Technical Bulletin

C

1

1997 Audi of America, Inc.

Subject:

Model(s):

Group:

Number:

Date:

Brake Squeal

➤

1998

46

97–01

Nov. 25, 1997

All with disc brakes

Supersedes T.B. Group 46 Number 94–01 dated August 1, 1994

Condition

Customer expresses concerns about brake

squeal.

Service

Brake squeal is mainly the result of vibrations

between components of the brake caliper

assembly.

The following procedure has proven effective in

reducing brake squeal and may be used for

both front and rear disc brake systems:

Note:

•

Illustrations used in this Bulletin are ge-

neric. Actual component design will vary

between different models and model

years.

•

Only use Plastilube Moly 3

high temper-

ature grease, Part No: ZVP 264 103.

CAUTION!

Part numbers are for reference only.

Always check with your Parts Dept.

for the latest parts information.

CAUTION!

Never use compressed air to clean brake

dust from a brake system.

– Remove wheels, disassemble brake caliper

and remove brake discs,

⇒

appropriate

Repair Manual for model vehicle you are

working on.

(Cont. on Page 2)

46-A033

46-A044

Technical Bulletin

C

2

1997 Audi of America, Inc.

Brake discs, cleaning

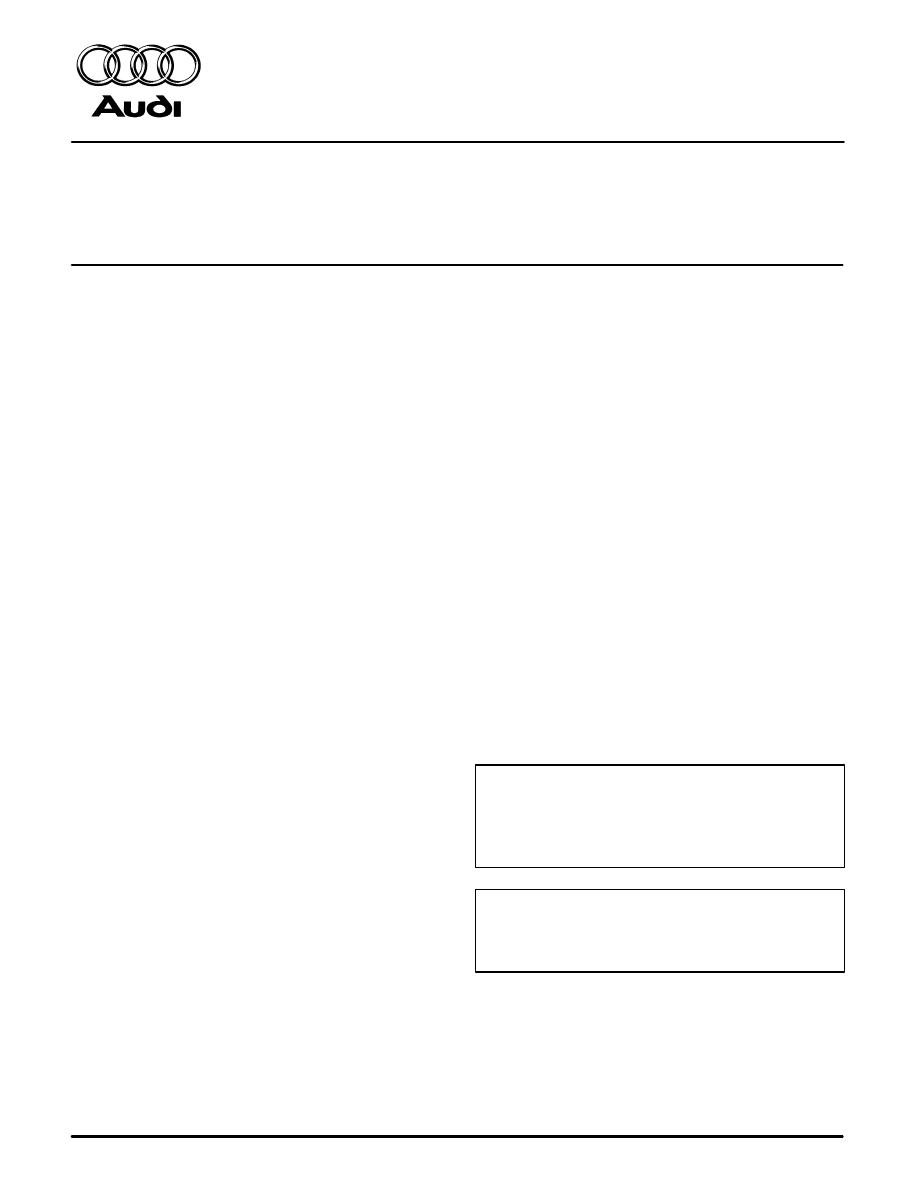

Clean brake discs using a power disc–type

sander with 80 grit sanding disc.

Sand brake discs as follows:

– Lightly sand rotor in a clockwise direction

using the leading edge of sanding disc.

– To achieve a cross hatch pattern, continue

sanding in a clockwise direction using the

trailing edge of sanding disc.

(Cont. on Page 3)

46-A023

46-A024

Technical Bulletin

C

3

1997 Audi of America, Inc.

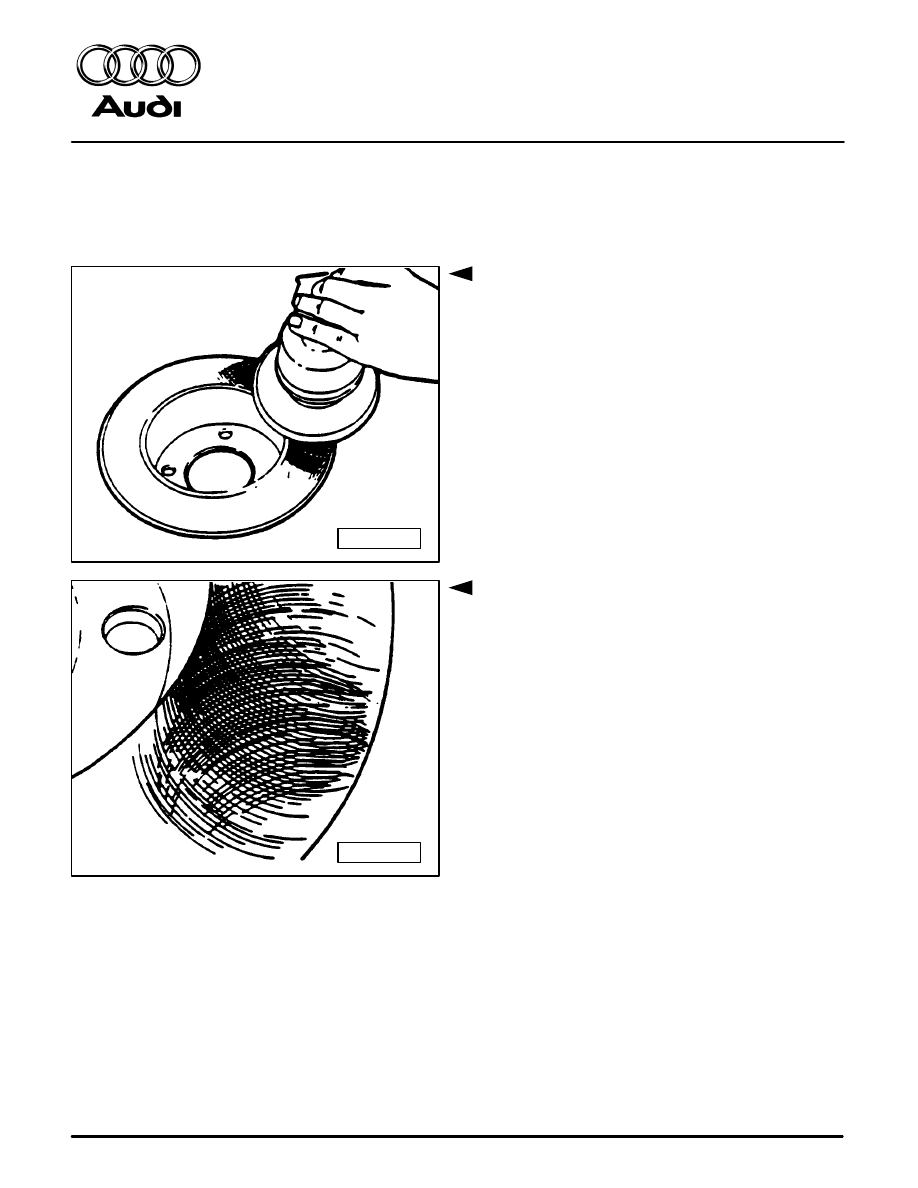

Brake pads, cleaning

– Deglaze and clean face of brake pads with

sand paper as necessary

Slightly chamfer (bevel) edges of brake pads

with a file.

Note:

Some front/rear brake pads were supplied

with an adhesive (sticky) backing which

helps adhere brake pad to the brake caliper

housing and/or brake carrier.

If vehicle is equipped with this type of pad,

remove this (sticky) backing and residual

adhesive from brake pad and brake caliper

housing and/or brake carrier.

Some front/rear brake pads are supplied

with an anti–vibration backing (non–sticky).

Do Not remove this type of backing.

– Clean brake pads using a suitable cleaning

method.

– Apply a thin coat of Plastilube Moly 3

high

temperature grease to the back of the brake

pads.

CAUTION!

Plastilube Moly 3

high temperature

grease must not come into contact with

the braking surface of the brake pad or

the brake rotor.

(Cont. on Page 4)

46-A025

46-A027

46-A032

Technical Bulletin

C

4

1997 Audi of America, Inc.

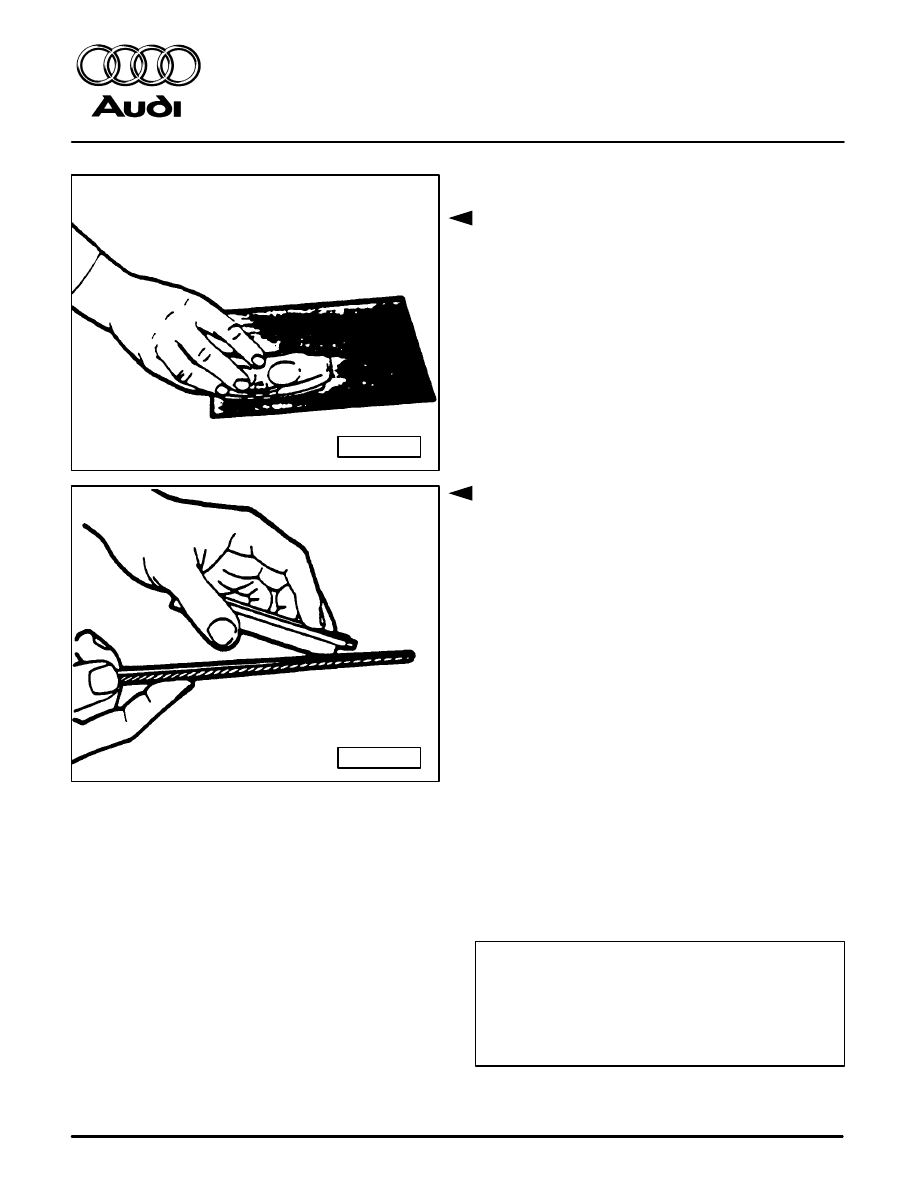

Brake calipers, cleaning

Clean brake pad carrier contact points

–arrows– and apply a thin coat of Plastilube

Moly 3

high temperature grease to these

points.

– Clean caliper piston to brake pad contact

surfaces and apply a thin coat of Plastilube

Moly 3

high temperature grease to the

contact surfaces.

– Reinstall brake rotors.

– When reassembling the brake calipers,

apply a thin coat of Plastilube Moly 3

high

temperature grease to all spring contact

points.

CAUTION!

Do not allow Plastilube Moly 3

high tem-

perature grease to come into contact

with the braking surface of the brake pad

or brake rotor.

(Cont. on Page 5)

Technical Bulletin

C

5

1997 Audi of America, Inc.

– Reinstall brake calipers and wheels.

When procedure applies to vehicles within

The New Vehicle Limited Warranty, use the

following:

Front brakes:

Part Identifier:

4636

Labor Operation: 4636550

90 TU

Rear brakes:

Part Identifier:

4638

Labor Operation: 4638660

110 TU

Wyszukiwarka

Podobne podstrony:

Panasonic P2 Chassis Bullettin TB 97 01

2015 08 20 07 46 07 01

2015 08 20 07 46 17 01

2015 08 20 07 46 42 01

2015 08 20 07 46 28 01

73 SC DS300 R MERCEDES C CLASSE W202 A 97 01

2015 08 20 07 46 07 01

2015 08 20 07 46 17 01

2015 08 20 07 46 07 01

73 SC DS300 R MERCEDES C CLASSE W202 A 97 01

2014 03 02 11 46 47 01

2015 08 20 07 46 42 01

2015 08 20 07 46 17 01

2015 08 20 07 46 28 01

Audi A4b5 licznik do 97

Audi TB 01 03 05 Readiness Quick Reference

Audi TB 01 03 05 Readiness Quick Reference

Bentley com Audi TB 01 03 07

Audi TB 01 03 05 Readiness Quick Reference

więcej podobnych podstron