* Corresponding author. Tel.: 0049 3731 39 2666; fax: 0049 3731

39 3129; e-mail:heimann@orion.hrz.tu-freiberg.de

1 In this paper the cement chemistry notation will be used: C"CaO,

P"P

2

O

5

, H"H

2

O, S"SiO

2

, T"TiO

2

and Z"ZrO

2

.

Biomaterials 19 (1998) 1507 — 1511

Development of plasma-sprayed bioceramic coatings with bond

coats based on titania and zirconia

H. Kurzweg

!, R.B. Heimann!,*, T. Troczynski", M.L. Wayman#

!Department of Mineralogy, Freiberg University of Mining and Technology, Brennhausgasse 14, 09596 Freiberg, Germany

"Department of Metals and Materials Engineering, University of British Columbia, Vancouver, Canada, B.C., V6T 1Z4

#Department of Chemical and Materials Engineering, University of Alberta, Edmonton, Alberta, Canada, T6G 2G6

Abstract

Bond coats for plasma-sprayed hydroxyapatite (HAp) coatings on Ti—6Al—4V hip endoprotheses are being developed for improved

in vivo performance. Bond coat powders consisting of (i) CaO-stabilized zirconia, (ii) a eutectic composition of titania and

non-stabilized zirconia, and (iii) titania were applied by atmospheric plasma spraying (APS) to Ti—6Al—4V-coupons and 100

lm-thick

Ti—6Al—4V foils. Subsequently, a thick layer of HAp was sprayed onto the thin bond coats.

Peel tests on Ti—6Al—4V foil/bond coat/HAp top coat assemblies revealed that titania and titania/ zirconia bond coats increased the

peel adhesion strength in a statistically significant way from 22 N m

~1 (HAp without a bond coat) to'42 and 32 N m~1, respectively.

Microstructural investigations by SEM on cross-sections of coatings leached in simulated body fluid for up to 28 days led to the

conclusion that the chemically very stable bond coats act as an improved chemical barrier against in vivo release of metal ions from

the implant, as well as an improved adhesive bond by development of very thin well-adhering reaction layers, presumbly composed of

perovskite, calcium dititanate, and/or calcium zirconate.

( 1998 Elsevier Science Ltd. All rights reserved

1. Introduction

Bioactive ceramics such as calcium phosphate in general,

and hydroxyapatite (C10P3H,1 HAp) in particular, are in

widespread use as implant substitute components or as

interfacing osseoconductive layers in metallic surgical

implants. Since incomplete fixation to living bone of

uncoated cementless joints for total hip replacement

(THP) is a common problem, application of hydroxyapa-

tite coatings by plasma spray processing to the surfaces

of titanium alloy hip endoprothetic implants constitutes

the state-of-the-art procedure to induce osseointegration

by bonding osteogenesis [1—3].

The in vivo performance of such coatings depends on

a large array of factors, most notably coating thickness,

chemical composition, crystallinity, phase purity, cohe-

sive and adhesive strengths, and resorption resistance

[4]. In particular, adhesion strength of the coating to

the implant surface appears to be a property that needs

to be maximized to avoid cracking, shearing off, and

chipping of the HAp coating during emplacement of the

implant.

Some limited improvement of the adhesion strength

can be achieved by carefully controlling the plasma spray

parameters [5], or by microstructural engineering of the

spray powder through pre-spray annealing [6]. A com-

pletely different way to achieve improved adhesion is to

consider biocompatible bond coats.

The aim is to support the mechanical inter-locking be-

tween the HAp-coating and the titanium alloy substrate

by a chemical bonding. Preliminary work indicated that

the application of a dicalcium silicate (C2S) bond coat

(10—50

lm thick)/hydroxyapatite top coat (30—130 lm

thick) system to a Ti—6Al—4V substrate by atmospheric

plasma spraying (Plasmadyne 3610-D; plasma current:

700—900 A; plasma gas: argon/helium 10%) led to a sta-

tistically significant increase of the adhesion strength to

over 30 MPa [7].

In applications for bioceramic coatings bond coats

should also, in addition to improving adhesion strength:

(1) prevent direct contact between Ti and HAp since this

is thought to catalyse the thermal transformation of

0142-9612/98/$19.00

( 1998 Elsevier Science Ltd. All rights reserved.

PII S 0 1 4 2 - 9 6 1 2 ( 9 8 ) 0 0 0 6 7 - 2

Table 1

Plasma spray conditions

(CaO)ZrO

2

TiO

2

#

ZrO

2

TiO

2

HAp

Plasma power

(kW)

42.2

42.2

41.6

25.8

Argon : Hydrogen (l min

~1) 40 : 12

40 : 12

40 : 12

50 : 4

Carrier gas Ar

(l min

~1) 2.6

2.6

2.6

6.0

Powder feed rate (g min

~1) 18.5

23.0

20.0

23.5

Stand-off

(mm)

100

100

80

100

distance

HAp towards tri- or tetracalcium phosphate or even

non-biotolerant CaO [8, 9],

(2) reduce the release of metal ions from the substrate to

the surrounding living tissue that has been shown to

induce massive hepatic degeneration in mice [10] and

impaired development of human osteoblasts [11],

(3) reduce the thermal gradient at the substrate/coating

interface caused by the rapid quenching of the molten

particle splats that leads to deposition of amorphous

HAp with a concurrent decrease in resorption resis-

tance [6] and hence to reduced in vivo performance,

i.e. longevity of the implant,

(4) prevent a steep gradient in the coefficients of thermal

expansion between substrate and coating that pro-

motes the formation of strong tensile forces in the

coating giving rise to crack generation, chipping

and/or delamination, as well as

(5) cushion damage by cracking and delamination of the

coating initiated by cyclic micromotions of the im-

plant during movement of the patient in the initial

phase of the healing process [12].

Thus, it is highly desirable to engineer the substrate/

HAp coating interface in such a way that by application

of a suitable thin biocompatible bond coat layer the

advantages addressed above can be realized.

Suitable bond coats are being developed within the

binary system ZrO2—TiO2 [13]. The plasma spray

conditions, the in vitro resorption resistance and the

adhesion strength of those coating systems will be de-

scribed below.

2. Plasma spraying of hydroxyapatite/ bond coat systems

Various hydroxyapatite/bond coat systems were

plasma sprayed onto grit-blasted Ti—6Al—4V coupons

of dimension 50

]20]2 mm3 and onto Ti—6Al—4V foils

of dimensions 120

]16]0.1 mm3 using atmospheric

plasma spray equipment (Plasmatechnik AG, F4 torch).

Grit blasting of the coupons was performed using silicon

carbide (grain size range 0.71—1.0 mm) at an air pressure

of 500 kPa and a distance of 50 mm from the target. Grit

blasting of the foils was done using alumina grit

(600—800

lm) at an air pressure of 250 kPa and a distance

of 50 mm. After grit blasting the coupons and foils were

cleaned ultrasonically with acetic acid ethylester and

ethyl alcohol. Foils were attached to copper blocks using

a 1 : 2 mixture (by weight) of a silicone sealant (Dow

Corning 732) and copper powder (ALCAN 154, grain

size range (44

lm). The adhesive was cured at room

temperature for 12 h. The presence of copper powder in

the adhesive provides, during plasma spraying, excellent

conduction of heat away from the foil into the copper

block acting as an effective heat sink. The type of adhes-

ive used allows for an easy removal of the foil from the

copper block for post-spray sample preparation.

Bond coats of thickness 10—15

lm, deposited onto

Ti—6Al—4V substrate coupons and foils, consisted of par-

tially CaO-stabilized zirconia (DYNAZIRKON C, Hu¨ls

AG, grain size 0.45—60

lm, series 2), a mechanically

mixed powder of 73 mol% titania and 27 mol% non-

stabilized zirconia, corresponding to the eutectic com-

position (Type 9303, Carl Roth GmbH, grain sizes

0.18—26

lm, series 3), and titania (AMDRYTM 6500, Sul-

zer Metco GmbH, grain size 5—22

lm, series 4). The

plasma spray parameters used are shown in Table 1.

Subsequently, a thick (150—180

lm and 100—120 lm, re-

spectively) layer of hydroxyapatite (AMDRY

TM 6021,

Sulzer Metco Deutschland GmbH) was sprayed onto the

bond coat using the parameters shown in Table 1. In

addition, foils were sprayed with HAp using the same

parameters but without using a bond coat (series 1) to

establish a bench mark for estimating the effect of the

various bond coats on the adhesion behaviour.

3. The in vitro resorption resistance

Investigations into the microstructure and the chem-

ical behaviour during immersion in simulated body fluid

(Hank’s Balanced Salt Solution, HBSS) will give valuable

information on the anticipated in vivo performance of

such coating systems.

5 mm slices cut from the as-sprayed coupons were

immersed in 50 ml of simulated body fluid (Hank’s Bal-

anced Salt Solution, HBSS) for 7, 14 and 28 days to study

the in vitro resorption resistance of the various coating

systems. The composition of HBSS is shown in Table 2.

The leaching experiments were performed in cylindrical

glass containers held in a constant temperature bath at

37$0.5°C. At the end of the leaching period the sample

was removed from the HBSS, cleaned with distilled

water, acetone and methanol, and dried in a dust-free

environment.

After the immersion the samples were investigated by

SEM.

It could be shown that the HAp coatings onto titanium

alloy substrates with various bond coats, display differ-

ent stability against leaching in HBSS. In particular,

1508

H. Kurzweg et al. / Biomaterials 19 (1998) 1507—1511

Table 2

Composition of Hank’s Balanced Salt Solution in 1 l deionized water

8000 mg NaCl

140 mg CaCl2

400 mg KCl

100 mg MgCl2

60 mg Na2HPO4

60 mg KH2PO4

1000 mg MgSO4

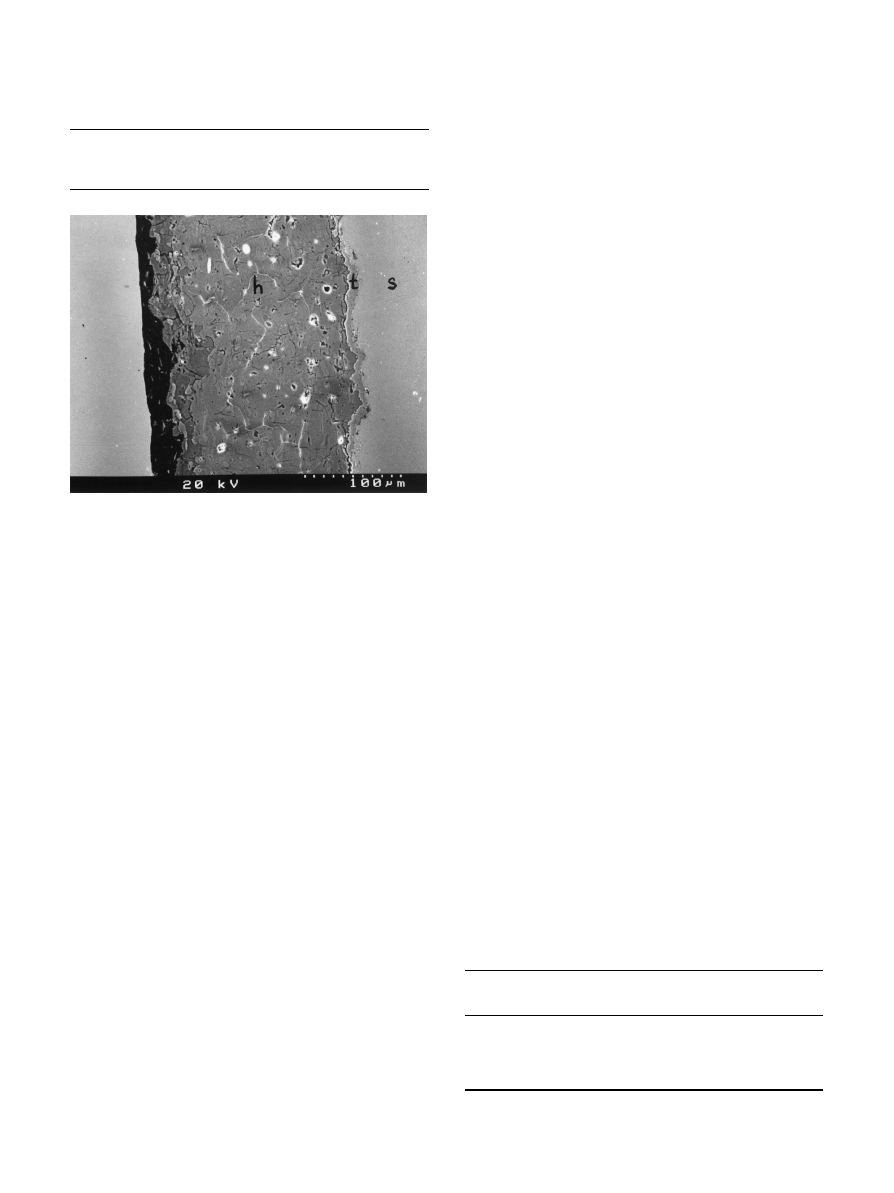

Fig. 1. SEM micrograph of a cross-section of a titania bond coat/hy-

droxyapatite top coat system.

Table 3

Calculated peel strengths (N/m) for the coating systems investigated

Series

Regression line

Peel strength

Dt

3

(a)

D

t

.,2

(N/m)

1

y"34.7#1.59x

21.9

2

y"30.3#1.68x

18.0

2.54

2.07

3

y"51.1#1.61x

31.8

2.15

2.06

4

y"65.2#1.55x

42.1

2.67

2.07

stresses introduced into the hydroxyapatite by thermally

induced transformation of the zirconia bond coat (series

2) lead to extensive scaling and concurrent leaching dur-

ing treatment in HBSS. In contrast to this, titania/zirco-

nia bond coat/ HAp top coat (series 3) and, in particular,

titania bond coat/HAp top coat ‘tandems’ (series 4) stand

up well to the leaching with little damage done to the

cohesion of the coating system. For the latter samples the

amounts of titania and zirconia measured in the HBSS

after 28 days remained below 5 ng l

~1.

Figure 1 shows a sample of series 4 leached for 28 days

in HBSS. The cross-section shows the titania bond coat

very well adhering to the titanium alloy substrate that in

some places has separated from the HAp top coat, pre-

sumably due to damage done during preparation. The

outermost leached HAp layer of approximately 30

lm

thickness has a Ca/P ratio of 1.27 and shows some

cracking perpendicular to the interface indicating mech-

anical weakening during leaching.

4. The peel adhesion test

Since the uncontrolled mode of coating/ substrate sep-

aration in the conventional tensile pull test contributes to

a large extent to the uncertainty of the test results a modi-

fied ASTM D3167-76 peel test was introduced recently

[14, 15].

A thin metal foil is attached to a massive copper block

that provides mechanical support and acts as a heat sink.

After grit blasting a coating is deposited onto this thin

metal foil. The block, foil and coating assembly is glued

to a stiff aluminium plate, and the copper block is then

removed. The coated titanium foil/epoxy/aluminium

plate assembly was mounted on a jig (for a detailed

description cp.[14]) in an INSTRON 4200 universal test-

ing machine (Instron Corporation, Canton, MA). The

end of the foil was clamped to the upper grip of the

machine and pulled away from the coating at a constant

rate of 2.5 mm min

~1. The load and the crosshead dis-

placement were recorded digitally, and the correspond-

ing stress—strain curve calculated from the recorded data.

Different dead weights were attached to the other end of

the foil in order to make the foil conform to the mandrel

of the jig. The peeling force was averaged over 5—10 mm

of crosshead displacement, and more weight was added

as the test progressed. Since the measured force is

the sum of the peel force, the dead weight, the fric-

tional force and the plastic work per increment

peeled, from a plot of the measured force versus the

known dead weight, the peel force can be obtained

[16, 17]. Peeling off the foil from the coating causes

a crack to propagate precisely along the coating/foil

interface in a stable and controllable manner since the

sample geometry forces the crack tip to move along the

interface [18] where it encounters the local least-energy

path. While the conventional tensile pull test measures

failure stress, expressed as the ratio of applied force to

coating area in dimension: N m

~2, the novel peel test

measures the energy required to separate the coating and

the foil along a line in dimension: N m

~1.

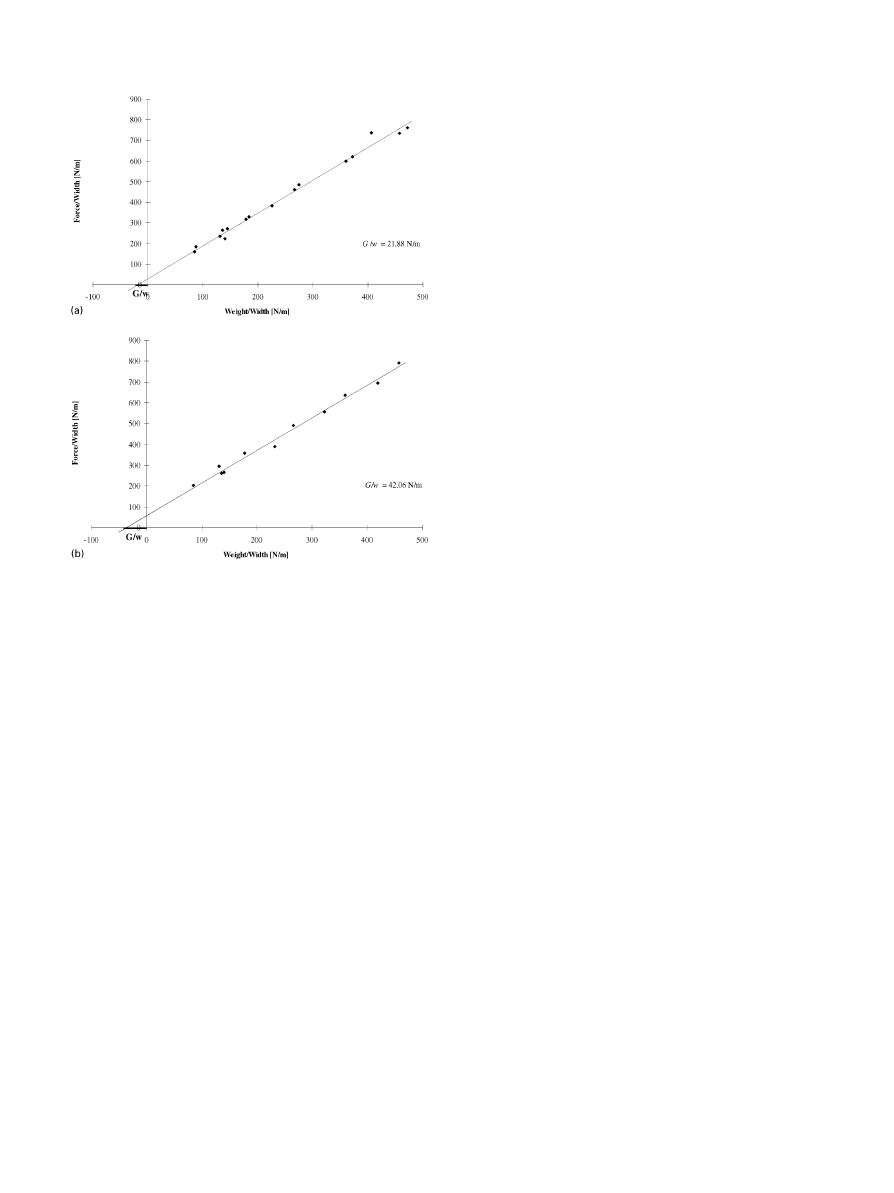

Fig 2 shows typical results of the peel adhesion test.

Here the normalized total force (F/w) is plotted against

dead weight (D/w) from which lines the normalized peel

strengths (G/w) of a hydroxyapatite coating without

a bond coat (series 1, Fig. 2a) and a hydroxyapatite/

titania bond coat system (series 4, Fig. 2b) were

calculated. The calculated peel strengths of all samples

are shown in Table 3 together with the relevant linear

regression lines y"a#bx where x is the normalized

dead weight D/w.

Based on the comparison of the intersection with the

y-axes, (a) of series 1 (no bond coat) to series i (i"2, 3, 4),

a significance test was done [19]. The calculated

Dt3(a)D-

values are always higher than the tabulated t.,2 values

H. Kurzweg et al. / Biomaterials 19 (1998) 1507—1511

1509

Fig. 2. Peel strength of series 1 (a) and series 4 (b).

for m degrees of freedom and a level of confidence

a"0.05. These values are also included in Table 3. Thus,

there is a significant difference between the peel strengths.

It can be shown that series 2 (CaO-stabilized zirconia)

has a significantly lower peel adhesion strength than the

HAp coating without a bond coat. On the other hand,

the results for series 3 (titania/zirconia bond coat) and

series 4 (titania) show that those bond coats improve the

peel adhesion strength in a statistically significant way. In

particular, a titania bond coat leads to a peel strength

twice the value of a HAp coat without a bond coat. The

reason for this behaviour may be seen in the development

of a thin reaction zone at the immediate interface be-

tween bond coat and HAp top coat consisting of calcium

titanates and/or zirconates [20]. Calcium titanates have

been reported to occur at the interface of a titanium

substrate terminated by a thin layer of native oxide and

a HAp coating by de Groot et al. [1] (perovskite, CT)

and Ji et al. [9] (calcium dititanate, CT2).

5. Summary

Bond coats for plasma-sprayed hydroxyapatite (HAp)

coatings on titanium alloy hip endoprotheses are being

developed for improved in vivo performances.

The application of various bond coats based on titania

and zirconia to the Ti—6Al—4V substrate influences the

adhesion of the entire coating ‘tandem’ (bond coat#

HAp top coat). Titania/zirconia (73/27 mol%) and

titania bond coats increase the peel strength by 50% and

100%, respectively.

It could be shown that the HAp coatings, APS-

sprayed onto Ti—6Al—4V substrates with various bond

coats, display different stability against leaching in

simulated body fluid (HBSS).

Titania/zirconia bond coat/HAp top coat and, in par-

ticular, titania bond coat/HAp top coat ‘tandems’ stand

up well to the leaching with little damage done to the

cohesion of the coating system.

Acknowledgements

The support of the first author (HK) by the Studienstif-

tung des deutschen Volkes (Education Foundation of the

German People) during a four-months student visit to

the Department of Metals and Materials Engineering,

University of British Columbia, Vancouver, B.C., Cana-

da is gratefully acknowledged. One of the authors

(R.B.H.) is indebted to the German Federal Ministry of

Education, Research, Science and Technology (BMBF)

for sponsoring a four-months sabbatical at the Depart-

ment of Chemical and Materials Engineering, University

of Alberta, Edmonton, Alberta, Canada within the aus-

pices of the German—Canadian Agreement on Scientific

and Technological Cooperation, during which part of

this work was carried out. Thanks are also due to Dr.

Walter Kunert, Freiberger Nichteisen-Metall GmbH,

Freiberg, Germany who kindly granted access to the

plasma spray equipment and to Dr. N. Dorin Ruse and

Ms. Edith Breslauer, Faculty of Dentistry, University of

British Columbia for providing access to the Instron

universal testing machine.

References

[1] de Groot K, Geesink RTG, Klein CPAT, Serekian P. J Biomed

Mater Res 1987;21:1375.

[2] Klein CPAT, Patka P, van der Lubbe HBM, Wolke JGC, de

Groot K. J Biomed Mater Res 1991;25:53.

[3] Caulier H, van der Waerden JPCM, Wolke JGC, Kalk W, Naert

I, Jansen JA. In: P. Vincenzini Techna Srl, editors. Materials in

Clinical Application 1995:477.

[4] Heimann RB, Vu TA, Wayman ML. Europ J Mineral 1997;

9:597.

[5] Yang CY, Wang BC, Chang E, Wu JD. J Mater Sci: Mater Med

1995;6:249.

[6] Heimann RB, Vu TA. J Thermal Spray Technol 1997;6:145.

[7] Vu TA, Heimann RB. Second Interim Report SMWK Project

d 7541.82-0390/414, 15 February 1996.

[8] Weng J, Liu X, Zhang X, Ji X. J Mater Sci Lett 1994;13:159.

[9] Ji H, Ponton CB Marquis PM. J Mater Sci: Mater Med

1992;3:283.

[10] Pereira ML, Abreu AM, Sousa JP, Carvalho GS. J Mater Sci

Mater Med 1995;6:523.

1510

H. Kurzweg et al. / Biomaterials 19 (1998) 1507—1511

[11] Tomas H, Carvalho GS, FerNandes MH, Freire AP, Abrantes

LM. J Mater Sci: Mater Med 1996;7:291.

[12] S

+balle K. Acta Orthop Scand 1993;255(64):58.

[13] Kurzweg H. PhD thesis, Freiberg University of Mining and

Technology, Germany, in progress.

[14] Sexsmith M, Troczynski T. J Thermal Spray Technol 1996;3(4):

404.

[15] Sexsmith M, Troczynski T. J Thermal Spray Technol 1996;

5:196.

[16] Sexsmith M, Troczynski T, Breslauer E. J Adhes Sci Technol,

in press.

[17] Breslauer E, Troczynski T. J Adhes Sci Technol, to be published.

[18] Crocombe A, Adams R. J Adhes 1981;12:127.

[19] Storm R. Wahrscheinlichkeitsrechnung, mathematische Statistik

und statistische Qualita¨tskontrolle. Fachbuchverlag 1995:253—6.

[20] Figueiredo MO, Correia DOS, Santos A. In: Meriani S, Pal-

monari C, editors. Zirconia ’88. Advances in Zirconia Science and

Technology, London, New York, Elsevier, 1989:81.

H. Kurzweg et al. / Biomaterials 19 (1998) 1507—1511

1511

Wyszukiwarka

Podobne podstrony:

Microstructure and mechanical properties of plasma sprayed H

Activity of plasma sprayed yttria stabilized zirconia reinfo

Development of Carbon Nanotubes and Polymer Composites Therefrom

Development of BBM turbine

Development of financial markets in poland 1999

Development of a highthroughput yeast based assay for detection of metabolically activated genotoxin

01 [ABSTRACT] Development of poplar coppices in Central and Eastern Europe

43 597 609 Comparison of Thermal Fatique Behaviour of Plasma Nitriding

Development of vertical bulb turbine

Development of organic agriculture in Poland, Technologie

Aristoteles # Guthrie (The Development of Aristotle's Theology 1) BB

Development of wind turbine control algorithms for industrial use

An experimental study on the development of a b type Stirling engine

DEVELOPMENT OF FACTORING MARKET IN TURKEY

Progressive development of sonographic features

Advanced Methods for Development of Wind turbine models for control designe

Development of Communist Theory

Development of Plot Plan

więcej podobnych podstron