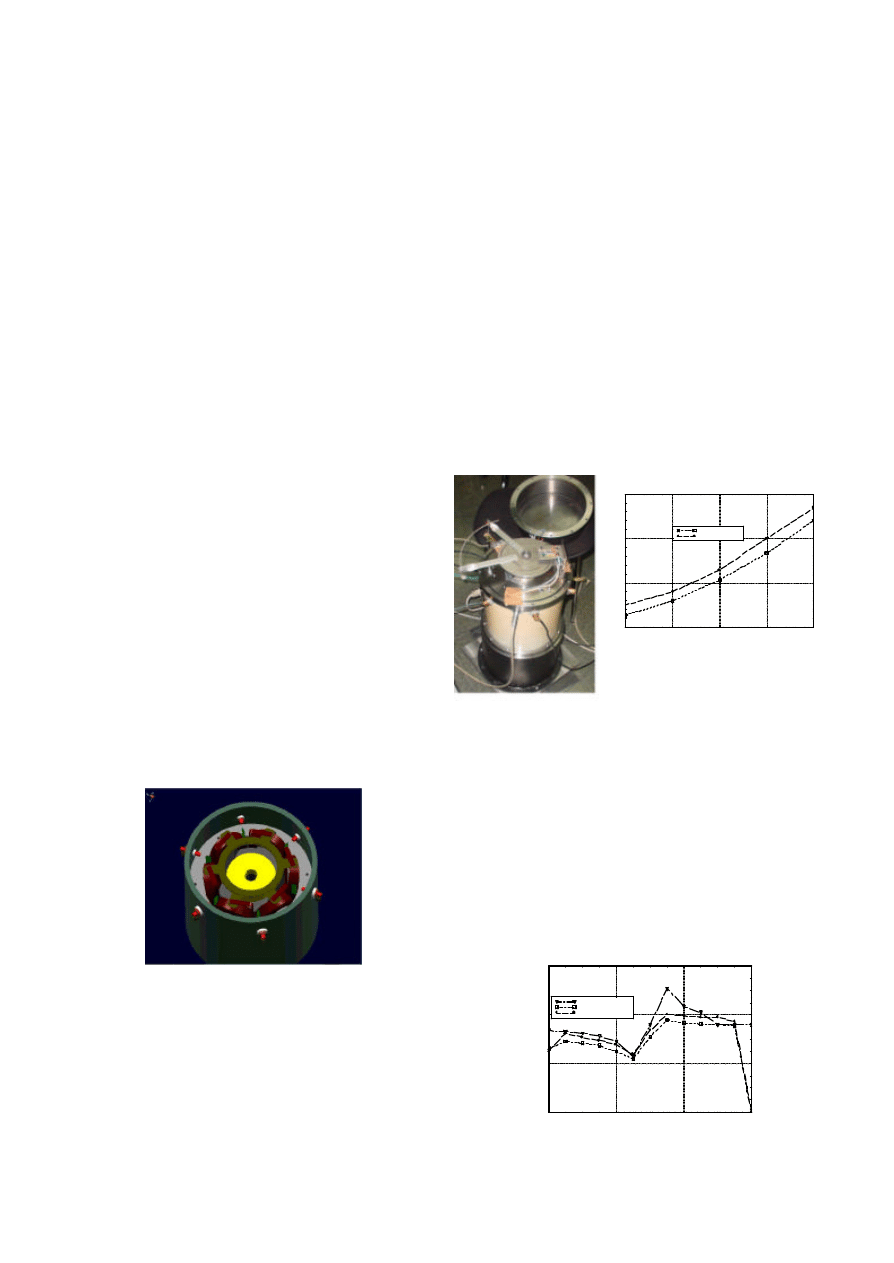

Figure 6 shows a 3-D view of the machine where the

coils, the external and internal connections, the rotor and

the stator can be seen.

Fig.6. 3-Dimensional view of the SRM

To monitor the rotor position for switching the

converter, a grooved disk was fixed at one end of the shaft.

A set of photo-diodes and photo-transistors placed in

between the disk, were in charge of coding the rotor

position. Temperature sensors were also placed at the inner

side of the coils ends as well as closed to the bearings to

monitor this magnitude during machine operation.

3.3. Machine Tests

After the machine was built, some initial tests were

performed to verify general aspects of the operation.

During this stage, the speed was limited to 12,000 rpm and

magnitudes such as temperature in the bearings or phase

current shapes were recorded. Rotor position signals were

also adjusted to optimum levels.

Two more specific tests were then performed, closely

related with the SRM design aspects. The first one was

strictly thermal. A d.c. current was applied to the coils and

the temperature increasing recorded and compared to

theoretical predictions. During this test, the machine was at

stand still so that only Joule losses were generated. Tests

were performed at different current levels as it is shown in

figure 7.b, which is a plot of incremental temperature (coil

minus external wall) versus current. Theoretical

predictions are also compared in the same plot.

As it can be seen, these predictions show that thermal

insulation resistance has been underestimated in a factor of

about 10% .

Fig. 7. a) Set up for torque measurements b) Thermal measurements

The second test was the measurement of static torque. A

certain phase of the machine is energised at stand-still and

the force exerted against a plate with a strain-gauge sensor

measured for different rotor positions. Figure 7.a shows a

picture of the SRM with the torque measuring device at the

top, while figure 8 is a comparison of measured and

calculated static torque values using F.E.M. and

expressions from model b) for a d.c current of 30A. In the

short term it is foreseen to measure at higher currents

where saturation can have a significant role. As much

higher torques will be developed, the force sensor must be

adapted.

Fig .8. Static torque results for 30 A.

0

10

20

30

20

30

4 0

5 0

60

PR EDI CTED

EXP ERI MENTA L

I (A)

?

T

(º

C

)

a) b)

0

0.4

0.8

1.2

0

2 0

4 0

60

A nalyt ical (Model b)

F EM Cal culat ions

E xperiment al

?

(DEGREES)

T

O

R

Q

U

E

(

N

m

)

4. Switched Reluctance Motor Drive

A double bi-directional power converter will drive the

switched reluctance motor. This converter is composed of

a AC/DC converter, an asymmetrical half-bridge converter

and a DC chopper. Figure 9 presents the topology of the

two converters and the DC chopper [5].

Fig. 9. Double converter and DC chopper topology.

The network side converter is a conventional hysteresis -

band current controlled VSI, capable of injecting or

absorbing both active and reactive power into the network,

according to some external control references. Based on d-

q transformation of the network voltages, a voltage phase

detector has been developed in order to shift the current

waveform with an appropriate delay according to the

reactive power reference.

The motor side converter presents a half-bridge topology

with two IGBTs and two diodes per phase, this topology

allows the SRM to operate as a motor or generator,

depending on the system requirements, with an almost

complete symmetry between these two operation modes.

Figure 10 presents the SRM converter control block

scheme [2],[3]. The DC voltage will be modify by the

network according to the amount of the injected or

absorbed power. The SRM converter is controlled with the

objective of maintaining the DC voltage close to a fixed

reference value. This is achieved with an absolute value

limited PI controller.

In this way, a decrease of this voltage in the motor

operation mode will cause a decrease of the current

amplitude reference. However a decrease of DC voltage, in

the generator operation mode, will cause an increase of the

current amplitude reference.

When the current reaches the maximum limit (PI

controller saturated) the DC voltage is moving away from

the nominal value. If it is outside the voltage hysteresis

band defined around the nominal value, the operation

mode should be changed. For example, if the SRM is

working as a generator and the DC voltage increases over

the upper voltage limit, it will change to the motor

operation mode. In this situation, the SRM evolves from

supplying to receiving power from the DC link. Therefore,

the DC voltage decreases while the rotational speed

increases.

A speed control is also implemented in order to ensure

the mechanical safety of the system. If the rotational speed

overpasses a defined maximum speed, the generation

operation mode is the only one permitted. In the same way,

if the rotational speed is lower than a defined minimum

speed, the motor operation mode is the only one permitted,

not depending on the voltage control both cases. This

algorithm acts therefore as an electrical brake.

If the wind generator supplies an excessive power, the

grid frequency will be increased. The control reacts

increasing the absorbed power towards the storage system.

If the SRM reaches the maximum speed in the motor

operation mode, no more energy can be stored. Therefore,

the DC voltage increases. As the double converter is not

able to avoid it, a DC chopper is used to dissipate the

excessive power into an electrical resistor, maintaining the

DC voltage level. The DC chopper has an analogue

control presented in figure 11.

Fig. 10. SRM converter control block scheme.

Fig. 11. DC chopper control block scheme.

Both network converter and SRM converter control is

based on a Digital Signal Processor (Lucent DSP32C) and

a microcontroller (Hitachi H8) for the algorithms

calculation. Analogue current comparators are used to

generate the IGBT switching pulses.

5. Experimental Results

A 50kW bi-directional power converter and a DC

chopper are constructed to drive the SRM. Some

experimental results obtained with the complete three

electronic converters, working together, are presented in

this chapter in order to check the good behaviour of them.

(a) (b)

Fig. 12. Network-side converter phase voltage and current.

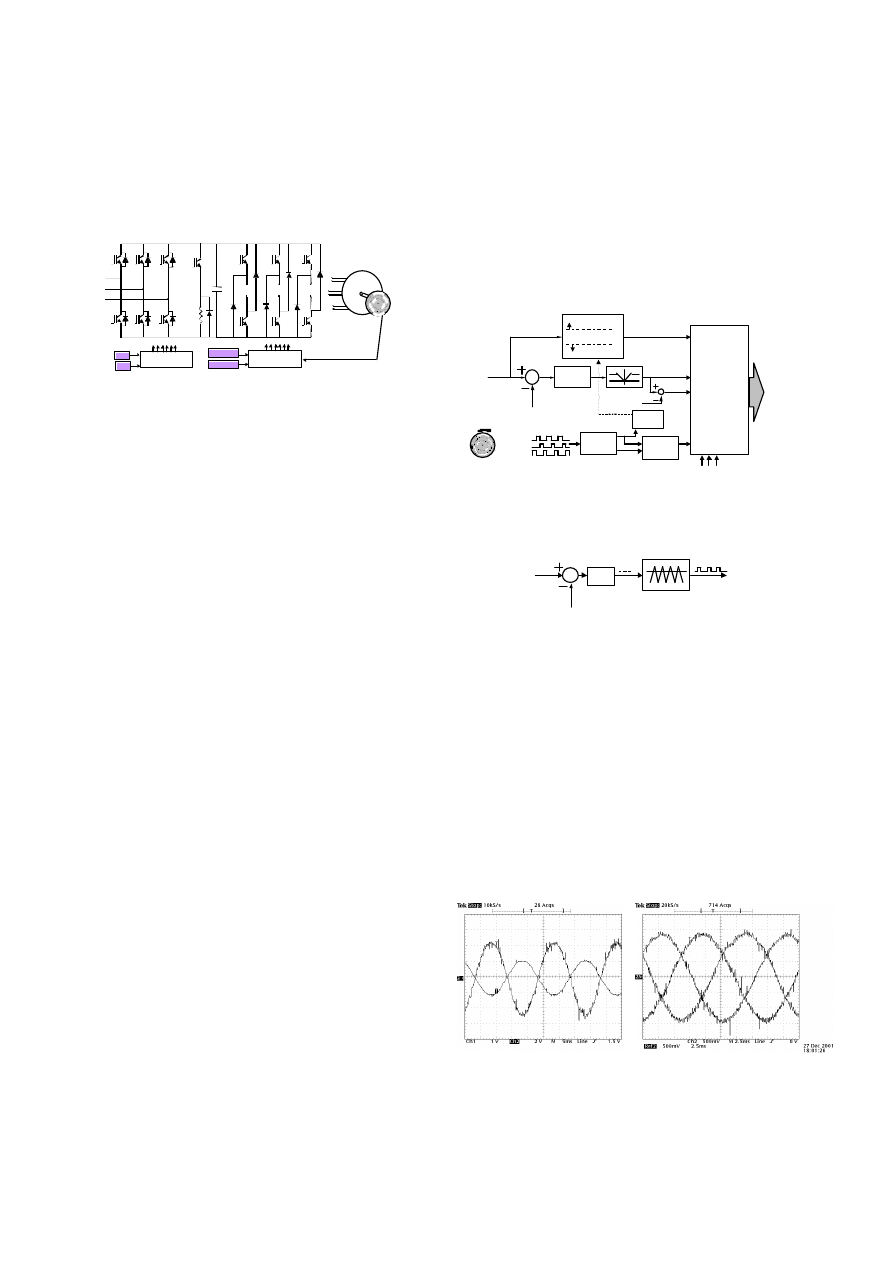

Figure 12(a) shows the network voltage together with

the line nominal current (75A) when the network-side

converter supplies energy to the network. No reactive

P.I.

Vdc_max

Vdc_min

Operation Mode

(Generator - Motor)

Current

limits

Band Width

I

lim

M o t o r

Generator

I

max

I

min

DC Voltage

Reference

DC Voltage

Measurement

S1 -> (BIT bajo)

S3 -> (BIT medio)

S2 -> (BIT alto)

Rotational

speed (w)

Rotor

Angle (? )

DSP Sextant

Detection

On and off

angles

calculation

IGBTs

switching

pulses

generation

Current

Measurement

(Ir, Is, It)

- Phases

activation.

- Current

comparation.

- Hard/Soft

switching.

12 IGBTs

switching

pulses.

Speed

Protection

Optical

Sensor

Sextant

Phase A

Phase B

Phase C

Phase B

Phase C

C

SRM Inverter

Front-End Inverter

Control Unit

P

ref

Q

ref

SRM Inverter

Control Unit

V

dc (measured)

V

dc (reference)

Phase A

SRM

R

S

T

VSI

Chopper

Discharge

Resistors

P.I.

Chopper IGBT

switching pulses

DC Voltage

Measurement

Chopper

DC Voltage

Reference

power is supply in this case. Also, three phases line current

are shown in this figure (b).

Figure 13 presents the estimated network voltage phase

and the current waveform based on it when reactive power

reference is zero and when some reactive power reference

is given to the control system.

(a) (b)

Fig. 13. Line current and estimated voltage phase.

Three optical sensors and a grooved disk are used to

determinate the machine rotor angle in the DSP. Figure

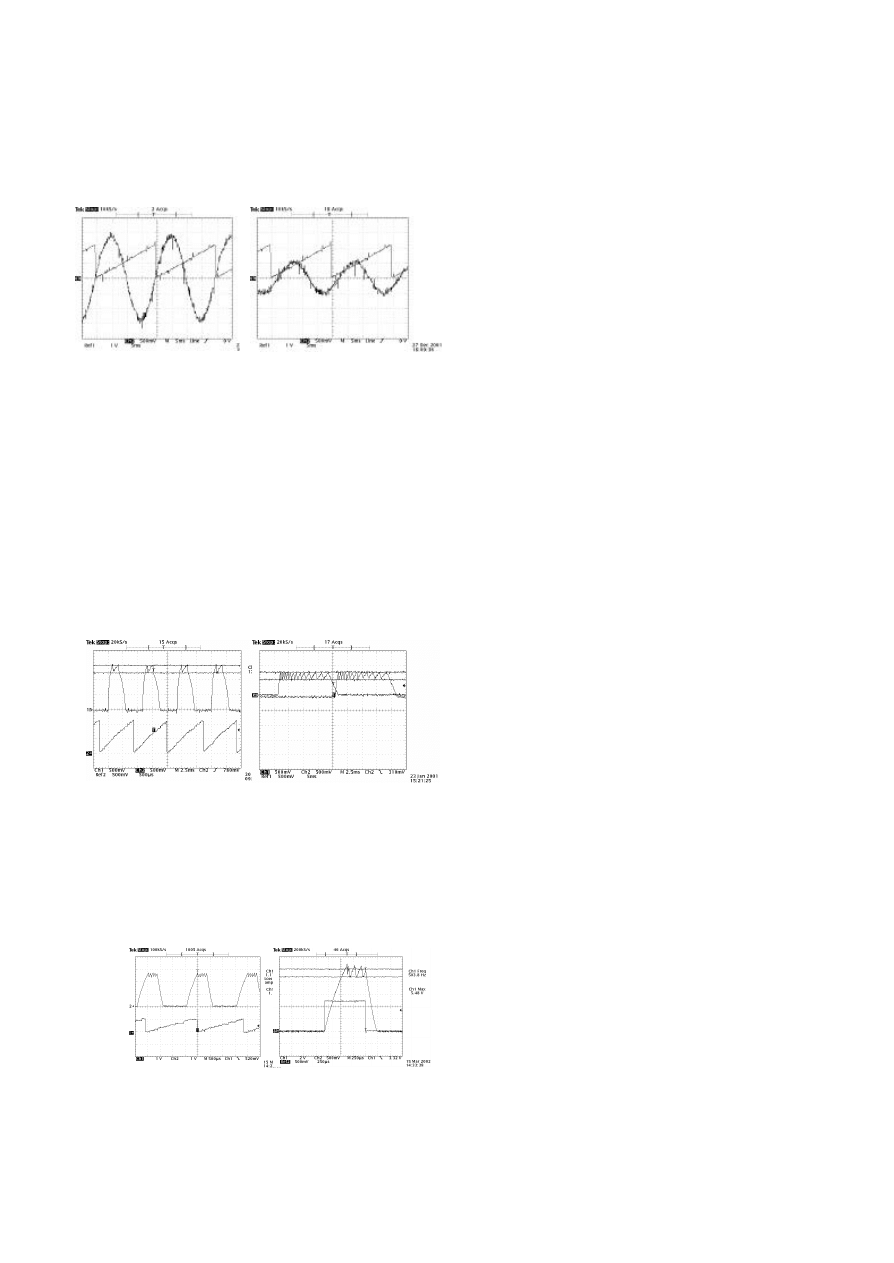

14(a) shows the rotor angle estimation by the SRM

converter control and one phase current waveform,

activated in the appropriate angle interval in order to get

the maximum torque. In this way, a simulation study with

SABER has been developed for different speed situations,

getting the most appropriate on and off angles for the

IGBT switching in order to obtain the maximum torque.

Current commutation limits are also presented in figure

14(b). The lower current limit can be changed and

determinates the IGBT conmutation frequency.

(a) (b)

Fig.14. SRM current, rotor angle detection and current

commutation limits.

Figure 15(a) shows one phase current waveform and the

estimated rotor angle and figure 15(b) a detail of the

current commutation limits and current activation signal,

when 160A are obtained from the SRM converter with a

15000 rpm speed.

(a) (b)

Fig. 15.SRM converter current results.

6. Conclusions

We have presented the description of a switched

reluctance drive for applications as an energy storage

system for a stand alone wind generator acting as an output

power filter.

-

The SRM is a 6/2 pole unit which has been selected

for its robustness, efficiency and capability of

working at high speeds. A conceptual and basic

design based on simple magnetic considerations has

been the core of the overall design which was refined

using F.E.M. computations. Special importance was

given to the thermal calculations as the device runs

under vacuum conditions.

-

This machine has been built using a “double pancake”

procedure for winding the coils which fit to the stator

back iron allowing a good thermal evacuation to the

outside. Experiments have been performed to confirm

both, the electromechanical and the thermal

behaviour.

-

A bi-directional converter is used to drive the SRM

and injecting or absorbing the required active and

reactive power from an external frequency and

voltage control. In the SRM converter, a current

control, an operation mode selection, a speed control

and a DC chopper will maintain the DC voltage in the

reference value.

-

Experimental results demonstrate the good behaviour

of the double converter and the DC chopper, in the

nominal current situation.

7. References

1. Ray Hunter & George Elliot (1994) “Wind Diesel Systems. A

Guide to the Technology and its Implementation”. Edited by

Cambridge University Press.

2. Iglesias I.J. L García-Tabarés ,A. Agudo, I. Cruz and L.

Arribas ”Design and Simulation of a Stand-alone Wind-Diesel

Generator with a Flywheel Energy Storage System to Supply

the Required Active and Reactive Power”. I.J. Proceedings of

the31

st

Annual Power Electronics Specialists Conference. Vol.

3. pp 1381-1386.

3. Miller, T.J.E. “Switched Reluctance Motors and their control”.

Magna Physics Publishing & Clarendon Presss. Oxford.1993.

4. J. Kokernak, D.Torrey.” Magnetic Circuit Model for the

Mutually Coupled Switched Reluctance Machine”. IEEE

Transactions on Magnetics. Vol. 36 nº2 March 2000.

5. S.Mir “ Classification of SRM Converter Topologies for

Automotive Applications”. SAE 2000 World Congress.

Detroit, March 2000.

Wyszukiwarka

Podobne podstrony:

[2000] Long term R&D Needs for Wind Energy

Directly Driven Low speed Permanent Magnet Generators For Wind Power Application

A neural network based space vector PWM controller for a three level voltage fed inverter induction

A Low Speed, High Torque, Direct Drive Permanent Magnet Generator For Wind Turbines

(Wind) A Low Speed, High Torque, Direct Drive Permanent Magnet Generator For Wind Turbines

Plans For Wind Generator Pt250 Blade Plan10A

Blade sections for wind turbine and tidal current turbine applications—current status and future cha

Compliant Blades For Wind Turbines

Time Series Models For Reliability Evaluation Of Power Systems Including Wind Energy

Bearden Tech papers Vision 2000 The New Science Now Emerging for the New Millennium (www cheniere

Small Wind Energy Systems for the Homeowner

Ebook Wind Power Savonius Generator Wind Energy For Earth Keepers Savonius Wind Mill

Vector Controlled Doubly Fed Induction Generator for Wind Applications

Wind Turbine 5 Metre Diameter Carbon Fibre Blades For Wind Turbine10Kwblades

Design Of Direct Driven Permanent Magnet Generators For Wind Turbines

więcej podobnych podstron