2009 ENGINE

Ignition Control - Service Information - Grand Caravan, Town & Country

DESCRIPTION

DESCRIPTION

The 3.3/3.8L engines use a distributorless ignition system and is commonly referred to as Direct Ignition

System (DIS). The 4.0L engine uses a Coil on Plug design. The system's main components are the ignition

coils, crankshaft position sensor, camshaft position sensor and spark plugs.

OPERATION

OPERATION

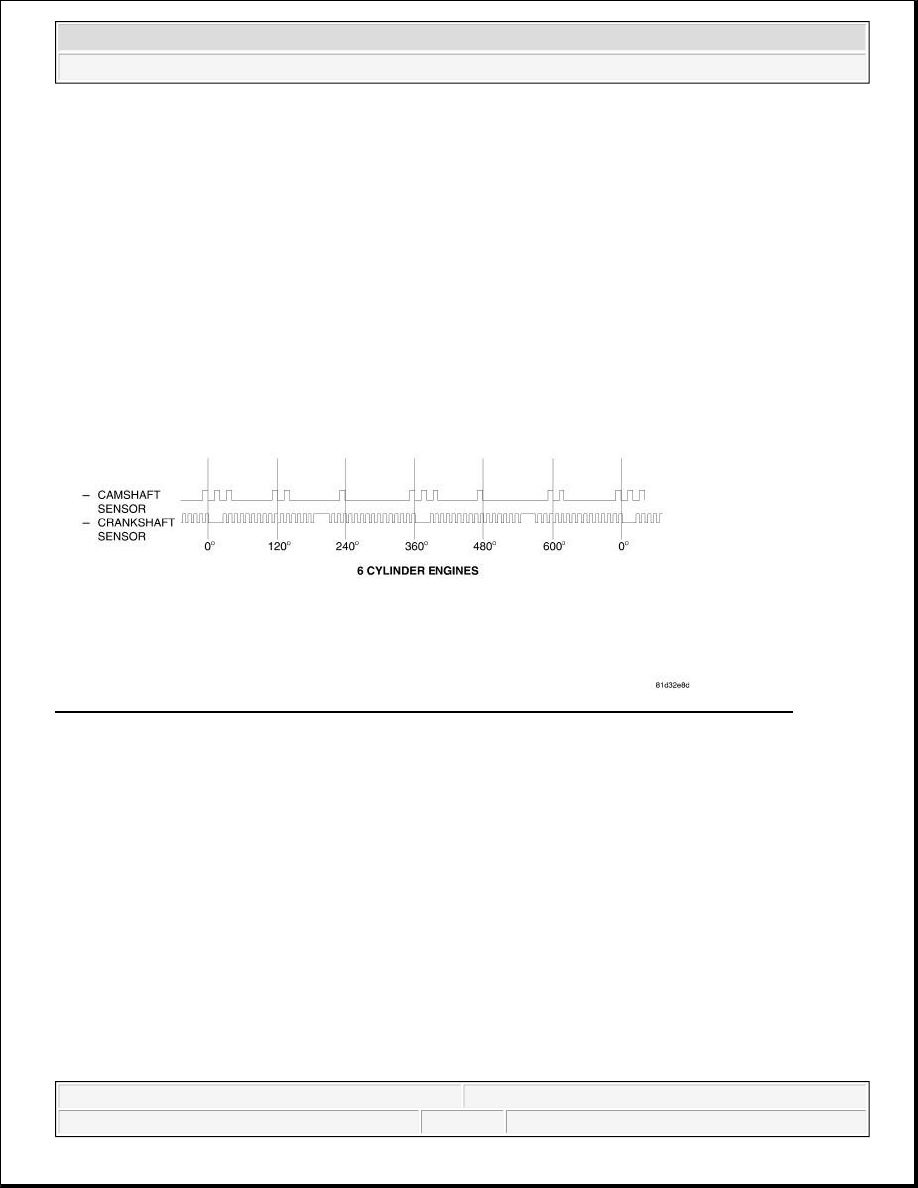

The crankshaft position sensor and camshaft position sensor are hall effect devices. The camshaft position

sensor and crankshaft position sensor generate square wave pulses that are inputs to the PCM. The PCM

determines engine position from these sensors. The PCM calculates injector sequence and ignition timing from

crankshaft AND camshaft position.

SPECIFICATIONS

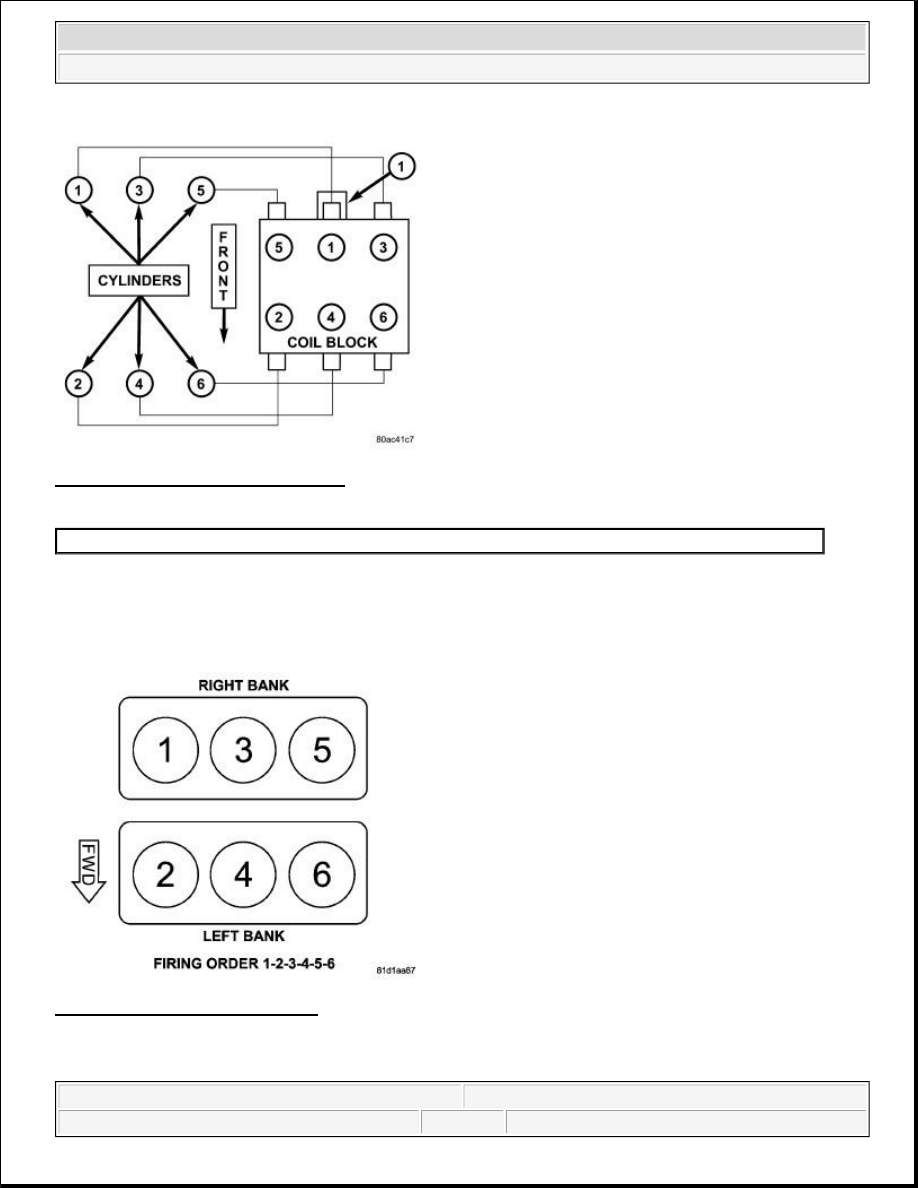

FIRING ORDER

3.3/3.8L

NOTE:

All engines use a fixed ignition timing system. Basic ignition timing is not

adjustable. All spark advance is determined by the Powertrain Control Module

(PCM).

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 1

© 2006 Mitchell Repair Information Company, LLC.

steve

Monday, May 30, 2011 12:02:14 PM

Page 1

© 2006 Mitchell Repair Information Company, LLC.

Fig. 1: Firing Order - 3.3/3.8L Engine

Courtesy of CHRYSLER LLC

The firing order is 1-2-3-4-5-6.

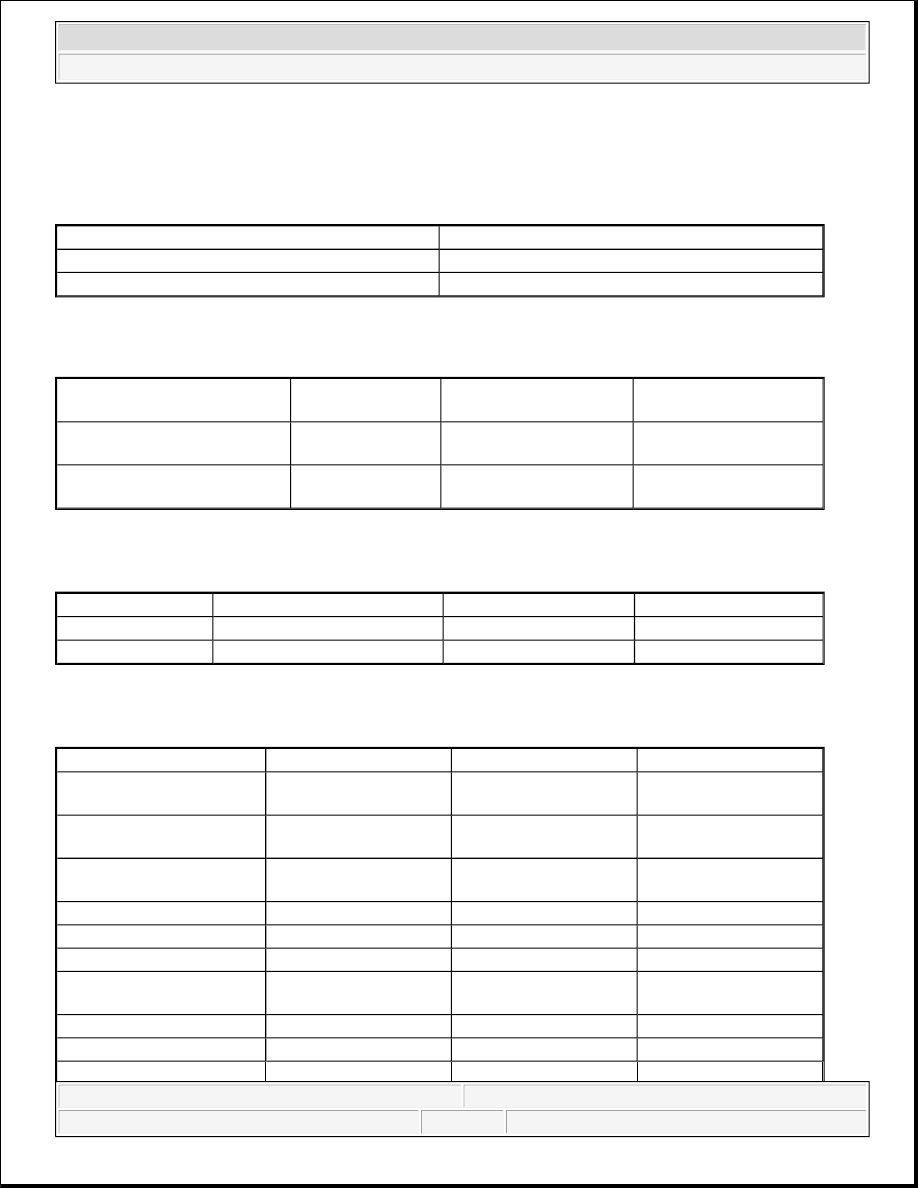

4.0L

Fig. 2: Firing Order - 4.0L Engine

Courtesy of CHRYSLER LLC

The firing order is 1-2-3-4-5-6.

1 - Electrical Connector

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 2

© 2006 Mitchell Repair Information Company, LLC.

IGNITION RESISTANCE

IGNITION CABLE RESISTANCE

IGNITION CABLE RESISTANCE

IGNITION COIL RESISTANCE

IGNITION COIL RESISTANCE

SPARK PLUGS

SPARK PLUGS

TORQUE

TORQUE

MINIMUM

MAXIMUM

250 Ohms Per Inch

750 Ohms Per Inch

3000 Ohms Per Foot

9,000 Ohms Per Foot

Manufacturer

Engine

Primary Resistance at

21°C-27°C (70°F-80°F)

Secondary Resistance at

21°C-27°C (70°F-80°F)

Diamond Electric Mfg.

Corporation

3.3, 3.8L

0.530 to 0.650 ohms

10.9K to 14.7K ohms

Diamond Electric Mfg.

Corporation

4.0L

0.495 to 0.605 ohms

5.13K to 6.27K ohms

Engine

Spark Plug

Electrode Gap

Thread Size

3.3/3.8L

RE14PLP5

1.27 mm (0.050 in.)

M14 X 1.25

4.0L

ZFR5LP-13G

1.27 mm (0.050 in.)

M14 X 1.25

DESCRIPTION

N.m

Ft. Lbs.

In. Lbs.

Camshaft Position Sensor

Bolt 2.8L

5.4

-

48

Camshaft Position Sensor

Bolt 3.3/3.8L

14

10

-

Camshaft Position Sensor

Bolt 4.0L

12

9

-

Knock Sensor 3.3/3.8L

20

15

-

Knock Sensor 4.0L

20

15

-

Ignition Coil Bolt 4.0L

8

-

71

Ignition Coil Capacitor Bolt

4.0L

28

20.5

-

Ignition Coil Nuts 3.3/3.8L

12

-

106

Spark Plug 3.3/3.8L

17.5

13

-

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 3

© 2006 Mitchell Repair Information Company, LLC.

CABLE, IGNITION

REMOVAL

REMOVAL

Disconnect and isolate negative battery cable at battery.

Remove spark plug cable from coil first.

Always remove the spark plug cable by grasping the top of the spark plug insulator, turning the boot 1/2 turn

and pulling straight up in a steady motion.

INSTALLATION

INSTALLATION

Failure to route the cables properly could cause the radio to reproduce ignition noise, cross ignition of the spark

plugs or short circuit the cables to ground. Install spark plug insulators over spark plugs. Ensure the top of the

spark plug insulator covers the upper end of the spark plug tube, then connect the other end to coil pack.

Install negative battery cable to battery.

CAPACITOR, IGNITION

REMOVAL

REMOVAL

Spark Plug 4.0L

27

20

-

Negative Battery Cable Nut

5

-

45

WARNING:

Always turn the engine off and disconnect the battery prior to servicing

the spark plug cables. Do not attempt to remove a spark plug cable while

the motor is running. Failure to follow these directions may result in

serious or fatal injury.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 4

© 2006 Mitchell Repair Information Company, LLC.

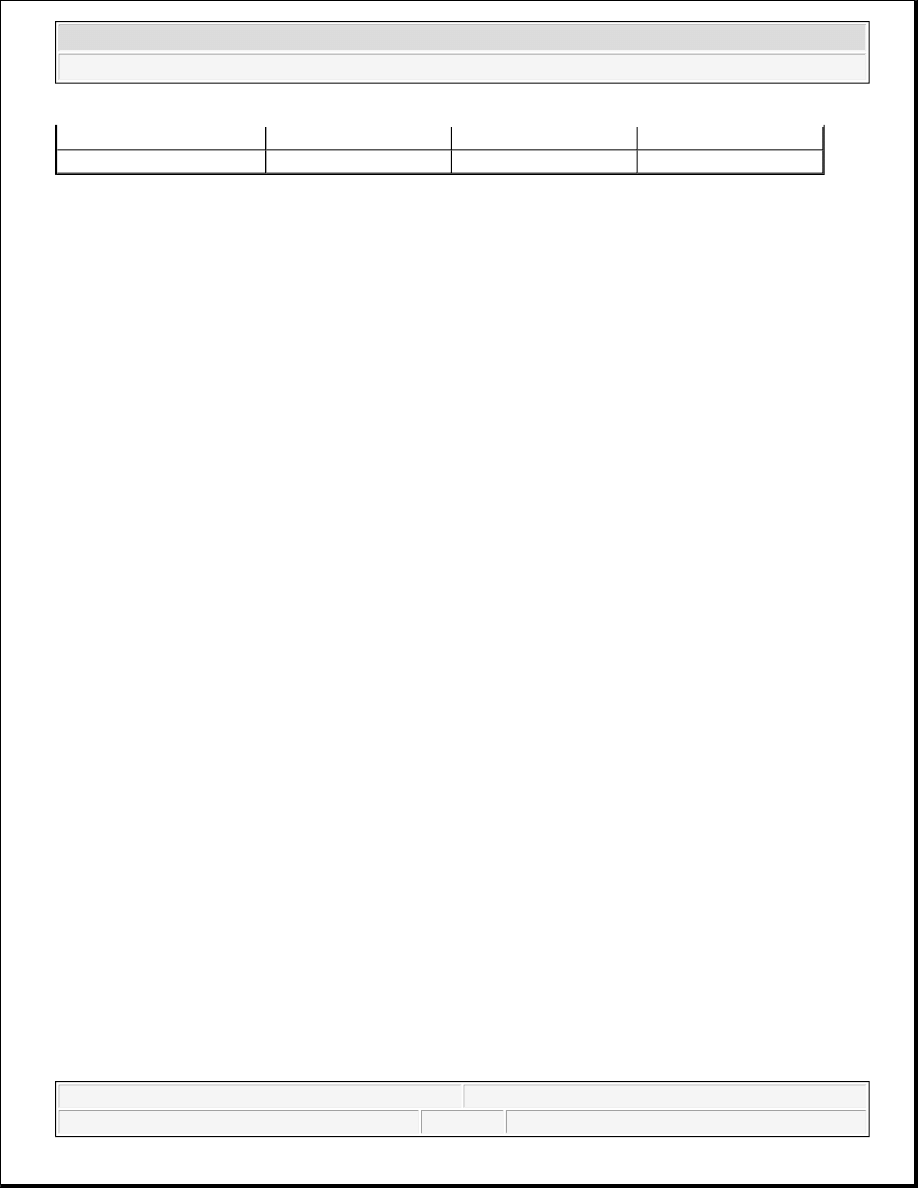

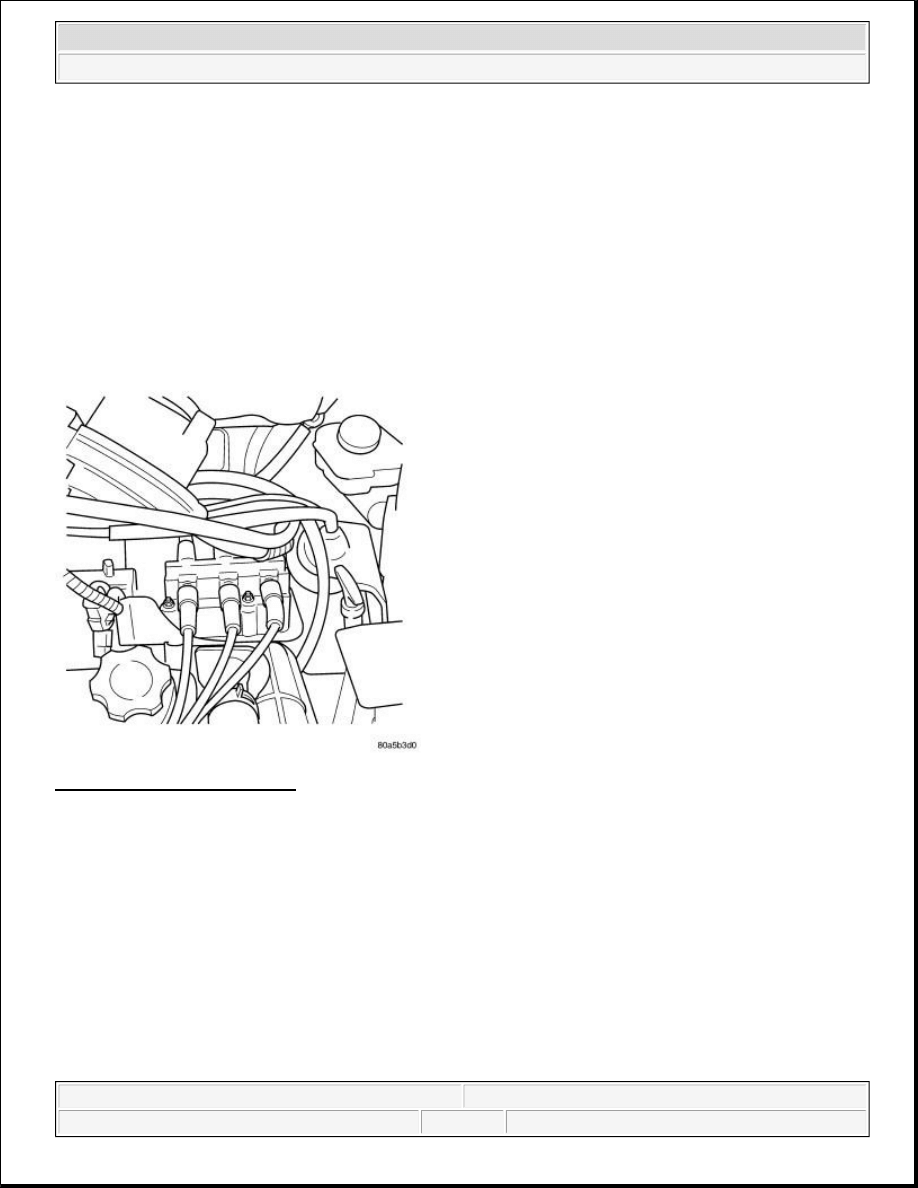

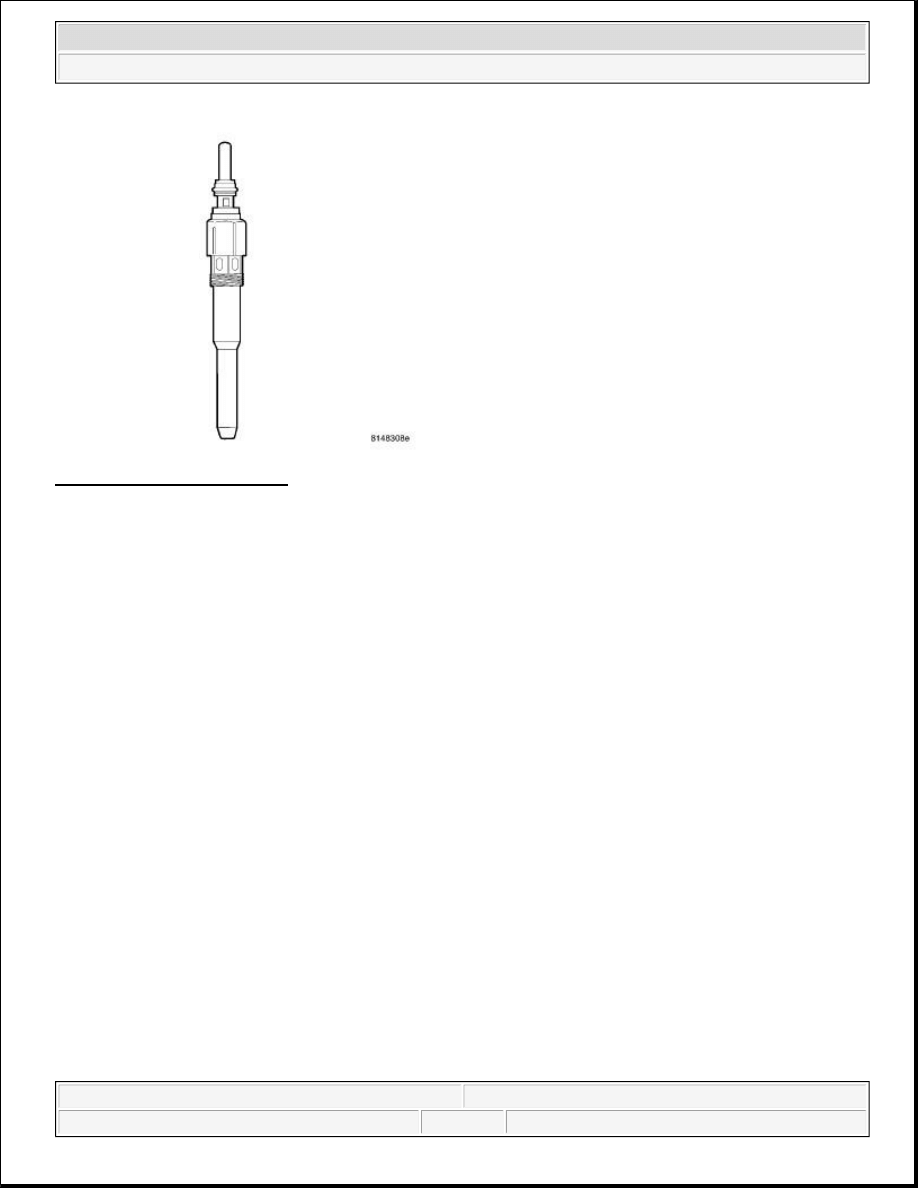

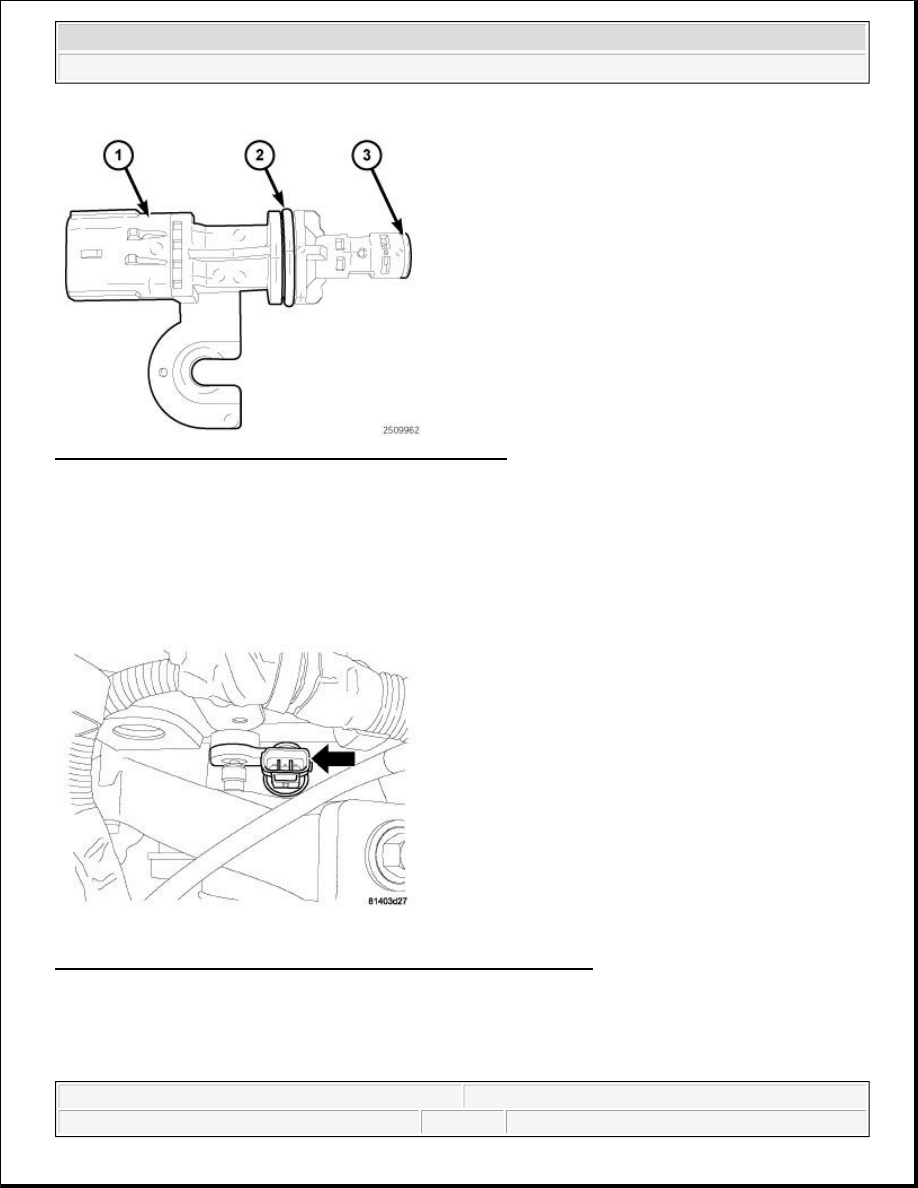

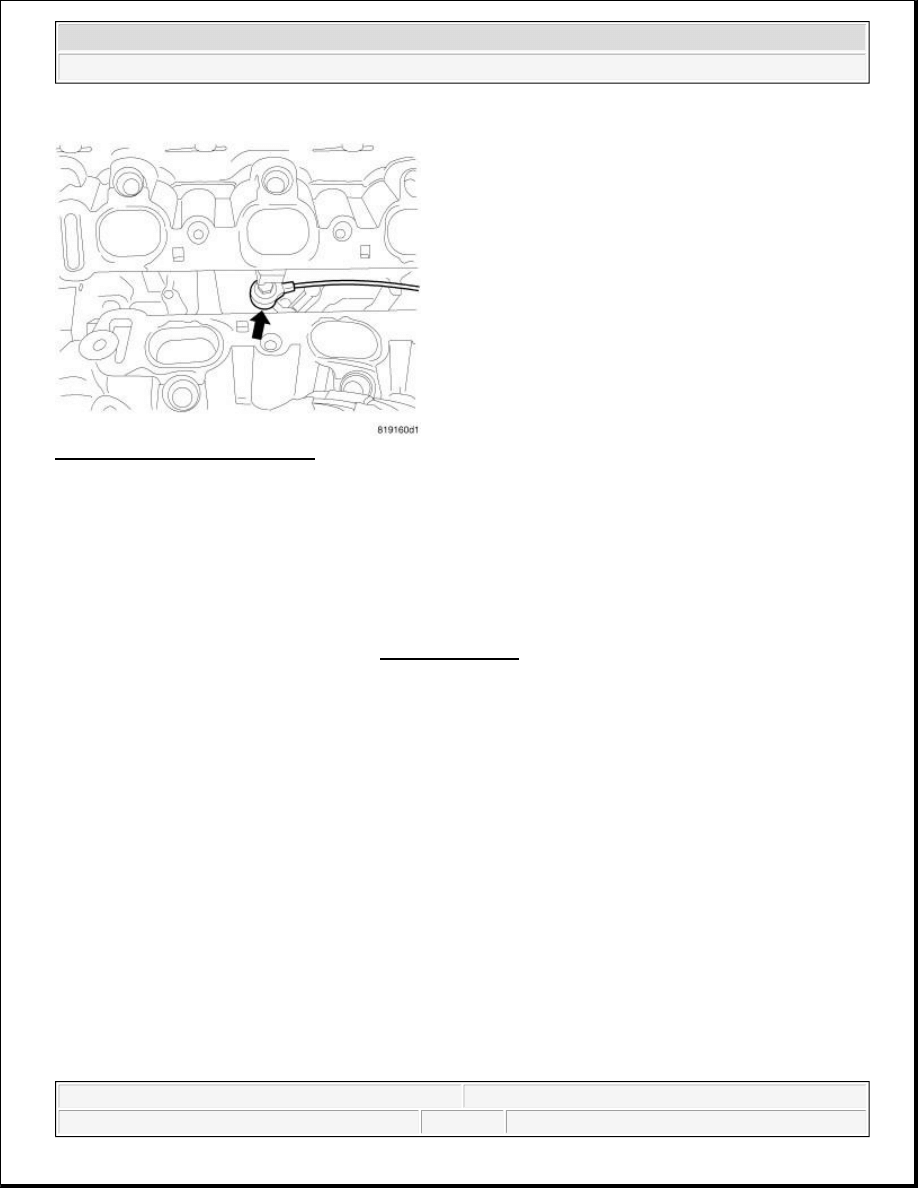

Fig. 3: Removing/Installing Ignition Capacitor

Courtesy of CHRYSLER LLC

The ignition capacitor is located on the drivers side of the engine.

1. Disconnect and isolate the negative battery cable at battery.

2. Remove electrical connector (3).

3. Remove mounting bolt (1) and ignition capacitor (2).

INSTALLATION

INSTALLATION

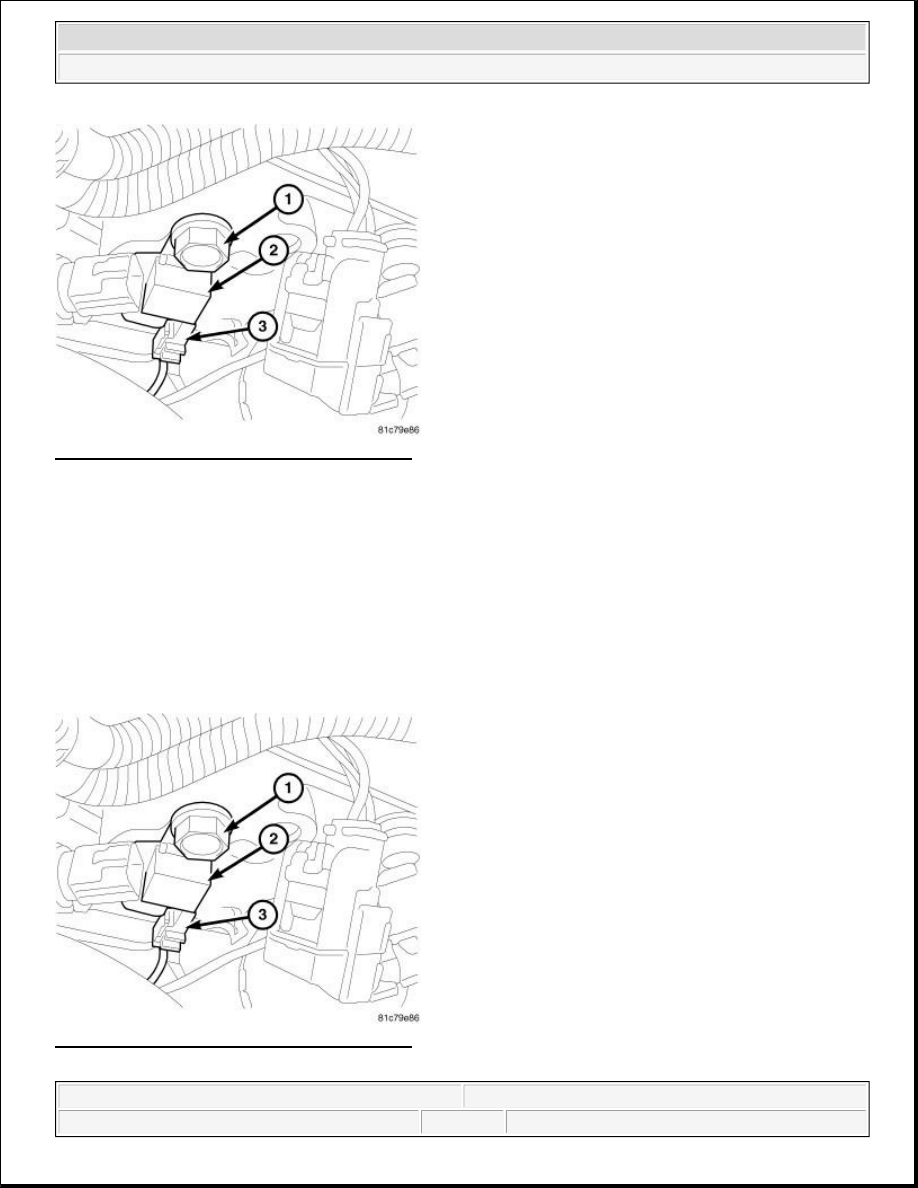

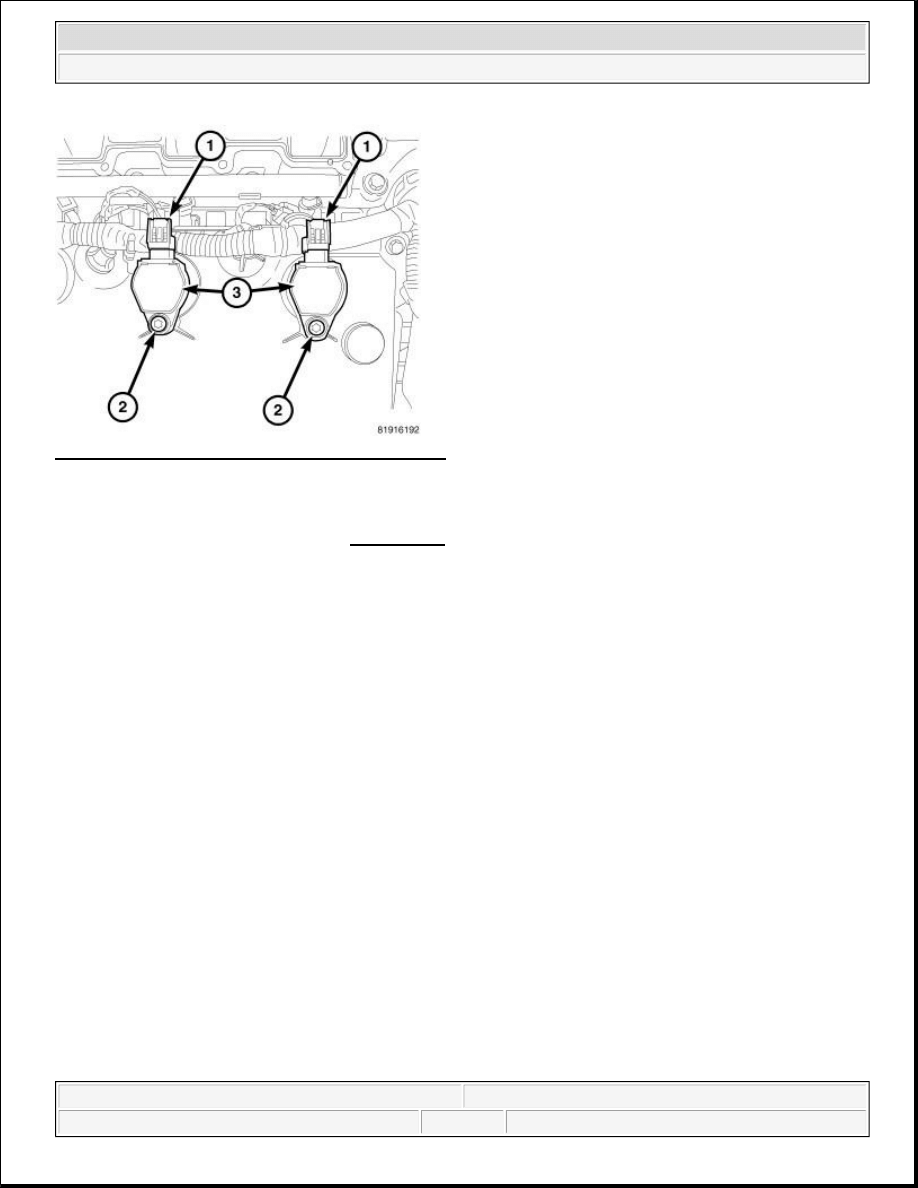

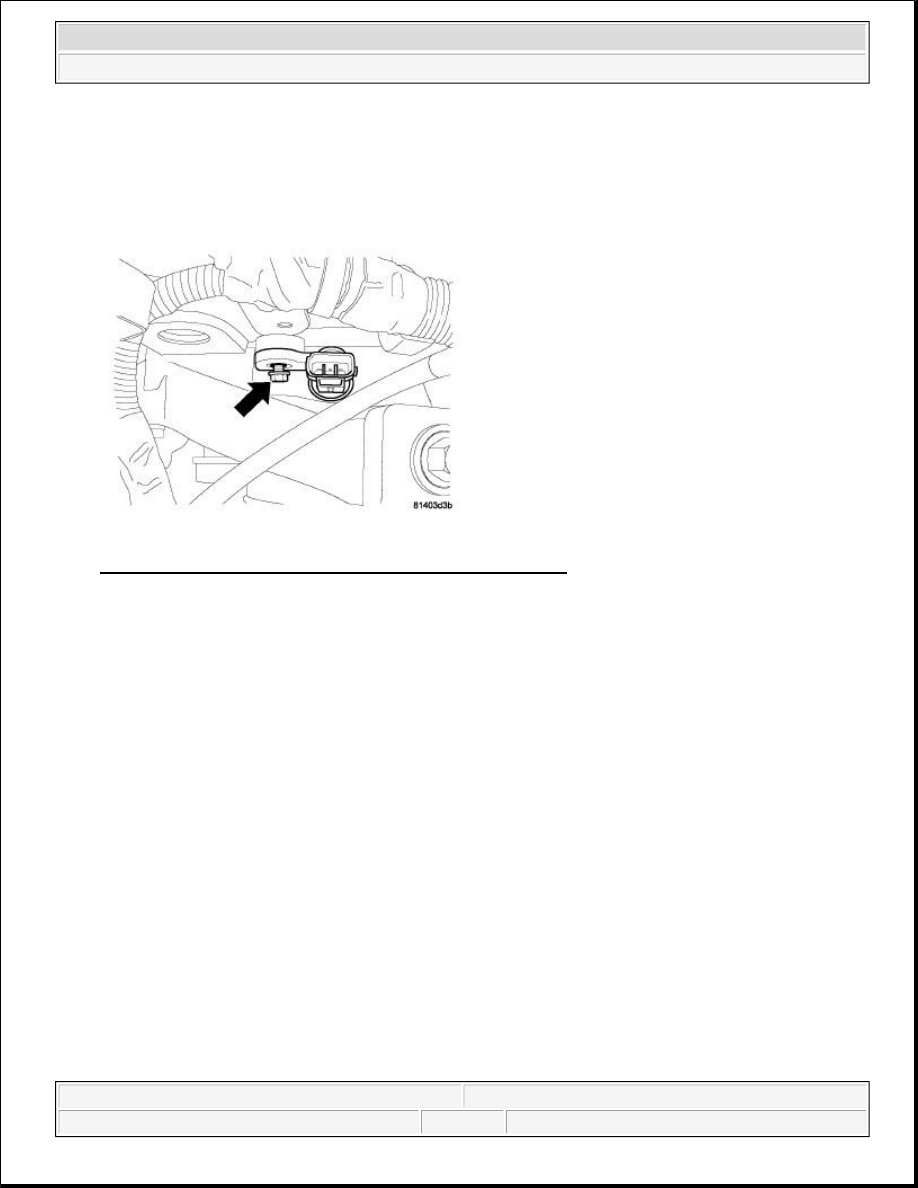

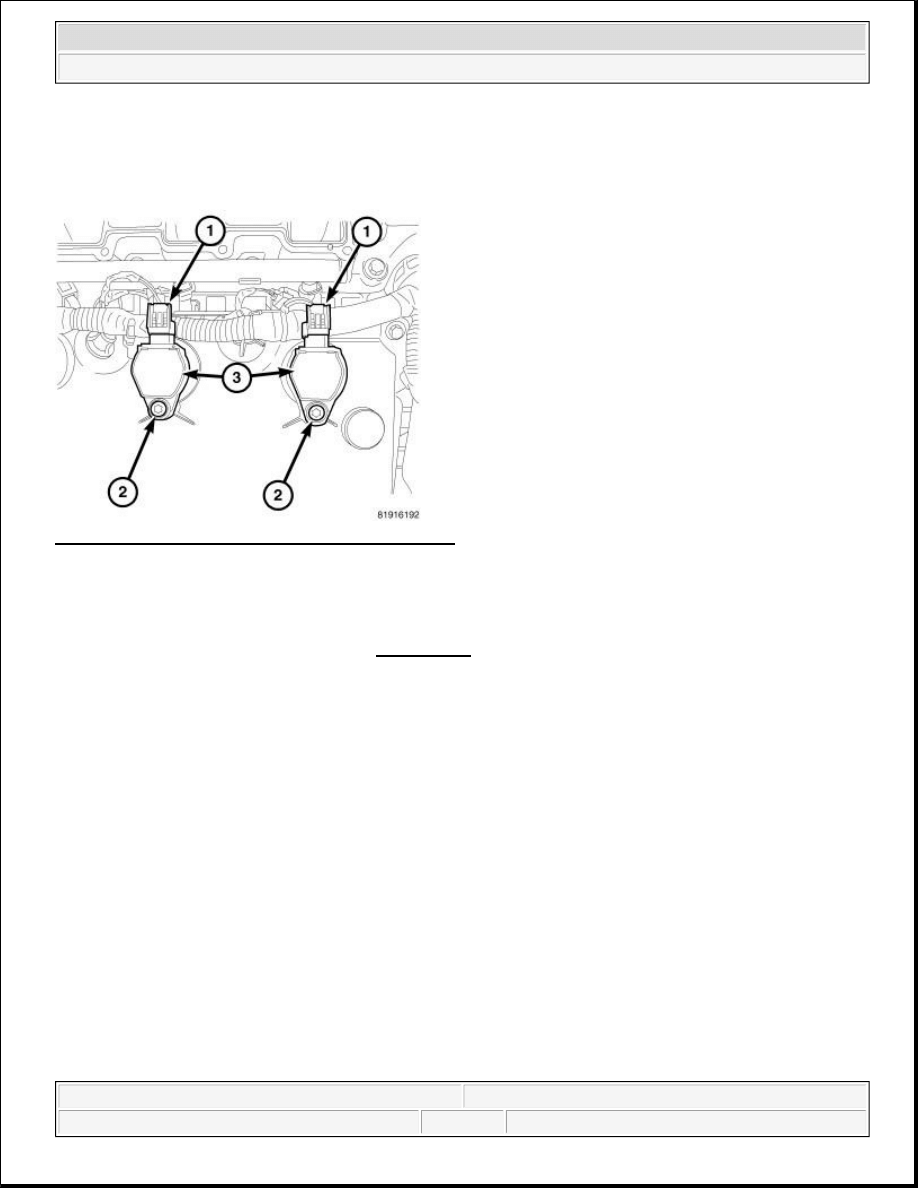

Fig. 4: Removing/Installing Ignition Capacitor

Courtesy of CHRYSLER LLC

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 5

© 2006 Mitchell Repair Information Company, LLC.

1. Install ignition coil capacitor (2) and bolt (1).

2. Tighten bolt to 28 N.m (20.5 ft. lbs.).

3. Connect electrical connector (3).

4. Connect negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

COIL, IGNITION

REMOVAL

3.3/3.8L

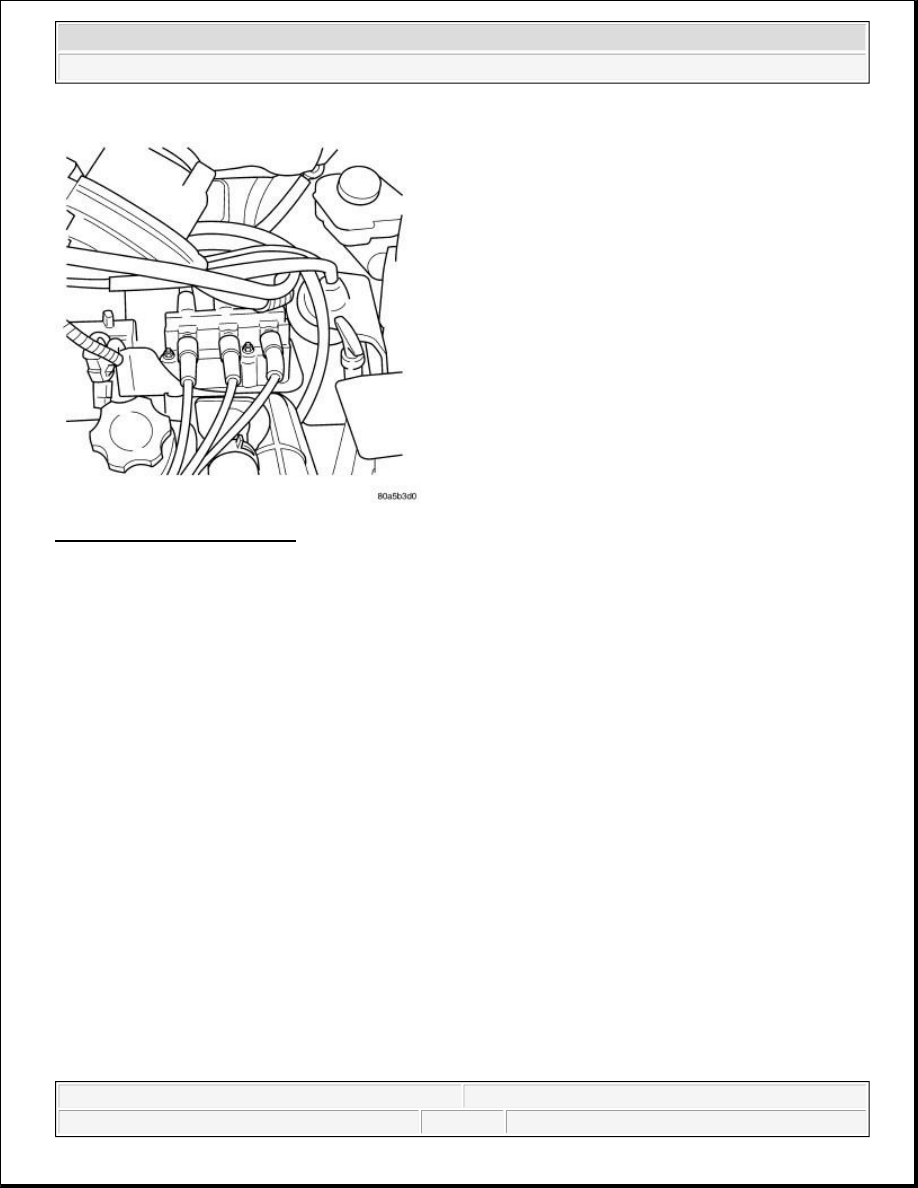

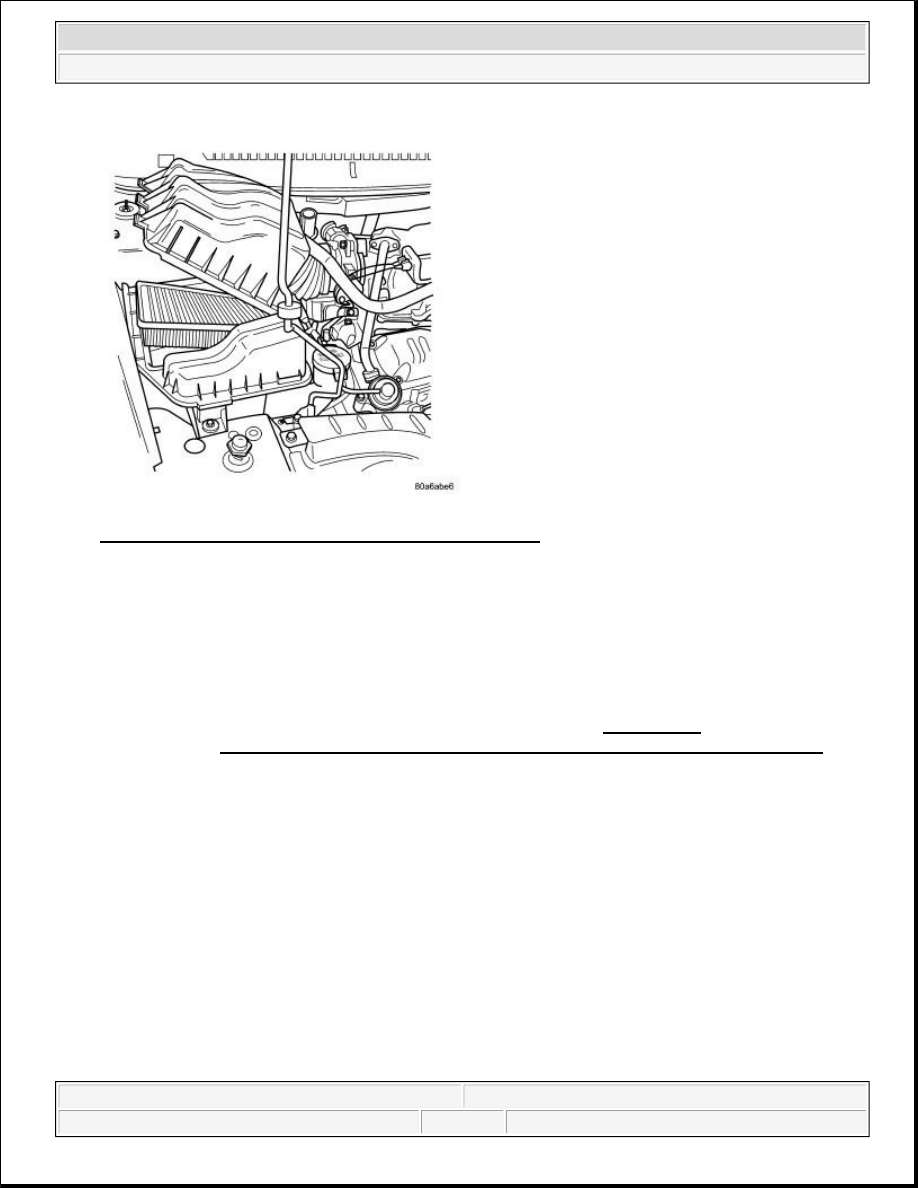

Fig. 5: Identifying Ignition Coil

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable at battery.

2. Remove 2 bolts from the Power steering reservoir to intake manifold.

3. Loosen the lower nut for the power steering reservoir from stud on ignition coil bracket.

4. Reposition the power steering reservoir.

5. Remove the ignition cables from the ignition coil.

6. Disconnect the electrical connector from the ignition coil.

7. Remove 2 nuts from the ignition coil studs.

8. Remove ignition coil from engine.

4.0L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 6

© 2006 Mitchell Repair Information Company, LLC.

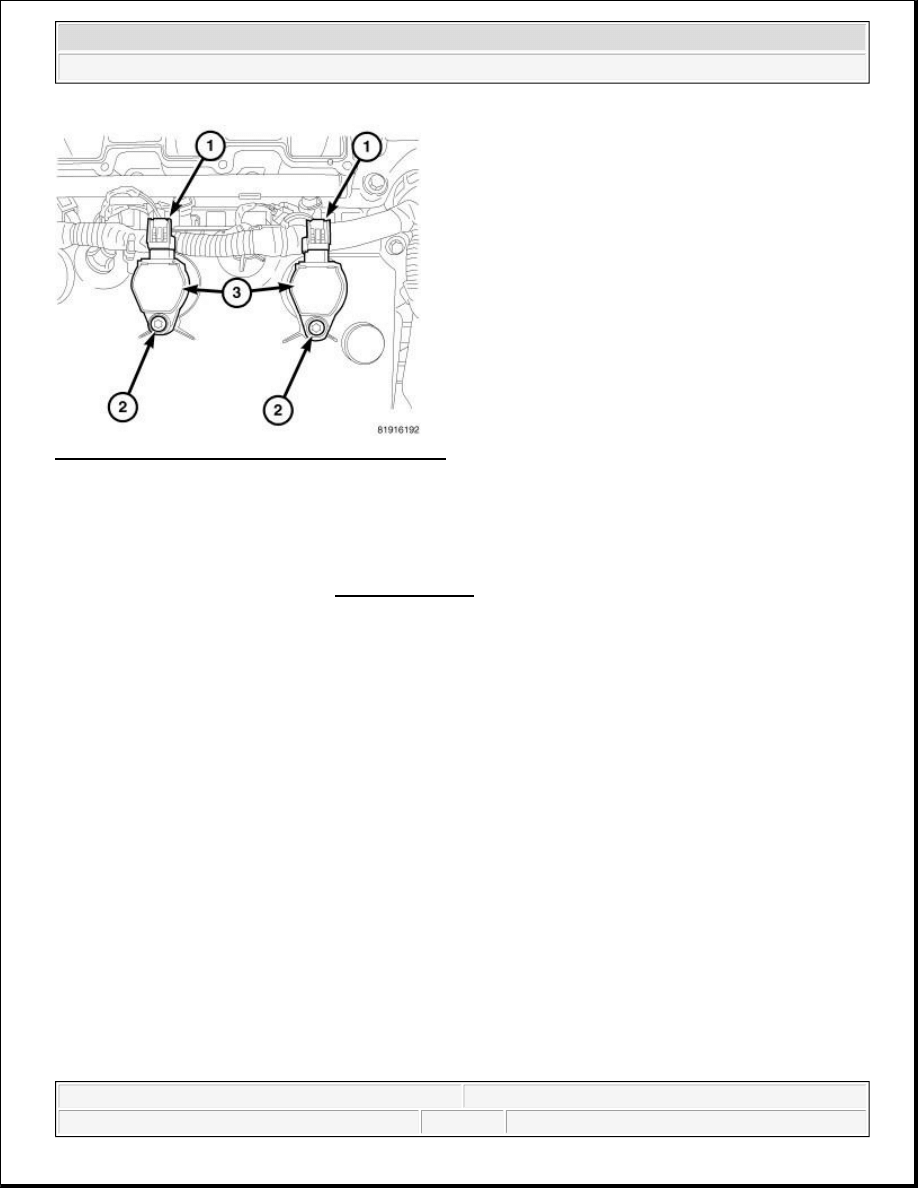

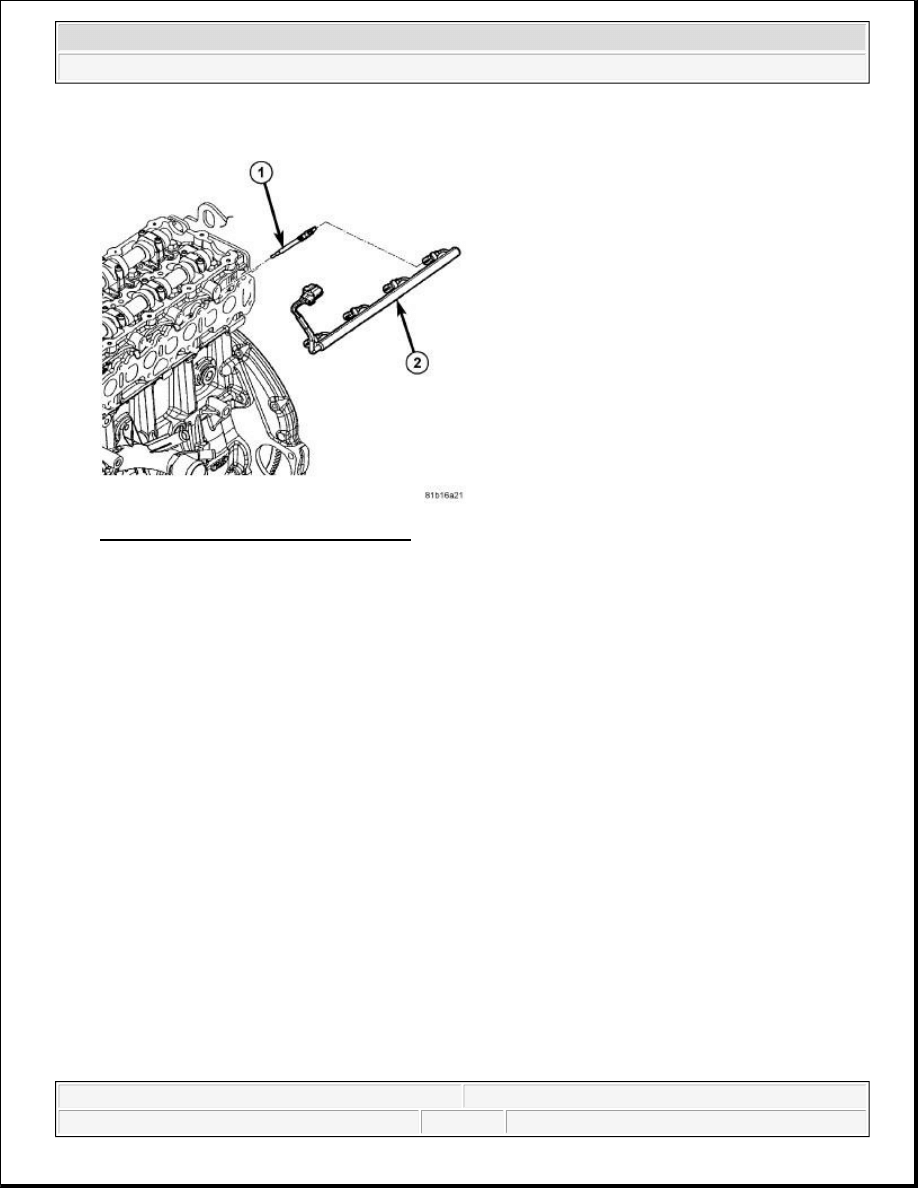

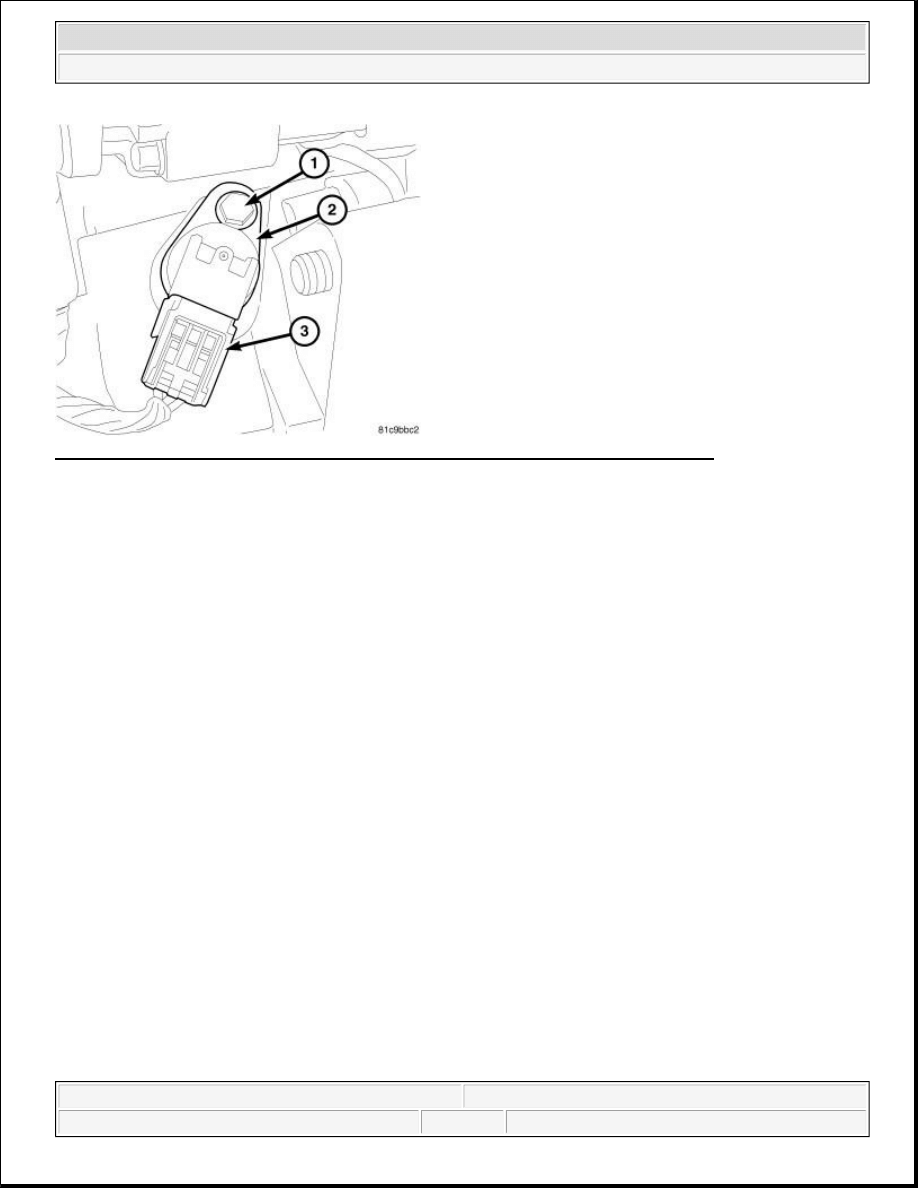

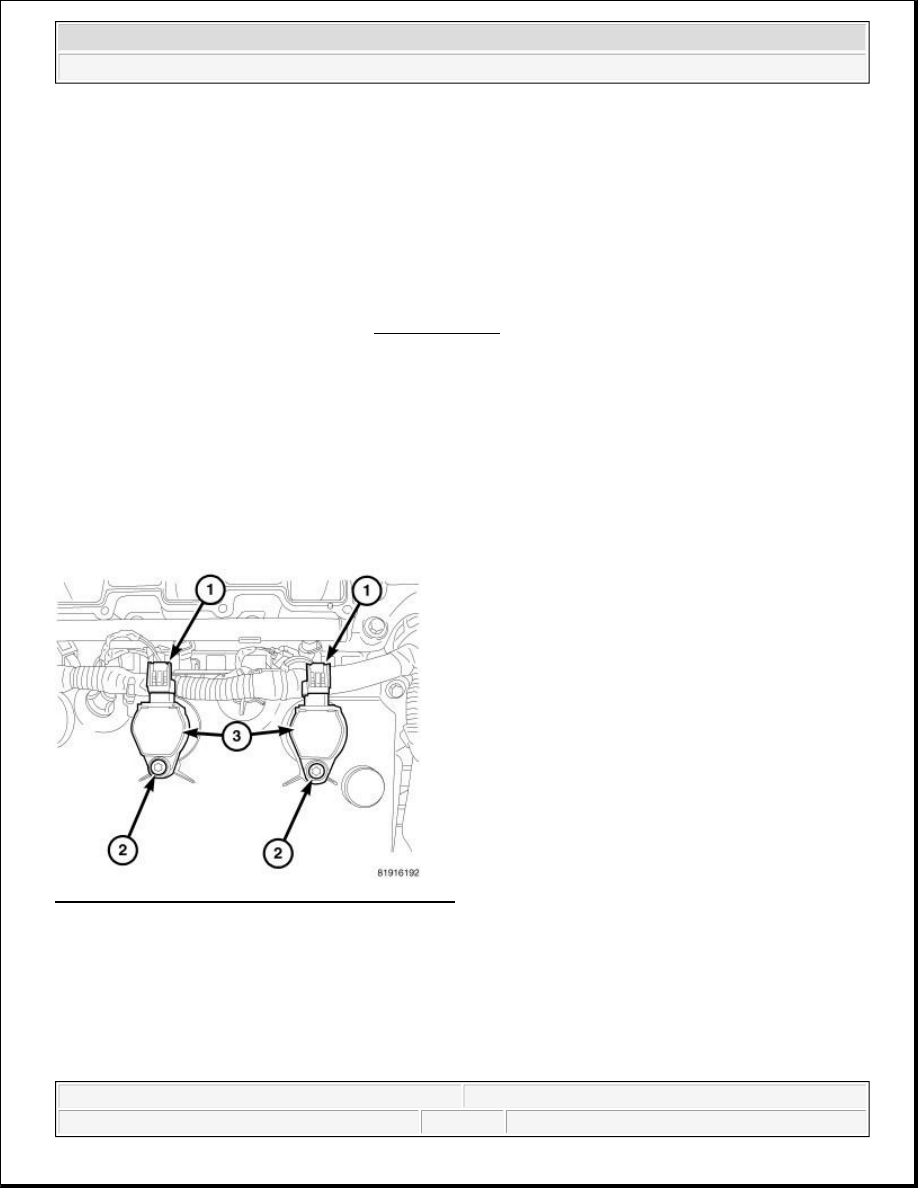

Fig. 6: Removing/Installing Ignition Coil Assembly

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable at battery.

2. Remove intake manifold. Refer to REMOVAL .

3. Disconnect electrical connector (1) from ignition coils (3).

4. Remove mounting bolt (2).

5. Remove the ignition coil assembly (3) by turning the assembly 1/2 turn and pulling straight up in a steady

motion.

INSTALLATION

3.3/3.8L

NOTE:

Prior to removing coil, spray compressed air around coil top to make sure

no dirt drops into the spark plug tube.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 7

© 2006 Mitchell Repair Information Company, LLC.

Fig. 7: Identifying Ignition Coil

Courtesy of CHRYSLER LLC

1. Install coil over studs on bracket.

2. Install 2 nuts to the ignition coil studs and tighten nuts.

3. Connect the electrical connector to the ignition coil.

4. Install the ignition cables to the ignition coil.

5. Reposition the power steering reservoir. Slide bracket over the mounting stud.

6. Install 2 bolts to the Power steering reservoir to intake manifold.

7. Tighten the lower nut to stud on ignition coil bracket.

8. Connect negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

4.0L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 8

© 2006 Mitchell Repair Information Company, LLC.

Fig. 8: Removing/Installing Ignition Coil Assembly

Courtesy of CHRYSLER LLC

1. Install ignition coil (3) and bolt (2).

2. Tighten bolt to 8 N.m (71 in. lbs.).

3. Connect the electrical connector (1) to ignition coil.

4. Install intake manifold. Refer to INSTALLATION .

5. Connect negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

PLUG, GLOW

DESCRIPTION

DESCRIPTION

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 9

© 2006 Mitchell Repair Information Company, LLC.

Fig. 9: Identifying Glow Plug

Courtesy of CHRYSLER LLC

Glow plugs are used to help start a cold or cool engine. The glow plugs will heat up and glow to heat the

combustion chamber of each cylinder. An individual glow plug is used for each cylinder.

OPERATION

OPERATION

CAUTION: The glow plugs operate on a 4.4-volt system. The glow plugs DO NOT

tolerate any over voltage. Full battery voltage will destroy the glow plug

immediately. DO NOT test the glow plugs with a 12V source as damage will

occur to the glow plug.

CAUTION:

Never bend, bump or knock the fast metallic glow plugs.

Fast metallic glow plugs must not be handled loose in a container.

Store, handle, and transport them only in original boxes.

If there is any doubt about the proper condition of a glow plug, do not

reuse it.

Do not clean the glow plugs with abrasive or aggressive media.

Avoid dipping the glow plug into fluids.

Read Diagnostic Trouble Codes (DTCs). If a glow plug problem is

indicated, do not start the engine.

CAUTION: Disregarding these instructions may cause severe engine damage.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 10

© 2006 Mitchell Repair Information Company, LLC.

Fig. 10: Identifying Glow Plug

Courtesy of CHRYSLER LLC

The Engine Control Module (ECM) monitors various engine sensors. When the ignition key is turned to the ON

position, the ECM sends a signal to the glow plug module (relay) to turn on, and cycle, the glow plugs for a pre-

determined amount of time, plus illuminate the glow plug light in the instrument panel. Once activated, the

element inside of the core of the glow plug begins to glow. Each glow plug draws approximately 8 amps, for a

total system amperage of 32 amps at 22° C (72° F) ambient temperature. If there is a fault with the glow plug

system, the ECM will store a fault code.

DIAGNOSIS AND TESTING

GLOW PLUGS

1. Measure the electrical resistance of each glow plug while it is still installed in the cylinder head.

Resistance should be less than 0.8ohms between the electrical connector point on the glow plug and the

cylinder head. The ground contact on the DVOM must be as close as possible to the point where the glow

plug contacts the cylinder head to avoid erratic resistance measurements.

2. If the resistance is out of tolerance, remove the glow plug from the cylinder head and check the resistance

again.

3. Use the actuator test function of the scan tool to test the glow plug module and glow plug lamp. The glow

plug module's on-board diagnostic tests will automatically check the electrical condition of the entire

CAUTION: The glow plugs operate on a 4.4-volt system. DO NOT test the glow plugs

with a 12 V source as damage will occur to the glow plug(s).

CAUTION: DO NOT attempt to start the engine until the glow plug system tests

correctly.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 11

© 2006 Mitchell Repair Information Company, LLC.

glow plug system.

4. After the scan tool glow plug actuator test function is complete, if MIL is OFF and no glow plug DTCs

are present, testing is complete and the engine can be started.

5. If MIL is still ON, check the harness connectors of glow plugs, repair any loose or damaged connections,

and run the glow plug actuator test again.

6. If MIL is still ON and glow plug DTCs are present, refer to the appropriate Diagnostic Information and

follow the diagnostic test(s) related to the active or stored DTCs.

REMOVAL

REMOVAL

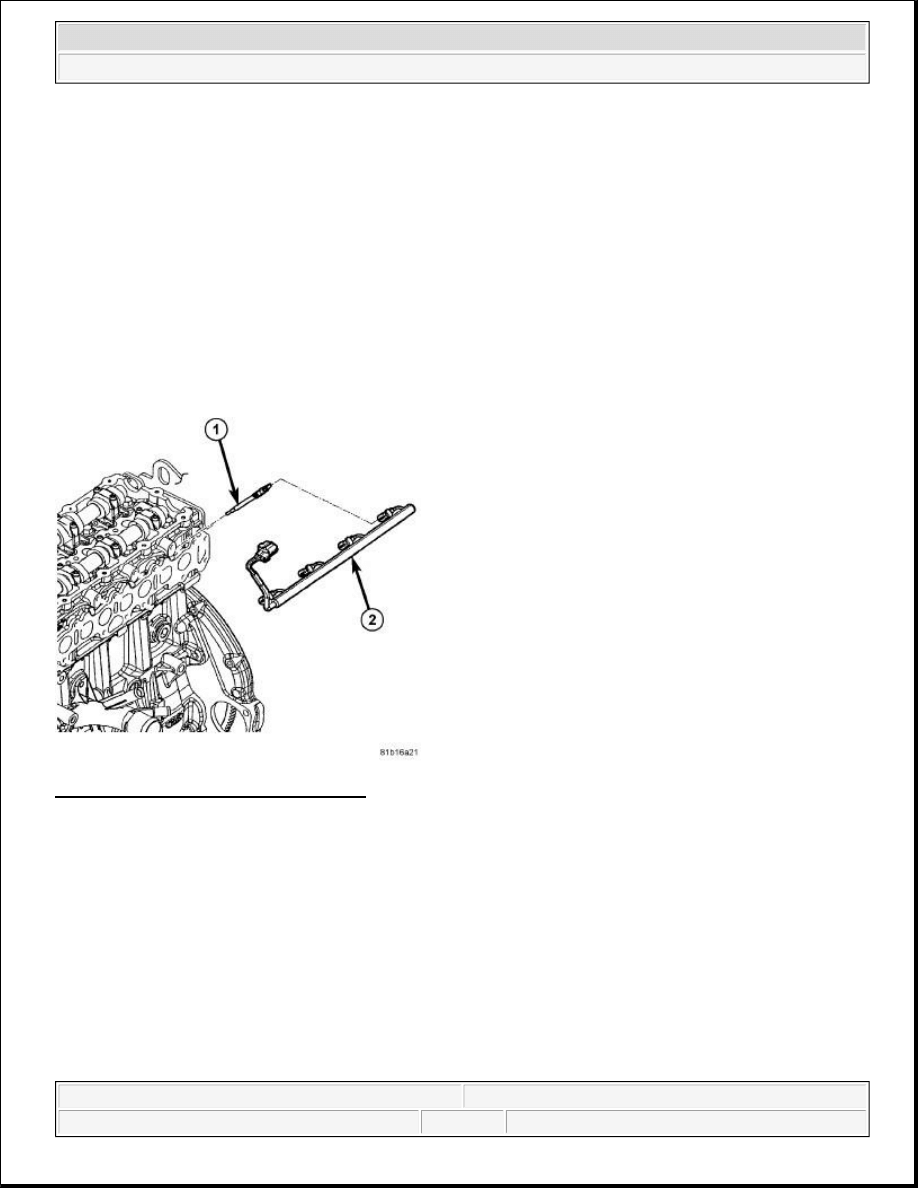

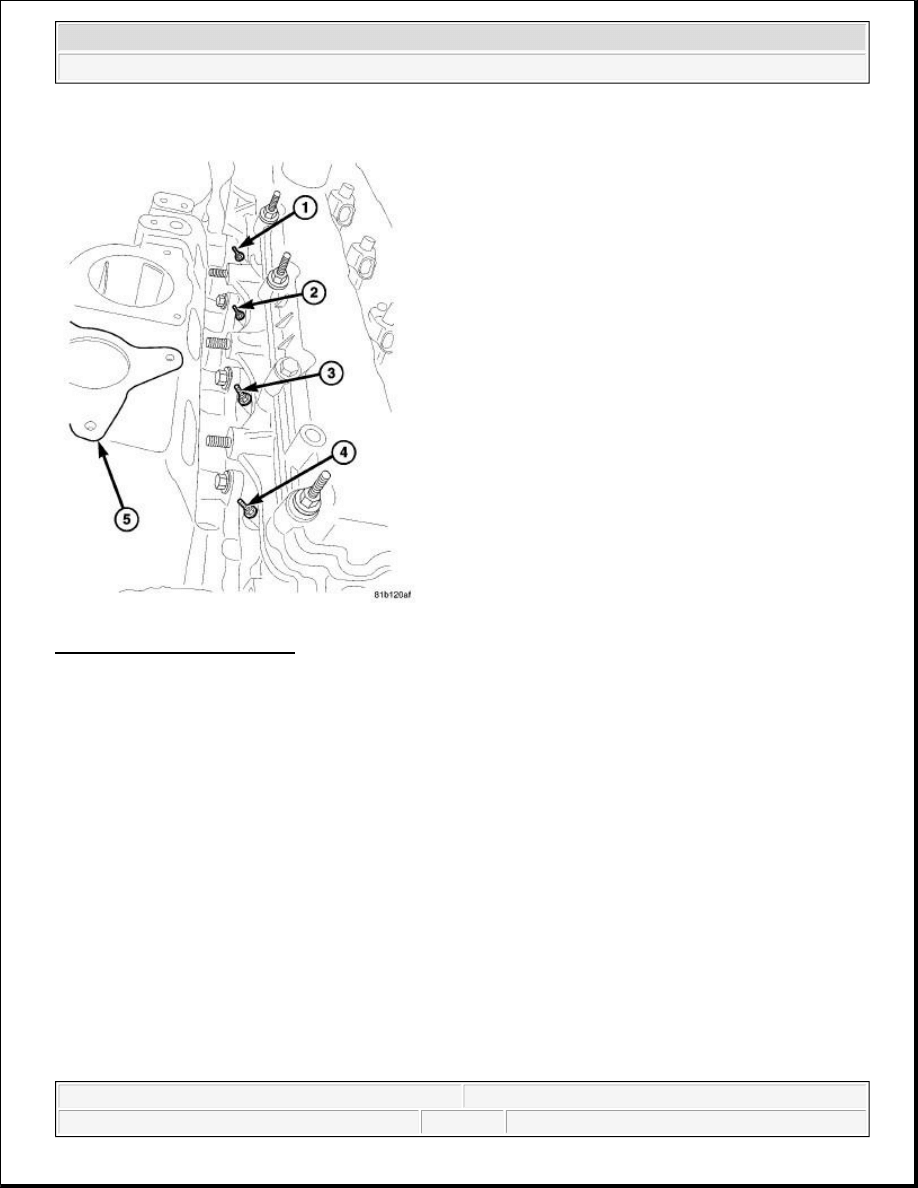

Fig. 11: Removing/Installing Glow Plugs

Courtesy of CHRYSLER LLC

The four glow plugs (1) are attached to cylinder head below fuel rail.

1. Disconnect negative battery cable.

2. Remove fuel rail and high-pressure fuel lines.

3. Disconnect glow plug wiring harness (2) at all four glow plugs (1).

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 12

© 2006 Mitchell Repair Information Company, LLC.

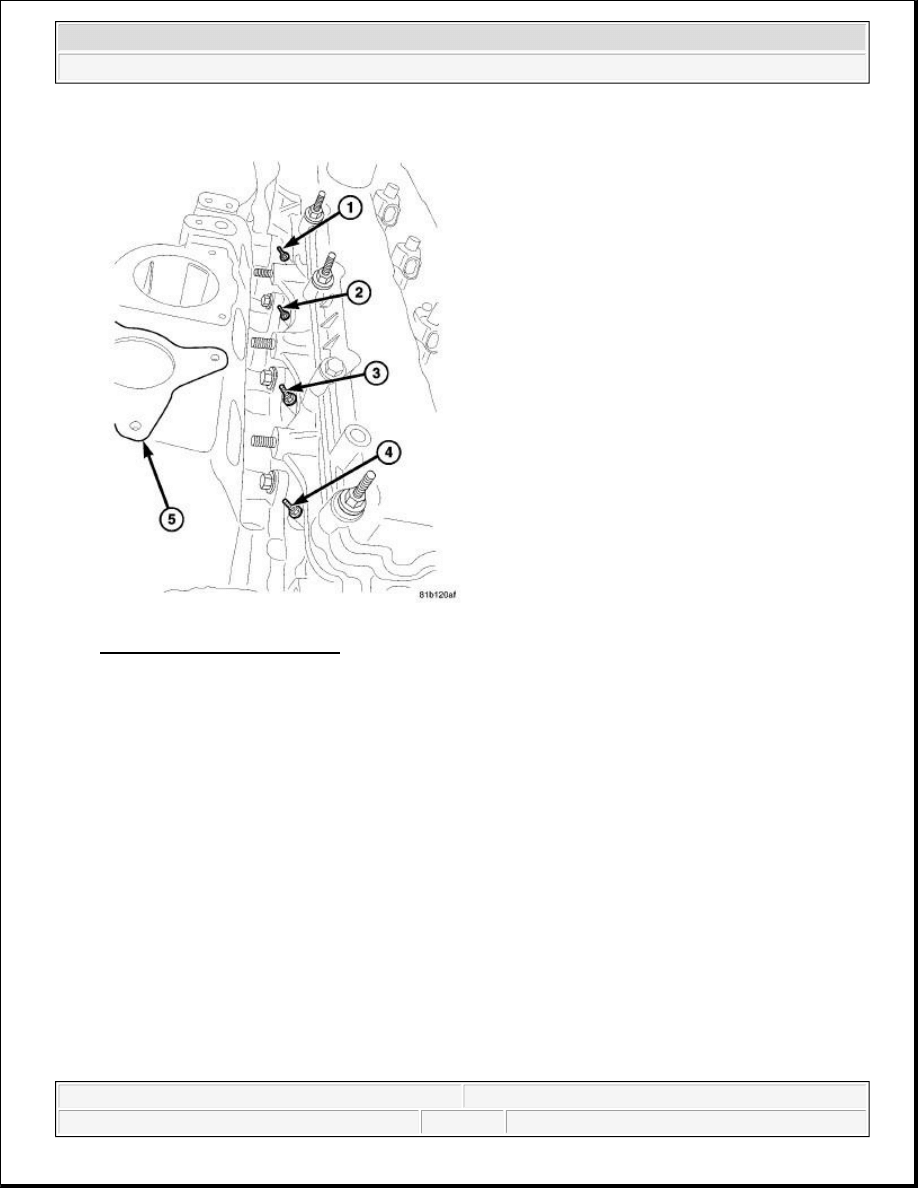

Fig. 12: Identifying Glow Plugs

Courtesy of CHRYSLER LLC

4. Use a socket to loosen glow plug(s) (1), (2), (3) or (4). After loosening, attach a flexible tool such as a

rubber hose to remove glow plug from cylinder head.

INSTALLATION

INSTALLATION

CAUTION: After plug removal, do not bend, knock, or drop the glow plugs while

handling (any mechanical impact may damage the glow plug).

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 13

© 2006 Mitchell Repair Information Company, LLC.

Fig. 13: Identifying Glow Plugs

Courtesy of CHRYSLER LLC

1. Apply a small amount of clean diesel oil or motor oil to glow plug threads.

2. Attach a flexible tool such as a rubber hose to install glow plug into cylinder head. Tighten each plug to

14 N.m (10 ft. lbs.) (124 in. lbs.).

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 14

© 2006 Mitchell Repair Information Company, LLC.

Fig. 14: Removing/Installing Glow Plugs

Courtesy of CHRYSLER LLC

3. Connect glow plug wiring harness (2) to all four glow plugs (1).

4. Install fuel rail and high-pressure fuel lines.

5. Connect negative battery cable.

RELAY, GLOW PLUG

REMOVAL

REMOVAL

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 15

© 2006 Mitchell Repair Information Company, LLC.

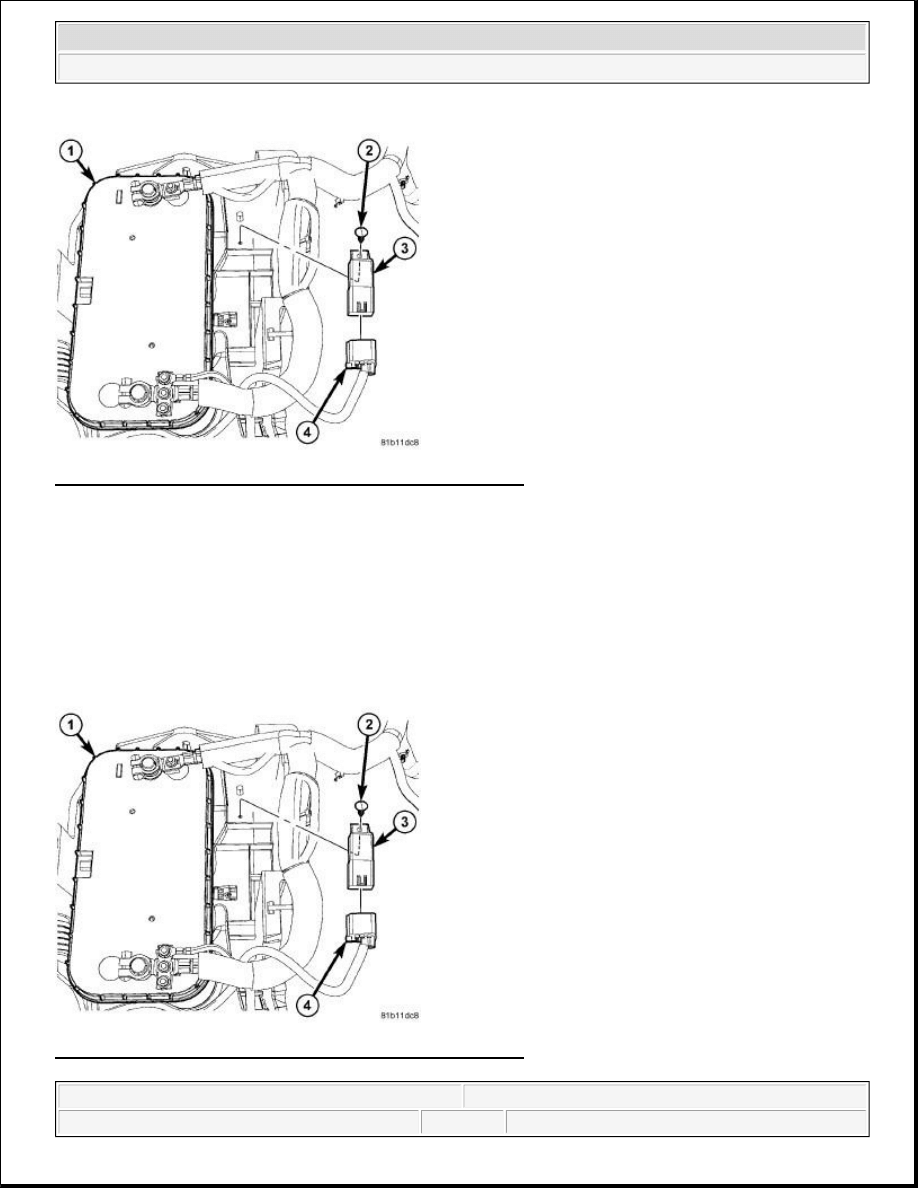

Fig. 15: Identifying Electrical Connector At Glow Plug Relay

Courtesy of CHRYSLER LLC

1. Disconnect negative battery cable.

2. Carefully pull out mounting pin (2).

3. Disconnect electrical connector (4) from relay (3).

INSTALLATION

INSTALLATION

Fig. 16: Identifying Electrical Connector At Glow Plug Relay

Courtesy of CHRYSLER LLC

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 16

© 2006 Mitchell Repair Information Company, LLC.

1. Connect electrical connector (4) to relay.

2. Push mounting pin (2) through relay (3).

3. Connect negative battery cable.

SENSOR, CAMSHAFT POSITION

OPERATION

OPERATION

Fig. 17: Identifying Good Camshaft & Crankshaft Square Wave Signals For 6 Cylinder Engines

Courtesy of CHRYSLER LLC

Depiction of good camshaft and crankshaft square wave signals for 6 cylinder engines.

REMOVAL

3.3/3.8L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 17

© 2006 Mitchell Repair Information Company, LLC.

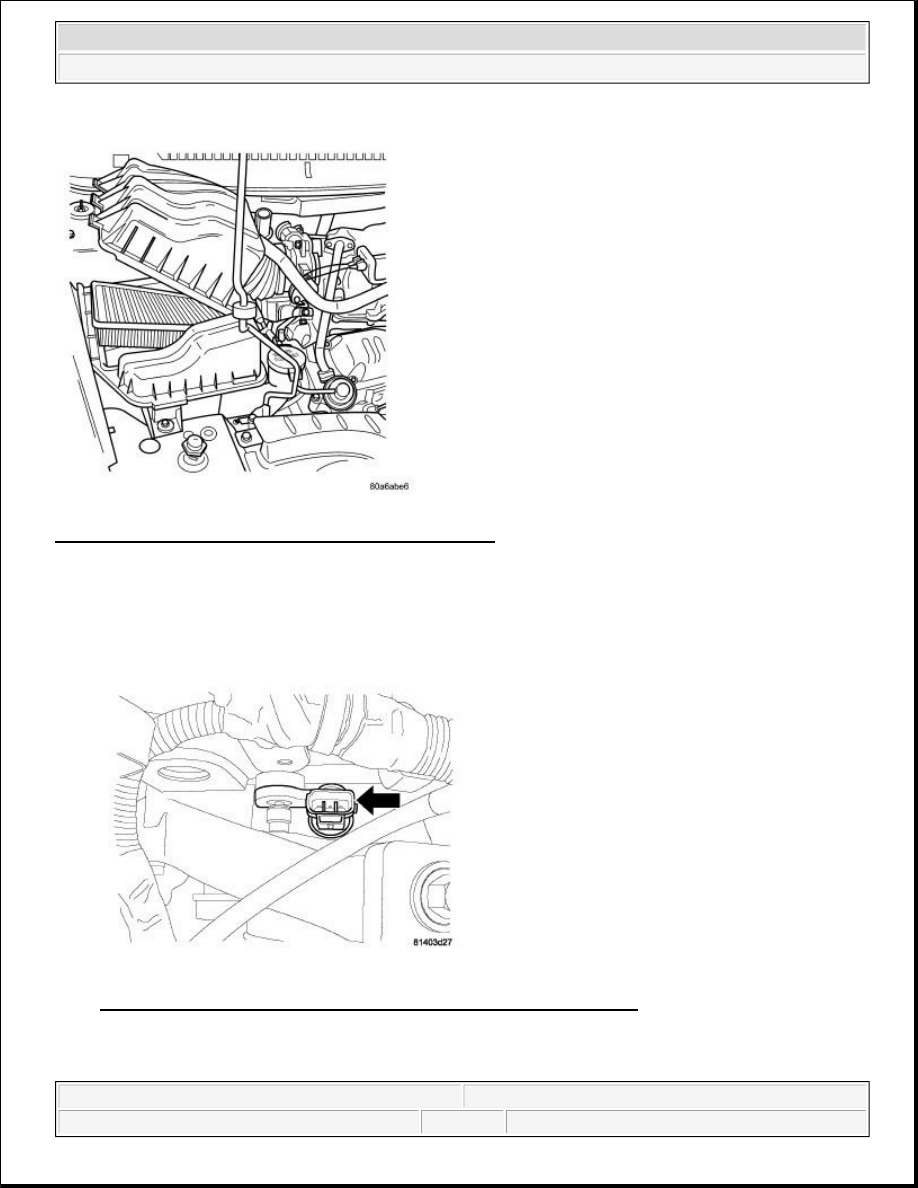

Fig. 18: Removing/Installing Air Box Cover & Inlet Tube

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable.

2. Remove the air box cover and inlet tube.

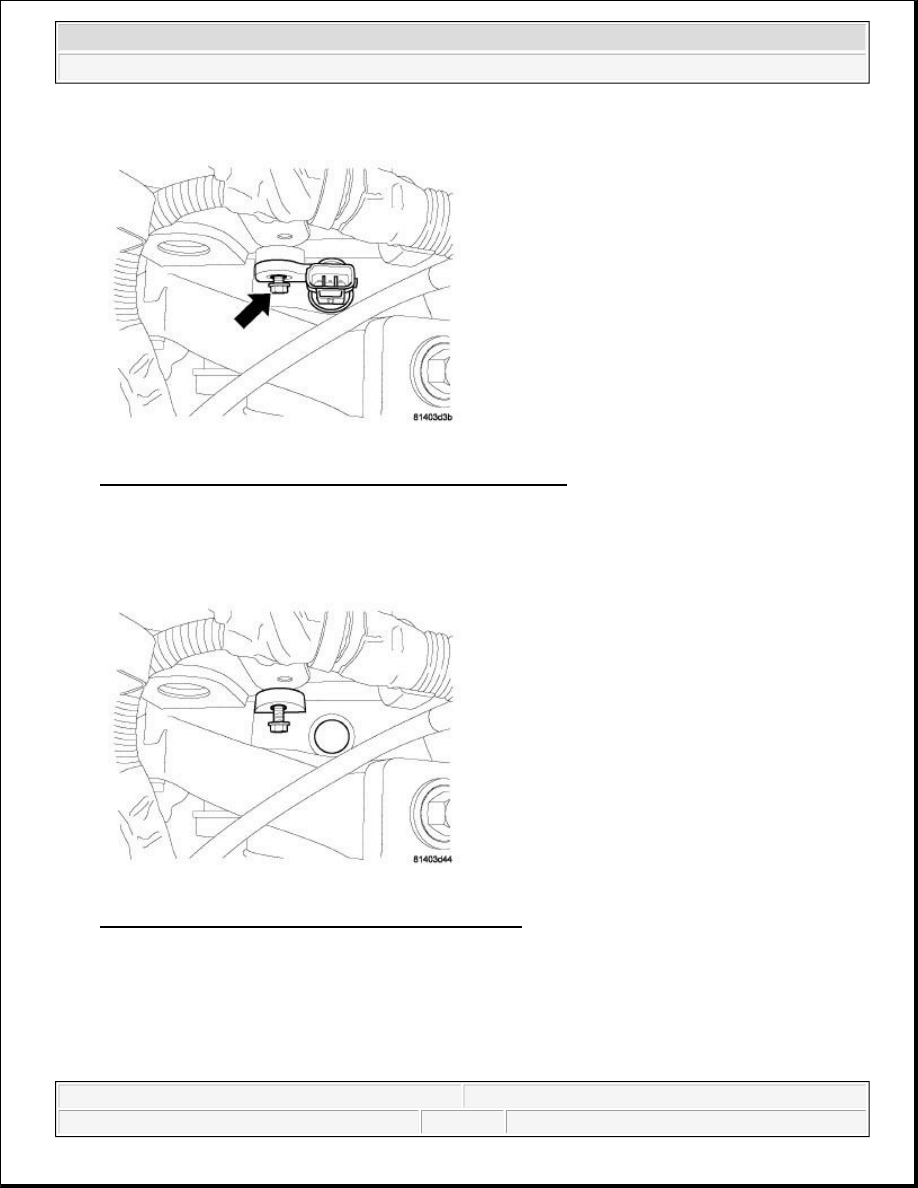

Fig. 19: Identifying Electrical Connector At Camshaft Position Sensor

Courtesy of CHRYSLER LLC

3. Disconnect the electrical connector from the camshaft position (CMP) sensor.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 18

© 2006 Mitchell Repair Information Company, LLC.

Fig. 20: Identifying Camshaft Position Sensor Retaining Bolt

Courtesy of CHRYSLER LLC

4. Loosen the CMP sensor retaining bolt.

Fig. 21: Removing/Installing Camshaft Position Sensor

Courtesy of CHRYSLER LLC

5. Pull the sensor up and out of the chain case cover. Leave the retaining bolt in place.

4.0L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 19

© 2006 Mitchell Repair Information Company, LLC.

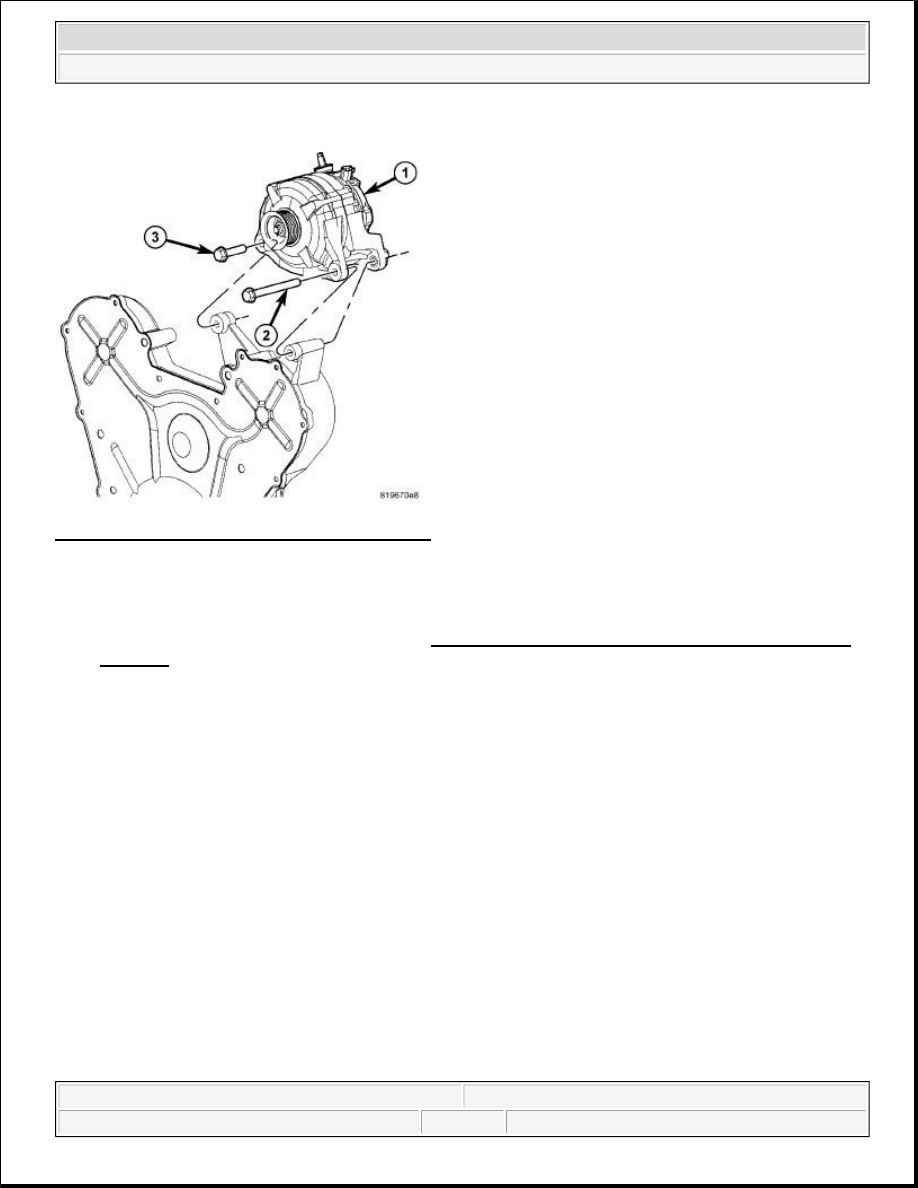

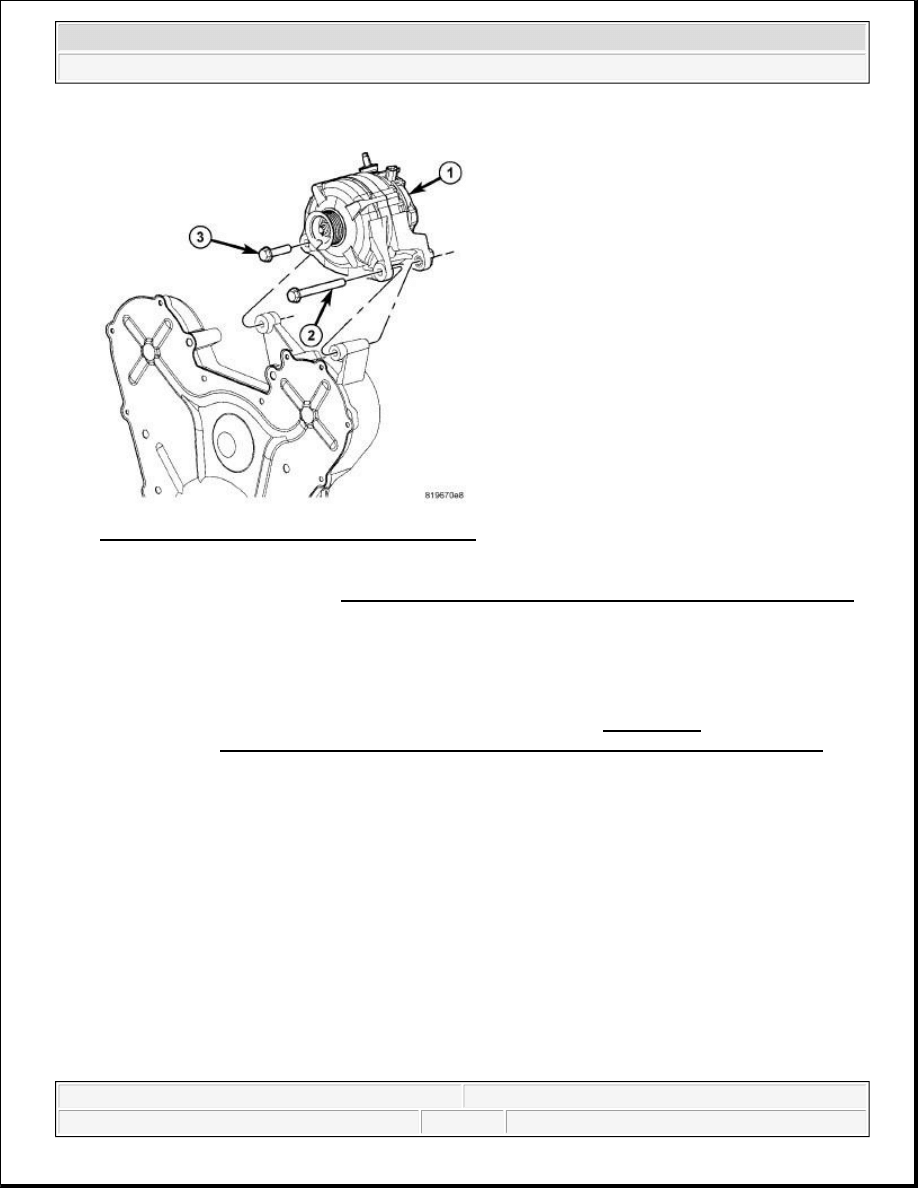

Fig. 22: Identifying Generator & Mounting Bolts

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable at battery.

2. Remove generator mounting bolts (2), (3) and position the generator (1) aside in order to gain access to

the camshaft position (CMP) sensor. Refer to Electrical - Engine Systems/Charging/GENERATOR -

Removal .

3. Disconnect electrical connector from CMP sensor.

4. Remove bolt and CMP.

DIESEL

1. Disconnect and isolate the negative battery cable.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 20

© 2006 Mitchell Repair Information Company, LLC.

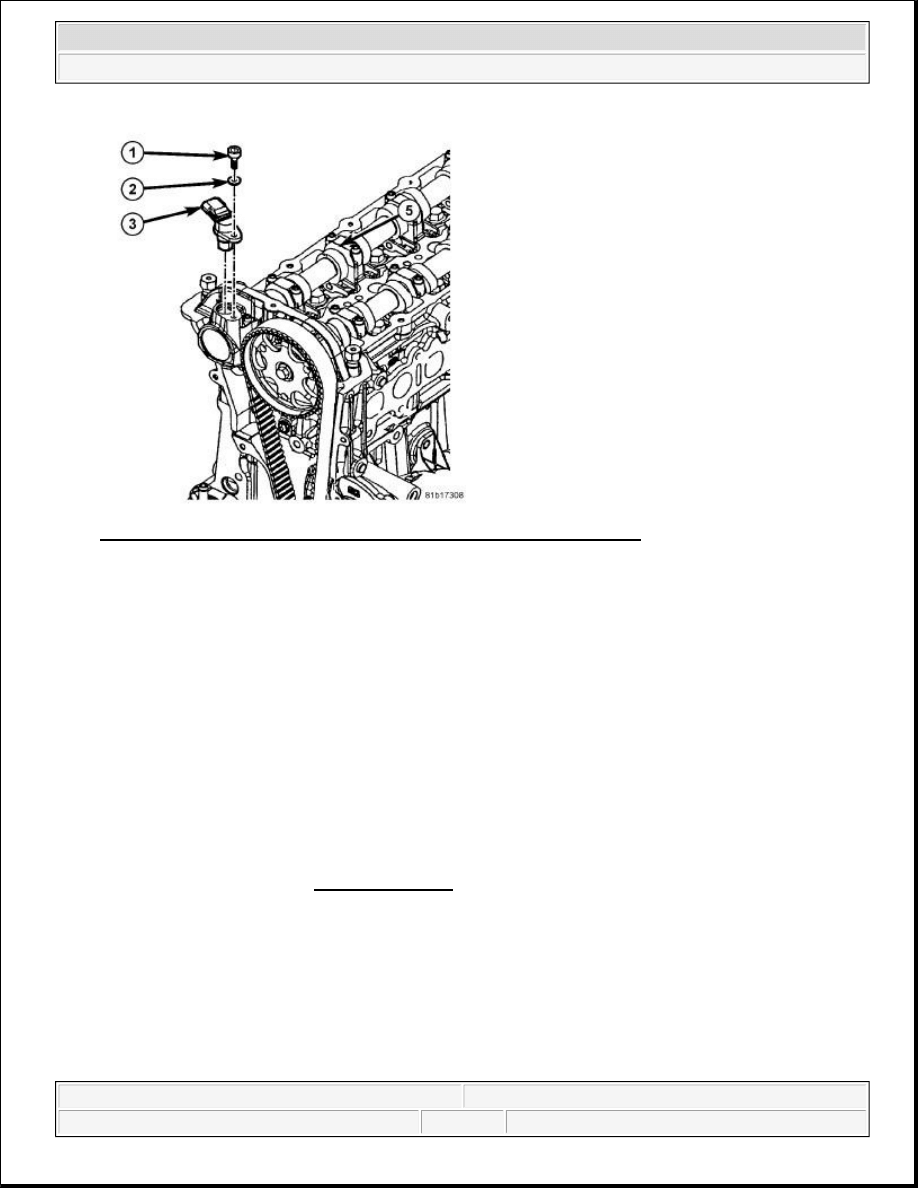

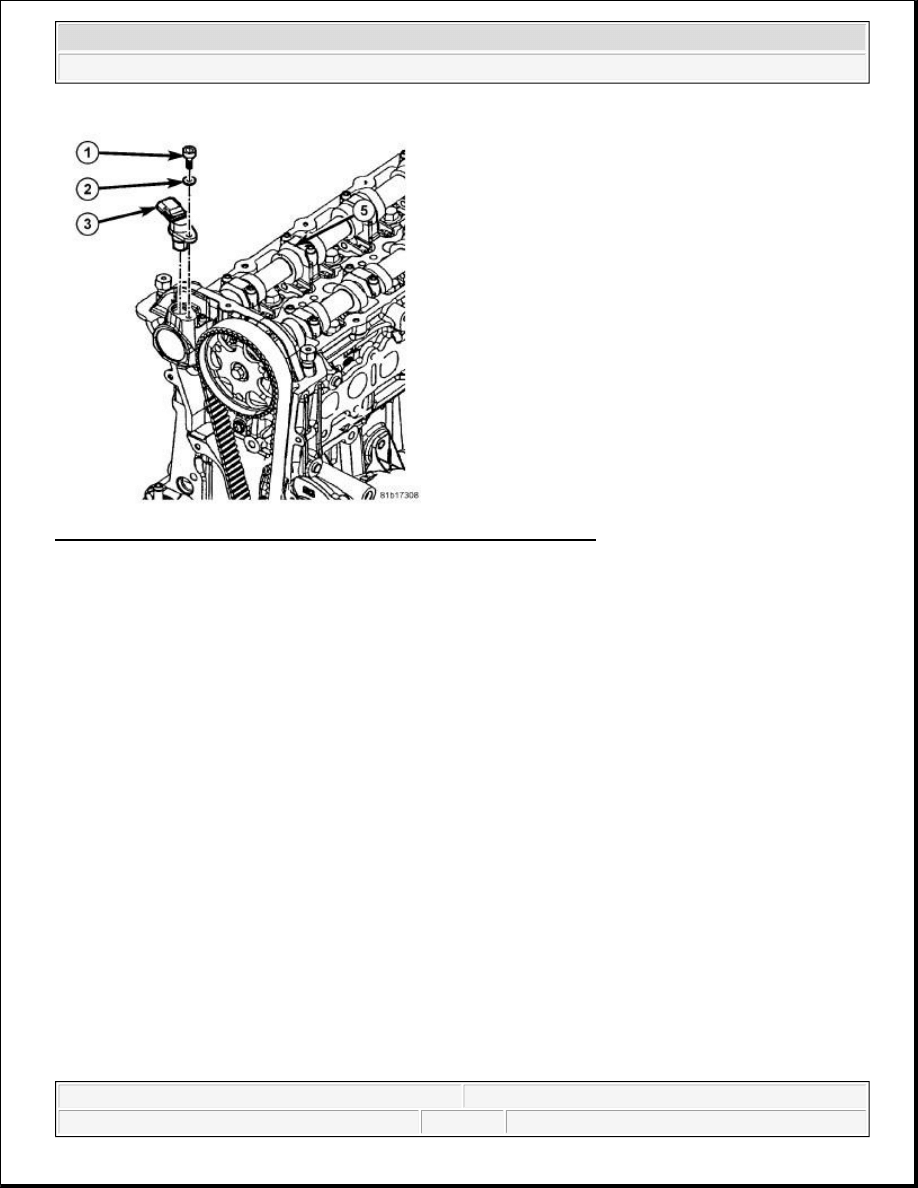

Fig. 23: Removing/Installing Camshaft Position Sensor - Diesel Engine

Courtesy of CHRYSLER LLC

The Camshaft Position Sensor (CMP) (3) is located at the front/top of the cylinder head.

2. Remove electrical connector from CMP sensor (3).

3. Clean area at base of sensor.

4. Remove sensor mounting bolt (1) and washer (2).

5. Pull sensor (3) straight up for removal.

INSTALLATION

2.8L

1. Lubricate O-ring and install sensor in cylinder head cover. Torque retaining bolt to 5.4 N.m (48 in. lbs.).

2. Connect camshaft position sensor electrical connector.

3. Install engine cover. Refer to INSTALLATION .

4. Connect negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

3.3/3.8L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 21

© 2006 Mitchell Repair Information Company, LLC.

Fig. 24: Identifying Camshaft Position Sensor Components

Courtesy of CHRYSLER LLC

Fig. 25: Identifying Electrical Connector At Camshaft Position Sensor

Courtesy of CHRYSLER LLC

NOTE:

If reinstalling the sensor (1), check the sensor O-ring (2) for damage and replace

if necessary. Lubricate the O-ring with clean engine oil before installing the

sensor. Clean off the old spacer (3) on the sensor face. A NEW SPACER (3)

must be attached to the face before installation.

CAUTION: A NEW SPACER must be attached to the face of the sensor before

installation. The spacer sets the correct clearance between the sensor and

the camshaft gear. An improperly positioned sensor can result in sensor

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 22

© 2006 Mitchell Repair Information Company, LLC.

1. Install the camshaft position (CMP) sensor in the chain case cover and rotate into position.

Fig. 26: Identifying Camshaft Position Sensor Retaining Bolt

Courtesy of CHRYSLER LLC

2. Push the sensor down until contact is made with the camshaft gear. While holding the sensor in this

position, install and tighten the retaining bolt to 14 N.m (125 in. lbs.).

3. Connect and lock the electrical connector to the CMP sensor.

damage, a faulty signal or no signal at all.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 23

© 2006 Mitchell Repair Information Company, LLC.

Fig. 27: Removing/Installing Air Box Cover & Inlet Tube

Courtesy of CHRYSLER LLC

4. Install the air box cover and inlet tube.

5. Connect the negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

4.0L

NOTE:

The Cam/Crank Variation Relearn procedure must be performed using a

scan tool anytime there has been a repair/replacement made to a

powertrain system, for example: flywheel, valvetrain, camshaft and/or

crankshaft sensors or components. Refer to DTC-Based

Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure .

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 24

© 2006 Mitchell Repair Information Company, LLC.

Fig. 28: Identifying Camshaft Position Sensor, Electrical Connector, & Retaining Bolt

Courtesy of CHRYSLER LLC

1. Push the CMP sensor (2) into the timing belt cover with a twisting motion until fully seated.

2. While holding the sensor (2) in this position, install and tighten the retaining bolt (1) to 12 N.m (106 in.

lbs.).

3. Connect and lock the electrical connector (3) to the CMP sensor (2).

CAUTION: Install camshaft position (CMP) sensor utilizing twisting motion. Make sure

CMP sensor is fully seated. Do not drive CMP sensor into the bore with

mounting screw. This may cause CMP sensor to be incorrectly seated

causing a faulty signal or no signal at all.

NOTE:

If reinstalling the sensor, check the sensor O-ring for damage and replace if

necessary. Lubricate the O-ring with clean engine oil before installing the

sensor.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 25

© 2006 Mitchell Repair Information Company, LLC.

Fig. 29: Identifying Generator & Mounting Bolts

Courtesy of CHRYSLER LLC

4. Install the generator (1). Refer to Electrical - Engine Systems/Charging/GENERATOR - Installation .

5. Connect the negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

DIESEL

NOTE:

The Cam/Crank Variation Relearn procedure must be performed using a

scan tool anytime there has been a repair/replacement made to a

powertrain system, for example: flywheel, valvetrain, camshaft and/or

crankshaft sensors or components. Refer to DTC-Based

Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure .

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 26

© 2006 Mitchell Repair Information Company, LLC.

Fig. 30: Removing/Installing Camshaft Position Sensor - Diesel Engine

Courtesy of CHRYSLER LLC

1. Position CMP sensor (3) into mounting hole.

2. Install sensor mounting bolt (1) and washer (2). Tighten bolt to 11 Nm ( 8 ft. lbs.).

3. Connect electrical connector to CMP sensor (3).

4. Reconnect the negative battery cable.

SENSOR, KNOCK

REMOVAL

3.3/3.8L

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 27

© 2006 Mitchell Repair Information Company, LLC.

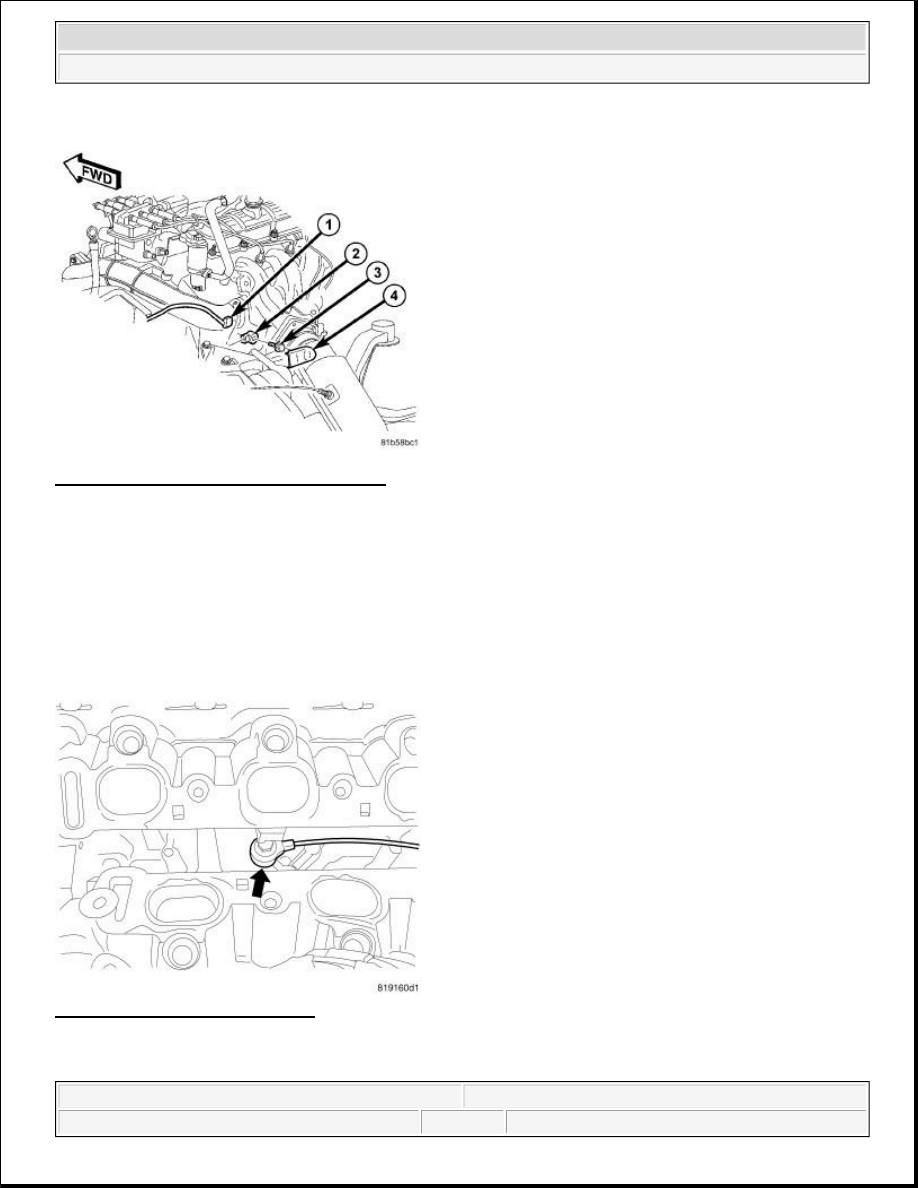

Fig. 31: Removing/Installing Knock Sensor

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable at battery.

2. Remove knock sensor cover (4).

3. Disconnect electrical connector (1) from knock sensor (2).

4. Remove bolt (3) and knock sensor (2) from engine.

4.0L

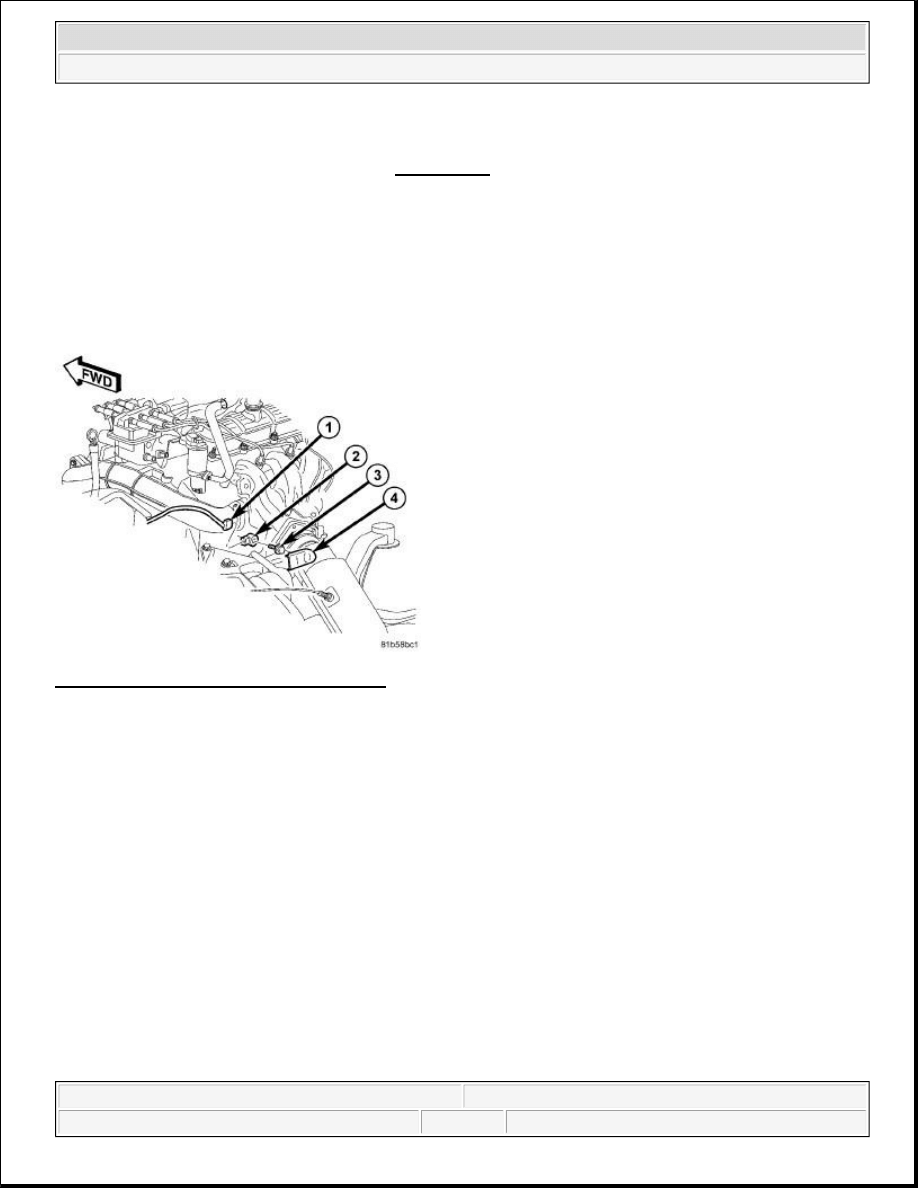

Fig. 32: Identifying Knock Sensor

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable at battery.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 28

© 2006 Mitchell Repair Information Company, LLC.

2. Remove engine cover.

3. Remove upper intake manifold. Refer to REMOVAL .

4. Disconnect electrical connector.

5. Remove knock sensor.

INSTALLATION

3.3/3.8L

Fig. 33: Removing/Installing Knock Sensor

Courtesy of CHRYSLER LLC

1. Install knock sensor (2) and bolt (3) to engine and tighten to 20 N.m (15 ft. lbs.).

2. Connect electrical connector (1) to knock sensor (2).

3. Install knock sensor cover (4).

4. Connect the negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

4.0L

CAUTION: Torque the knock sensor to correct specification. Over or under tightening

effects knock sensor performance, possibly causing improper spark

control and damage to the sensor.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 29

© 2006 Mitchell Repair Information Company, LLC.

Fig. 34: Identifying Knock Sensor

Courtesy of CHRYSLER LLC

1. Install knock sensor and bolt. Tighten bolt to 20 N.m (15 ft. lbs.).

2. Route knock sensor wire in the proper location.

3. Install upper intake manifold. Refer to INSTALLATION .

4. Connect electrical connector.

5. Connect the negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

SPARK PLUG

REMOVAL

3.3/3.8L

When replacing the spark plugs and spark plug cables, route the cables correctly and secure them in the

appropriate retainers. Failure to route the cables properly can cause the radio to reproduce ignition noise, cross

ignition of the spark plugs or short circuit the cables to ground.

Always remove cables by grasping at the boot, rotating the boot 1/2 turn, and pulling straight back in a steady

motion.

1. Prior to removing the spark plug, spray compressed air around the spark plug hole and the area around the

spark plug.

2. Remove the spark plug using a quality socket with a foam insert.

CAUTION: Torque the knock sensor to correct specification. Over or under tightening

effects knock sensor performance, possibly causing improper spark

control and damage to the sensor.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 30

© 2006 Mitchell Repair Information Company, LLC.

3. Inspect the spark plug condition.

4.0L

Fig. 35: Removing/Installing Ignition Coil Assembly

Courtesy of CHRYSLER LLC

1. Disconnect and isolate the negative battery cable.

2. Remove engine cover.

3. Remove the intake manifold. Refer to REMOVAL .

4. Disconnect electrical connectors (1).

5. Remove mounting bolt (2).

6. Remove the ignition coil assembly (3) by turning the assembly 1/2 turn and pulling straight up in a steady

motion.

7. Remove the spark plug using a quality socket with a foam insert.

INSTALLATION

3.3/3.8L

NOTE:

Prior to removing coil, spray compressed air around coil top to make sure

no debris drops into the spark plug tube.

NOTE:

Prior to loosening the spark plug, use compressed air to blow out any

debris that might be in the spark plug tube.

NOTE:

When replacing spark plugs and ignition cables, route cables correctly and

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 31

© 2006 Mitchell Repair Information Company, LLC.

1. Apply a small amount of anti-seize to threads of each spark plug.

2. Check and adjust spark plug gap. See SPARK PLUGS.

3. Install spark plug and tighten to 17.5 N.m (13 ft. lbs.).

4. Install ignition cables over spark plugs. An audible click noise can be heard and felt when the ignition

cable is properly attached to spark plug.

4.0L

Fig. 36: Removing/Installing Ignition Coil Assembly

Courtesy of CHRYSLER LLC

1. Tighten spark plugs to 27 N.m (20 ft. lbs.).

2. Install ignition coil (3) and bolt (2).

secure in appropriate retainers. Failure to route ignition cables properly can

cause the radio to reproduce noise, cross ignition of the spark plugs or short

circuit the cables to ground.

CAUTION: Do not over apply anti-seize compound. Only use enough to lightly coat

threads on the spark plug.

CAUTION: Start each spark plug by hand to avoid cross threading and plug

damage, use a quality socket with a rubber insert and start each

spark plug into the cylinder head by hand.

CAUTION: Start each spark plug by hand to avoid cross threading and plug damage,

use a quality socket with a rubber insert and start each spark plug into the

cylinder head by hand.

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 32

© 2006 Mitchell Repair Information Company, LLC.

3. Tighten bolt to 8 N.m (71 in. lbs.).

4. Connect electrical connector (1) to ignition coil (3).

5. Install intake manifold. Refer to INSTALLATION .

6. Install engine cover.

7. Connect negative battery cable and tighten nut to 5 N.m (45 in. lbs.).

SWITCH, IGNITION

DESCRIPTION

DESCRIPTION

This vehicle is equipped with a Wireless Ignition Node (WIN). The WIN, along with the FOB with Integrated

Key (FOBIK) are the primary components of the keyless ignition system. The only visible component of the

WIN is the ignition switch located on the face of the instrument panel just to the inboard side of the steering

column. The remainder of the WIN including its mounting provisions and electrical connections are concealed

within the instrument panel.

In addition to replacing a conventional keyed ignition switch, the WIN is an integrated electronic receiver that

serves as the base station in the vehicle. It communicates with other electronic modules in the vehicle over the

Controller Area Network (CAN) data bus.

The WIN interfaces with the Remote Keyless Entry (RKE) FOBIK and the Tire Pressure Monitor (TPM)

sensors (if equipped) using Radio Frequency (RF) communication, with the Sentry Key Immobilizer System

(SKIS) transponder within the FOBIK using Low Frequency (LF) RF communication.

The WIN cannot be adjusted or repaired, but is flash update capable. If ineffective or damaged the entire WIN

must be replaced. Refer to Electrical - Electronic Control Modules/Electronic Control

Modules/RECEIVER, Wireless Ignition Node - Removal .

2009 Chrysler Town & Country LX

2009 ENGINE Ignition Control - Service Information - Grand Caravan, Town & Country

steve

Monday, May 30, 2011 12:02:11 PM

Page 33

© 2006 Mitchell Repair Information Company, LLC.

Wyszukiwarka

Podobne podstrony:

Damage Control Plan

14 Controllingid 15298 ppt

Controlling w przedsiębiorstwie

overview simatic controllers 04 2007 en plc

Control System Toolbox

control el heater pl

instrumenty Controllingu - praca zaliczeniowa (7 str), Zarządzanie(1)

rachunkowosc zarzadcza i controlling w 7

~$O Fire Control Symbols Regulations

Controlling ćw 14 10 27

controlling finansowy wykład 2 & 11 2011

10 Emission control system

02 ZELIO CONTROL CATALOGUE

Climate Control

(1 1)Fully Digital, Vector Controlled Pwm Vsi Fed Ac Drives With An Inverter Dead Time Compensation

12 Werntges controling KNX from Linux and USB

Ebsco Gross The cognitive control of emotio

Dynapower Model 66 & 99 Modular Controls Parts

M31f1 Engine Controls 1 54

więcej podobnych podstron