New MOEMS-Switch Device with Electrostatic Actuator

E. Thielicke, E. Obermeier

Technical University of Berlin, Microsensor and Microactuator Technology Center (MAT),

TIB 3.1, Gustav-Meyer-Allee 25, 13355 Berlin, Germany; www-mat.ee.tu-berlin.de

Abstract

This paper presents a new concept for a 1-by-N-

switch, which can be used in tree-structured

optical networks.

Although the switch works with any large

displacement actuator, a new curved electrode

electrostatic actuator for linear motion of up to

180 µm has been designed. No tilting mechanism

is needed, and the mirror surface is smooth and

easily coated with highly reflecting materials.

A 1-by-4-switch has been fabricated using

classical low cost micromechanical technologies

like surface and bulk micromachining.

Introduction

The signal paths of optical MEMS-switches can be

actuated in three ways [1]:

1) by tilting mirrors or mirror arrays, whereby the

tilting angles are controlled precisely to minimize

signal loss

2) by microlens-devices, whose fabrication is

technologically demanding

3) and by on/off- or crossbar-switches, which use

shutters or mirrors that are mounted perpendicular

to the wafer surface and block or give way to the

beam. However, they are difficult to assemble

and/or may have rough mirror surfaces resulting

from their fabrication process.

Design

The switch consists of two passive and one active

silicon chip bonded to a glass spacer. The fibers

are placed under a fixed angle (e.g. 45° in the

corners of a KOH etched groove in <100>-Si) over

a row of aperture-holes, which are equally spaced.

The signal-path is chosen by a combined opening

and closing of the holes and beam reflection in

two levels.

passive silicon components

bonded glass spacer

micromachined chip

fiber in

shutter-mirror

fiber out 1

out 2

out 3

out 4

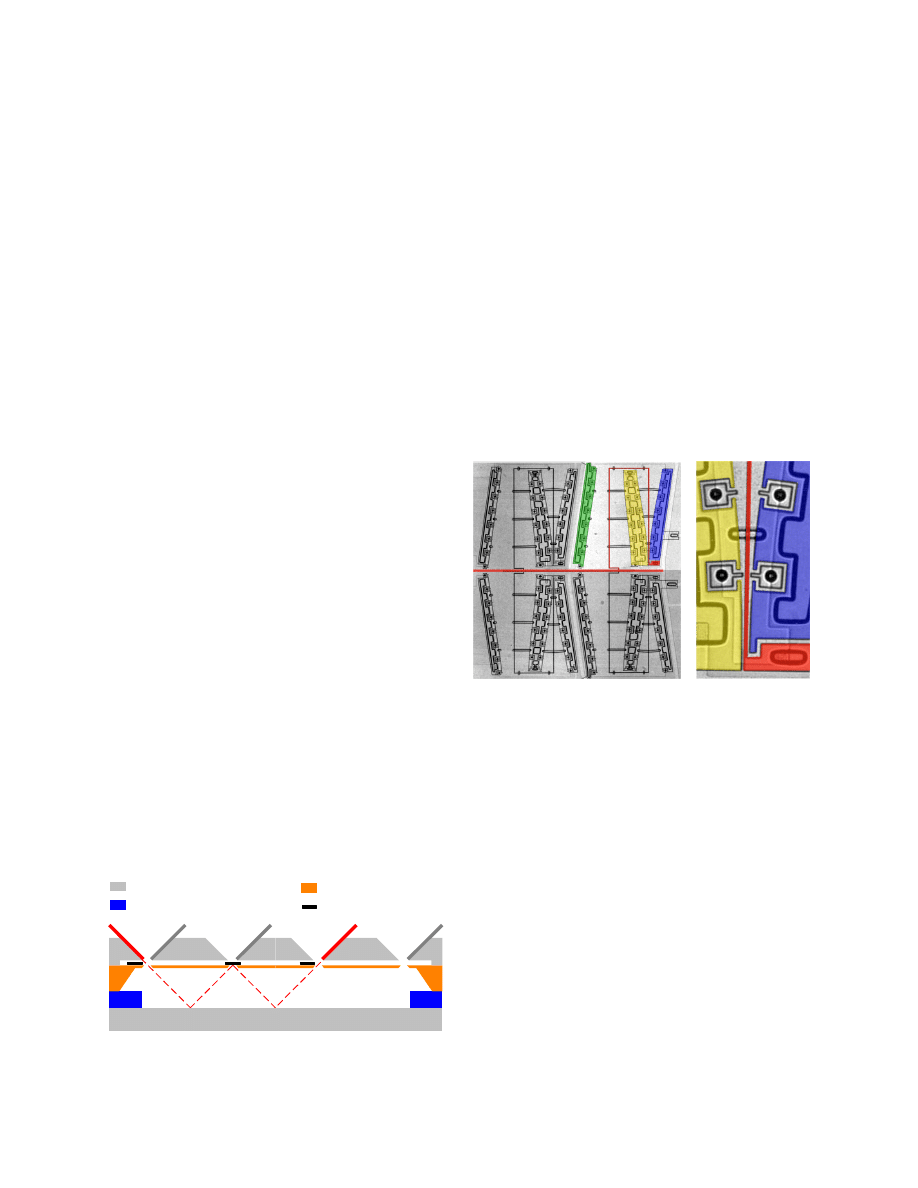

Fig 1: Schematical drawing of the switch (cross section).

The switched signal-path is marked by a dashed line.

Fig. 1 shows one possible signal path and the

corresponding binary states of the three shutter-

mirrors.

The shutter-mirrors can be moved by any kind of

long stroke linear or rotational actuator [2, 3, 4],

but a new fast switching curved electrode linear-

actuator was designed, which uses the moving-

wedge principle of actuation [5, 6].

The middle rod, to which the shutter-mirror is

mounted, is suspended by four 2 - 3 µm wide U-

shaped tethers. Each of the four tethers together

with their stator electrodes are built up similarily,

forming a unit, which is marked in the photograph

of the actuator, shown in Fig. 2.

Fig 2: Electrostatic actuator with four similar units. Each

unit consists of a clamped U-shaped tether electrode,

which is attached to the middle rod (red), and its right

(blue), middle (yellow) and left (green) curved stator

electrode. The total size amounts to 1x1 mm².

The clamping and four stoppers, which prevent short

circuits, are shown in the close-up on the right.

The tethers form the moving electrodes, which are

attracted electrostatically by the curved stator

electrodes. The electrostatic force is

approximately proportional to the square of the

reciprocal distance of the electrodes, so that

attraction only occurs in the part of the electrodes,

where they come close to each other.

If voltages between 100 and 200 V are applied

(depending on design) the moving electrode

beams are pulled towards the stator electrodes

like a closing zipper and push the middle rod

towards the left or right in linear motion parallel to

the wafer surface.

To perform a total displacement of up to 180 µm,

the electrostatic force at each point of bending has

to be always just big enough to maintain further

moving. This can be achieved by rising the voltage

or choosing a suitable design for the stator

electrodes; i.e., the curvatures of the stator

electrodes define the deflection-voltage behaviour

of the actuator.

Additionally, the curvature of the stator electrodes

depends on the number and size of the stoppers

that prevent short circuits. It must be calculated

using a coupled electro-mechanical FEM-

simulation, which can be seen in Fig. 3 and 4.

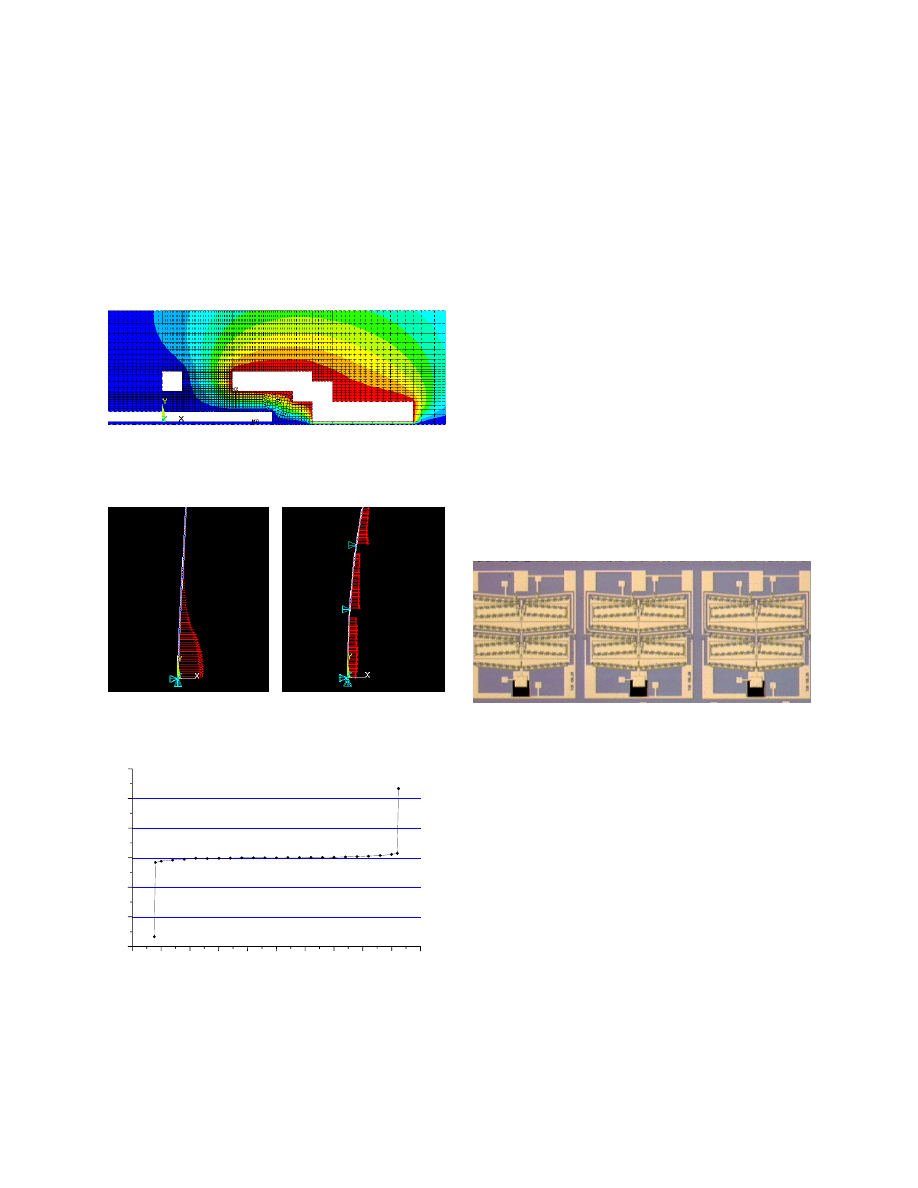

Fig 3: FEM-simulation of the electric potential from

which the electrostatic forces are calculated (cross

section of the tether and ground electrode [0 V] on the

left side and the stator electrode [100 V] on the right).

Fig 4: Part of the FEM-simulation of the tether deflection

a) in the starting phase; b) when in contact with the

stoppers (force arrows in arbitrary units).

125

100 75 50 25 0 25 50 75 100 125

-75

-50

-25

0

25

50

75

Fig 5: This diagram shows the deflection-voltage of the

middle rod for the binary 130 µm type actuator.

Depending on the electrode design, the actuator

allows a variety of deflection-voltage curves, but in

this application, an electrode setup for binary

deflection behaviour with two states (open &

close) was used, as shown in Fig. 5.

Fabrication

The actuator has been realized using standard

surface micromachining technology with two

polysilicon layers (one ground and one active

layer) and one LTO sacrificial layer. The aperture

hole is then opened from the backside using wet

chemical etching with KOH.

The chips are anodically bonded to a patterned

glass-Si wafer-stack, which defines the distance of

1190 µm between the two reflecting levels.

The surface quality of the shutter-mirror and the

lower Si-chip is very good due to the polished

surfaces of which they are made, resp. on which

they are deposited. Additionally, they may be

coated with gold for better reflection.

Results

A 1-by-4-switch has been realized. The

micromachined chip with the aperture holes and

shutter-mirrors is shown in Fig. 6.

The functionality has been demonstrated by

switching a laser beam into each of the four

outgoing paths.

Fig 6: Top view of a fabricated switch. The aperture

holes can bee seen in the lower part of the photograph.

(The 4th hole is not shown). Total size is 4x1.2 mm².

References

[1] S. J. Walker, D. J. Nagel: ”Optics & MEMS: An

Overview of Current Technology”, MOEMS ’97, Nara,

Japan, 1997

[2] E. Thielicke, E. Obermeier: “Microactuators and their

Technologies”, J. Mechatronics 10, 2000, 431-455

[3] Th. Kraus, M. Baltzer, E. Obermeier: „A Micro

Shutter for Applications in Optical and Thermal

Detectors“, Transducers ‘97, Chicago, USA, 1997

[4] G. Perregaux, P.Weiss, B. Kloeck, H. Vuilliomenet,

J.-P. Thiébaud: “High-Speed Micro-Electromechanical

Light Modulation Arrays”, Transducers ’97

[5] J. Schimkat, L. Kiesewetter, H.-J. Gevatter, F. Arndt,

A. Steckenborn, H. Schlaak: „Moving Wedge Actuator:

An Electrostatic Actuator for Use in a Microrelay”,

MST ’94, Potsdam, Germany, 1994

[6] R. Legtenberg, F. Berenschot, M. Elwenspoek, J.

Fluitman: „Electrostatic Curved Electrode Actuators”,

IEEE MEMS, Amsterdam, The Netherlands, 1995

U [Volt]

right, then middle

stator electrodes

middle, then left

stator electrodes

deflection [µm]

Wyszukiwarka

Podobne podstrony:

16 Electrostatic actuators with P silicon diaphragms

16 Electrostatic actuators with P silicon diaphragms

NEVER mess with electricity

10 Large Displacement Electrostatically Actuated Microrelay

How to build a USB device with PIC 18F4550 or 18F2550 (and the microchip CDC firmware)

PP MEMS 03 Electrostatic Actuation

13 IMPROVING ELECTROSTATIC ACTUATORS for micro mirrors

Bearden EXPLANATION OF THE MOTIONLESS ELECTROMAGNETIC GENERATOR WITH 0(3) ELECTRODYNAMICS

10 Large Displacement Electrostatically Actuated Microrelay

How to build a USB device with PIC 18F4550 or 18F2550 (Website)

Rachmaninov Press op34 14 Vocalise vln pno (with vln part)

Example CV 14 Clean shaded titles with emphasis on skills CV

Electrostatic micro actuator for HD

Medical devices 14

Making Electricity With a Hydrogen Fuel Cell

A Novel Switch Mode Dc To Ac Inverter With Nonlinear Robust Control

Electronics 3 Switches,Relays, Transducers S

New planetary based hybrid automatic transmission with true on demand actuation

więcej podobnych podstron