Enzymatic hydrolysis of microcrystalline cellulose in reverse micelles

Nan Chen, Jun-Bao Fan, Jin Xiang, Jie Chen, Yi Liang

⁎

State Key Laboratory of Virology, College of Life Sciences, Wuhan University, Wuhan 430072, China

Received 24 August 2005; received in revised form 12 March 2006; accepted 28 March 2006

Available online 4 April 2006

Abstract

The activities of cellulases from Trichoderma reesei entrapped in three types of reverse micelles have been investigated using microcrystalline

cellulose as the substrate. The reverse micellar systems are formed by nonionic surfactant Triton X-100, anionic surfactant Aerosol OT (AOT), and

cationic surfactant cetyltrimethyl ammonium bromide (CTAB) in organic solvent mediae, respectively. The influences of the molar ratio of water to

surfactant

ω

0

, one of characteristic parameters of reverse micelles, and other environmental conditions including pH and temperature, on the

enzymatic activity have been studied in these reverse micellar systems. The results obtained indicate that these three reverse micelles are more

effective than aqueous systems for microcrystalline cellulose hydrolysis, and cellulases show

“superactivity” in these reverse micelles compared with

that in aqueous systems under the same pH and temperature conditions. The enzymatic activity decreases with the increase of

ω

0

in both AOT and

Triton X-100 reverse micellar systems, but reaches a maximum at

ω

0

of 16.7 for CTAB reverse micelles. Temperature and pH also influence the

cellulose hydrolysis process. The structural changes of cellulases in AOT reverse micelles have been measured by intrinsic fluorescence method and a

possible explanation for the activity changes of cellulases has been proposed.

© 2006 Elsevier B.V. All rights reserved.

Keywords: Cellulase; Microcrystalline cellulose; Reverse micelle; Enzymatic hydrolysis

1. Introduction

The Trichoderma reesei cellulase complex is a true cellulase

mixture in the most rigid sense, which includes endoglucanases

(EC 3.2.1.4), exoglucanases (cellobiohydrolases, EC 3.2.1.91),

and

β-glucosidases (EC 3.2.1.21), being able to hydrolyze the β-

1,4-glucosidic linkages of cellulose, and convert crystalline,

amorphous, and chemically derived celluloses quantitatively to

glucose

. Cellulose is the most abundant renewable energy

source on earth. Complete hydrolysis of cellulose yields the

easily fermentable sugar glucose. When this product is biolo-

gically converted into other products, such as ethanol, it can

provide environmental, economic, and strategic benefits on a

large scale. Cellulose hydrolysis will be one of the most impor-

tant biotechnologies in the 21st century

. Therefore, there is

great interest in understanding the process of enzymatic

cellulose degradation and its industrial applications

Reverse micelles are at present considered as simple organic

media mimicking membranous biological systems, to perform

biocatalysis. Reverse micelles containing enzymes have been

thought of as

“micro-reactors” in which the enzymes can be

sheltered and protected from the detrimental effects of solvents

. The structure of a reverse micelle consists of an aqueous

micro-domain (water pool) surrounded by inward-facing polar

heads of the surfactants. The outward-facing hydrophobic chains

of the surfactants are soluble in the non-aqueous bulk solvent

. According to the different surfactants used in different

systems, reverse micelles can be divided into anionic, cationic,

and nonionic classes

. The water concentration in reverse

micelles is generally defined in terms of the parameter

ω

0

, the

molar ratio of water to surfactant. Owing to the water limiting

conditions in reverse micelles,

ω

0

becomes an important deter-

minant of the rates of enzymatic hydrolytic reactions. Therefore

it is of interest to study the correlation between

ω

0

and the

enzyme-catalyzed reaction rate in reverse micelles.

Biopolymers can be solubilized in the water pool of the

reverse micelles and be easily studied by various methods, since

the system is stable, homogeneous, and transparent. Continuous

efforts have been made by various workers to demonstrate that

Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

http://www.elsevier.com/locate/bba

Abbreviations: AOT, Aerosol OT or sodium bis(2-ethylhexyl)sulfosuccinate

⁎ Corresponding author. Tel.: +86 27 6875 4902; fax: +86 27 6875 2560.

E-mail address:

(Y. Liang).

1570-9639/$ - see front matter © 2006 Elsevier B.V. All rights reserved.

doi:

reverse micellar water pool constitutes a unique microenviron-

ment for hydrophilic enzymes, which protects them against

denaturation by the surrounding organic solvents. The structure

of this microenvironment may affect reaction rates through a

variety of mechanisms

:

(1) Shifts of thermodynamic equilibrium in enzyme-catalyzed

condensation and hydrolysis reactions due to a control-

lable water concentration.

(2) Possibility of suppressing product inhibition.

(3) Possibility of enhanced activity and stability of enzymes.

For a few enzymes, an enhancement of the turnover number

over that found in aqueous solution has been observed. In the

case of

α-chymotrypsin, as reported first by Menger and Yamada

, and later by other groups

, this enhancement takes

place at rather low

ω

0

values. The enhancement is, however,

modest. Martinek and co-workers

and Luisi's group

have observed much larger enhancements in the case of

peroxidase and ribonuclease.

Nowadays, the key challenge for the application of cellulases

to the breakdown of cellulosic biomass into sugars for fermen-

tation to ethanol and other commodity products is to make

biomass depolymerization more rapid and less costly. Thanks to

the properties mentioned above, the use of reverse micelles as

reaction media could be an effective method for increasing the

enzymatic hydrolysis of cellulose.

The principal goal of this work is to examine comprehensively

the kinetics of enzymatic hydrolysis of microcrystalline cellulose

in reverse micelles, the subsequent fermentation to chemical

products such as ethanol, and the possibility of future application

in industry. Toward this goal, the following objectives were

achieved for the first time: (i) we compared the enzymatic activity

in reverse micelles composed of nonionic surfactant Triton X-

100, anionic surfactant Aerosol OT or sodium bis(2-ethylhexyl)

sulfosuccinate (AOT), and cationic surfactant cetyltrimethylam-

monium bromide (CTAB) with that in aqueous medium under the

same pH and temperature conditions; (ii) we investigated the

influence of

ω

0

, pH, and temperature on the enzymatic hydrolysis

and thereby obtained an optimum environment for reaction; (iii)

we studied the structural changes of cellulases in AOT reverse

micelles by intrinsic fluorescence method.

2. Materials and methods

2.1. Materials

Cellulase mixture from Trichoderma reesei (Shanghai Boao Bio-technical Co.,

Shanghai, China, average MW

∼52 kDa) was used without further purification. Its

concentration was determined by the weight method and its filter paper activity was

determined by the anthrone method

to be 15 U/mg. Here, U is defined as 1 mg

sugar formed per min at 25.0 °C and pH 5.4. The molar concentration of cellulases

in the entire reaction volume of Triton X-100, AOT, and CTAB reverse micelles

was 0.23

μM. Microcrystalline cellulose was obtained from Shanghai Forth

Reagent factory (Shanghai, China). Its behavior, such as size, solubility, pH, and

temperature stability, is described in

. Triton X-100, AOT, and CTAB were

purchased from Amresco (Amresco Chemical Co., Solon, OH), Sigma (Sigma-

Aldrich Co, St. Louis, MO), and Shanghai Boao Bio-technical Co., respectively.

All chemicals used were made in China and of analytical grade. All reagent

solutions were prepared in 0.02 M citric acid-phosphate buffer (pH 4.7

–7.4) for

enzyme assay and all fluorescence experiments.

2.2. Reverse micellar solutions

The enzyme-containing reverse micelles were prepared by injecting a

buffered enzyme stock solution at a given pH and concentration into 250 mM

Triton X-100 in xylene/n-hexanol (1:2, v/v), 50 mM AOT in isooctane, or 50 mM

CTAB in isooctane/chloroform (1:1, v/v), to obtain different values of

ω

0

, while

being vigorously shaken at room temperature until a completely transparent

solution had been obtained (ca 10

–15 s). For example, 20 μl of 35 μM buffered

enzyme stock solution was added into 3.0 ml of AOT/isooctane solution to obtain

AOT reverse micelles at

ω

0

of 7.4.

Since the structures of biomacromolecules are very sensitive to the organic

solvent involved, the embedding of cellulases in reverse micelles was performed

using the popular

“injection method”

. That is, the aqueous solution of

cellulases was injected into the surfactant organic solvent solution.

2.3. Enzyme assays

The activities of cellulases were determined by estimating the glucose units

released from microcrystalline cellulose. The substrate concentration (3.33 mg/ml) in

the entire reaction volume of Triton X-100, AOT, and CTAB reverse micelles was

kept above the enzyme saturation level. Here, the enzyme saturation level was

determined by investigating the enzymatic hydrolysis of microcrystalline cellulose in

aqueous systems with different cellulose concentrations. The sugar formed reached a

maximum when the substrate concentration was 3.33 mg/ml, and the concentration

of cellulose was kept constant at this level in our experiments. For the experiments in

the reverse micelles, the enzyme-containing reverse micelles were incubated at 30.0,

35.0, 40.0, 45.0, 50.0, 55.0, and 60.0 °C for 5 min. The reaction was started by the

addition of cellulose, and then the reaction mixture was incubated at the same

temperature for 5 min. After centrifuging at 5000 rpm for 3 min, 1.0 ml of the upper

solution without cellulose, containing 6

–36 μl of water pool was taken and diluted by

the addition of 60

–360 μl of buffer. The mixture was vigorously shaken and allowed

to equilibrate thermally for 45 min. After the addition of 1.0 ml chloroform and

centrifugation at 8000 rpm for 5 min, an aliquot of the supernatant (10

μl) was taken

and diluted by the addition of buffer to 1.0 ml for the anthrone analysis. The anthrone

assay of reverse micelles containing only cellulases was also performed under the

same conditions in order to correct the observed background given by cellulases.

For the experiments in aqueous systems, the buffered solutions of cellulases

(pH 6.0) were incubated at 50.0 °C for 5 min. The reaction was started by the

addition of cellulose, and the reaction mixture was incubated at 50.0 °C for 5 min.

The sample was centrifuged at 5000 rpm for 3 min, and an aliquot of the

supernatant (10

μl) was taken and diluted by the addition of buffer to 1.0 ml for

the anthrone analysis.

2.4. Intrinsic fluorescence spectroscopy

Intrinsic fluorescence spectroscopic measurements on the structural changes of

cellulases in AOT reverse micelles at different water pool volumes and in aqueous

systems were carried out at 50.0 °C using a LS-55 luminescence spectrometer

(PerkinElmer Life Sciences, Shelton, CT). The excitation wavelength at 295 nm

was used for the intrinsic fluorescence measurements and the emission spectra were

recorded between 320 and 400 nm. The excitation and emission slits were both

10 nm, and the scan speed was 200 nm min

− 1

. The enzyme-containing AOT

reverse micelles were prepared as described above and the enzyme concentration in

Table 1

The behavior of the substrate, microcrystalline cellulose

Granularity

(

μm)

Solubility in water

pH

Temperature stability

15

–40

Insoluble (

b0.2%)

6.9

–7.3

Darkening of color and slow

softening only occur

at temperatures above 140 °C.

Decomposition occurs

at temperatures above 200 °C.

1030

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

the whole system was 0.23

μM. The prepared enzyme-containing reverse micelles

were placed in a 1-cm thermostated quartz fluorescence cuvette. The fluorescence

measurements of the protein samples were carried out with optical density less than

0.3 at 295 nm in order to avoid the inner filter effects. The fluorescence of reverse

micelles containing only buffer were also measured under the same conditions in

order to correct the observed fluorescence. Each spectrum was scanned for two or

three times to acquire the final fluorescence emission spectra.

3. Results

3.1. Effect of

ω

0

on the activities of cellulases in Triton X-100,

AOT, and CTAB reverse micelles

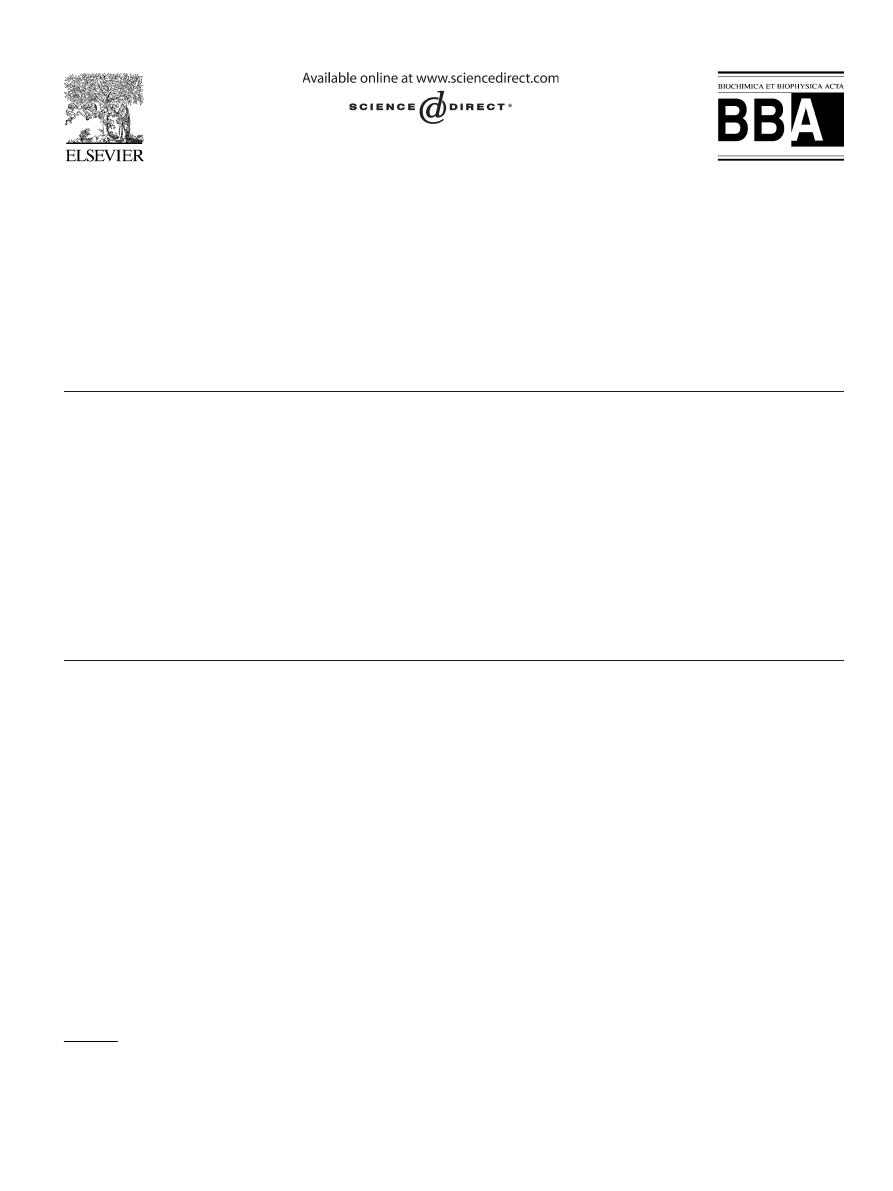

The change of

ω

0

affects all kinetic data including the

enzymatic activity. Because the reverse micelles formed by

different surfactants and organic solvents have different contents

of buffer solution, different ranges of

ω

0

were used for Triton X-

100, AOT, and CTAB reverse micelles in the present study. The

activities of cellulases at various values of

ω

0

, represented by the

glucose concentrations after hydrolysis in the water pools of the

reverse micelles, are presented in

and compared with that in

aqueous medium at the same pH and temperature (

). As

shown in

, with increasing the value of

ω

0

, the activities of

cellulases in Triton X-100 and AOT reverse micelles decreased

gradually. Lower glucose concentrations were observed in the

bigger water pools of these two types of reverse micelles, com-

pared with those in the smaller water pools. From

, it can

also be seen that the activity of cellulases in CTAB reverse

micelles increased with increasing the value of

ω

0

from 7.4 to

16.7, reaching a maximum when

ω

0

was 16.7. With further

increasing the value of

ω

0

to 44.0, however, the activity of

cellulases declined. As shown in

, the activities of cellulases

in the smallest water pools of Triton X-100 and AOT reverse

micelles (the values of

ω

0

were 1.0 and 7.4 for Triton X-100 and

AOT reverse micelles respectively) and in the optimum water

pools of CTAB reverse micelles were much higher than those in

aqueous systems under the same pH and temperature conditions.

It should be pointed out that when

ω

0

N17.9 (or 22.2), the glucose

concentration in AOT (or CTAB) reverse micelles was lower than

that in aqueous systems. The activities of cellulases at higher

ω

0

in

were even closer to zero. A possible explanation for this

observation may be due to the deduction of the background given

by cellulases in the anthrone assay.

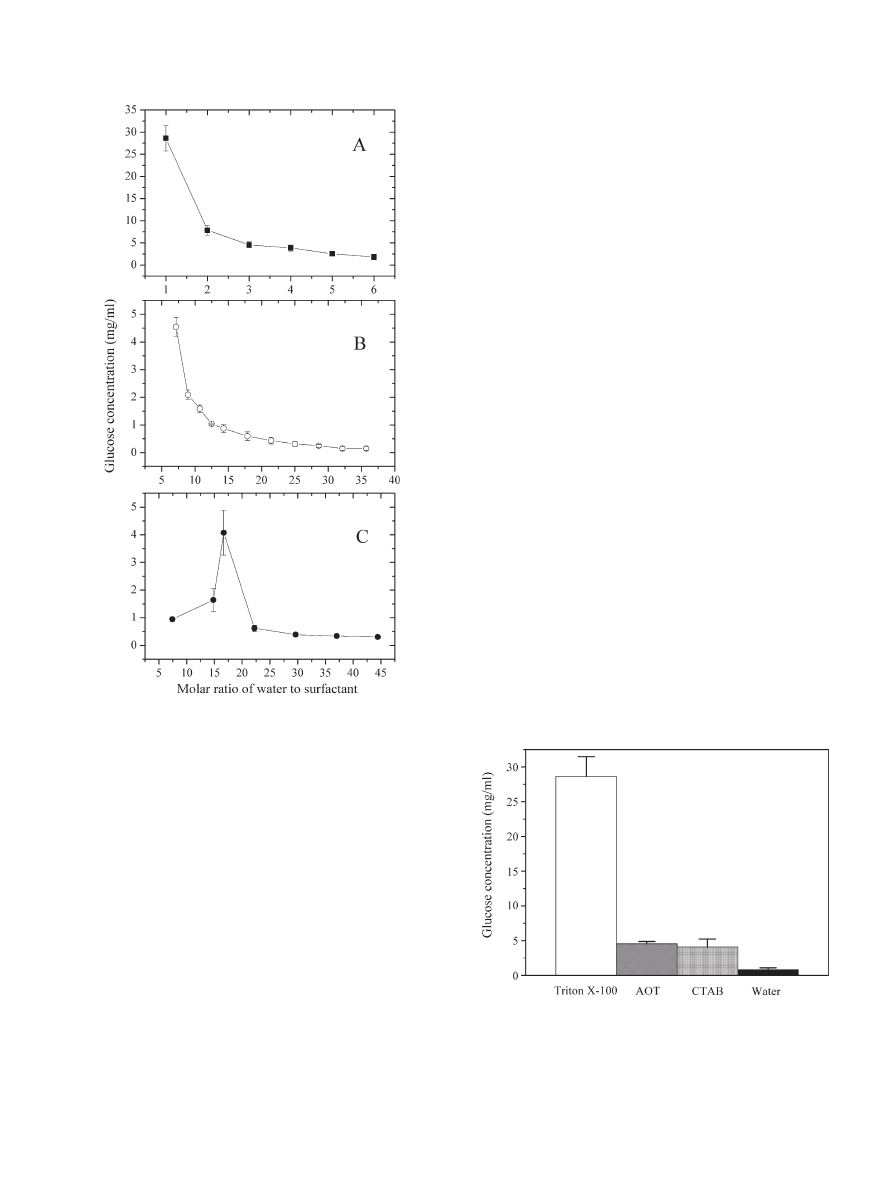

3.2. Effect of temperature on the activities of cellulases in

Triton X-100, AOT, and CTAB reverse micelles

shows the temperature dependence of the activities of

cellulases in Triton X-100, AOT, and CTAB reverse micelles at

pH 6.0 and at a specified

ω

0

(

ω

0

= 1.0 for Triton X-100 reverse

micelles, 7.4 for AOT reverse micelles, and 16.7 for CTAB reverse

Fig. 1. The activities of cellulases represented by glucose released in reverse micelles

at different molar ratios of water to surfactant. A: glucose concentration in the water

pools of Triton X-100 reverse micelles after cellulose hydrolysis (solid square). The

range of

ω

0

was 1.0

–6.0. B: glucose concentration in the water pools of AOT reverse

micelles (open circle). The range of

ω

0

was 7.4

–37.0. C: glucose concentration in the

water pools of CTAB reverse micelles (solid circle). The range of

ω

0

was 7.4

–44.4.

Experiments were performed at 50.0 °C in 0.02 M citric acid

–phosphate buffer at

pH 6.0. The data with error bars were expressed as mean ± S.D. (n = 2

–3).

Fig. 2. Comparison of the activities of cellulases represented by glucose

released in Triton X-100 reverse micelles (white bar), AOT reverse micelles

(grey bar), and CTAB reverse micelles (light grey bar) with that in aqueous

systems (black bar). All the four systems were under the same pH and

temperature conditions, and the values of

ω

0

were 1.0, 7.4, and 16.7 for Triton

X-100, AOT, and CTAB reverse micelles, respectively. Experiments were

performed at 50.0 °C in 0.02 M citric acid

–phosphate buffer at pH 6.0. The

data with error bars were expressed as mean ± S.D. (n = 2

–3).

1031

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

micelles). The temperature range was 30.0

–60.0 °C. As shown in

, the activities of cellulases in Triton X-100 and AOT (or

CTAB) reverse micelles increased with the increase of the tem-

peratures from 30.0 to 50.0 °C (or 45.0 °C). With a further increase

of the temperature to 60.0 °C, however, the activities of cellulases

declined. In control experiments, the optimum temperature for the

same enzymatic reaction in aqueous systems was 50.0 °C (figure

not shown), similar to that measured in these reverse micelles.

3.3. pH dependence of the activities of cellulases in Triton

X-100 and CTAB reverse micelles

shows the pH-dependence of the activities of cellulases

in Triton X-100 (

ω

0

= 1.0) and CTAB (

ω

0

= 16.7) reverse mi-

celles at 50.0 °C. The pH ranges were 5.2

–6.4 and 4.7–7.4 for

Triton X-100 and CTAB reverse micelles, respectively. As

shown in

, the activity of cellulases in Triton X-100 reverse

micelles increased with the increase of the pH values from 5.2 to

6.0, reaching a maximum at pH 6.0. With further increasing the

pH to 6.4, however, the activity of cellulases declined. From

, it can also be seen that the optimum pH value for this

enzymatic reaction in CTAB reverse micelles was 6.5, which is

closed to the physiological pH value. However, the optimum pH

value for the same enzymatic reaction in aqueous systems

(pH 5.4, figure not shown) was more acidic than those measured

in both reverse micelles.

The influences of

ω

0

, temperature, and pH on cellulose

hydrolysis were studied as described above, and the optimum

conditions for Triton X-100, AOT, and CATB reverse micelles

were thus obtained. When

ω

0

= 1.0 and 7.4, temperature = 50.0 °C,

and pH = 6.0, the enzymatic hydrolysis of cellulose reached a

maximum in Triton X-100 and AOT reverse micelles, respec-

tively. When

ω

0

= 16.7, temperature = 45.0 °C, and pH = 6.5, the

enzymatic hydrolysis of cellulose reached a maximum in CTAB

reverse micelles. The activity of cellulases in Triton X-100 reverse

micelles under such optimum conditions was 35-fold larger than

that in aqueous systems. Similarly, the activities of cellulases in

AOT and CTAB reverse micelles under such optimum conditions

were 5-fold and 7-fold larger than that in aqueous systems,

respectively.

Fig. 3. Effect of temperature on the activities of cellulases represented by glucose

released in Triton X-100, AOT, and CTAB reverse micelles. A: glucose

concentration in Triton X-100 reverse micelles after hydrolysis (solid square). B:

glucose concentration in AOT reverse micelles after hydrolysis (open circle). C:

glucose concentration in CTAB reverse micelles after hydrolysis (solid circle).

The temperature range was 30.0

–60.0 °C. The values of ω

0

for Triton X-100,

AOT, and CTAB reverse micelles were 1.0, 7.4, and 16.7, respectively.

Experiments were performed in 0.02 M citric acid

–phosphate buffer at pH 6.0.

The data with error bars were expressed as mean ± S.D. (n = 2

–3).

Fig. 4. pH dependence of the activities of cellulases represented by glucose

concentration in Triton X-100 reverse micelles at 50.0 °C (A), and CTAB reverse

micelles at 45.0 °C (B). For Triton X-100 reverse micelles, the pH range was 5.2

–

6.4 and the value of

ω

0

was 1.0. For CTAB reverse micelles, the pH range was

4.7

–7.4 and the value of ω

0

was 16.7. The data with error bars were expressed as

mean ± S.D. (n = 2

–3).

1032

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

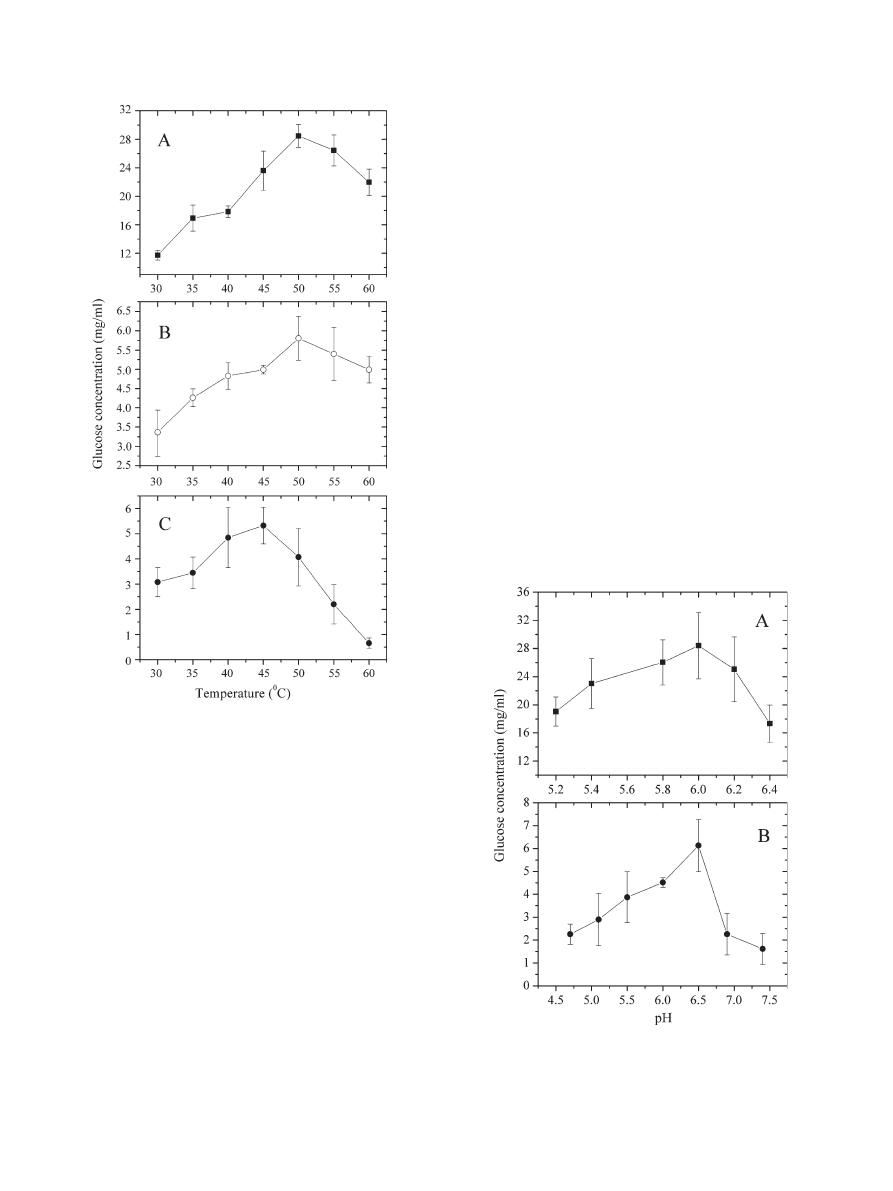

3.4. Conformational changes of cellulases with the increase of

ω

0

in AOT reverse micelles

Tryptophan is a very useful intrinsic probe since its emission

fluorescence spectra reflect the molecular environment of the

side chain; disruption of the native structure leads to changes in

the exposure of the tryptophan side chains to solvent that can

readily be monitored by recording the protein fluorescence

emission spectra

. As shown in

, a regular increase

in the intrinsic fluorescence intensity of tryptophan residues of

cellulases together with a remarkable blue shift of fluorescence

emission maximum from 362 to 348 nm took place upon

increasing the molar ratio of water to surfactant from 5 to the

infinite (the bulk aqueous systems) at 50.0 °C, suggesting that a

more rigid conformation for cellulases was induced in AOT

reverse micelles than that in aqueous systems.

4. Discussion

Studies during the past two decades have revealed that the

technological utility of enzymes in low water content systems

cannot only enhance the catalytic efficiency greatly, but also

lead enzymes to catalyze reactions which are impossible in

water

. It has been established firmly that many enzymes

can work in reverse micelles, such as lipase

, cutinase

, dihydrofolate reductase

, and lysozyme

. How-

ever, information on the activities of cellulases in reverse

micelles, which is necessary for a thorough understanding of the

mechanism for enzymatic hydrolysis of cellulose in low water

content systems, is eagerly awaited.

The results obtained herein indicated that Triton X-100, AOT,

and CTAB reverse micelles were more effective than aqueous

systems for cellulose hydrolysis under the same pH and

temperature conditions. That is, cellulases showed

“superactiv-

ity

” in these three types of reverse micelles. The “superactivity”

of other enzymes, such as

α-chymotrypsin

, ribonuclease

, and peroxidase

, in reverse micelles has been reported.

Luisi et al. have suggested that this enhancement is associated

with the artificial environments and electric fields of the enzyme,

and perhaps with the particular state of water in reverse micelles

. García-Carmona et al. have explained their observations by

a greater reactivity of the structured water in the micelle and/or

by the relatively high rigidity of the enzyme molecule caused by

the surfactant layer

. The present fluorescence study

demonstrated that a rigid conformation for cellulases induced

by reverse micelles might result in the superactivity of cellulases.

The quite high rigid surfactant shells of reverse micelles

surround and confine the molecules of the solubilized cellulases,

thereby functioning as a buffer (or absorber) of excessive

fluctuations that may destroy the catalytic conformation in the

aqueous systems.

The activities of cellulases in Triton X-100 and AOT reverse

micelles reached a maximum at quite low

ω

0

, which is similar to

those of other enzymes

. For several enzymes, optimal

activity is observed in the range of

ω

0

from 8 to 13. For

example, the maximal activity of

α-chymotrypsin is found at ω

0

of 7

, for lysozyme at 13

, and for lipase at around 10

. The low

ω

0

probably causes the decrease in the

conformational flexibility of the proteins in reverse micelles.

The results of the pH study presented herein were only to

determine the apparent optimal pH value for cellulose

hydrolysis in reverse micelles. Because of the micro heteroge-

neity of reverse micelles, common expressions like pH must be

carefully redefined. For instance, pH in reverse micelles is a

controversial phenomenon. It has been clearly shown that the

acidity of a compound strongly depends on its location in a

reverse micelle because an acidity gradient is formed from the

interface to the micellar center

. Upon increasing the

ω

0

value in a reverse micellar medium, the pH of solutes in the

water pool begins to resemble that in bulk water. So far, there

still has been no accepted definition or measurement of pH in

reverse micelles.

Another important factor for enzymatic activities in reverse

micelles is the temperature. The stability of reverse micelles

themselves is temperature-sensitive. Therefore, when assaying

enzyme activity in reverse micelles at different temperatures,

these effects should be considered. A suitable high temperature

leads to the percolation and changes of the electrical conductivity

Fig. 5. Conformational changes of cellulases in AOT reverse micelles with

increasing

ω

0

values. A: intrinsic fluorescence emission spectra of cellulases under

different

ω

0

conditions (red lines), compared with that in aqueous systems (blue

line). The arrow represented the value of

ω

0

for AOT reverse micelles increased

gradually from 5.0 (the bottom red line) to 35.0 (the top red line). B: effects of

ω

0

on

the intrinsic fluorescence intensity (open circle) and emission maximum (solid

square) of cellulases. The excitation wavelength was 295 nm. Experiments were

performed at 50.0 °C in 0.02 M citric acid

–phosphate buffer at pH 6.0. (For

interpretation of the references to colour in this figure legend the reader is refred to

the web version of this article.)

1033

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

of reverse micelles

, which is advantageous to the hydrolysis

of cellulose and the diffusion of the product. The activities of

cellulases in Triton X-100, AOT, and CTAB reverse micelles

increased with the increase of the temperatures at first, reaching a

maximum at a specified temperature, which is the most critical

point according to enzyme stability and subsequent activity in

reverse micelles as well as the stability of reverse micelles.

Since the surfactant is one of the components of reverse

micelles, the influence of surfactant on the activities of

cellulases cannot be neglected. Different kinds of surfactants

have different effects on the stability and activity of enzymes.

When the net charge on the enzyme molecule is opposite to that

on the surfactant layer, the enzyme molecule interacts with the

surfactant layer remarkably. The crystal structures of cellobio-

hydrolase and endoglucanase from Trichoderma reesei have

shown that the net charge on the surfaces of these cellulases is

positive

, while the net charge is negative on the AOT

composed layer and positive on the CTAB surfactant layer. So

there may be strong electrostatic attractions between the

opposite charges of the proteins and AOT, and strong

electrostatic repulsive forces between the same charges of the

proteins and CTAB, and the surfactant

–enzyme interactions and

the electrostatic repulsive forces may partially inhibit the

activities of cellulases in both reverse micelles. This could be an

explanation why the cellulose hydrolysis efficiencies in AOT

and CTAB reverse micelles were lower than that in Triton X-

100 reverse micelles.

It remains unclear whether the substrate, microcrystalline

cellulose, can be entrapped in these reverse micelles during the

enzymatic reaction. According to the induced fit model

, the

molecules of cellulases can be entrapped in the water pools of

these reverse micelles, surrounded by surfactant layers. In the

enzyme-containing reverse micelles, there is some structured

water used for enzymatic hydrolysis of the microcrystalline

cellulose, and cellulases maintain a rigid conformation.

Microcrystalline cellulose is typically an insoluble powder

having a mean size range of about 15 to 40

μm (

), much

larger than the size of a reverse micelle (with a diameter of

hundreds of angstroms). Therefore, the substrate could not be

entrapped in these reverse micelles during the enzymatic

reaction. In the present study, we assumed that these reverse

micelles could carry cellulases in their water pools and

“force”

them to

“dock to” as well as remain seated on cellulose through

diffusion. When the reaction was started, these reverse micelles

could

“force” the sugar formed “dock into” their water pools

through hydrogen bond and diffusion. Therefore, glucose

concentration in reverse micelles we measured is really from

the water pools of the reverse micelles.

It remains unclear whether the insoluble microcrystalline

cellulose affects the stability of the reverse micelles. In other

words, when the insoluble microcrystalline cellulose was mixed

with the enzyme-containing reverse micelles, does it disturb the

structure of the reverse micelle? Pileni has given a case in his

review

that if the solute is located in the hydrocarbon phase

or in the external interface, there may be no perturbation of the

characteristic radius of the reverse micelles. According to the

assumption that cellulases may

“dock to” and remain seated on

the microcrystalline cellulose, and the fact that cellulases show

“superactivity” in these three types of reverse micelles compared

with that in aqueous systems, we conclude that the insoluble

microcrystalline cellulose does not disturb seriously the

structure of the reverse micelles.

The frequency of diffusion-controlled collision of discrete

micelles is readily calculated by Smoluchowski equation to be

10

9

–10

11

M

− 1

s

− 1

, and the values for the exchange frequency of

guest molecules in the water pools of the reverse micelles have

also been reported in the range of 10

6

and 10

8

M

− 1

s

− 1

. This

means that only one in every thousand collisions leads to an

exchange and that reverse micelles communicate with each other

on a micro-to millisecond timescale. Such high collision

frequency and exchange rate may be one of the reasons that

lead to

“superactivity” of cellulases in reverse micelles. Since all

cellulases are dependent on diffusion to

“dock to” as well as

remain seated on the non-diffusing substrate, all parameters

affecting diffusion (temperature, surrounding solution, etc.) are

very important. An environment which forces the enzymes to be

seated on cellulose for a longer time is most likely to increase the

chance for more hydrolysis instead of loosening from the

cellulose chain. This environment should, on the other hand, also

increase the risk for product inhibition, although the concentra-

tion of cellobiose/glucose needed for inhibition is rather high.

It has been reported that the refolding of denatured protein in

reverse micelles is reminiscent of intracellular chaperone-aided

protein folding

. As enzyme molecules entrapped in the

water pool interact with reverse micelles, various amphiphilic

sequences may dock onto reverse micelles in a structurally

ordered and thus stable form. Such ordered and stable structure

may be another reason that leads to

“superactivity” of cellulases

in reverse micelles.

In summary, Triton X-100, AOT, and CTAB reverse micelles

are more effective than aqueous systems for cellulose hydroly-

sis, and cellulases show

“superactivity” in these three types of

reverse micelles compared with that in aqueous systems under

the same pH and temperature conditions. Information obtained

from the present study can enhance our understanding of the

mechanism for enzymatic hydrolysis of cellulose in low water

content systems, and is helpful to the application of cellulases to

the breakdown of cellulosic biomass into sugars for fermentation

to ethanol and other commodity products. The cost of detergents

and the problems with the presence of detergents in biological

material aimed for fermentation should also be considered. So

the extension of the study of enzymatic hydrolysis of cellulose to

other reverse micelles, which are more effective for cellulose

hydrolysis and less consumable and toxic to the environment,

should lead to future applications of this new technology in

industry.

Acknowledgements

We thank Prof. Allen P. Minton and Dr. Peter McPhie

(National Institute of Diabetes and Digestive and Kidney

Diseases, National Institutes of Health) for their critical reading

of the manuscript. This work was supported by National Natural

Science Foundation of China (Grants 30370309 and 90408012),

1034

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

Project 863 (Grant 2004AA404260) from the Ministry of

Science and Technology of China, and Program for New

Century Excellent Talents in University (Grant NCET-04-0670)

from the Ministry of Education of China.

References

[1] E.A. Bayer, H. Chanzy, R. Lamed, Y. Shoham, Cellulose, cellulases and

cellusomes, Curr. Opin. Struct. Biol. 8 (1998) 548

–557.

[2] M.E. Himmel, M.F. Ruth, C.E. Wyman, Cellulase for commodity products

from cellulosic biomass, Curr. Opin. Biotechnol. 10 (1999) 358

–364.

[3] M. Schülein, Protein engineering of cellulases, Biochim. Biophys. Acta

1543 (2000) 239

–252.

[4] M.K. Baht, Cellulases and related enzymes in biotechnology, Biotechnol.

Adv. 18 (2000) 355

–383.

[5] J. Xiang, Y. Liang, N. Chen, Studies on the binding of sodium dodecyl

sulfate to cellulase by isothermal titration calorimetry and fluorescence

titration, Acta Chimi. Sin. 61 (2003) 1949

–1954.

[6] C. Divne, J. Ståhlberg, T. Reinikainen, L. Ruohonen, G. Pettersson, J.K.C.

Knowles, T.T. Teeri, T.A. Jones, The three-dimensional crystal structure of

the catalytic core of cellobiohydrolase I from Trichoderma reesei, Science

265 (1994) 524

–528.

[7] M. Sandgren, A. Shaw, T.H. Ropp, S. Wu, R. Bott, A.D. Cameron, J.

Ståhlberg, C. Mitchinson, T.A. Jones, The X-ray crysal structure of the

Trichoderma reesei family 12 endoglucanase 3, cel12A, at 1.9 Å resolution,

J. Mol. Biol. 308 (2001) 295

–310.

[8] L.R. Lynd, C.E. Wyman, T.U. Gerngross, Biocommodity engineering,

Biotechnol. Prog. 15 (1999) 777

–793.

[9] N.E. Levinger, Chemistry. Water in confinement, Science 298 (2000)

1722

–1723.

[10] P.L. Luisi, M. Giomini, M.P. Pileni, B.H. Robinson, Reverse micelles as

hosts for proteins and small molecules, Biochim. Biophys. Acta 947

(1988) 209

–246.

[11] K. Martinek, A.V. Levashov, Y.L. Khmelnitsky, N.L. Klyachko, I.V.

Berezin, Colloidal solution of water in organic solvents: a microheter-

ogeneous medium for enzymatic reactions, Science 218 (1982) 889

–891.

[12] B. Orlich, R. Schomacker, Enzyme catalysis in reverse micelles, Adv.

Biochem. Eng. Biotechnol. 75 (2002) 185

–208.

[13] K. Martinek, A.V. Levashov, N. Klyachko, Y.L. Khmelnitski, I.V. Berezin,

Micellar enzymology, Eur. J. Biochem. 155 (1986) 453

–468.

[14] K. Martinek, N.L. Klyachko, A.V. Kabanov, Y.L. Khmelnitsky, A.V.

Levashov, The second E.C. Slater lecture. Micellar enzymology: its

relation to membranology, Biochim. Biophys. Acta 981 (1989) 161

–172.

[15] A. Sanchez-Ferrer, F. Garcia-Carmona, Biocatalysis in reverse self-

assembling structures: reverse micelles and reverse vesicles, Enzyme

Microb. Technol. 16 (1994) 409

–415.

[16] F.M. Menger, K. Yamada, Enzyme catalysis in water pools, J. Am. Chem.

Soc. 101 (1979) 6731

–6734.

[17] S. Barbaric, P.L. Luisi, Micellar solubilization of biopolymers in organic

solvents. 5. Activity and conformation of

α-chymotrypsin in isooctane-

AOT reverse micelles, J. Am. Chem. Soc. 103 (1981) 4239

–4244.

[18] R. Wolf, P.L. Luisi, Micellar solubilization of enzymes in hydrocarbon

solvents, enzymatic activity and spectroscopic properties of ribonuclease

in n-octane, Biochem. Biophys. Res. Commun. 89 (1979) 209

–217.

[19] D.M. Updegraff, Semimicro determination of cellulose in biological

materials, Anal. Biochem. 32 (1969) 420

–424.

[20] P.L. Luisi, B. Steinmann-Hofmann, Activity and conformation of enzymes

in reverse micellar solutions, Methods Enzymol. 136 (1987) 188

–216.

[21] Y. Liang, F. Du, S. Sanglier, B.R. Zhou, Y. Xia, A. Van Dorsselaer, C.

Maechling, M.C. Kilhoffer, J. Haiech, Unfolding of rabbit muscle creatine

kinase induced by acid. A study using electrospray ionization mass

spectrometry, isothermal titration calorimetry and fluorescence spectros-

copy, J. Biol. Chem. 278 (2003) 30098

–30105.

[22] B.R. Zhou, Y. Liang, F. Du, Z. Zhou, J. Chen, Mixed macromolecular

crowding accelerates the oxidative refolding of reduced, denatured

lysozyme: Implications for protein folding in intracellular environments,

J. Biol. Chem. 279 (2004) 55109

–55116.

[23] H. Stamatis, A. Xenakis, F.N. Kolisis, Bioorganic reactions in microemul-

sions: the case of lipases, Biotechnol. Adv. 17 (1999) 293

–318.

[24] C.M.L. Carvalho, J.M.S. Cabral, Reverse micelles as reaction media for

lipases, Biochimie 82 (2000) 1063

–1085.

[25] S. Avramiotis, C.T. Cazianis, A. Xenakis, Interfacial properties of lecithin

microemulsions in the presence of lipase. A membrane spin-probe study,

Langmuir 15 (1999) 2375

–2379.

[26] P.K. Das, A. Chaudhuri, On the origin of unchanged lipase activity profile

in cationic reverse micelles, Langmuir 16 (2000) 76

–80.

[27] C.M.L. Carvalho, M.R. Aires-Barros, J.M.S. Cabral, Cutinase: from

molecular level to bioprocess development, Biotechnol. Bioeng. 66 (1999)

17

–34.

[28] E.P. Melo, R.P. Baptista, J.M.S. Cabral, Improving cutinase stability in

aqueous solution and in reverse micelles by media engineering, J. Mol.

Catal., B Enzym. 22 (2003) 299

–306.

[29] H. Zhu, Y.X. Fan, N. Shi, J.M. Zhou, Activity and conformation changes

of Chinese hamster dihydrofolate reductase in reverse micelles, Arch.

Biochem. Biophys. 368 (1999) 61

–66.

[30] C. Grandi, R.E. Smith, P.L. Luisi, Micellar solubilization of

biopolymers in organic solvents. Activity and conformation of

lysozyme in isooctane reverse micelles, J. Biol. Chem. 256 (1981)

837

–843.

[31] F. García-Carmona, R. Bru, A. Sánchez-Ferrer, Expression of enzyme

activity, in: A. Gornez-Puyou (Ed.), Biomolecules in Organic Solvents,

CRC Press, Boca Raton, Florida, 1992, pp. 163

–188.

[32] D. Han, J.S. Rhee, Characteristics of lipase-catalyzed hydrolysis of olive

oil in AOT-isooctane reversed micelles, Biotechnol. Bioeng. 28 (1986)

1250

–1255.

[33] E. Bardez, E. Monnier, B. Valeur, Absorption and fluorescence

probing of the interface of aerosol OT reversed micelles and micro-

emulsions, J. Colloid Interface Sci. 112 (1986) 200

–207.

[34] O.A. El Seoud, A.M. Chinelatto, Acid-base indicator equilibria in aerosol-

OT reversed micelles in heptane. The use of buffers, J. Colloid Interface

Sci. 95 (1983) 163

–171.

[35] M. Almgren, R. Jóhannsson, J.C. Eriksson, Polydispersity of AOT

droplets measured by time-resolved fluorescence quenching, J. Phys.

Chem. 97 (1993) 8590

–8594.

[36] M.P. Pileni, Water in oil colloidal droplets used as microreactors, Adv.

Colloid Interface Sci. 46 (1993) 139

–163.

[37] S.S. Atik, J.K. Thomas, Transport of photoproduced ions in water in oil

microemulsions: movement of ions from one water pool to another, J. Am.

Chem. Soc. 103 (1981) 3543

–3550.

[38] A.A. Vinogradov, E.V. Kudryashova, A.V. Levashov, W.M.A.M. van

Dongen, Solubilization and refolding of inclusion body proteins in reverse

micelles, Anal. Biochem. 320 (2003) 234

–238.

[39] M. Sakono, Y. Kawashima, H. Ichinose, T. Maruyama, N. Kamiya, M.

Goto, Direct refolding of inclusion bodies using reversed micelles,

Biotechnol. Prog. 20 (2004) 1783

–1787.

[40] W. Parker, P.S. Song, Protein structures in SDS micelle

–protein

complexes, Biophys. J. 61 (1992) 1435

–1439.

1035

N. Chen et al. / Biochimica et Biophysica Acta 1764 (2006) 1029

–1035

Document Outline

- Enzymatic hydrolysis of microcrystalline cellulose in reverse micelles

- Introduction

- Materials and methods

- Results

- Effect of ω0 on the activities of cellulases in Triton X-100, AOT, and CTAB reverse micelles

- Effect of temperature on the activities of cellulases in Triton X-100, AOT, and CTAB reverse mi.....

- pH dependence of the activities of cellulases in Triton X-100 and CTAB reverse micelles

- Conformational changes of cellulases with the increase of ω0 in AOT reverse micelles

- Discussion

- Acknowledgements

- References

Wyszukiwarka

Podobne podstrony:

Dance, Shield Modelling of sound ®elds in enclosed spaces with absorbent room surfaces

Proteomics of drug resistance in C glabrata

Microstructures and stability of retained austenite in TRIP steels

MMA Research Articles, Risk of cervical injuries in mixed martial arts

Development of financial markets in poland 1999

Antigone Analysis of Greek Ideals in the Play

Analysis of Police Corruption In Depth Analysis of the Pro

Low Temperature Differential Stirling Engines(Lots Of Good References In The End)Bushendorf

01 [ABSTRACT] Development of poplar coppices in Central and Eastern Europe

13 161 172 Investigation of Soldiering Reaction in Magnesium High Pressure Die Casting Dies

Mankiewicz Boczek, J i inni Bacteria homologus to Aeromonas capable of microcystin degradation (201

feminism and formation of ethnic identity in greek culture

86 1225 1236 Machinability of Martensitic Steels in Milling and the Role of Hardness

Formation of heartwood substances in the stemwood of Robinia

54 767 780 Numerical Models and Their Validity in the Prediction of Heat Checking in Die

Causes and control of filamentous growth in aerobic granular sludge sequencing batch reactors

Development of organic agriculture in Poland, Technologie

więcej podobnych podstron