USA 800.323.1233 CANADA 800.268.4977 HEAT TREATMENT 800.265.0862

www.schmolz-bickenbach.us www.schmolz-bickenbach.ca

THYROTHERM

®

2367 SUPRA ESR

Technical Data Sheet

Chemistry

Typical

C

Si

S

Cr

Mo

V

Analysis % 0.37 0.40 .003 max. 5.0 3.0 0.60

Description

• THYROTHERM® 2367 SUPRA is an electro slag remelted

(ESR) hot work die steel developed for applications where

high temperature properties (tensile strength & thermal con-

ductivity) are required to resist thermal fatigue and temper-

ing.

Characteristics

• Excellent resistance to heat checking

•

Excellent resistance to wear (erosion & abrasion)

•

Excellent high-temperature strength

•

Good tempering resistance

•

Good toughness

Applications

•

High pressure die casting dies

•

Hot forging dies

•

Hot extrusion tooling

•

Forming dies

•

Plastic molds

•

Mandrels

Physical Properties

(Hardened and tempered to 46 HRC)

Mechanical Properties

Density:

0.281 lbs/in

3

(room temperature)

Toughness (CVN): Average 10 ft-lbs. at 44-46 HRC

Tensile Properties: (room temperature)

Hard-

ness

HRC

Y.S

(0.2%)

ksi

T.S.

Ksi

EL

(%)

RA

(%)

52

48

44

225

193

171

267

234

203

12

13

12

35

38

40

Coefficient of

Thermal

Expansion

70

0

F – 200

0

F

6.6

X 10

-6

/

0

F

70

0

F – 400

0

F

6.9

X 10

-6

/

0

F

70

0

F – 750

0

F

7.0 X 10

-6

/

0

F

Thermal

Conductivity

70

0

F

206

Btu/in/ft

2

/

hr/

0

F

650

0

F

235

Btu/in/ft

2

/

hr/

0

F

1300

0

F

245 Btu/in/ft

2

/

hr/

0

F

Heat Treatment

Welding

Soft Annealing

Stress Relieving

Hardening (Refer to TTT diagram on page 2)

Tempering (See tempering diagram on page 2)

• Tempering hardness is approximate and based on two hours at

temperature

• In order to achieve faster quench rates, generous radii and ma-

chining stock should be left on during rough machining.

• Optimal heat treatment parameters should be followed to achieve

maximum potential die performance.

• Please contact your Schmolz & Bickenbach heat treat representa-

tive for more detailed in

formation.

Temperature

Cooling

Hardness

1345

o

F - 1435

o

F

Furnace 20

o

F/hour to 1200

o

F

Then air cool.

235 HB

Max

Temperature

Cooling

Hardness

1200

o

F for 2

hours

Cool slowly to 900

o

F in air

230 HB

Max

Temperature

Cooling

Hardness

1875

o

F - 1920

o

F

Hold at

temperature for

30 minutes

Vacuum quench at 50

o

F/min.

to 1000

o

F then cool to below

150

o

F

55 HRC

Max

Quenched

Temperature

o

F

752

932

1022

1112

1202

1292

Hardness

HRC

52

55

55

52

45

36

• THYROTHERM® 2367 Supra can be welded in an annealed and

hardened condition if machining errors, design changes or minor

cracking have occurred. TIG (Tungsten Inert Gas) should pref-

erably be used.

Welding Guidelines

Welding Temperatures

Process

Tig

Current

D.C.

Amperage (A)

100-150

Electrode

Tungsten Thorium

Electrode Diameter

0.10 – 0.17

Protective Gas

Argon

Flow (L/mm)

10

Filler Rod

AISI H-13

Preheat

Temp.

Maintained

Temperature

during

welding

Cool

Down to:

Stress Relieve

620

o

F to

900

o

F

Above 600

o

F 150

o

F

1050

o

F for 2 hours

or 30-50

o

F below previous

tempering temperature

Polishing

For highly cosmetic applications, the tool should be heat treated to the

highest hardness possible. Size of the tool will determine the maxi-

mum hardness. A-1 polish is achievable when proper procedures are

followed. A Schmolz & Bickenbach

representative should be con-

sulted when

determining the hardness.

USA 800.323.1233 CANADA 800.268.4977 HEAT TREATMENT 800.265.0862

www.schmolz-bickenbach.us www.schmolz-bickenbach.ca

THYROTHERM

®

2367 SUPRA

Technical Data Sheet (cont.)

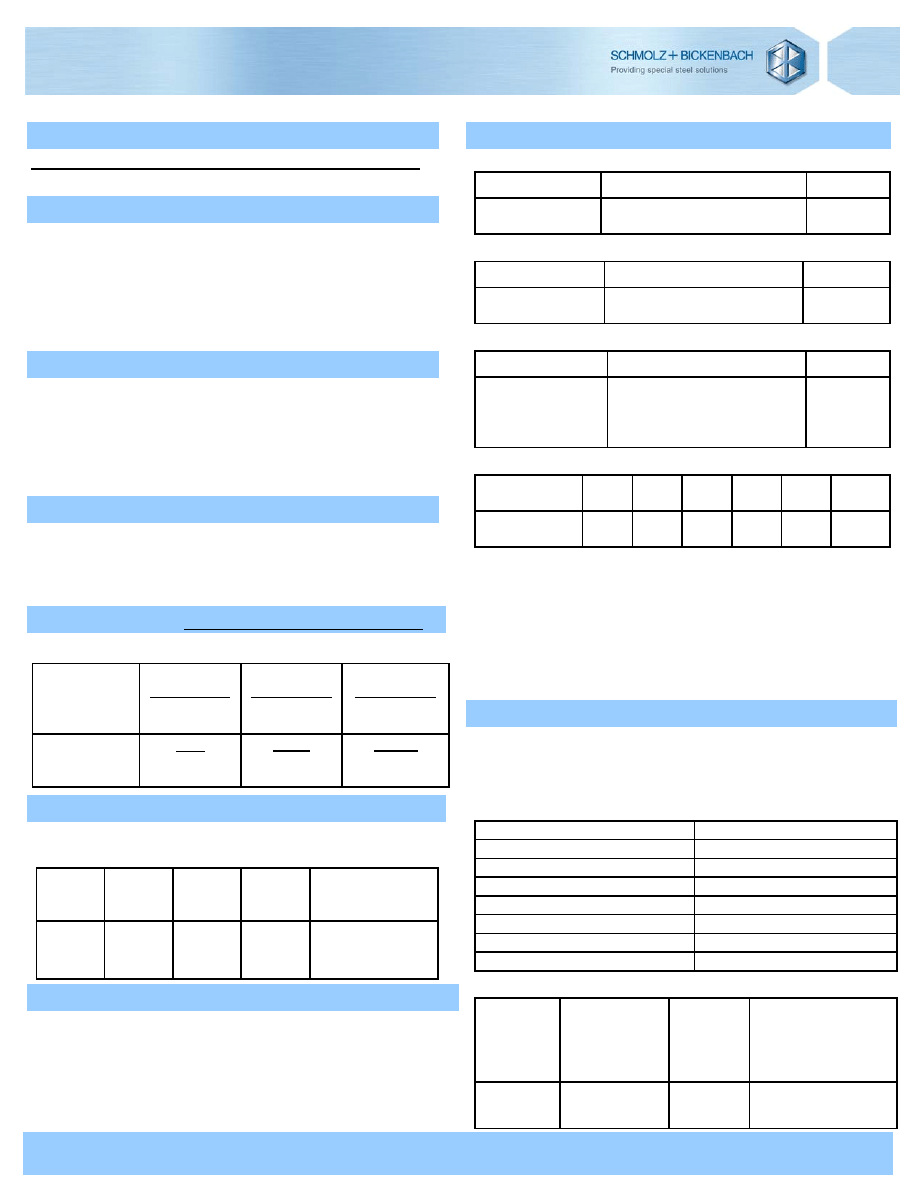

Time-Temperature-Transformation Diagram.

Austenitizing Temperature 1875—1920

o

F

Cooling Curve Number

1

2

3

4

5

6

7

8

9

10

11

Hardness (HV 10)

690 673 665 627 620 620 634 606 606 554 548

Hardness (HRc approx.) 62 61 59 58 58 58 59 57 57 54.5 54

12

525

53

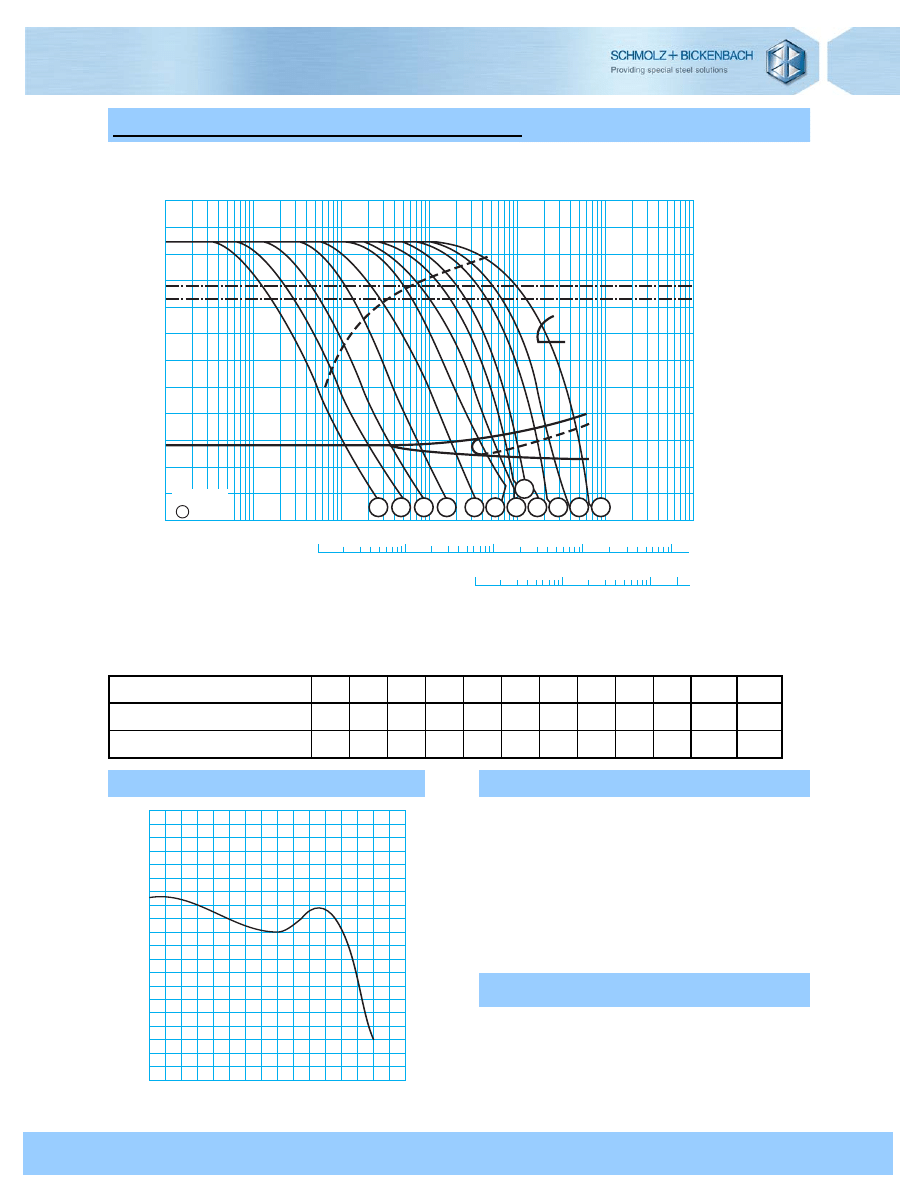

Tempering Diagram

Industry Standards

THYROTHERM® 2367 SUPRA ESR meets or ex-

ceeds the following standards:

• NADCA #207-2006

• Ford Motor Company AMTD-DC2010

•

All statements regarding the properties or utilization

of the materials or products mentioned are for the

purposes of description only. Guarantees regarding

the existence of certain properties or a certain utiliza-

tion are only valid if agreed upon in writing.

General Notes

30

34

42

38

46

50

54

58

62

66

70

212 392 572 752 932 1112

0

1292 1472

Hardness in HRC

Temperature in °F

2 1 9 2

2 0 1 2

1 8 3 2

1 6 5 2

1 4 7 2

1 2 9 2

111 2

9 3 2

7 5 2

5 7 2

3 9 2

2 1 2

0

10

0

10

1

10

2

10

0

10

1

10

2

10

3

10

4

10

0

10

1

10

2

10

3

10

4

10

5

10

6

Ac

1b

A + C

M

S

M

P

1

2

3

4

5

6

6

7

8

9

10

11

Ac

1c

Temperature in

o

F

Time (s)

Time (min)

Time

Hardness

:1560oF

:1740oF

Wyszukiwarka

Podobne podstrony:

2367 THYROTHERM Supra

2367 THYROTHERM Supra

2367 Zamek szyfrowy

2714 THYROTHERM

2365 THYROTHERM H10

2367

2885 THYROTHERM H10A

2367

2367

2367

2344 THYROTHERM Magnum

2367

2343 Thyrotherm H11

Supra Sword

więcej podobnych podstron