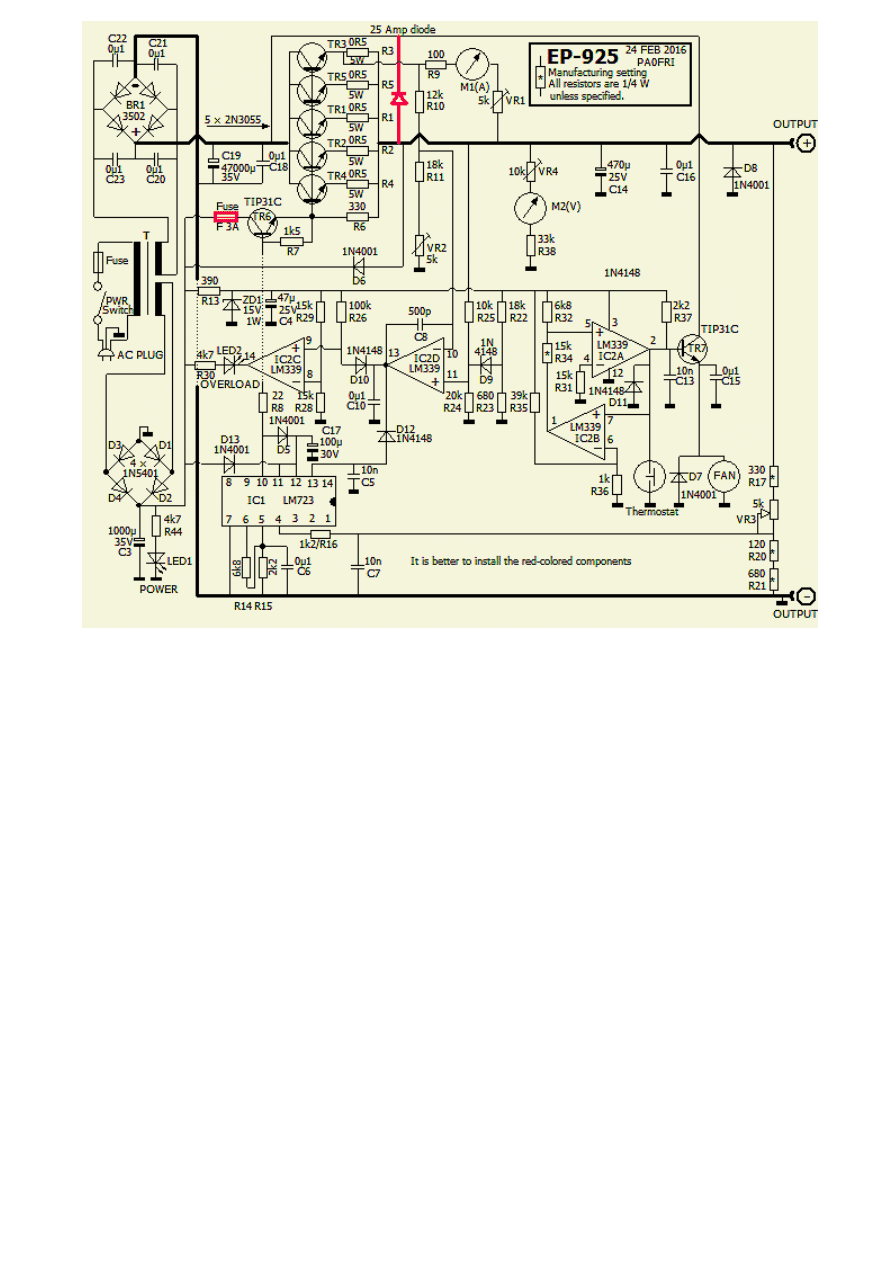

MANSON EP-925 MODIFICATIONS

EP-925 and PALSTAR PS-30M

On the Internet circulates an unclear copy of this supply's diagram and one is regularly

asked for a better drawing. As owner of this device I also wanted a good readable diagram.

So I draw a compact one using the Internet's example but it turned out the example had a

lot of errors.

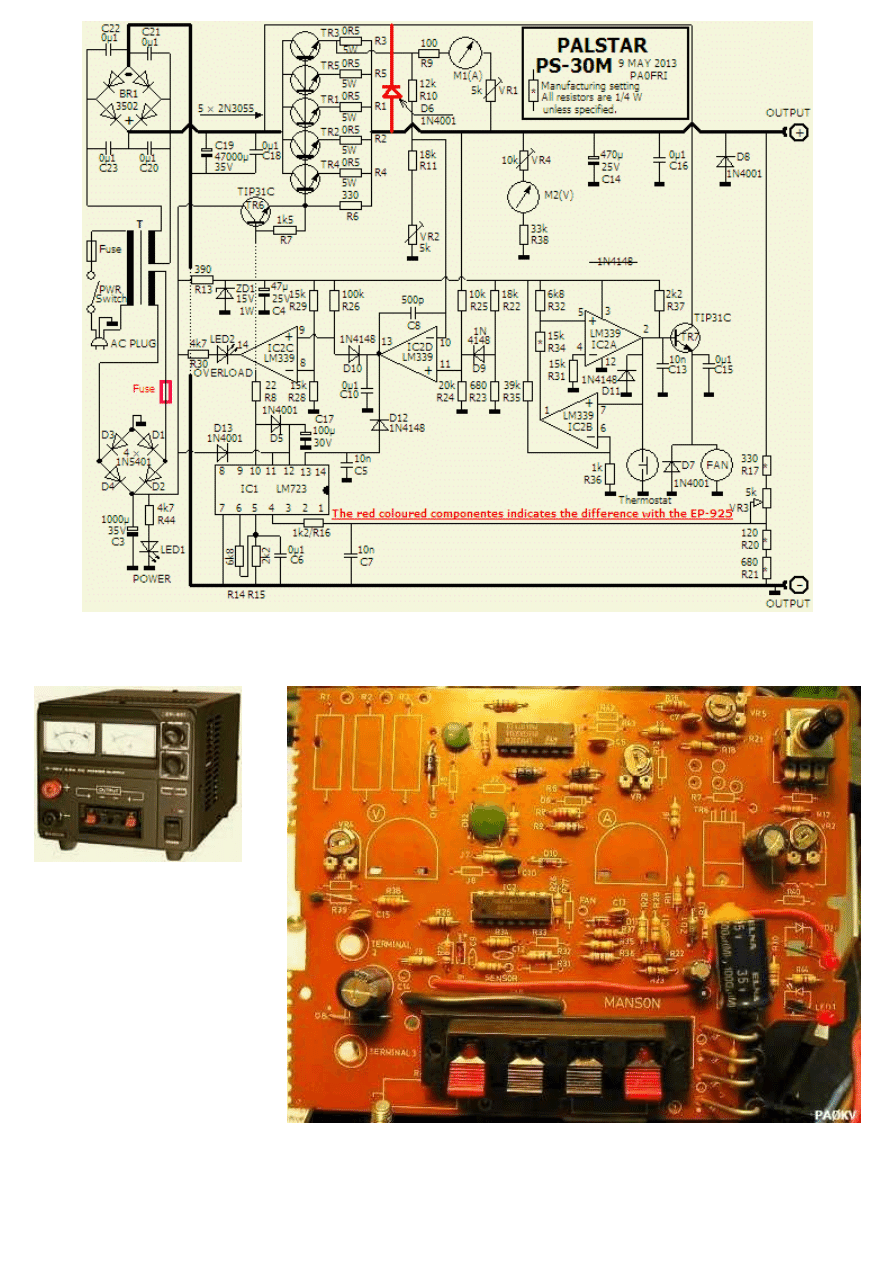

The Palstar below is almost similar except two red coloured components.

SHORTCOMINGS

This power supply («fig) is

also for sale as EP-925 by

Conrad, Daiwa, ITM,

Manson, Palstar, Stabo,

Velleman, Voltcraft and

others. The unit is used in

many shacks but it has

some shortcomings, which

have resulted in failures.

Fortunately the device can be improved by some modifications.

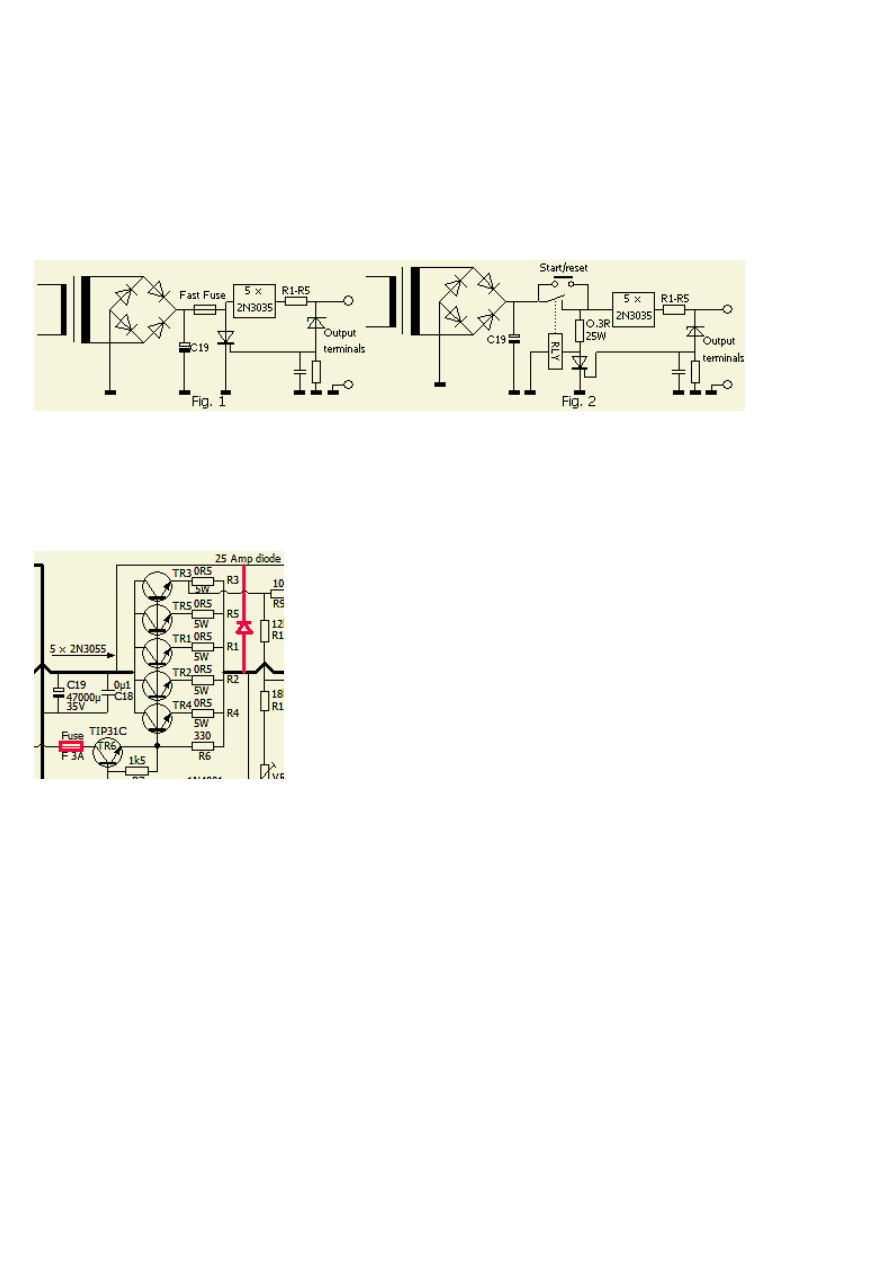

OVERVOLTAGE

Remember that a surge protector is not present. If one transistors (TR1-TR5) blows, the

entire unregulated voltage (~ 24V) is connected to your set and it will usually not survive.

Such protection is still not in my EP-925 installed. You know the routine, the plan exists but

it need not be directly because I have other power supplies available. When use the EP-95

with a transceiver I always connect a small battery in parallel.

At right (fig.1») is the principle of a (15 V) overvoltage protection system. It is almost a

standard "brute force" circuit with a Zener diode driving a thyristor, which short-circuit the

overvoltage, a fuse blew and the set is no longer energised. Details of such security can be

found on the Internet.

A less crude system (fig.2) is very similar. After turning the

main switch and press the start/reset button, the relay connects and the power supply is on.

If the voltage at the terminals is too high, the thyristor is conducting and the voltage is

reduced to a safe value by the large current through the 0.3 Ohm resistor. Simultaneously,

the voltage across the relay is almost zero and disconnects the load. This is not a brute

force system and the thyristor is less affected.

G3MWO

wrote me: "With the crowbar applied, then there is a path from the auxillary

smaller power supply up through the TIP31C (TR6) and back through the combined

path through the base/collector junctions of all the 2N3055 transistors in parallel" (or

via the extra diode #PAØFRI)

In order to protect TR6 install a 3 Amp fast fuse in series with TR6's collector.

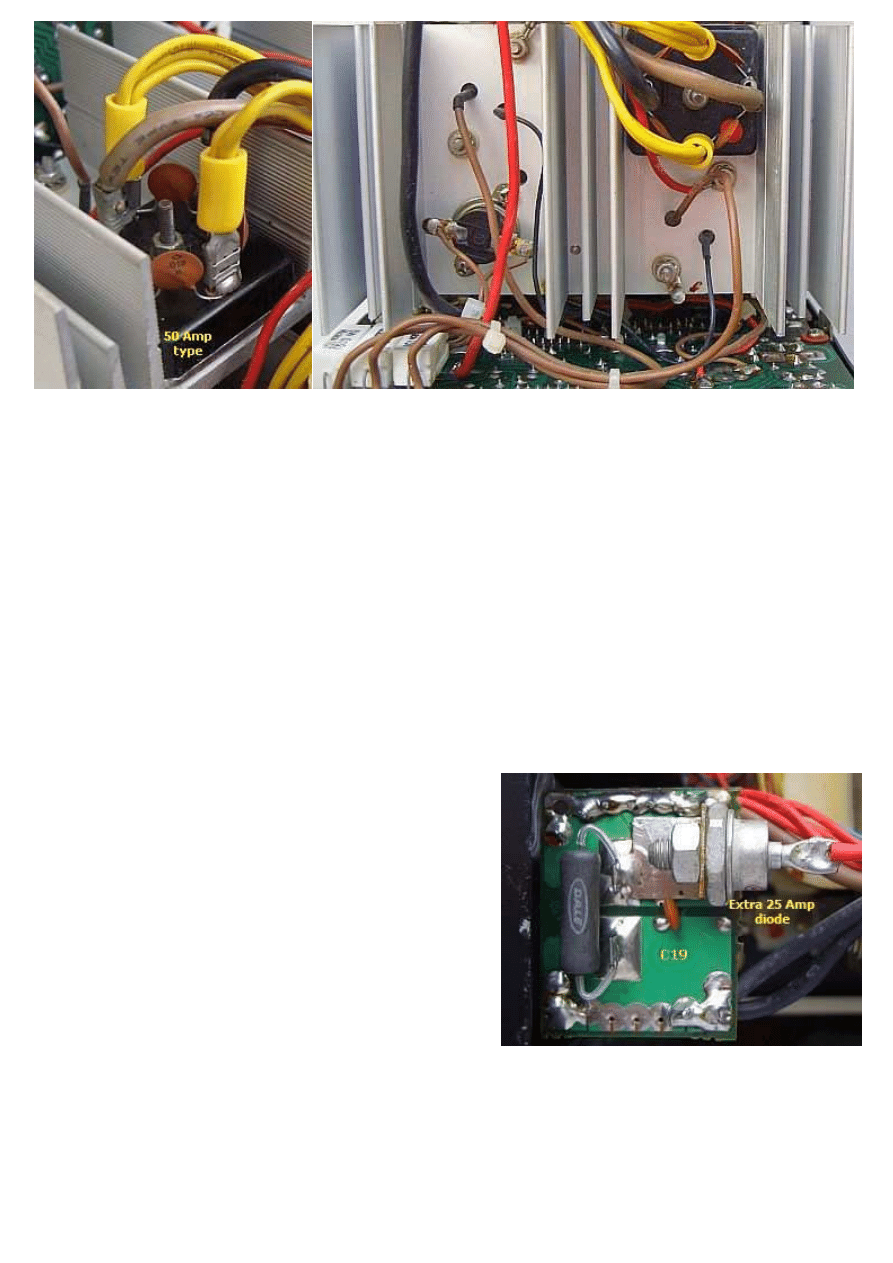

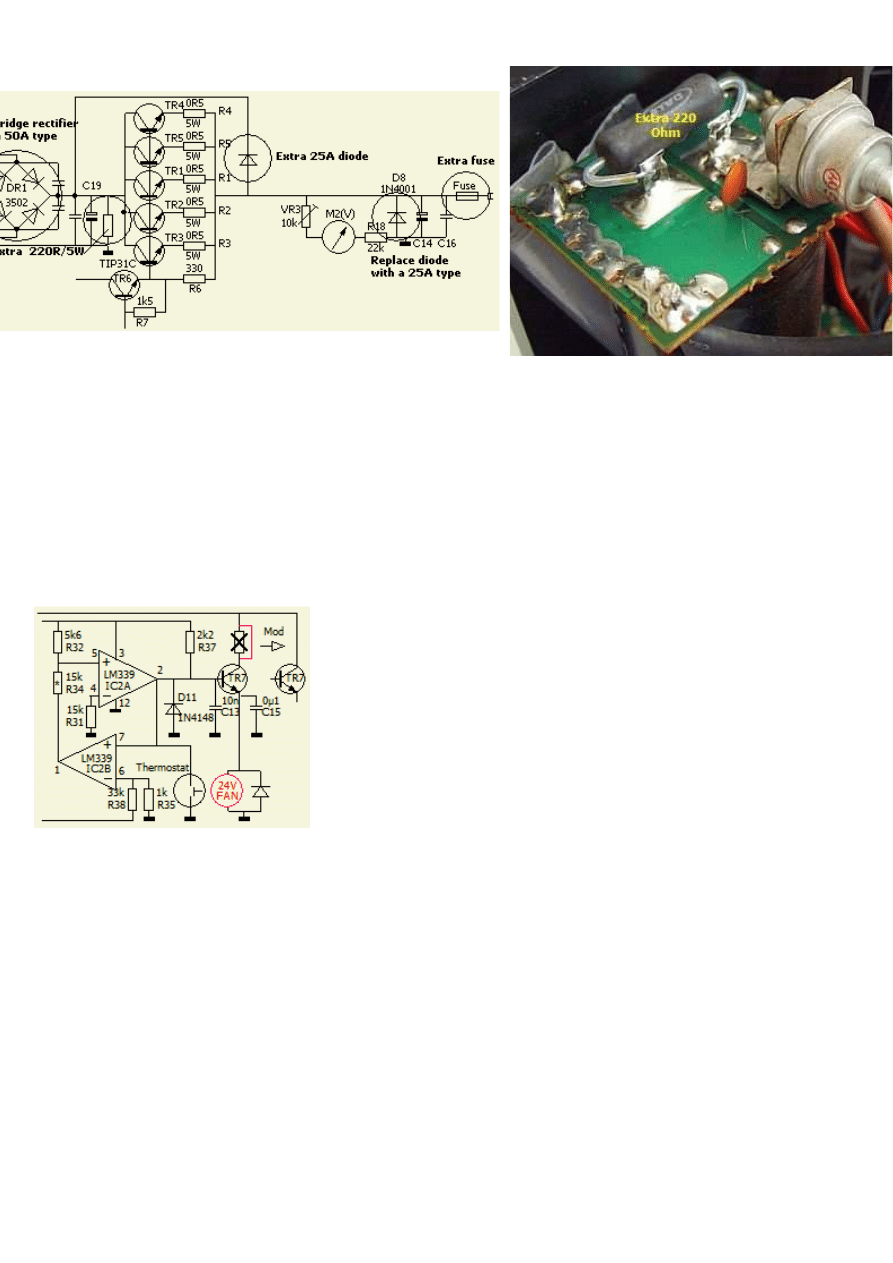

BRIDGE RECTIFIER

In my EP-925 only a 20 amperes bridge rectifier (DR1) was mounted, but the factory fitted

also a 25 Amp type.

Both rectifiers are only suitable for continuous use with about 12 A or 15 A and not to the

specifications of a 25 A continuous current or 30 A peak current. One has experienced that

a sustained large current will develop a fault.

I did not believe the factories specifications and therefore I tested the supply thoroughly.

The rectifier collapsed, but that was partly due to lack of cooling. The cause: the mounting

screw and nut were lose and there was no thermal paste applied between bridge rectifier

and heat sink. It is advisable to check all the fixing and thermal paste because my

transistors were providing with almost nil paste. After a 50 A rectifier bridge was installed

the power supply specifications were right and the unit has not failed since 1994.

SERIE TRANSISTOR

During the mentioned test a 2N3055-power

transistor had gone short circuit also by lose fixing

and nil paste. Again, check your power supply for

essential fixings and sufficient thermal paste.

VOLTAGE REMAINS

When the power is switched off, the voltage

remains for some time. For a faster discharge a

load resistor (fig») was installed parallel to the

unregulated voltage across capacitor (C19).

EXTRA DIODE

If the supply is used for battery charging it may happen that the power is switched off

before the battery is removed or the battery is connected before the unit is on. Temporarily

components can have a reverse polarity and failure. A large diode (fig») mounted from the

positive terminal to the plus pole of C19 can avoid this.

DIODE EN EXTRA FUSE

If accidentally the poles of a battery are reversed, diode D8 (1N4001) conducts and not

survives. One can installed the known reverse protection circuit by replacing a stronger

diode type (> 20A) and an additional output (25A) fuse. In case of wrong connection the

diode conducts and the fuse blow.

OTHER FAN

The original 12 V fan was too noisy and did not sufficiently cooled at maximum load. That is

mainly because the insufficient mounting of all components. One resistor («fig) was

removed or short circuit and a powerful fan type was replaced: a 24 V PAPST Multifan 8314.

Now the airflow is sufficient with less noise.

The resistor in TR7's collector is not always installed in this type of power supply!

G3MWO

cured the overheating by running the fan slowly all the time - but also added

a series of 6 mm holes in the bottom of the case just in front of the heatsinks for air

flow through the lower heatsinks.

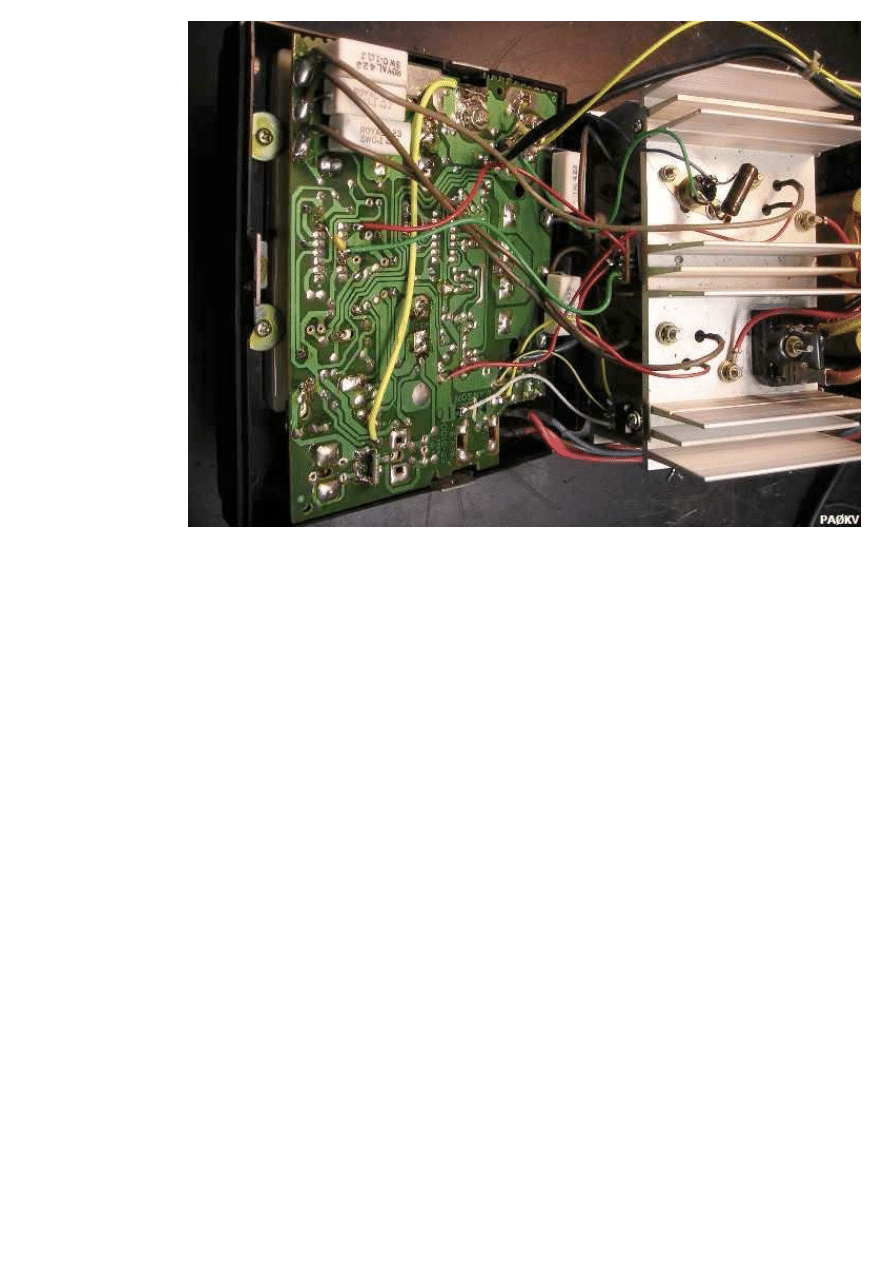

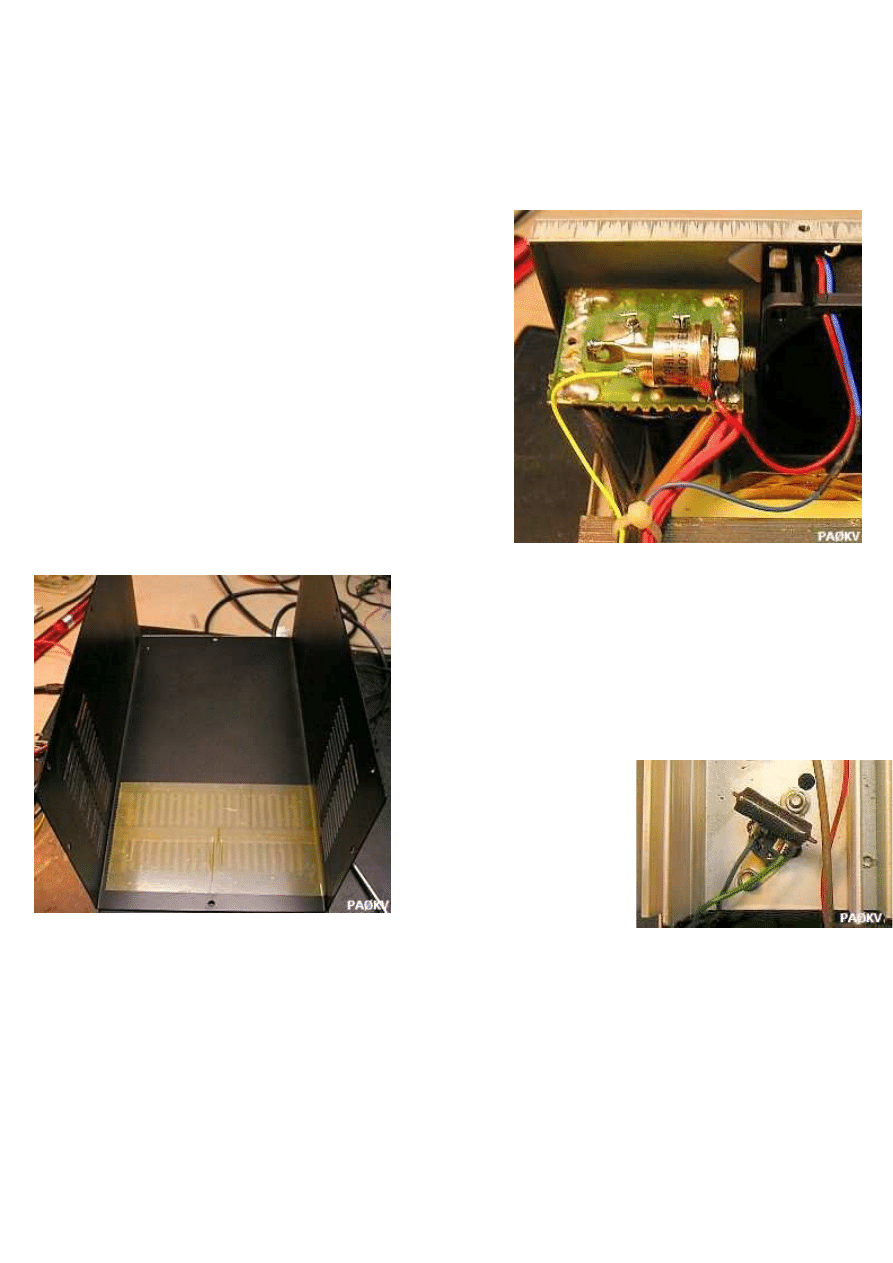

PAØKV's MODIFICATIONS

PAØKV has

designed some

interesting

changes. He

was not

satisfied with

the voltage

stabilization at

maximum load.

In examining

the cause he

discovered a

number of

weaknesses of

the design. In

his enthusiasm

to proceed, he

thought the

changes might be too far. However the result was a safe, quiet and stable 13.8 V supply for

its transceiver. His findings are given below

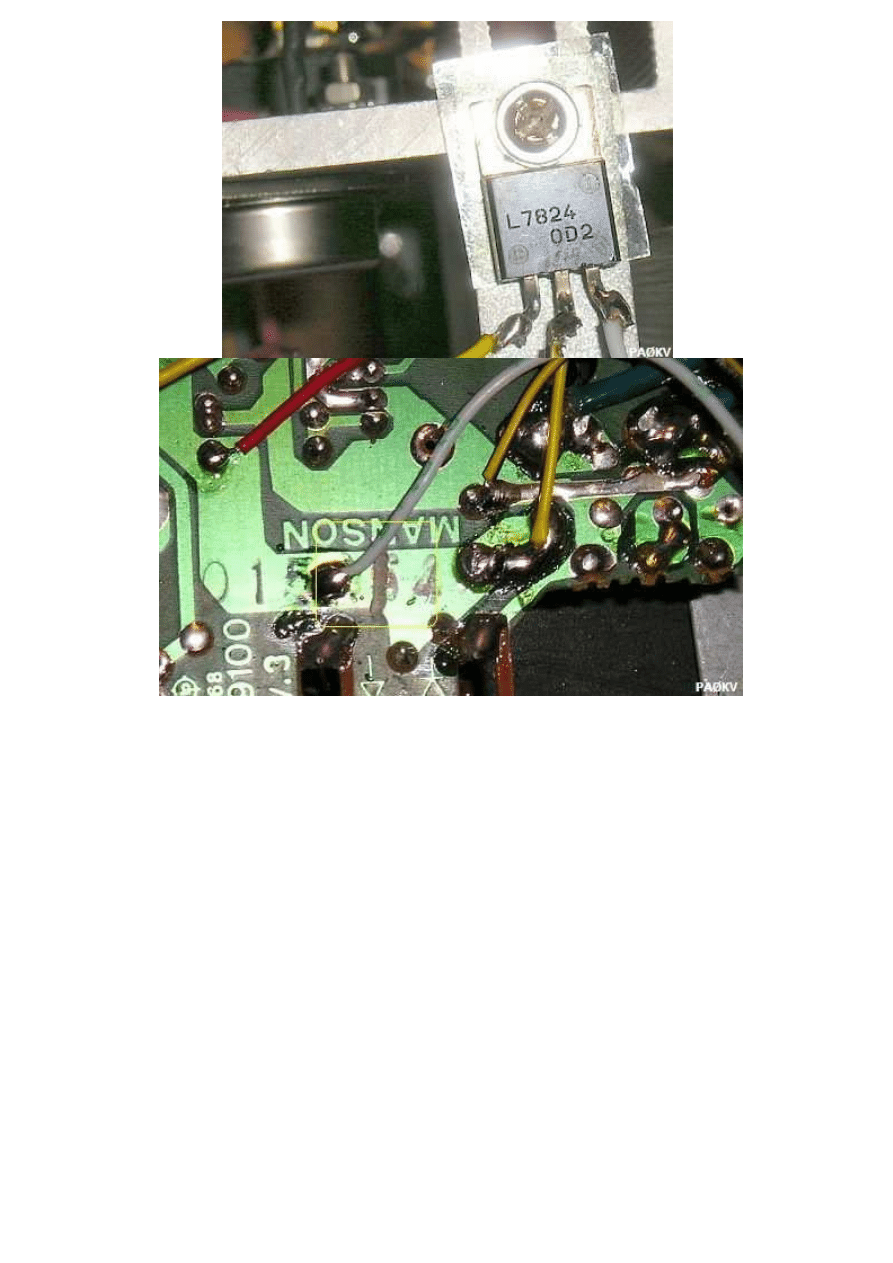

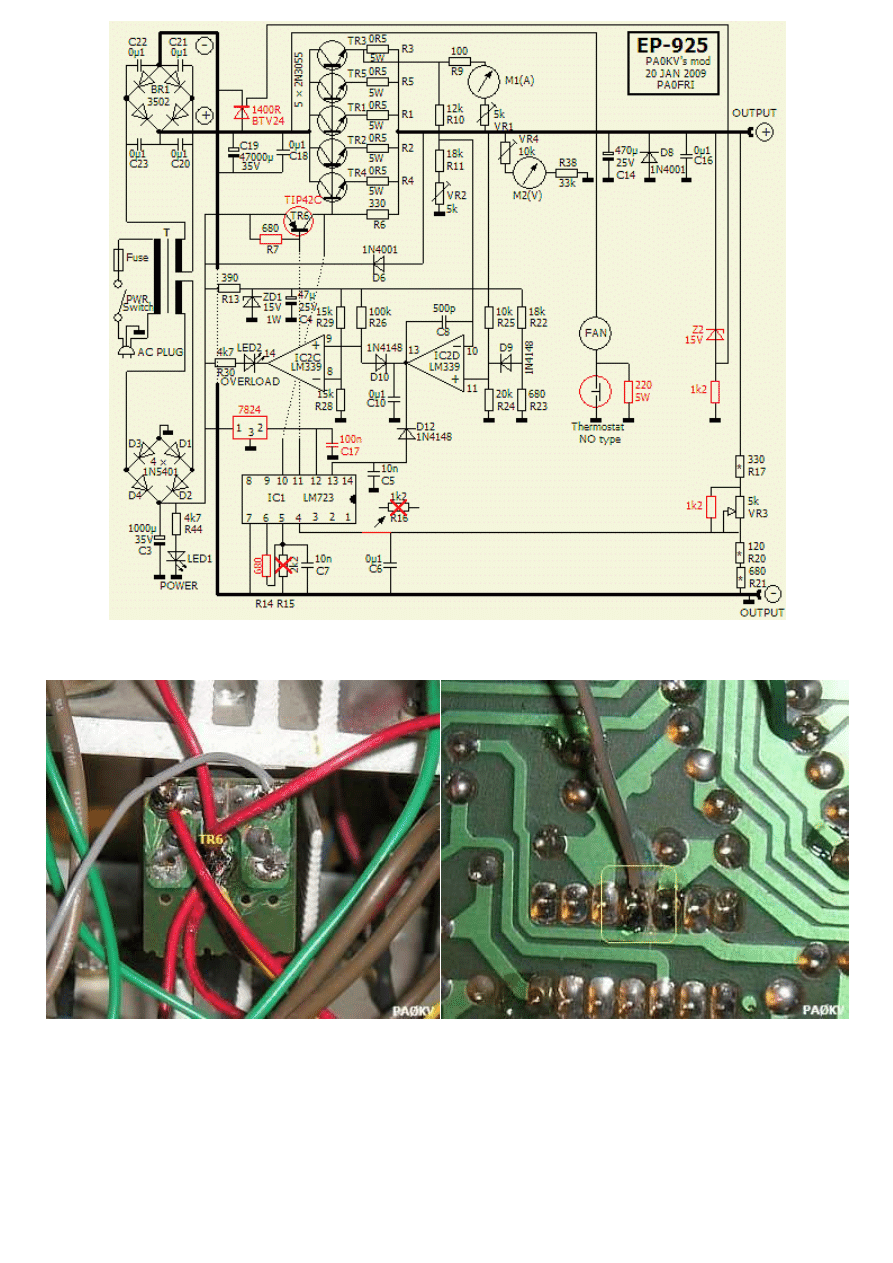

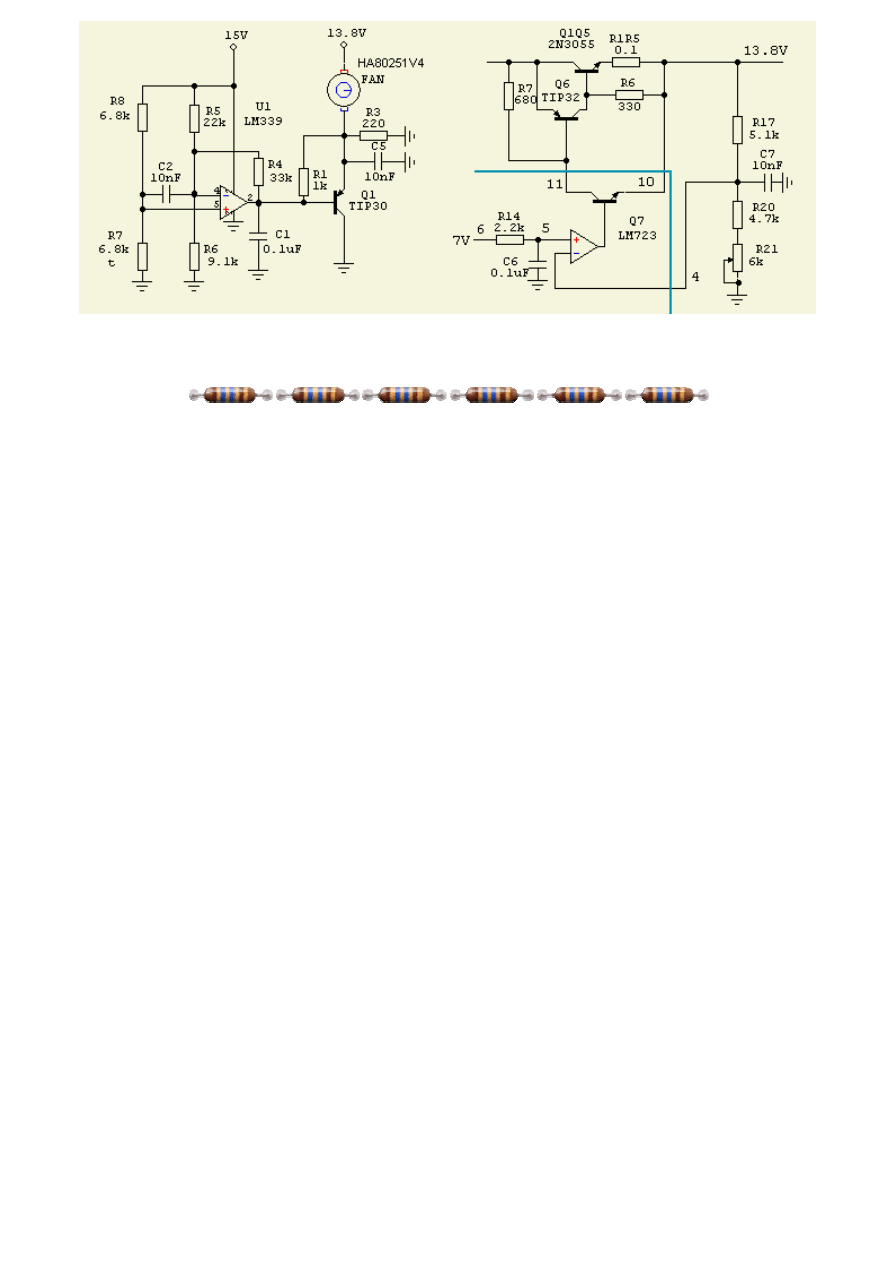

STABILITY

The LM723 (IC1) voltage regulator is not working properly despite feeding with a separate

winding on the transformer. The output voltage varies considerably due to the heavy load of

the system to the other secondary winding and probably by thin wire on the primary

windings.

To improve, he replaced D13 (1N4001) with an additional 24 V stabilizer (7824) mounted on

the heat sink and a track was interrupted. Since C17 was not installed in his EP-925 he

mounted a 100 nF capacitor.

The changes are marked in red. The circuit for the fan is simplified.

The circuit of the LM723 (IC1) voltage regulator could be improved. NPN TR6 (TIP31C) was

replaced by a PNP transistor TIP42C with increased HFE that contribute to the stabilization.

A track (fig») below IC1 was cutted. Further pin 12 (V

+

) was connected to 7824, pin 11 (Vc)

to the base of TIP42C, pin 10 (Vout) to the emitter of TIP42C. Resistor R7 (1.8 k) replaced

by 680 ohms and R8 (22 Ohm) and D5 (1N4001) removed.

The inputs of the LM723 were designed for lower voltages (up to 9 V) to the outputs. He

chose for 13.8 V, R14 was reduced to 680 ohms. He decreased the maximum voltage across

VR3 (5 kOhm) to 14 V with a 1.2 kOhm resistor in parallel of VR3.

SAFE OVERVOLTAGE

For maximum 14 V voltage at the output terminal

he applied a 16 V overvoltage protection. A thyristor

(BTV24/1400R) was mounted in parallel with (fig»)

an installed bridge rectifier (50 A/120 V). A zener

diode (ZD2) and resistor (100 ohms) across the

output trigger the action.

FAN

In his opinion the circuit for the fan is overly

complicated: a thermostat, two opamps and a

transistor to switch a fan! I am agreeing! The

reason is probably the use of an NC (Normal

Closed) thermostat.

The fan was replaced by a PAPST 844414NG and

mounted to suck the hot air out of the casing.

Thus reduces noise considerably. To increase the

airflow through the side slits, he sealed the air

gaps («fig) of the lid with tape.

The original fan's supply

system was

superfluously because

the thermostat was

replaced by an N-type

(Normal Open) in series with the fan. With a (fig») 220 Ohm/5 W

resistor parallel to the thermostat the fan runs quietly at half speed and constantly cooled

the heat sinks. It's never happened that the fan was running at full capacity.

LY3BG MODIFICATIONS

Left: R7 (6k8) is a thermistor, FAN = silent fan; Right: R1-R5 = 0.1 Ohm.

Wyszukiwarka

Podobne podstrony:

Convert Computer ATX Power Supply to Lab Power Supply

Jvc Power Supply Description And Trouble Shooting Procedure

Battery Inverter For Modularly Structured Pv Power Supply Systems

0 50V 2A LM10C, 0 50V 2A Bench power supply circuit diagrams, schematics, electronic projects

(Wydruk – ATX Switching Power Supply 13,8 V Proste zmiany w celu zwiększenia napięcia wyjściowego Ja

Alarm Power Supply L78Sxx id 61 Nieznany (2)

3 2 Lab Install Power Supply

HY3010 power supply, Elektronika, Zasilacze, Zasilacz HY3010, Zasilacz HY3010, HY3010 ,INSTRUKCJA

Lekturki Power Supply Unit Lekturka

How to Modify an ATX Computer Power Supply

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

Control and Power Supply for Resistance Spot Welding (RSW)

Performance Improvements in an arc welding power supply based on resonant inverters (1)

Convert Computer ATX Power Supply to Lab Power Supply

(ebook free energy) 50000 vdc power supply

(ebook electronics) Schematics Power Regulated Power Supply for CB & Ham Radio

Sovereign XS Power Supply Schematic

03a E46 Power Supply and Bus Systems

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

więcej podobnych podstron