Metallic Looking Plastics. With New Silver and

Colored Aluminum Pigments

Hans-Henning Bunge

Eckart America L.P., USA

ABSTRACT

The application of aluminum pigments in plastics presented a problem in the past because of

the flow lines which they caused in injection molded parts. By using large size aluminum pig-

ments, with an average particle size of 60 µm to 330 µm and larger, it is possible to avoid

these flow lines and produce metallic looking plastic parts. This concept was taken one step

further by depositing colorants on these large size aluminum pigments, thereby creating a

blue, green, and golden metallic looking colorant that can be used in plastics without flow

lines. These pigments offer exceptional styling effects by themselves and in combination with

other colorants including bronze pigments.

INTRODUCTION

Aluminum pigments have not been favored in the past for injection molded parts for more

than one reason. If they were used as powders there was always a concern that they could

present a hazard. This was widely overcome by using these pigments pasted in polyethylene

wax or in a predispersed form as concentrates provided by their supplier. The second reason

was that aluminum pigments cause flow lines in injection molded parts which in most cases

can not be tolerated.

APPLICATION OF ALUMINUM PIGMENTS IN PLASTICS

Aluminum pigments did find wide application in plastic films for garbage bags, canvases, as

heat reflectors and for agricultural applications. Because plastic films are inherently thin, alu-

minum pigments with only a relatively small average particle size in the range of 10 µm and

below are applied.

Aluminum particles of this size display two main properties, excellent hiding but de-

creasing brightness with decreasing particle size. Excellent hiding, because contrary to regu-

lar pigments, the hiding of aluminum pigments increases as the particle size decreases due to

their lamellar structure. But the smaller the aluminum particles the darker their appearance

because of the increasing amount of light that is scattered. On the other hand, the larger the

aluminum flake the more light is reflected and the brighter and the more metallic like its ap-

pearance. Again this brightness is reduced by the amount of smaller particles or fines that are

present.

AVOIDING FLOW LINES

For plastics, large particles have an additional advantage. Aluminum flakes starting at a parti-

cle size of around 125 µm to 700 µm and even above cause in injection molded parts no flow

lines or in the 60 µm range strongly diminished flow lines.

The following additional steps

1

can be taken to insure the elimination of flow lines and

thereby optimizing the optical appearance of injection molded parts prepared with such alu-

minum pigments:

• optimum concentration of the aluminum pigment

• resins with a high viscosity (low MFI) reduce flow lines, because the aluminum

flakes will orient less

• a strong turbulence in the mold, created by large diameter of the gates and a high in-

jection velocity

• when designing the mold the wall thickness of the molded part should be optimized

as well as the locations of the gates

• for large parts cascading gates are preferred.

METALLIC LOOKING PLASTIC PARTS

Because of the high reflectivity of these large size aluminum pigments they can provide metal

like appearance of injection molded parts. These type of aluminum pigments are available as

powders, pastes in mineral oil, or predispersed as pellets. The pellets which are the most

widely used version have a pigment concentration ranging from 80-90%. Some of these pel-

lets are dispersed in polyethylene wax only, restricting their use primarily to polyolefin resins.

Others contain only a small percentage of polyolefin wax in combination with other additives

widening their application to most commercially available resins.

The advantages of the predispersed version are that they are much easier to handle. Also

they have been dispersed on equipment that is designed to do as little as possible damage to

the flakes during the extrusion process because aluminum flakes that are bend during pro-

cessing are less bright.

50

Coloring Technology for Plastics

To make these flakes tougher and more resistant to bending they are offered by one sup-

plier at a thickness of 8-10 µm compared to 2 µm of regular aluminum pigments. These

thicker flakes are available at particle sizes of 125 µm, 225 µm and 330 µm. The larger the

particle the less their ability to hide. Therefore to achieve a convincing metallic appearance

the pigment loading has to be increased in relation to the particle size. In some cases the best

effect is obtained at a 10% aluminum pigment concentration particularly if the average parti-

cle size is 330 µm and higher.

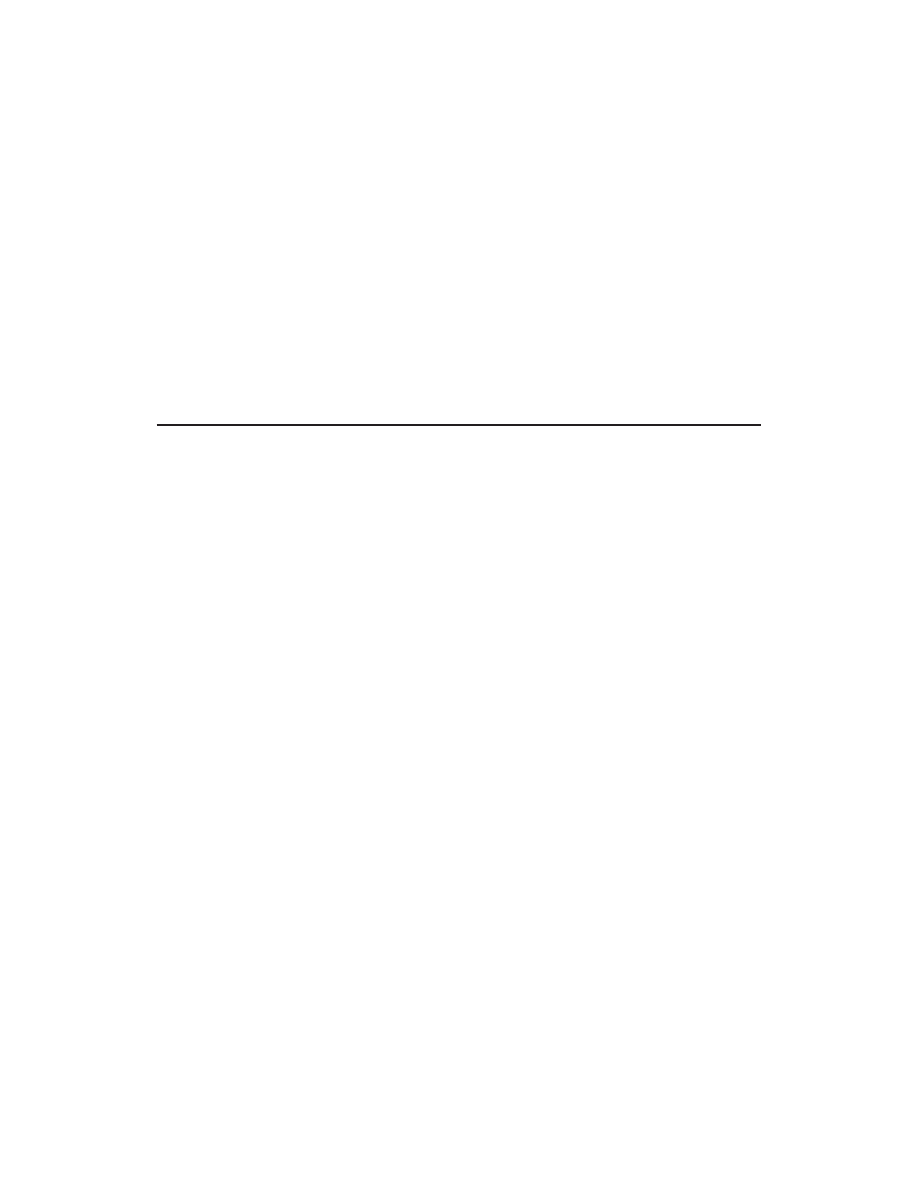

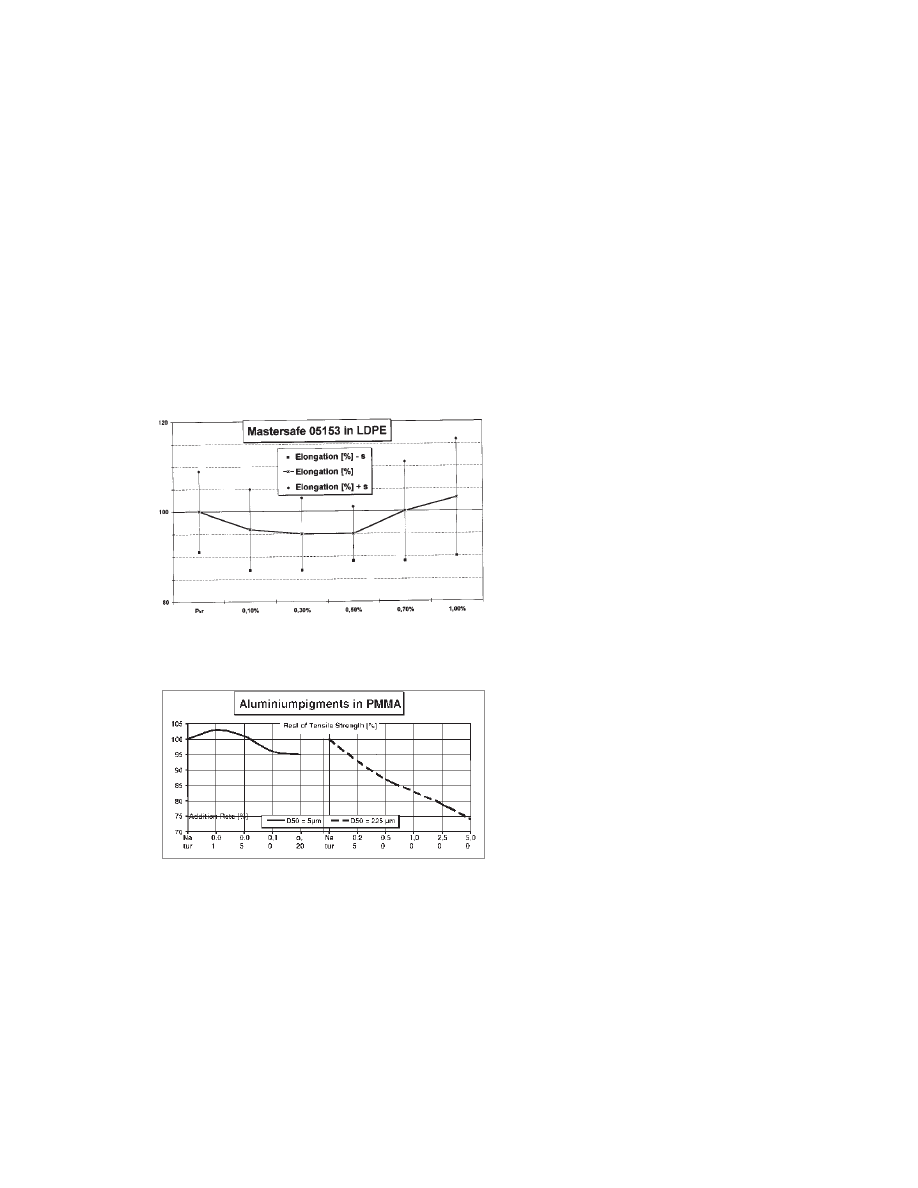

EFFECT ON PHYSICAL PROPERTIES

With increasing pigment concentration

some of the physical properties start to

suffer. As is evident from these mea-

surements the influence of aluminum

pigments on the physical properties de-

pends on the loading as well as on their

particle size. Aluminum pigments with

a particle size of 5 µm which are mainly

applied in films have little or no effect

on the film properties. While aluminum

with a particle size of which we are talk-

ing about here, i.e., 60 µm and larger re-

duce the tensile strength notably.

These properties will differ in

chemically different resins but even

chemically similar resins by different

supplier can show different perfor-

mance characteristics. However, in

many cases the lowering of the physical

properties can be tolerated depending

on the end use of the injection molded

part. It should be noted based on cus-

tomer reports that the physical proper-

ties of fiber reinforced polyamide parts

are not effected by such high aluminum

pigment loading.

Metallic Looking Plastics

51

Figure 1. Elongation vs. concentration of Mastersafe 05153 having

average particle size of 5

m µ

m.

Figure 2. Tensile strength vs. pigment concentration.

APPLICATIONS

Besides handles, toys, knobs and other plastic objects where a metallic appearance are desir-

able these type of aluminum pigments are widely applied in automotive parts under the hood.

These automotive parts are mostly made from reinforced polyamide resins and are pres-

ently mainly colored black. However, the automotive industry is making a strong effort to

give these parts a metallic appearance. Companies as VW and BMW are already equipping

there cars with metallic looking engine covers and others are also in the process of converting

from black to a silvery look.

COLORED ALUMINUM PIGMENTS

This concept of obtaining injection molded parts without flow lines was carried one step fur-

ther by creating colored aluminum pigments at a particle size of 125 µm. At the present time

three colors are available gold, blue and green. The colored aluminum pigments are manufac-

tured by depositing organic pigments on the aluminum which is then encapsulated by a silica

coating.

To insure excellent heat stability and good out door durability of these pigments only

colorants were selected which met these requirements like phthalo-blue and green. This gives

them a distinct advantage over cut aluminum foil which has mostly borderline heat stability

and is coated with a colored ink film. By adding a pigment layer plus a silica layer during the

production of these colored aluminum pigments their thickness increases to 12-15 µm mak-

ing them even less fragile during the dispersing and injection molding process thereby insur-

ing a brilliant, specular effect of the injection molded part.

STYLING POSSIBILITIES

Due to their own color these aluminum pigments offer unique styling possibilities. The best

effects are achieved in combination with dark colorants including black at a colored alumi-

num pigment level of 1.5%. In general, it is recommended to combine aluminum pigments

with transparent colorants because opaque pigments will hide the metallic effect.

However combinations of the colored aluminum pigments with different bronze pig-

ments offer very unusual rich looking shades. For these combinations the gold colored alumi-

num is less suited than blue and green.

PIGMENT CONCENTRATION OF COLORED ALUMINUM

When the object is to create a metallic looking plastic part, the function of the aluminum pig-

ment is to form a uniform layer within the molded product for which a high pigment loading

52

Coloring Technology for Plastics

up to 10% can be necessary. With colored aluminum, the object is to create unique color ef-

fects in combination with other mostly transparent colorants. To avoid that the other colors

are blocked out by the aluminum pigment. The loading of the metallic colorant should be

fairly low ranging from 0.2% to 1.5%.

CONCLUSIONS

By offering silver and colored metallic pigments, which avoid flow lines of injection molded

plastic parts due to their large particle size, totally new possibilities have been opened for

achieving brilliant, metallic like appearance and new, unique color effects of plastic products.

REFERENCES

1

B. Klein/H-H.Bunge, Cost Reduction by Metallic Pigments, Kunststoffe, 9/96.

Metallic Looking Plastics

53

Wyszukiwarka

Podobne podstrony:

Victoria Fontan Voices from Post Saddam Iraq, Living with Terrorism, Insurgency, and New Forms of T

Spanish Influence in the New World and the Institutions it I

Lumiste Betweenness plane geometry and its relationship with convex linear and projective plane geo

An Evolutionary Algorithm with Advanced Goal and Priority

All the Way with Gauss Bonnet and the Sociology of Mathematics

M 5009 Jacket with shawl collar and decorative trimming

Dua'a in Arabic with Englsih Translation and Transilitration

Whats Wrong with Our Food and Drugs

Nial Fuller Why I Only Trade With New York Close Forex Charts

Developing Your Intuition With Distant Reiki And Muscle Test

20 Disciplinary problems with very young and young learners age 4 11

Aerobic granules with inhibitory strains and role of extracellular polymeric substances

Getting Started with Data Warehouse and Business Intelligence

[16]Peroxynitrite reactivity with amino acids and proteins

new media and the permanent crisis of aura j d bolter et al

L 5009 Jacket with shawl collar and decorative trimming

Analysis of Roosevelt's New?al and the Great?pression

New Media and Politics syllabus EN

więcej podobnych podstron