Design and construction of a three-phase transformer for a 1 kW multi-level

converter

Nancy Mondragón-Escamilla, Alejandro Villarruel-Parra, Ismael Araujo-Vargas, Juan Carlos

Sánchez-García

Email:

naytsu10@hotmail.com

,

alexvip_22@hotmail.com

School of Mechanical and Electrical Engineering, Postgraduate Section, SEPI-ESIME Culhuacan, National Polytechnic

Institute of Mexico, Av. Santa Ana No. 1000, Col. San Francisco Culhuacan, Del. Coyoacan, D.F.

Abstract

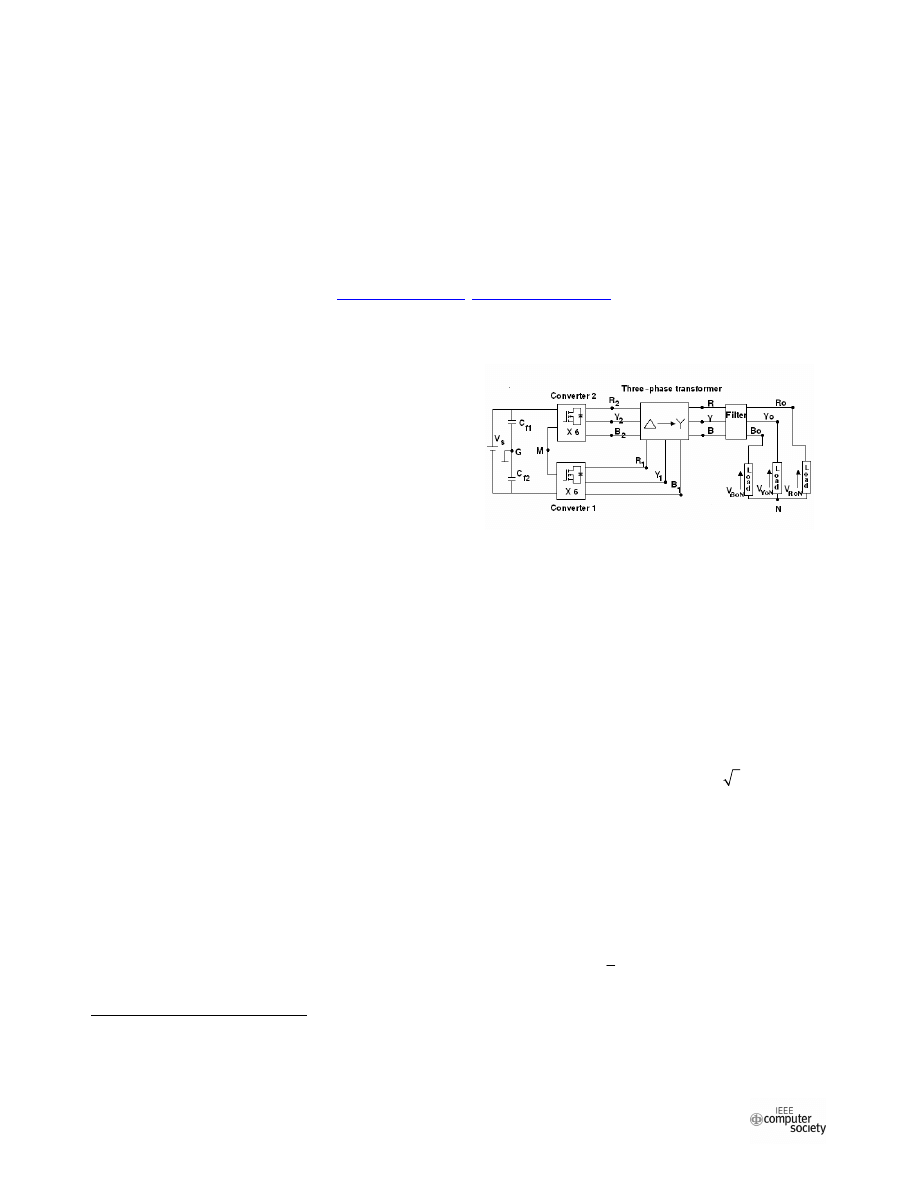

Figure 1. Block diagram of the multi-level

converter.

This paper describes the techniques used to design a

three-phase transformer which is a fundamental

component of a 1 kW multi-level inverter. The

transformer interconnects the outputs of two 6-pulse

inverters to produce 12-pulse voltage waveforms at the

output. The transformer transfers half of the throughput

power to the inverter output. The design and construction

of a 500 VA three-phase transformer for a 1kW inverter is

presented in this paper together with the practical issues

and considerations to build a transformer prototype.

1. Introduction

1

Inverters have been significant power converters for the

development of modern electric transportation systems;

however, high harmonic components generated by 6-

pulse inverters can modify the load behaviour. Several

strategies have been studied to obtain sinusoidal voltage

waveforms. For example, one method to diminish the

harmonic output content of standard 6-pulse inverters is

using PWM, multi-pulse and/or PWM multi-level

techniques.

Multi-pulse techniques were original developed for AC-

DC converters. These normally consist of arrangements

of 6-pulse converters interconnected in series or parallel

by three-phase transformers, reactors and/or capacitors at

the input or output of the converters.

A variant of multi-pulse inverter has been visualised

from the work reported in [1], which may be operated as

12, 24-pulse or even PWM multi-level inverter. To study

this variant of multi-pulse inverter and build a preliminary

prototype, a three-phase transformer design is required.

This paper presents the design and construction of the

three-phase transformer of the converter shown in Fig. 1,

which is part of a new generation of power inverters. The

This work was financially supported by the National Council of

Science and Technology (CONACyT), under the repatriation project

number 75648, and the National Polytechnic Institute (IPN) of Mexico,

under the project number SIP-20082849.

techniques used to design and select the transformer

components are described together with the design results

obtained to build a 500 VA transformer for a 1kW

converter.

1. Multi-level converter description

The 12-pulse inverter shown in Fig. 1, which is

composed of a DC rail, two capacitors connected in series

to filter the supply current and two 6-pulse three-phase

converters connected in series. The converters outputs are

connected to a delta-star transformer of 3 :1 turns-ratio,

and the star winding terminals are passed through a filter

stage before the load connection.

The transistors of each converter are operated in such a

way that the voltage waveforms v

R1G

, v

Y1G

, v

B1G

, v

R2G

and

v

B2G

are like those shown in Fig. 2, where v

R1G

, v

Y1G

and

v

B1G

are the outputs of converter 1 and, v

R2G

and v

B2G

are

the outputs of converter 2. v

R1N

is obtained subtracting the

common mode voltage of the converter, such that:

1

1

1

1

2

3

2

R N

R G

Y G

B

v

v

v

v

G

(1)

The voltage waveform at the transformer primary, v

Rprim

,

is obtained subtracting the voltages v

R2G

and v

B2G

at the

inputs of the delta windings, and therefore, the voltage at

the secondary winding, v

Rsec

,

is:

2009 International Conference on Electrical, Communications, and Computers

978-0-7695-3587-6/09 $25.00 © 2009 IEEE

DOI 10.1109/CONIELECOMP.2009.23

74

Figure 3. Mechanical diagram of the transformer.

sec

1

2

1

3

R

R N

B N

v

v

v

(2)

The 12-pulse converter reported in [2] produces

waveforms as those shown in Fig. 2 by the natural

switching of diodes. In contrast, the converter shown in

Fig. 1 produces the same waveforms but switching

transistors by an external control stage.

In Fig. 2 v

R1G

, v

Y1G

and v

B1G

have a negative semi-cycle

of magnitude V

S

/2; in contrast, v

R2G

and v

B2G

have a

positive semi-cycle and are phase-shifted by /6

respective to converter 1. The last waveform in Fig. 2

shows the phase voltage v

RN

, which is a 12-pulse wave

obtained by adding v

Rsec

and

v

R1N

. The duration of each

pulse of v

RN

is /6 due to the transistor switching period of

each converter.

The waveform v

Rsec

is useful to begin the design of the

transformer and calculate the maximum core flux density.

This is described in the following section.

3. Analysis of voltage and flux density

waveforms of the transformer

The analysis of the core flux is described assuming that

the three windings have equal core dimensions, as shown

in the mechanical diagram of Fig. 3, and the total flux in

the core produced by the three phases may be expressed

as:

Figure 2. Ideal waveforms of the converter.

0

I I I

R

Y

B

(3)

where the amplitudes and waves of

I

R

,

I

Y

, and

I

B

, are

equal, but phase-shitted by 120°. The magnetic flux

produced by the voltage impressed across the transformer

delta windings may be calculated using the Faraday’s law:

sec

1

I

³

R

R

s

v

dt

N

(4)

where N

s

is the number of turns of the secondary winding

and v

Rsec

is given in Eq. (2).

A flux core density, B

c

, can be assumed uniform

throughout the cross sectional area, A

c

, such that B

c

is

proportional to the flux density,

I

R

I

%

R

c

c

A

(5)

and hence, Eq. (4) and (5) may be used to calculate B

c

as

follows:

sec

1

c

R

s

c

B

v

N A

³

dt

(6)

Fig. 4 shows the ideal waveform of B

c

obtained with Eq.

(6). This waveform has negative and positive slopes

produced by the respective negative and positive steps of

v

Rsec

, and the constant periods of B

c

are obtained when the

steps of v

Rsec

are zero. The amplitude of B

c

, B

pk

, can be

deduced geometrically from Eq. (6) and Fig. 4, such that:

12 3

s

pk

s

c

o

V

B

N A f

(7)

75

where f

o

is the fundamental frequency output and V

s

is the

supply voltage of the converter. The product N

s

A

c

of Eq.

(6) may be arranged in terms of Vs, f

o

and B

pk

:

12 3

s

s

c

pk

o

V

N A

B f

(8)

where N

s

A

c

should be constant to keep the flux density

below the saturation level of the core material under a

fixed ratio of Vs/f

0

. In this way, Eq. (8) is utilized to

obtain the number of turns for the primary and secondary

windings by choosing A

c

from the manufacturer core

datasheets.

4. Power loss evaluation

Part of the power that is transferred from the primary to

the secondary of the transformer is lost in form of heat

due to the core excitation, Eddy currents in the core and

copper resistance of the windings, [4]. These losses

depend on the voltage and currents applied to the

transformer windings. For example,

I

R

is produced from

v

Rsec

, Eqs. (5) and (6), and the core reluctance will

produce an electro-motive force (emf),

F=

I

R

R

c

, such that

the back-emf of the secondary windings is not equal to

that of the primary, since:

p

p p

s s

R

N i

N i

c

I

F

R (9)

where N

P

i

P

is the back-emf of the primary, and

I

R

R

c

is

the back-emf equivalent to the excitation and heat

disipated in the core; whereas a small resistance may be

considered for the windings since these are formed by

several meters of copper wire. The copper loss is

therefore an important issue for the transformer design,

since:

Figure 4. Ideal flux density waveform of the

transformer core.

Figure 5. Mechanical diagram of one winding

inside the E core.

2

1

cu

R

cu

P

i R

(10)

Several transformer design methods have been

developed based on Eq. (8) in order to choose the

appropriated core dimensions and wire diameters for the

windings. For example, a transformer design with

maximum efficiency is described in [3], which equates

the copper and core losses, P

cu

= P

c

; whilst in [4], an

optimization method to reduce the total losses, P

T

= P

c

+

P

cu

, is described assuming that the flux density amplitude

is below the saturation level.

Following the techniques given in [3] and [4], an

iterative method is described below to determine the

optimum number of turns for the windings and the core

size.

5. Determination of the optimum parameters

for the transformer components

A 3% Si, 97% Fe wound E core was selected since this

type of core can be built with thinner strip widths in

contrast to laminated cores. Furthermore, three-phase

transformers can be easily designed over wound E cores

because all the core limbs are equal in dimension;

however, wound E cores tend to be noisy due to the

contact of their half faces, [5], as shown in Fig. 3.

Firstly, the number of turns and wire gauge for primary

and secondary windings, W

gp

and W

gs

respectively, may

be determined considering the available core window area

W

A

, the current density J and losses of the copper, and the

bobbin former dimensions. In order to determine these

parameters, N

p

and N

s

may be first calculated using Eq.

(7), ranging the value of A

c

from the manufacturer core

datasheet and fixing B

pk

below the core flux density

saturation level, B

SAT

. Once obtained N

p

and N

s

, W

gp

and

W

gs

are selected in such a way that J should be lower than

5 A/mm

2

, [6], otherwise the temperature of the copper

wire will be high and the copper insulation could melt.

76

Table 1. Transformer ratings

Total Power

1 kW

Output Voltage

127 V

rms

±15%

Output Frequency

60 Hz

Turns-Ratio

3 :1

Phase Current (

I

R1

)

3.9321 A

Maximum Flux Density (

B

pk

)

1.5 T

Next Core Type

Transformer Design

Next Wire Gauge

NWPT ++

End of

Core Types?

End of

Wire Gauges?

2

2

5 A/mm

5 A/mm

p

s

J

J

2

A

P

s

W

A

A

? &

?

p

s

N

N

?

T

P

End

Yes

No

Yes

No

No

No

Yes

Yes

Figure 6. Flux diagram of the transformer design

strategy.

Table 2. Transformer winding parameters

Core Type

3Q6

N

p

278

N

s

481

NWPT

p

2

NWPT

s

1

Total layers per winding

12

Total power losses

34.27 W

One strategy to reduce J is by using multiple wires per

turn of the same gauge such that the total copper area is

increased; this is a solution to the current density

constraint of 5 A/mm

2

. The number of wires per turn for

the primary and secondary windings is referred as NWPT

p

and NWPT

s

respectively.

Secondly, the winding dimensions are estimated to

verify that these fit into W

A

using the calculated values of

N

p

, N

s

, NWPT

p

, NWPT

s

, W

gp

and W

gs

. The thickness of an

inter-layer thermal insulator and the dimensions of a

bobbin former are also considered in the calculation of the

winding dimension since these reduce the available

window area for the windings. This is shown in Fig. 5

where the bobbin former thickness and the primary and

secondary windings areas, A

p

and A

s

respectively, are

indicated. If the total winding area, A

T

= A

p

+ A

s

, is

higher than W

A

the wire gauge need to be selected again

until A

T

fits into W

A

. These areas are shown in the

mechanical diagram of Fig. 5.

Once the windings fit into the core, P

T

is estimated

calculating P

c

and P

cu

. P

c

is obtained from the

performance curves of the manufacturer core datasheets

for a fixed value of B

pk

, and P

cu

is calculated as follows:

sec

3

3

cu

prim

P

P

P

(11)

where P

prim

and P

sec

are the primary and secondary

winding copper losses which may be obtained using Eq.

(10).

Finally, the above procedure is iteratively repeated for a

core type range and different wire gauges, and is

illustrated in the block diagram shown in Fig. 6. In this

way, minimal values of P

T

are gathered from the results

and the core size and wire gauges are therefore selected.

6. Design Results

A three-phase transformer for the converter shown in

Fig. 1 was designed using a spreadsheet and the

description given above. The transformer ratings used for

this design are listed in Table 1.

The core size was ranged from 3Q1 to 3Q12 using the

Wiltan datasheet specification for wound E cores, [7]. In

the same way, the wire gauge was ranged from 15 to 27

using the American Wire Gauge standard. The

spreadsheet showed that the optimum core size were

between 3Q6 and 3Q7; whereas the appropriate wire

gauges were between 19 and 25. Minimal total power

losses were obtained in these ranges assuming that J and

the winding size were below the maximum values.

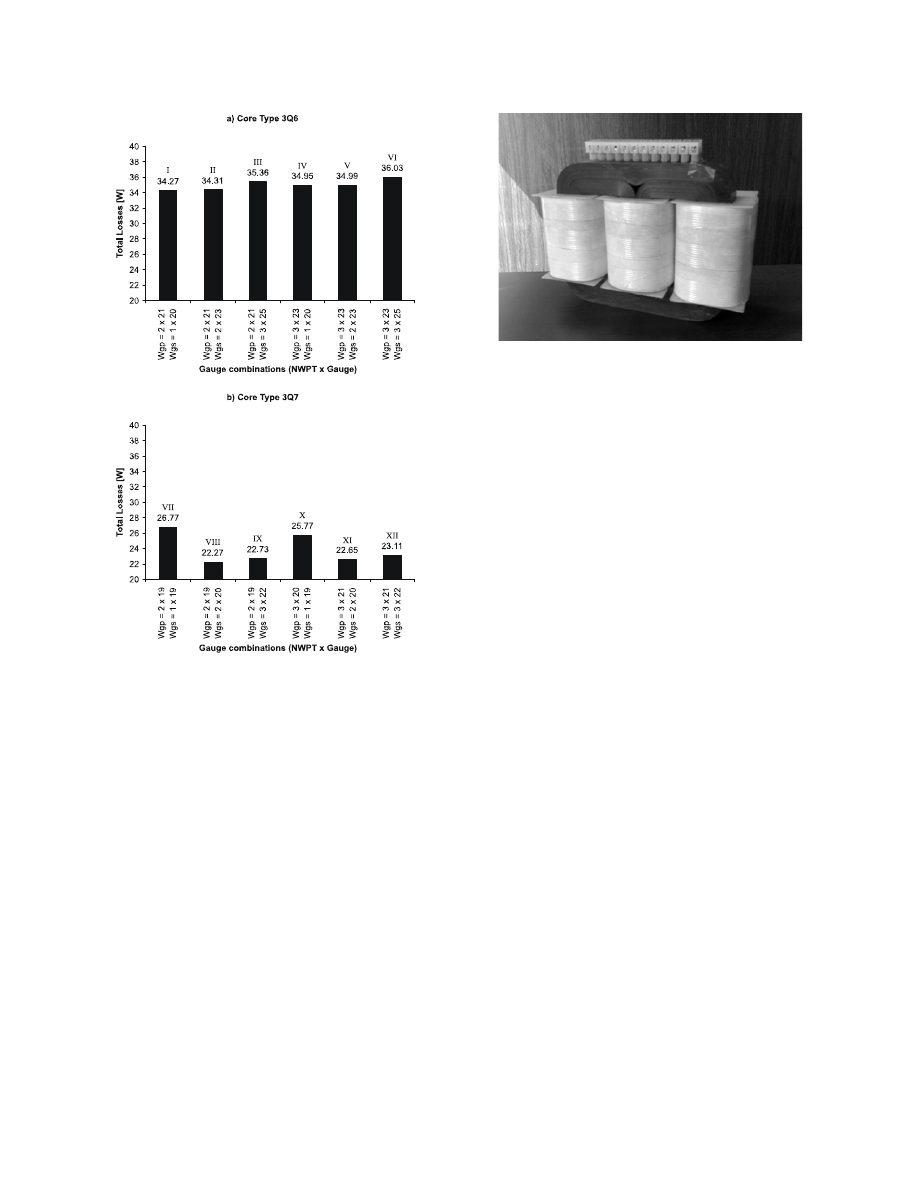

Figs. 7(a) and 7(b) show in bar charts the power losses

obtained in the spreadsheet for the cores 3Q6 and 3Q7

respectively, with combinations of W

gp

, W

gs

, NWPT

P

and

NWPT

s

. Fig. 7(a) shows that minimal values of P

T

are

obtained for combinations (I) and (II), 34.27 W and 34.31

W respectively; whilst in Fig. 7(b) combinations (VIII)

and (XI) produce the lowest power losses, 22.27 W and

22.65 W respectively.

The figures show that the lowest power loss is obtained

using a 3Q7 core with combination (VIII); however, the

transformer dimensions for this result are greater than the

results obtained with the 3Q6 core and, therefore, a 3Q6

core with combination (I) was chosen to build the

77

transformer. Table 2 shows the winding construction

parameters with a 3Q6 core and combination (I).

The windings were built using an academic winding

machine. NOMEX paper, [8], was used as interlayer

thermal insulator and a small gap between the windings

was considered for cooling purposes along their

construction. Fig. 8 shows a photograph of the

constructed transformer.

7. Conclusion

A three-phase transformer design for a new generation

multi-pulse inverter was presented in this paper. The

design was focused to obtain minimal power losses and

was performed using an iterative process of component

selection.

The transformer core and winding characteristics were

obtained from several combinations of core and wire

gauges that produced minimal power losses. In this

fashion, an optimum transformer design was obtained

with low power losses and reduced dimensions.

Figure 7. Total losses for different wire gauge

combinations: (a) 3Q6 core; (b) 3Q7 core.

Figure 8. Constructed Transformer.

Future work could consider the use of other core and

wire materials in order to improve the transformer size

and weight with low power losses.

8. Acknowledgments

The authors are grateful to National Polytechnic Institute

of México (IPN) and the National Council of Science and

Technology (CONACyT) for their encouragement and

support to build the prototype.

9. References

[1] Ismael Araujo-Vargas, Andrew J. Forsyth, “High-

Performance Multi-pulse with single-transistor active

injection”, IEEE transactions on Power Electronics,

Vol. 23-3, 2008, pp. 1299-1308.

[2] F.J. Chivite – Zabalza, A.J. Forsyth, D.R. Trainer, “A

simple, passive 24 – pulse ac-dc converter with in

herent load balancing”, IEEE transactions on Power

Electronics, Vol. 21-2, 2006, pp. 430-439.

[3] T. McLyman Colonel WM., “Transformer and

inductor design handbook”, third edition, California,

U.S.A., 2004.

[4] Erickson Robert W., D. Maksimovic, “Fundamentals

of power electronics”, second edition, Colorado,

2001, ISBN 0-7923-7270-0.

[5] William M. Flanagan, “Handbook of transformer

design and applications”, second edition, U.S.A.,

1993, ISBN 0-07-021291-0.

[6] N. Mohan, T. M. Undeland, W. P. Robbins, “Power

electronics converters, applications, and design”,

second edition, U.S.A., 1995, ISBN 0-471-58408-8.

[7] http://www.wiltan.co.uk/client_files/default/wiltan_g

uide.pdf, “Silicon steel wound E&C cores”, Wiltan

Telmag magnetic components.

[8] http://www.pleo.com/dupund/nomex.htm, 0.13mm

Nomex Around paper for Thermal Insulation.

78

Wyszukiwarka

Podobne podstrony:

[architecture ebook] Design And Construction Of Japanese Gardens

Properties and Structures of Three phase PWM AC Power Controllers

A Composite Pwm Method Of Three Phase Voltage Source Inverter For High Power Applications

Design and implementation of Psychoacoustics Equalizer for Infotainment

The Discrete Time Control of a Three Phase 4 Wire PWM Inverter with Variable DC Link Voltage and Bat

The Discrete Time Control of a Three Phase 4 Wire PWM Inverter with Variable DC Link Voltage and Bat

Optimal Control of Three Phase PWM Inverter for UPS Systems

Sexual behavior and the non construction of sexual identity Implications for the analysis of men who

A Composite Pwm Method Of Three Phase Voltage Source Inverter For High Power Applications

Sonpar, Pazzaglia The Paradox and Constraints of Legitimacy

Development Of A Single Phase Inverter For Small Wind Turbine

DESIGN AND DEVELOPMENT OF MICRO TURBINE

Energy performance and efficiency of two sugar crops for the biofuel

Command and Control of Special Operations Forces for 21st Century Contingency Operations

Design and Performance of the OpenBSD Statefull Packet Filter Slides

Design and manufacturing of plastic

Ship Design and Construction Volume II Contents

więcej podobnych podstron