A New Medium Voltage PWM Inverter Topology for Adjustable Speed Drives

E. Cengelci*, S. U. Sulistijo*, B. O. Woo*, P. Enjeti*,

R. Teodorescu**, F. Blaabjerg**

Power Quality Laboratory*

Department of Electrical Engineering

Texas A&M University

College Station, TX – 77843

Tel: 409-845-7466

Fax: 409-845-6259

Email: enjeti@tamu.edu

Institute of Energy Technology**

Department of Electrical Engineering

Aalborg University

9220 Aalborg East, Denmark

Tel: 45 96 35 92 54

Fax: 45 98 15 14 11

Email: fbl@iet.auc.dk

Abstract: In this paper a new PWM inverter topology suitable for

medium voltage (2300 / 4160 V) adjustable speed drive (ASD)

systems is proposed. The modular inverter topology is derived by

combining three standard 3-phase inverter modules and a 0.33

pu output transformer. The output voltage is high quality, multi-

step PWM with low dv/dt. Further, the approach also guarantees

balanced operation and 100% utilization of each 3-phase inverter

module over the entire speed range. These features enable the

proposed topology to be suitable for powering constant torque as

well as variable torque type loads. Clean power utility interface of

the proposed inverter system can be achieved via an 18-pulse

input transformer. Analysis, simulation, and experimental results

are shown to validate the concepts.

1. INTRODUCTION

Power converters for medium voltage adjustable speed drive

(ASD) systems (2300V, 4160V) are primarily current

source inverter (CSI) based [5]. The CSI approach employs

SCR/GTO devices and has the following disadvantages:

higher cost per kW; suffers from stability problems;

unsuitable for running multiple motors from a single

inverter; can excite torsional resonance’s in the motor;

results in increased motor heating and poor input current

quality. On the other hand, the conventional voltage source

inverter (VSI) for medium voltage ASDs suffers from high

output dv/dt; elevated common mode output voltage & dv/dt

which necessitates additional motor insulation or a

dedicated output isolation transformer in retrofit

applications.

Both of the above CSI/VSI approaches employ power

devices which are manufactured in low volume. With

corrective measures to improve utility power quality, the

cost of the overall medium voltage ASD per kW is at least

five times the cost per kW of a present day 480V PWM

ASD employing IGBT devices. In view of this, references

[1-4] have suggested the use of series connected single-

phase PWM inverter modules for medium voltage ASD

systems. This topology despite its many advantages suffers

from the following drawbacks:

i.

Employs many series connected single-phase

inverter modules.

M

K

L

M

c

1

a

1

b

1

3 P h a s e

Inverter

M o d u l e

1

c

3

a

3

b

3

3 P h a s e

Inverter

M o d u l e

3

c

2

a

2

b

2

3 P h a s e

Inverter

M o d u l e

2

1

2

3

V

D C

+

-

V

D C

+

-

V

D C

+

-

(a)

L

a

2

2

b

2

K

b

1

c

1

1

a

1

b

3

M

3

c

3

a

3

c

2

(b)

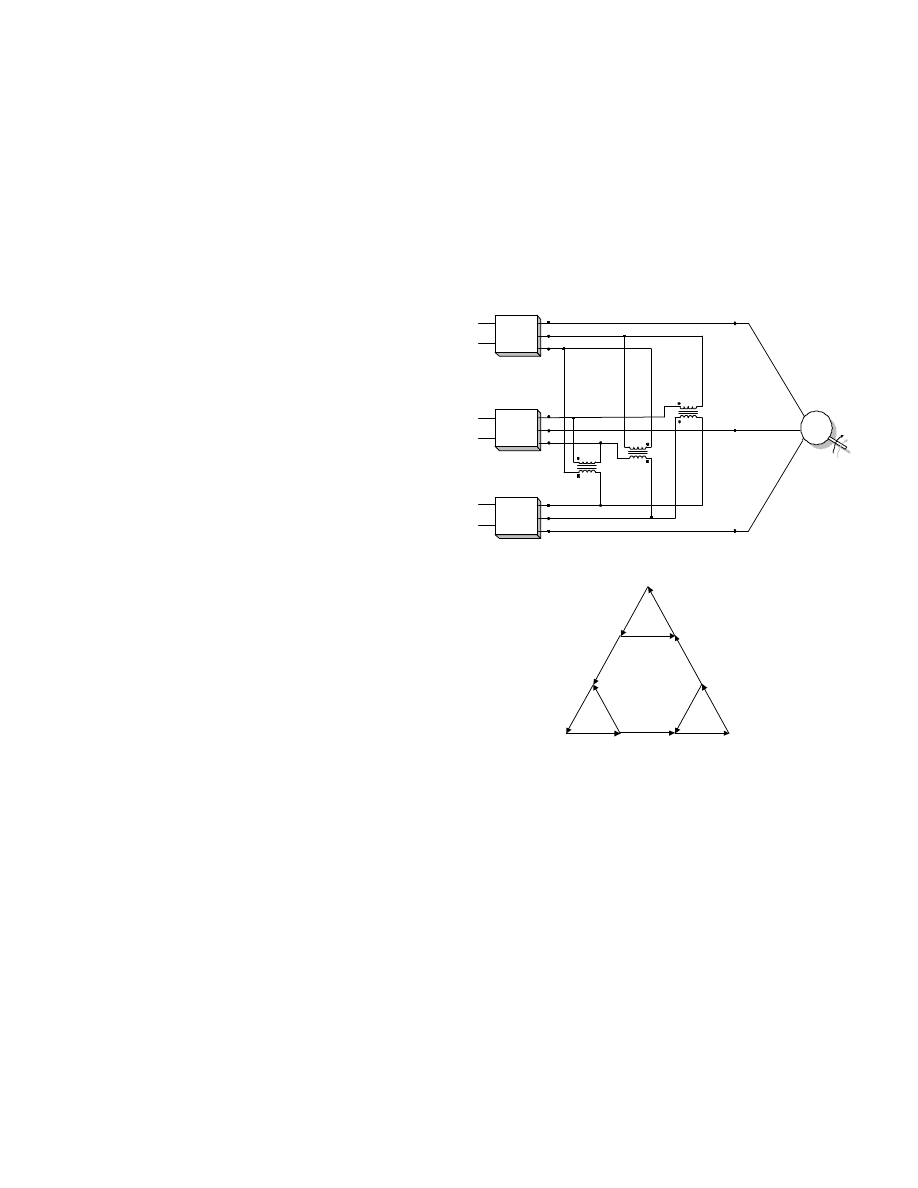

Fig. 1. (a) Proposed new medium voltage PWM inverter topology.

(V

dc

= 1090V, IGBT’s rated at 1700V for 2300V ac (rms) output)

(V

dc

= 1970V, IGBT’s/IGCT’s rated at 3300V for 4160V ac (rms) output)

(b) Vector diagram of the system with the fundamental voltages.

ii.

In constant torque applications at low speeds, the

dc-link capacitive energy storage requirements are

high.

iii.

Larger number of single-phase inverter modules

also require larger number of isolated secondary

windings in the input transformer which results in

higher manufacturing cost.

In this paper a new medium voltage PWM inverter topology

is proposed [6]. The proposed inverter employs three

standard 3-phase PWM inverter modules along with a 0.33

pu output transformer (Figs. 1 and 2). The advantages of the

proposed system can be summarized as follows:

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

M

i

a

2

V

dc

+

-

V

dc

+

-

V

dc

+

-

-20

o

3-phase

Rectifier/Inverter

ASD modules

Output

transformer

Medium

voltage ASD

a

1

b

1

c

1

a

2

b

2

c

2

a

3

b

3

c

3

s

t

v

r

q

p

o

w

x

y

z

u

i

1

i

2

i

3

i

4

i

5

i

6

K

L

M

0

o

+20

o

A

C

B

3-Phase

medium voltage

utility

18-pulse

polyphase

transformer

I

A

I

B

I

C

A

1

B

1

C

1

A

2

B

2

C

2

A

3

B

3

C

3

1

2

3

i

c

1

i

b

1

i

a

1

i

c

2

i

b

2

i

a

3

i

b

3

i

c

3

i

o

1

i

o

2

i

o

3

(a)

K

M

a

3

b

3

3

c

3

a

1

1

b

1

c

1

c

2

2

a

2

b

2

L

o

p

s

t

x

w

q

r

z

y

u

v

i

1

i

2

i

4

i

5

i

6

i

3

i

a

1

i

c

1

i

b

1

i

a

3

i

c

3

i

b

3

i

a

2

i

c

2

i

b

2

o

p

q

r

s

t

u

v

w

x

y

z

i

1

i

2

i

3

i

4

i

5

i

6

(b) (c)

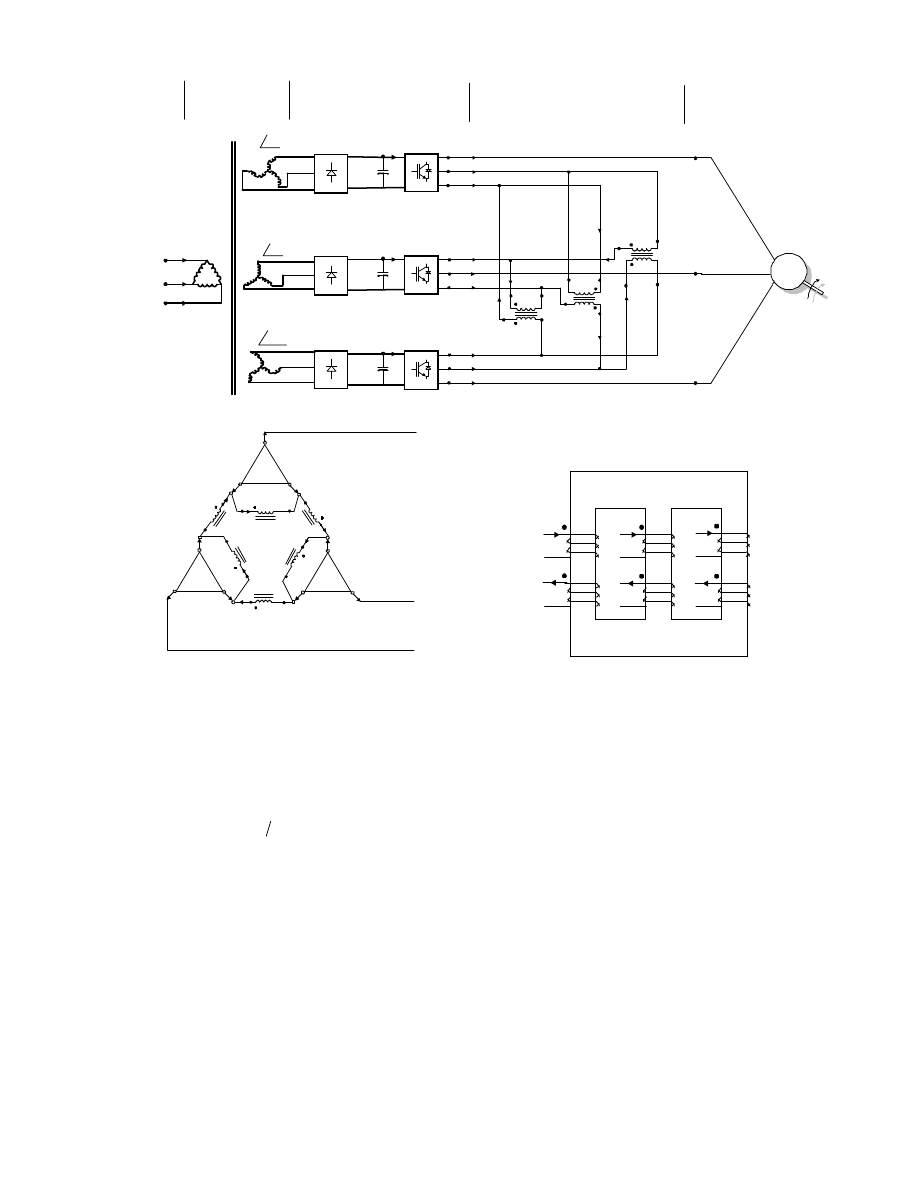

Fig. 2 (a) Complete medium voltage ASD with the proposed topology along with an 18-pulse input transformer for clean input power. (b) Connection of

inverter modules and the output transformer. (c) Winding configuration of output transformer on a three- limb core.

i.

Only three standard 3-phase rectifier/inverter

modules are necessary to generate medium voltage

output.

ii.

Each inverter is balanced in operation, equally

loaded and supplies 3

1

output power.

iii.

Modular construction of the medium voltage

inverter system facilitates the use of lower voltage

IGBT devices which are available in larger volume,

easy maintenance and spare management.

iv.

The output voltage is 3 pu, high quality multilevel

PWM with low dv/dt.

v.

The dc-link capacitive energy storage requirement is

low due to balanced operation of each three-phase

inverter module.

vi.

The proposed system is suitable for powering

constant/variable torque type loads over a wide

speed range.

vii.

The inverter system is flexible for generating

different medium voltage levels for ASD

applications.

viii.

The output transformer contributes to higher output

voltage and eliminates any circulating current

within the inverter modules.

2. OPERATION OF THE INVERTER SYSTEM

Fig.1a shows the interconnection of three standard 3-phase

inverter modules along with an output transformer to

generate higher output voltage. The vector diagram

representing the complete inverter system is shown in Fig.

1b. Each three-phase inverter generating balanced three-

phase output voltages is represented by a delta. For

example,

1

a ,

1

b and

1

c (Fig. 1b) represent the inverter

module-1 in Fig. 1a. Also three transformers of 1:1 turn

ratio are connected to the inverter output (Fig. 1a). The

purpose of the output transformer is to generate the vectors

(Fig. 1a, 1b)

3

1

a

c

,

2

3

c

b

,

1

2

b

a

from inverter output voltage

vectors

2

2

c

a

,

1

1

b

c

and

3

3

a

b

, respectively. A more detailed

connection diagram of the output transformer to accomplish

this task is shown in Fig. 2. The output transformer

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

therefore increases the output voltage and also ensures that

the addition of voltage vectors (Fig. 1b)

1

1

b

c

,

2

1

a

b

,

2

2

c

a

,

3

2

b

c

,

3

3

a

b

and

1

3

c

a

is zero at any switching instant, this

eliminates any circulating current within the loop.

The proposed inverter topology can power a 2300V

adjustable speed drive system with a dc bus voltage

=

dc

V

1090V. Hence IGBT’s rated at 1700V or higher can

be employed. Further, a

=

dc

V

1970V is sufficient to power

a 4160V adjustable speed drive system. For 4160V output

each inverter IGBT’s/IGCT’s could be rated at 3300V.

Further details are available in section 4.

Fig. 2a shows an approach to interface the proposed inverter

topology to electric utility via an 18-pulse transformer. The

input transformer essentially has three secondary windings

arranged in 0

°

,

±

20

°

phase shift to achieve harmonic current

cancellation in the utility line currents. Since each three-

phase inverter is loaded equally, the 5

th

, 7

th

, 11

th

, and 13

th

,

harmonic currents generated by each rectifier/inverter

module are cancelled in the input line. This results in clean

input power.

3. ANALYSIS

In this section analysis of the modular inverter system is

presented. Considering Fig. 2a, the load (motor) is

connected to inverter terminals

1

a ,

2

b and

3

c . Assuming a

balanced load, the fundamental components of the load

currents can be expressed as

)

sin(

2

1

t

I

i

a

ω

=

)

120

sin(

2

2

°

−

=

t

I

i

b

ω

(1)

)

120

sin(

2

3

°

+

=

t

I

i

c

ω

From Fig. 2b, the following equations can be written:

6

4

1

i

i

i

a

−

=

(2)

2

6

2

i

i

i

b

−

=

(3)

Since the voltage vectors

1

1

b

c

,

2

1

a

b

,

2

2

c

a

,

3

2

b

c

,

3

3

a

b

and

1

3

c

a

within the hexagon formed by the windings of the

output transformer, shown in Fig. 2b, add to zero at any

instant of time, there is no circulating current in the loop.

Therefore,

0

6

4

2

=

+

+

i

i

i

(4)

From (1) to (4) the currents

2

i ,

4

i ,

6

i can be solved as,

)

90

sin(

3

2

2

°

+

=

t

I

i

ω

)

30

sin(

3

2

4

°

−

=

t

I

i

ω

(5)

)

150

sin(

3

2

6

°

−

=

t

I

i

ω

Assuming that the output transformer has a large

magnetizing impedance, we have

2

1

i

i

=

4

3

i

i

=

(6)

6

5

i

i

=

The output currents of each inverter can be written as (Fig.

2b):

1

6

1

i

i

i

b

−

=

4

1

1

i

i

i

c

−

=

6

3

2

i

i

i

a

−

=

3

2

2

i

i

i

c

−

=

(7)

5

4

3

i

i

i

a

−

=

2

5

3

i

i

i

b

−

=

Using (1), (5), (6) and (7), the output currents of each

inverter module can be shown to be,

)

sin(

2

3

2

1

t

I

i

i

i

a

a

a

ω

=

=

=

)

120

sin(

2

3

2

1

°

−

=

=

=

t

I

i

i

i

b

b

b

ω

(8)

)

120

sin(

2

3

2

1

°

+

=

=

=

t

I

i

i

i

c

c

c

ω

The fundamental component (rms) of the output voltage of

inverter-1 (Fig. 2) is given by [5],

a

dc

b

a

m

V

V

2

2

3

1

1

=

(9)

where

dc

V is the dc-link voltage and

a

m is the amplitude

modulation index [5]. The range for

a

m for a sinusoidal

(with third harmonic injection) or space vector modulation

is

15

.

1

0

≤

≤

a

m

Similarly, the fundamental output voltages of inverter-2 and

inverter-3 are given by,

a

dc

b

a

m

V

V

2

2

3

2

2

=

(10)

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

and

a

dc

b

a

m

V

V

2

2

3

3

3

=

(11)

Now due to transformer action,

2

1

3

3

a

b

b

a

V

V

=

(12)

Therefore, the fundamental line-to-line output voltage of the

medium voltage inverter system is given by (Fig. 1b),

2

2

2

1

1

1

b

a

a

b

b

a

KL

V

V

V

V

+

+

=

(13)

From (9) to (13), we have,

a

dc

KL

m

V

V

2

2

3

3

=

(14)

Also, fundamental output VA of each inverter module is

given by,

rms

a

b

a

I

V

VA

,

1

1

1

1

3

⋅

⋅

=

rms

a

b

a

I

V

VA

,

2

2

2

2

3

⋅

⋅

=

(15)

rms

a

b

a

I

V

VA

,

3

3

3

3

3

⋅

⋅

=

From (8), (9), (10), (11) and (15), it can be shown that

I

m

V

VA

VA

VA

a

dc

2

2

3

3

2

1

=

=

=

(16)

Thus, (16) demonstrates that each inverter module is equally

loaded and fully utilized. Further, the total output VA of the

medium voltage inverter system is given by,

rms

a

KL

total

I

V

VA

,

1

3

⋅

⋅

=

I

m

V

a

dc

2

2

9

=

(17)

Comparing (16) to (17) it is clear that

total

VA

is three times

the VA rating of each inverter.

Equations (8) and (16) suggest that output currents of each

3-phase inverter are balanced and each inverter is fully

utilized. It should be noted that balanced operation of each

inverter module does not generate any low frequency

current components in the inverter input currents (

1

o

i ,

2

o

i ,

3

o

i ) when the output frequency is widely varied, particularly

at reduced speed. This is an important advantage of the

proposed inverter topology compared to the approach

discussed in [1-4].

3.A. VA Rating Of The Output Transformer:

Fig. 2 shows the connection diagram of the output

transformer. (5) and (6) illustrate the transformer winding

currents. Further, from (9) to (12) voltages across the

transformer windings are given by,

a

dc

rms

qr

rms

op

m

V

V

V

2

2

3

,

,

=

=

a

dc

rms

yz

rms

wx

m

V

V

V

2

2

3

,

,

=

=

(18)

a

dc

rms

uv

rms

st

m

V

V

V

2

2

3

,

,

=

=

Using (5) and (6), the rms currents through the output

transformer windings are

3

6

5

4

3

2

1

I

I

I

I

I

I

I

=

=

=

=

=

=

(19)

The VA rating of the output transformer can be computed as

follows:

+

⋅

+

⋅

+

⋅

=

3

,

6

,

1

,

(

2

1

I

V

I

V

I

V

VA

rms

st

rms

yz

rms

op

tr

)

4

,

5

,

2

,

I

V

I

V

I

V

rms

uv

rms

wx

rms

qr

⋅

+

⋅

+

⋅

(20)

Using (18), (19) and (20),

I

m

V

VA

a

dc

tr

2

2

3

=

(21)

Comparing (17) to (21), it is clear that VA rating of the

output transformer is

3

1

of total VA rating of the inverter

output.

4. DESIGN EXAMPLE

In this section a detailed design example of a 2300V,

2000hp medium voltage inverter is discussed (Fig. 2).

Motor parameters:

Power

( )

HP

P

o

2000

=

Power factor

( )

8

.

0

=

pf

Efficiency

( )

85

.

0

=

η

Line-to-line voltage

( )

rms

KL

V

V

2300

=

Fundamental output frequency

Hz

f

o

60

=

Apparent power

( )

S and line current

(

)

rms

a

I

,

1

of the motor

can be calculated as follows:

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

kVA

pf

P

S

o

2200

=

⋅

=

η

(22)

A

V

S

I

LL

rms

a

552

3

,

1

=

⋅

=

(23)

Since the rms inverter output currents are all equal and same

as the load currents, each 3-phase inverter module should be

rated for 552A.

By equating the output voltage

KL

V

in (14) to 2300V at

60Hz and assuming

1

.

1

=

a

m

5, we have

V

m

V

V

a

KL

dc

1090

3

3

2

2

=

⋅

⋅

=

(24)

Further, the rms current of the IGBT and diode pairs,

2

,

,

1

rms

a

rms

sw

I

I

=

. (25)

From (23) and (25)

A

I

rms

sw

390

,

=

(26)

Peak switch current is the same as peak motor current.

Therefore,

A

I

peak

sw

780

2

552

,

=

⋅

=

(27)

The IGBT’s in inverters are rated at rms current of 390A

and peak current of 780A. Further, IGBT’s rated at 1700V

or higher can be employed in each inverter module to

operate at a

=

dc

V

1090V.

If we assume the same motor parameters in the previous

design example, except the line-to-line voltage of the motor

( )

rms

KL

V

V

4160

=

, the inverter ratings are as follows:

From (24) to (27), we have,

V

V

dc

1970

=

,

A

I

rms

sw

215

,

=

,

A

I

peak

sw

431

,

=

The IGBT’s in inverters for 4160V motor design are rated at

rms current of 215A and peak current of 431A. IGBT’s

rated at 3300V [7] can be employed in each inverter module

to operate at a

=

dc

V

1970V.

5. PWM CONTROL STATEGY

In this section the necessary PWM control strategy required

to operate the proposed medium voltage topology (Fig. 1,

Fig. 2) is discussed. It is obvious that for proper operation of

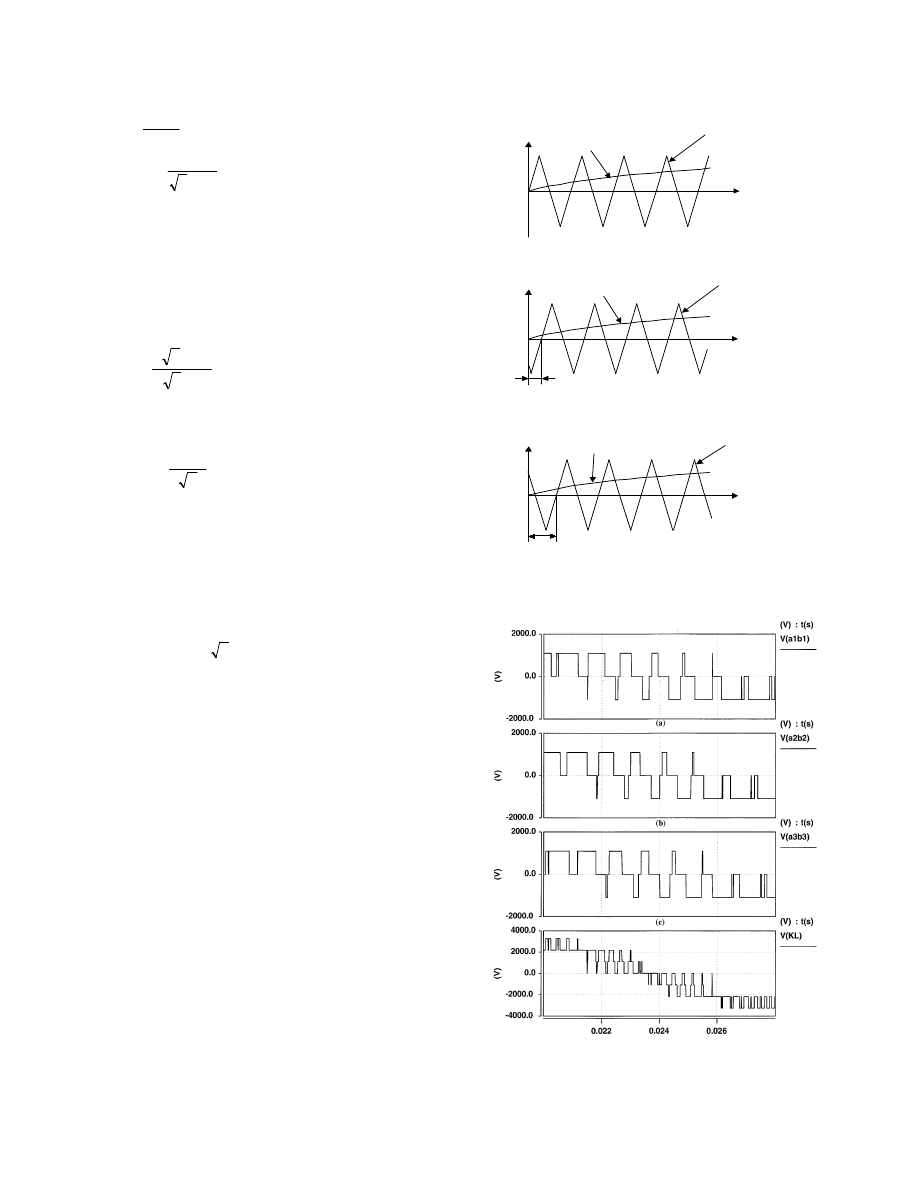

( a )

t

Modulating signal

f o r p h a s e A

Triangular carier signal

for inverter-1

120

o

t

Modulating signal

f o r p h a s e A

Triangular carier signal

for inverter-2

(b)

240

o

t

Modulating signal

f o r p h a s e A

Triangular carier signal

for inverter-3

( c )

Fig. 3 PWM control strategy for the proposed topology (Notice the 120

°

phase-shift among the high frequency triangular carriers for inverters 1,2,3)

(d)

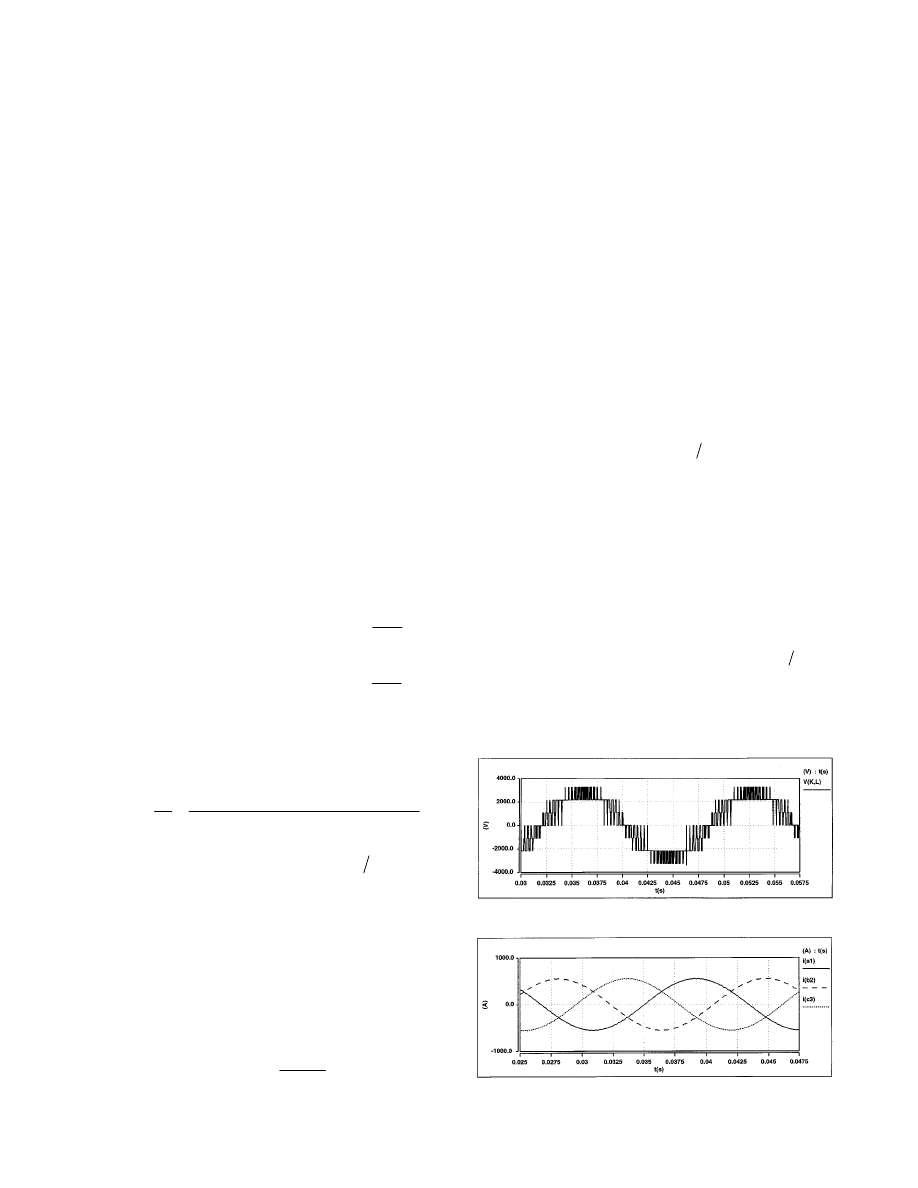

Fig.4 The voltages across “a” and “b” terminals of each 3-phase inverter

and the voltage across the motor terminals K and L.

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

the modular inverter system the three 3-phase inverter

modules need to be synchronized. Further, the high

frequency triangular carriers employed in each inverter are

so chosen that a phase-shift of 120

°

exists between them.

Then the overall output voltage

KL

v

(Fig. 4) applied to the

motor is not only multi-step in nature but also low in

harmonic content.

Fig. 3 shows the intersection of high frequency triangular

carrier signals and the low frequency modulating sinusoidal

signal for one phase. Notice the 120

°

phase shift among the

high frequency triangular carriers employed for the control

of inverters 1, 2 and 3.

Fig. 4 (a), (b) and (c) show the line-to-line voltages of the

inverters 1, 2 and 3, i.e.

1

1

b

a

v

,

2

2

b

a

v

and

3

3

b

a

v

, respectively.

Fig. 4 (d) illustrates the overall output voltage

KL

v

, which is

multi-step in nature.

Assuming that the triangular carrier frequency is much

higher than the fundamental output frequency, the Fourier

components of voltages

1

1

b

a

v

,

2

2

b

a

v

and

3

3

b

a

v

can be

expressed as follows [5]:

( )

( )

∑

∞

=

+

=

2

sin

sin

1

1

h

h

dc

a

dc

b

a

t

h

A

V

t

m

V

v

ω

ω

( )

∑

∞

=

°

−

+

=

2

120

sin

sin

2

2

h

f

h

dc

a

dc

b

a

m

t

h

A

V

t

m

V

v

ω

ω

(28)

( )

∑

∞

=

°

+

+

=

2

120

sin

sin

3

3

h

f

h

dc

a

dc

b

a

m

t

h

A

V

t

m

V

v

ω

ω

where h is the order of the harmonics in the inverter output

voltage,

h

A is the amplitude of

th

h harmonic and

signal

modulating

of

Frequency

signal

carrier

triangular

of

Frequency

1

=

=

f

f

m

s

f

The phases of harmonics of

f

m

h

°

⋅

±

120

in the

expressions of

2

2

b

a

v

and

3

3

b

a

v

in (28) are primarily due to

the inherent 120

°

phase-shifts among the high frequency

triangular carrier signals (Fig. 3).

From Fig. 2 the overall inverter output voltage

KL

v

is,

3

3

2

2

1

1

b

a

b

a

b

a

KL

v

v

v

v

+

+

=

( )

+

=

t

m

V

a

dc

ω

sin

3

( )

t

h

m

h

A

V

h

f

h

dc

ω

sin

120

cos

2

1

2

∑

∞

=

°

⋅

+

(29)

For sine-triangular PWM, h is given by [5] as,

,

4

,

2

,

±

±

=

f

f

f

m

m

m

h

,

5

2

,

3

2

,

1

2

±

±

±

f

f

f

m

m

m

6

3

,

4

3

,

2

3

,

3

±

±

±

f

f

f

f

m

m

m

m

(30)

etc.

Substituting (30) into (29) we can deduce that for a large

value of

f

m (i.e. high switching frequency) the harmonic

components of h , around the side-bands of

f

m ,

f

m

2

,

f

m

4

,

f

m

5

, are cancelled in

KL

v

in (29). The dominant

harmonics in

KL

v

are around

f

m

3

. Therefore, in the

proposed PWM strategy the overall inverter line-to-line

output voltage (

KL

v

) is multi-step with the dominant

harmonics at three times the inverter switching frequency.

Also the voltage

KL

v

experiences level change in steps of

dc

V , which contributes to low

dt

dv

across the motor

terminals. Fig.5, Fig. 10, and Fig 11 validate the above

conclusions.

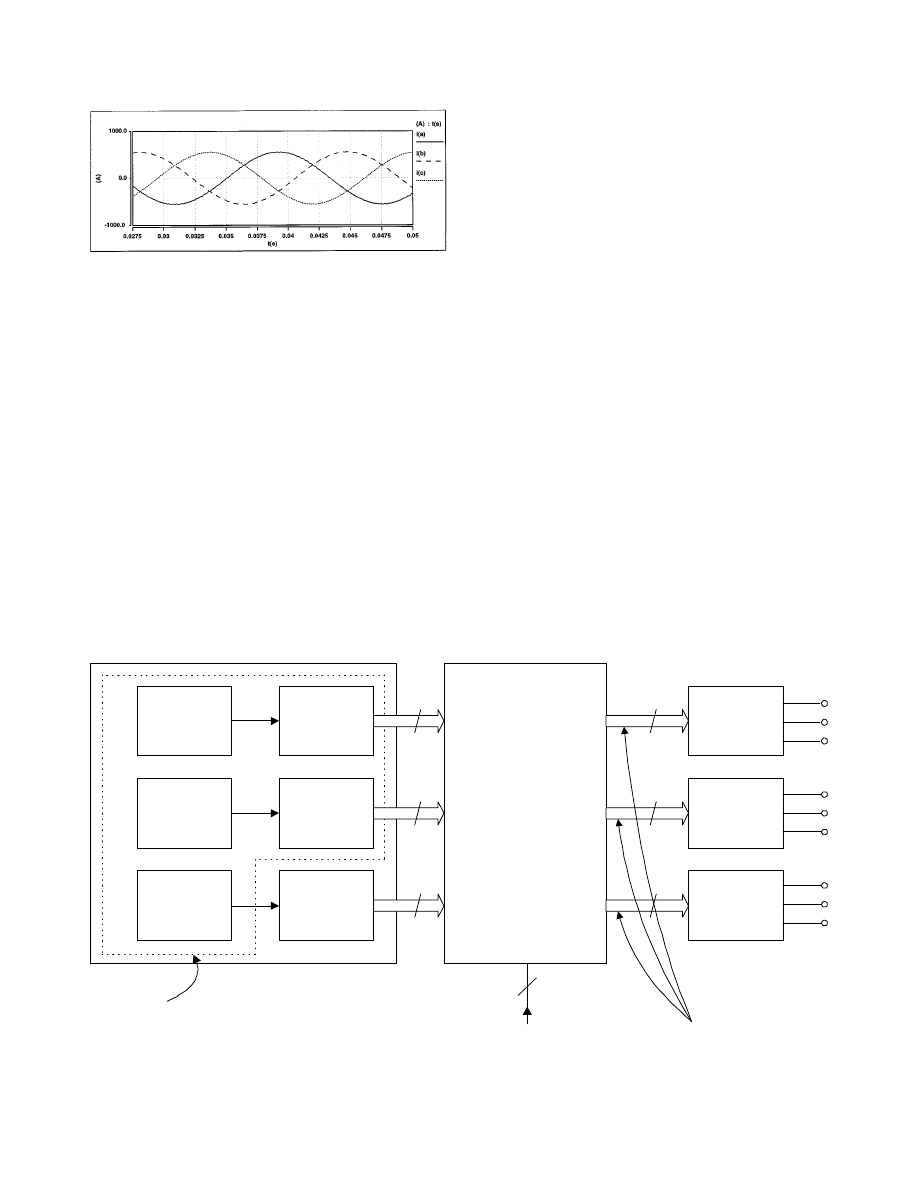

6. SIMULATION RESULTS

In this section simulation results of the proposed system

powering a 2300V motor detailed in the design example are

discussed. The switching frequency is set at 1kHz for each

inverter module in the simulation. Fig. 5 shows the line to-

line output voltage of the inverter system across the motor

terminal. It is clear from Fig. 5 that the voltage across the

motor terminal is multilevel, therefore is of low

dt

dv

and

its harmonic content is also low. Fig. 6 shows the motor

currents, which are balanced and nearly sinusoidal. Lastly,

Fig. 7 shows the three output currents of an inverter module,

which are balanced.

Fig. 5 Line-to-line multi-step PWM voltage across the motor terminals.

Fig. 6 The currents of the motor (

1

a

i

,

2

b

i

,

3

c

i

).

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

Fig. 7 O utput currents of inveter-1 (

1

a

i

,

1

b

i

,

1

c

i

).

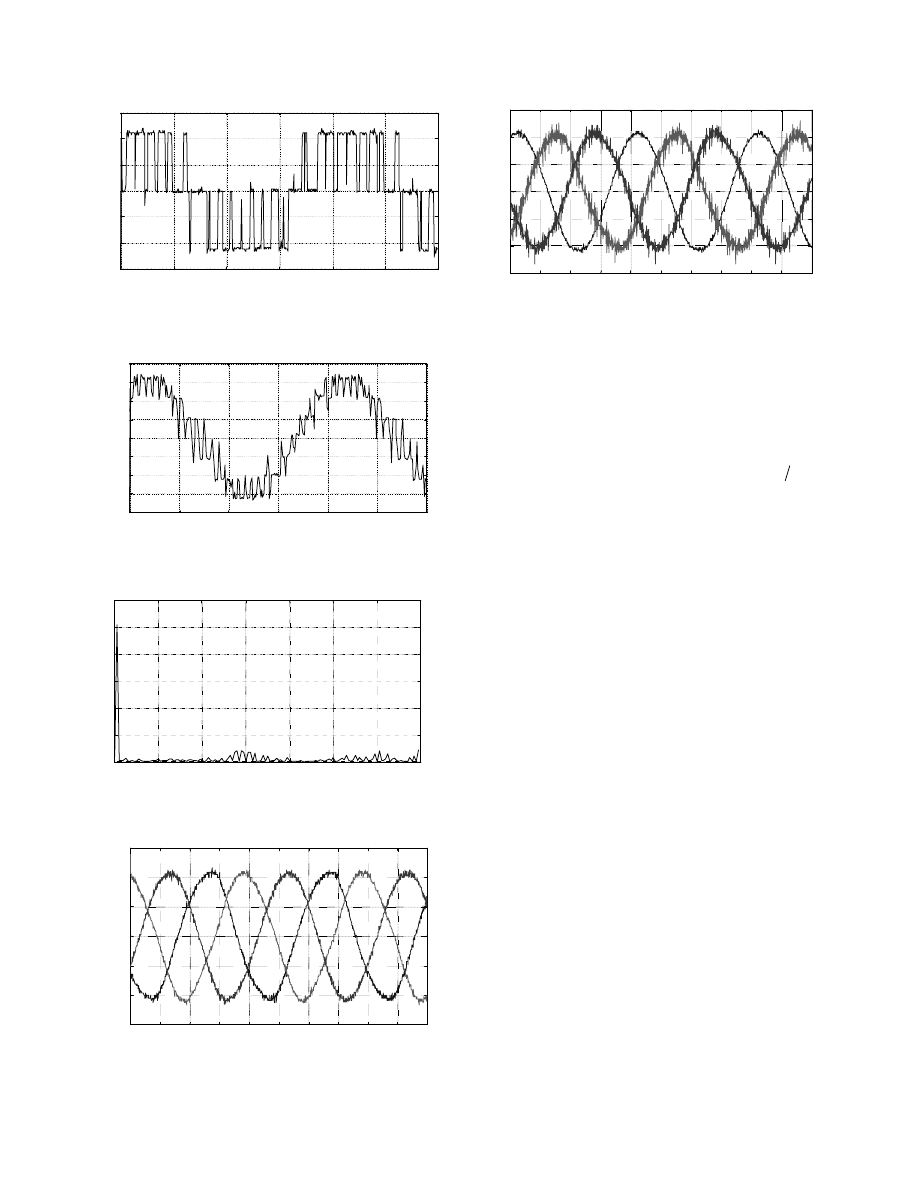

7. EXPERIMENTAL RESULTS

A scale down experimental prototype of the proposed

inverter topology (Fig. 2) was tested in the laboratory for the

following specifications:

Dc bus voltages: 110V

Motor power: 4kW

Switching frequency: 1kHz

Fundamental output frequency: 50Hz

Fundamental voltage across the motor terminals: 260V

rms

The control signals for the inverter system in Fig. 2 are

obtained by using a DSP evaluation module of

TMS320F240 of Texas Instruments. TMS320F240 is a

fixed-point, 16 bit low cost DSP, incorporating a 20 MIPS

processor designed specifically for motor drive applications.

The block diagram of the PWM control system is shown in

Fig. 8. The PWM control signals for inverter-1 and -2 are

generated by the full compare and simple compare PWM

channels of the DSP (Fig. 8). The control signals for

inverter-3 are generated by software using GP Timer 3. The

full compare unit is capable of generating gating signals

with their dead-bands for inverter-1. However, the dead-

band generation of gating signals for inverters 2 and 3 is

obtained by hardware. The implementations of triangular

carrier signals are done by the GP timers 1, 2 and 3. A sine

table is used to implement the low frequency modulating

sinusoidal signals. The gating signals generated in the

control board are applied to the inverters via fiber optic

isolation hardware. A protection signal from each inverter is

fed back to the control hardware unit to ensure safe

operation of the system.

Fig. 9 shows the experimental PWM line-to-line voltage of

inverter-1. Fig. 10 shows the multilevel PWM voltage

KL

v

applied to the motor terminals. Fig. 11 shows the frequency

spectrum of voltage

KL

v

. The dominant harmonics in

KL

v

are around 3kHz, i.e. three times the inverter switching

frequency (Equation 29). Fig. 12 shows the motor currents

1

a

i ,

2

b

i ,

3

c

i (Fig. 2). Fig. 13 shows the inverter-1 output

currents

1

a

i ,

1

b

i ,

1

c

i . These results demonstrate the

feasibility of the proposed inverter topology. More

extensive tests are underway and will be reported at the

conference presentation.

GP Timer 1

GP Timer 2

GP Timer 3

Full Compare

6 PWM

Channels

with Dead-band

Simple

Compare

3 PWM

Channels

Output ports of

D/A Converter

Event Manager

TMS320F240 Evaluation Module

6

3

Optical Isolation

and Dead-band

Generation Module

3

3-Phase

Inverter 1

3-Phase

Inverter 2

3-Phase

Inverter 3

6

6

6

Fiber Optic Cables

a

1

b

1

c

1

a

2

b

2

c

2

a

3

b

3

c

3

Protection feedback signals

from three 3-phase inverters

3

Gating signals

for three

inverters

Fig. 8 DSP implementation of the PWM generation for the medium voltage inverter.

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

0

0. 00 5

0. 01

0 .0 1 5

0 .0 2

0. 02 5

0 .0 3

-1 5 0

-1 0 0

-5 0

0

5 0

10 0

1 5 0

Fig. 9 Line-to-line output voltage of inverter-1 (

1

1

b

a

v

).

(Vertical scale: 50V/div, Horizontal scale:5ms/div)

0

0.005

0.01

0.015

0.02

0.025

0.03

-400

-300

-200

-100

0

100

200

300

400

Fig. 10 The voltage across the motor terminals (

KL

v

).

(Vertical scale: 100V/div, Horizontal scale:5ms/div)

0

1000

2000

3000

4000

5000

6000

7000

0

50

100

150

200

250

300

Fig. 11 Frequency spectrum of

KL

v

.

(Vertical scale: 50V/div, Horizontal scale:1kHz/div)

0

0.005

.010

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0.05

-3

-2

-1

0

1

2

3

i

b

i

a

i

c

Fig. 12 Motor currents (

1

a

i

,

2

b

i

,

3

c

i

).

(Vertical scale: 1A/div, Horizontal scale:5ms/div)

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0.05

-3

-2

-1

0

1

2

3

ib1

ic1

ia1

Fig. 13 O utput currents of inverter-1 (

1

a

i

,

1

b

i

,

1

c

i

).

(Vertical scale: 1A/div, Horizontal scale:5ms/div)

7. CONCLUSIONS

In this paper a new PWM inverter topology suitable for

medium voltage adjustable speed drive systems have been

proposed. The proposed approach is modular, flexible

architecture suitable for different output voltage levels.

Advantages of the proposed inverter topology include: high

quality multilevel PWM output, low output

dt

dv

and

modular construction facilitating the use of lower voltage

IGBT devices. Analysis, simulation and experimental

results demonstrate the feasibility of the proposed inverter

system.

REFERENCES

1.

D.A. Paice and C.W. Charles, “High voltage modular inverter and

control system thereof”,US Patent No: 4674024, June 16, 1987.

2.

P. W. Hammond, “Medium voltage PWM drive and method”, US

Patent No: 5625545, April 29, 1997.

3.

K. Opal, H. Abrams, P. W. Hammond, “Low and medium voltage

PWM AC/DC power conversion method and apparatus”, US Patent

No: 5638263, June 10, 1997.

4.

P. W. Hammond, “A New Approach to Enhance Power Quality for

Medium Voltage Drives”, Petroleum and Chemical Industry

Conference Record, Sept. 1995, pp. 231-235.

5.

N. Mohan, T. M. Undeland, W. P. Robbins, "Power Electronics:

Converters, Applications, and Design," Chapter 8, 1995 Second

Edition, John Wiley & Sons.

6.

“Method and System of Medium Voltage Inverter Topologies For

Adjustable Speed AC Motor Drive Systems”, Texas A&M

University, US Patent Application, 1998.

7.

“Eupec IGBT Databook”, Eupec Inc., 1998.

0-7803-4943-1/98/$10.00 (c) 1998 IEEE

Wyszukiwarka

Podobne podstrony:

Single Phase Line Frequency Commutated Voltage Source Inverter Suitable for fuel cell interfacing

A new control strategy for instantaneous voltage compensator using 3 phase PWM inverter

A new control strategy for instantaneous voltage compensator using 3 phase PWM inverter

A neural network based space vector PWM controller for a three level voltage fed inverter induction

A Composite Pwm Method Of Three Phase Voltage Source Inverter For High Power Applications

A Composite Pwm Method Of Three Phase Voltage Source Inverter For High Power Applications

A Digital Control Technique for a single phase PWM inverter

Conducted EMI in PWM Inverter for Household Electric Appliance

A ZVS PWM Inverter With Active Voltage Clamping Using the Reverse Recovery Energy of the Diodes

A New Low Cost Cc Pwm Inverter Based On Fuzzy Logic

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

Algebraic PWM Strategies of a Five Level NYC Voltage Source Inverter

A Digital Control Technique for a single phase PWM inverter

Adaptive fuzzy control for uninterruptible power supply with three phase PWM inverter

A New Low Cost Cc Pwm Inverter Based On Fuzzy Logic

A Simplified Functional Simulation Model for Three Phase Voltage Source Inverter Using Switching Fun

The Discrete Time Control of a Three Phase 4 Wire PWM Inverter with Variable DC Link Voltage and Bat

The Discrete Time Control of a Three Phase 4 Wire PWM Inverter with Variable DC Link Voltage and Bat

więcej podobnych podstron