TETRAHEDRON

LETTERS

Tetrahedron Letters 44 (2003) 3579–3580

Pergamon

A new direct synthesis of cinnamic acids from aromatic

aldehydes and aliphatic carboxylic acids in the presence of

sodium borohydride

Constantin I. Chiriac,* Fulga Tanasa and Marioara Onciu

Institute of Macromolecular Chemistry

‘Petru Poni’, Aleea Grigore Ghica Voda 41A, Iasi 6600, Romania

Received 23 September 2002; revised 4 February 2003; accepted 21 February 2003

Abstract—Cinnamic acids have been prepared in 59–86% yields by a new direct synthesis from aromatic aldehydes and aliphatic

carboxylic acids in the presence of sodium borohydride and N-methyl-2-pyrrolidinone (NMP) as solvent, at reflux (185–190°C),

for 9–12 hours. Without sodium borohydride, this reaction is not possible. © 2003 Published by Elsevier Science Ltd.

Cinnamic acids can be prepared from aromatic alde-

hydes and aliphatic anhydrides, in the presence of

bases, particularly with sodium or potassium salts of

the carboxylic acids corresponding to the anhydrides

used in the reaction (the Perkin reaction).

1

Thus, potassium acetate can be used for the reac-

tion between acetic anhydride and benzaldehyde,

yields are 70–72% at 180°C in 8 h. With sodium

acetate, the yields are lower under the same condi-

tions.

2

This reaction is not suitable for aliphatic alde-

hydes.

3

If the aliphatic carboxylic anhydrides are replaced by

the corresponding aliphatic carboxylic acids, the reac-

tion is not successful.

We have now found that this reaction is possible with

aliphatic carboxylic acids in the presence of sodium

borohydride.

It is known that the aliphatic carboxylic acids can react

with sodium borohydride resulting in different prod-

ucts. For example, when using acetic acid the following

reactions take place:

Scheme 1.

* Corresponding author.

0040-4039/03/$ - see front matter © 2003 Published by Elsevier Science Ltd.

doi:10.1016/S0040-4039(03)00529-X

C. I. Chiriac et al.

/

Tetrahedron Letters

44 (2003) 3579–3580

3580

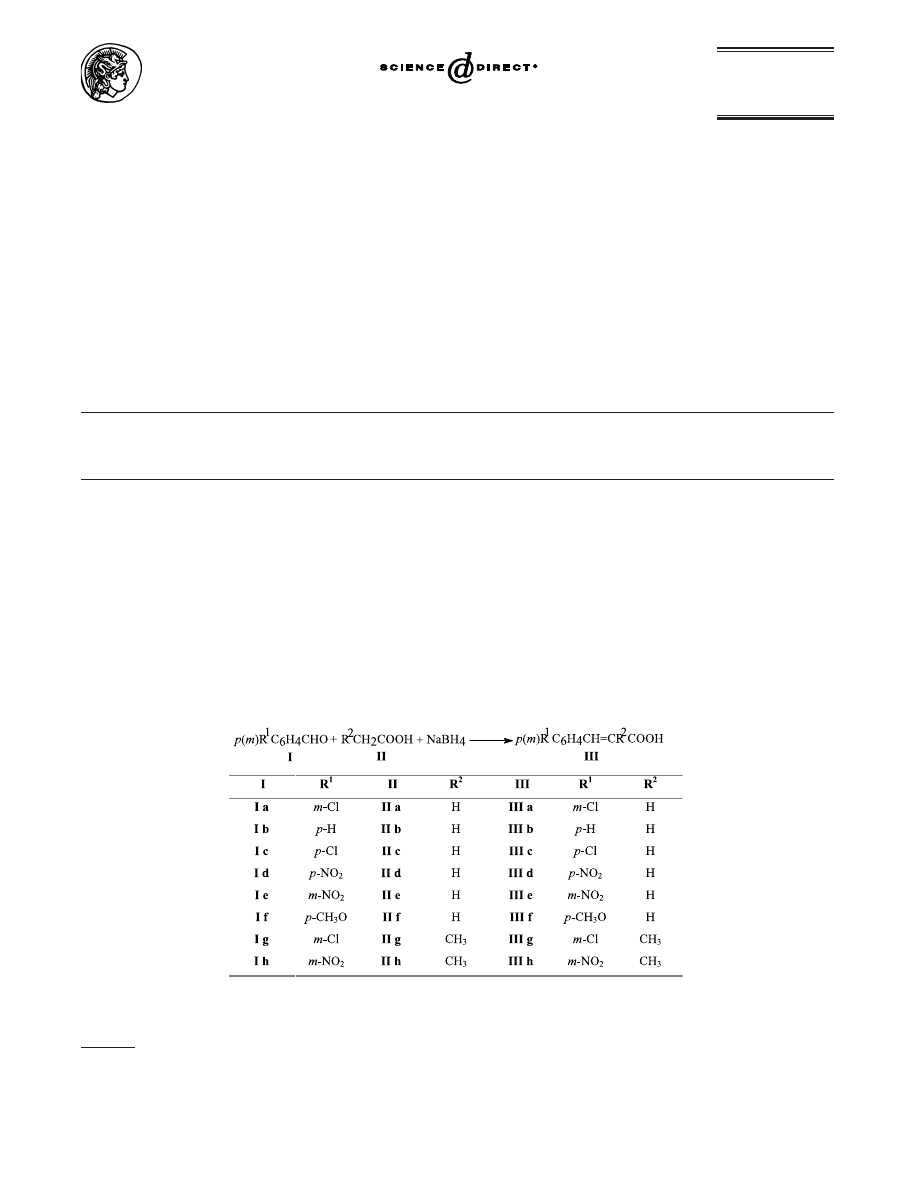

Table 1. Cinnamic acids obtained by direct synthesis in the presence of sodium borohydride

Reaction time (h)

M.p.

c

(°C)

Yield

b

(%)

Literature m.p. (°C)

Cinnamic acids

a

10

176–177

III a

175–177

7

74

12

131–133

66

132–133

8

III b

9

248–250

III c

249–250

7

83

9

285–286

86

284–286

9

III d

81

III e

10

195–197

196–197

10

12

173–175

59

173–175

8

III f

10

105–107

III g

106–107

9

72

10

195–197

77

196–197

9

III h

a

The cinnamic acids obtained were identified by comparison of their m.p. and IR spectra with authentic samples.

b

Yields calculated based on the aromatic aldehydes I employed.

c

After recrystallization.

NaBH

4

(1 mole)+CH

3

COOH (1 mole)

Na

+

B

−

H

3

OOCCH

3

+H

2

Ref. 4

NaBH

4

(1 mole)+CH

3

COOH (3 mole)

Na

+

B

−

H(OOCCH

3

)

3

+3H

2

Ref. 5

NaBH

4

(1 mole)+CH

3

COOH (4 mole)

Na

+

B

−

(OOCCH

3

)

4

+4H

2

Ref. 6

We found that this last compound 3, prepared in situ in

acetic acid solution, can react with aromatic aldehydes

to give the corresponding cinnamic acids.

By stepwise investigations, we established that aromatic

aldehydes I can react with aliphatic carboxylic acids II

in the presence of sodium borohydride, in the mole ratio

1: excess: 1.33, resulting in cinnamic acids III, as presented

in Scheme 1.

Using a mole ratio between the aldehyde I and NaBH

4

of 1:1.33, good yields for this reaction were obtained.

Without a suitable solvent, this reaction is difficult to

perform. We tested many solvents, such as DMSO, DMF,

N-methyl-2-pyrrolidinone (NMP), HMPTA etc. From

these solvents, we selected NMP because it is a good

solvent for our products, is stable under the reaction

conditions and has a high boiling point (202°C).

The synthesis necessitates high temperatures (reflux at

180–190°C), during 9–12 h (Table 1). At lower temper-

atures, the yields decrease. For example, the yield for

product IIIa decreased to 45–48% when the reaction was

performed at 145–150°C, for 6 h.

As can be seen in Table 1, cinnamic acids III were obtained

in yields which ranged from 59 to 86% depending on the

reaction conditions and structure of the aldehyde. The

cinnamic acid IIIf was obtained with the lowest yield.

Cinnamic acids with electron-withdrawing groups were

obtained in good yields.

11

The detailed mechanism of this reaction will be discussed

in a separate communication.

In conclusion, we have found a new synthesis for the direct

preparation of cinnamic acids from aromatic aldehydes

and aliphatic carboxylic acids in the presence of sodium

borohydride. This method is a very effective alternative

to the classical Perkin synthesis. Without the sodium

borohydride, the synthesis is not possible.

References

1. (a) Johnson, J. R. Org. React. 1942,

1, 210; (b) Johnson,

J. R. Org. Syn. Coll. 1955,

3, 426.

2. Kalnin, P. Helv. Chim. Acta 1928,

11, 977.

3. Crawford, M.; Little, W. T. J. Chem. Soc. 1959, 722.

4. Reetz, T. J. Am. Chem. Soc. 1960,

82, 5039.

5. Hutchins, R. O. J. Org. Chem. 1978,

43, 2301.

6. Markini, P. J. Org. Chem. 1975,

40, 3455.

7. Cleland, G. H. J. Org. Chem. 1961,

26, 3362.

8. Fedorov, B. S. Prom. Org. Sin. Akad. Nauk SSSR 1967,

173 (Chem. Abstr. 1968,

68, 77903h).

9. Urushibara, Y.; Hirota, M. Nippon Kagaku Zasshi 1961,

82, 351 (Chem. Abstr. 1962, 56, 10025g).

10. Zimmerman, H. J. Am. Chem. Soc. 1959,

81, 2091.

11. General procedure for the synthesis of cinnamic acids: In

a 100 mL three-necked Claisen flask fitted with a mechanical

stirrer, 0.14 mole (excess) of aliphatic carboxylic acid II was

added. Then, 1 g (0.0266 mole) of sodium borohydride was

added slowly in small portions, under stirring and cooling

with ice, in order to maintain the temperature in the flask

at 20–30°C. Then, the solution obtained was stirred for 1

h at room temperature, and then for 1 h at 90–100°C. To

this solution, at 70–90°C, 0.02 mole of aromatic aldehyde

I was added and then 2mL of NMP as solvent. The solution

obtained was stirred for 2–3 min. The mechanical stirrer

was replaced with a condenser and the excess of compound

II was removed by distillation, until the temperature in the

flask increased to 185–187°C. Then, the distillation set was

replaced with an air-cooled reflux condenser 30 cm long and

2.9 cm in diameter, which was extended with a water-cooled

reflux condenser. This solution was heated under reflux, at

185–190°C, for 9–12 h (see Table 1). At the end of the

reaction, the final solution was treated with 70–80 mL water

and then with NaOH solution 20%, to pH=9–10. From

this solution, the unreacted aromatic aldehyde I was

distilled with water under vacuum (30–40 mm Hg), until

the distillate was no longer cloudy. The solution was diluted

with water until a volume of 80–90 mL was obtained which

was then filtered at 30–40°C. The filtrate was treated with

HCl solution 15–20%, until pH=1–2, when cinnamic acid

III precipitated. After 2–3 h of stirring under cooling with

ice, the final product III obtained was filtered, washed with

15–20 mL cold water and dried. Yields ranged from 59 to

86% (Table 1).

Document Outline

Wyszukiwarka

Podobne podstrony:

rotter cat

Hyd prd cat 2009 english webb

A32 Ziyang J Cat 2001 id 49773 Nieznany (2)

podrecznikII 1 cat id 365892 Nieznany

CAT BĘBEN

cat patterns sept02

cat today 75 2002 459

Benzaldehyd

Benzaldehyd

Twisty Cat, Dokumenty Textowe, Koty, Rasy kotów

CAT 330D

Cat Schield Zawrót głowy

cat comm 8 2007 1621

C7 200611 CAT PL

Cat Illusion

cat 6AD en id 108772 Nieznany

Benzalkonii chloridum

więcej podobnych podstron