Monolithic CMOS Power Supply for

OLED Display Driver / Controller IC

Cheung Fai Lee

SOLOMON Systech Limited

Abstract

This paper presents design considerations of a power supply IC to meet requirements for

new generations of display panel technologies, especially for OLED display panels. Major factors

include current consumption, efficiency and size. An integrated DC-DC boost converter with

current-limited minimum-off-time PFM control is designed with a standard 0.35

µm CMOS

process. Simulation results show that the efficiency can be over 80% for a load current ranging

from 1mA to 100mA for an OLED display driver/controller IC application.

I. INTRODUCTION

The portable telecommunication market has been growing rapidly, especially shifting the

focus from GSM and CDMA to wide bandwidth 3G technologies. With wider bandwidth, these

cellular phones not only support voice message, but also multimedia applications. In order to cope

with the technological change, cellular phone display technology needs to be enhanced. Beginning

with the heart of the display system, the display driver / controller plays a very important role,

which efficiently improves the display interface.

At present, Super-Twisted Nematic (STN) LCD driver IC is dominant in the display driver

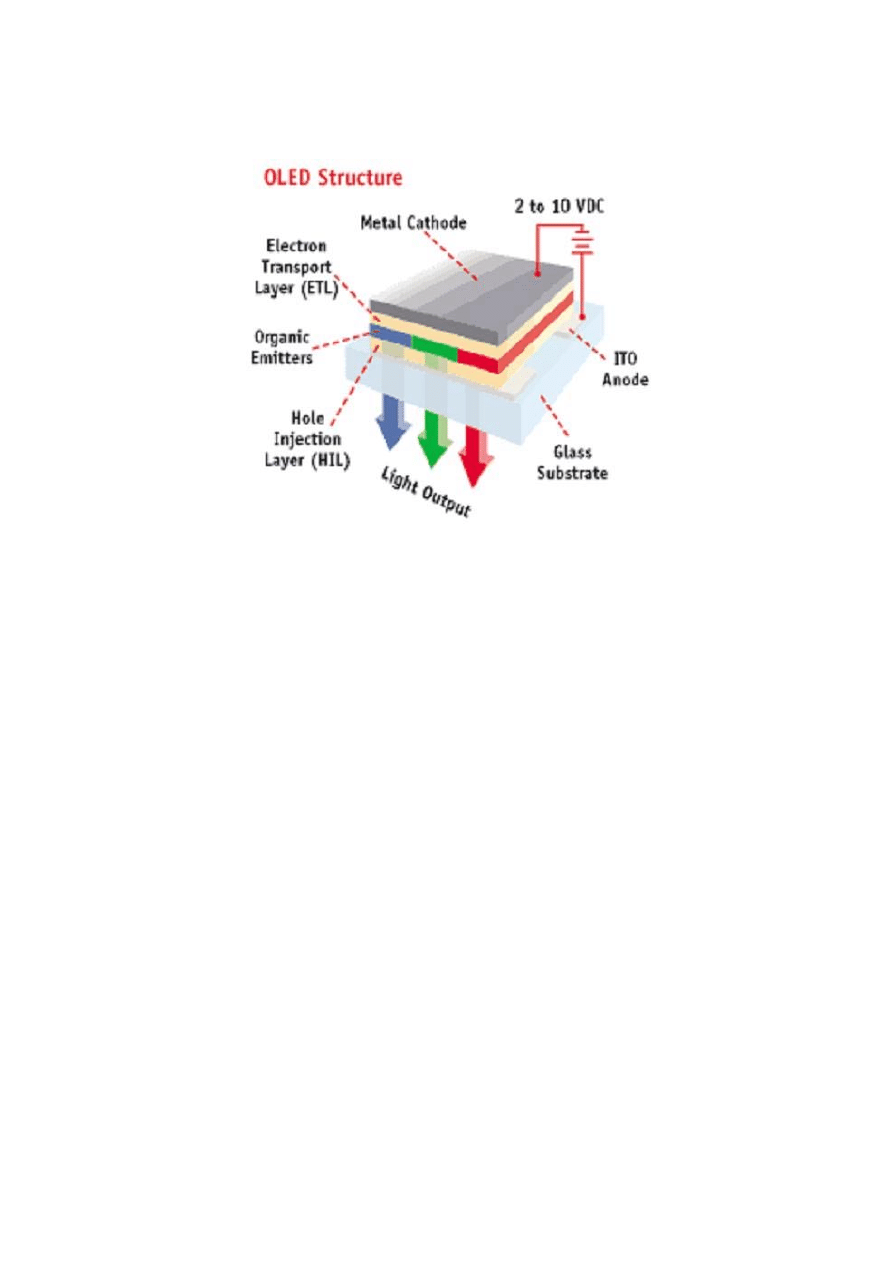

market [1]. However, Organic Light-Emitting Diode (OLED) displays (Figure 1) are expected to

take off over the next decade [2]. The main advantages of OLED are simpler construction, thinner,

better viewing angle (160 degree), saturated emissive color, lower power consumption, etc. The

comparison of STN and OLED panel display technologies are shown in Table 1.

Figure 1: The OLED Driver with Controller IC

Table 1: Comparison of STN and OLED flat panel display technologies

STN

OLED

Viewing Angle

50

o

160

o

Response Time

10 ms - 100 ms

< 1 ms

Driving Method

Passive

Passive for PMOLED

Active for AMOLED

Contrast Ratio

~ 8:1

~ 100:1

Power Consumption with

Backlight

~ 100 mW

~ 10 mW

An STN LCD driver IC is needed to provide a high voltage of 10 to 18V for the STN

display panel (charging and discharging the panel), with a current consumption of the order of

100

µA. From a supply of 1.8 to 3.3V, a 3x to 6x charge pump circuit is suitable for integrated STN

LCD display IC as it requires fewer external components and no inductor. On the other hand,

OLED pixels are self-luminous. While it requires no backlighting and electrical current to supply

the OLED panels, the current consumption of an OLED driver is larger than 40mA, which also

depends on the application and the mode of operation. It is not appropriate to build a charge pump

to supply such a large loading current. Instead, inductor-based switch-mode power supply should

be considered.

II. REVIEW ON OLED DISPLAY DRIVER IC

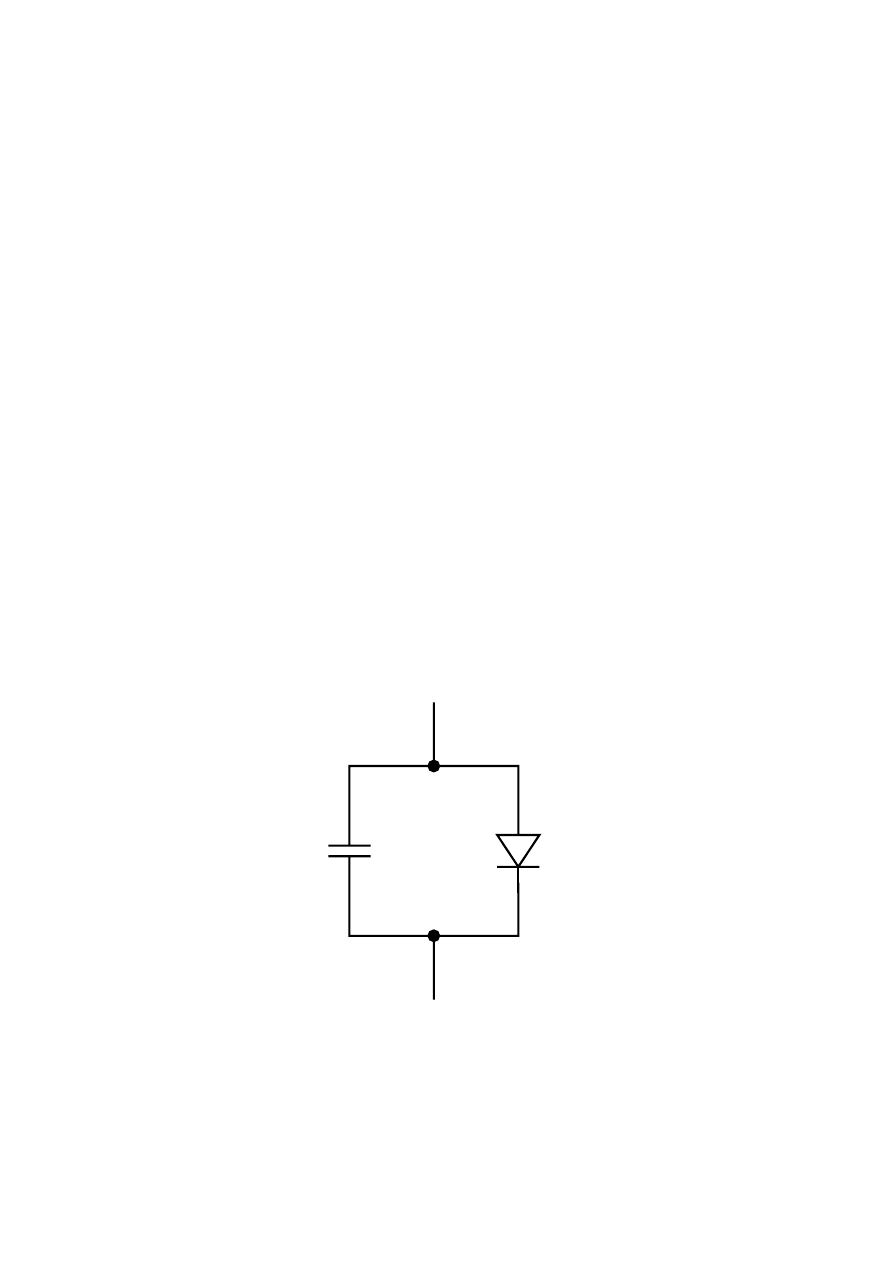

As mentioned above, OLED panels are current-controlled devices. The electrical model

and the structure of an OLED is shown in Figure 2 and Figure 3 [3], respectively, where D is the

light emitting diode and C is the parasitic capacitor of one pixel. Electrons and holes are injected

from the cathode and anode electrodes, respectively, into the electron transport layer (which can

also be the emission material) and the hole transport layer. The charge carriers then migrate under

an applied electric field to form electron-hole pairs (excitons) which then recombine, resulting in

light emission.

The maximum source current of each segment driver is around 300

µA. The total current

required is determined by the number of segments in the panel. For example, a 128 x 128 matrix

panel has 128 segments, and therefore, the maximum total current consumption from the power

supply is around 40mA. The threshold voltage of OLED panels is typically in the range of 2 to

10V. From a supply of 1.8 to 3.3V, a boost DC-DC converter is required in the OLED display

driver IC.

d

Anode

Cathode

D

C

c

I

I

Figure 2: The electrical model of OLED

Figure 3: The structure of OLED

Since the pattern of the cellular phone display varies and the cellular phone would have

power save mode, the loading current of the OLED panel would be changing. Therefore, a good

DC-DC converter should provide high efficiency in a large range of load.

III.

CONTROL TECHNIQUES FOR OLED DRIVERS: PWM vs PFM

In terms of switching frequency, there are two control topologies for a switching converter:

the pulse width modulation (PWM) control and the pulse frequency modulation (PFM) control [4].

For a PWM converter, the output ripple voltage is usually smaller and easier to be filtered. Also,

the higher the switching frequency, the smaller the components (L and C) are needed in the power

stage. However, in the light load condition, the efficiency of the PWM control would decrease due

to switching / gate drive loss, and such power loss is dominant when comparing to conduction loss.

For the application with power save mode, the efficiency can be optimized in a PFM converter

because the switching loss would decrease with the low switching frequency at light load

condition.

As for battery-operated portable electronic devices, the two critical design issues are size

and efficiency. In a PWM control scheme, more than 2 external components are needed for

compensating the closed-loop system [4]. The number of external components in the

compensation network depends on the mode of control (current-mode control or voltage-mode

control), and the mode of operation, (DCM or CCM operations [5]). For example, 5 extra

components are required for a voltage-mode CCM boost converter. However, in the PFM control

scheme, compensation is done through the change in switching frequency, and no explicit

compensation network is needed, and therefore, fewer external components are required.

Moreover, cellular phone often operates in the standby mode, which means that the loading

current of a display panel is small. Thus, the efficiency at light load condition is very important.

Based on the above criteria, the PFM control scheme is more suitable in the OLED display driver

application.

IV.

CURRENT-LIMITED MINIMUM-OFF-TIME PULSE FREQUENCY

MODULATION

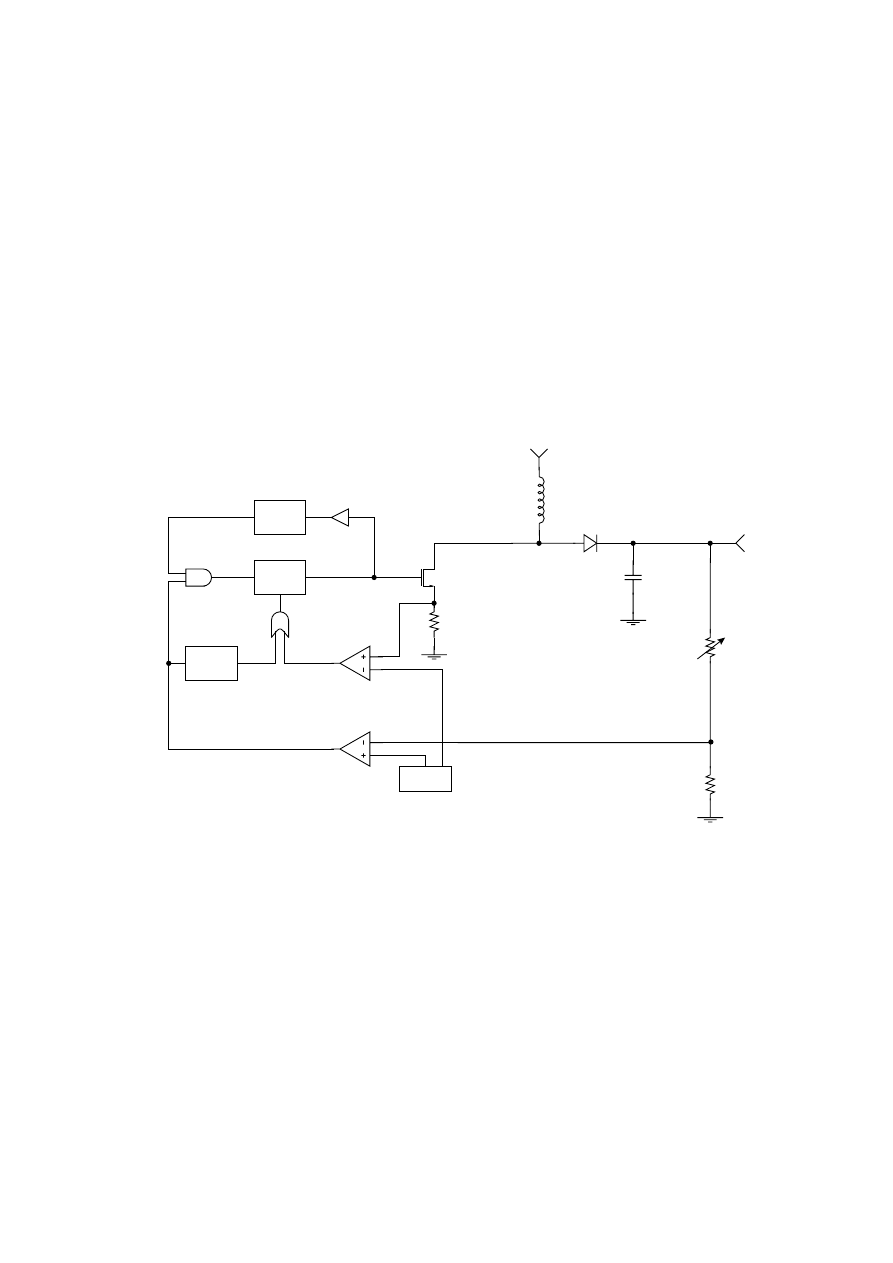

The current-limited minimum-off-time PFM scheme is widely used in the industry when

comparing to other PFM schemes, which is shown in Figure 4 [6]. The output voltage is fed back

through a voltage divider to a comparator and compared with the bandgap reference voltage. The

output of this comparator controls the trigger of a one-shot multivibrator (maximum on-time).

Another comparator looks at the peak inductor current as a voltage across a current sense resistor

in the source of the power NMOS. When the output is less than desired voltage, the SR flip-flop

turns the power NMOS on until the voltage across the current sense resistor is equal to the

reference voltage V

pk

. Then the flip-flop resets, turning off the power NMOS, the one-shot

(minimum off-time) is triggered. The power NMOS remains off for the duration of the one-shot. If

the output voltage is still out of regulation, the flip-flop will set again and the cycle repeats itself.

Besides, a variable resistor, R

fb1

, can be used to control the output voltage such that the boost

converter can provide high efficiency during the power save mode.

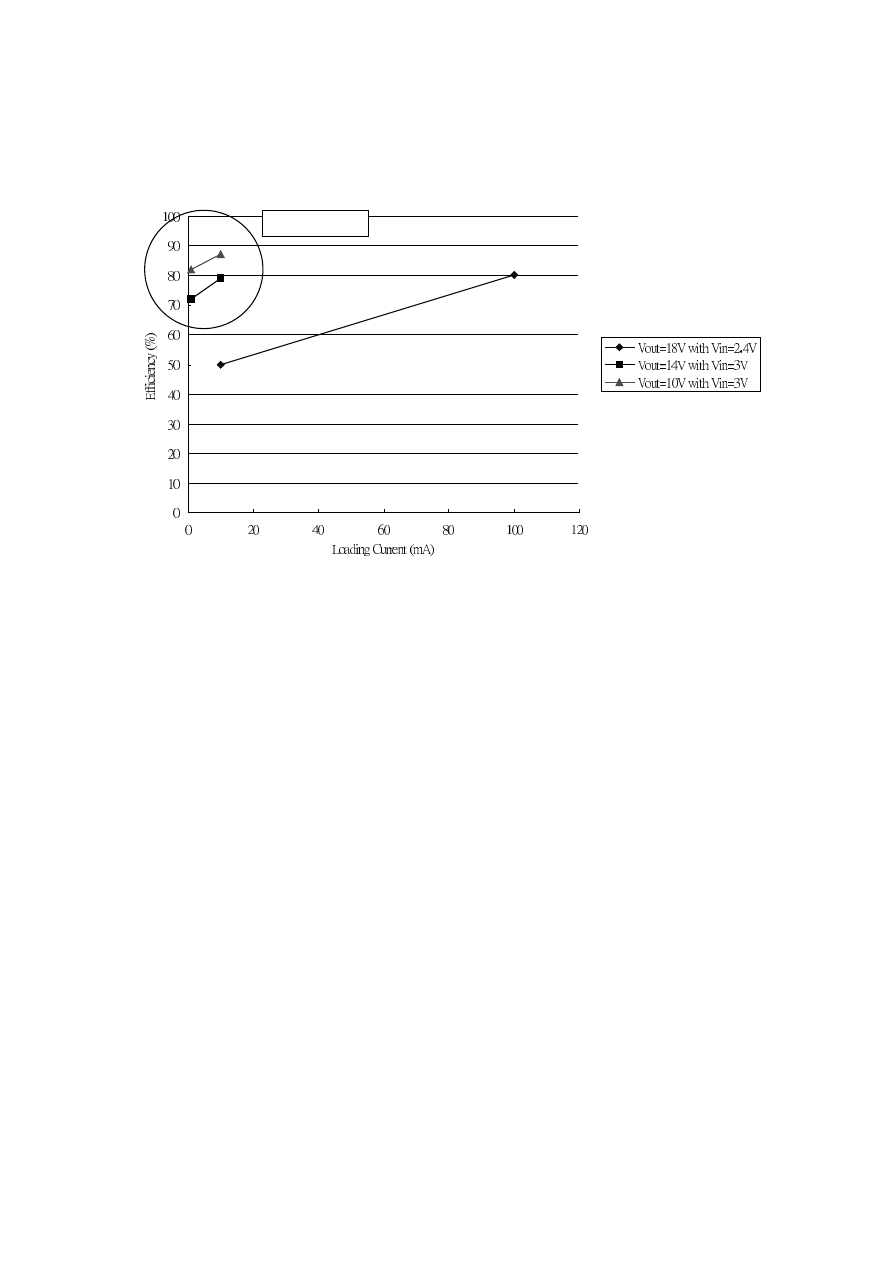

V. SIMULATION

RESULTS

This controller is implemented with a standard 0.35

µm CMOS process. The simulation

results are shown in Figure 5. The maximum efficiency is 87 %, which is corresponding to the

power save mode at output voltage 10 V with 10mA load current. The efficiency is 80 % at output

voltage 18 V with load current 100mA when the OLED display panels are in heavy load condition.

The results show that this control scheme provides high efficiency over a wide range of load

condition.

C

D

L

Reference

One-Shot

One-Shot

S

Flip-Flop

Q

R

Max.

On Time

One-Shot

Min.

Off Time

One-Shot

Rsense

Peak Output Current

Limiting Comparator

Output Voltage

Limiting Comparator

Rfb1

Vbat

Vout

R

V

fb2

pk

Figure 4: Current-limited minimum-off-time PFM DC-DC boost converter

VI. CONCLUSIONS

Due to high current consumption in the demand of color features in portable

telecommunication market, switch-mode power supply would be one of the best solutions for

OLED display driver ICs. And the current-limited minimum-off-time PFM controller is suitable in

this application as it does not only reduce the external components comparing to PWM control

schemes, but also provides high efficiency over a wide range of load condition.

Figure 5: The efficiency at different V

out

and V

in

VII. REFERENCES

[1] SOLOMON Systech Limited, LCD Driver / Controller IC.

(http://www.solomon-systech.com)

[2] SOLOMON Systech Limited, OLED Driver / Controller IC.

(http://www.solomon-systech.com)

[3]

KODAK, Display Products: Passive Displays. (http://www.kodak.com)

[4]

R. W. Erickson and D. Maksimovic, Fundamentals of Power Electronics, Norwell Mass:

Kluwer Academic Publishers, 2001.

[5]

D. Mitchell and B. Mammano, Designing Stable Control Loops, Unitrode Power Supply

Design Seminar, 2001.

[6]

Maxim, DC-DC Converter Tutorial . (http://www.maxim-ic.com)

Power save mode

Wyszukiwarka

Podobne podstrony:

Control and Power Supply for Resistance Spot Welding (RSW)

(ebook electronics) Schematics Power Regulated Power Supply for CB & Ham Radio

Battery Inverter For Modularly Structured Pv Power Supply Systems

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

Layout guidlines for switching power supply

Computer Pc Power Supply Repair for print

Convert Computer ATX Power Supply to Lab Power Supply

Jvc Power Supply Description And Trouble Shooting Procedure

Innovative Solutions In Power Electronics For Variable Speed Wind Turbines

0 50V 2A LM10C, 0 50V 2A Bench power supply circuit diagrams, schematics, electronic projects

(Wydruk – ATX Switching Power Supply 13,8 V Proste zmiany w celu zwiększenia napięcia wyjściowego Ja

Ir2111 High Voltage High Speed Power Mosfet And Igbt Driver

Alarm Power Supply L78Sxx id 61 Nieznany (2)

3 2 Lab Install Power Supply

HY3010 power supply, Elektronika, Zasilacze, Zasilacz HY3010, Zasilacz HY3010, HY3010 ,INSTRUKCJA

Lekturki Power Supply Unit Lekturka

How to Modify an ATX Computer Power Supply

więcej podobnych podstron