Ursa Minor.

Mark Aspery, Instructor of Blacksmithing

Sierra Forge and Fire.

As a professional smith and blacksmith

instructor, I am often reminded how little I

actually know about the craft of blacksmithing.

To that end I usually try and attend a week-long

blacksmithing class a year.

This year I attended a Darryl Nelson class at the

John C. Campbell School in North Carolina.

My thanks go to the Francis Whitakker

Blacksmith Education fund for approving a

grant that made this possible.

As a class we made a number of different

animal heads during the week. The class started

with a bearʼs head. The stock was 1 1/2” square

hot rolled A36. Length can vary, but you will

need enough to hold in the vice with about 4-

inches protruding above the jaws. The other end

needs to extend past the box/screw mechanism

so that the work-piece does not turn cartwheels

in the vice as you work. A handle welded on

will address this situation as well as making the

bar a little lighter to work with.

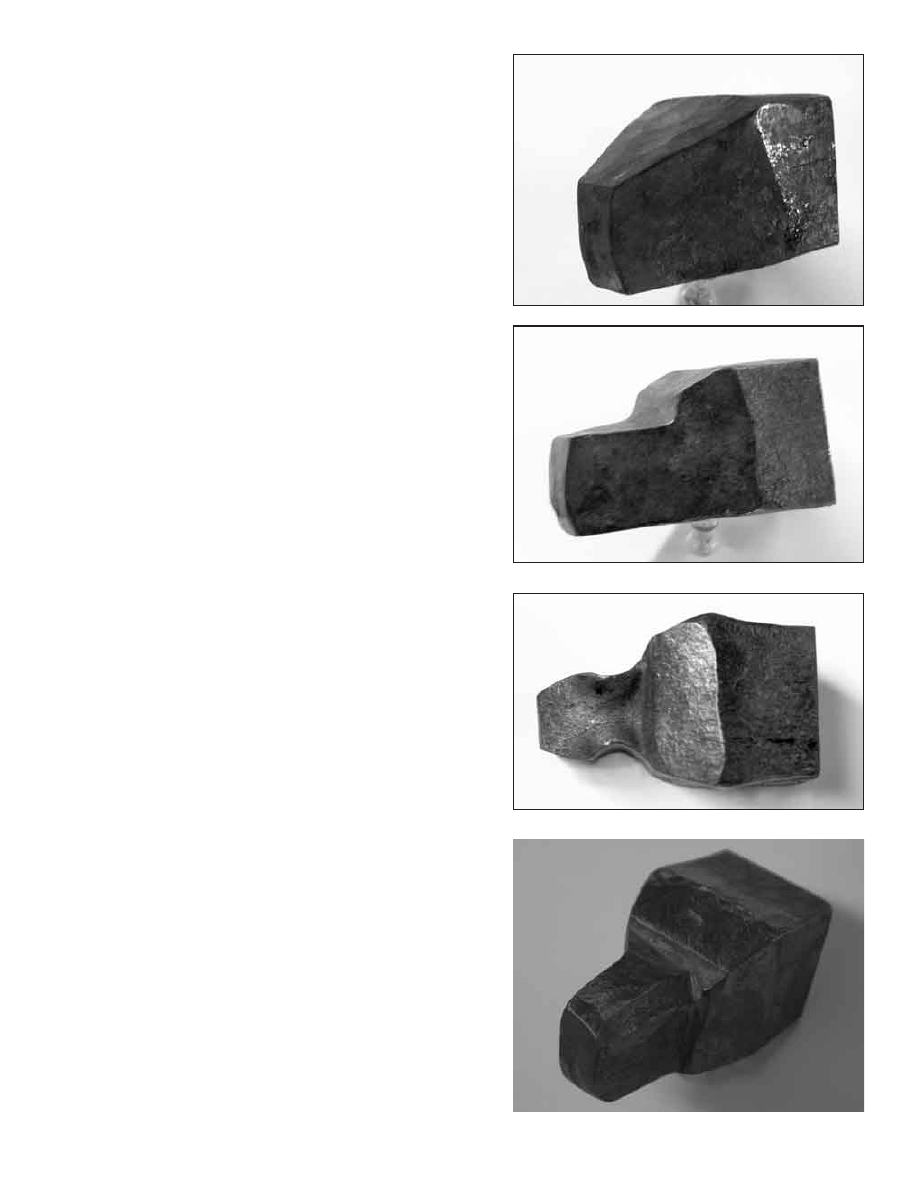

Step 1; The basic shape

Forge a taper to the end on three sides only. The

end should measure about 9/16” wide by 7/8”

tall and taper back to the parent bar-stock over

1 1/2 inches.

Step 1 A

To create the brow, turn the bar so that the

straight side is uppermost and with about 2/3 of

the taper resting on the anvil deliver a half faced

blow. You should be working over a rounded

portion on the nearside edge of the anvil when

you do this. Leave a slight taper from the

shoulder to the end of the bar.

Step 1 B

To define the jaw and front of the cheeks, either

use a top and bottom fuller as shown or a spring

swage at least 1/2-inch diameter. The rear of

the fullers should not extend past the brow line.

Fuller in to leave about 5/8-inch and a slight

taper to the front of the jaw.

Step 1 C

Forge in the remaining stock using the edge of

the anvil and your hand hammer. The snout

Step 1 A

Step 1 B

Step 1 C

Step 1 D

will have a rounded top and a flat bottom to start

with. Place the bottom of the jaw on the anvil and

knock the corners of the top of the snout with a

view to making it round.

Step 1 D

If you cannot see a bearʼs head in the rough at this

time, itʼs time to get the book out and see what

exactly it is that you are making!

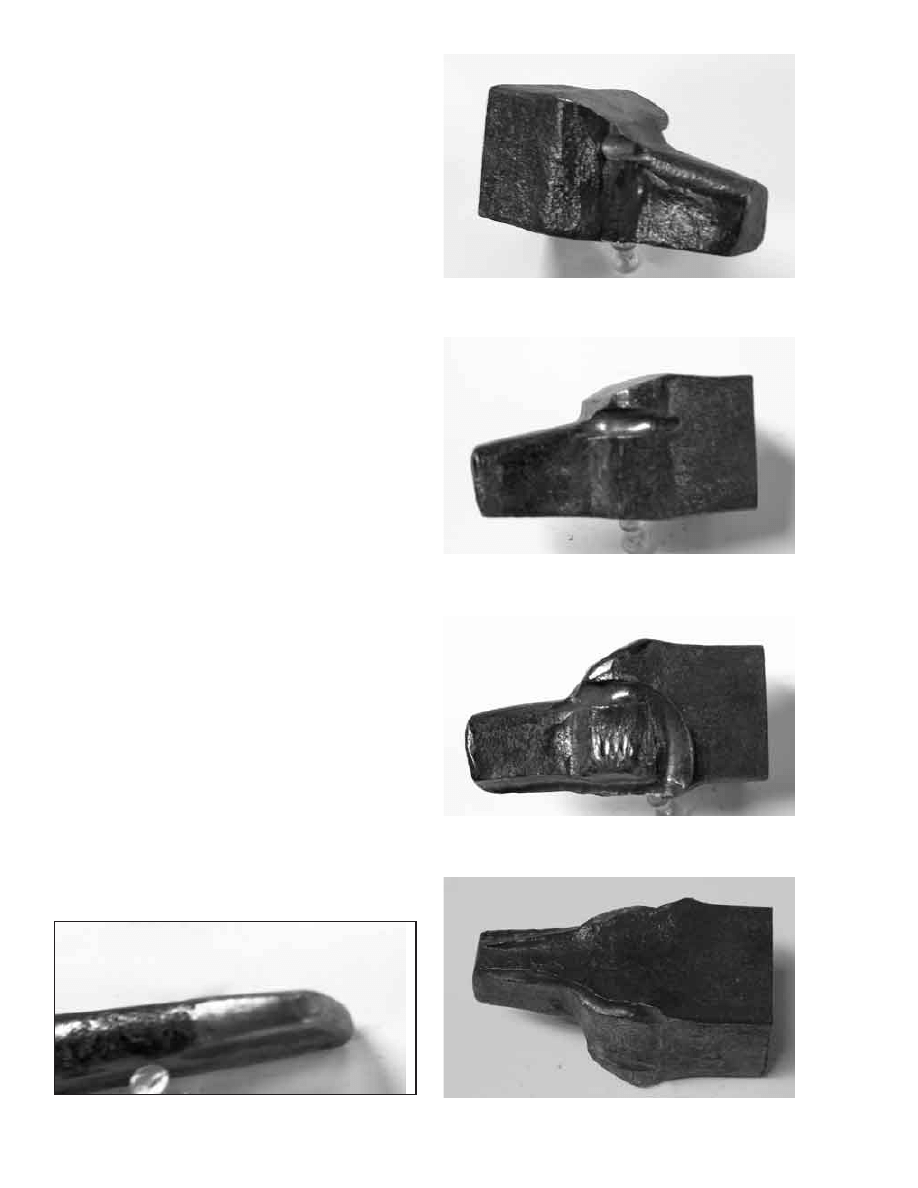

Step 2; Fuller work

To create the eye socket, define the brow and the

top of the cheek bone you will need a hand held

1/4 to 5/16-inch fuller about 7/8th to 1-inch wide.

Fig 1.

With the center-line of the fuller in line with

the top of the snout and the side of the fuller

extending slightly over the snout forge in the

eye socket. Remember that carnivores have their

eyes facing forwards, so do most of your work

from the front. Herbivores have their eyes on the

side of the head. My wife seems to have eyes

everywhere, especially when it comes to sneaking

in a new tool!

Step 2 A

Extend the fullering around the side of the head

and blend it into the parent bar-stock.

Step 2 B

Bears sometimes have a ruff around the neck and

a beard under the jaw. This next use of the fuller

defines both of these features. Starting with the

edge of the fuller where the eye socket finished

fuller in a walk to tool down the side of the bar.

Angle the fullered groove towards the jaw to

define the rear of the cheeks. First create a groove

by fullering at 90-degrees to the bar and then

come back and push the stock back to create the

ruff. I am breaking this step into two parts but in

reality the making of the ruff and the beard are the

same step and techniques.

Step 2 C

Figure 1

Step 2 A

Step 2 B

Step 2 C

Step 2 D

Once you reach the bottom of the bar when

creating the ruff, turn towards the jaw and with

the fuller on the corner of the bar start to push

the corner into the bar to create the beard. The

beard does not run to the very end of the jaw but

stops someway before.

Steps 2 D and E show work in progress.

The forehead is formed using the same tool. A

bear has a pronounced forehead. With the inside

of the tool on the centre-line form two grooves

each running back and angled away from the

centre-line. Do most of the work by the snout

and feather out the fullering as you get to the top

of the head. Blend in the sharp edges with the

same tool. Step 2 F

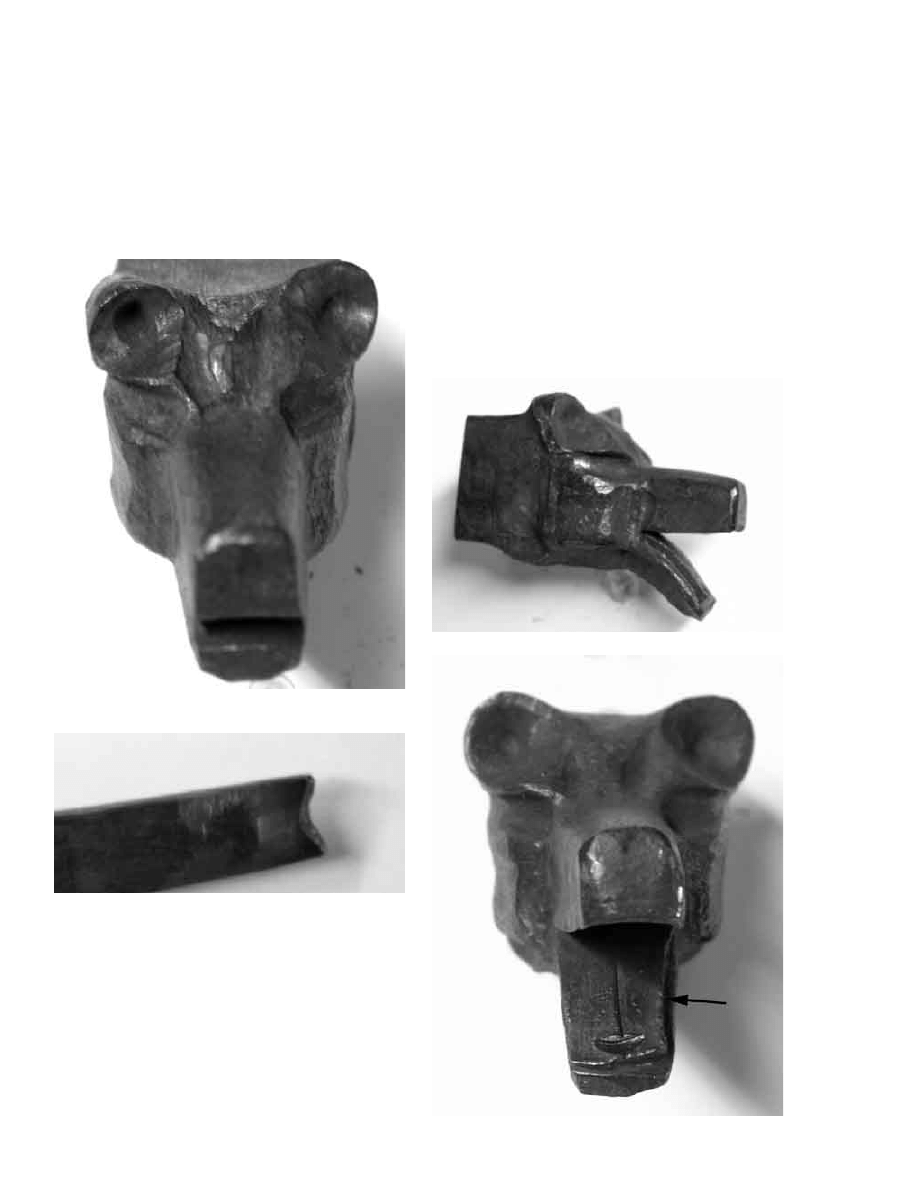

Step 3;The Ears

Using the same tool as above, place the business

end above the eye socket and hold the tool at

an angle. You will push material back from the

face to create an ear and at the same time create

the eyebrow. As you push the material back

drive the material slightly towards the centre

of the bar. If you omit this step the tool will be

deflected upwards and you will have very small

ears. Of course, too much angle and you end up

with bat ears. Step 3 A

Taking a sharper than normal centre punch,

place the point at the bottom, centre of the ear.

Drop the angle of the punch so that the taper

on the end rests flat upon the brow and make a

depression of about 1/8-inch or so. If you feel

like youʼre driving towards the brain you are

holding the centre punch at too steep an angle!

Step 3 B

Step 2 E

Step 2 F

Step 3 A

Step 3 B

Using a hollow ended fuller, (Fig 2) place one

corner in the depression you just made. Rock

the tool out so that it touches the body of the ear

as well. Start from one side and spread the ear

out giving it texture as you go.

You may need some clean-up work from the

back of the ear with either the fuller or the

hollow ended fuller.

Step 3 B and 4 A show the results

Step 4; The Jaw and tongue

Drive a curved hot chisel held about 2/3ʼs down

from the tip of the nose cut the mouth. Angle the

cut down towards to bottom of the head as you

go. This will leave a nice taper to the snout from

the tip of the nose back to the cheeks with the

curve leaving a hollow in the upper jaw.

I have my chisel ground on the outside edge to

help with this.

Step 4 A.

Step 4 A

Figure 2

Step 4 B

Step 4 C

Using a hand held butcher or your hand chisel;

cut a groove around the lower jaw about 1/16-

inch down.

A hand held side set will push the upper section

in to create the lower lips and give you the mass

to cut the lower teeth.

Step 4 B and C show the progression with the

arrow in Step 4 C showing the result of using

the side set on one side only.

Mark the center of the tongue with an offset

chisel

Taking a small curved chisel, again ground on

the outside of the tool edge, cut the tongue. Start

about 1/16

th

-inch back from the front of the

teeth. Step 4 C

Start by cutting down; but quickly change the

angle of the cut to the back of the jaw. If you dig

too deep you can seriously shorten or upset the

lower jaw and give your bear an overbite.

Work the chisel back to the rear of the mouth.

Donʼt allow the tongue to touch the top of the

mouth as getting it down can be both frustrating

and damaging.

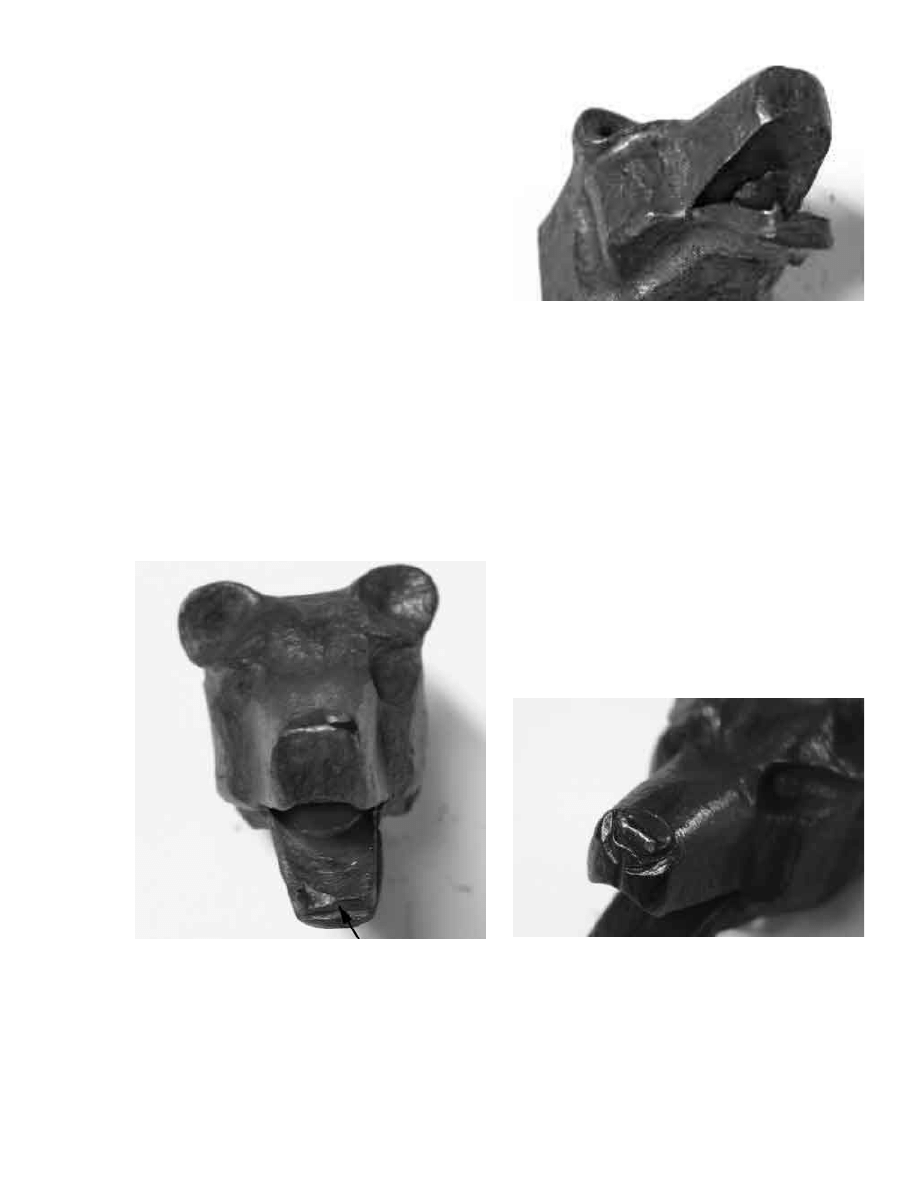

Step 5; The Teeth

Using the same curved chisel, start at the center

of the front teeth and cut first to one side and

then the other. This creates the mass for the

canines. Donʼt aim too deep as you cut. Use a

smaller hollow ended fuller and work the mass

into sharp canines.

The offset chisel will mark the other teeth both

on the side and on top as shown.

Step 5 A and B

Step 6; The Nose

Using the same curved chisel as above mark a

line for the nose. Remember that a bear has poor

vision but a really keen sense of smell. Donʼt

skimp on the nose!

On the front of the snout create a good line

leaving the nose forward of the rest of the stock.

On the top of the snout use light blows as you

are identifying only the edge of the hairline.

Use a smaller curved chisel and aiming slightly

towards the centre of the snout put in the

nostrils. Allow them to flare a little. Leave a

little gap between the two chisel marks.

Use the side set to push away the stock to the

side of the nose to make it stand out a bit farther.

The result is shown in Step 6 A

Step 5 A

Step 6 A

tep 5 B

Step 7; The Eyes and Eyebrow

The eyes on a bear are quite small and round.

If we copied the natural bear our bearʼs head

would look a little out of proportion.

Use a round eye punch and drive it in from the

front. Remember, carnivorʼs have their eyes

facing forwards.

Once you have got a complete ring around the

eye. use the fuller tool to form the eyebrow.

Again the results are shown in the next photo,

the left hand side complete and the other as

punched. Step 7 A

Step 7 A

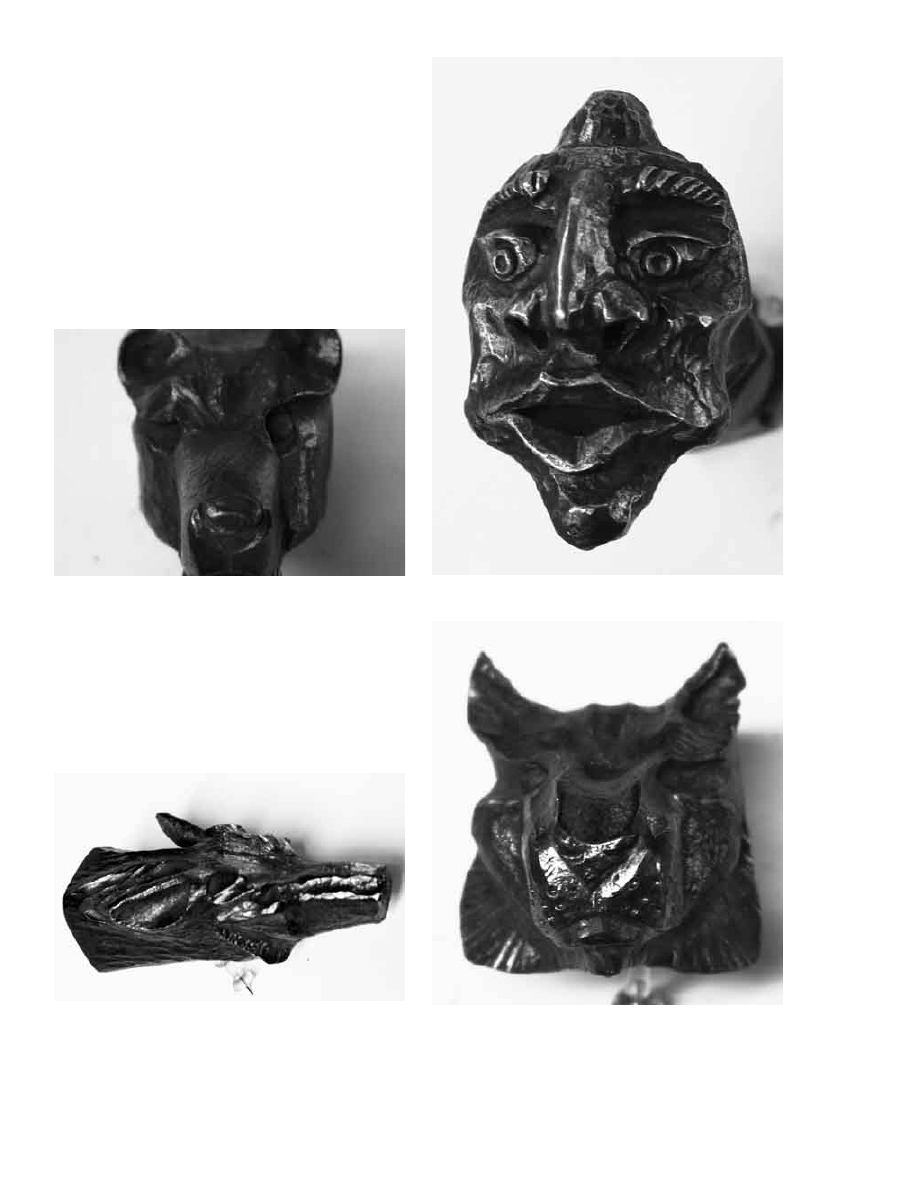

Wolfʼs head

Lynx head

Gargoule

By tweaking the techniques and the tooling

slightly, other forms can be created.

If this sort of work appeals to you look for the

Darryl Nelson Demo and clinic dates contained

in this magazine

Wyszukiwarka

Podobne podstrony:

tomtom 7.910 krok po kroku jak wgrać i uruchomić navi, NAWIGACJA TomTom

Jak zainstalowa Windows 7 Instrukta krok po kroku

Metoda żelowa na tipsie krok po kroku, Stylizacja Paznokci 1

organizacja spotkania biznesowego krok po kroku

Abolicja Podatkowa krok po kroku

Kąpiel noworodka krok po kroku, Dziecko

[Suski] Krok po kroku

Lekka mokra krok po kroku (2)

METODA ŻELOWA NA TIPSIE KROK PO KROKU

Jak założyć własną firmę krok po kroku

Niezwyke zdjcia HDR krok po kroku cz 1

więcej podobnych podstron