Intermittent drying of bioproducts––an overview

K.J. Chua

*

, A.S. Mujumdar, S.K. Chou

Department of Mechanical Engineering, National University of Singapore, 9 Engineering Drive 1, Singapore 117576, Singapore

Received 8 March 2002; received in revised form 2 May 2003; accepted 3 May 2003

Abstract

Unlike the conventional practice of supplying energy for batch drying processes at a constant rate, newly developed intermittent

drying processes employ time-varying heat input tailored to match the drying kinetics of the material being dried. The energy re-

quired may be supplied by combining different modes of heat transfer (e.g. convection coupled with conduction or radiation or

dielectric heating simultaneously or in a pre-selected sequence) in a time-varying fashion so as to provide optimal drying kinetics as

well as quality of the bioproduct. This is especially important for drying of heat-sensitive materials (such as foods, pharmaceutical,

neutraceutical substances, herbs, spices and herbal medicines). Intermittent heat supply is beneficial only for materials which dry

primarily in the falling rate period where internal diffusion of heat and moisture controls the overall drying rate. Periods when little

or no heat is supplied for drying allow the tempering period needed for the moisture and heat to diffuse within the material. As the

moisture content increases at the surface of the biomaterial during the tempering period, the rate of drying is higher when heat input

is resumed. It is possible to control the heat input such that the surface temperature of the product does not exceed a pre-determined

value beyond which thermal damage of the material may occur. This process results in reduction in the use of thermal energy as well

as the mass of air used in convective drying. Thus, the thermal efficiency of such a process is higher. The quality of the product, as

such color and ascorbic acid content, is also typically superior to that obtained with a continuous supply of heat. However, in some

cases, there will be a nominal increase in drying time. In the case of microwave-assisted and heat pump drying, for example, the

capital cost of the drying system can also be reduced by drying in the intermittent mode.

This paper provides an overview of the basic process, selected results from experiments and mathematical models for a variety of

biomaterials dried in a wide assortment of dryers. It begins with a classification of intermittent drying processes that may be applied

e.g. time-varying temperature, air flow rate, operating pressure as well as heat input by different modes and in different temporal

variations. The beneficial effects of improving the quality of dried bioproducts by different intermittent processes are also included

and discussed.

Ó 2003 Elsevier Ltd. All rights reserved.

Keywords: Drying technologies; Product quality; Drying kinetics

1. Introduction

Traditional convective drying processes employ con-

tinuous constant air temperature, humidity and airflow

for moisture removal. For heat-sensitive products, the

quality of the dried product depends largely on the

conditions of the air employed. It is well known that

heat transfer has quality-control applications involving

either a raising or lowering of temperature and often

requires precise monitoring of the product spatial dis-

tribution of thermal histories that are required to con-

form to certain quality protocol. It is, therefore,

essential to acquire an in-depth understanding of the

thermal behavior of these heat-sensitive products and

the corresponding related product quality and equip-

ment energy consumption when non-steady drying

conditions are employed.

For heat-sensitive materials much of the resistance to

drying resides within the material. Thus, unduly high

heat and mass transfer rates applied at the surface only

result in overheating or over-drying of the surface layer

resulting in quality problems without major increase in

the drying kinetics. The rate of migration of the mois-

ture from within the solid to the evaporation front often

controls the overall drying rate. Thus, for optimal en-

ergy consumption and improved quality, it is important

to match the energy demand of the product during

drying with the external supply of energy using several

possible modes of heat transfer simultaneously or

*

Corresponding author. Fax: +65-779-1459.

E-mail address:

(K.J. Chua).

0960-8524/$ - see front matter

Ó 2003 Elsevier Ltd. All rights reserved.

doi:10.1016/S0960-8524(03)00133-0

Bioresource Technology 90 (2003) 285–295

sequentially. Often it is not possible to control the exter-

nal heat/mass transfer rate obtained by convection alone

e.g. in a fluidized bed dryer the criterion which decides

the choice of the gas flow rate is the need for fluidiza-

tion. In fact, it is necessary to use a flow rate far in ex-

cess of the already high minimum fluidization velocity.

In the falling rate period for most solids this represents

a much higher external heat/mass transfer coefficient

than is required to remove the moisture arriving at

the surface. In such cases it is a good idea to fluidize

the material periodically or to increase and decrease the

fluidizing air temperature as required by the material. It

is also possible to use a simple control strategy to keep

the bed temperature constant and vary the fluidizing air

temperature to avoid overheating and save energy con-

currently.

It is noteworthy that numerous traditional drying

processes which are considered continuous are in fact

inherently intermittent. Freeze drying, rotary drying,

spouted bed drying and paper drying on conventional

multi-cylinder paper machines are some of the major

large scale examples of inherently intermittent processes.

With a careful look at the actual processes involved in

these common dryers one can readily see that much of

the heat/mass transfer occurs in only a part of the dryer

while the other part of the dryer essentially acts as a

tempering period allowing time for the internal moisture

to migrate to the surface before the material sees the

high heat/mass transfer zone again in a cyclic fashion.

The main difference here is that the frequency of this

cyclic operation is typically fixed by the choice of the

geometric and operating parameters of the design and

cannot be de-coupled from them. For intermittent dry-

ing considered here, the discussion will be limited to

drying systems whereby the frequency or time-variation

of heat input by any mode of heat transfer can be in-

dependently controlled. Note that temporal variation is

possible only for batch dryers while for continuous

dryers this translates to spatial variation in heat input

along the length of the dryer, e.g. a continuous plug-flow

fluid bed dryer with sections along its length utilizing

spatially varying fluidizing air temperature.

Under the umbrella of intermittent drying are all

types of batch dryers that employ time-varying operat-

ing conditions e.g. periodic variation of pressure (from

high to atmospheric) or cyclic variations in level of

vacuum applied. Thus, dryers that employ time-varying

temperature, gas flow rate and/or operating pressure are

included. The frequencies involved in such operations

are typically low. Such an operation is applicable mainly

for heat-sensitive materials and those with long periods

of drying mainly or exclusively in the falling rate period.

One may generally expect a slight-to-moderate increase

in drying time but this reflects in compensating decrease

in energy consumption and enhancement of product

quality.

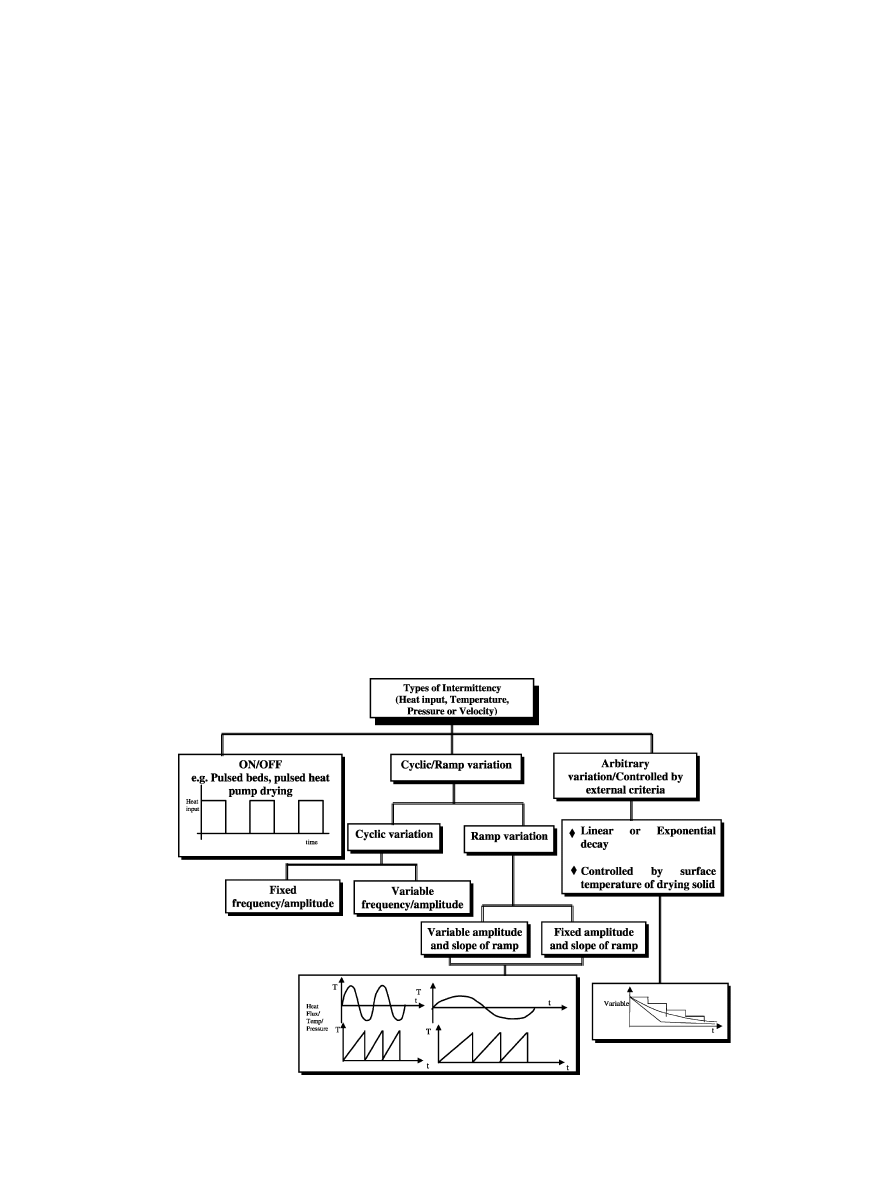

In this paper, selected recent works on intermittent

drying and its impact on drying kinetics and product

quality are reviewed. A generalized classification scheme

of the types of intermittency is portrayed in Fig. 1. The

general impression of intermittent drying among engi-

neers is one involving on/off pulsating of the three main

Fig. 1. A generalized classification scheme for intermittent drying.

286

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

process parameters: heat input, chamber pressure and

air velocity. However, other intermittencies that can also

be implemented in such a drying process are e.g. cyclic/

ramp and arbitrary variation of the three process para-

meters. They can be programmed in a fixed or variable

frequency mode with fixed or variable amplitude.

2. Intermittent drying

Time-dependent drying schemes which imply time-

varying supply of thermal energy for drying under batch

or continuous drying modes can be conveniently clas-

sified into the following categories: (a) intermittent

drying whereby heat flux is supplied intermittently

rather than continuously. This can be done by interrupt-

ing the air flow to provide the material a ‘‘rest’’ or

‘‘tempering’’ period, by a continuous air flow periodi-

cally heated, or by periodic variation of air flow or both;

(b) aeration which is a drying process involving a com-

bination of high temperature short drying period, tem-

pering, and slow cooling followed by drying finish; (c)

air reversal drying which is reversing the direction of the

airflow for a period of time and then reverting it back to

its original direction. This is applied to deep bed drying

of particulates to minimize temperature and moisture

gradients in the bed; and (d) cyclic drying which is a

drying process whereby the air temperature, humidity or

velocity undergoes a specified cyclic pattern variation

such as sinusoidal, square-wave or saw-tooth patterns.

The operating pressure can also be cycled.

Several experimental modeling studies have appeared

in the literature on intermittent drying. For example,

Giowacka and Malczewski (1986) solved LuikovÕs

equations to predict drying of granular materials using

time-varying inlet air temperature. The effect of inter-

mittency on energy saving was studied by Jumah et al.

(1996) in their study of intermittent drying of grains in a

novel rotating jet spouted bed; they found that signifi-

cant energy and quality advantages arise from inter-

mittent drying of heat-sensitive particles. Ratti and

Mujumdar (1993) have presented a simulation study on

batch drying of shrinking hygroscopic materials in a

fixed bed under time-varying flowrates. Their work has

shown that the total air consumption for drying is re-

duced with minor or no increase in drying time. The

economic implication is a reduction of energy con-

sumption for air handling which will eventually impact

the overall operating cost of the dryer. Optimal drying

performance can now also be obtained using general

thermal dehydration method with some modifications,

such that the drying temperature and flow of drying

medium can be intermittently controlled.

Experimental evidence of the potential benefits of

intermittent temperature variation on product quality

has been recently demonstrated by Chua et al. (2000a,b).

Chua et al. (2000a) have shown that, with proper se-

lection of intermittent drying air temperature, the im-

provement in ascorbic acid of guava (Psidium guajava)

pieces could be up to 20% higher than those dried under

isothermal condition. Chua et al. (2000b) have demon-

strated that employing intermittent drying air tempera-

ture could reduce the overall color change of potato,

guava and banana samples by 87%, 75% and 67%, re-

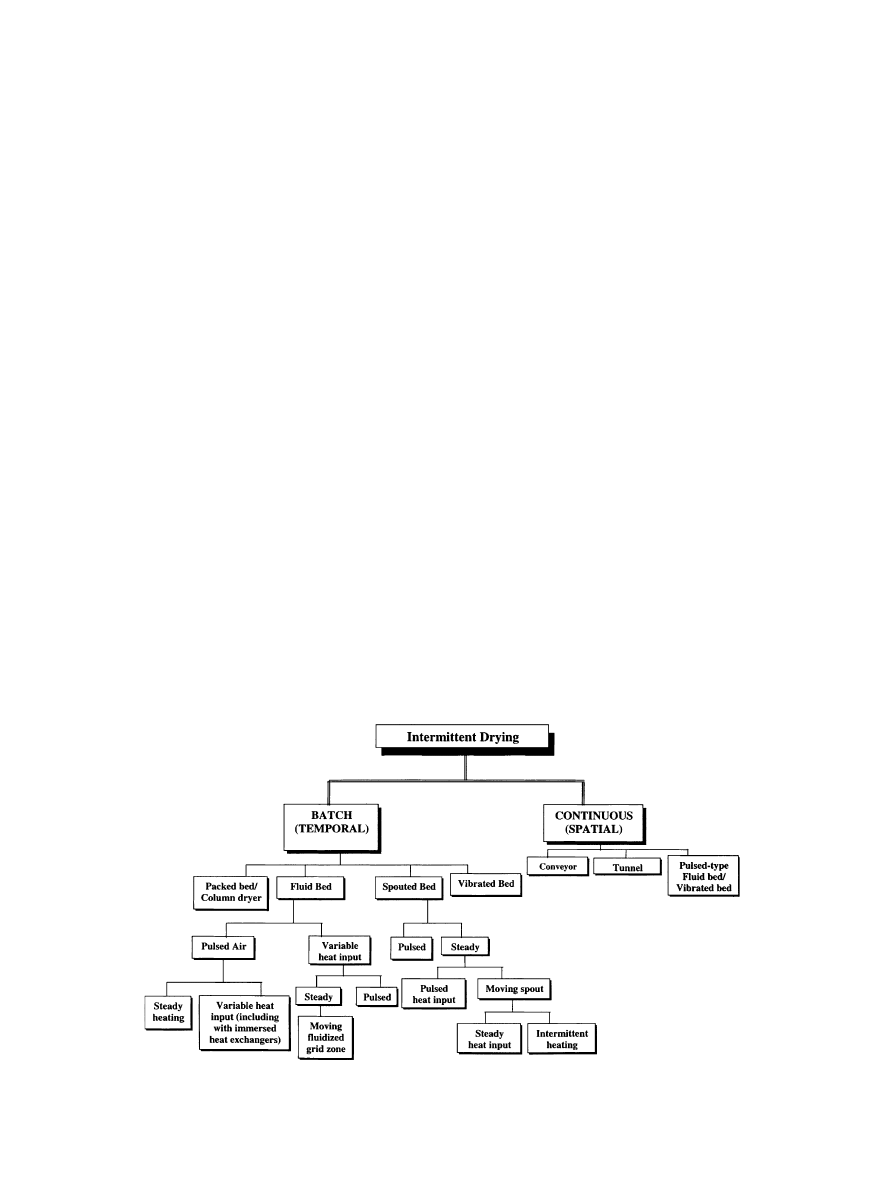

spectively. A classification scheme for intermittent dry-

ing based on processing mode and types of intermittent

Fig. 2. General types of intermittent drying modes for various dryers. Note: Above flowchart is limited to intermittent heat input. Intermittent drying

may also include cyclic or abrupt variation in operating pressure (e.g. cyclic compression and decompression).

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

287

heat input is shown in Fig. 2. This flowchart is limited to

intermittent heat input. In general, intermittent drying

may include cyclic or abrupt variation in operating

pressure or air flow as for the case of convective drying.

Based on this flowchart, the various intermittent drying

processes reported in recent literature will be presented.

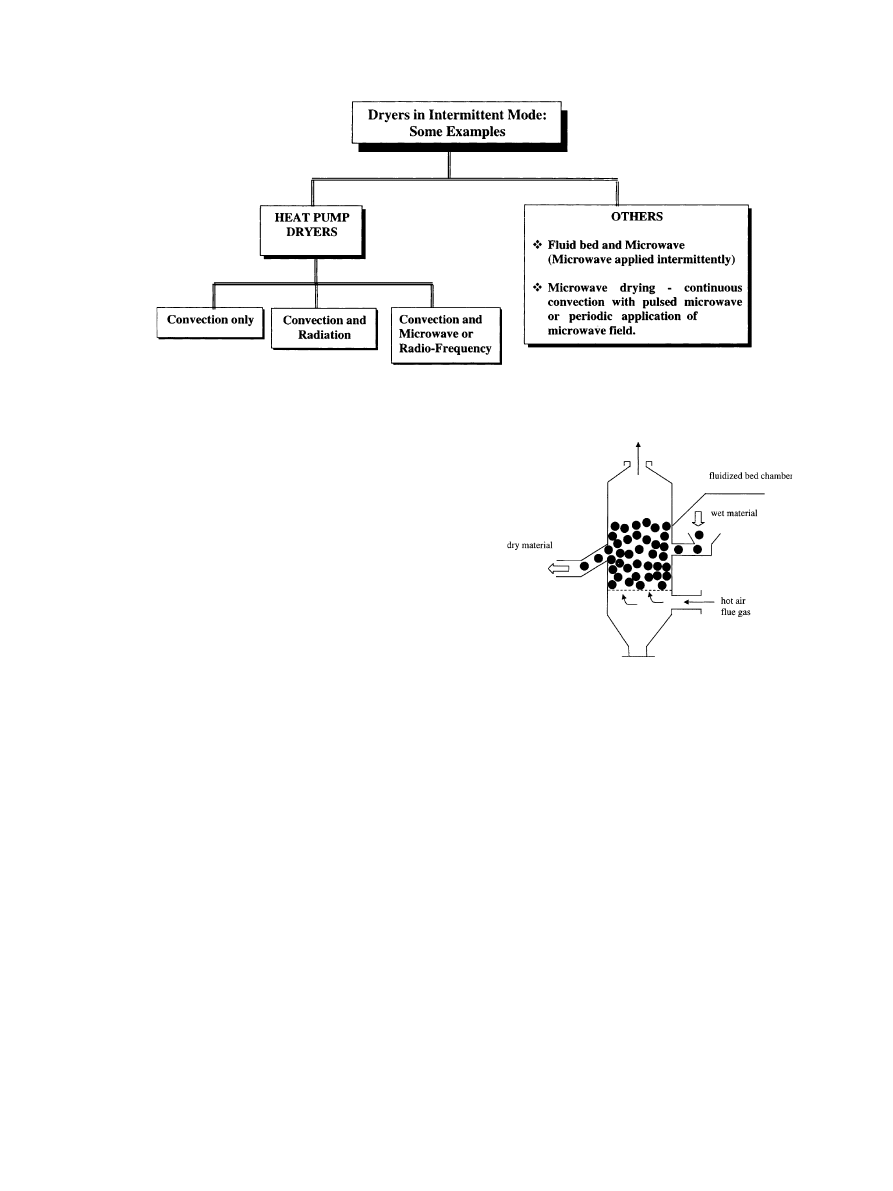

Also, some examples of dryers operating under inter-

mittent drying conditions are included in Fig. 3.

3. Batch drying

3.1. Fluidized bed

Fluidized bed drying (FBD) has found many appli-

cations for drying of granular solids in the food, ce-

ramic, pharmaceutical and agriculture industries. For

drying of powders in the 50–2000 lm range, fluidized

beds FBD competes successfully with other more tra-

ditional dryer types, e.g., rotary, tunnel, conveyor and

continuous tray. FBD has the following advantages

(Mujumdar and Devahastin, 1999): (a) high drying rates

due to excellent gas–particle contact leading to high heat

and mass transfer rates; (b) smaller flow area; (c) higher

thermal efficiency; (d) lower capital and maintenance

costs compared to rotary dryers; and (e) ease of control.

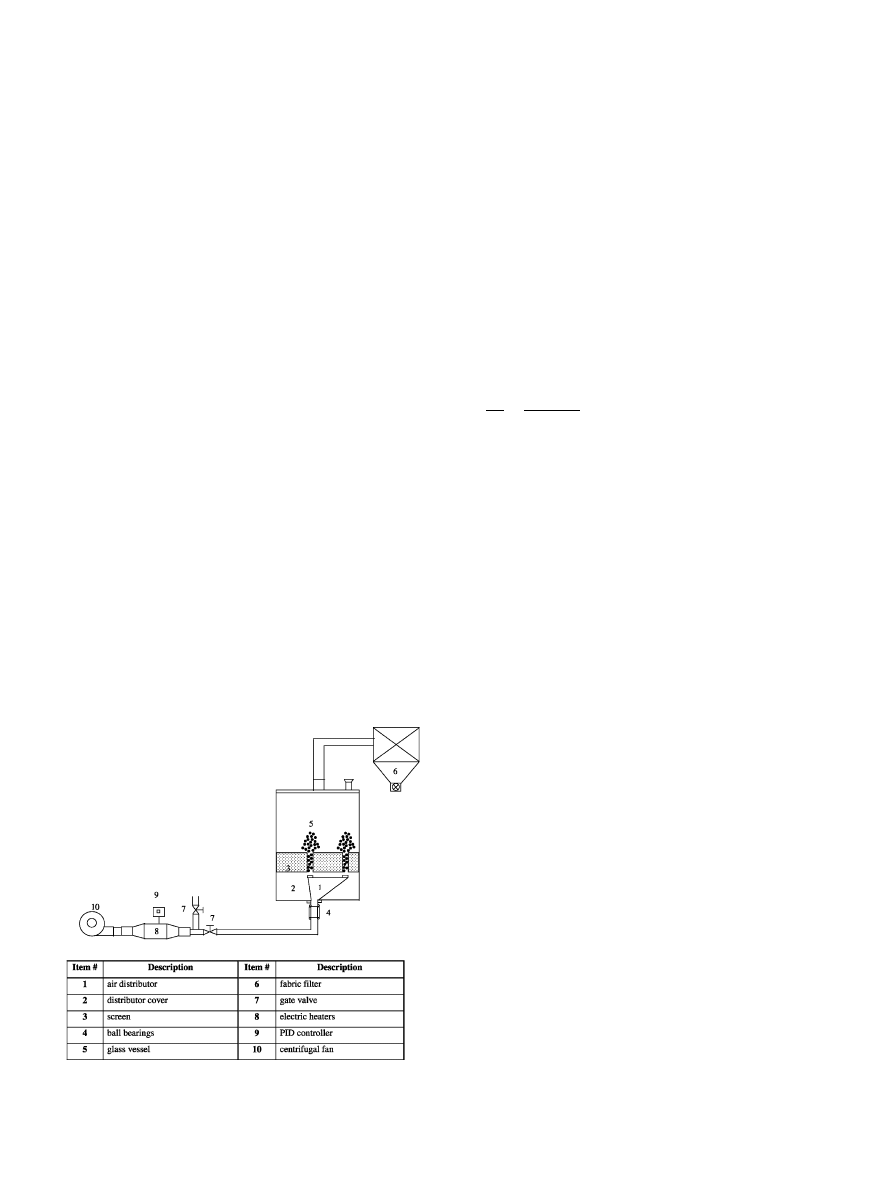

A typical layout of a fluidized bed dryer is shown in

Fig. 4. One easy way to implement intermittent drying

for fluidized bed dryer is to regulate the airflow to the

bed in an intermittent manner. Pan et al. (1999a), in

their study of intermittent drying of carrot cubes in a

vibro-fluidized bed, investigated the nutritional value of

dry carrot, which was quantified in terms of b-carotene

retention in the dried product. From their experiments,

they have shown that the concentration of b-carotene in

carrot undergoing continuous drying decreased with

drying time due to thermal degradation. With inter-

mittent regulation of the airflow, there was significant

improvement in b-carotene retention. They reasoned

that intermittent drying reduces product degradation

because of inherent continuous moisturizing of the

partially dry surface layers during the tempering period.

For similar final moisture content, the preservation of b-

carotene for carrots undergoing intermittent drying was

observed to be 18.5% higher than that of conventional

continuous drying. Pan et al. (1999a), while conducting

experiments on rehydration of dried carrot samples, also

found that the rate of dried carrot rehydration after

intermittent drying was higher than that after continu-

ous drying.

In a separate work, Pan et al. (1999b) conducted

drying experiments for squash slices in a vibrated flui-

dized bed. Squash samples were taken out of a vibrated

fluidized bed after 40 min, and tempered in ambient air

for 7.5 h. From their experimental data, a reduction in

drying time of up to 40% was observed based on a

drying time of 96 min for the squash slice to reach

14.75% moisture content. Comparing the preservation

Fig. 3. Examples of dryers that can operate under intermittent drying mode. Note: Convection can be applied intermittently or supplementary heat

source applied intermittently ascending to a s schedule or control system.

Fig. 4. Well-mixed continuous fluidized bed dryer.

288

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

of b-carotene for continuous and intermittent air drying,

Pan et al. (1999b) showed that 87.2% of b-carotene in

squash could be preserved in tempering–intermittent

drying while only 61.5% was found for conventional

continuous drying. Similar to earlier experiments con-

ducted with carrot samples, the rehydration ability of

the product gained by tempering-intermittent drying

was found to be better than product gained by contin-

uous drying. In this second study, Pan et al. (1999b)

attributed the improvement in product quality to the

moisture from the center of the material being redis-

tributed to the surface during the tempering period. The

consequent positive impacts were lower material tem-

perature, resulting in better dried-product quality, and

reduction in energy consumption.

3.2. Spouted bed drying

Jumah et al. (1996) implemented the principle of in-

termittent drying in a novel spouted bed system. They

studied the drying kinetics of corns using a rotating jet

spouted bed. A schematic of their set-up is shown in Fig.

5. The intermittent drying schedule was characterized by

periodic gas–particle contact which may be idealized as

a series of active drying periods separated by much

longer tempering periods. By varying the rotational

speed of the spouting jet of heated (or unheated air),

they varied the magnitudes of ÔonÕ and ÔoffÕ periods while

keeping the ratio of the two fixed.

Experiments were carried out to test the hypothesis

that corn as a slow drying material could be dried to

produce high quality grain with lower energy con-

sumption via prescribing an intermittent air schedule.

The intermittent scheduling was achieved by using var-

ious drying periods alternated by long tempering peri-

ods. During the active periods, the particles were

observed to be subjected to very intense mixing and

circulation due to the hydrodynamics of rotating spouts.

The resulting effect was a period of high intensity of heat

and mass transfer. During the no-flow periods, the

temperature and moisture gradients were effectively re-

laxed with favorable moisture re-distribution inside the

particle. They also observed minimal mechanical dam-

age to the kernels due to reduced attrition caused by

inter-particle collisions during spouting.

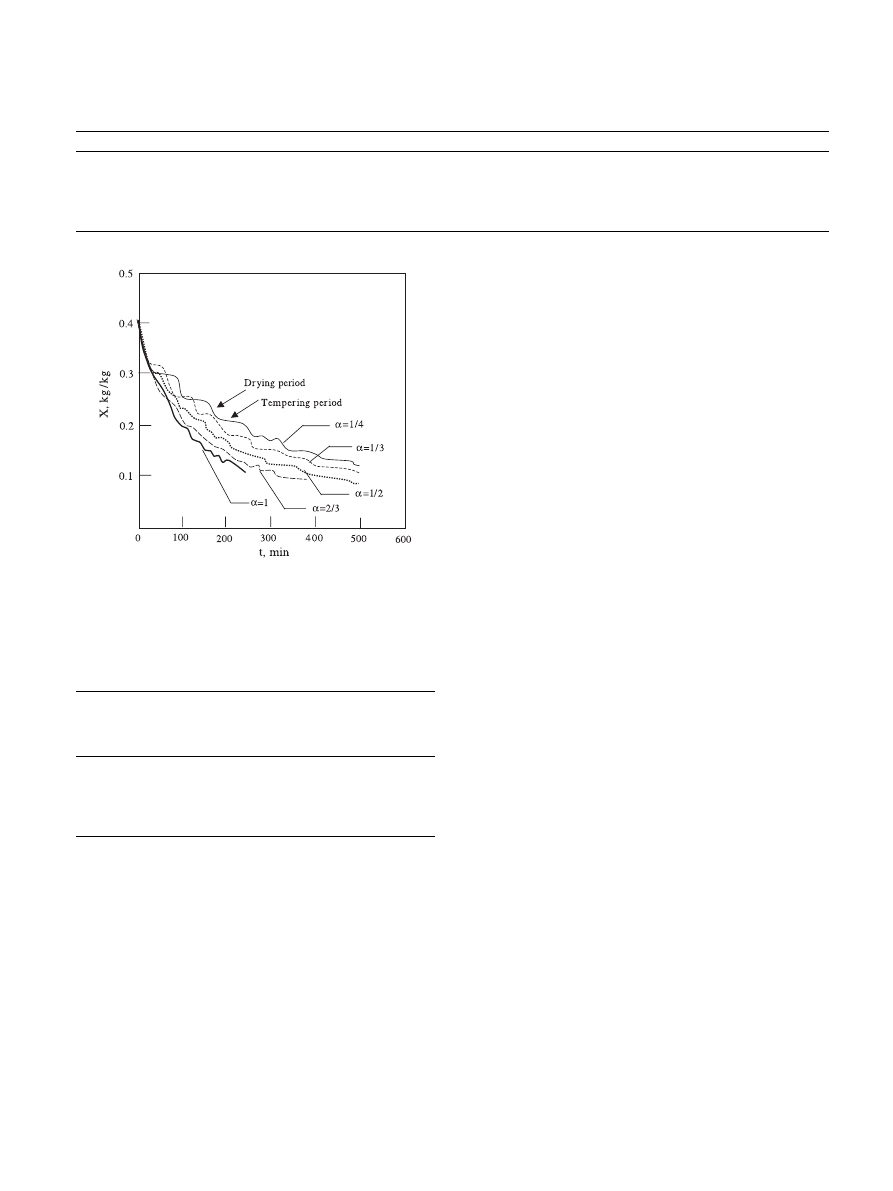

Jumah et al. (1996) defined an intermittency ratio, a,

as the fraction of cycle time during which spouting gas is

supplied for drying, i.e.,

a

¼

s

on

s

¼

s

on

s

on

þ s

off

;

where s

on

and s

off

are the on and off period of each cycle,

respectively.

The drying conditions used in their studies for re-

wetted corn are given in Table 1. They have shown that

for continuous drying curve (a

¼ 1) rapid loss of mois-

ture occurred during the initial stage of drying followed

by the conventional falling rates. The initial high drying

rate was short because the surface zone of the material

was rapidly dried to its equilibrium value, and then the

process was controlled by internal moisture diffusion.

According to their observations indicated in Fig. 6, for

intermittent drying (a < 1), the initial high drying rate

was repeated during each active drying period so that

steeper drying curve segments could be obtained. It

further demonstrated that moisture leveling occurred

during the tempering periods with moisture migration to

the corn kernel surface.

As shown in Table 2, for any a, intermittent drying

took a longer time than the corresponding continuous

one when the total elapsed time was considered, but a

shorter time in terms of the effective spouting time re-

quired to achieve the desired final moisture content. The

total process time to reach 13% dry basis final moisture

content increased by 19% when a 10-min tempering

period (a

¼ 2=3) was employed relative to the continu-

ous drying with no tempering periods. However, the

effective or net drying time decreased by 19%. Further-

more, the total process time was less than doubled when

the tempering period was increased by a factor of 6, i.e.

increasing s

off

from 10 to 60 min or decreasing a from 2/

3 to 1/4. However, the effective drying time was observed

to decrease by 22%. All these savings could be translated

directly to energy savings as shown in Table 2. The

maximum energy saving of 37% occurred using drying

air with 60 min of tempering period (a

¼ 1=4) for the

conditions employed by Jumah et al. (1996).

Fig. 5. Schematic diagram of a rotating jet spouted bed (Jumah et al.,

1996).

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

289

3.3. Vibrated bed drying

For drying of smaller particles, Li et al. (1999) con-

ducted experiments to study the effect of intermittent

drying on stress distributions of rough rice. Tempering

of rice during the drying operation has become a com-

mon practice in order to reduce the fissuring of rice. In

their experiments, Li et al. (1999) initiated the inter-

mittent drying by discontinuing the drying process in a

convective experimental set-up. In general, Li et al.

(1999) observed that discontinuing the drying process

with tempering could reduce the hydro-stresses in the

rice kernel. As part of their parametric study, they also

found that increasing the intermittent ratio reduced the

stresses in the rice kernel during intermittent drying.

Higher intermittency ratio would subsequently result in

lower percentage of fissured rice. During the tempering

period, the moisture in the kernel was equalized through

moisture diffusion. The moisture equalization increased

the drying rate of grain in the next cycle of drying, and

reduced the stresses caused by moisture gradient within

the kernel. Measurements taken during the experiments

showed that the central portion of the rice was con-

tracted and greater tensile stresses were created during

the holding period as the moisture was transported from

the central portion to the central portion to the surface.

Discontinuing the drying process during the tempering

period resulted in lower maximum tensile stresses at the

grain center. It was further observed that increasing the

tempering time would decrease the maximum tensile

stresses at the center of the rice kernel.

3.4. Microwave drying

According to a finite element model proposed by

Zhang and Mujumdar (1992), employing intermittent

volumetric heating in a thermal drying process is a

possible solution to reduce drying-induced stresses in a

grain kernel. The tempering period allows time for the

internal moisture to diffuse to equalize moisture and

temperature gradients during the resting period when no

heat is supplied or a reduced level of heat is provided. In

the case of intermittent volumetric heating, the tem-

peratures of the nodes do not increase continuously; and

the values of the node temperatures are much lower than

those in continuous heating while the moisture poten-

tials of different points of the body tend to be more

uniform. Since the moisture field of the body is more

uniform; it is clear that the drying-induced stresses must

decrease as well. For some materials of biological origin

that are sensitive to thermal treatment, problems per-

taining to germinability, vigor, protein denaturation and

cracks might result for continuous hot air drying. In-

termittent drying should mitigate these problems to a

great extent.

Gong et al. (1998) conducted a numerical study to

understand the effect of intermittent microwave heating

on the drying behavior of clay and its internal stress

development. From their numerical results, they ob-

Fig. 6. Effect of intermittency on the evolution of moisture content

with time for corn samples (results from Jumah et al., 1996).

Table 1

Summary of the operating conditions applied in the intermittent spouting experiments (Jumah et al., 1996)

Drying period, s

on

(min)

Tempering period, s

off

(min)

Intermittency, a

Process conditions

20

60

1/4

T

gi

¼ 80 °C,

20

40

1/3

U

¼ 0:475 m/s

20

20

1/2

X

0

¼ 0:4 kg/kg dry basis

20

10

2/3

m

s

¼ 12 kg

Continuous

0

1

N

¼ 4 rpm

Table 2

Effect of the intermittency on the performance of the drying process

(results from Jumah et al., 1996)

a

Total process

time ratio

Effective drying

time ratio

¼ energy con-

sumption ratio

Percent energy

saving over

continuous drying

1/4

2.32

0.63

37

1/3

1.95

0.70

30

1/2

1.48

0.77

23

2/3

1.19

0.81

19

1

1

1

–

290

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

served that the maximum tensile and compressive

stresses within the dried clay could be reduced signifi-

cantly when intermittently microwave heating was em-

ployed. Also, the time for the peak stresses to develop

was observed to be somewhat reduced. Recently, Itaya

et al. (2001) demonstrated clearly the beneficial effect of

microwave drying of ceramics. With continuous micro-

wave heating or microwave heating with long cycle

times, cracks developed in the ceramic samples were

tested. With higher frequency of pulsation, crack for-

mation could be avoided or delayed at lower moisture

contents although the sample attained higher tempera-

ture. Note that ceramics are not heat-sensitive so a

higher temperature does not result in lower quality.

However, they observed that the mechanical crack for-

mation was affected by the intermittency of microwave

energy input.

Gunasekaran (1999) has demonstrated the advanta-

ges of pulsed microwave vacuum drying of cranberries

both in terms of energy efficiency and quality of the

dried product in terms of its color (redness) and texture.

They found that the longer the power-off time relative to

the power-on better was, the better were the energy ef-

ficiency and product quality. He employed MW oven

operated at pressures of 5.33 and 10.67 kPa with power-

on to total cycle time ranging from 1 to 6. Based on his

experimental data, it appeared that when the power-on

time was shorter, more of the microwave energy was

used for evaporating moisture while a longer power-on

time tended to increase the product temperature and

resulted in degradation of the quality of a heat-sensitive

material.

Several studies have been carried out to investigate

the use of intermittent microwave drying and the effect

on shrinkage (Raghavan and Silveira, 1999; Raghavan

and Venkatachalapathy, 1999). Intermittent microwave

drying studies, both experimental and numerical, have

been reported to improve the quality of dried product

and even the temperature distribution of product. Sanga

et al. (2001) have reported experimental and numerical

analysis of intermittent microwave-convection drying of

heat-sensitive materials such as carrot and potato pieces.

They measured the drying rate on-line along with tem-

perature distribution in the drying product using fibre-

optics probes. They showed that a diffusion model

including temperature and concentration dependent dif-

fusivity as well as allowing for shrinkage in an empirical

fashion yielded results which agreed with the measured

drying rates. Their finite element model permitted

modeling of discretely composite materials as well. Such

a model could be applied to blends of wet solids with

different loss factors for absorption of microwave en-

ergy. Their quality measurements (color) showed that

intermittent microwave input to continuous convection

drying gave a better quality product than continuous

microwave input.

Chen and Wang (2001) made a theoretical analysis of

the effect of the intermittent microwave heating patterns

on batch fluid drying of porous particles. They consid-

ered three MW power patterns viz., uniform, sinusoidal

and rectangular. Under constant electric field strength

conditions, they computed the temperature and mois-

ture variation of apple particles in batch fluidized bed

drying. Their results indicated that the magnitude and

distribution of the moisture, temperature and pressure

within a particle could be substantially affected. More

importantly, the drying time and microwave energy

consumption changed with the pattern of how micro-

wave heating was applied. Particularly, intermittent

heating with a rectangular wave pattern had the most

microwave energy consumption but the shortest drying

time. For a particle size of 5 mm, air flow rate of 2 m/s

and temperature of 60

°C, the drying time was, respec-

tively, 1600, 2000, 2400 s for rectangular, sinusoidal and

constant microwave heating. The values of microwave

energy consumed for the three cases were respectively,

2145, 1980, and 1560 kJ/kg water evaporated. The

model could be extended to include kinetics of quality

change (e.g. color and vitamins). Also, a more detailed

parametric study including different MW energy pat-

terns could be carried out. It should also be possible to

dynamically optimize such a process for the best quality

at lowest energy consumption or minimum overall cost.

3.5. Aeration process

Farouk (1967) based on his work on peanuts drying

observed that for any particular aeration time per hour

of total operation time, the shorter cycling periods were

more effective than the longer ones. When drying by

heating and aeration only, the higher temperature and

shorter aeration periods were more effective in rapid

drying. The intermittent heating–drying process were

more economical, in terms of hours of aeration required

to dry through any particular moisture range, than the

continuous aeration process for the aerating periods of

less than 6 h per cycle.

Filho et al. (1982) conducted intermittent drying ex-

periments for soybean comprising a convective heating

period followed by an aeration period. In other words,

warm air was used for the heating and cooling periods.

The intermittent application of warm and cool air was

repeated until the moisture content of beans reached the

desired value. They observed that soybean intermittent

drying took longer than continuous drying, but the ex-

periments demonstrated that it prevented some damage

from occurring as compared to the continuous process

at the same temperature. The probable explanation for

this phenomenon was that during the resting period,

water diffused to the surface and brought itself into

equilibrium with the remainder of the material. During

the subsequent drying period, the surface again dried

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

291

rapidly so that the steep part of the drying curve was

again repeated.

3.6. Heat pump drying

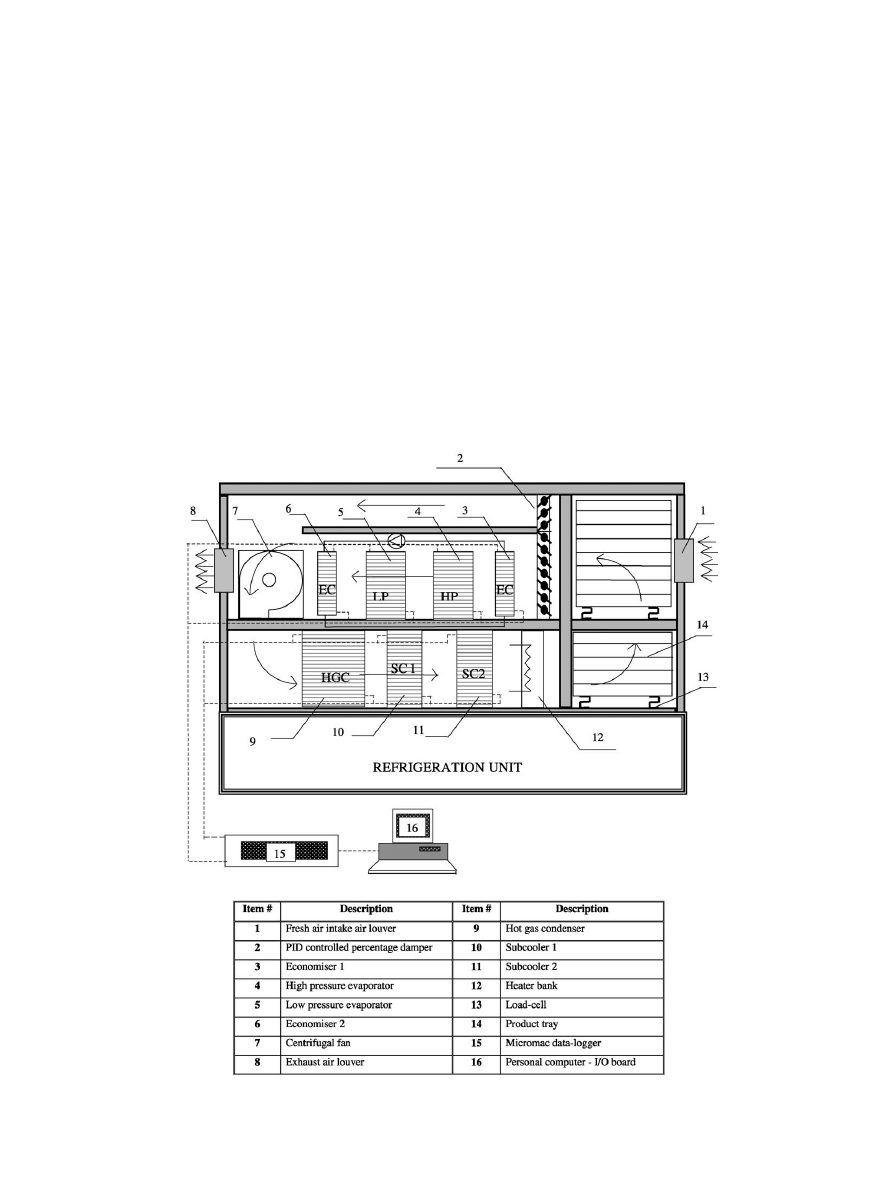

For a batch heat pump drying system, intermittent

drying processes can be classified into three categories:

(a) intermittent variation of the air temperature; (b) in-

termittent supply of air flow; (c) intermittent regulation

of the air humidity; and (d) intermittent addition of

other energy sources e.g. infra-red, microwave and

radio-frequency.

Among the three, the intermittent regulation of air

temperature is considered to have the most substantial

influence on the product drying kinetics and various

quality parameters and is the focus of the following

sections. A schematic of a heat pump dryer set-up is

shown in Fig. 7.

The intermittent conditions employed in the studies

presented in this section are given in Table 3. Chou et al.

(2000) observed that employing intermittent tempera-

ture profile resulted in savings in drying time by about

25%, 48% and 61% for a

¼ 1=4, a ¼ 1=2 and a ¼ 2=3,

respectively. A longer product tempering period oc-

curred for a

¼ 1=4, resulting in a plateau in the drying

curve. From the study conducted by Chou et al. (2000),

it was also found during each tempering process, i.e.

during s

off

period, partial drying did occur, particularly

during the early stage of drying. However, towards the

latter stage of drying, little or no drying occurred. For a

longer tempering period, a

¼ 1=4, the effect of moisture

equilibrating could be observed even during the last

cyclic period (180–240 min).

Chou et al. (2000) have taken a mechanistic approach

to compare the degradation of ascorbic acid kinetics due

to the employment of intermittent temperature and

Fig. 7. Schematic diagram of a heat pump drying system (Chua et al., 2000a).

292

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

continuous constant temperature drying. In their work,

they have also shown that the changes in ascorbic acid

content were different for different intermittent drying

schemes. They observed that the improvement in re-

ducing ascorbic acid degradation was more effective for

a longer period of tempering. A lower level of ascorbic

acid improvement was observed for shorter resting pe-

riods (a

¼ 2=3). This may be attributed to the fact that

products subjected to longer tempering periods were

allowed more uniform temperature and moisture dis-

tribution and hence resulted in a positive influence in

minimizing ascorbic acid degradation. A longer tem-

pering period was indeed favorable in minimizing the

degradation of product ascorbic acid. The tempering

period affected the internal product temperature and

ensured more uniform internal temperature. Results

from their work are presented in Table 4. The percent-

age improvement in minimizing ascorbic acid degrada-

tion based on the net change under continuous 35

°C

drying were 11.6%, 9.1% and 7.4% for intermittent air

varying with a

¼ 1=4, a ¼ 1=2 and a ¼ 2=3, respectively.

Product color change owing to exposure to elevated

temperatures is a well-known phenomenon. The product

color change is a surface phenomenon. Any surface

temperature fluctuation would influence the degree of

color change for the period in which sensible heat is

transferred from the drying air to the product surface.

The change in external air temperature influences the

exchange of heat flux from the drying air to the product

surface. Based on the surface temperature profiles, it

was expected that net change in product color was re-

duced for various time–temperature heating schemes as

compared to a constant temperature drying process with

fixed inlet temperature of 35

°C.

The percentage improvement in minimizing net color

change in comparison to the net change under contin-

uous constant 35

°C drying were 45.7%, 33.6% and

25.6% for intermittent air varying with a

¼ 1=4, a ¼ 1=2

and a

¼ 2=3, respectively (Table 5). It was clear that

longer tempering period at lower temperature had the

most significant effect in reducing color change due to

non-enzymatic browning.

3.7. Osmotic-infrared drying

Tan et al. (2001) conducted an experimental study on

infrared (IR) drying of osmosed fruit products in a heat

pump dryer. Their results showed that application of

intermittent infrared heating, as expected, reduced the

drying time in convective drying of both osmosed and

non-osmosed products. However, depending on the

product, intermittent infrared heating may or may not

reduce color degradation, compared to continuous in-

frared heating. Osmotic dehydration affected the color

of the food product during osmosis as well as in air

drying. Osmotically treated samples of potato and

pineapple had less color change than untreated ones

during convective drying with intermittent infrared

heating. Tan et al. (2001) further designed a feedback to

decide the intermittent IR schedule based on a pre-

selected maximum product surface temperature. Using

temperature feedback from the food samples to auto-

matically turn the infrared lamps on and off resulted in

even greater reduction in drying time and significantly

less color degradation. This is a case of variable inter-

mittency.

4. Continuous drying

4.1. Heat pump/IR tunnel drying

Dryers that have tunnel-like drying chambers can

operate in both batch and continuous drying modes. The

heat pump dryer is one such dryer. Under intermittent

Table 5

Summary of the effect of time–temperature varying profiles on non-

enzymatic browning (Chou et al., 2000)

Drying profile

Percentage improvement in

reducing non-enzymatic

browning (%) over continuous

35

°C drying

Intermittent (a

¼ 1=4)

45.7

Intermittent (a

¼ 1=2)

33.6

Intermittent (a

¼ 2=3)

25.6

Table 4

Summary of the effect of time–temperature varying profiles on ascorbic

acid degradation (Chou et al., 2000)

Drying profile

Percentage improvement in

reducing ascorbic acid

degradation (%) over continuous

35

°C drying

Intermittent (a

¼ 1=4)

11.6

Intermittent (a

¼ 1=2)

9.1

Intermittent (a

¼ 2=3)

7.4

Table 3

Summary of the intermittent heat pump drying conditions

Drying period, s

on

(min)

Tempering period, s

off

(min)

Cyclic time, s (min)

Intermittency, a

Process conditions

15

45

60

1/4

T

a

¼ 30 °C, DT

a

¼ 5 °C

30

30

60

1/2

V

a

¼ 2:5 m/s, RH ¼ 30%

40

20

60

2/3

X

i

¼ 4:2 kg/kg dry basis

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

293

heating mode, the bioproduct enters at one end of the

tunnel chamber, moves at controlled speed to the other

end. Since the product enters the chamber under wetter

condition, it is possible to combine an intermittent step-

down variation of the air temperature. Similarly for an

IR-tunnel dryer, the heat intensity of the IR-lamps can

be selected such that higher intensity IR-heat is employed

at the tunnel entry with decreasing IR-heat flux along the

direction of flow in the tunnel chamber. All IR-lamps

may operate under intermittent mode. Alternatively, the

frequency of the IR-lamps may be regulated so that

product entering the chamber receives higher frequency

IR-intermittency and the periodicity of the intermittence

is gradually reduced towards the exit of the chamber.

Both IR-drying arrangements are expected to enhance

drying performance while minimizing product quality

degradation.

4.2. Pulsed-fluid bed drying

Gawrzynski and Glaser (1996) have studied pulsed-

fluid bed drying (PFBD) technology for drying of heat-

sensitive materials. The PFBD concept essentially

involves intermittent fluidization in a batch/continuous

dryer. For greater product throughput, the continuous

drying mode is usually preferred. Only a part of the

dryer cross section (typically one-third or one-fourth of

the area) is fluidized in a periodic fashion. They have

reported on hydrodynamics, heat and mass transfer as

well as drying of such materials as granulated sugar,

beans, seeds, wheat, carrot and onion. PFB dryers of

different designs are already commercialized in Poland.

It appeared that the pulsation of the flow helped to

disintegrate or de-lump granular materials that were

susceptible to agglomeration. In their design the pulsa-

tion and periodic relocation of the gas stream was ob-

tained with a suitable design of rotating butterfly valves

installed below the distributor plate. A PFB dryer/cooler

for granulated sugar with a capacity of 21 tons/h has

been operating in Poland since the early 1980s. PFB

dryers have also been used successfully for drying of

seeds, chopped vegetables as well as pharmaceutical

formulations. The authors claimed that higher energy

efficiency and better product quality could be obtained

with PFBD as compared to conventional drying tech-

nologies. Although not reported by these authors, it

should be possible to vary the fluidizing air temperature

for improved energy efficiency. Such dryers are now

available commercially.

5. Conclusions

Intermittent drying is a novel method for improving

the drying kinetics, enhancing product quality and re-

ducing energy consumption per unit of moisture re-

moved. The manner in which several bioproducts react

to intermittent drying has been elucidated in both ex-

perimental and modeling works. However, because of

the complexity of these products, the basic under-

standing presented here may not be sufficient. As a re-

sult, future efforts have to be devoted to both

experimental works and analytical modeling to enable

greater in-depth understandings on the product mois-

ture and thermal distributions when transient or quasi-

steady drying process are employed. This must be coupled

with prediction of product quality and dynamic opti-

mization schemes. The present transient drying models

for intermittent drying processes are only in the early

stages of development; they represent an arena in which

further engineering analysis may result in important

pioneering contributions.

References

Chen, G., Wang, W., 2001. Theoretical study of microwave heating

patterns on batch fluidized bed drying of porous material.

Chemical Engineering Science 56 (24), 6823–6835.

Chou, S.K., Chua, K.J., Hawlader, M.N.A., Mujumdar, A.S., Ho,

J.C., 2000. On the intermittent drying of an agricultural product.

Transactions of the Institution of Chemical Engineers 78 (Part C),

193–203.

Chua, K.J., Chou, S.K., Ho, J.C., Mujumdar, A.S., Hawlader,

M.N.A., 2000a. Cyclic air temperature drying of guava pieces:

effects on moisture and ascorbic acid contents. Transactions of the

Institution of Chemical Engineers 78 (Part C), 72–78.

Chua, K.J., Mujumdar, A.S., Chou, S.K., Hawlader, M.N.A., Ho,

J.C., 2000b. Heat pump drying of banana, guava and potato pieces:

effect of cyclical variations of air temperature on convective drying

kinetics and color change. Drying Technology––An International

Journal 18 (5), 907–936.

Farouk, S.M., 1967. Drying spinach peanuts with intermittent heating,

aerating and tempering processes. Ph.D. thesis, Texas A&M

University.

Filho, J.B.P., Fortes, M., Sweat, V.E., Okos, M.R., 1982. Intermittent

drying of soyabeans. In: Mujumdar, A.S. (Ed.), DryingÕ82.

Hemisphere Publishing Corporation, Washington, pp. 220–225.

Gawrzynski, Z., Glaser, R., 1996. Drying in a pulsed-fluid bed with

relocated gas stream. Drying Technology––An International Jour-

nal 14 (5), 1121–1172.

Giowacka, M., Malczewski, J., 1986. Oscillating temperature drying.

In: Mujumdar, A.S. (Ed.), Drying of Solids. Wiley Eastern, Delhi,

pp. 77–83.

Gong, Z.X., Mujumdar, A.S., Itaya, Y., Mori, S., Hasatani, M., 1998.

Drying of clay and non-clay media: heat and mass transfer and

quality aspects. Drying Technology––An International Journal 16

(6), 1119–1152.

Gunasekaran, S., 1999. Pulsed microwave-vacuum drying of food.

Drying Technology––An International Journal 17 (3), 395–412.

Itaya, Y., Uchiyama, S., Mori, S., 2001. Internal heating effect on

ceramic drying by microwaves. In: Ramli, E.W. (Ed.), Proceedings

of Asia–Australia Drying Conference 2001. Institution of Chemical

Engineers Publication, Malaysia, pp. 277–286.

Jumah, R.Y., Mujumdar, A.S., Raghavan, G.S.V., 1996. A mathe-

matical model for constant and intermittent batch drying of grains

in a novel rotating jet spouted bed. In: Turner, I., Mujumdar, A.S.

(Eds.), Mathematical modeling and numerical techniques in drying

technology. Marcel Dekker, New York, pp. 339–380.

294

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

Li, Y.B., Cao, C.W., Yu, Q.L., Zhong, Q.X., 1999. Study on rough rice

fissuring during intermittent drying. Drying Technology––An

International Journal 17 (9), 1779–1793.

Mujumdar, A.S., Devahastin, S., 1999. Fluidized bed drying. In:

Mujumdar, A.S., Suvachittanont, S. (Eds.), Developments in

Drying: Food Dehydration, vol. 1. Kasetsart University Press,

Bangkok, Thailand, pp. 59–111.

Pan, Y.K., Zhao, L.J., Dong, Z.X., Mujumdar, A.S., Kudra, T.,

1999a. Intermittent drying of carrot in a vibrated fluid bed: effect

on product quality. Drying Technology––An International Journal

17 (10), 2323–2340.

Pan, Y.K., Zhao, L.J., Hu, W.B., 1999b. The effect of tempering-

intermittent drying on quality and energy of plant material.

Drying Technology––An International Journal 17 (9), 1795–

1812.

Raghavan, G.S.V., Silveira, A.M., 1999. Shrinkage characteristics of

strawberries osmotically dehydrated in combination with micro-

wave drying. In: Proceedings of the First Asia–Australia Drying

Conference. Bali Press, Indonesia, pp. 117–135.

Raghavan, G.S.V., Venkatachalapathy, K., 1999. Shrinkage of straw-

berries during microwave drying. Drying Technology––An Inter-

national Journal 17 (10), 2309–2321.

Ratti, C., Mujumdar, A.S., 1993. Fixed-bed batch drying of shrinking

particles with time varying drying air conditions. Drying Technol-

ogy––An International Journal 11, 1311–1355.

Sanga, E., Mujumdar, A.S., Raghavan, G.S.V., 2001. Experimental

and numerical analysis of intermittent microwave-convection

drying. In: Ramli, E.W. (Ed.), Proceedings of Asia–Australia

Drying Conference 2001. Institution of Chemical Engineers Pub-

lication, Malaysia, pp. 203–215.

Tan, M., Chua, K.J., Mujumdar, A.S., Chou, S.K., 2001. Osmotic

dehydration of potato and pineapple: effect of intermittent radia-

tion and continuous convection in a heat pump dryer. Drying

Technology––An International Journal 19 (9), 2193–2207.

Zhang, D., Mujumdar, A.S., 1992. Deformation and stress analysis of

porous capillary bodies during intermittent volumetric thermal

drying. Drying Technology––An International Journal 10 (2), 421–

443.

K.J. Chua et al. / Bioresource Technology 90 (2003) 285–295

295

Document Outline

Wyszukiwarka

Podobne podstrony:

Clint Leung An Overview of Canadian Artic Inuit Art (2006)

Master Wonhyo An Overview of His Life and Teachings by Byeong Jo Jeong (2010)

Heathen Ethics and Values An overview of heathen ethics including the Nine Noble Virtues and the Th

An Overview of Property Investing

Steve Stemler An Overview of Content Analysis

An Overview of Computer Viruses in a Research Environment

Jim Marrs An Overview of the War on Terror

Clive Grey TOWARDS AN OVERVIEW OF WORK ON GENDER AND LANGUAGE VARIATION htm(1)

An Overview of Pacific Northwest Native Indian Art

Modeling with shrinkage during the vacuum drying of carrot (daucus carota) (Arévalo Pinedo, Xidieh M

Law An Overview

Influence of drying methods on drying of bell pepper (Tunde Akintunde, Afolabi, Akintunde)

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Microwave Application in Vacuum Drying of Fruits (Drouzaf, H SchuberP)

więcej podobnych podstron