Optimisation of sanitary landfill leachate treatment

in a sequencing batch reactor

A. Spagni, S. Marsili-Libelli and M. C. Lavagnolo

ABSTRACT

A. Spagni

ENEA, Italian National Agency for New

Technologies, Energy and the Environment,

Environment Department, Water Resource

Management Section, Via M. M. Sole 4,

40129 Bologna,

Italy

E-mail: alessandro.spagni@bologna.enea.it

S. Marsili-Libelli

Department of Systems and Computers,

University of Florence, Via S. Marta 3,

50139 Florence,

Italy

E-mail: marsili@dsi.unifi.it

M. C. Lavagnolo

Department of Hydraulic, Maritime, Environmental

and Geotechnical Engineering (IMAGE),

University of Padua, Via Loredan, Padova,

Italy

E-mail: mariacristina.lavagnolo@unipd.it

A bench-scale SBR was operated for almost three years in an attempt to optimise the treatment

of leachates generated in old landfill. The results of the first two years were used to design

a monitoring and control system based on artificial intelligence concepts. Nitrogen removal was

optimized via the nitrite shortcut. Nitrification and N removal were usually higher than 98%

and 90%, respectively, whereas COD (of the leachate) removal was approximately 30 –40%.

The monitoring and control system was demonstrated capable of optimizing process operation,

in terms of phase length and external COD addition, to the varying loading conditions. Using

the control system developed, a significant improvement of the process was obtained: COD

and N load were increased (HRT decrease) and a significant decrease (approximately 34%)

of the ratio of COD added to N leachate content was observed.

Key words

|

denitritation, fuzzy control, nitritation, nitrite shortcut, nitrogen removal

INTRODUCTION

Sanitary landfill leachate treatment is usually accomplished

by multistage systems using chemical, physical and biologi-

cal processes. Leachate generated in old landfills is a high-

strength wastewater characterized by a low BOD/TKN

ratio. Therefore, biological nitrogen removal can be

achieved only if an external biodegradable COD source is

provided for the denitrification process (

). Among several technologies, sequen-

cing batch reactors (SBRs) have been demonstrated to be

feasible for biological leachate treatment (

).

Nitrogen removal from wastewaters is usually accom-

plished through nitrification and denitrification processes.

Instead of using the full nitrification/denitrification path,

biological nitrogen removal via nitrite is a promising

alternative for the optimization of nitrogen removal, in

particular in the presence of a low biodegradable COD to

TKN ratio. Nitrite pathway decreases the oxygen demand

and the carbon consumption up to 25% and 40%,

respectively. During the last decade, several processes

have been proposed for nitrogen removal optimization via

nitrite (reviewed by

). Among these pro-

cesses, nitrite build-up may be sustained by optimizing

phase duration in SBRs, switching nitritation process to

denitritation once the maximum nitrite concentration has

been reached (

Dissolved oxygen (DO), pH and oxidation-reduction

potential (ORP) have been frequently used for monitoring

and control of batch reactors (

). The

majority of studies using these process measurements have

been focussed on municipal wastewaters (e.g.

), though a few have also

been carried out on industrial (

) or agricultural

wastewaters (

). In the last

few years, some applications of artificial intelligence, such

as fuzzy logic (

), have been reported for

wastewater treatment monitoring and control.

In the present study a lab-scale SBR treating leachate

from an old landfill was kept in operation for almost three

doi: 10.2166/wst.2008.399

337

Q IWA Publishing 2008

Water Science & Technology—WST

|

58.2

|

2008

years in order to optimise nitrogen removal and external

COD addition (used for denitrification). During the first

year the SBR was extensively monitored in order to

optimise nitrogen removal using conventional nitrification

and denitrification procedures. During the second year, the

plant was operated in order to accumulate nitrite in an

attempt to improve nitrogen removal (via nitritation and

denitritation process) and external COD addition. During

the third year a fuzzy control system (based on DO, pH and

ORP process signals) was applied to supervise the switching

sequence of the phases.

METHODS

A lab-scale SBR, with a maximum working volume of 24 L,

treating raw leachate originating from an old municipal

landfill, was operated for more than 900 days in a

thermostatic room at 20 ^ 0.58C. Initially, the SBR was

operated with a “full”-cycle of 24 hours divided in series of 4

sub-cycles of 5.75 hours, followed by one hour of settling.

During the present study, operational conditions were

modified according to leachate characteristics. In particu-

lar, due to the large variations registered in leachate

strength (

), the length of anoxic

and aerobic phases, feed load and the sludge age were

modified in accordance with leachate concentration.

During the I and II experimental period (EP) operational

conditions were modified manually, whereas during the III

EP the plant was operated by a control system based on

fuzzy logic. As a result (during I and II EP), each sub-cycle

was operated starting with an anoxic-anaerobic phase of 1.0

to 2.0 h hours followed by an oxic phase of 3.75 to 4.75

hours (with a constant reaction of 5.75 hours). At onset of

the anoxic-anaerobic phase (of each sub-cycle), leachate

(flow of 1.2 L/h) was added to the tank. In order to supply

biodegradable COD for denitrification, a concentrated

solution (20 g/L: 9.4 gCOD/L) of sodium acetate trihydrate

was added during the anoxic-anaerobic phase (flow of

0.36 L/h during the I and II EP and 0.14 L/h during the III).

The external COD was neglected in the calculation of the

organic loading rate (OLR) and of the COD removal

efficiency. The effluent was drawn during the last 3 minutes

of the settling phase to reach a minimum reactor volume

of 15 L. During the last minute of the fourth sub-cycle, a

small amount of mixed liquor was drawn in order to

control the suspended solids concentration in the reactor:

the mean solid retention time was approximately 25 days

(with wide variations due to time-varying operational

conditions).

The plant was extensively monitored with analytical

measurements (according to

), and

using pH, ORP and DO on-line signals. More details about

the monitoring methods and results and plant layout are

reported in

Four experimental periods can be identified:

† SU (start-up): the plant was seeded with sludge from a

municipal wastewater treatment plant.

† I: the reactor was operated in order to optimize nitrogen

removal via nitrification and denitrification processes.

Table 1

|

Leachate characteristics

Unit

Mean

Max

Min

TSS

g/L

0.25

1.10

0.03

VSS

g/L

0.14

0.54

0.02

TKN

mgN/L

1,191

1,812

252

NH

þ

4

mgN/L

1,061

1,540

167

pH

–

8.05

8.90

7.55

Alkalinity (to pH 4.3)

meq/L

119

162

35

Conductivity (208C)

mS/com

14.2

19.7

5.6

Ptot

mgP/L

5.7

9.5

2.1

PO

32

4

mgP/L

4.6

9.0

0.3

BOD

5

mg/L

301

1,000

30

CODt

mg/L

1,759

3,060

528

CODf

mg/L

1,620

2,980

440

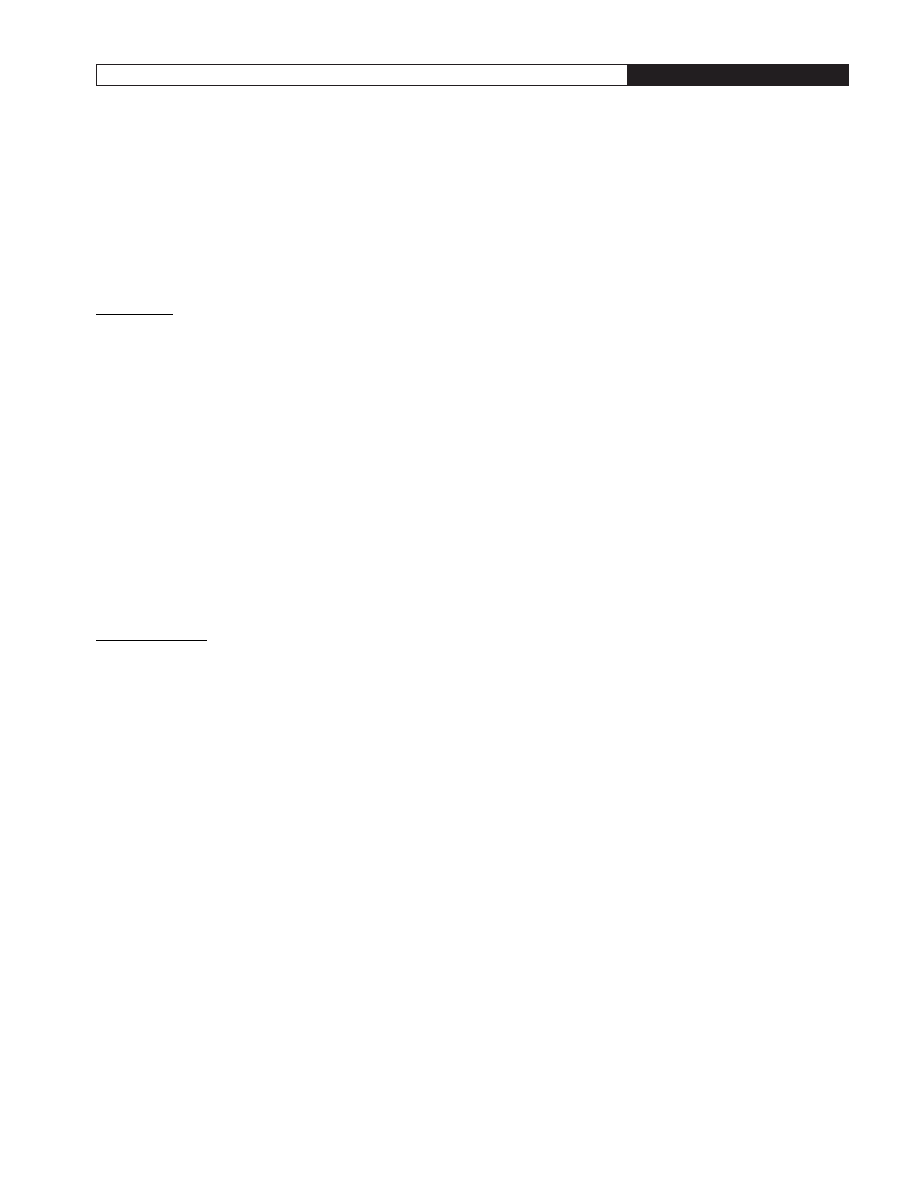

Figure 1

|

Total (t) and filtered (f) COD in the influent (CODt_in, CODf_in) and effluent

(CODt_out, CODf_out).

338

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

† II: the reactor was operated in an attempt to optimize

nitrogen removal and external COD addition via

nitritation and denitritation. During this experimental

period the phases length (in particular the fill phase)

were manually modified (almost every day) according

the analytical measurements and the behaviour of pH,

ORP and DO signals (

† III: a fuzzy supervisory system was introduced to identify

and manage the correct switching sequence of the plant.

The control system performed the phase-end detection

and managed the on/off switching of the blower, mixer

and pumps (filling, acetate addition, sludge and effluent

withdrawal). The monitoring and control system (III EP)

is based on a number of successive operations on the

data. Upon acquisition, the data are validated and

denoised using a wavelet filter, then numerical deri-

vation is performed and a fuzzy inference algorithm is

used to detect the end of the current phase. At the end of

the decision chain, the phase termination signal activates

the relevant actuators, thus closing the control loop

(the control algorithm is described in

). During the first part of the III EP (IIIa) the SBR

was operated with fixed timed phases (in order to

stabilize the process to the new operation and verify

the algorithm) whereas during the second part (IIIb) the

fuzzy supervisor took over the operation entirely,

determining the duration of the anoxic and the oxic

phase, and the addition of the external COD.

The fuzzy inferential system used in the III EP was

developed in the LabView 7.1 platform (National Instru-

ments, Austin TX, USA) and provided both local and

remote control through the Internet.

shows some of the characteristics of the raw

sanitary landfill leachates used for the entire duration of the

study. The leachates were characterised by high nitrogen

content with respect to COD and BOD, which is typical of

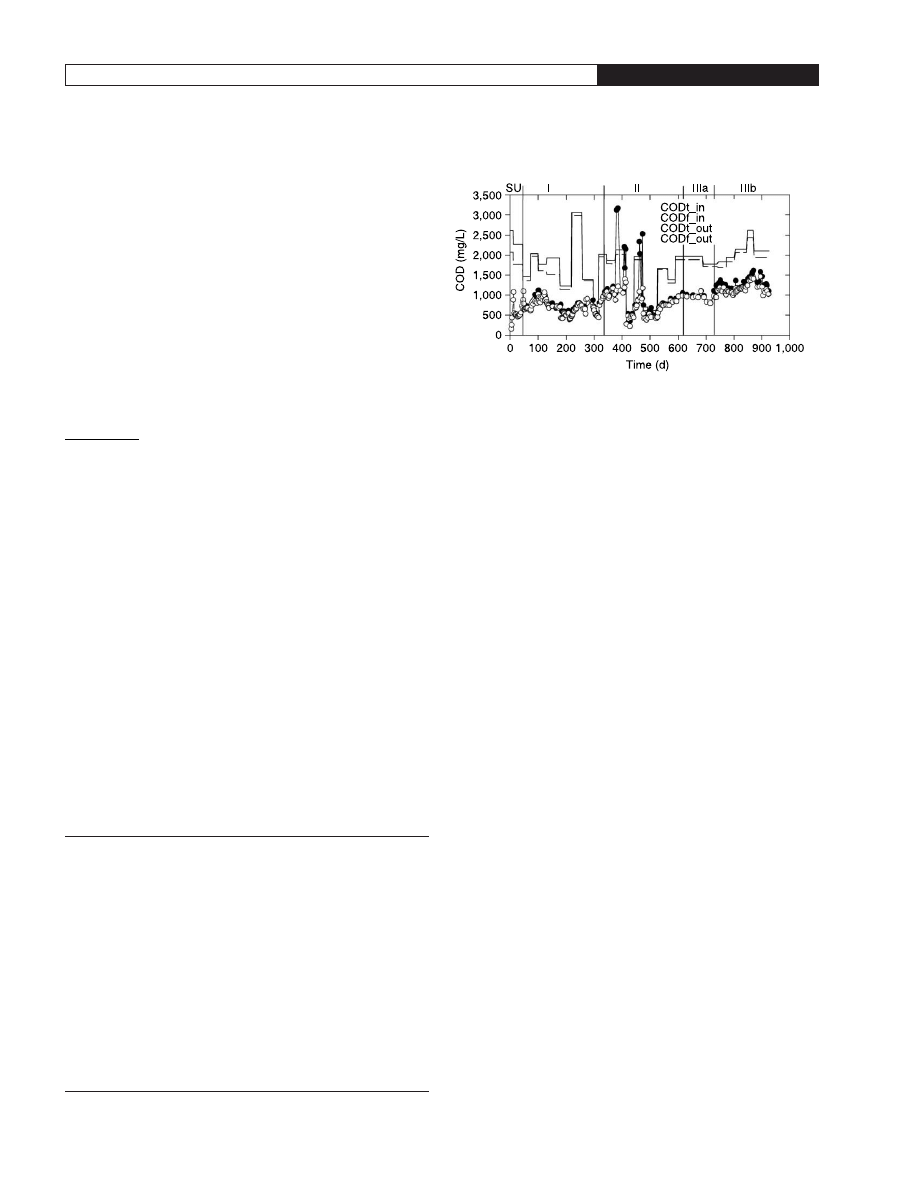

Figure 2

|

TKN and ammonia concentration in the influent (a); ammonia, nitrite and nitrate in the effluent (b); and nitrification and nitrogen removal efficiency (c).

339

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

old landfills. Due to the low P concentration (relative to N

and COD), a concentrated solution of KH

2

PO

4

was added

to the SBR to maintain phosphate concentration in the

reactor effluent between 0.5 and 1.0 mgP/L.

RESULTS AND DISCUSSION

Leachate showed very high variation in COD and nitrogen

concentration (

). As a result, the COD

removal efficiency varied widely, between 20 and 60% (the

external COD added for denitrification was neglected in the

calculation), occasionally reaching negative values (below

zero). This has two different explanations. First, the very

high variability in leachate COD concentration caused a

sort of “memory” in the reactor and, therefore, when the

COD had a sudden decrease, the effluent concentration was

still influenced by the bulk liquid present in the reactor. This

effect is visible, for example, after approximately 300 day of

operation when COD in the influent decreased from 3,060

to 1,390 first and then to 715 in approximately forty days.

The same also occurred between day 410 and 470.

Secondly, a very high effluent COD concentration was

measured when sludge showed poor settling characteristics

and wash out of suspended solids was observed (between

day 400 and 450). It is worth mentioning that the lowest

settling characteristic of the sludge was measured during

the II EP. This could be explained by the occurrence of low

DO concentration in the oxic phase; indeed, because DO

limitation (among other operational parameters) seems to

facilitate the nitritation process (

),

dissolved oxygen was kept at low concentrations (between

0.5 and 1 mg/L) during II EP, in an attempt to optimise

nitrite accumulation.

During EP III, COD removal was stable at an average

value of approximately 30%. It is not possible to claim

that the stability was caused by the control system

because during this EP the influent COD concentration

showed the lowest variability of the entire three-year

period (

).

The plant exhibited a generally good nitrification,

reaching levels of more than 99%, with the exception of a

few cases in which inhibition occurred (

). After

approximately 100 days of operation the SBR produced a

severe case of nitrification inhibition. Because in leachate

treatment phosphorus limitation can inhibit biological

processes and analytical measurements in the effluent

revealed a phosphate concentration lower than 0.1 mgP/L,

a solution of potassium phosphate was subsequently

added to the SBR maintaining the effluent phosphate

concentration higher than 0.5 mgP/L. After about 200 days

of operation a malfunctioning of the pump of phosphorus

addition occurred and the phosphate concentration again

decreased below 0.1 mgP/L causing nitrification inhibition

for the second time. Furthermore, to coincide with change of

the leachate, sometimes a slight (approximately 50%)

reduction in nitrification efficiency was observed. When

nitrification inhibition was observed the loading rate was

decreased; with the temporary decrease of the load, nitrifica-

tion activity was recovered within a few days. During the II

EP, with daily manual adjustments of the load and length of

the SBR phases, nitrite built-up was observed but the process

was quite unstable (

). The instability was demon-

strated by the high concentration not only of nitrite but also of

ammonia and nitrate: in fact, the N removal efficiency (h)

was also affected by the incorrect operation of the SBR

and during EP II it was the lowest of the study (

and

). The observed instability was mainly caused by

the inability to correctly regulate the phase length by means

of manual adjustment. On the contrary, N removal during

the other experimental periods was higher (92 – 95%) than

during the II EP (

). During EP IIIa the nitrification

and denitrification processes restarted showing good

nitrification (98%) and nitrogen removal (95%) efficiency

(

and

). Immediately after the activation

of the fuzzy controller (EP IIIb), nitrite built-up was

observed and nitritation and denitritation processes

occurred (

). Contrary to the EP II behaviour,

nitrite built-up during EP IIIb was stable and nitrate

concentration was usually below 1.0 mgN/L. The low

ammonia concentration in the effluent (below 10.0 mgN/L)

confirms the good nitrification efficiency (

). The

very high nitrite concentration (243 mgN/L) observed

approximately at day 900, was due to a break down of the

pump of acetate addition. It is noteworthy that the control

system was able to decrease the nitrite concentration in a few

days once the pump was repaired.

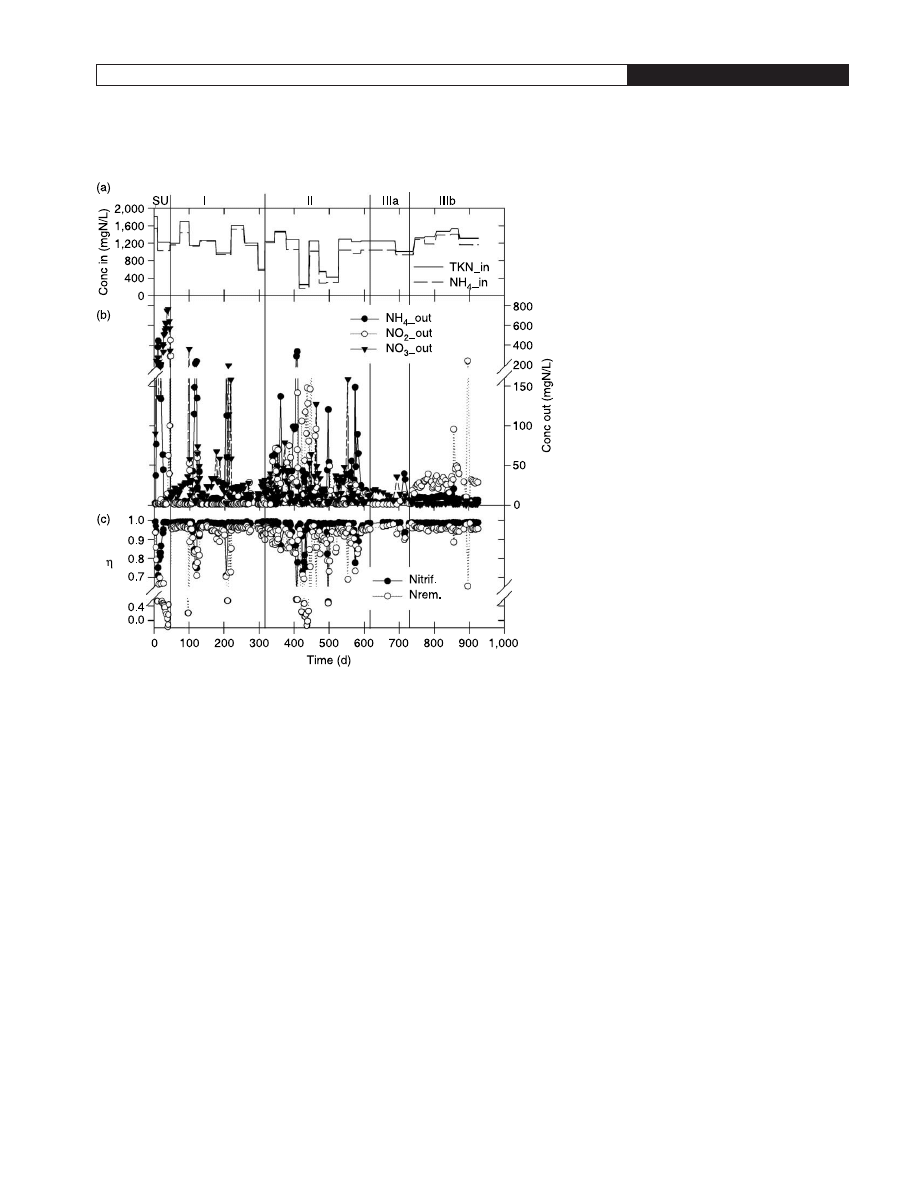

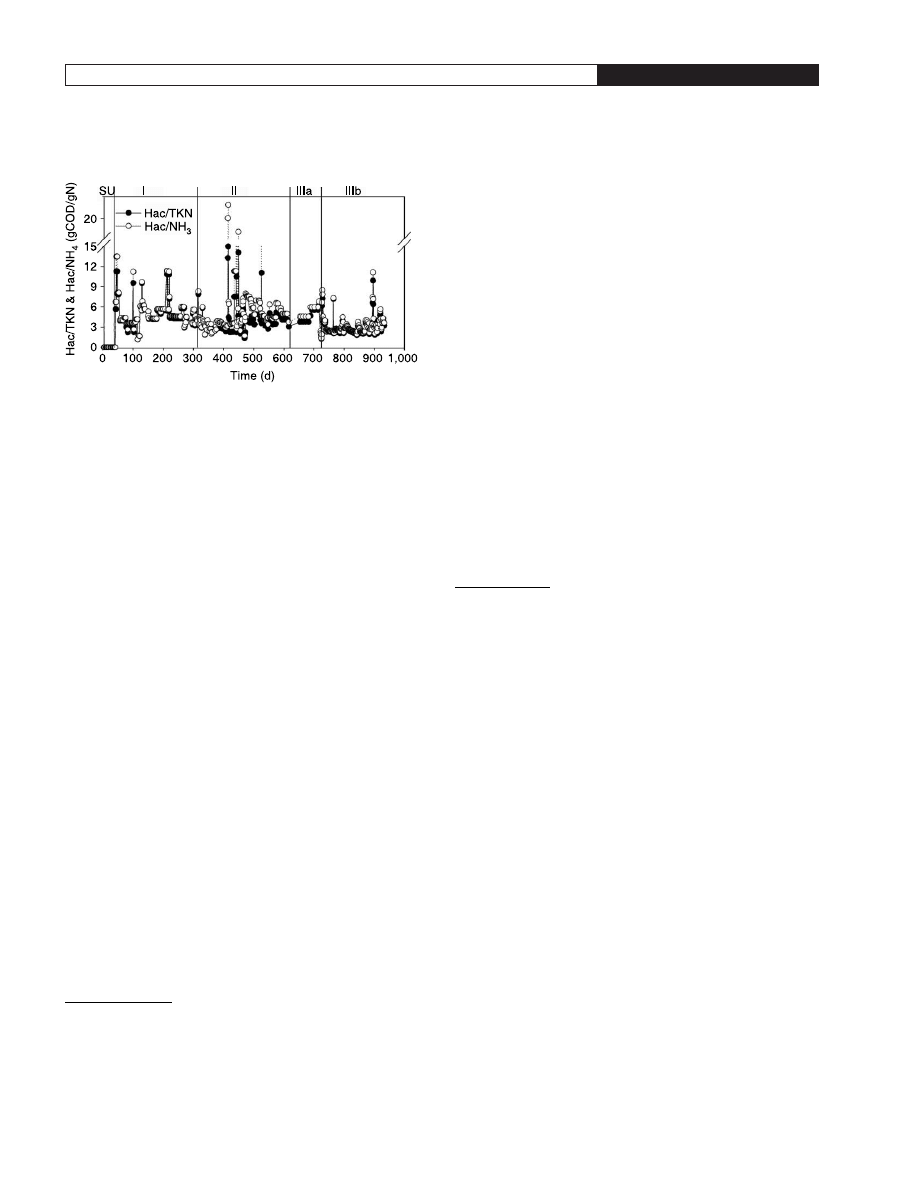

The SBR was started up applying an OLR of approxi-

mately 0.3 gCOD/(L p d) and a nitrogen load rate (NLR) of

340

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

0.2 gN/(L p d), with a hydraulic retention time (HRT) of 8

days (

). At these loads ammonia accumulated in the

reactor up to a concentration of approximately 450 mgN/L

(

). Therefore, the load was immediately decreased

causing an immediate increase in the nitrification efficiency.

Due to the low COD/N ratio of the leachate (

),

nitrate accumulated in the reactor (up to approximately

750 mgN/L) and, therefore, acetate was added to improve

the denitrification process. During the entire experimental

period both HRT and loading (COD and N) were very

variable because of the wide variation of leachate charac-

teristics. The high HRT measured in this SBR is typical for

landfill leachate treatment. It is noteworthy that during EP

II and EP IIIb the SBR showed (as average values) the

Table 2

|

Summary of the main operational results: data as average (standard deviation)

Experimental period (days, from– to)

I (45 –308)

II (309 –649)

IIIa (650 –734)

IIIb (735– 936)

h

Nitrification (2)

0.98 (0.049)

0.95 (0.077)

0.98 (0.023)

0.99 (0.0025)

h

N removal (2 )

0.92 (0.12)

0.84 (0.20)

0.95 (0.032)

0.95 (0.050)

HRT (d)

7.22 (3.78)

5.63 (2.41)

7.85 (2.03)

5.80 (2.17)

Load COD [gCOD/(L p d)]

0.166 (0.065)

0.208 (0.093)

0.164 (0.053)

0.288 (0.085)

Load TKN [gN/(L p d)]

0.121 (0.048)

0.144 (0.065)

0.096 (0.030)

0.189 (0.057)

Load NH

4

-N [gN/(L p d)]

0.114 (0.041)

0.120 (0.064)

0.087 (0.028)

0.174 (0.055)

Hac/TKN (gCOD/gN)

4.68 (1.78)

3.87 (1.91)

4.15 (1.81)

2.73 (0.86)

Hac/NH

4

-N (gCOD/gN)

4.91 (1.83)

5.06 (2.95)

4.64 (1.96)

2.98 (0.99)

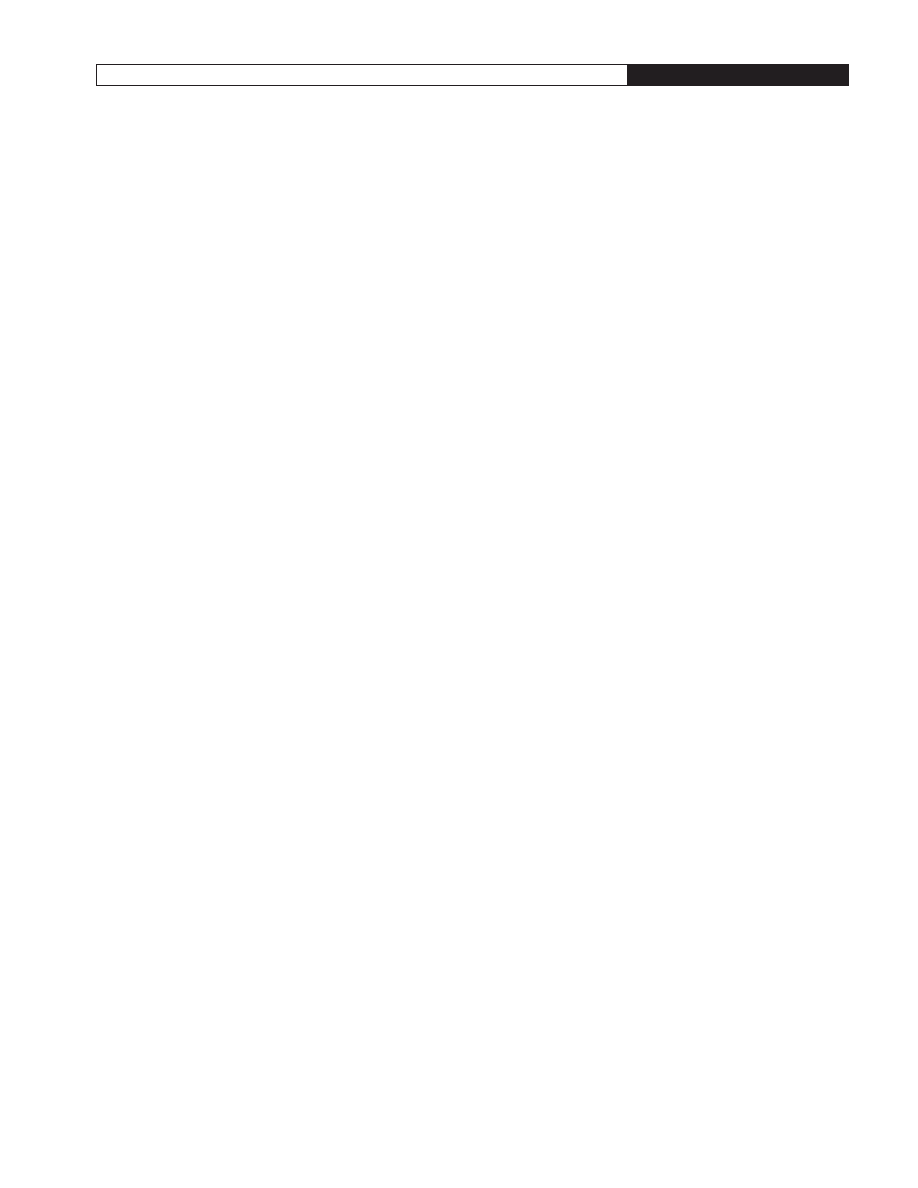

Figure 3

|

HRT (a), COD (b), TKN and ammonia loading rate (c).

341

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

lowest HRT and the highest loads (

) demonstrating

the effectiveness of using the “nitrite short-cut” for nitrogen

removal optimization. Therefore, the best improvement in

HRT and loading seems to be related to the application of

the control system (

).

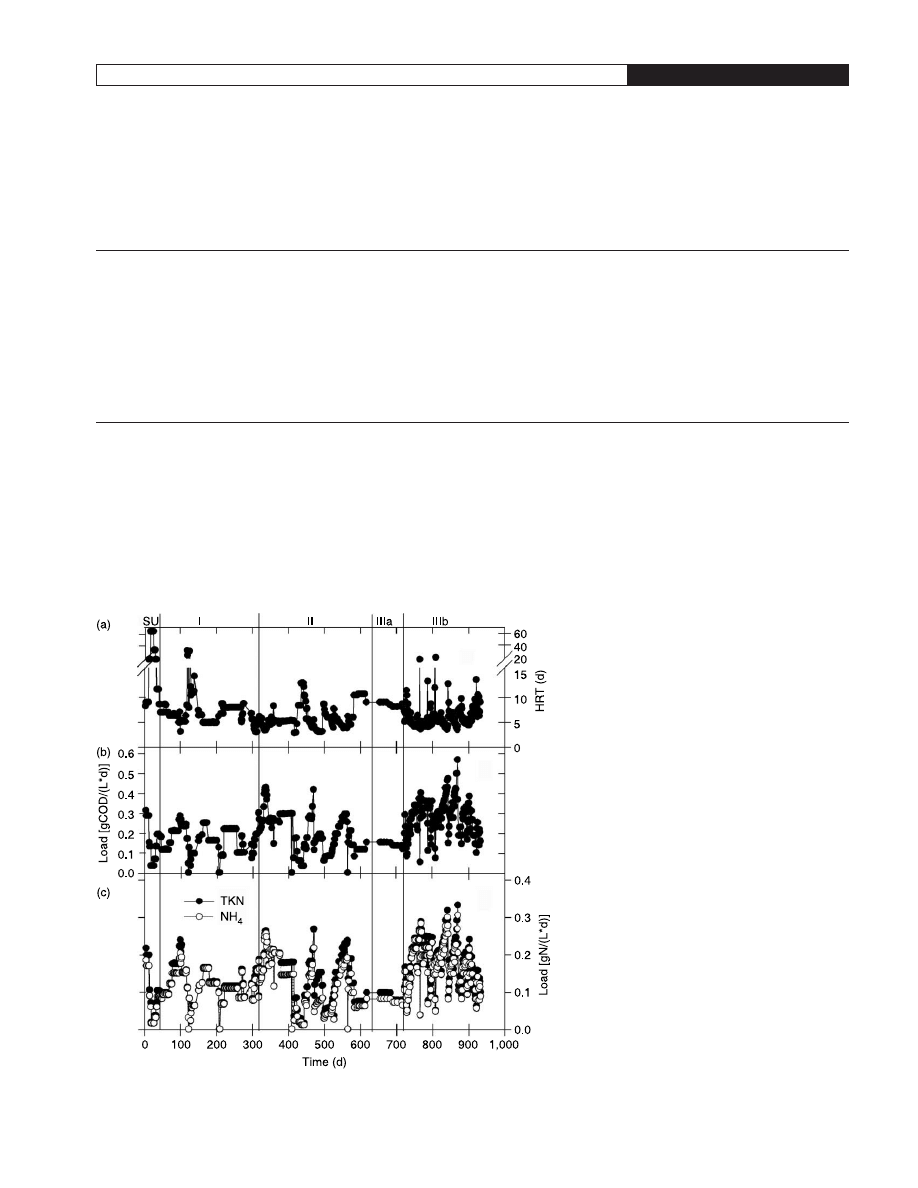

shows that applying the nitrite short-cut a large

saving in external COD addition can be obtained. In fact, the

Hac/TKN ratio during EP II was 17% lower than during EP

I whereas that ratio in EP IIIb was 34% lower than during

EP IIIa. Similar results were obtained for Hac/NH

4

-N ratio

during EP IIIb and IIIa. On the contrary, the Hac/NH

4

-N

ratio during EP II was similar (or a little higher) to that

measured during EP I. Again, this finding could be

explained by the wide variation in leachate strength;

moreover, during this experimental period the leachate

presented the lowest strength and the highest TKN/NH

4

-N

ratio (average values). The variability of the ratio of the

COD added to the nitrogen content of the leachate also

depends on the biodegradable organic matter in the

leachate. It is of note that during the application of the

control system the Hac/TKN and Hac/NH

4

-N ratios

showed the lowest standard deviations, compared to the

same ratio during the other experimental periods (approxi-

mately 1/2). This finding seems to highlight the effectiveness

of the control system in adding an accurate amount of

external COD.

CONCLUSIONS

The SBR process proved itself as a suitable technology for

biological treatment of leachates resulting from old landfills.

Nitrification and N removal were usually higher than 98%

and 90%, respectively: COD removal was approximately

30 – 40% (as average value) due to the low biodegradability

of organic matter present in leachate from old landfills.

External COD was needed to accomplish the denitrification

process.

The study confirms the effectiveness of the nitrite path

for N removal optimisation in leachate treatment, in

particular when external COD has to be added to improve

the denitrification process. Due to the variations of the

leachate characteristics, a control system based on artificial

intelligence concepts was designed and engineered to

monitor and operate the SBR. With this control system a

significant improvement of the process was obtained: the

COD and N load were increased (and HRT decreased).

Moreover, it is noteworthy that, using the control system, a

significant decrease (approximately 34%) in the ratio of the

amount of external COD added to N leachate content was

also obtained.

REFERENCES

Abeling, U. & Seyfried, C. F. 1992 Anaerobic-aerobic treatment of

highstrength ammonium wastewater—nitrogen removal via

nitrite. Water Sci. Technol. 26(5–6), 1007 –1015.

Battistoni, P., De Angelis, A., Boccadoro, R. & Bolzonella, D. 2003

. Ind. Eng. Chem.

Res.

42

(3), 509– 515.

Cheng, N., Lo, K. V. & Yip, K. H. 2000 Swine wastewater

treatment in a two stage sequencing batch reactor using real-

time control. J. Environ. Sci. Health B35(3), 379– 398.

EPA Manual –Ground Water and Leachate Treatment Systems 1995

U.S. Environmental Protection Agency, Washington, DC,

EPA/925/R-94/005. pp. 119.

Fux, C., Velten, S., Carozzi, V., Solley, D. & Keller, J. 2006

. Water

Res.

40

, 2765 – 2775.

Garrido, J. M., van Benthum, W. A. J., van Loosdrecht, M. C. M. &

Heijnen, J. J. 1997

Influence of dissolved oxygen concentration

on nitrite accumulation in a biofilm airlift suspension reactor

Biotechnol. Bioeng.

53

(2), 168 –178.

Standard Methods for the Examination of Water and Wastewater

1998 20th edition, American Public Health Association/

American Water Works Association/Water Environment

Federation, Washington DC, USA.

Kjeldsen, P., Balzan, M. A., Rooker, A. P., Baun, A., Ledin, A. &

Christensen, T. H. 2002

Present and long-term composition of

MSW landfill leachate, a review

. Crit. Rev. Environ. Sci.

Technol.

32

(4), 297 –336.

Figure 4

|

Ratio of acetate added to TKN and ammonia concentration in the influent.

342

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

Lema, J. M., Mendez, R. & Blazquez, R. 1988 Characteristics of

landfill leachates and alternatives for their treatment, a review.

Water Air Soil Pollut.

40

(3– 4), 223– 250.

Li, Y. Z., Peng, C. Y., Peng, Y. Z. & Wang, P. 2004 Nitrogen

removal from pharmaceutical manufacturing wastewater via

nitrite and the process optimization with on-line control.

Water Sci. Technol.

50

(6), 25 –30.

Marsili-Libelli, S. 2006

Control of SBR switching by fuzzy pattern

. Water Res. 40, 1095 –1107.

Marsili-Libelli, S., Spagni, A. & Susini, R. 2007 Intelligent

monitoring system for long-term control of Sequencing Batch

Reactors. Proceedings of AutMoNet 2007 IWA Conference,

Gent (B). 5 –7 Sept. 2007.

Ra, C. S., Lo, K. V. & Mavinic, D. S. 1997

treatment by batch-mode 4-stage process, loading rate control

using ORP

. Environ. Technol. 18(6), 615 –622.

Spagni, A., Buday, J., Ratini, P. & Bortone, G. 2001 Experimental

considerations on monitoring ORP, pH, conductivity

and dissolved oxygen in nitrogen and phosphorus

biological removal processes. Water Sci. Technol. 43(11),

197– 204.

Spagni, A., Lavagnolo, M. C., Scarpa, C., Vendrame, P.,

Rizzo, A. & Luccarini, L. 2007

optimization in a sequencing batch reactor treating

sanitary landfill leachate

. J. Environ. Sci. Health A 42,

757– 765.

Villaverde, S. 2004

Recent developments on biological nutrient

removal processes for wastewater treatment

. Rev. Environ. Sci.

Bio/Technol.

3

, 171– 183.

Wareham, D. G., Hall, K. J. & Mavinic, D. S. 1993 Real-time

control of wastewater treatment systems using ORP. Water Sci.

Technol.

28

(11 –12), 273– 282.

343

A. Spagni et al.

|

Optimisation of sanitary landfill leachate treatment in SBR

Water Science & Technology—WST

|

58.2

|

2008

Document Outline

Wyszukiwarka

Podobne podstrony:

Is sludge retention time a decisive factor for aerobic granulation in SBR

hist1, RZYM -ROMA

Obliczenia i dobór SBR

do porównania z różnymi opcjami w SBR

SBR (Biologiczny reaktor sekwencyjny)

55 SBR

Is sludge retention time a decisive factor for aerobic granulation in SBR

10 Roma Criola

378424464 La Roma Imperial 13 doc

Arrivederci Roma

Calderon de la Barca El Ano Santo en Roma

Alberti Rafael Nocturno (de Roma peligro para caminantes)

34908 ROMA DMC

O Roma nobilis, S 54 (Liszt, Franz)

Silverberg, Robert Roma Eterna Getting To Know the Dragon(1)

więcej podobnych podstron