24

Grain Property Values and Their

Measurement

Digvir S. Jayas and Stefan Cenkowski

CONTENTS

24.1 Introduction.......................................................................................................................................... 575

24.2 Physical Properties................................................................................................................................ 576

24.6 Optical Properties ................................................................................................................................. 596

24.7 Aerodynamic Properties ....................................................................................................................... 598

List of Symbols .............................................................................................................................................. 599

References ...................................................................................................................................................... 600

24.1 INTRODUCTION

The world produces annually about 2 billion tonnes (Gt)

of grains and oilseeds [1] that are handled and stored

on- and off-farm for periods of up to 3 y. Often the

storage period may be longer than 3 y, for example,

when the grain is stored for potential famine relief. To

design handling, inspection, and storage systems for

grains and oilseeds, data on many properties of indivi-

dual seeds and seeds in bulk are needed. The properties of

interest are: bulk and particle densities, porosity, round-

ness, sphericity, friction coefficients of grains against

commonly used bin wall materials, emptying and fill-

ing angles of repose, equilibrium moisture content

(EMC), specific heat, thermal conductivity, dielectric

constant, electrical conductivity, reflectance, terminal

ß

2006 by Taylor & Francis Group, LLC.

velocity, and drag coefficient. There are many

methods of measuring these properties. In this chap-

ter, only the methods that are currently in use or

widely accepted methods are described. Representa-

tive property values for common grains and oilseeds

are summarized from the published literature.

The properties of grains and oilseeds are measured

on representative samples and are affected by many

factors such as moisture content, growing location,

amount and type of foreign material in the sample,

and conditions of the surroundings. Many properties

also depend on other properties. For example, ther-

mal conductivity of bulk grain depends on its bulk

density. Care must be taken in obtaining a represen-

tative sample because the great care taken in measur-

ing a property will only give a good property value for

the sample used. Ideally, representative samples from

many different growing locations, growing years, and

cultivars should be used to arrive at a grain property

value that can be used in engineering design. Unfor-

tunately, such studies become cost prohibitive and

coordinated efforts among world scientists are needed

to improve on the database for grain properties. At

times, results of a well planned and executed project

on measurement of grain properties become less use-

ful when incomplete information about the sample is

given in the published literature. Therefore, when

reporting, a complete description of the sample

should be given. For example, usefulness of data on

bulk density of wheat without knowing at least its

moisture content and class of wheat may be dimin-

ished considerably for an engineering design.

24.2 PHYSICAL PROPERTIES

24.2.1 B

ULK

D

ENSITY

(T

EST

W

EIGHT

)

Bulk density is defined as the ratio of the mass of the

sample to the volume occupied by the bulk sample and

is expressed in the units of kg/m

3

. The bulk volume

includes the volume of intergranular air and grain. In

the grain trade, the term test weight is used, which is

defined as the mass of a measured volume of grain

expressed in kg/hL (lb/bu). Standard methods for de-

termining test weights are used by regulatory agencies

around the world (e.g., Canadian Grain Commission

[2]). The bulk density values reported in the literature

are usually determined for clean grain at a specified

moisture content by using the equipment and proced-

ure for determination of test weight. The values thus

determined are lower than the values that are expected

in storage. The bulk density of grain in storage can be

affected by the method used for filling the structure

and by the amount and type of foreign material in the

grain. For example, a bin filled using a spreader gives a

higher bulk density than a bin filled using a spout, or

increasing the drop height during spout filling in-

creases the bulk density. Also, the presence of foreign

materials that are finer and heavier than grain kernels

increases storage bulk density.

Bulk density of a clean grain sample (for corn, the

sample is not cleaned) is determined by filling a 500-

mL metallic container (90 mm diameter and 78 mm

high) from a funnel with a 38.1 mm opening and

having a flat slide gate. The opening of the funnel is

maintained at 44.1 mm above the top of the con-

tainer. Grain required to fill the container plus a

small additional amount are loaded into the funnel

whereas its gate is closed. When the gate is opened,

the sample flows freely from the funnel into the center

of the container and fills the container to overflowing.

The grain in the container is leveled by striking off the

excess grain with a round rod (19-mm diameter hard-

wood) using three equal zigzag movements at an

angle to the direction of movement of approximately

458. The mass of the grain in the container is meas-

ured and the bulk density (kg/m

3

) or the test weight

(kg/hL) is calculated (Canadian Grain Commission

[2]). The bulk density for common grains and oilseeds

are summarized in Table 24.1 (ASAE [3]).

TABLE 24.1

Approximate Bulk Density of Grains and Other Seeds

Seed

Bulk Density (kg/m

3

)

Alfalfa

772

Barley

618

Beans Lima dry

721

Buckwheat

618

Canola (rapeseed)

669

Corn shelled

721

Lentils

772

Oats

412

Peanuts, unshelled

Virginia type

219

Spanish

322

Rice, rough

579

Rye

721

Sorghum grain

721

Sunflower seed (nonoil)

309

Sunflower seed (oil)

412

Soybeans

772

Timothy seed

579

Wheat

772

Source: From ASAE, D241.4 Feb. 93, Density, specific gravity,

and mass–moisture relationships of grain for storage, 40th ed.,

Standards, Engineering Practices, and Data (Am. Soc. Ag. Eng.),

St. Joseph, MI, 1993, pp. 408–410. With permission.

ß

2006 by Taylor & Francis Group, LLC.

24.2.2 P

ARTICLE

D

ENSITY

Two other terms true density and kernel density are

used as synonyms to the particle density. Particle dens-

ity is defined as the ratio of the mass of a sample to the

volume occupied by the kernels (excluding the inter-

granular air) of the sample. The kernel volume can be

determined using either of these two methods: liquid

displacement method (LDM) and air comparison

pycnometer (ACP) (e.g., Model 930, Beckman Instru-

ments Inc., Fullerton, CA). In the LDM, a known

mass of grain is poured into a graduated cylinder

filled with a liquid to a known level. The change in

the volume of the liquid is determined by subtracting

the initial liquid volume reading from the final liquid

volume reading. The liquid should not be sorbed

(adsorbed or absorbed) by the solid particles; there-

fore, toluene is commonly used for grains and oil-

seeds. The main problem with the LDM is that tiny

air bubbles on the surface of the solid particles may

be present and included in the volume of the particles.

Also, liquid may not displace all the intergranular air.

The ACP measures the true volume of the solid par-

ticles. The particle densities of some grains are given

in Table 24.2 (ASAE [3]).

24.2.3 P

OROSITY

The terms percent voids, percent airspace, percent

pore volume, and porosity are used interchangeably

in the literature. Porosity is defined as the ratio of the

volume occupied by the intergranular air to the total

volume of the bulk sample and is expressed in per-

cent. Usually, the porosity is calculated from the bulk

and particle densities of a sample and thus can be

considered as a derived quantity*:

¼ 1

r

b

r

t

100:

(24:1)

TABLE 24.2

Porosity and Particle Density of Selected Seeds

Seed

Cultivar

Moisture Content (% wet basis)

Porosity (%)

Particle Density (kg/m

3

)

Barley

Coast (6 rows)

10.3

57.6

1130

Barley

Hannchen

9.7

44.5

1260

Barley

Synasota

9.8

45.4

1210

Barley

Trebi (6 rows)

10.7

47.9

1240

Barley

White hullness

10.4

39.5

1330

Buckwheat

Japanese

10.1

41.0

1100

Canola

Tobin

6.5

38.4

1150

Canola

Westar

6.7

38.9

1100

Corn, mixed

Yellow and white

9.0

40.0

1190

Corn, shelled

Yellow, dent

25.0

44.0

1270

Corn, shelled

Yellow, dent

15.0

40.0

1300

Flaxseed

5.8

34.6

1100

Grain sorghum

Blackhull kafir

9.9

36.8

1260

Grain sorghum

Yellow milo

9.5

37.0

1220

Millet

Siberian

9.4

36.8

1110

Oats

Iowar

9.7

51.4

950

Oats

Kanota

9.4

50.9

1060

Oats

Red Texas

10.3

55.5

0990

Oats

Victory

9.8

47.6

1050

Rice

Honduras

11.9

50.4

1110

Rice

Wataribune

12.4

46.5

1120

Rye

Common

9.7

41.2

1230

Soybeans

Wilson

7.0

33.8

1130

Wheat, hard

Turkey, winter

9.8

42.6

1300

Wheat, hard

Turkey, winter (yellow)

9.8

40.1

1290

Wheat, soft

Harvest Queen

9.8

39.6

1320

Source: From ASAE, D241, 4 Feb. 93, Density, specific gravity, and mass–moisture relationships of grain for storage, 40th ed.,

Standards, Engineering Practices, and Data (Am. Soc. Ag. Eng.), St. Joseph, MI, 1993, pp. 408–410. With permission.

*Symbols are defined in the List of Symbols.

ß

2006 by Taylor & Francis Group, LLC.

Porosit y can be measur ed directly using a method

describ ed by Day [4]. The por osities for common

seeds a re given in

24.2.4 P

ROJECTED

A

REA

Kernels of all grains and oilseeds, when dropp ed on a

flat horizont al surfa ce, rest in their most stable pos -

ition. The area covered (viewed from the direction

perpend icular to the surfa ce) by a kernel in its most

stable posit ion is defined as the project ed area (mm

2

)

and can be determ ined by tracin g the kernel on a

graph paper and by esti mating the numb er of squ ares

in the enclosed tracin g. A planimeter can also be used

for quantific ation of the area. The lengt h an d width of

the minimum rectangle that encloses the pro jected

area are de fined as princip al major and minor ax es

or lengt h and wi dth of grain kernels, respectivel y. The

length obta ined by traci ng along the circum ferenc e of

the project ed area is defi ned as the perimeter of a

kernel. The projecte d area, lengt h, width, an d perim -

eter of kernels can be measu red easily using a digit al

image process ing system [5] and the values for many

seed types are given in Table 24.3.

24.2.5 R

OUNDNESS

Roundn ess of a grain kernel is de fined as the ratio of

the kernel’ s projected area in its most stabl e position

to the area of the smallest circum scri bing circl e:

R

¼

A

p

A

c

(24 : 2)

24.2.6 E

QUIVALENT

V

OLUME

(E

QUIVALENT

D

IAMETER

)

A sphere whose volume is equal to the volume of a grain

kernel is defined as the equivalent sphere of the kernel.

The diameter of the sphere of equivalent volume is

defined as the equivalent diameter of the kernel. The

average equivalent volume of kernels can be determined

by using a particle density method (

and counting the kernels. The equivalent diameter is

calculated from the measured volume as

d

e

¼

6V

e

p

1 = 3

(24 : 3)

Common ly, the volume occupied by 10 00 ke rnels

(random ly selec ted) is measur ed and the average

equival ent volume and the diame ter are calculated

and report ed (

The geomet ric mean diame ter, D

g

, is another term

that is used to describ e the shape of ke rnels. It is

calculated as

D

g

¼ ( a b c )

1 =3

(24 : 4)

Physical ly, the terms a, b, and c are the lengt h, wi dth,

and height, respectivel y of the smallest parallelepi ped

that will full y en close the kernel.

TABLE 24.3

Physic al Dimens ions of Var ious Seeds

Seed Projected Area (mm

2

) Perimeter (mm)

a

Length (mm) Width (mm)

Mean SD

b

Mean SD

b

Mean SD

b

Mean SD

b

Wheat (HRS)

c

15.0 2.2 14.6 1.1 5.3 0.4 3.2 0.4

Barley 23.0 2.9 20.5 1.7 8.3 0.8 3.4 0.3

Canola 2.4 0.5 5.1 0.6 1.6 0.2 1.5 0.2

Brown mustard 1.9 0.3 4.5 0.5 1.5 0.2 1.3 0.2

Yellow mustard 3.9 0.6 6.8 0.6 2.2 0.2 1.9 0.2

Oriental mustard 2.4 0.3 5.1 0.4 1.7 0.2 1.5 0.2

Laird lentils 36.0 3.6 21.8 1.2 6.7 0.4 6.4 0.4

Eston lentils 16.0 2.0 14.5 1.0 4.5 0.3 4.3 0.3

Pea beans 40.0 4.6 23.4 1.4 7.8 0.5 6.1 0.5

Green peas

35.0

3.3

21.6

1.0

6.6

0.3

6.4

0.4

Black beans

45.0

5.7

25.3

1.7

8.4

0.6

6.6

0.6

Buckwheat

19.0

2.9

16.5

1.5

5.6

0.7

4.2

0.4

Flaxseed

6.4

0.5

10.1

0.4

3.9

0.2

1.8

0.1

a

b

SD

¼ Standard deviation based on n ¼ 1000.

c

HRS, Hard red spring.

Source: From Shatadal, P., Jayas, D.S., Hehn, J.L., and Bulley, N.R., Can. Agric. Eng., 37(3), 163, 1995. With permission.

ß

2006 by Taylor & Francis Group, LLC.

24.2.7 S

PHERICITY

Spherici ty of a ke rnel is define d as: the ratio of the

volume of a kernel to the vo lume of the smallest

circum scribing sph ere; or the rati o of the equival ent

diame ter of the kern el to the diame ter of the smallest

circum scribing sphere; or the rati o of the geomet ric

mean diameter of a kernel to the diame ter of the

smallest circum scrib ing sph ere.

24.2.8 S

URFACE

A

REA

Surface area is the area of the outer surfa ce of a kernel.

An approxim ate su rface area can be de termined by

assum ing grain ke rnels are ellip soids wi th major or

minor axes a and b, an d by calcul ating the surface

area of the ellipsoid using known mathe matical rela-

tionsh ips [6]. An approxim ate surfa ce area can also be

estimat ed by assum ing the kerne l as a sph ere of equiva-

lent diameter. A method of measur ing su rface area of

grains is by c oating grains with a single layer of meta l

particles [7–9] . A known mass of kernels is dipped in

varnish . The excess varnis h is remove d by roll ing ker-

nels on pa per tow el and by air drying. The kernels are

swirled with nickel particles and the mass of coa ted

kernels is determ ined. For convert ing the chan ge in

mass of the kernels to the surfa ce area, parti cles of

known geo metry (surf ace area) having specific gravi ty

simila r to the specific gravi ty of grain ke rnels are

coated in a sim ilar mann er and change in their mass

is determined . By applyin g the pr oportio nality rule the

surface area of particles is calculated. The surfa ce a rea

of some grains is given in Tabl e 24.4.

24.2.9 E

MPTYING AND

F

ILLING

A

NGLES OF

R

EPOSE

Emptying angles of repose of samples are measured by

emptying grain from a box (e.g., a wooden box 430 mm

long, 200 mm wide, and 430 mm high). The dimensions

of the box are arbitrary except that the accuracy of

measurement improves with increased length of slope.

The box is filled with samples to a depth of 350 mm.

Samples are allowed to flow out through a 50-mm high

and 200-mm wide rectangular opening provided along

the width of the box at the bottom of one end wall.

Emptying angles are calculated from measurements of

horizontal and vertical scale readings.

Fill ing angles of repose can be measur ed using a

box wi th one side made of Pl exiglass (e.g., a wooden

box 12 00 mm long, 100 mm wi de, and 76 0 mm high).

Sample s are allow ed to flow freel y through a 50-m m

square opening in a wooden hopper, whose center is

maintained 1000 mm above the bottom of the receiv-

ing box. Filling angles are calculated from measure-

ments of sample profile depth at two horizontally

spaced points 300 mm apart. The first point is chosen

approximately 100 mm away from the impact flat-

tened apex of the cone. Filling angles are measured

on both sides of the apex and averaged for individual

replicates. Typical values of emptying and filling

angles of repose of grains and oilseeds are given in

TABLE 24.4

Equivalent

a

Diameter (d

e

), Surface Area (A), and Volume (V

e

) of Kernels of Selected Seeds

Seed

d

e

(mm)

A (mm

2

)

V

e

(mm

3

)

Ref.

Beans

b

6.64

138

153

103

Corn

7.37

170

209

104

Corn

7.88

195

256

105

Corn, Inra 258

7.28

166

199

106

Corn, Velox

7.14

160

190

106

Corn, Dekalb XL72A

c

7.61

182

231

107

Corn, Pioneer 3388

c

7.16

161

192

107

Corn, N7A X N28

c

8.18

210

286

107

Flax

1.90

11.34

3.59

104

Fababeans

b

8.63

234

336

103

Lupin

b

5.73

103

98

103

Peas

b

6.28

124

130

103

Poppy seed

0.99

3.11

0.52

104

Wheat

3.48

38.04

22.07

104

a

Equivalent diameter was calculated from measured V

e

and A was calculated from d

e

.

b

Moisture content

¼ 0% wb.

c

Moisture content

¼ 10.5% wb.

ß

2006 by Taylor & Francis Group, LLC.

24.2.10 F

RICTION

C

OEFFICIENTS AGAINST

S

TRUCTURAL

M

ATERIALS

Coeffic ients of sli ding fri ction agains t v arious struc -

tural surfa ces are determ ined by using a tilting table .

The surface of inter est is atta ched to the tilting

table. A wooden fram e (305 mm long and 255 mm

wide), made of 18-mm square wood, is placed lengt h-

wise on the surfa ce to prev ent kernels from roll ing

down the surfa ce. It is filled wi th the sample and

leveled. The frame is lifted slowly to an approxim ate

height of 2–3 mm, so that the fram e does not rest on

the surfa ce. Usin g a man ually driven screw, the table

is tilted slowly until the sampl e starts to slide. The

angle of the tilting table is measur ed using a pro -

tractor and a plu mb bob. The co efficien t of fri ction

is calcul ated as the tangent of the angle measur ed [10] .

The fri ction coeffici ent agains t verti cal surfa ces is

needed in bin design. To measur e the fri ction coeffi-

cients agains t vertical walls, a system de scribed by

Irvine e t al. [11] can be used. The values of sliding

frictio n agains t fou r struc tural mate rials for common

grains and oils eeds are given in

24.3 HYGROSCOPIC PROPERTIES

24.3.1 M

OISTURE

M

EASUREMENT

A common method for de termining mois ture co ntent

of grains an d oilseeds is to dry samples in triplic ate in

a co nvection air oven at a specified tempe ratur e for a

specified durati on (

; ASAE [12]). Abou t

10–15 g samples a re weighed in covered aluminum

dishes . The dishes are unc overed and placed with

their covers in the oven at the set tempe rature. At

the end of the drying period, dishes are covered and

placed in a de siccator for coo ling to the room tem-

peratur e. The dishes wi th dried sample are weighed

again. Moisture co ntent of sampl es is calculated a s

the ratio of the mass loss divide d by the mass of the

original sample and is exp ressed in percent age on a

wet mass basis (wb ). In theo ries of grain dr ying, the

moisture co ntents of sampl es are usua lly express ed

on a dry mass ba sis (db), whi ch is calcul ated as the

ratio of the mass of water divide d by the mass of dry

matter an d is express ed as a percent age or decim al

fraction. To avoid confusi on as to which basis the

moisture con tent is report ed in a pa rticular chapter ,

it is suggested that the scientific commun ity adop t a

conventi on to report moisture co ntents on wet basis

in percent age and moisture content s on dry ba sis in

decim al fraction.

24.3.2 M

EASUREMENT OF

E

QUILIBRIUM

M

OISTURE

C

ONTENT

There are two common methods (static and dynami c)

for measuring the EMC–equilibrium relative humidity

(ERH) relationships of grains and oilseeds. The static

method is also known as the EMC method and the

dynamic method is also known as the ERH method.

In the static method, a sample of known mass is

allowed to reach equilibrium with air maintained at a

constant relative humidity and temperature. The

moisture content of the sample at equilibrium is

measured and is defined as the EMC. The constant

relative humidity environments are usually created

using saturated salt solutions in containers [13].

TABLE 24.5

Emptying and Filling Angles of Repose of Selected Seeds

Seed

Moisture Content (% wb)

Emptying Angle (8)

Filling Angle (8)

Ref.

Barley (cv. ‘Bedford’)

12.7

26

24

108

Durum wheat (cv. ‘Wakoma’)

12.7

24

24

108

Oats (cv. ‘Harmon’)

12.7

27

28

108

Rye (cv. ‘Gazelle’)

12.7

21

25

108

Rapeseed (cv. ‘Candle’)

8.1

26

24

108

Sunflower (cv. ‘Sundak’)

8.1

22

21

108

Soybean (cv. ‘McCall’)

8.1

29

—

108

Triticale (cv. ‘Carman’)

12.7

21

23

108

Wheat (cv. ‘Neepawa’)

12.7

27

26

108

Fababeans (cv. ‘Ackerperle’)

12.6

28

29

10

Flaxseed (‘McGregor’)

7.0

30

26

10

Lentils (cv. ‘Laird’)

13.8

24

24

10

50%-Hulless barley (cv. ‘Condor’)

14.5

24

23

109

95%-Hulless barley (cv. ‘Condor’)

14.0

24

23

109

ß

2006 by Taylor & Francis Group, LLC.

A container with a 10- to 15-g sample suspended in

the environment above the saturated salt solution is

kept at a constant temperature. The experiment must

be repeated at several temperatures and relative

humidities. The sample is weighed at a regular inter-

val of 3–12 h until the change in sample mass between

two successive readings is less than 0.01 g (at this

stage it is assumed that the sample has reached

TABLE 24.6

Coefficients of Sliding Friction against Four Different Structural Materials for Selected Seeds

Seed

Moisture

Content (% wb)

Galvanized

Steel

Steel Troweled

Concrete

Wood Floated

Concrete

Plywood

Ref.

Barley (cv. ‘Bedford’)

12.7

0.29

0.38

0.45

—

108

Durum wheat (cv. ‘Wakoma’)

12.7

0.29

0.39

0.45

—

108

Oats (cv. ‘Harmon’)

12.7

0.27

0.40

0.44

—

108

Rye (cv. ‘Gazelle’)

12.7

0.30

0.38

0.41

—

108

Rapeseed (cv. ‘Candle’)

8.1

0.24

0.30

0.39

—

108

Sunflower (cv. ‘Sundak’)

8.1

0.35

0.40

0.40

—

108

Soybean (cv. ‘McCall’)

8.1

0.27

0.33

0.34

—

108

Triticale (cv. ‘Carman’)

12.7

0.39

0.38

0.39

—

108

Wheat (cv. ‘Neepawa’)

12.7

0.32

0.42

0.47

—

108

Fababeans (cv. ‘Ackerperle’)

12.6

0.29

0.31

0.29

0.28

10

Flaxseed (‘McGregor’)

7.0

0.27

0.42

0.44

0.33

10

Lentils (cv. ‘Laird’)

13.8

0.25

0.34

0.31

0.24

10

50%-Hulless barley (cv. ‘Condor’)

14.5

0.29

0.39

0.40

0.31

109

95%-Hulless barley (cv. ‘Condor’)

14.0

0.32

0.40

0.41

0.32

109

TABLE 24.7

Oven Temperature and Heating Period for Moisture Content Determinations

Seed

Oven Temperature +18C

Heating Temperature

Sample Size (g)

h

min

Alfalfa

130

2

30

10

Barley

130

20

0

10

Beans, edible

103

72

0

15

Bluestem, yellow

100

1

0

1

Corn

103

72

0

15 or 100

a

Fescue

130

3

0

5

Flax

103

4

0

5–7

Mustard

130

4

0

10

Oats

130

22

0

10

Orchard grass

130

1

0

5

Parsnip

100

1

0

10

Rape (Canola)

130

4

0

10

Rye

130

16

0

10

Ryegrass

130

3

0

5

Safflower

130

1

0

10

Sorghum

130

18

0

10

Soybeans

103

72

0

15

Sunflower

130

3

0

10

Timothy

130

1

40

10

Wheat

130

19

0

10

a

Use 100 g if moisture exceeds 25%.

Source: From ASAE, S352, 2 Dec. 92, Moisture measurement—unground grain and seeds, 40th ed., Standards, Engineering Practices, and

Data (Am. Soc. Ag. Eng.), St. Joseph, MI, 1993, p. 449. With permission.

ß

2006 by Taylor & Francis Group, LLC.

equilibrium). Depending on the vapor pressure of the

moisture in the seeds and the vapor pressure of the air

above the saturated salt solution the sample may reach

equilibrium by picking up or giving off moisture, thus

resulting in either a sorption or desorption EMC

value. For grains and oilseeds, the sorption EMC is

lower than the desorption EMC at the same relative

humidity because of the hysteresis phenomenon that is

exhibited by biological materials. The moisture uptake

can be by chemisorption, adsorption, absorption, or a

combination as moisture content increases. The term

sorption includes all mechanisms of moisture uptake.

The time for the samples to reach equilibrium may

vary from 1 to 5 weeks depending on the relative

humidity and temperature. Therefore, mold usually

develops on samples in high humidity environments

and treatment of the sample with a mold inhibitor such

as propionic acid is required.

To reduce the time to reach equilibrium and to

reduce the problem with mold development, another

version of the static method is to force conditioned air

of known temperature and relative humidity over the

sample until the change in mass of the sample is small

(<0.01 g). A variation to this method can be used when

determining thin-layer drying or wetting characteristics

of a sample. The variation is that it is not necessary to

bring the sample to equilibrium, and the EMC is deter-

mined as M

e

by nonlinear regression of the equation:

M

M

e

M

i

M

e

¼ exp (Kt

N

)

(24:5)

In the dynamic method, a small amount of air is

brought into equilibrium with a 0.5–1.0 kg sample of

known moisture content by recirculating the air in a

sealed unit [14] that is housed in a room at a constant

temperature within +0.18C. The relative humidity of

the recirculating air is monitored until it becomes

constant at which stage it is assumed that equilibrium

has been attained and the measured relative humidity

is the ERH. The moisture content of the sample is

measured again. The average of the initial and final

moisture contents is taken as the EMC. Because the

amount of recirculating air is small, the change in

moisture content of the sample usually is within the

error limits of the method of moisture measurement

and some researchers take the initial moisture content

of the sample as the EMC. The time to reach equilib-

rium is reduced to 6–12 h depending on the conditions

of the sample. When determining a desorption iso-

therm by the dynamic method, the initial relative

humidity of the air must be well below the expected

ERH so the grain loses moisture to the air; and the

reverse must be guaranteed when determining the

sorption isotherm.

24.3.3 A

NALYSIS OF

EMC–ERH D

ATA

The EMC–ERH data of grains and oilseeds are ana-

lyzed by fitting various equations to the data using

nonlinear regression. The commonly used equations

are: the modified Henderson, Chung–Pfost, Halsey,

Oswin, and Guggenheim–Anderdon–de Boer (G.A.B)

(Table 24.8). The modified Henderson [15,16] and

modified Chung–Pfost [17,18] equations have been

adopted as standard equations by the American So-

ciety of Agricultural Engineers for describing EMC–

ERH data for cereals and oilseeds. The modified

Halsey [19,20] and modified Oswin [21,22] equations

have been shown to describe the EMC–ERH data of

many seeds satisfactorily [22,23]. The G.A.B. equa-

tion has recently been recognized as the most satis-

factory theoretical isotherm equation, but it does not

TABLE 24.8

Equilibrium Moisture Content–Equilibrium Relative

Humidity Relationships Used to Analyze Sorption

and Desorption Isotherms of Grains and Oilseeds

Modified Henderson Equation

RH

¼ 1 2 exp(2A(T þ C)M

B

)

Modified Chung–Pfost equation

RH

¼ exp

A

T

þ C

exp

BM

100

Modified Halsey equation

RH

¼ exp

exp (A

þ BT)

M

C

Modified Oswin equation

RH

¼

1

A

þ BT

M

C

þ1

Guggenheim–Anderson–de Boer (G.A.B.) equation

M

¼

ACB

RH

(1

B RH)(1 B RH þ CB RH)

Modified Guggenheim–Anderson–de Boer (G.A.B.) equation

M

¼

A(C=T )B

RH

(1

B RH)(1 B RH þ (C=T)B RH)

A, B, C are constants, M is percent water content dry basis, RH is

equilibrium relative humidity, decimal, and T is temperature, 8C.

Source: From Henderson, S.M., Agric. Eng., 33(1), 29, 1952;

Thompson, T.L., Peart, R.M., and Foster, G.H., Trans. ASAE, 11(4),

582, 1968; Chung, D.S. and Pfost, H.B., Trans. ASAE, 10(4), 552,

1967; Pfost, H.B., Maurer, S.G., Chung, D.S., and Milliken, G.A.,

Summarizing and reporting equilibrium moisture data for grains,

Paper No. 76–3520, ASAE, St. Joseph, MI, 1976; Halsey, G.,

J. Chem. Phys., 16, 931, 1948; Iglesias, H.A. and Chirife, J., J. Food

Technol., 11, 109, 1976; Oswin, C.R., J. Soc. Chem. Ind. London, 65,

419, 1946; Chen, C. and Morey, R.V., Trans. ASAE, 32(3), 983, 1989;

Jayas, D.S. and Mazza, G., Trans. ASAE, 34(5), 2099, 1991; Jayas,

D.S. and Mazza, G., Trans. ASAE, 36(1), 119, 1993.

ß

2006 by Taylor & Francis Group, LLC.

incorpora te the e ffect of tempe ratur e on the EMC–

ERH relat ionship . Jayas and Mazza [24] modified the

G.A.B. eq uation by dividing the con stant C by tem-

peratur e to give a three-p arameter equatio n. The co n-

stants of the most appropri ate equati ons for common

seeds are given in Tabl e 24.9 (ASAE [25] ).

24.4. THERMAL PROPERTIES

24.4.1 S

PECIFIC

H

EAT

Specific heat, c , is the amo unt of he at in kilojo ules

requir ed to ch ange the tempe ratur e of 1 kg of material

by 18:

c

¼

1

m

dq

du

(24 : 6)

Specific heat of a moist agricultural product can be

related to its dry, c

db

, or wet, c

wb

, mass. From the

relationships between dry and wet masses it follows that

c

db

¼ c

wb

(1

þ M ) (24 : 7)

It has been empir ically shown that the specific hea t of

moist agricu ltural products can be presen ted as a sum

of the specific heat of its dry mass, c

d

, and the sp ecific

heat of wat er he ld in the produ ct, c

w

[26–29]. The

followin g relat ionship holds for 1 kg of dry mass of

the pro duct:

c

db

¼ c

d

þ c

w

M (24 : 8)

Com prehen sive revie ws of the method s of mea-

surem ent of therm al pro perties of grains have been

publis hed [28,30,31 ]. Pre cision and accuracy of meas-

urement are impor tant fact ors to consider when a

method is con sidered for possible use. How ever, the

variation in comp osition, size, and shape of agric ul-

tural products pre cludes the ne ed for accuracies

greater than +2–5%.

The common proced ures for measur ement of the

specific he at of grains at constant pr essure are ice calo-

rimetry [32], mixtu re methods [33], indir ect methods ,

where the specific heat is calcul ated from other therm al

propert ies such as therm al con ductiv ity and diffusiv ity

[34–37 ], method of different ial scann ing calori metry

(DSC) [38] , guarded plate method, an d the adiabat ic

method [28]. Only the most common method—

the method of mixt ures an d the mo st modern method

that utilizes sophisticat ed instrumen tation—t he DSC

method, are discus sed in this section.

The method of mixtures [33,39] consists of adding

a known mass of mate rial at one elevat ed tempe ra-

ture to a know n mass of water at another tempe ratur e,

and measur ing the eq uilibrium tempe ratur e. The test

TABLE 24.9

Constant s of Selected Equati ons

a

for the Isoth erm of Various Seeds

Seed Equation

b

Isotherm Equation Constants

A

B

C

Barley PF 475.12 0.14843 71.996

Corn (shelled corn) HE 6.6612E-05 1.9677 42.143

Oats (cv. ‘Dumont’) PF 433.157 21.581 41.439

Rough rice, long grain (Australia) HE 4.1276E-05 2.1191 49.828

Medium grain (California) HE 3.5502E-05 2.31 27.396

Short grain (Japan)

HE

4.8524E-05

2.0794

45.646

Wheat durum (‘Wakooma’)

OS

13.101

2

0.052626

2.9987

Wheat hard red (‘Waldron’)

OS

15.868

2

0.10378

3.0842

Wheat hard red (‘Napayo’)

OS

14.736

2

0.05459

3.3357

Rapeseed (‘Candle’)

HL

3.0026

2

0.0048967

1.7607

Canola (‘Tobin’)

HL

3.489

2

0.010553

1.86

Flaxseed (‘Linnot’)

HE

0.000176

1.9054

56.228

Peanut kernel

HL

3.9916

2

0.017856

2.2375

Safflower seed

HE

0.000203

1.8883

57.4013

Sunflower seed

HE

0.00031

1.7459

66.603

a

b

HE, mdified Henderson; PF, modified Chung–Pfost; HL, modified Halsey; OS, modified Oswin.

Source: From ASAE, D245.5. Moisture relationships of plant-based agricultural products, 43rd ed., Standards, Engineering Practices, and

Data (Am. Soc. Ag. Eng.), St. Joseph, MI, 1996. With permission.

ß

2006 by Taylor & Francis Group, LLC.

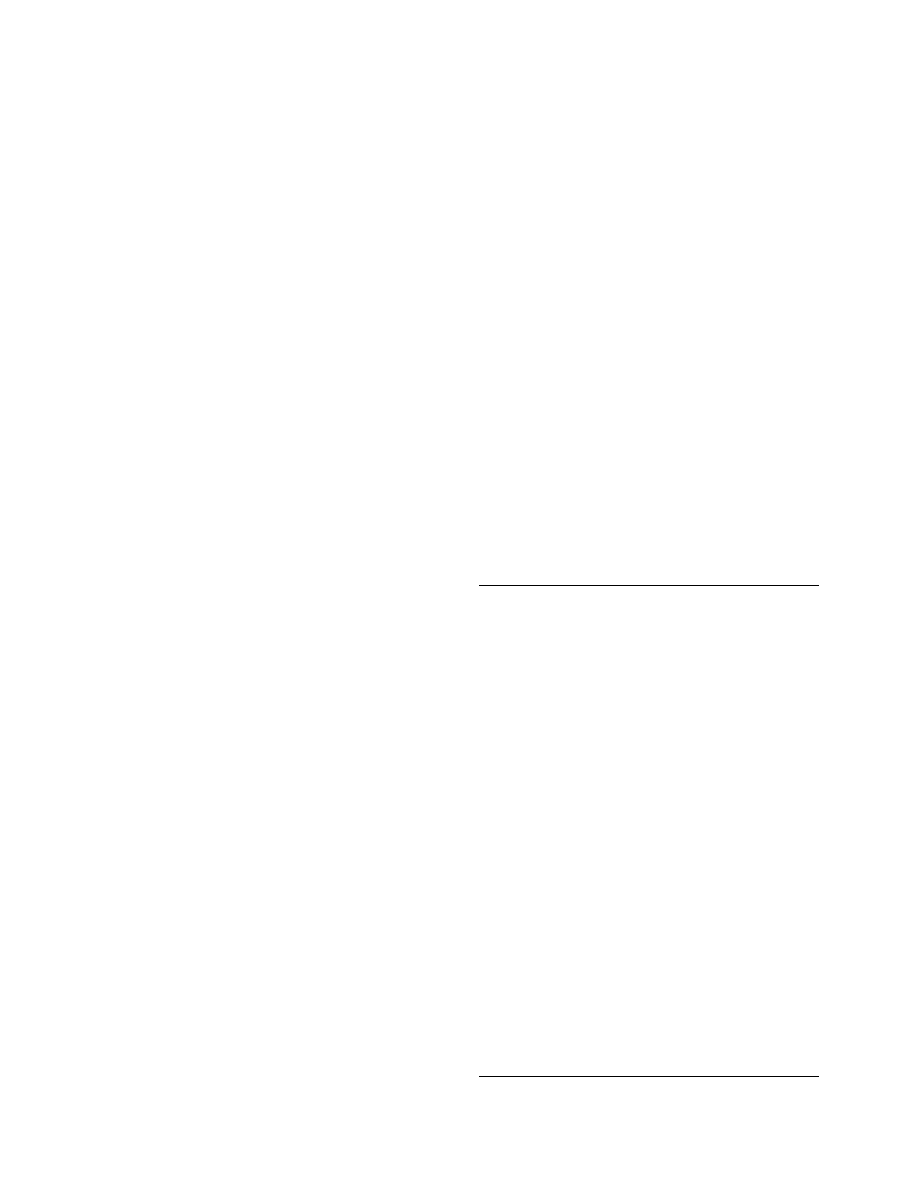

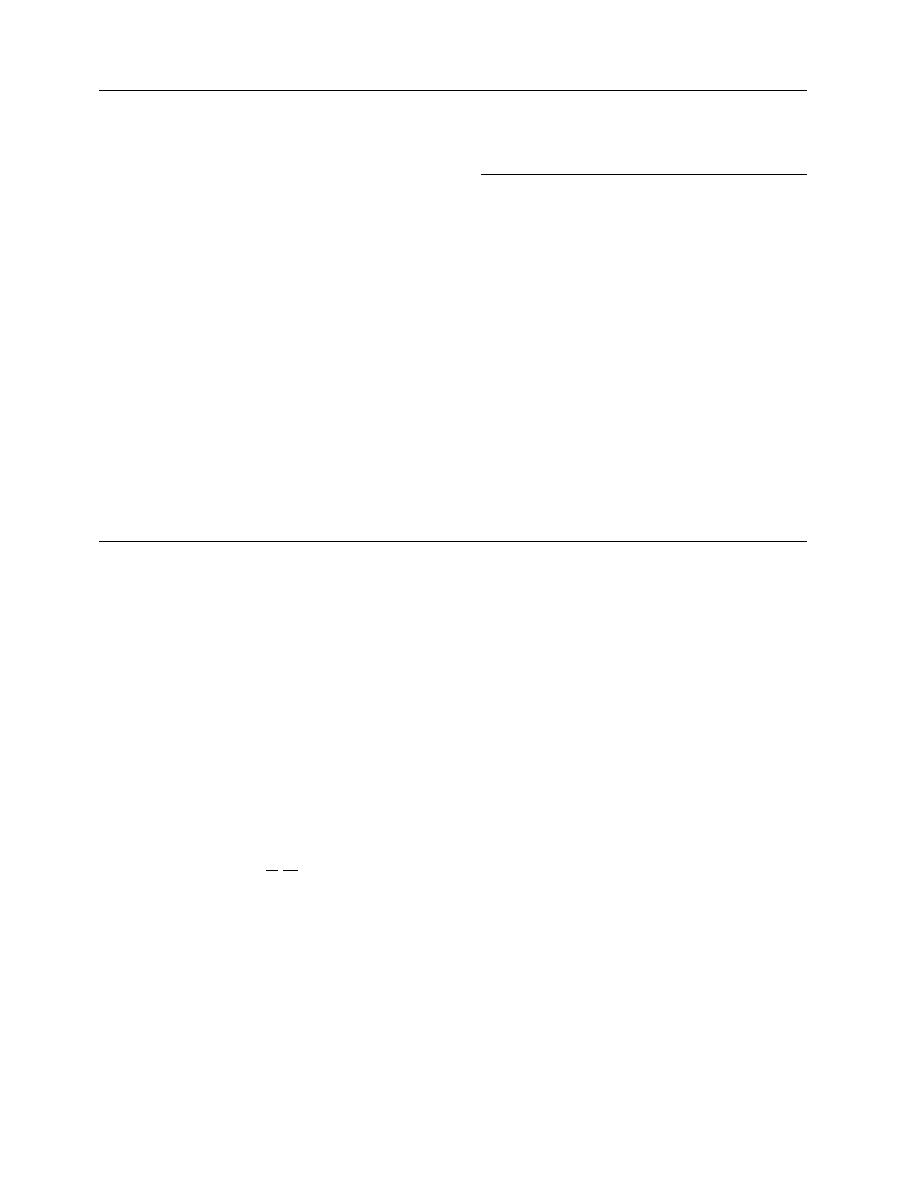

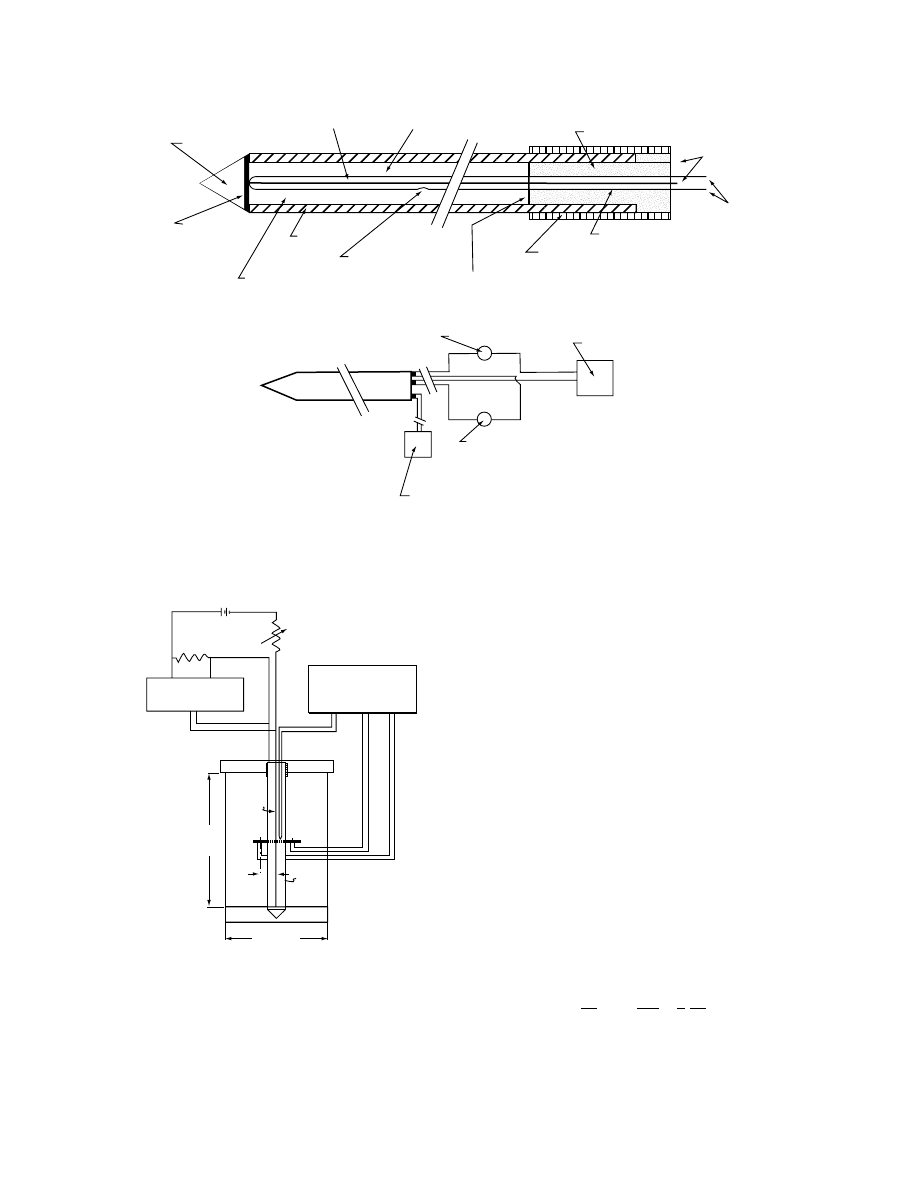

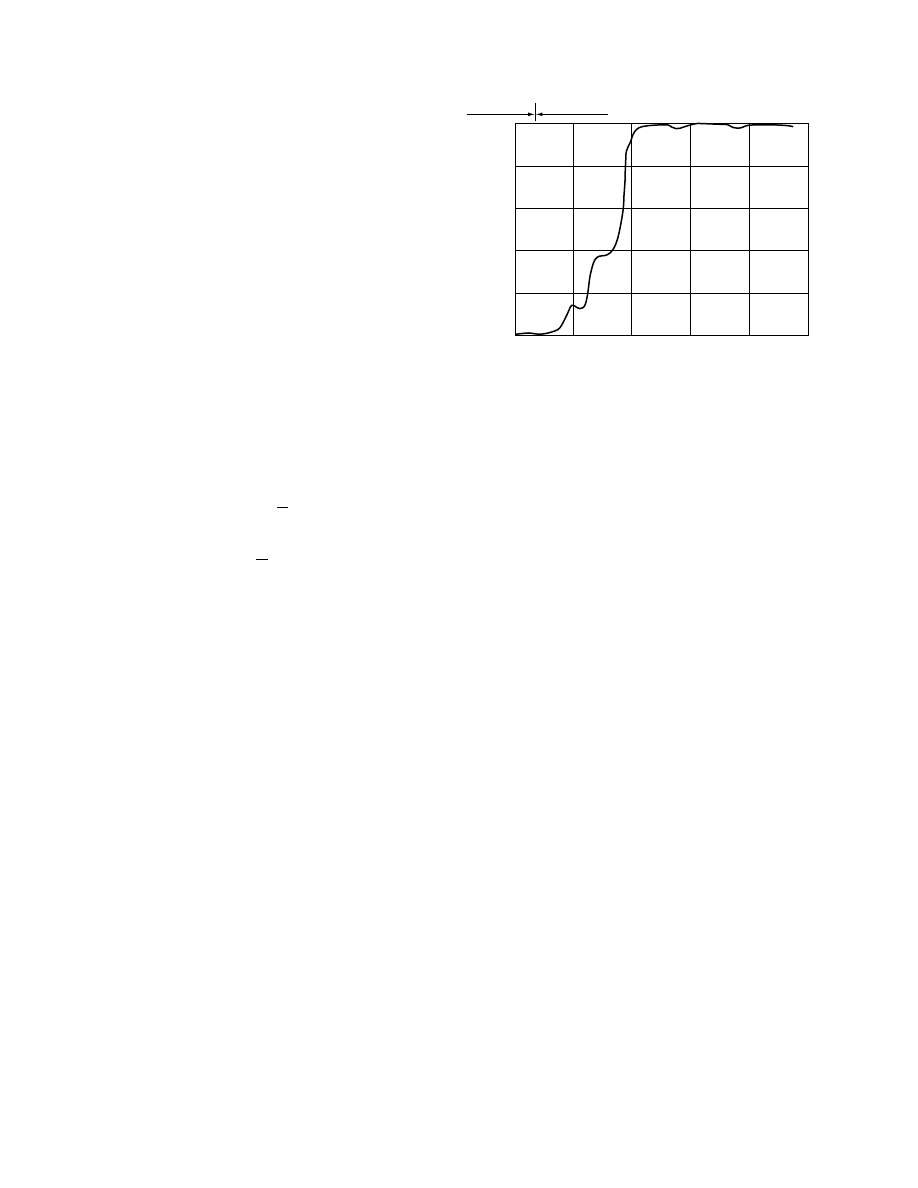

apparat us usually consis ts of an isot hermal Dewar

flask wi th a capacit y of 1000 mL from which the

metal jacket is remove d to allow the use of a magnet ic

stirrer (Figur e 24.1). The flask is insul ated with a p-

proxim ately 4 cm of fibe rglass insul ation to mini mize

heat exchange with the surroundi ngs. An insul ating

cover is divide d into two parts to facilitate measur e-

ment of the calorimet er wat er tempe ratur e an d to

reduce heat losse s whi le trans ferring a grain sample

into the calori mete r. A glass rod, 13 cm long, is at-

tached to the smal ler part of the cover an d pro trudes

into the calori meter flask. A c opper–con stantan

thermo couple (36-gauge) is attach ed to the en d of

the rod to measur e the tempe ratur e of the ca lorimete r

water. A magnet ic stirrer is used to maint ain a co n-

stant tempe rature through out the flask. Calibra tion

of the calori meter can be accompl ished using granula r

alumin um of known specific heat. The reliab ility of

the equ ipment can be checked with granula r copp er

as a reference sampl e. The typic al testing procedu re

is as follows [33] : abo ut a 20-g wheat sample

(+ 0.0001 g) a t various initial tempe ratures ( 236 to

21 8 C) is placed into the calori meter fla sk filled wi th

200 + 0.1 g of distilled wat er at room tempe ratur e,

and the tempe rature of the water is recorded until

therma l eq uilibrium of the mixtu re is establ ished. A

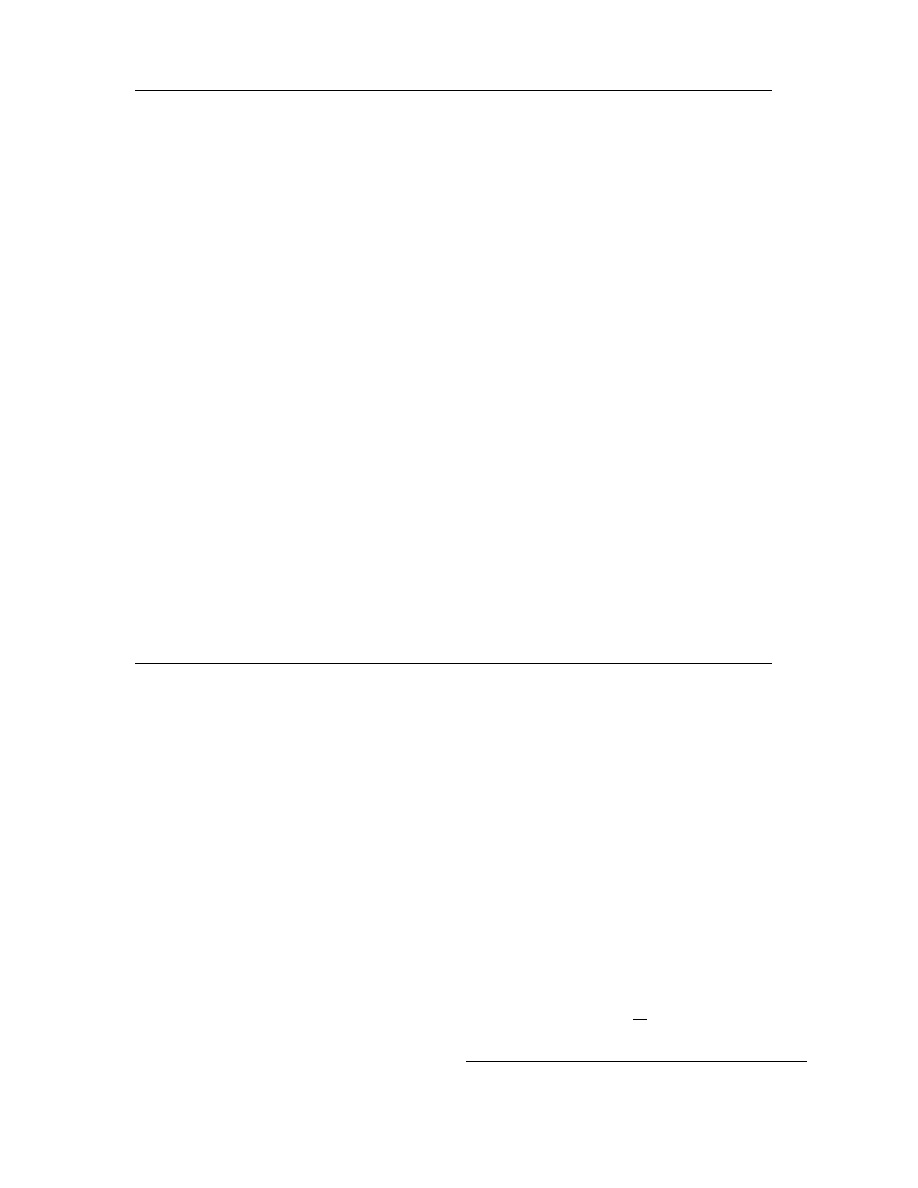

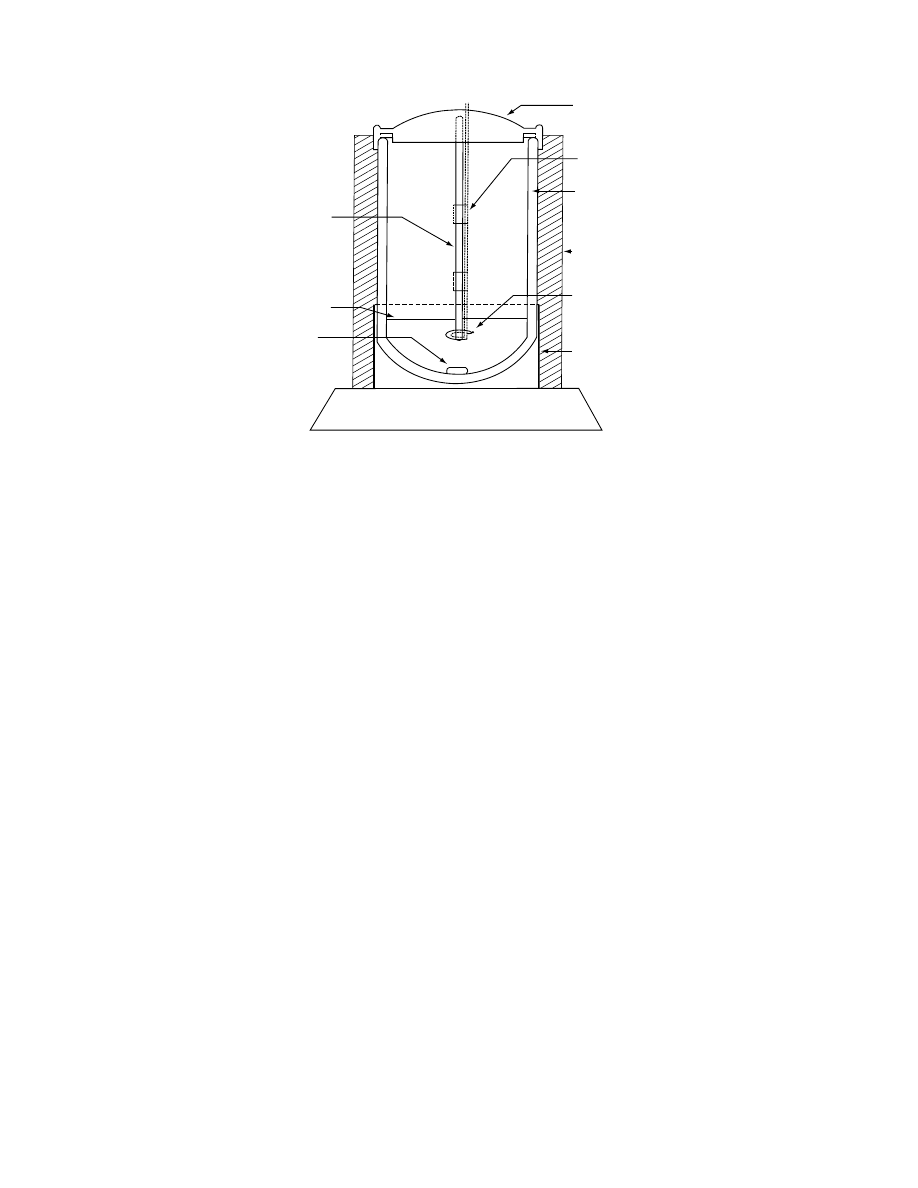

typical tempe ratur e–time cu rve of the water in the

calorimet er is shown in

. The tempe rature

of the mixt ure ( T

m

) is determ ined by extra polating

the straight -line portion of the tempe ratur e–time

curve ba ck to the transient tim e, which is the time at

which the sampl e is dropped into the calori meter

water. By equ ating the ch anges in the therm al energy

content s of the water and the sample, the foll owing

equati on can be written:

cm

s

( T

m

u

s

)

¼ ( m

w

þ E ) c

w

( T

c

T

m

) (24 : 9)

The water equivalent value, E, is obtained by rearran-

ging Equation 24.9 and conducting experiments with a

material such as water of known specific heat. The error

associated with specific heat values obtained with the

above-described apparatus is within 4.0% [40].

W hen using the method of mixtures water can be

replac ed with toluene . Tol uene has the added advan -

tages of a lower specific gravity (0.86) and specific

heat (0.39 kJ/(kg K)) than water; thus enab ling seed s

to sink more readily than in wat er, and resul ting in a

substa ntially great er temperatur e rise than is obtaine d

with wat er. With water, con densation on the calori m-

eter’s surface usu ally occurs, causing a loss of meas-

urement precision . Ther efore, a calorimet er of low

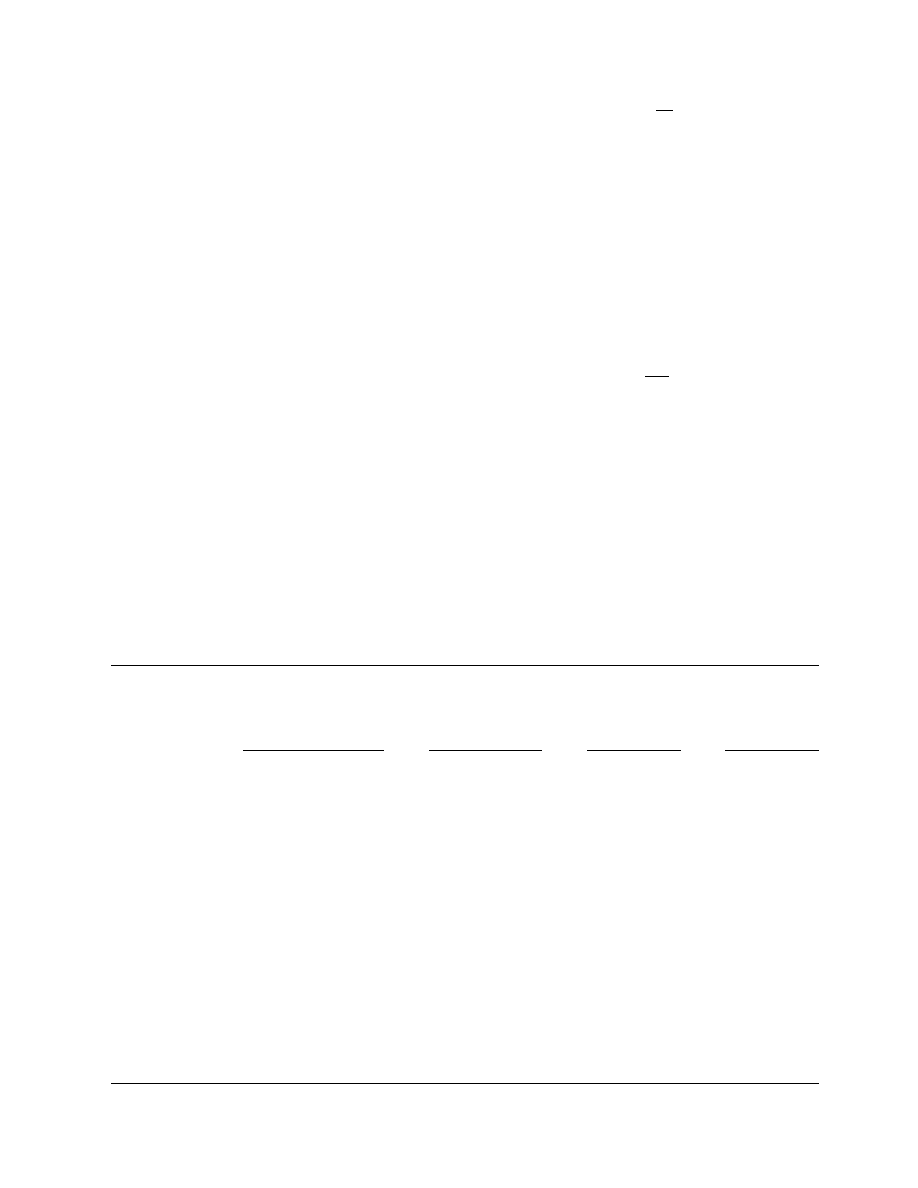

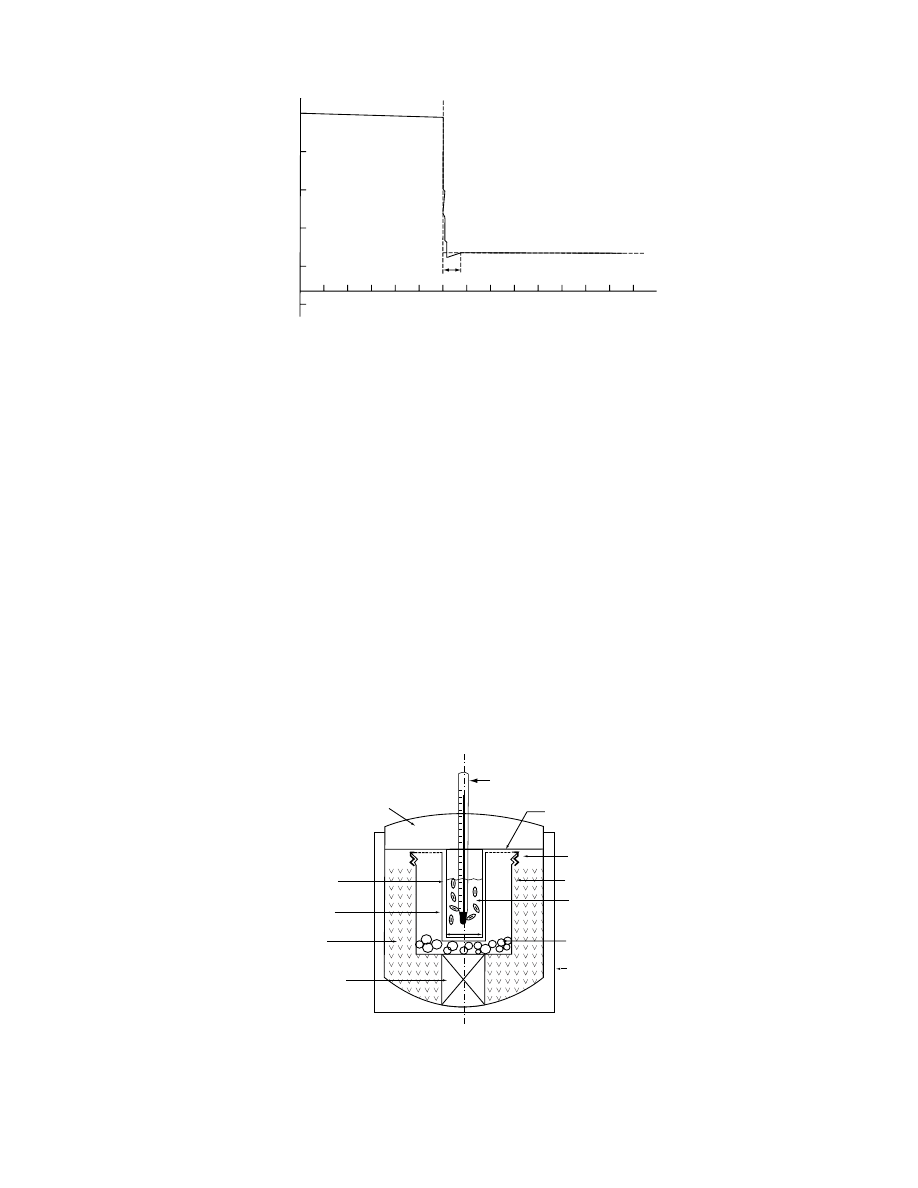

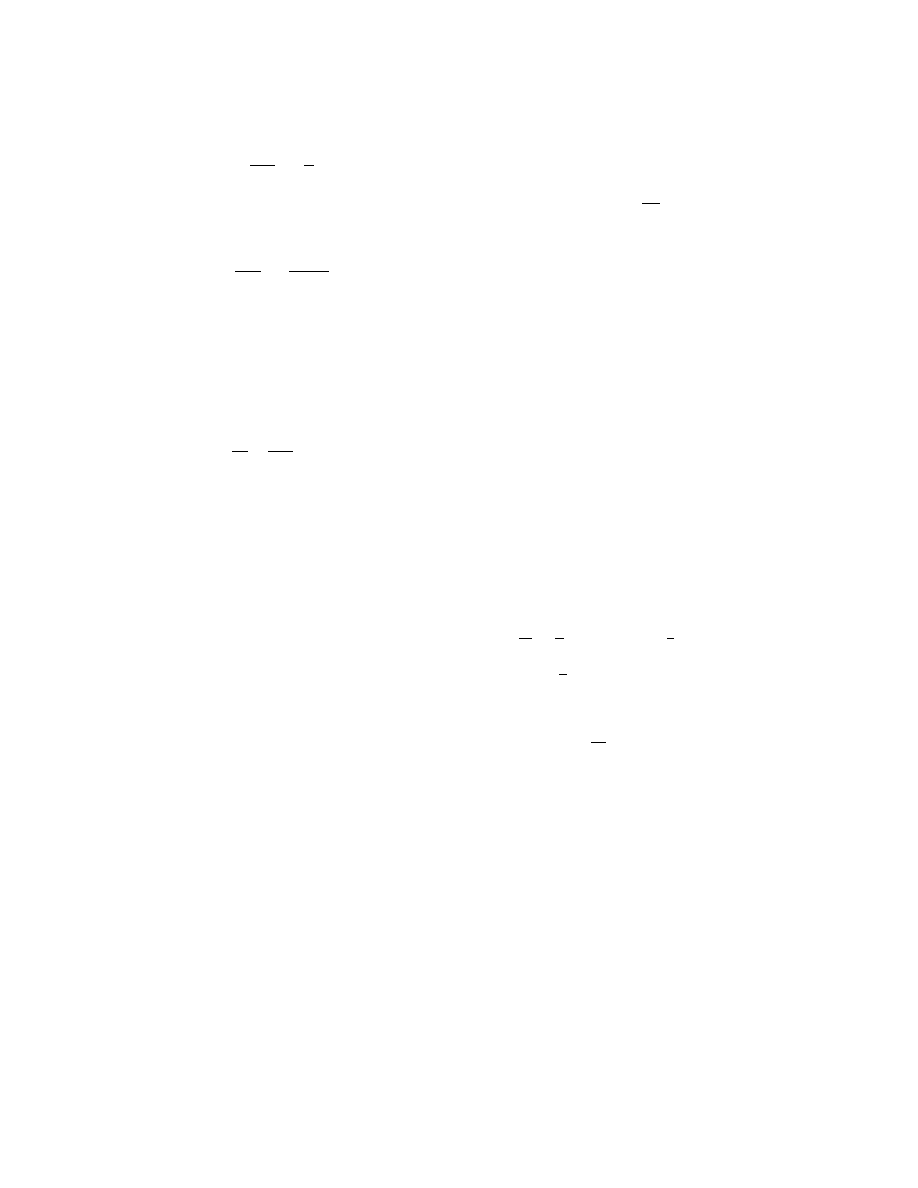

mass can be used [41]. The apparatus consists of two

closely fitting, thin-walled aluminum tubes of about

2.5 cm diame ter placed in a calori meter (

) .

The inner tube is used to house chilled toluene and a

sample. The outer tube is mounted by its top edge to a

sealing disk, which is attached to the cap of a screw-

top aluminum can. Air inside the can is dehydrated by

desiccant. The can is packed in melting ice, inside a

Glass rod

Water

Magnetic

stirring bar

Magnetic stirrer

Support

Thermocouple

Fiberglass

insulation

Isotherm Dewar

flask

Paper tape

Insulated cover

FIGURE 24.1 Schematic diagram of calorimeter. (From Viranichai, S., Effect of moisture content and temperature on

specific heat of wheat. M.Sc. dissertation (unpublished), Department of Agricultural Engineering, University of Manitoba,

MB, 1971. With permission.)

ß

2006 by Taylor & Francis Group, LLC.

vacuum flask , to provide a con stant and uniform

surface temperatur e aroun d the calorimet er. Tem per-

ature record ing accuracy shou ld be 0.01 8 C.

W hen low mois ture content g rain is used in the

method of mixtu res, absorpt ion of water by the grain

generat es heat of hydratio n. Thi s heat results in in-

crease d tempe ratur e rises in the wat er, whi ch can lead

to erroneou s results. Therefor e, to mini mize the error,

it may be ne cessary to incorpo rate a correct ion facto r

in the resul ts [27].

The method of DSC is based on measur ing the

very small therm al effects pro duced during therm al

process es and is recomm end ed as well suit ed for de-

termining the effect of tempe ratur e on specific he at

[38,42]. In the DSC method, any gain or loss of ther-

mal energy is recorded a s the equipment war ms the

test material at a control led rate of tempe ratur e rise

over a selec ted tempe ratur e interva l. The disadva n-

tages of this method are that it requ ires a small sam-

ple size (5–15 mg), whi ch makes it difficult to obtain a

homogen eous, repres entat ive sampl e, and it is a com-

parative device that must be calibrated. The measur e-

ment of specific he at with DSC is based on the

assum ption that the temperatur e is unifor m in the

sample a nd the sample pan during a test. How ever,

due to the low therm al diffusiv ity of biologi cal ma-

terials, thermal lag within a sample may introduce

error in the measured specific heat.

The measured specific heats of dry mass of some

agricu ltural produ cts are given in

Because of differences in the chemical composition

between crops and among cultivars of the same

2

Stabilization period

0

20.5

21.0

21.5

22.0

22.5

23.0

4

30–40 s

T

m

T

c

6

Time, min

Temperature,

⬚C

8

10

12

14

Straight line portion

Extrapolated back

FIGURE 24.2 Temperature–time characteristic from calorimetric test. (From Viranichai, S., Effect of moisture content and

temperature on specific heat of wheat. M.Sc. dissertation (unpublished), Department of Agricultural Engineering, University

of Manitoba, MB, 1971. With permission.)

Thermometer

Expanded polystyrene

Inner thin-wall

aluminum tube

Outer thin-wall

aluminum tube

Melting ice

Rubber stopper

Aluminum cap

Thermos

Aluminum can

Chilled toluene

and grain

Layer of

desiccant

Sealing disk

(perspex sheet)

25 mm

FIGURE 24.3 The calorimeter assembly. Modified from Sharp, R.B. and Nash, J.E., J. Agric. Eng. Res., 10, 355, 1965. With

permission.)

ß

2006 by Taylor & Francis Group, LLC.

crop, empirical equations have been developed. Usu-

ally, these equations describe the relationship between

the specific heat and moisture contents of various

crops [27,28,33,34,43–47] (Table 24.11):

c

¼ a þ bM þ c

1

u

(24:10)

Much of the published data on specific heat and

other thermal properties of grains are of limited value

because not enough supporting data are included, such

as a detailed product description, and the estimated

error in measurement. The description of grain should

include the cultivar, the size of the individual kernels,

the maturity, and the pretreatment. Details of an ex-

periment should include the sample size, the surface

conditions of the kernel, the porosity, the temperature,

the relative humidity, the pressure, and the sam-

pling procedure. The equipment description should

provide sufficient detail so that one can duplicate

the experiment.

24.4.2 T

HERMAL

C

ONDUCTIVITY AND

D

IFFUSIVITY

Thermal conductivity, k, is described by the formula:

q

¼ kA

du

dx

(24:11)

For solid bodies the heat flux, q, is directly propor-

tional to the temperature gradient, Hu, and the thermal

conductivity, k, of the body. The minus sign refers

to the direction of the flux, which is opposite to the

direction of the temperature gradient. Therefore, if the

temperature gradient (for a certain time period) is

constant, the thermal conductivity defines the amount

of thermal energy that is transmitted within a unit time

and through a unit cross-sectional area. The area is

perpendicular to the direction of flow.

Factors influencing the choice of method for the

determination of the thermal conductivity have been

discussed in the literature [28,31,48]. Basically, methods

of measurement of the thermal conductivity are div-

ided into three categories: (1) steady-state techni-

ques, (2) quasistatic techniques, and (3) transient-state

techniques [28,31].

The advantages of the steady-state techniques are

simplicity of the mathematical equations and high

control of experimental variables. The disadvantages

are: long equilibration time associated with possible

moisture migration, restriction to the simple geom-

etry of the sample (sphere, cylinder, or slab), and the

presence of convection in granular materials. Thermal

TABLE 24.10

Specific Heat of the Dry Mass of Agricultural Seeds

Seed

Specific Heat c

d

, J/(kg K)

Ref.

Alfalfa

1172

110

Barley

1245

111

Beans

1293

111

Corn

1534

44

Corn

2035

105

Oats

1277

46

Oats

1282

111

Oats

993–1278

112

Rapeseed

1553–1569

111

Rice (rough)

1109

46

Rice

1637

47

Rice (white)

1197

46

Rye

1272

111

Sorghum

1397

27

Wheat

1097

33

Wheat

1185–1260

28

Wheat

1287–1299

112

Wheat

1276

111

Wheat

1454

44

TABLE 24.11

Formulas for Specific Heat Determination

of Selected Agricultural Products

Seed

Equation

a,b

and its

Working Range

c

Ref.

Alfalfa seed

c

¼ 1172 þ 33M’, 0 < M’ < 28%

110

Chick-peas

c

¼ 24.19 10

2

3

þ 1.19 10

1

u

þ 2.15 10

2

2

u

2

2

3.73

10

4

M

2

1.65

10

3

M

2

þ 1.38 10

2

Mu

39

292

T 308 K, 0.12 M 0.32

Corn

(shelled)

c

¼ 1470 þ 36M’, 1 M’ 30%

44

c

¼ 1370 þ 27M’, 0 M’ 60%

45

Lentils

c

¼ [0.577 þ 0.0071u þ

(0.0622 2 0.0914M)

10

2

M]1000

113

10 < T < 808C, 0.02 < M < 0.35

Oats

c

¼ 1277 þ 32M’, 10 M’ 17%

46

c

¼ 992 þ 50M’, 12 M’ 18%

Rapeseed

c

¼ 1356 þ 32M’, at 19.48C

34

c

¼ 1288 þ 28.4M’, at 1.78C 1

M’ 20%

c

¼ 1328 þ 28.0M’, at 24.48C

Rice (rough)

c

¼ 1109 þ 45M’, 10 < M’ < 17%

46

Rice (white)

c

¼ 1197 þ 38M’, 10 < M’ < 17%

Sorghum

c

¼ 1397 þ 32M’, 0 < M’ < 30%

27

Soybeans

c

¼ 1637 þ 19M’, 0 M’ 24%

47

Wheat

c

¼ 1260 þ 36M’, 5 < M’ < 35%

28

c

¼ 1098 þ 4010

2

M, 0

M < 0.25

33

c

¼ 1184 þ 30M’, 0 M’ 13.6%

43

c

¼ 1452 þ 30M’, 1 M’ 32%

44

a

c, specific heat (J/(kg K)).

b

u

Measured as temperature of air in equilibrium with seeds.

c

M, moisture content (kg H

2

O/kg db) and M’, moisture content % wb.

ß

2006 by Taylor & Francis Group, LLC.

condu ctivities of grains have been measured by the

guarded hot-pl ate method [30] an d the con centric

spheres method [49].

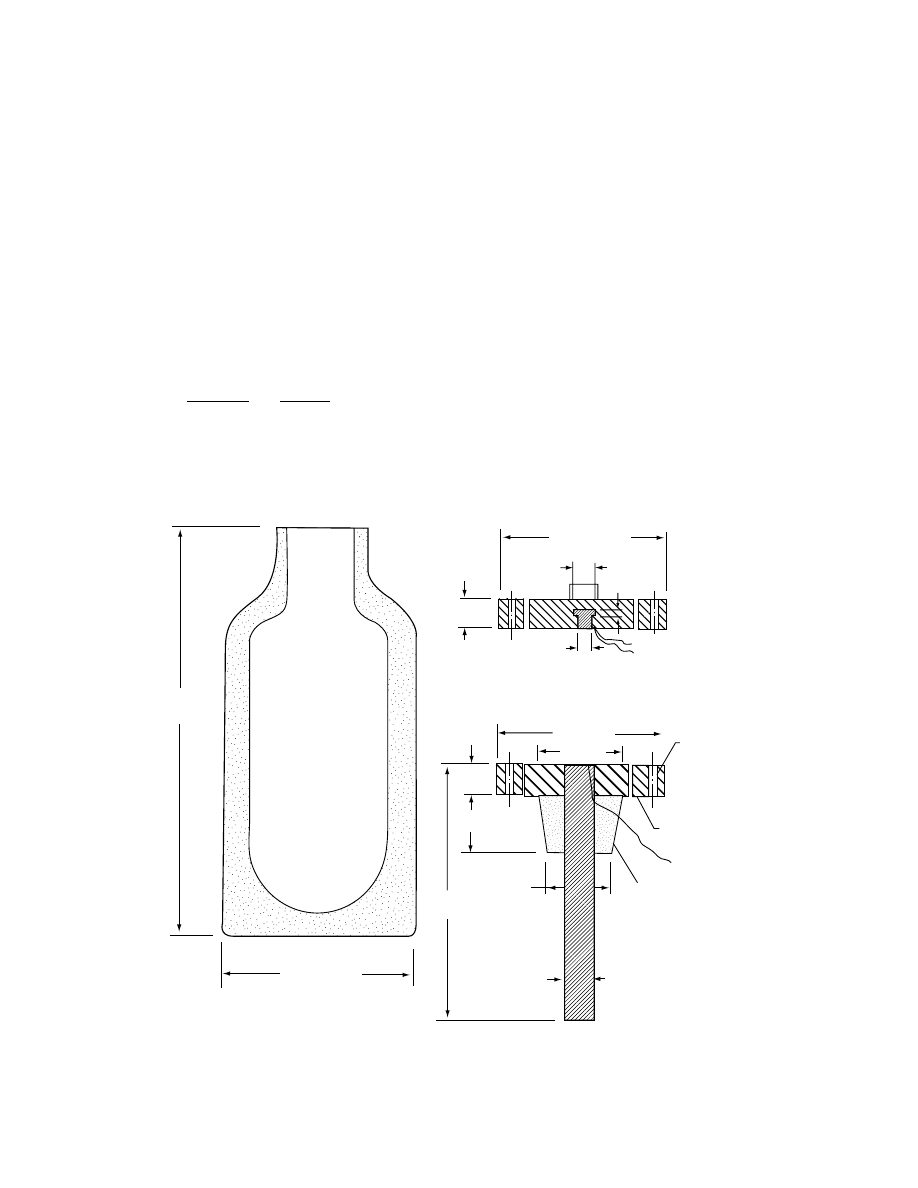

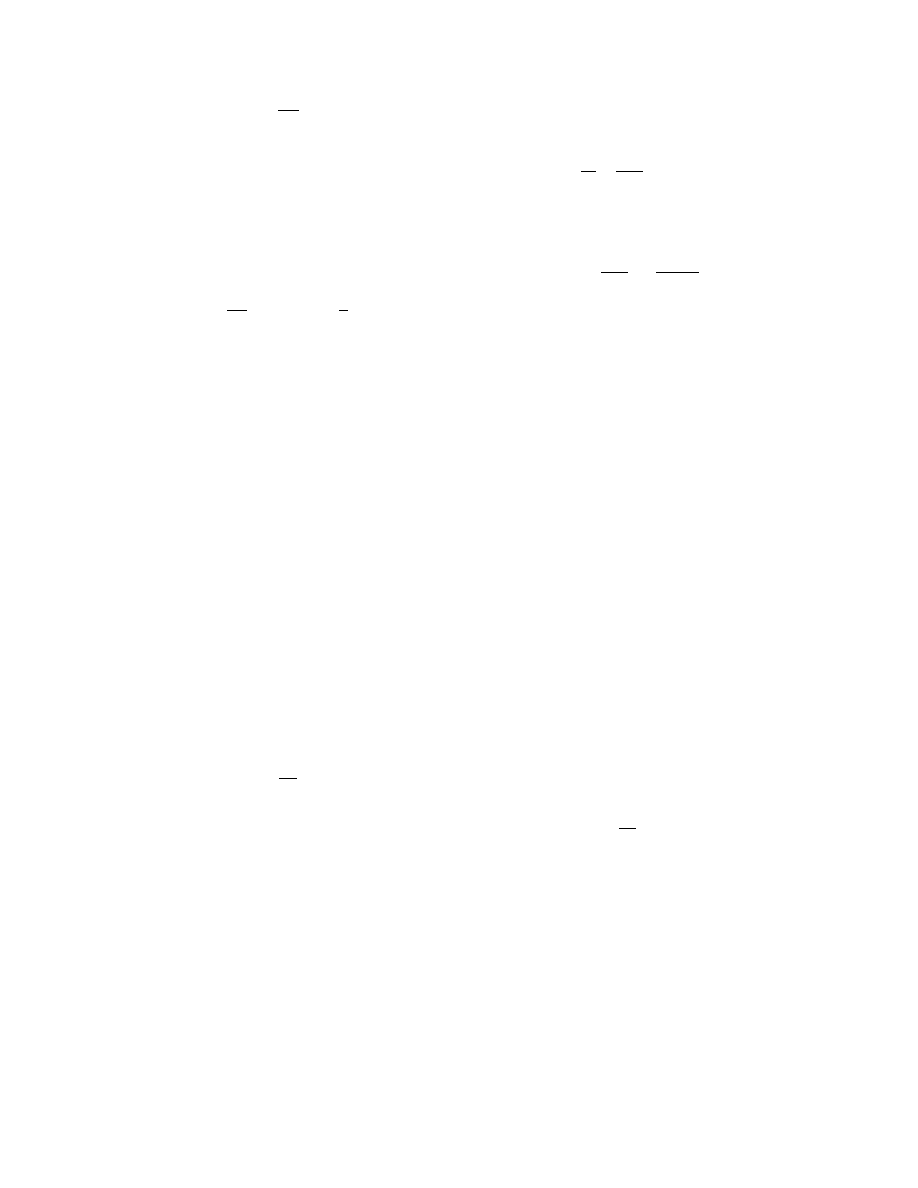

The Fitch method [50] and its various modifications

[31] are the most common quasistatic techniques used to

measure the thermal conductivity. The main advantage

of this method is that the test is simple and can be

c arr ie d out in 10 mi n. For a bs olu te m ea su re me nt s, how -

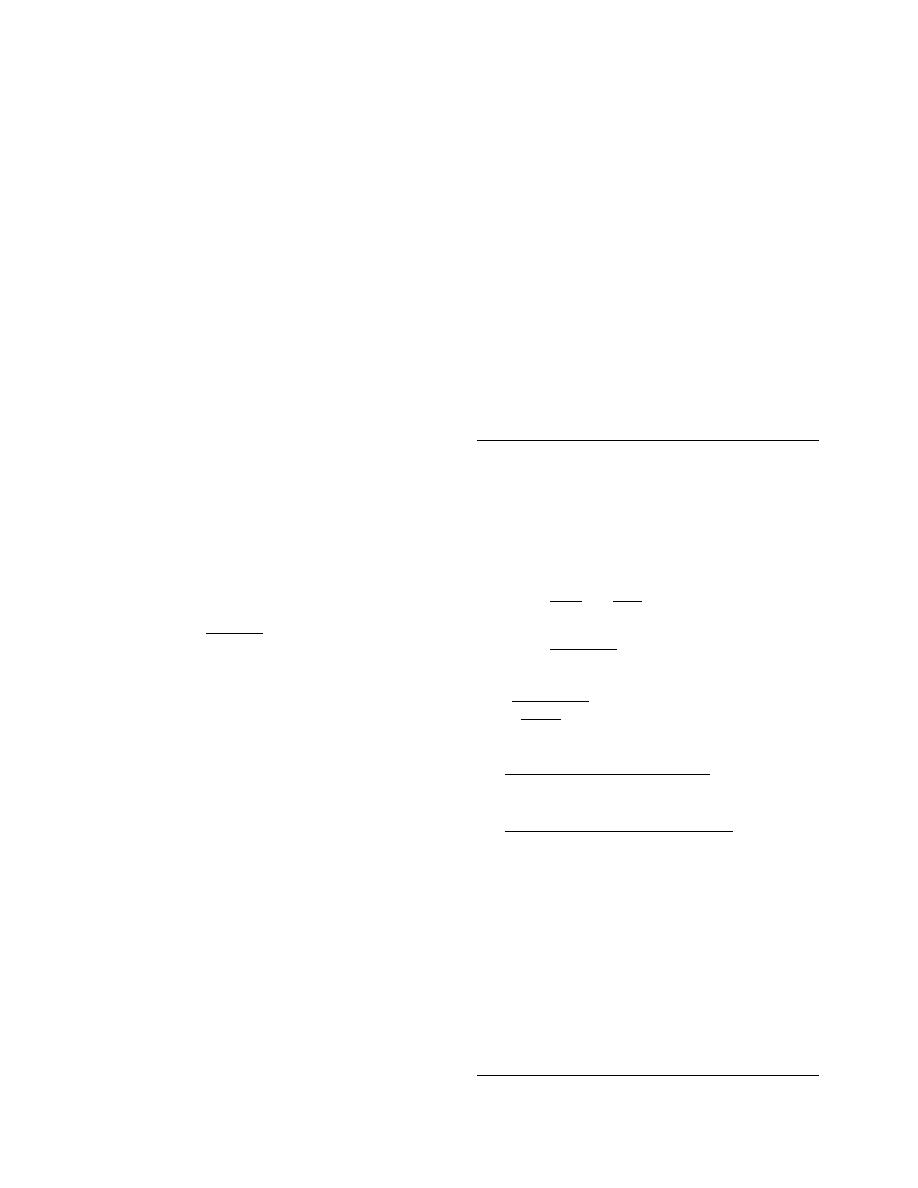

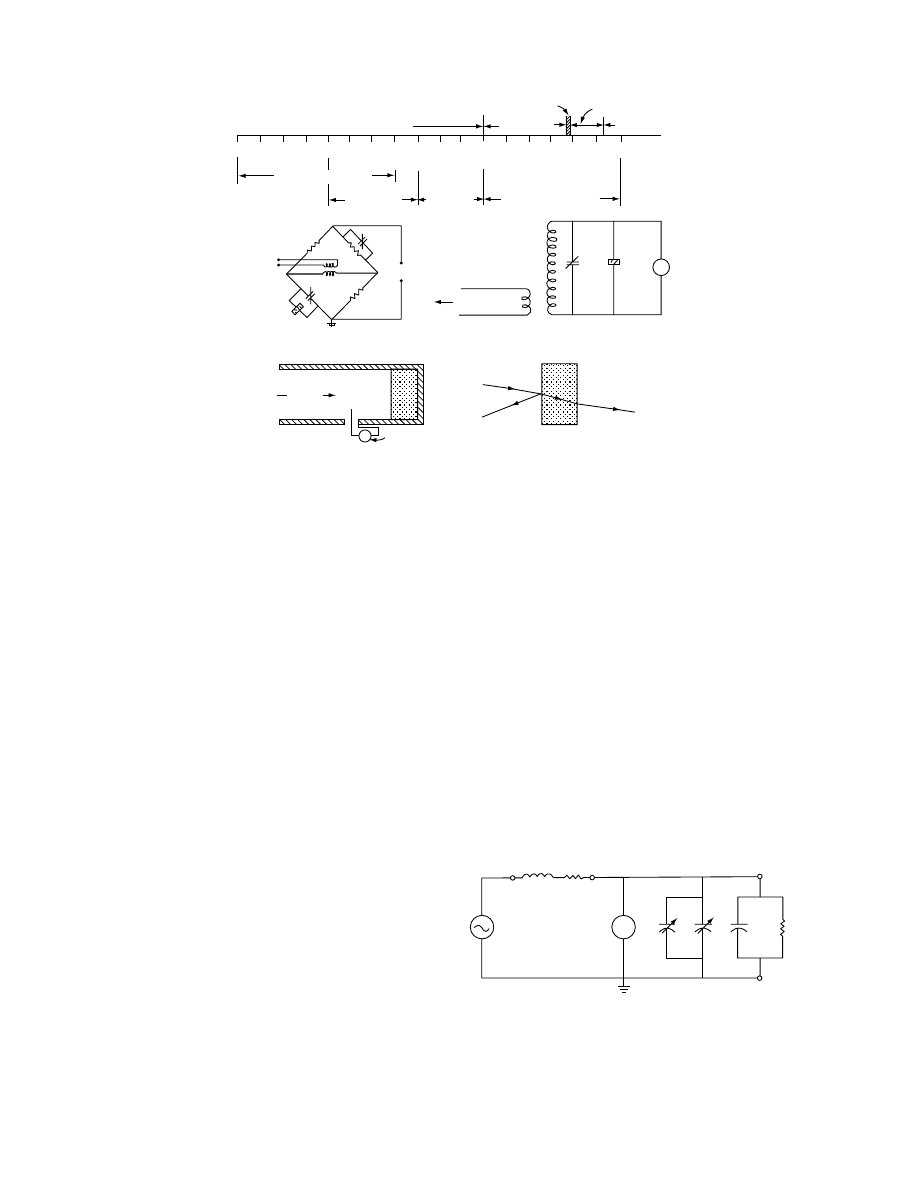

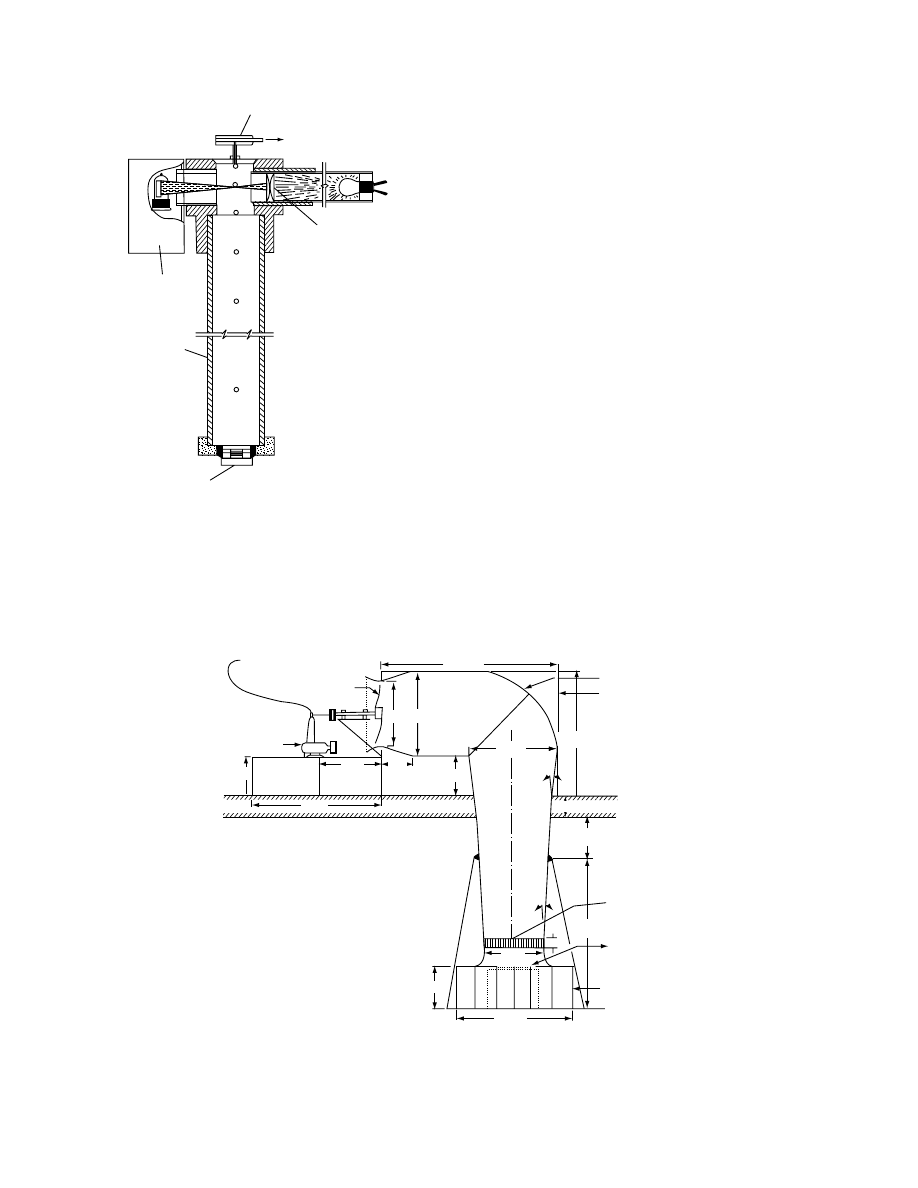

ever, the accuracy is rather low. Figure 24.4 shows a

modified Fitch apparatus [51]. The sliced sample is

placed between two copper plates. One plate acts as a

heat source and the other plate as a heat sink. The

the rm al c onduc tiv ity is c al cula te d by E qua ti on 2 4. 12 ,

which is the solution of the governing differential equa-

tion for the temperature field within the sample [51].

ln

u

0

T

1

u

( t)

T

1

¼

Akt

Lm

cp

c

cp

(24 : 12)

The plot of the tempe rature ratio (u

0

–T

1

)/(u (t ) – T

1

)

versus tim e on a semilog paper is a stra ight line. The

thermal condu ctivity is calcul ated from the slope ( Ak /

Lm

cp

c

cp

) of the tempe rature histo ry.

The essent ial difference between a steady state

and a trans ient state is that the tempe rature at a

particular locat ion c hanges with time under trans ient

conditio ns. A line he at source prob e has been re-

commende d by many resear chers [28,29,52 ,53]. The

method is simp le, fast, an d requires a relative ly smal l

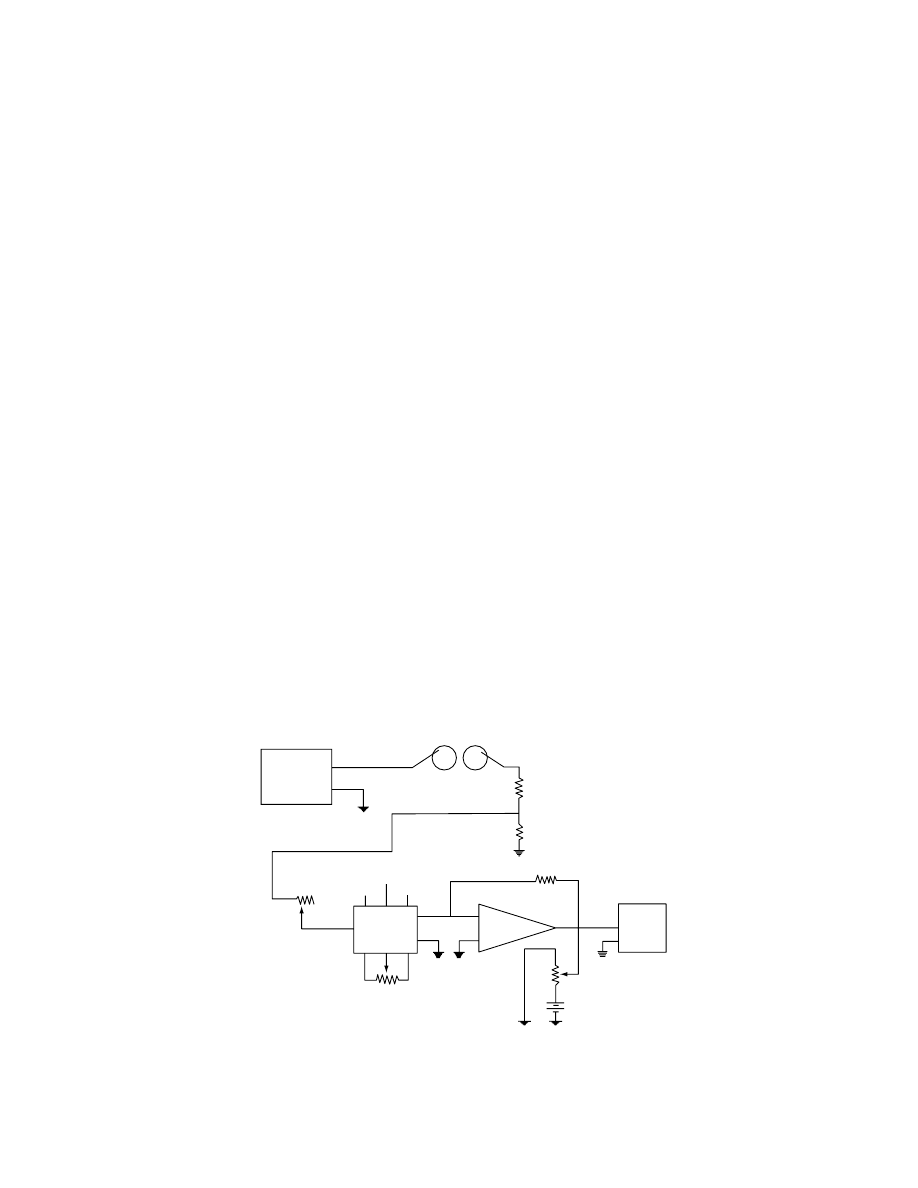

sample. A schema tic repres entat ion of the therm al

condu ctivity probe, the direct current (dc) su pply,

and the tempe ratur e measur ing system is sh own in

[54]. The prob e is inser ted into a sample

of a unifor m tempe ratur e and is heated at a constant

rate. The tempe ratur e adjacent to the line heat sou rce

is record ed. Var ious modificat ions of the line he at

source probe can be foun d in the lit erature. The

probe attached to a 20-cm diameter aluminum cylin-

der as a sampl e holder is one of them (

[35]. Other modifications are related to placement of

thermocouples directly on the heating element [55,56]

or at a fixed distance from it [43].

10 mm

20 mm

35 mm

3 mm hole

b. Copper plug assembly

6 mm

Thermocouple

wires

6

3 mm

150 mm

150 mm

45 mm

20 mm

40 mm

37 mm

140 mm

110 mm

260 mm

Polystyrene disc

Thermo couple wire

Cork

19 mm copper rod

c. Copper rod assembly

a. Vacuum flask (1 liter Cap.)

FIGURE 24.4 Modified Fitch apparatus. (From Zuritz, C.A., Sastry, S.K., McCoy, S.C., Murakami, E.G., and Blaisdell,

J.L., Trans. ASAE, 32, 711, 1989. With permission.)

ß

2006 by Taylor & Francis Group, LLC.

The determination of the thermal conductivity of

grain is based on the comparison of the temperature

history data obtained by using the line heat source

probe with the approximate analytical and numerical

methods [35,54]. The analytical method has the ad-

vantage of being quick in calculating thermal con-

ductivity. This method, however, requires a perfect

line source and a small diameter tube holding the line

heat source. In reality, this requirement is difficult to

meet. Therefore, a time-correction procedure has

been introduced [52,54,56]. Another objection to the

analytical method is that it cannot easily be used to

calculate the temperature distribution in the heated

grain and to compare it with the measured one. Such

a comparison can be easily accomplished by a numer-

ical method, where the estimated accuracy for ther-

mal conductivity is determined and the thermal

conductivity of the device is taken into account [54].

The analytical method for determination of the

thermal conductivity is presented below. The heat

flow from the line heat source (a heating wire) of

infinite length and infinitely small diameter imbedded

in an infinite homogeneous medium can be expressed

by the Fourier equation:

@u

@t

¼ a

@

2

u

@r

2

þ

1

r

@u

@r

(24:13)

Equation 24.13 is solved for a particular case of the

temperature at the line heat source for the heat input

Protective tip

Thermocouple wires

Silicon rubber

Copper leads

Copper leads

Styrofoam

handle

Insulating

disks

Digital ammeter

DC current supply

Digital voltmeter

Digital temp. meter

Thermocouple

junction

Space filled with

heat-conductive paste

Insulating

disc

Brass

tube

Thermocouple

wires

Constantan

heating wire

FIGURE 24.5 Thermal conductivity device. (From Papadakis, G., Giaglaras, P., and Kyritsis, S., J. Agric. Eng. Res., 45, 281,

1990. With permission.)

Oscilloscope

voltage, current

467 mm

Y

1

Y

2

Heater

6.4 mm

4.8 mm D. alum. tube

12 V

1

Ω

Potentiometer

recorder

time, temperature

203 mm

FIGURE 24.6 Schematic of thermal property apparatus.

(From Suter, D.A., Agrawal, K.K., and Clary, B.L.,

Trans. ASAE, 18, 370, 1975. With permission.)

ß

2006 by Taylor & Francis Group, LLC.

of q

l

. The tempe rature rise Du in the time inter val

between t

1

and t

2

is de termined as [52,57]

Du

¼

q

l

4p k

ln

t

2

t

1

(24 : 14)

To acc ommodat e the time-cor rection fact or, t

0

, Equa-

tion 24.14 is mo dified to the foll owing form [35,52,56 ]:

Du

¼

q

l

4pk

ln

t

2

t

0

t

1

t

0

(24 : 15)

The time-cor rection factor, t

0

, takes into accoun t

various effects (i.e., contact resistance s, position s of

thermo couples, specific he at of the pro be and sampl e)

and ha s to be de termined from experi menta l data.

Thus, dt/d u is plotted in relation to time. By diff eren-

tiation Equation 24.14 gives

dt

du

¼

4pk

q

l

t

c

(24 : 16)

Equation 24.16 can be repres ented as a plot of dt /du

in relat ion to correct ed tim e t

c

. Thus , the expres-

sion 4p k/ q

l

repres ents a slope an d at dt /du

¼ 0,

t

c

¼ t

0

whi ch is the time-cor recti on facto r util ized in

Equation 24.15.

The thermal conductivity of solid engineering

materials varies with chemical composition, physical

structure, state of the substance, temperature, and

moisture content. Because grains are stored, ventilated,

and dried in bulk, the bulk density of such products also

influences their thermal conductivity. At constant mois-

ture content the thermal conductivity can be expressed

as a linear function of the bulk density, r

b

:

k

¼ a þ br

b

(24 : 17)

Coeffic ients a and b for wheat , corn, and grain sor-

ghum at various mois ture co ntents an d at 22 8 C have

been given by Chang [58]. Also , the therm al con duct-

ivity of many grains can be expressed as a linear

functio n of mois ture con tent:

k

¼ k

d

þ a

1

M

þ b

1

u

(24 : 18)

gives common relationshi ps for de -

terminat ion of the therm al condu ctivity of selected

major seed types. To impr ove the fit of data to math-

ematical exp ressions, polyn omial equati ons are also

used or tempe rature is introd uced into the expression

[39,56].

Un steady-st ate or trans ient heat conduction com-

monly occurs during heating or coo ling of grains. It

involv es the accumu lation or deplet ion of heat wi thin

a body, which resul ts in tempe ratur e c hanges in the

kernel with tim e. The rate at whic h heat is diffused

out of or into a kernel or layer of ke rnels is depend ent

on the thermal diffusiv ity coeffici ent, a, of the grain:

a

¼

k

c r

t

(24 : 19)

The recomm ended method [29] for the determ in-

ation of the thermal diff usivity of individua l kernels is

to calcul ate it from experi menta lly measur ed values of

the thermal con ductivity of kernel material , specific

heat, and kernel (particle ) density —the so-cal led indir -

ect method. The method may lead to a pproxim ate

results with a relative error, which is difficul t to esti -

mate in respect to a true (real ) value, whi ch can onl y be

determined by direct measur ement s. The resul ts of

thermal prope rties for wheat an d corn [44] and for

single soyb eans [59] confi rm the abo ve.

The therm al diffusiv ity can also be measure d dir-

ectly by employ ing trans ient heat cond uction. The

basic diff erential equati on (Fou rier heat condu ction

equati on) governi ng heat condu ction in isotrop ic

bodies is used in this method. A recta ngular copp er

box filled with grain is placed in an ice bath (08C), and

the temperature at its center is recorded [44]. The

solution of the Fourier equation for the temperature

at the center of a slab is used:

u

c

u

0

¼

4

p

exp (

p

2

z)

1

3

exp (

9p

2

z)

þ

1

5

exp (

25p

2

z)

Þ

ð24:20Þ

and

z

¼

at

x

2

, dimensionless

(24:21)

For selected values of u

c

/u

0

obtained from the experi-

ments, the values of z can be obtained, and with the

measured values of time, t, and x the diffusivity is

calculated from Equation 24.21. The values of the

thermal diffusivities can also be determined for seeds

by solving the Fourier equation for either an infinite

cylind er [60], or a sphere [59] .

of thermal diffusivities for selected seed types

obtained with the direct or indirect method.

24.4.3 C

ONVECTIVE

H

EAT

T

RANSFER

C

OEFFICIENT

The main mechanism of air-to-particle heat transfer

during heating, cooling, and drying processes of

grains is forced convection. The forced convection

heat transfer coefficient (surface conductance), h, is

determined from the Nusselt number, Nu:

ß

2006 by Taylor & Francis Group, LLC.

TABLE 24.12

Equations for Calculating Thermal Conductivity, k (W/(m K)), for Grains and Oilseeds

Seed

Equations

a,b

(W/(m K))

Range

c

Ref.

Barley

k

¼ 0.173 þ 7.5110

2

4

T

þ1.5110

2

3

M’

9

M’ 23%

56

28

T 298C

Beans

k

¼ 0.0671 þ 32.84M

0.115

M 0.414

51

Corn

k

¼ 0.1409 þ 0.0011M’

0.9

M’ 30.2%

44

Corn

k

¼ 0.1326 þ 0.1547M 2 0.1454M

2

0

M 0.6

106

Chick-peas

k

¼ 2 5.0710

2

1

þ 2.5510

2

3

u

2

2.13

10

2

6

u

2

þ 4.2410

2

1

M

2

6.56

10

2

2

M

2

þ 6.4810

2

4

Mu

283

T 312 K

39

0.115

M 0.272

Lentils (cv. Laird)

k

¼ 0.193 þ 1.010

2

3

T

þ 1.5110

2

3

M’

9

M’ 23%

56

2

28

T 298C

Oats

k

¼ 0.0988 þ 0.307M

0

M 0.19

114

Peas

k

¼ 0.168 þ 8.410

2

4

T

þ 3.0510

2

3

M’

9

M’ 23%

56

2

28

T 298C

Rapeseed

k

¼ 0.1600 þ 0.043M

0

M 0.30

115

Rice, rough

k

¼ 0.0865 þ 0.0013M’

9.9

M’ 19.3%

116

Rice bran

k

¼ 20.0943 þ 3.8710

2

3

M’

þ 6.1910

2

4

T

þ 3. 1410

2

4

r

b

7

M’ 15%

117

410

r

b

490 kg/m

3

42

T 688C

Sorghum

k

¼ 0.0976 þ 0.0015M’

0

M’ 25%

27

Wheat (HRS)

k

¼ 0.1398 þ 0.0014M’, for T ¼ 208C

4.4

M’ 22.5%

118

k

¼ 0.1440 þ 0.0009M’, for T ¼ 58C

k

¼ 0.1365 þ 0.0014M’, for T ¼ 18C

k

¼ 0.1327 þ 0.0015M’, for T ¼ 268C

k

¼ 0.1407 þ 0.0009M’, for T ¼ 2178C

k

¼ 0.1436 þ 0.0009M’, for T ¼ 2278C

Wheat

k

¼ 0.1170 þ 0.0011M’

0.7

M’ 20.3%

44

a

k, Thermal conductivity W/(m K).

b

u

, Measured as temperature of air in equilibrium with seeds.

c

M, Moisture content kg H

2

O/kg db and M’, moisture content % wb.

TABLE 24.13

Thermal Diffusivities of Selected Seeds

Seed

Moisture Content % wb

Thermal Diffusivity (a, m

2

/s)

Method

Ref.

Chick-peas

12.0

11.6

10

2

8

Indirect

39

Corn, yellow dent

9.8

9.4

10

2

8

Direct

44

20.1

8.6

10

2

8

Rapeseed

10.5

9.2

10

2

8

Indirect

34

Rice, bran

7.0

9.7

10

2

8

Indirect

117

Rice, rough

12.0

16.4

10

2

8

Indirect

116

Soybeans

11.2

11.7

10

2

8

Direct

59

Wheat, soft

10.3

8.3

10

2

8

Direct

44

20.3

8.1

10

2

8

Wheat

9.2

11.4

10

2

8

Direct

43

Wheat

10.0

8.3

10

2

8

Direct

119

ß

2006 by Taylor & Francis Group, LLC.

Nu

¼

hd

e

k

a

(24:22)

The Nu number is determined from empirical correl-

ations between the Reynolds number, Re, and the

Prandtl number, Pr :

Nu

¼ CRe

m

Pr

n

(24:23)

The Reynolds and the Prandtl numbers are expressed as

Re

¼

vd

e

n

and

Pr

¼

n

a

(24:24)

For the temperature range used in drying grains,

the Prandtl number is assumed to be constant and

its value is usually incorporated into a constant, C,

which simplifies Equation 24.23 to one variable—the

air velocity (dependent on the Re number).

One of the first experiments to determine heat trans-

fer coefficients commonly cited in agricultural engi-

neering publications is that of Lo¨f and Havley [61]

who investigated heat transfer coefficients from air to

a 0.9-m deep bed of granitic gravel ranging in size from

4.8 to 38.1. The temperature of the hot air passing

through the gravel was monitored at selected loca-

tions through the bed. The experiments were conducted

for air velocities from 0.08 to 0.44 m/s and the entrance

air temperatures were maintained over the range

38 to 1218C.

To determine the mean volumetric heat transfer

coefficient, h

cv

, in a deep bed of gravel it was assumed

that: (i) any particle is at a uniform temperature at any

given time, (ii) resistance to heat transfer by conduc-

tion in the fluid or solid is negligible, and (iii) the rate of

heat transfer is described by Newton’s equation [61]:

h

cv

¼ A

m

a

d

e

0:7

(24:25)

The constant A depends on the nature of the material,

the porosity, and the average temperature of the deep

bed.

Using the same theoretical approach, the heat

transfer coefficient in a 240-mm deep bed of bone-

dry barley malt was determined [62]. The experiments

were performed for airflow rates in the range 0.35 to

0.65 kg/(m

2

s) and inlet temperatures from 50 to 708C.

The results were expressed as

h

cv

¼ 49,320m

0:6906

a

(24:26)

The heat transfer coefficient can also be determined

based on a heat and mass balance for a thin layer of

grain in which no moisture transfer takes place [63].

Thus, the following differential equation is used:

du

dt

¼

h

cv

c

g

r

b

(T

u)

(24:27)

with the solution

h

cv

¼

c

g

r

b

t

ln

T

u

T

u

0

(24:28)

The slope of the logarithm of the temperature ratio

versus time is used to evaluate h

cv

for specific values

of t and u determined experimentally. For barley

dried in a thin layer in the airflow range 0.0056–

0.023 kg/s (assuming no shreokage) the following re-

lationship is valid [63]:

h

cv

¼ 21:0m

0:6

(24:29)

The results from Equation 24.25, Equation 24.26, or

Equation 24.28 can be used for the calculation of

Nusselt numbers and presented in the form of Equa-

tion 24.23.

24.4.4 L

ATENT

H

EAT OF

V

APORIZATION

To overcome the attractive forces between the

adsorbed water molecules and the internal surfaces of

grain kernels extra energy is needed in addition to the

heat required to change the water from liquid to vapor.

As the moisture content is lowered, there is an increase

in the amount of energy required to evaporate the

water molecules in seeds. The change of state from

liquid to vapor at constant temperature and pressure

is expressed by Clapeyron’s equation, which after re-

arranging and integrating has the following form:

ln P

v

¼

h

fg

h

fg

ln P

vs

þ C

(24:30)

The vapor pressure, P

v

, can be calculated as

P

v

¼ RHP

vs

(24:31)

where RH is the relative humidity in decimal form.

The values of the saturation vapor pressure, P

vs

, at

different temperatures can be obtained from the steam

tables [64]. The values of the RH in Equation 24.31 can

be replaced by the ERH obtained from the EMC versus

ERH relationship. The values of P

v

and P

vs

at the same

EMCs can be plotted on a log–log scale. The slope of

the resulting straight line gives the ratio h

fg

*/h

fg

.

ß

2006 by Taylor & Francis Group, LLC.

The foll owing form ula has been e stablished to

determ ine the de pendence of the late nt heat of vap or-

ization of water in grain as a functi on of the mois ture

content , M [65] :

h

fg

¼ h

fg

[1

þ a exp ( bM )] (24 : 32)

The coeffici ents a an d b for selected seeds have been

determ ined and are given in Table 24.14 [66]. The

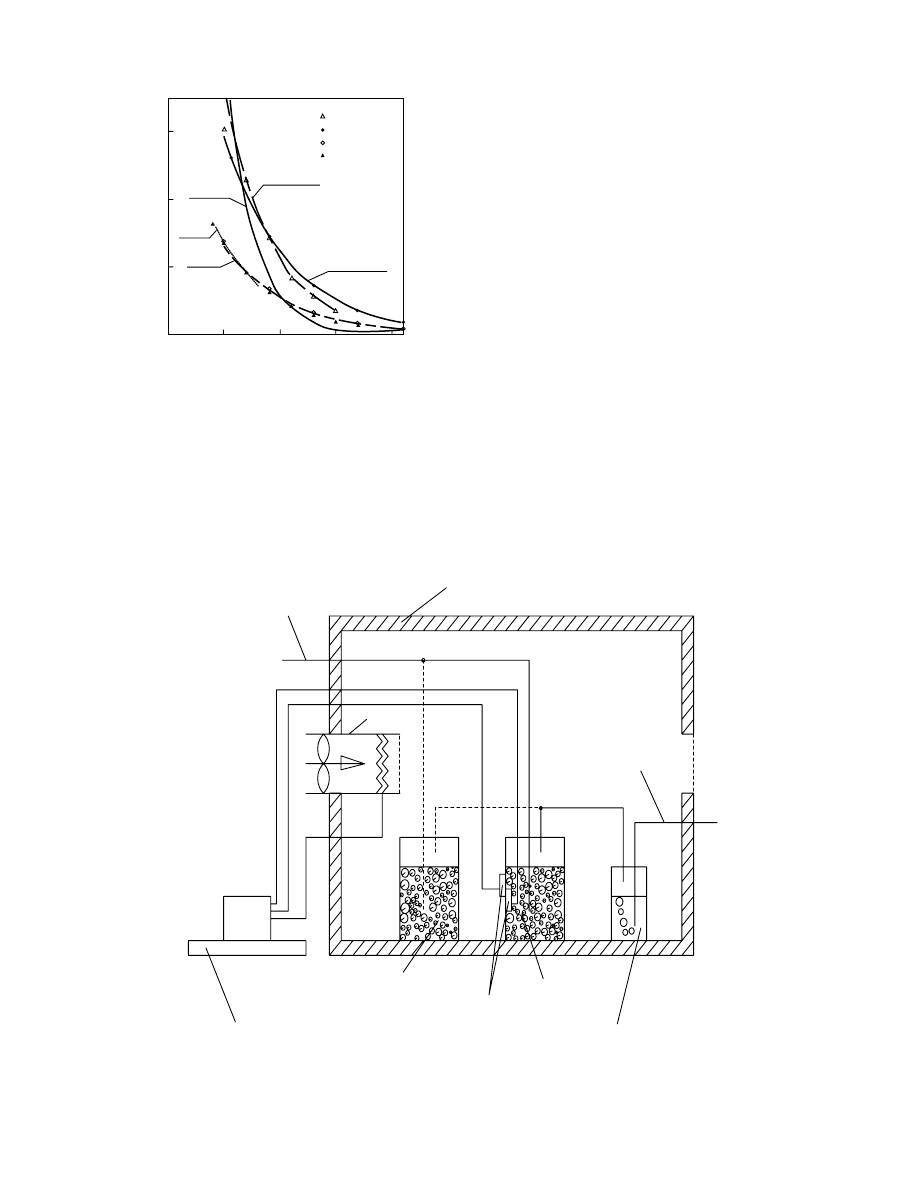

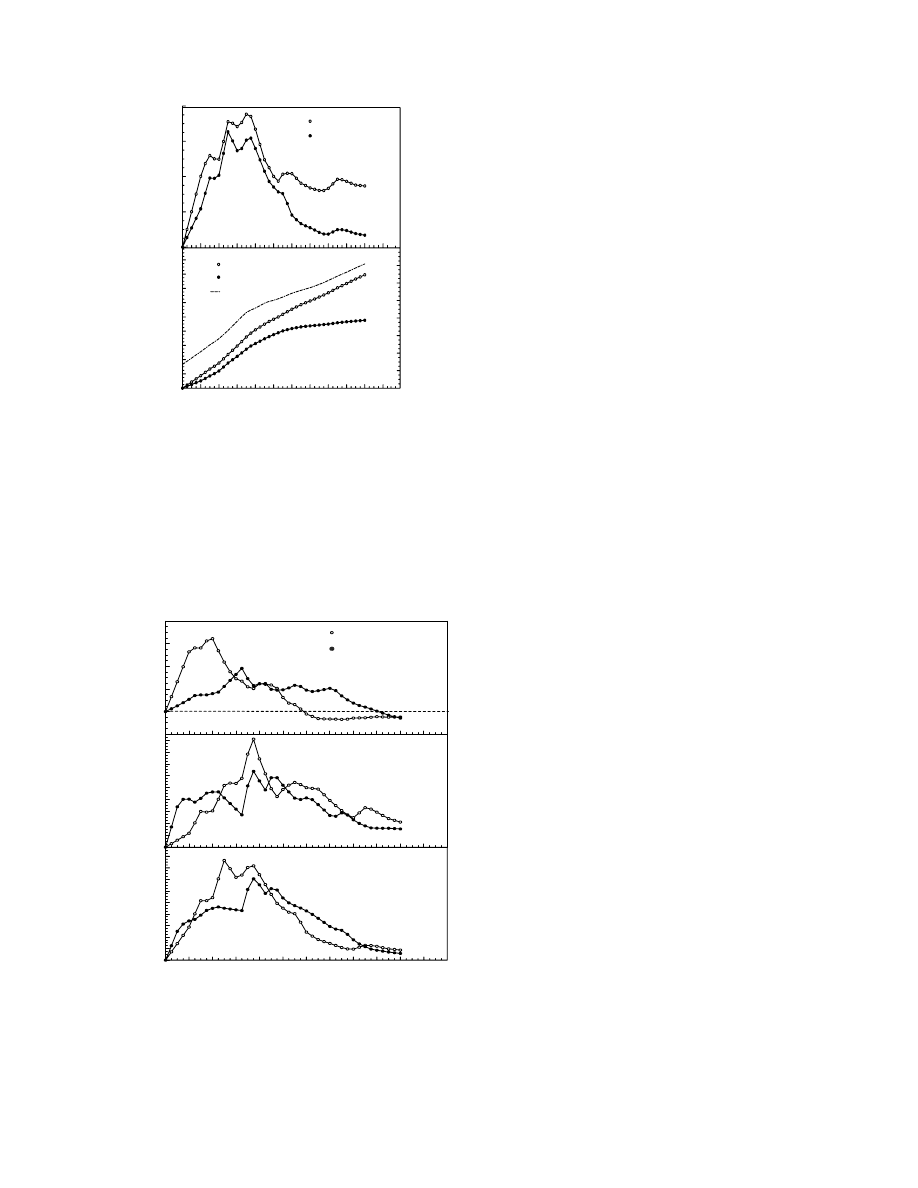

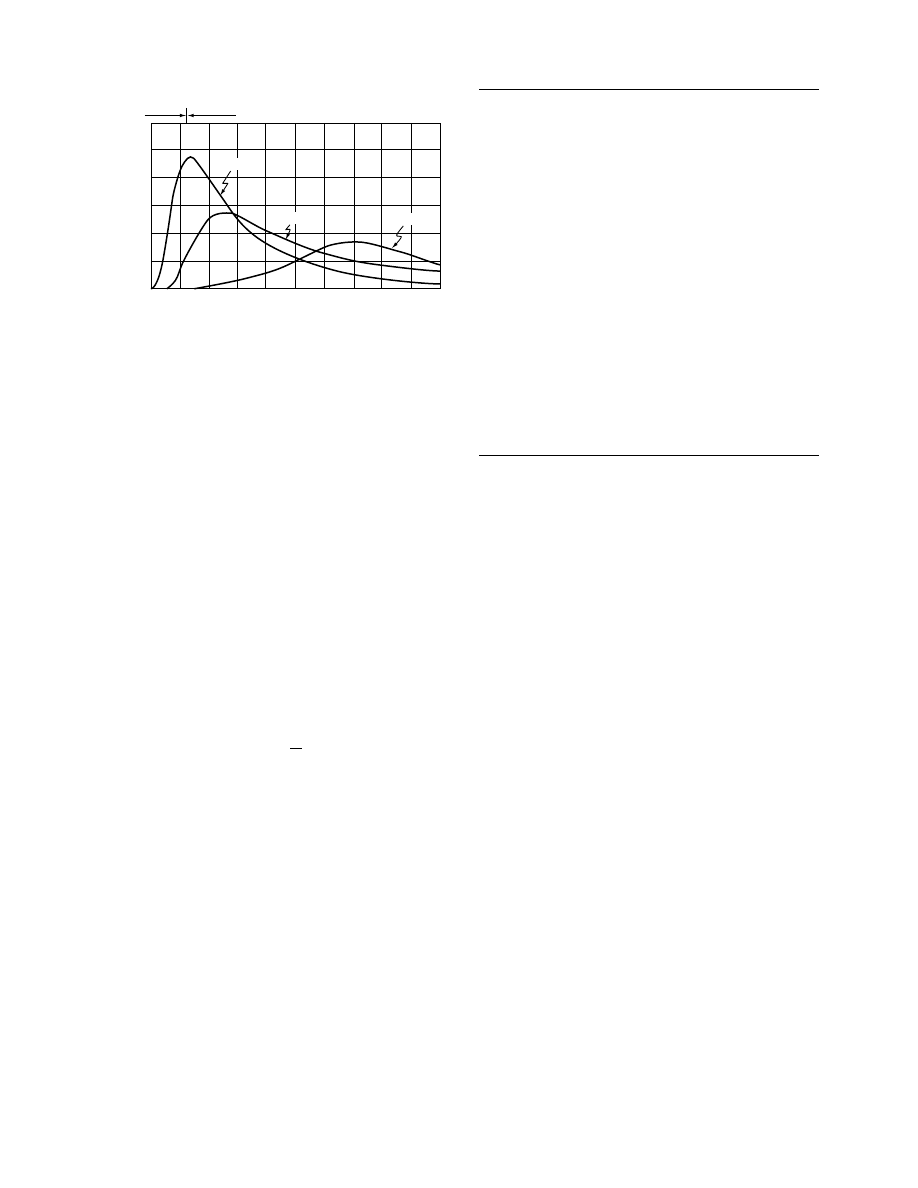

variation in the late nt he ats of barley an d three c ulti-

vars of wheat are shown in

. The symbol s

repres ent the values of h

fg

* / h

fg

calcul ated from the

EMC data [25] for selec ted moisture con tents. The

curves repres ent the be st-fit line based on Equation

24.32. Als o, predicted results based on the coeffici ents

given for wheat by Gall aher [65] are incorpora ted in

Figure 24.7.

The differences in h

fg

* for wheat can be attribu ted

to a difference in the chemi cal comp osition between

wheat types, whi ch affect the EMC charact eristic s on

which the calcula tion of h

fg

* is based.

24.4.5 H

EAT OF

R

ESPIRATION

Under stora ge con ditions grains generat e heat as a

result of respirati on an d mold activity . From the

engineer ing poin t of view, de terminat ion of the

amount of he at generat ed allows for the pr oper de-

sign of grain ae ration systems to maint ain crop qual-

ity. In extre me cases rain, snow, humid air from a

roof leak or ven tilation opening cau se wet poc kets in

a grain bin. Heat generat ed within the pock et of wet

grain provides a favorab le en vironmen t for grow th of

microo rganisms and excess ive he at generat ion.

No theory adeq uately e xplains the heat of respi r-

ation in store d grain, althoug h the respi ration equ a-

tion has often be en used to estimat e he at produ ction

[67,68]:

C

6

H

12

O

6

þ 6O

2

! 6CO

2

þ 6H

2

O

þ en ergy (24 : 33)

For each gram of dry matter (C

6

H

12

O

6

), which is oxi-

dized, 15.7 kJ of heat is produced. Equation 24.33 pro-

vides a simple way of calculating the heat production

from the CO

2

production. According to Equation 24.33

the respiratory quotient (ratio of oxygen consumption

to carbon dioxide production) is equal to 1.0. However,

measured quotients frequently deviate from 1.0 [69].

Heat production under the adiabatic conditions

similar to those in naturally occurring pockets of

wet grain is measured in a specially designed calorim-

eter [70] (

). A grain sampl e is split and

placed in two identical 1-L Dewar flasks, which are

housed in an insulated chamber. One of the flasks,

from which grain is sampled regularly for determin-

ation of the moisture content and microfloral infec-

tion, is used as a reference flask. To avoid disturbing

the test flask during grain sampling, the temperatures

inside and outside the test flask are continuously

monitored by six thermocouples, three inside and

three outside. When grain in the test flask starts to

heat, due to metabolic activity, the inside temperature

rises, causing a difference between the inside and

outside temperatures. If the difference exceeds the

preset value of 0.5–0.78C, the electric heater is turned

on to heat the air in the chamber, and thus equalizing

the outside and the inside temperatures. The tempera-

ture gradient across the flask wall is minimized

TABLE 24.14

Derived Coefficients a and b in Equation 24.32 for Some Major Crops

Seed

Coefficients

Moisture Content Range (db)

a

b

Barley

1.0

2

19.9

0.09

M 0.22

Beans

0.5

2

16.0

0.09

M 0.28

Corn

2.1

2

17.0

0.10

M 0.24

Peanut kernel

1.5

2

29.2

0.06

M 0.13

Rice

3.2

2

21.7

0.10

M 0.14

Sorghum

1.2

2

19.6

0.10

M 0.24

Soybeans

0.4

2

13.9

0.06

M 0.26

Wheat, durum

0.8

2

18.1

0.10

M 0.26

Wheat, hard

1.7

2

17.6

0.10

M 0.26

Wheat, soft

3.9

2

23.6

0.10

M 0.20

Wheat (Gallaher [65])

23.0

2

40.0

0.10

M 0.18

Source: From Cenkowski, S., Jayas, D.S., and Hao, D., Can. Agric. Eng., 34, 281, 1992.

ß

2006 by Taylor & Francis Group, LLC.

throughou t the course of heati ng; co nsequentl y, no

heat is trans ferred from or to the grain in the fla sk.

Under the adiabat ic co ndition , the meta bolic he at

produc ed insi de the flask by the seed and micr oflora

is measur ed directly.

Duri ng the initial 11 d, the he at prod uction rate in

wheat, calcul ated from measur ed CO

2

prod uction,

followed the directly measured rate of heat produc-

tion (

) . On the average , the directly meas-

ured rates were 27 and 14% higher than those

calculated from CO

2

production for 23.0 and 27.2%

moisture contents, respectively.

The respiratory quotient is not constant during adia-

batic heating (

). For wheat at 27.2% mois-

ture, it increased from 1 to 4.2 in 4 d, and then decreased

gradually. The peak respiratory quotient was lower for

23.0% moisture content wheat. At both moisture con-

tents, the respiratory quotient stayed at about 0.8 after

the temperature of the grain reached 528C.

24.5 ELECTRICAL PROPERTIES

24.5.1 D

IELECTRIC

P

ROPERTIES

A biological material (a dielectric) can be exposed

to electric or magnetic fields in frequencies from dir-

ect current (0 Hz) to x-rays (

10

18

Hz). From direct

current to ac frequencies up to about 8 Hz, lumped

circuits (composed of serial and parallel resistances

and capacitance elements) are used to measure

Soft wheat

Soft wheat

Hard wheat

Hard wheat

Gallaher

1.3

1.2

1.1

1.0

0.05

0.10

0.15

Moisture content, decimal db

Ratio of latent heats,

h

fg

/h

fg

0.20

0.25

Barley

Barley

Durum

Durum wheat

*

FIGURE 24.7 Effect of moisture content on the latent heat

of vaporization of selected grains compared to Gallaher’s

model. (From Gallaher, G.L., Agric. Eng., 32, 34, 1951;

Cenkowski, S., Jayas, D.S., and Hao, D., Can. Agric.

Eng., 34, 281, 1992. With permission.)