© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

VHDL-AMS Modeling of an Electric

Power Steering System in a Multi-

Physics Simulation Environment.

SEKISUE, Takayuki

Ansoft Japan K.K.

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Presentation Goals

• Mechanical modeling in SIMPLORER

– About the mechanical system model’s description and the

usage.

– About the description of the motor drive part

• VHDL-AMS model

• System simulation with power unit

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

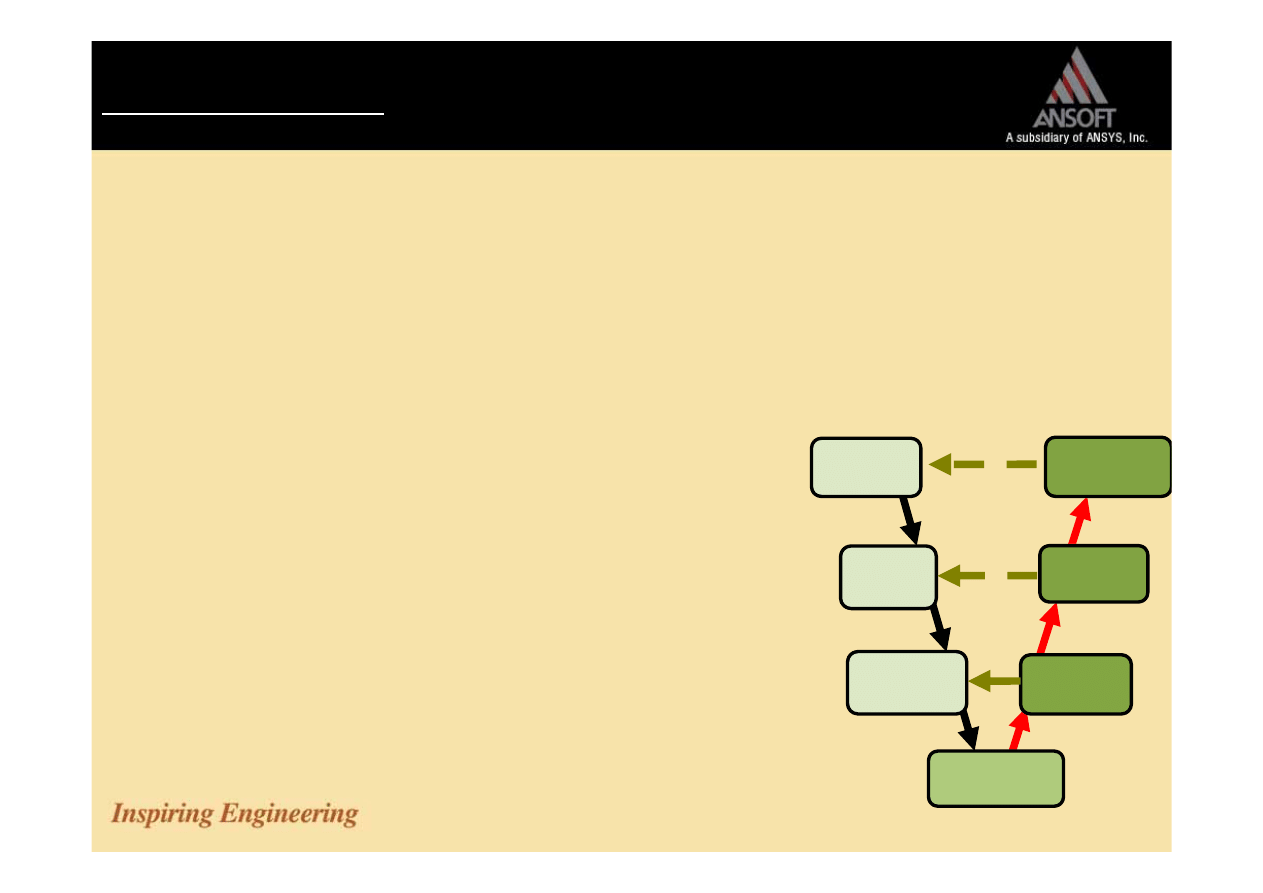

Introduction

•

In the design of the electric equipment component, the

optimization of the equipment unit has been advanced.

•

On the other hand, modeling a complex phenomenon

and detailed operation is requested by making to high

performance in the design of the system that controls

them.

•

Cannot a new solution point be found by sharing the

simulation model as both cooperating?

– This presentation introduces the example of

simulating the subsystem as an example of EPS

control model and driving system.

– The example of simulating a necessary element

technology is referred to make it to high accuracy.

– And this introduces everything from each

simulation result to the power management as an

example of designing the total system.

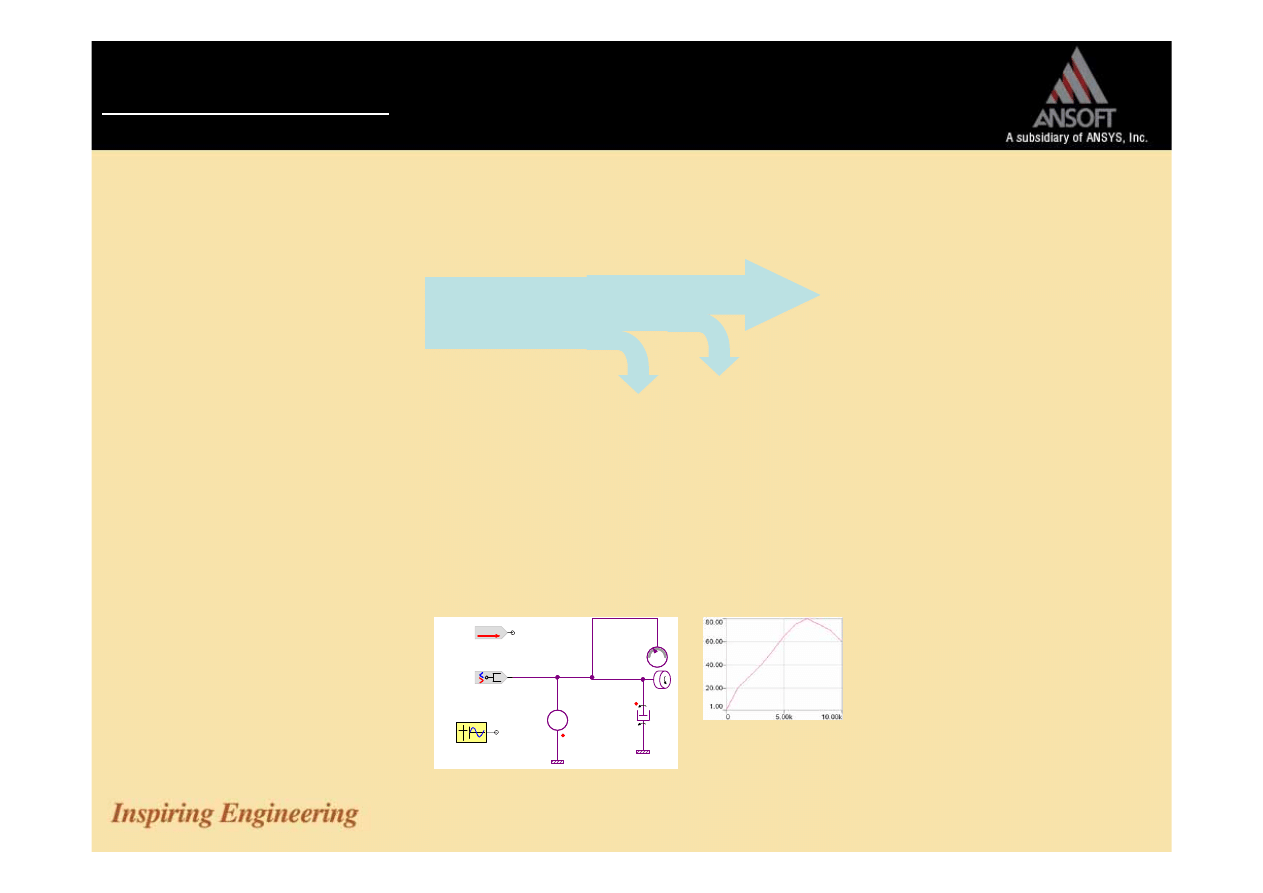

Accept total

system

Subsystem

verification

Built-in

verification

Demand

definition

Optimize of

elements

Subsystem

design

Topology

layout

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

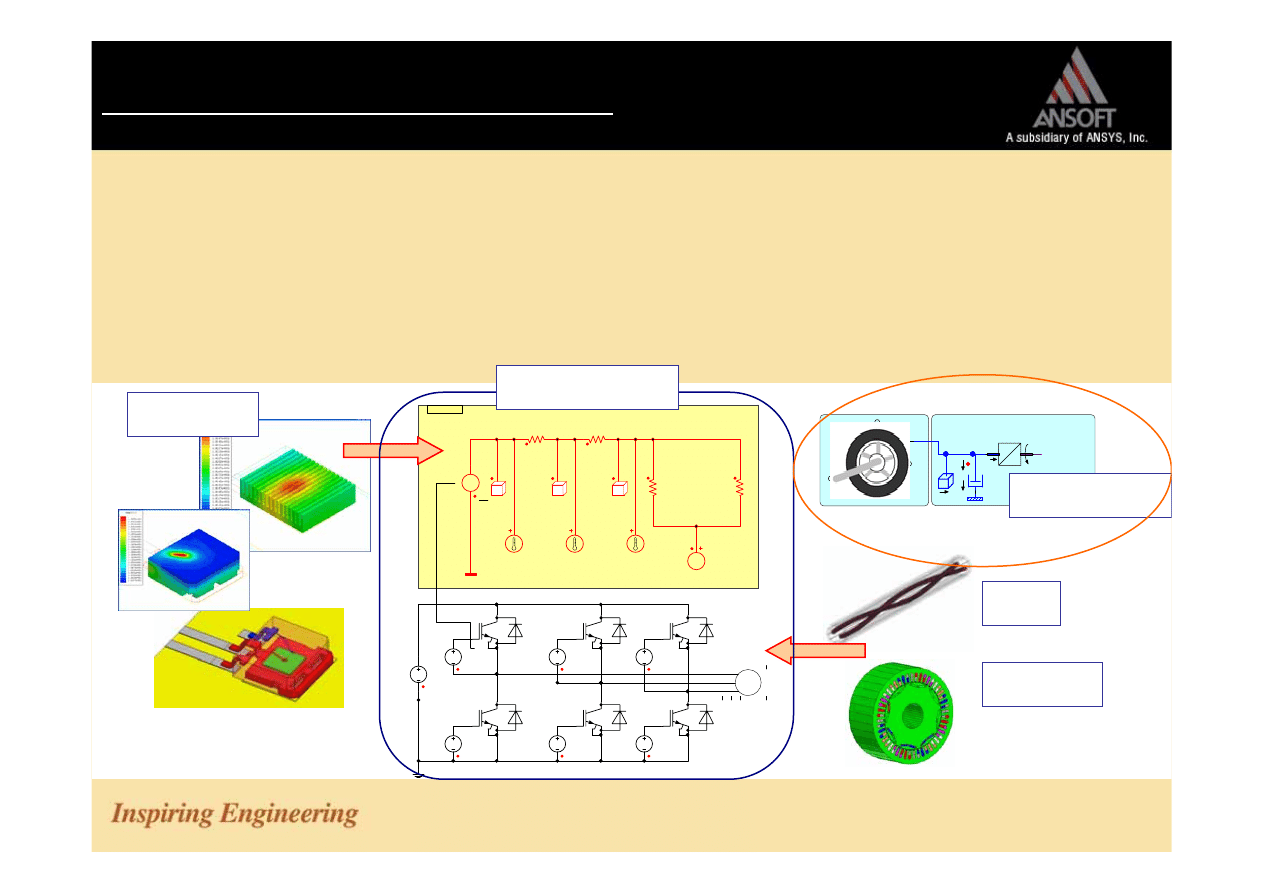

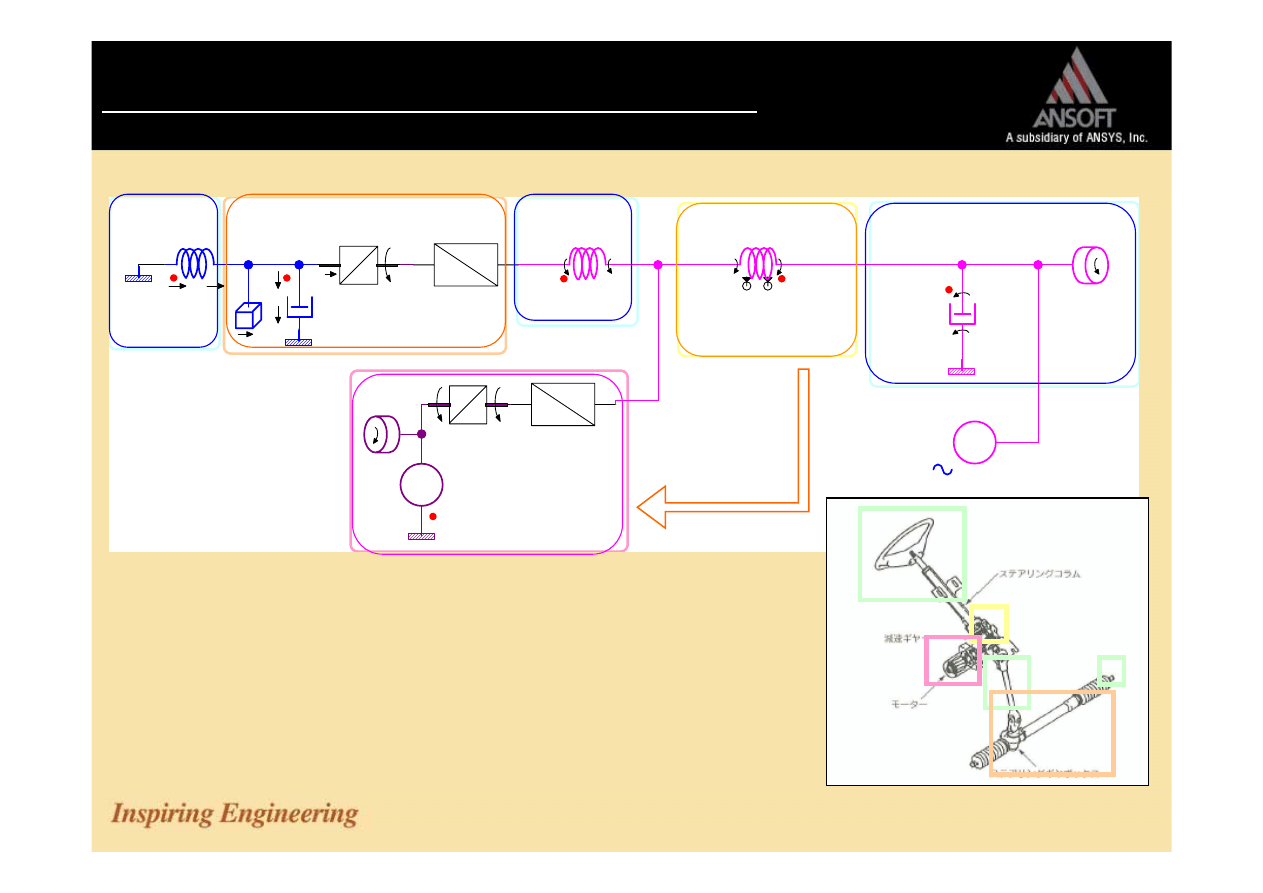

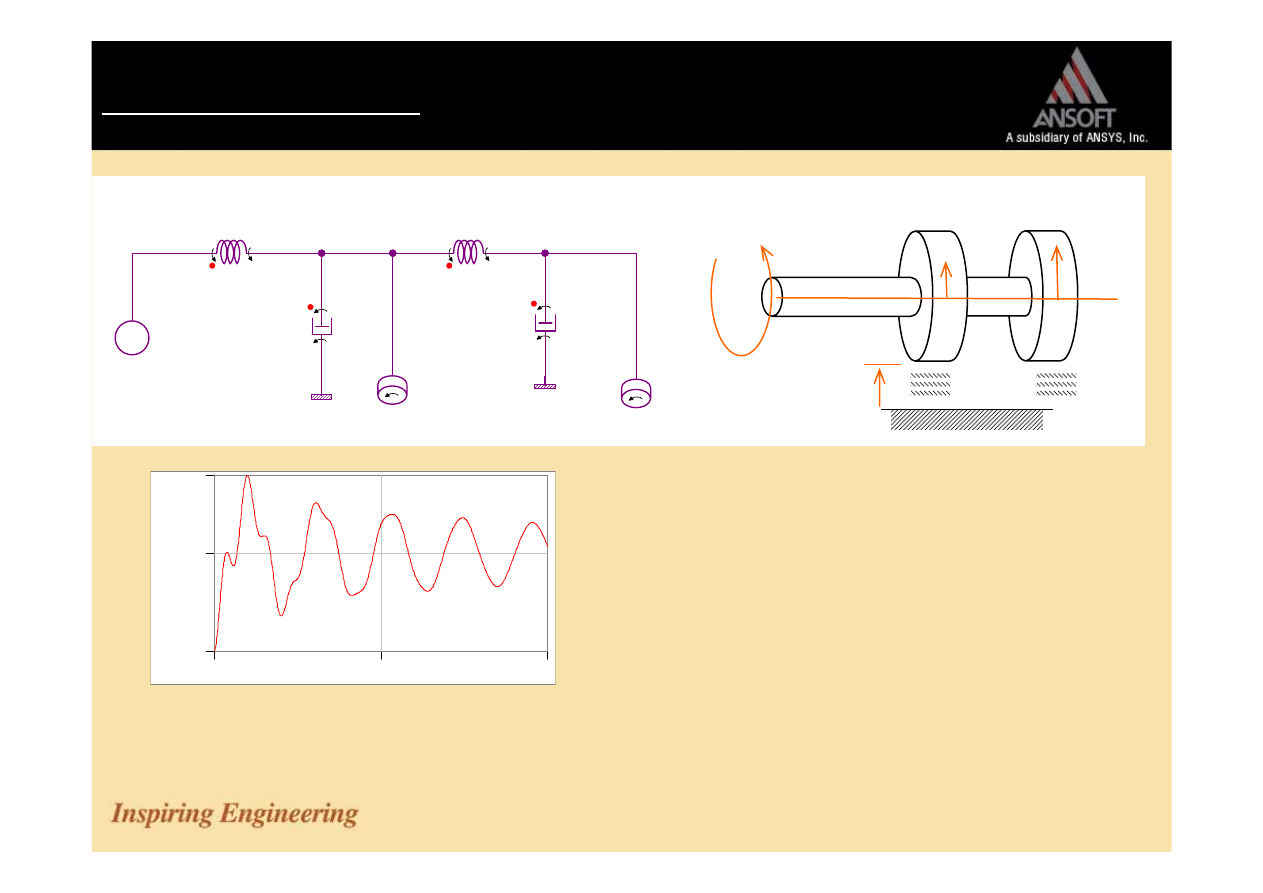

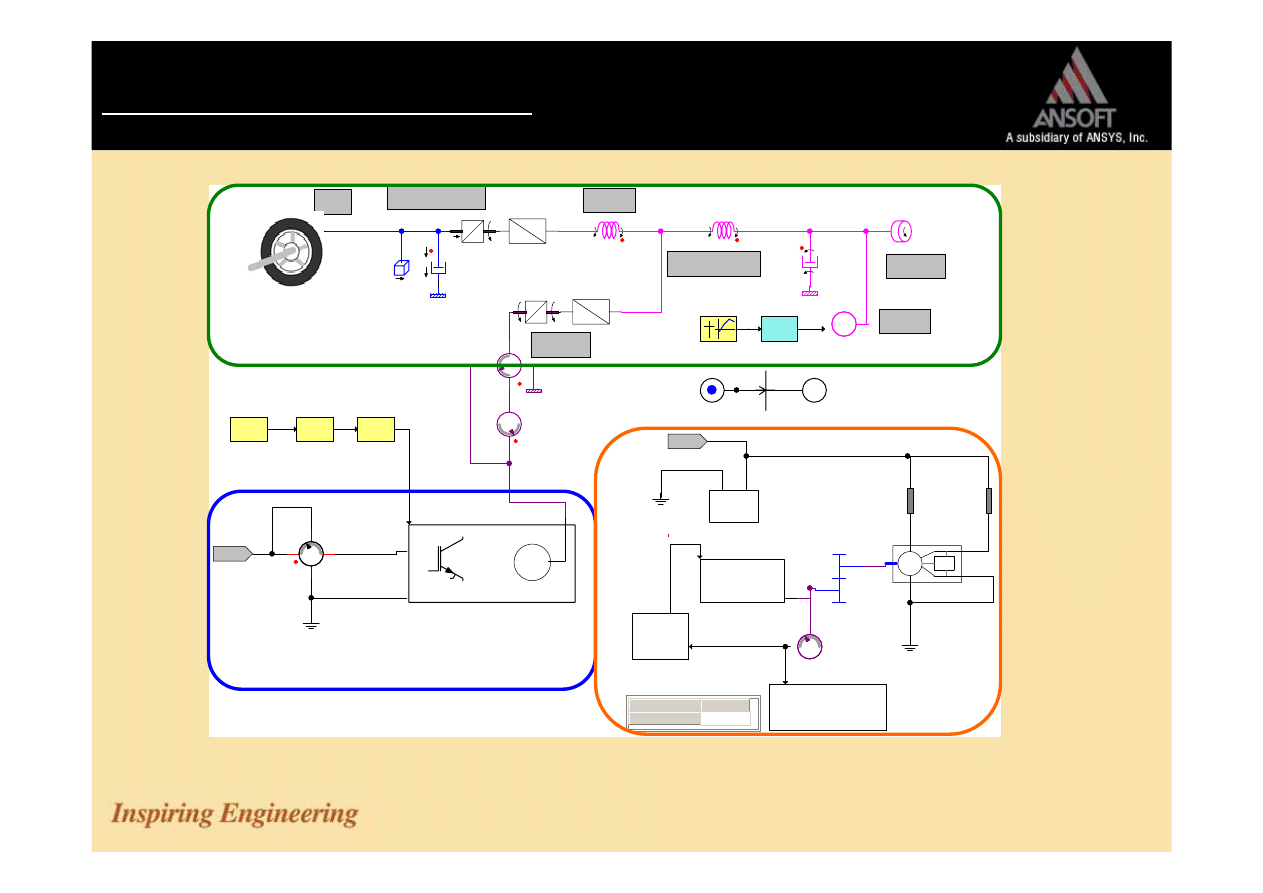

• SIMPLORER can be applied not only for electrical circuits

but also Multi-domain system & circuit.

SIMPLORER OverView

OMEGA

M

3 ~

B

A

C

I1C

I1B

I1A

N

H

Θ

EQU

RTH_Chip

K := 1.5

CTH_J

C_TH := 1m

H1

CTH_Chip

C_TH := 10m

RTH_Case

K := 0.2

CTH_Case

C_TH := 0.1

RTH_Sink_Conv

K := 1.02

THM1

THM2

THM3

RTH_Sink_Rad

K := 4.2

Tambient

VALUE := 300

Celsius

PEL

TR1

ROT2

TSF

tra

Wheel_dynamics

Thermal model design

Design of magnetic

components

Mechanical model design

Common mode- noise

SIMPLORER

ePhysics

Maxwell

Q3D

VHDL-AMS

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

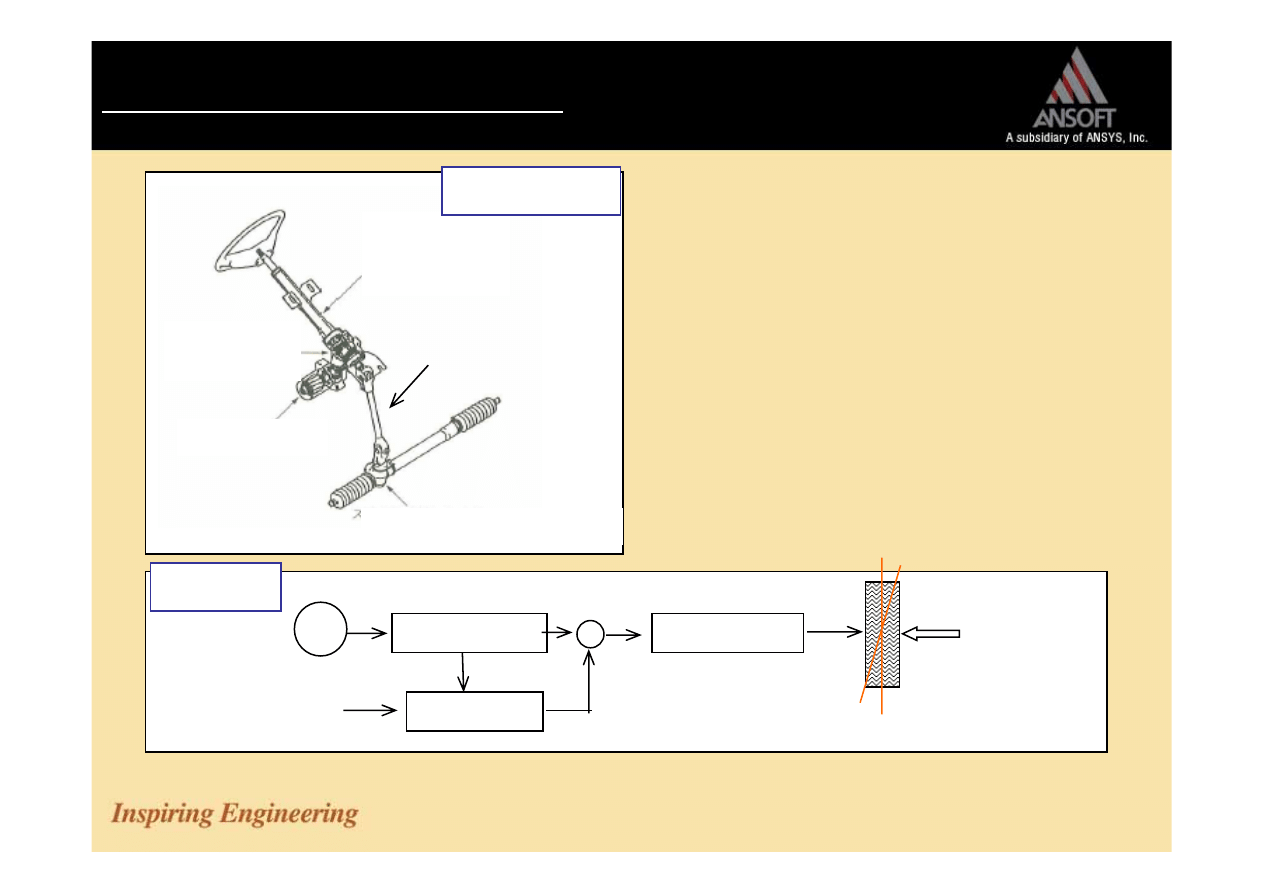

Steering assist system.

1. Steering

2. Torsion bar

&

Column shaft

3. Intermediate shaft

6.Assist motor

4.Rack & Pinion gear

Deceleration

gear

自動車工学入門 :野崎博路 著:山海堂 ISBN 4-381-08855-7

Steering

Torque sensor

+

+

Assist motor

Vehicle speed

Rack & Pinion

Slip angle

Side force

•

Change of the assistant gain by vehicle speed

• The moment of self aligning

=> These have not been considered yet

Diagram

Composition

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

TR1

ROT2

TSF

ROT1 ROT2

TSF

ROT

ROT_V

ROT

ROT_V

T

Φ

+

TBar

Motion model of steering system.

Steer Angle

Torque detection

1. Steering

1.

2. Torsion bar

2.

3. Intermid shaft

3.

4.Rack & Pinion gear

4.

6.Assist motor

6.

0.025[kgm2]

0.04[Nm s/rad]

130[Nm/rad]

130[Nm/rad]

12[kg]

6500[Ns/m]

210k [N/m]

Gear ratio 4

0.5m[kgm2]

• Reaction force imitates the set end with a high

rigidity spring.

• The detected torque of torsion bar refers from

assit motor.

Steer

inertia

Friction

Twist rigidity

Translation <> rotation

Rotor intertia

5. Reaction

5.

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

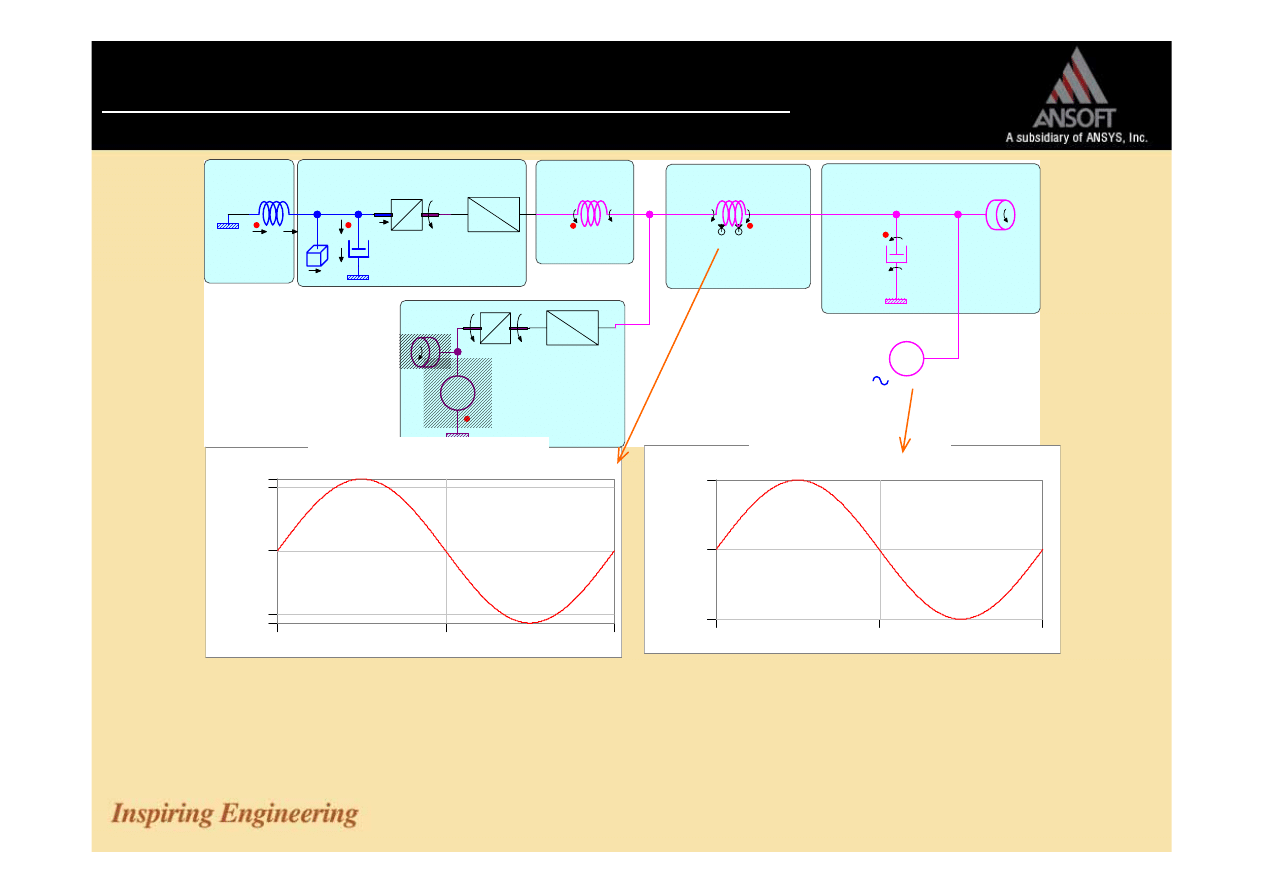

Steering angle and Steering torque

TR1

ROT2

TSF

ROT1 ROT2

TSF

ROT

ROT_V

ROT

ROT_V

T

Φ

+

TBar

-11.40

11.35

0

0

1.00

500.00m

トーションバー・トルク

TBar.TORQUE [Nm]

-10.00

10.00

0

0

1.00

500.00m

操舵量

S_ROTB1.PHI [deg]

Steering Angle

10[deg] 1Hz

Torsion bar

torque

• Input : steering angle 10[deg], 1[Hz]

• Confirm steering torque with out assist system

Steering angle [deg]

Torsion bar torque [deg]

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

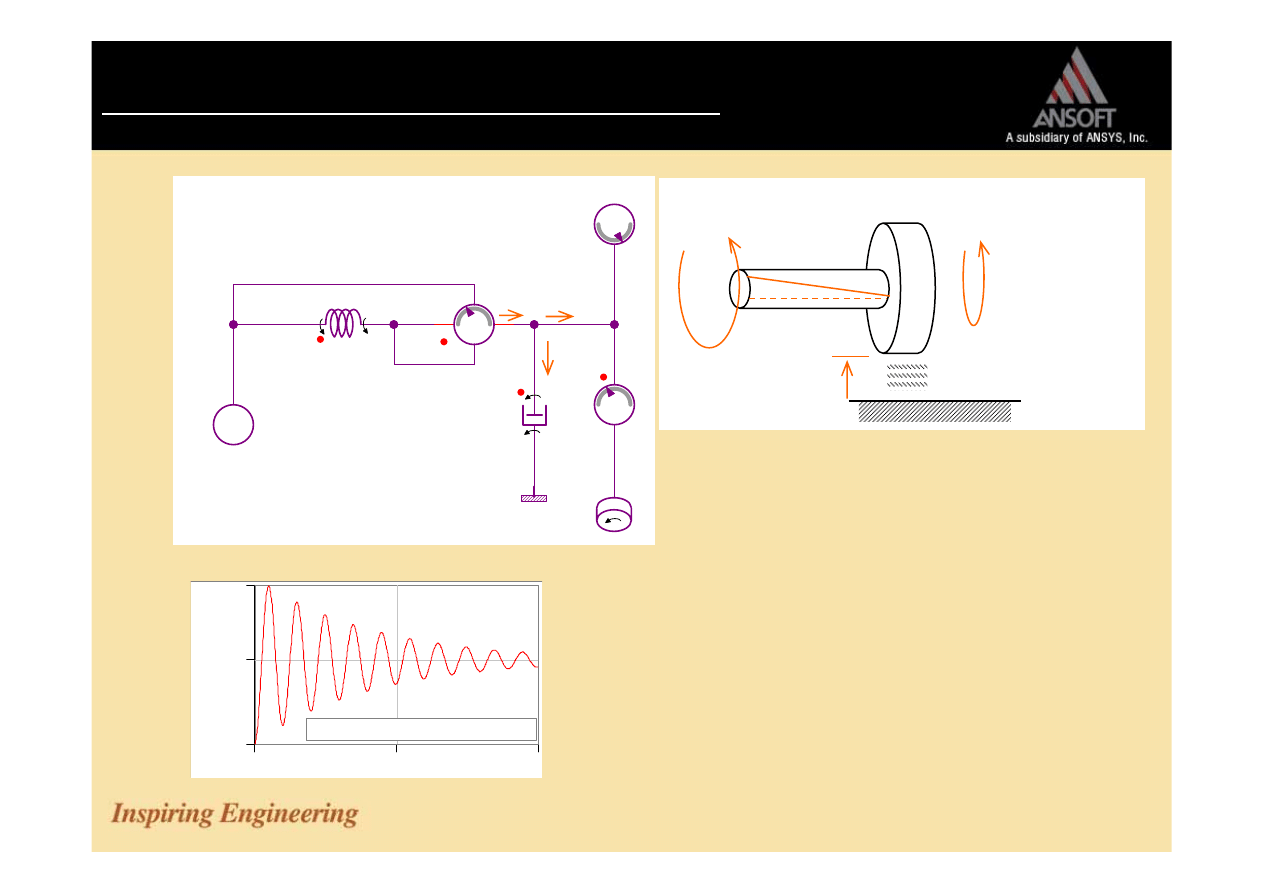

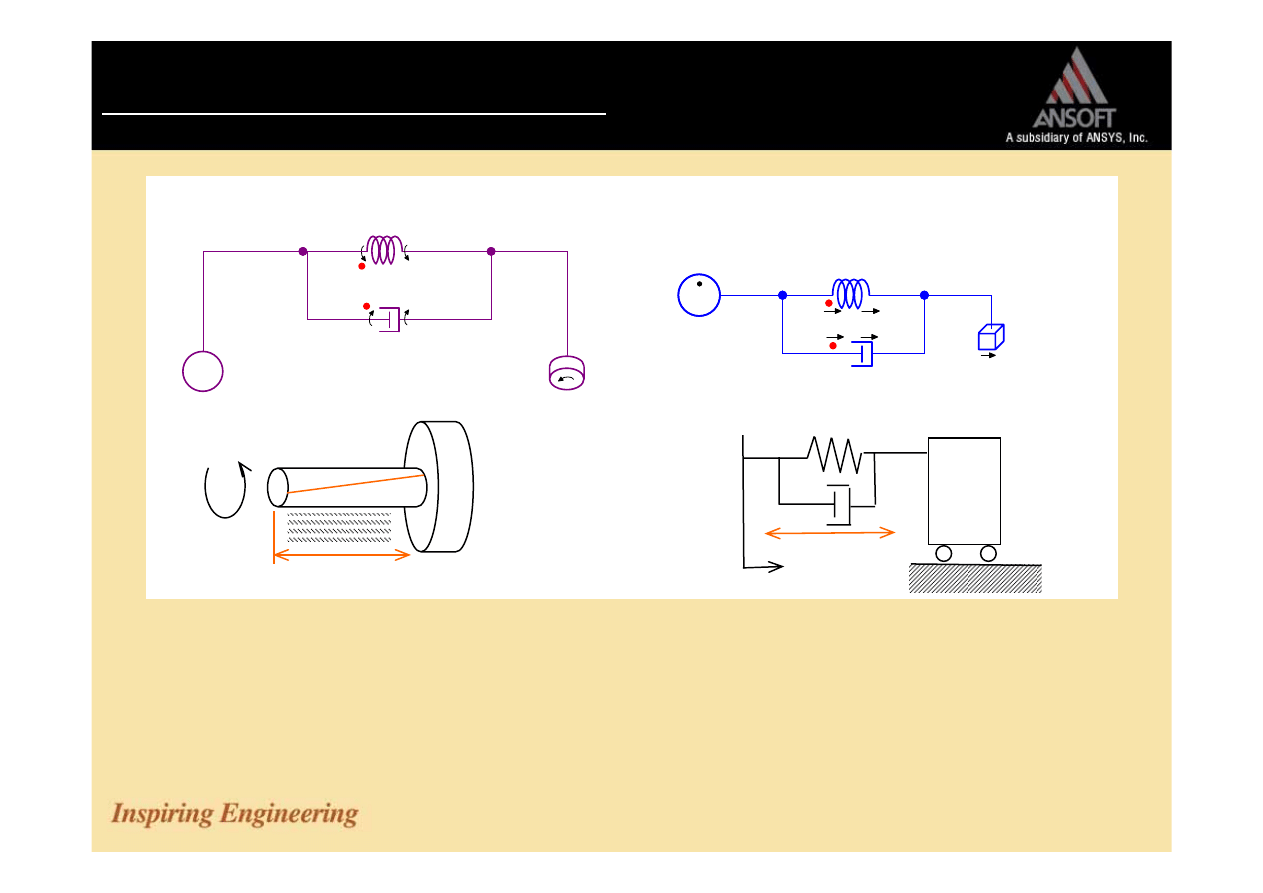

Modeling of motion system

ω

+

ω

+

W

+

DAMPING := .05 Nm*s/rad

C := 10 Nm/rad

VALUE := 10 rad/s

T

Angular speed source

Twist

Rigidity C

DAMPING

Inertia J

Inertia J

Rigidity

Viscous coeff.

1.44n

18.90

10.00

0

20.00

10.00

VM_ROT1.OMEGA [rad/s]

Velocity differential

Speed source

C: Rigidity over an angle difference of twist

Damping: Viscosity over a velocity differential

Tm

Td

Tk

0

=

−

−

Td

Tm

Tk

(

)

dt

D

C

J

∫

=

−

−

=

0

0

0

ω

θ

θ

θ

θ

θ

&

&&

Disturbance

Te =0

・Conservation law of torque.

0

ω

θ

θ

&

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

ω

+

10 rad/s

C := 10 Nm/rad

DAMPING := .05 Nm*s/rad

J := 1 kg m %

C := 10 Nm/rad

DAMPING := .05 Nm*s/rad

J := 2 kg m %

2 DOF system

Angle

Rigidity C

Inertia

Velocity differential

Speed source

0

18.00

10.00

0

20.00

10.00

MASS_ROT2.OMEGA [rad/s]

• Series connection of elasticity

• Easy expansion to the multi body system.

(

)

(

)

(

)

∫

=

−

−

=

−

−

−

−

=

dt

D

C

J

D

C

C

J

0

0

2

2

2

1

2

2

2

1

1

2

1

2

1

0

1

1

1

ω

θ

θ

θ

θ

θ

θ

θ

θ

θ

θ

θ

&

&&

&

&&

1

θ

2

θ

0

ω

Damping

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Connecting in parallel

ω

+

10 rad/s

C := 10 Nm/rad

DAMPING := .05 Nm*s/rad

J := 1 kg m %

Velocity differential

S

+

S

VALUE := 10 m/s

DAMPING := .05 N*s/m

C := .1 N/m

M := 1 kg

Velocity differential

• Consider damping to the speed difference in which section.

• Easy understanding where is the reference of a position and an angle

Rotational motion

Translational motion

x

ω

© 2008 Ansoft, LLC All rights reserved.

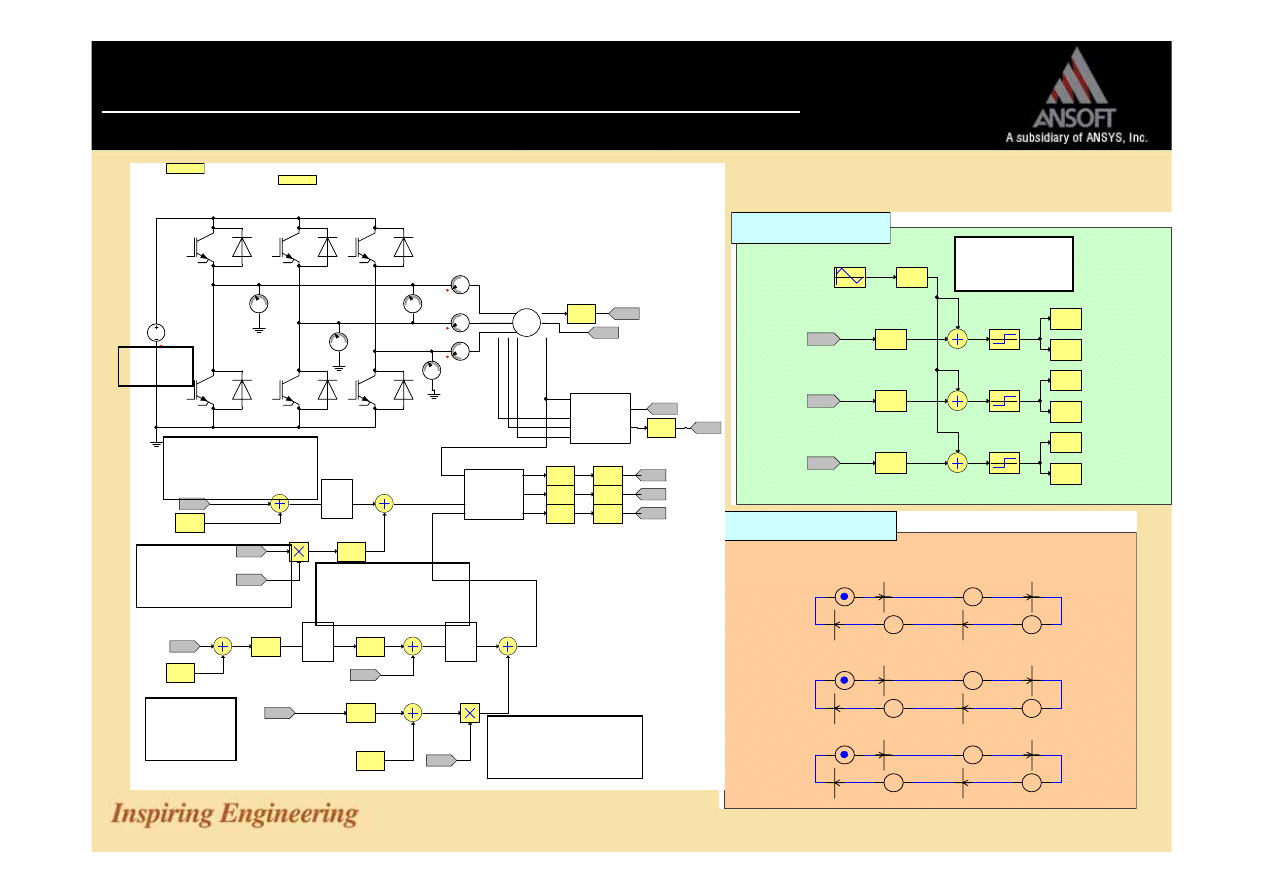

Ansoft, LLC Proprietary

GAIN

GAIN

GAIN

N EG

NPG

NPG

NPG

NPG

NPG

NPG

TSP1

TSP4

TSP2

TSP5

TSP3

TSP6

COMP1

COMP2

COMP3

TRIANG1

Vref_u

Vref_v

Vref_w

PWM Generator

Vector control of IPM : Basic model

FREQ := 20k

AMPL := 1

SET: := ST4:=0

SET: := ST1:=1

TSP4.VAL=1

SET: := ST4:=0

SET: := ST1:=0

U1

SET: := ST4:=0

SET: := ST1:=0

TSP1.VAL=1

SET: := ST1:=0

SET: := ST4:=1

U2

Dead Time Control

ICA:

deadtime:=5u

Friction:=8e-3

A

A

A

+

V

MS

MS

3 ~

B

A

C

ST1

ST2

ST3

ST4

ST5

ST6

Vdc

DC_bus

AM1

AM2

AM3

Motor

theta

d

q

dq_abc

GAIN

GAIN

GAIN

GAIN

GAIN

GAIN

Vref_u

Vref_v

Vref_w

EQU

Dw:=Friction*Motor.N*2*pi/60

a

b

c

theta

abc_dq

Input

PI_1

CONST

Omega

N

Omega

N

id

id

iq

CONST

Idref

GAIN

Input

PI_2

Input

PI_3

GAIN

GAIN

iq

id

GAIN

CONST

Psi

Omega

GAIN

+

V

VMA

+

V

VMB

+

V

VMC

DC_bus:=12

Motor.KE

Motor.L1D

Motor.P

GAIN

Motor.P

2 * PI/60.0

Motor.L1Q

P_Gain 0.5

I_Gain 2

0.6

20m

P_Gain 13

I_Gain 3

1/(DC_bus/2)

200

PWM carrier = 20kHz

q-axis voltage

compensation

Speed

control

q-axis

current control

d-axis

current control

12[V]

d-axis voltage

compensation

© 2008 Ansoft, LLC All rights reserved.

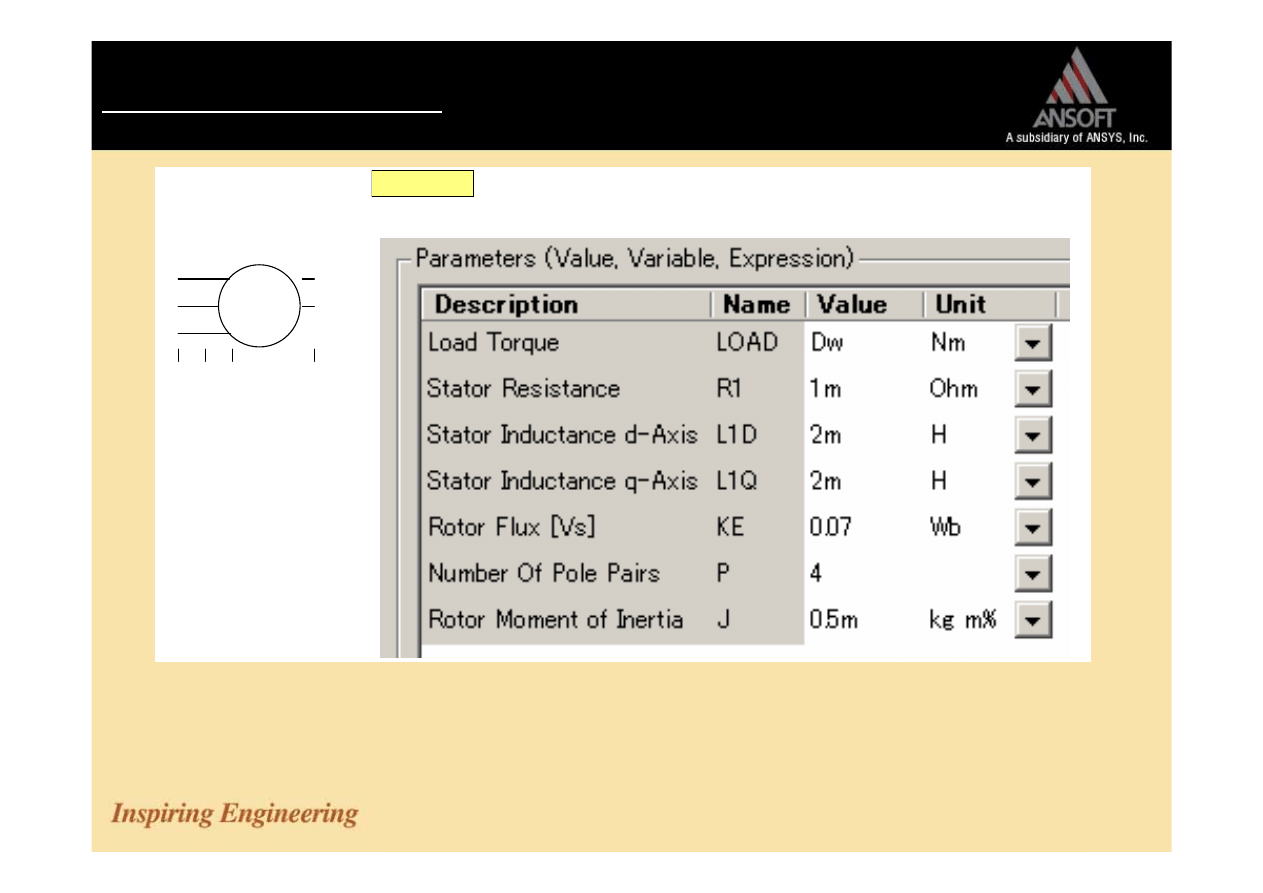

Ansoft, LLC Proprietary

Basic Component :

PM 3Phase synchronous motor(SYMP1)

MS

3 ~

B

A

C

N:

Rotor Speed [rpm]

OMEGA: Rotor Angular Velocity [rad/s]

MI:

Inner Torque [Nm]

PHI

Electrical Angle [rad]

PHIDEG

Electrical Angle [deg]

PHIM

Mechanical Angle [rad]

PHIMDEG Mechanical Angle [deg]

PHI := PolePairs * PHIM

LOAD:

Load torque [Nm]

R1:

Stator Resistance [Ohm]

L1D

d-axis Inductance [H]

L1Q

q-axis Inductance [H]

KE

Rotor Flux [Wb]

P

Pole pairs

J

Rotor Moment of Inertia [kgm

2

]

PWRELEC:

Input Power [W]

PWRMECH:

Output Power [W]

PWRLOSS:

Losses [W]

Input parameters

Output parameters

© 2008 Ansoft, LLC All rights reserved.

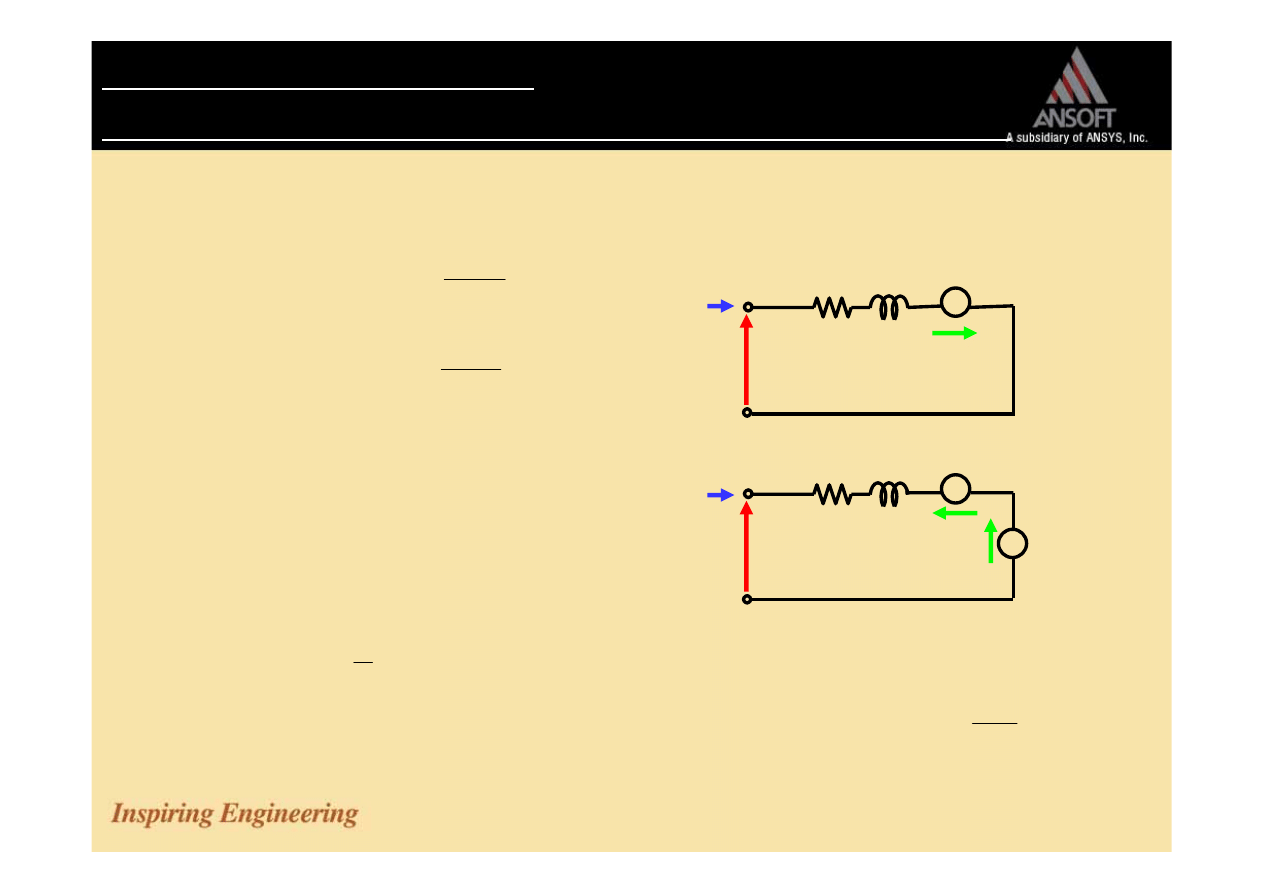

Ansoft, LLC Proprietary

Basic Component :

PM 3Phase synchronous motor(SYMP1)

d

q

q

q

q

d

d

d

p

dt

d

R

i

v

p

dt

d

R

i

v

ωψ

ψ

ωψ

ψ

+

+

⋅

=

−

+

⋅

=

q

q

q

e

d

d

d

L

i

k

L

i

⋅

=

+

⋅

=

ψ

ψ

(

)

{

}

q

d

q

d

q

e

i

i

L

L

i

k

p

mi

⋅

−

+

⋅

=

2

3

dt

d

J

Load

mi

ω

=

−

R

L

q

v

q

e

k

p

ω

〜

dq-Axis Voltage Equation

dq-Axis Flux Linkage

Motor Torque

Equation of Motion

R

L

d

v

d

q

q

i

L

p

ω

d

d

i

L

p

ω

d

i

q

i

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Input parameters

MS

3 ~

B

A

C

Temporary Load model

Friction := 10.0 e-3

Torque

ω

⋅

= Friction

Dw

EQU

Dw:=Friction*Motor.n*2*pi/6

Dw := Friction * Motor.N * 2 * PI/60

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

MS

3 ~

B

A

C

Mo to r

theta

d

q

d q_ab

GAIN

GAIN

GAIN

GAIN

GAIN

GAIN

Vref_u

Vref_v

Vref_w

a

b

c

theta

ab c_d q

Input

PI_1

Omega

N

Omega

id

iq

id

iq

CONST

Id re

GAIN

Input

PI_3

iq

id

GAIN

CONST

Ps

Omega

GAIN

Motor.KE

Motor.L1D

GAIN

Motor.P

Motor.L1Q

P_Gain 0.5

I_Gain 2

P_Gain 13

I_Gain 3

1/(DC_bus /2)

CONST

TR ef

1

GAIN

1/(1.5 * Motor.KE * Motor.P)

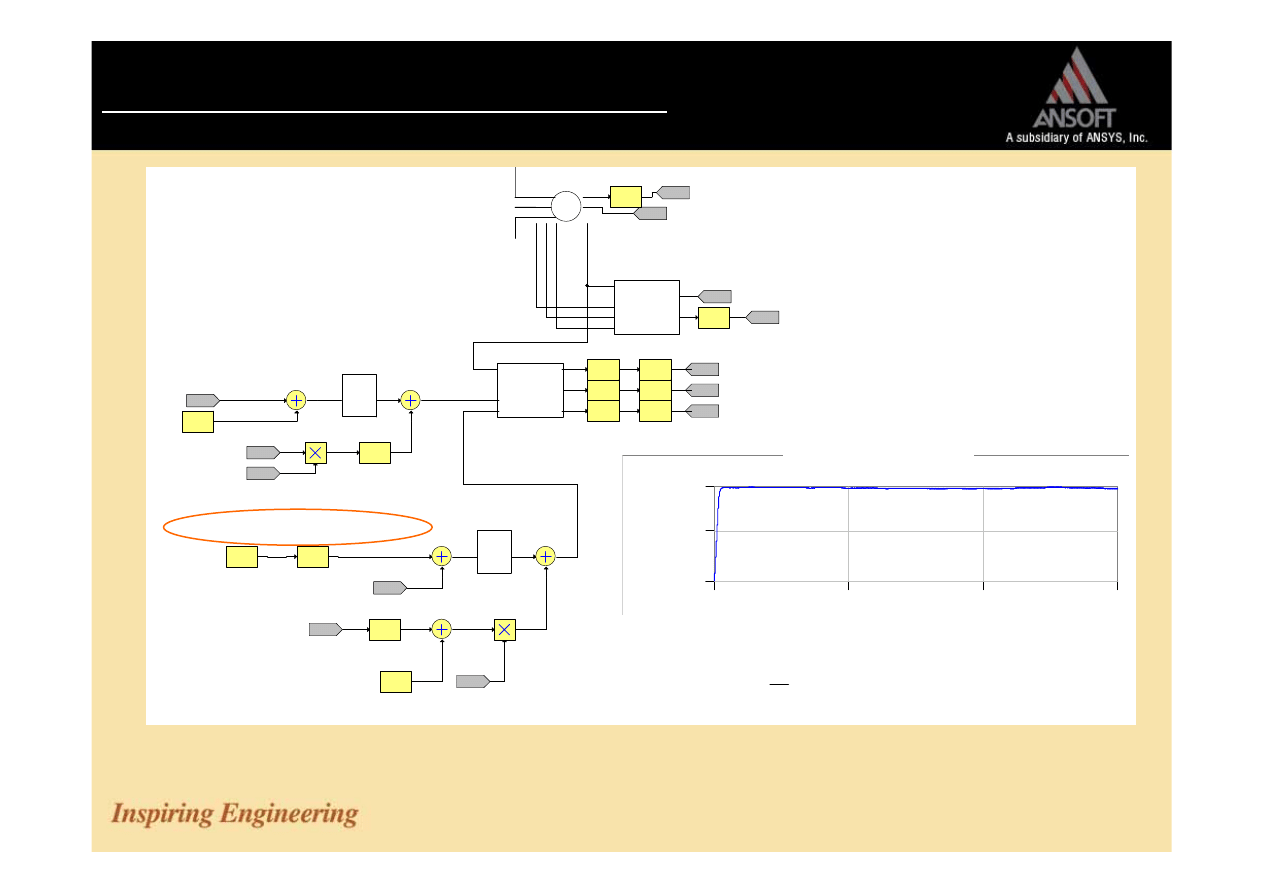

Check : Motor torque control

-50.00u

935.00m

500.00m

0

60.00m

20.00m

40.00m

モータトルク [Nm]

Motor.MI [(kg m)/s]

• Convert the reference torque into iq

• Check the following capability and steady-state error at reference torque = 1[Nm]

(

)

{

}

q

d

q

d

q

e

i

i

L

L

i

k

p

mi

⋅

−

+

⋅

=

2

3

Motor torque

Motor Torque [Nm]

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Parametric : searching gains for torque control

-10.00m

1.84

1.00

0

60.00m

20.00m

40.00m

モータート ルク [Nm] /KP

-5.00m

940.00m

500.00m

0

60.00m

20.00m

40.00m

モータトルク [Nm] / KI

KP valid

KI fixed=3

KP fixed=13

KI valid

KP = 0.1

0.2

0.8

1

2

8

10

20

KP = 20

KP=0.1

KI = 0.1

0.2

0.8

1

2

8

10

20

KI = 20

KI = 0.1

KP = 2

Check : KP

following capability

Check : KI

Steady state error

• Gain KP influences the following capability.

• In this case, KP >= 2 is required.

Motor Torque [Nm] / KP

Motor Torque [Nm] / KI

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

TR1

ROT2

TSF

ROT1 ROT2

TSF

ROT

ROT_V

ROT

ROT_V

T

Φ

+

TBar

The load model system and motor torque

MS

3 ~

B

A

C

Torque Source

• The load torque in standard SML motor model is defined as a simple signal.

• How much torque should we refer as load ?

The parameter display of a SML motor model.

Motor torque

Where can we get the load torque ??

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Intricate case : Described as individual system.

MS

3 ~

B

A

C

MS

3 ~

B

A

C

Motor

Omega

N

GAIN

Motor.P

ROT1

ROT2

TSF

ROT

ROT_V

T

ROTB_ROT3

+

ω

+

Motor.J

OMEGA

LOAD

• Load torque from axis.

• Add rotor inertia.

• Motor speed is compelled to axis

OR

• Motor torque is compelled to axis

• Note that the direction of the torque meter.

• Don’t forget that the addition of rotor inertia at the terminal.

• Though thinking the motor to be a torque source…

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

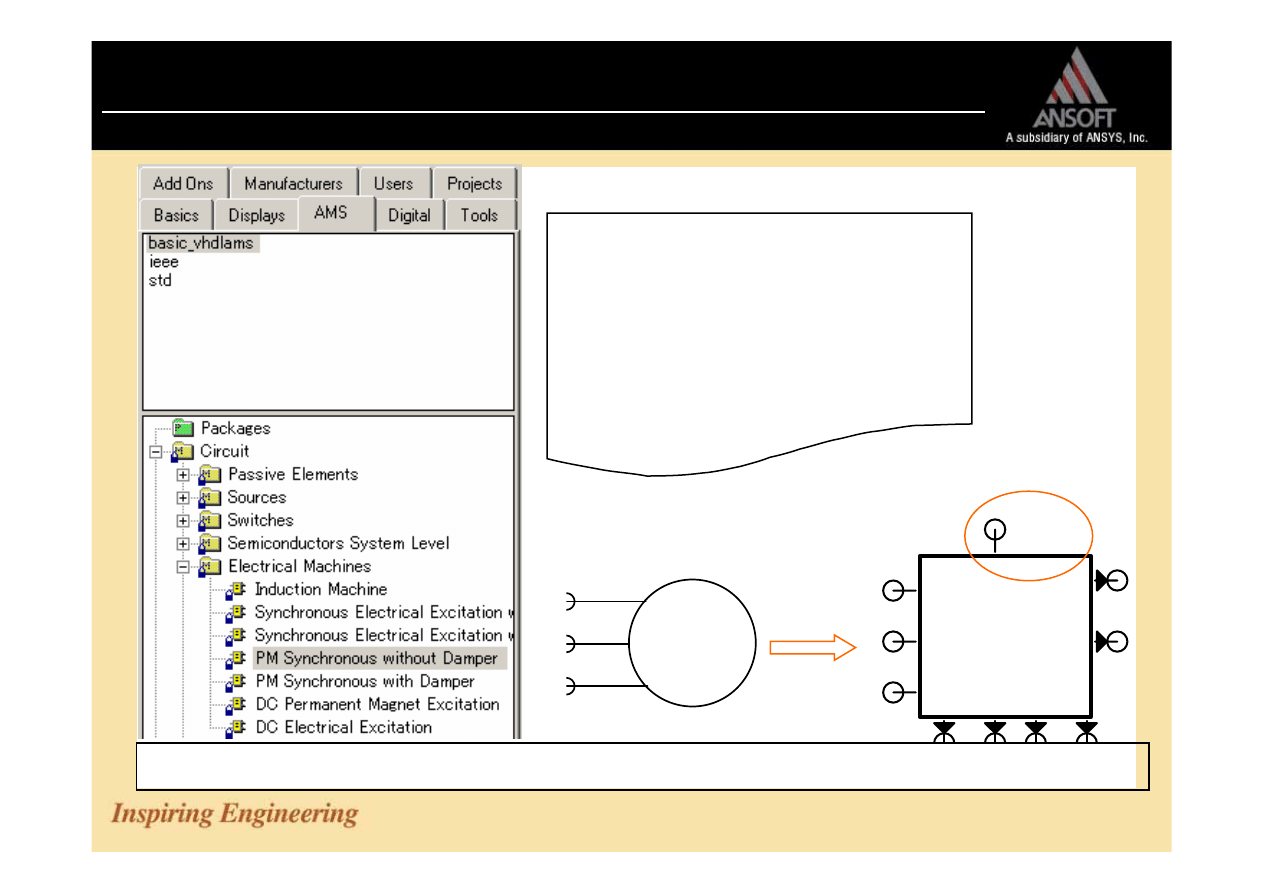

Improvement motor model : using VHDL-AMS

shaft

c

b

a

Motor

LIBRARY

IEEE;

USE

IEEE.ELECTRICAL_SYSTEMS.ALL;

USE

IEEE.MECHANICAL_SYSTEMS.ALL ;

USE

IEEE.MATH_REAL.ALL;

ENTITY

SYMP

IS

GENERIC

(

L1d : INDUCTANCE :=

0.042

;

L1q : INDUCTANCE :=

0.042

;

…..

MS

3 ~

B

A

C

・ Equal 3PH synchronous motor model included in AMS library.

• Improve the AMS model to create the shaft output to connect mechanical model.

Copy the definition and create subsheet.

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

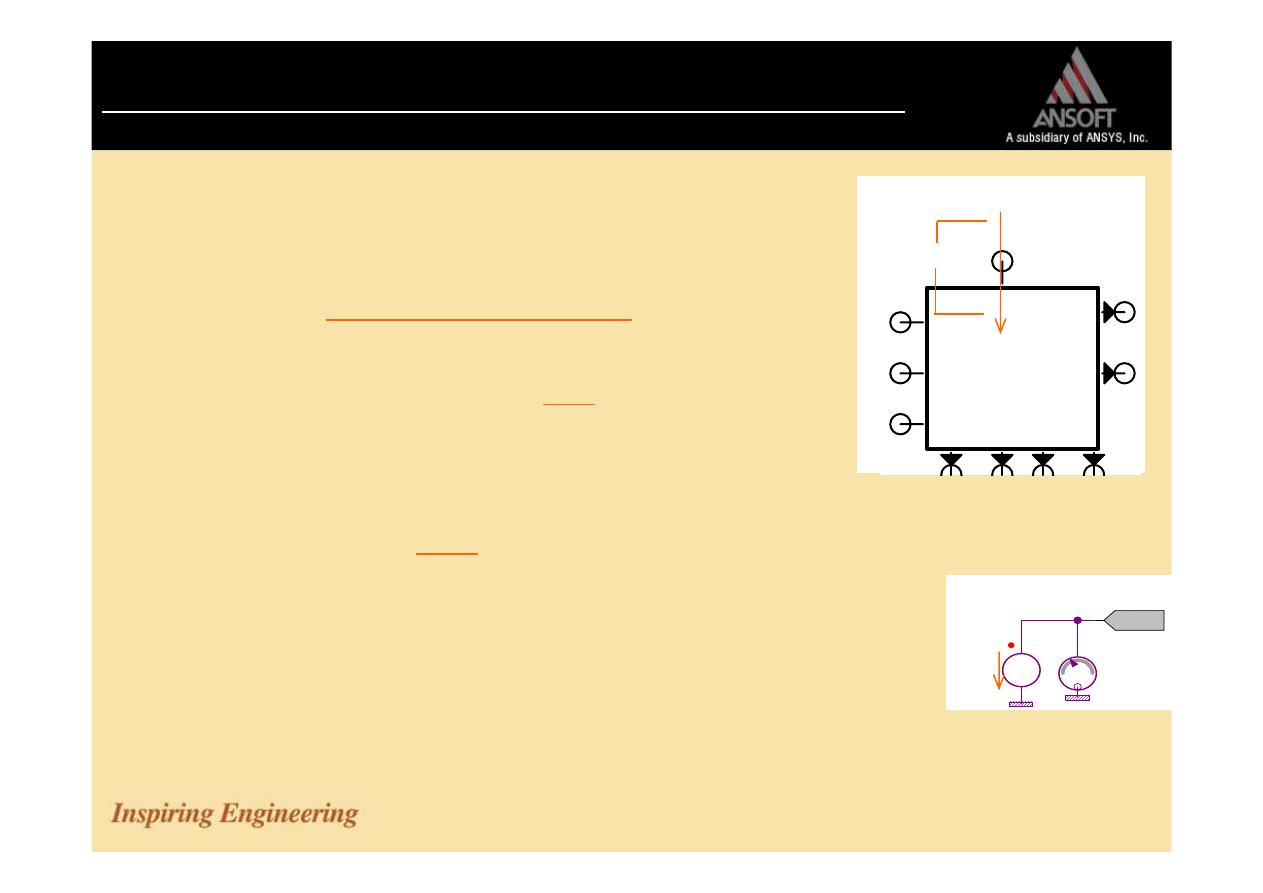

• Addition of a rotation system terminal

• Quantity definition

• Equation of motion

Improvement of VHDL-AMS motor model.

PORT

(

TERMINAL

a, b, c : ELECTRICAL;

TERMINAL

shaft : ROTATIONAL_V ;

shaft

c

b

a

Motor

QUANTITY

omega

across

load

through

shaft

to

ROTATIONAL_V_REF ;

mi ==

3.0

/

2.0

* P * (psi1d * i1q - psi1q * i1d);

j * omega‘dot == mi + load ;

mi : motor torque

P : pole pairs

psi1d, psi1q : d,q axis flux

load

omega

+

• “shaft

to

ROTATIONAL_V_REF” expresses the direction which

load torque flows.

Note that the direction is opposite with “load” of a standard model.

⇒ With equation of motion, “load” should be added.

T

shaft

ω

+

omega

load

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

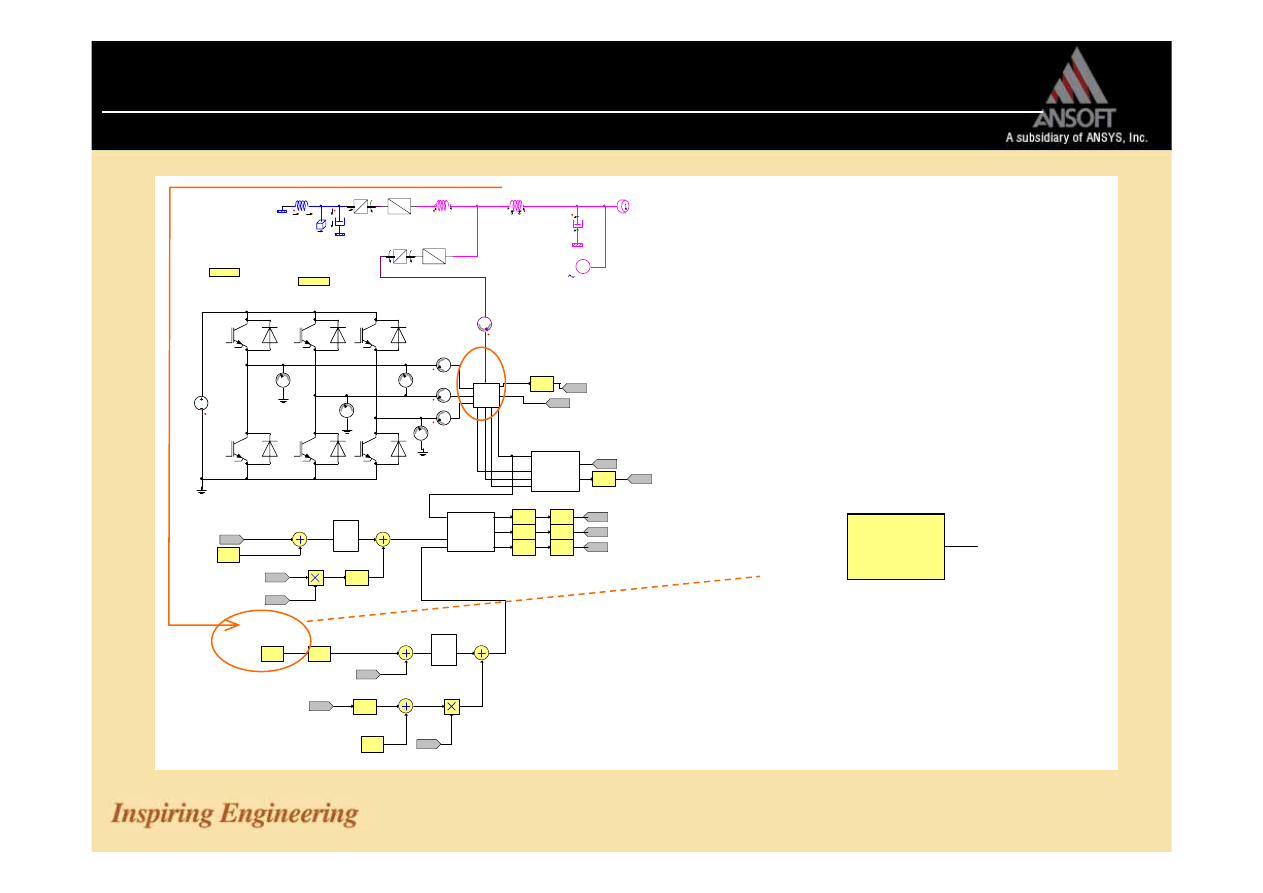

Integrate Steering model and electrical system.

ICA:

deadtime:=5u

Friction:=8e-3

A

A

A

+

V

ST1

ST2

ST3

ST4

ST5

ST6

Vdc

DC_bus

AM1

AM2

AM3

theta

d

q

dq_abc

GAIN

GAIN

GAIN

GAIN

GAIN

GAIN

Vref_u

Vref_v

Vref_w

EQU

Dw:=Friction*Motor.n*2*pi/60

a

b

c

theta

abc_dq

Input

PI_1

Omega

N

Omega

id

iq

id

iq

C ON ST

Idref

GAIN

Input

PI_3

iq

id

GAIN

C ONST

Psi

Omega

GAIN

+

V

VMA

+

V

VMB

+

V

VMC

DC bus:=12

Motor.ke

Motor.l1d

GAIN

Motor.p

Motor.l1q

P_Gain 0.5

I_Gain 2

P Gain 13/*20*/

I Gain 3 /*0.2*/

1/(DC_bus/2)

C ON ST

TRef

TBar.TORQUE

GAIN

1/(1.5 * Motor.ke * Motor.p)

TR1

ROT2

TSF

ROT1

ROT2

TSF

ROT

ROT_V

ROT

ROT_V

Φ

+

TBar

shaft

c

b

a

Motor

T

FM_ROT1

Reference

Torque

CONST

CONST

TRef

TBar.TORQUE

1) Connect motor shaft terminal to steering model.

2) Add torque reference value into a control block.

• Refer to torsion bar torque.

(1)

(2)

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

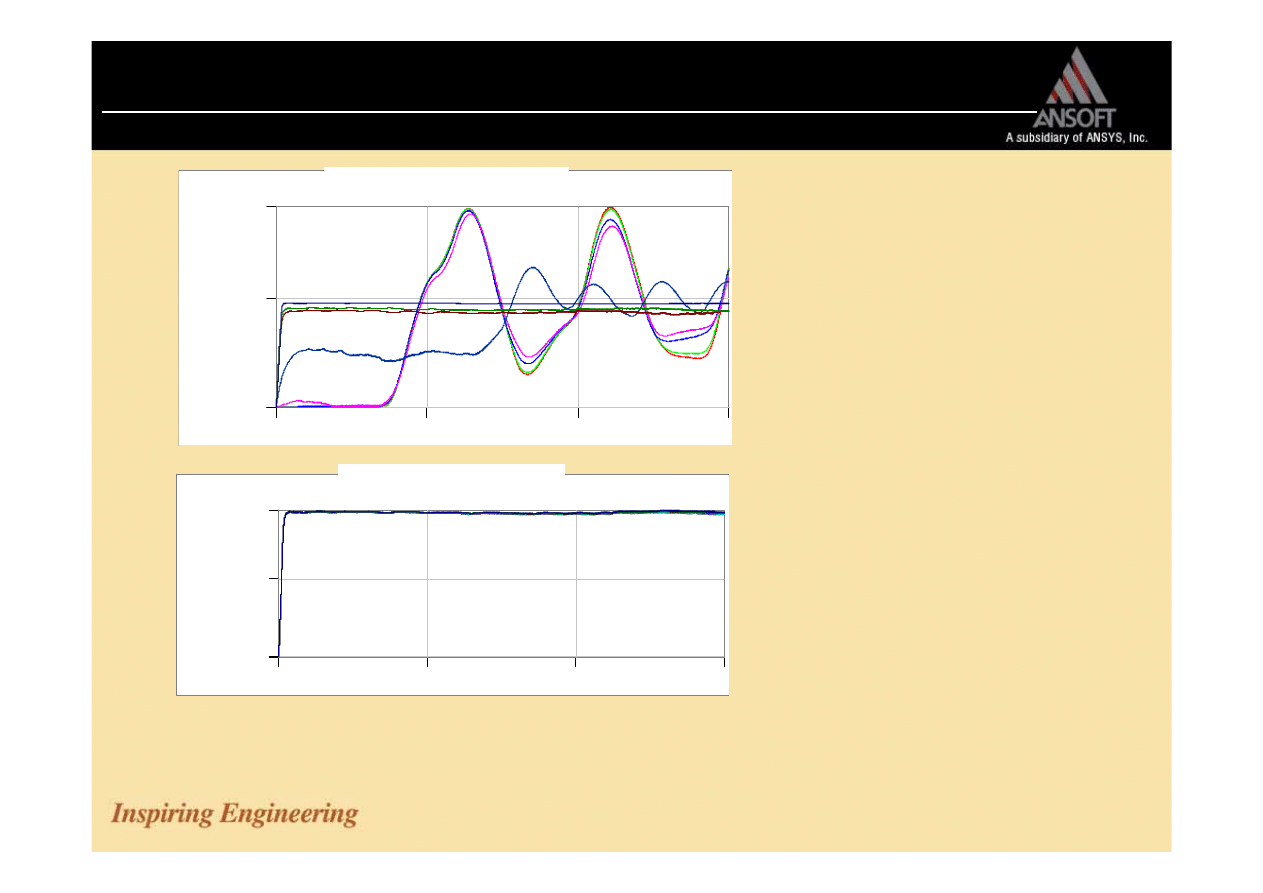

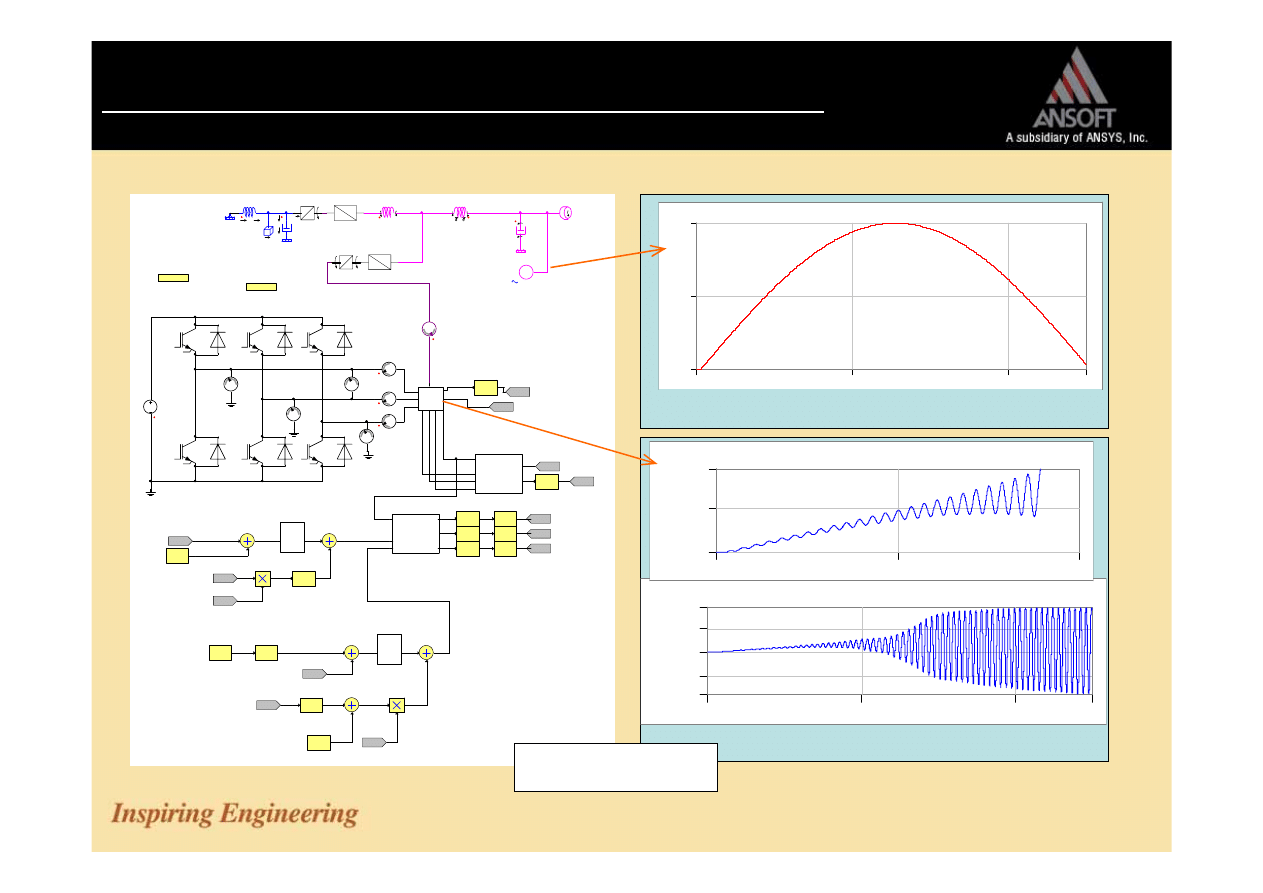

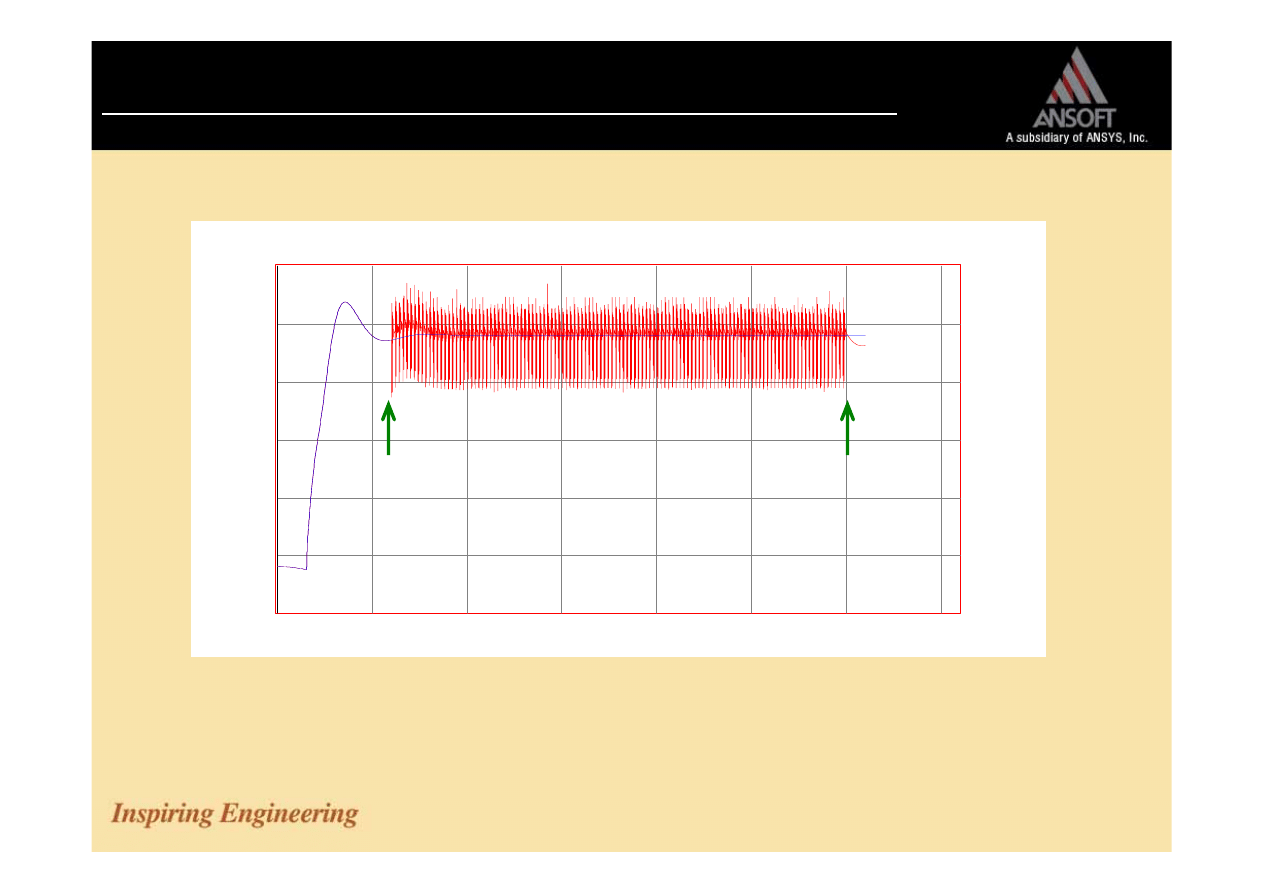

Integrated model : Simulation result.

0

10.00

5.00

0

500.00m

200.00m

400.00m

操舵量 [d...

S _ROT B 1.PHI [deg

-36.00

38.50

0

0

500.00m

200.00m

モータトルク [Nm]

Motor.mi

-5.00m

9.45

5.00

0

200.00m

100.00m

モータトルク [Nm]

Motor.mi

ICA:

deadtime:=5u

Friction:=8e-3

A

A

A

+

V

ST1

ST2

ST3

ST4

ST5

ST6

Vdc

DC_bus

AM1

AM2

AM3

theta

d

q

dq_abc

GAIN

GAIN

GAIN

GAIN

GAIN

GAIN

Vref_u

Vref_v

Vref_w

EQU

Dw:=Friction*Motor.n*2*pi/60

a

b

c

theta

abc_dq

Input

PI_1

Omega

N

Omega

id

iq

id

iq

CONST

Idref

GAIN

Input

PI_3

iq

id

GAIN

CONST

Psi

Omega

GAIN

+

V

VMA

+

V

VMB

+

V

VMC

DC_bus:=12

Motor.ke

Motor.l1d

GAIN

Motor.p

Motor.l1q

P_Gain 0.5

I_Gain 2

P Gai n 13/*20*/

I Gain 3 /*0.2*/

1/(DC_bus/2)

CONST

TRef

TBar.TORQUE

GAIN

1/(1.5 * Motor.ke * Motor.p)

TR1

ROT2

TSF

ROT1

ROT2

TSF

ROT

ROT_V

ROT

ROT_V

Φ

+

TBar

shaft

c

b

a

Motor

T

FM_ROT1

Steering Angle [deg]

Time < 200ms

Whole time

Motor Torque [Nm]

•

Oscillation !!

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

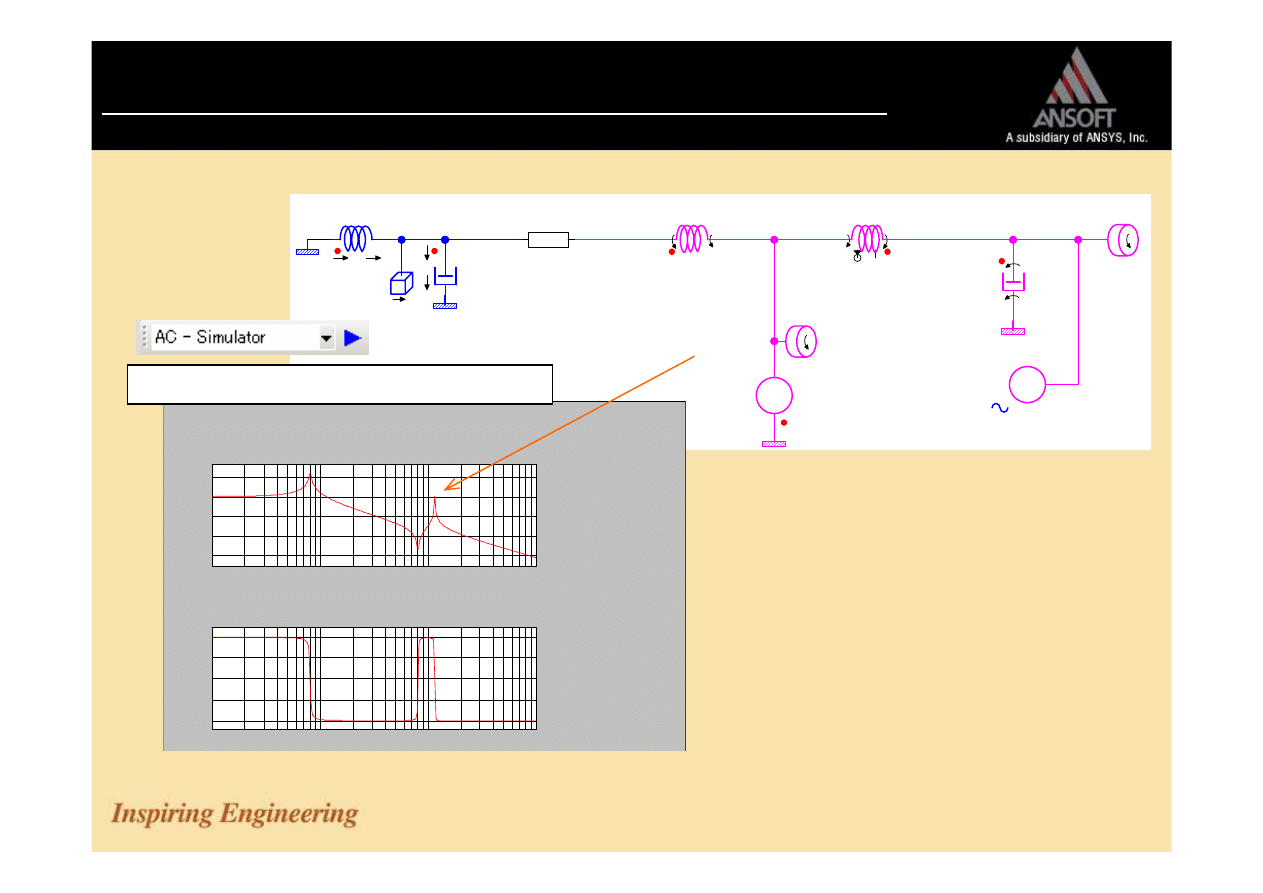

Frequency response of mechanics

Φ

+

TBar

D2D

D2D1

T

Steering Inertia

BodePlotSel3

TBar.TORQUE

Gain

Phase

1

1

2

2

3

3

4

4

5

5

6

6

10

10

20

20

30

30

50

50

100

100

200

200

400

400

1k

1k

1

1

2

2

3

3

4

4

5

5

6

6

10

10

20

20

30

30

50

50

100

100

200

200

400

400

1k

1k

-75.00

-50.00

-25.00

0.00

25.00

-75.00

-50.00

-25.00

0.00

25.00

0.00

45.00

90.00

135.00

180.00

0.00

45.00

90.00

135.00

180.00

f [Hz]

f [Hz]

[dB]

[deg]

Inertia of Motor

• The resonance point by the inertia

of motor is seen in 100Hz.

• other point 8Hz caused by the

steering inertia.

Transfer ratio : Steering Torque/Motor Torque

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

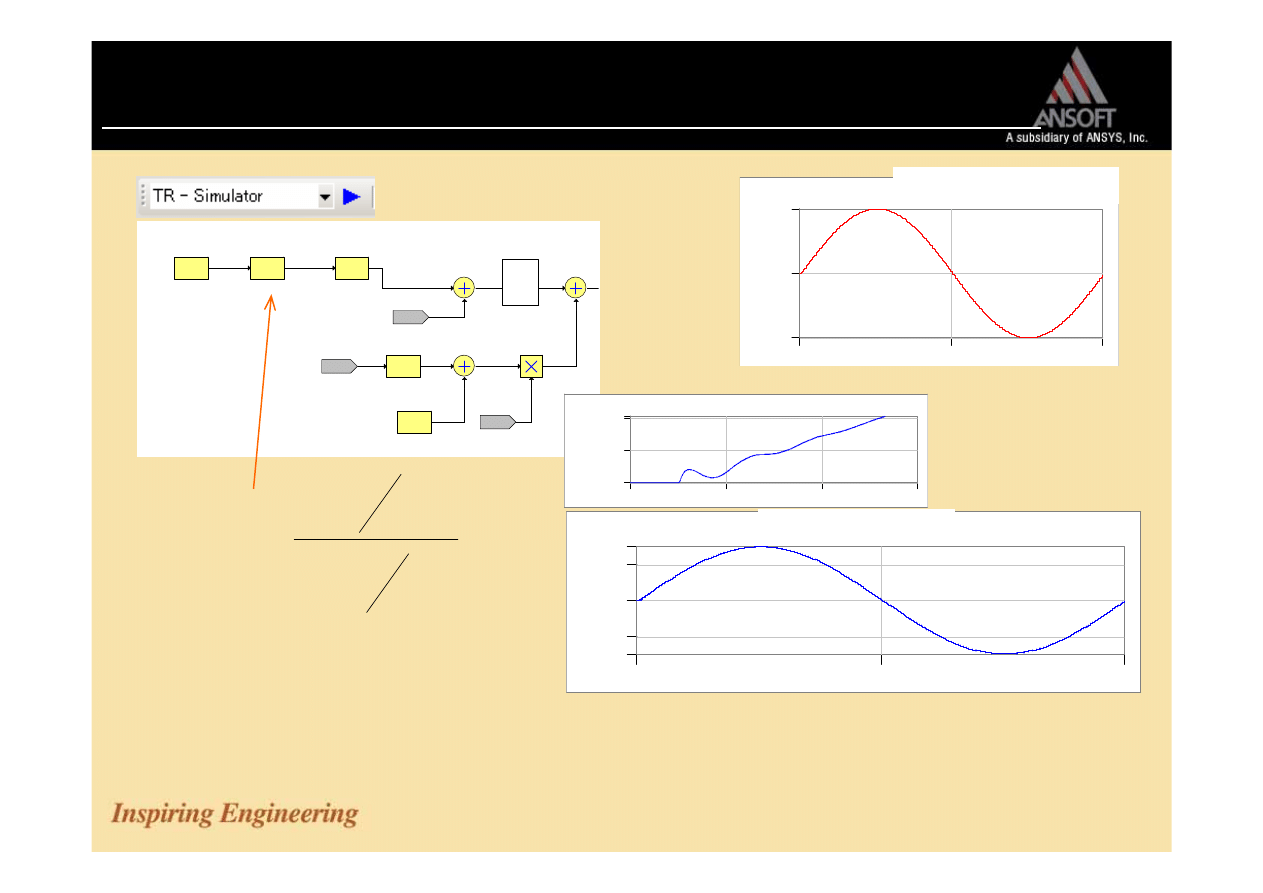

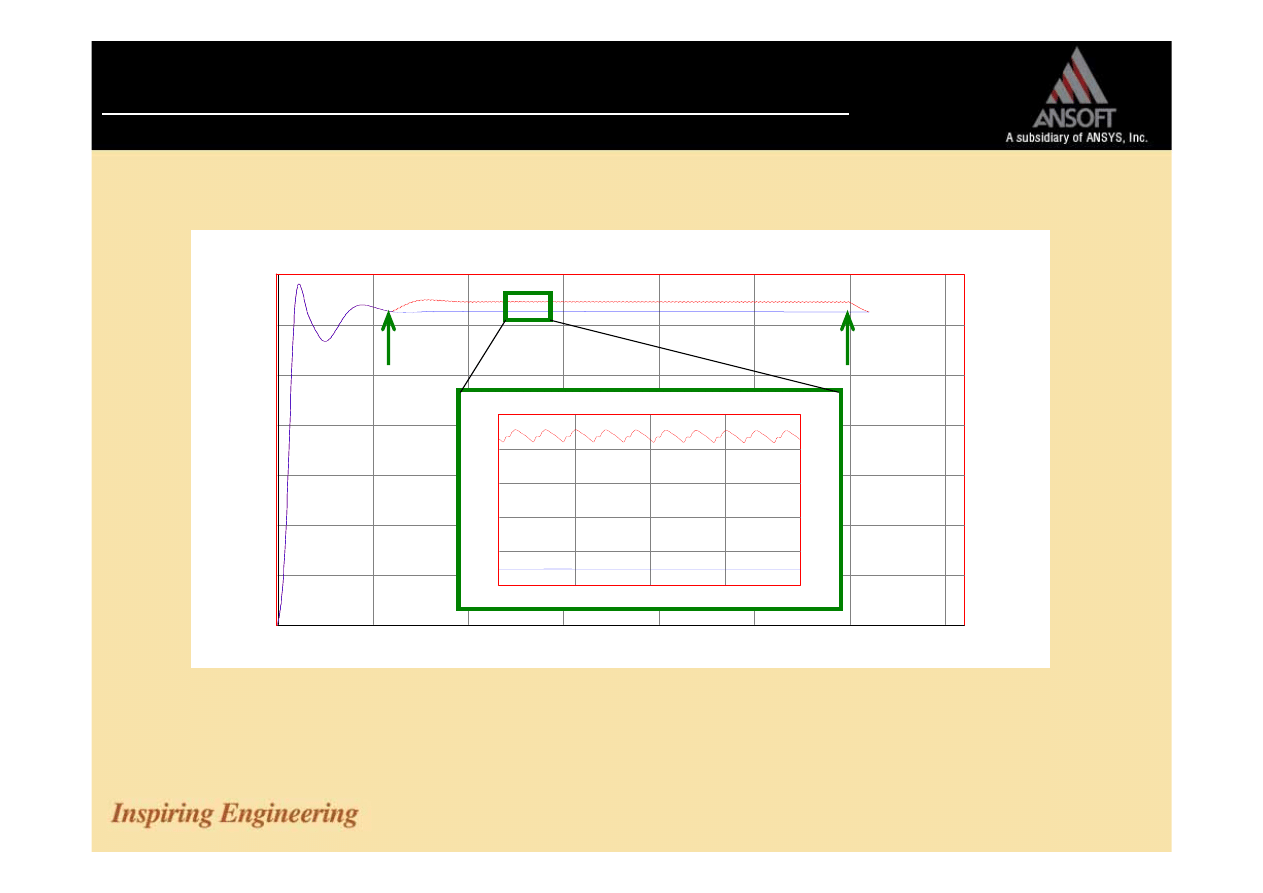

Oscillation control / phase compensation

Input

PI_3

iq

id

GA IN

C ON ST

Ps

Omeg a

Motor.ke

Motor.l1d

P Gain 13 /*20*/

I Gain 3 /*10 */

C ON ST

TR ef

TBar.TORQUE

GA IN

1/(1.5 * Motor.ke * Motor.p)

G(s)

GS1

-10.00

10.00

0

0

1.00

500.00m

操舵 量

S _ROT B 1.P HI [deg

-7.60

7.55

0

0

1.00

500.00m

モータトルク [Nm]

Motor.mi

-1.00m

1.03

500.00m

0

30.00m

10.00m

20.00m

モータトルク [Nm]

Motor.mi

Motor Torque

(Zoom )

( )

s

s

G

c

c

s

⎟

⎠

⎞

⎜

⎝

⎛

+

⎟

⎠

⎞

⎜

⎝

⎛

+

=

ω

ω

1

.

0

1

1

1

Primary progress compensation

• The oscillation frequency of the mechanical system was avoided and

the torque assistance was attained.

Steering Angle 10[deg]

Motor Torque [Nm]

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

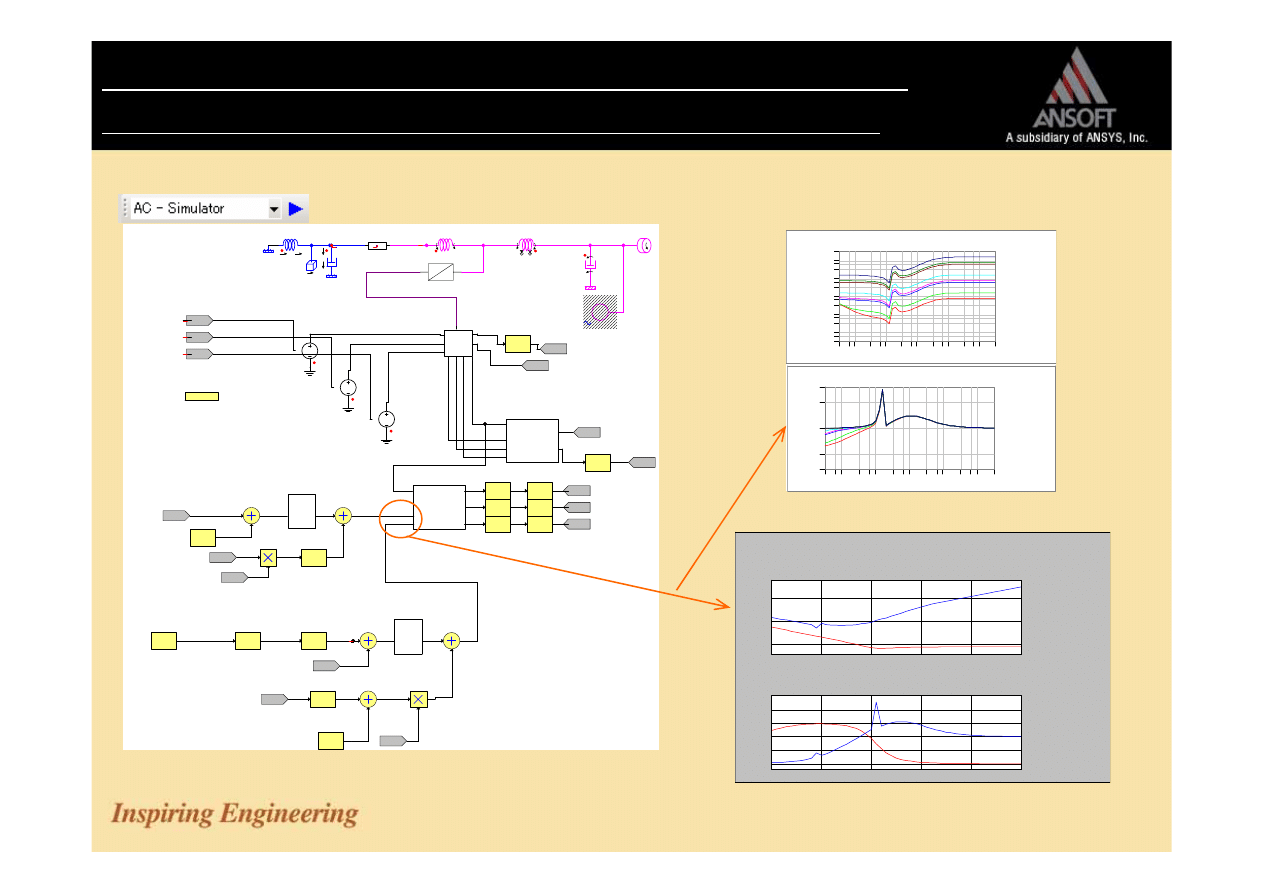

VHDL-AMS model can use AC simulation.

System stability : mechanics + controls

shaft

c

b

a

Motor

E1

E2

E3

Φ

+

D2D

ROT

ROT_V

TBar

D2D1

theta

d

q

GAIN

GAIN

GAIN

GAIN

GAIN

GAIN

a

b

c

theta

Input

CONST

GAIN

Input

GAIN

CONST

GAIN

GAIN

CONST

GAIN

G(s)

dq_abc

1/(DC_bus/2)

Vref_u

Vref_v

Vref_w

abc_dq

PI_1

P_Gain 0.5

I_Gain 2

Omega

N

Omega

id

id

iq

Idref

Motor.l1q

PI_3

P_Gain 13/*13*/

I_Gain 3 /*3*/

iq

id

Motor.l1d

Psi

Motor.ke

Omega

Motor.p

TRef

TBar.TORQUE

1/(1.5 * Motor.ke * Motor.p)

GS1

ICA:

Friction:=8e-3

deadtime:=5u

DC_bus:=12

iq

Vref_u

Vref_v

Vref_w

BodePlotSel9

dq_abc.d

dq_abc.q

Gain

Phase

1

1

10

10

100

100

1k

1k

10k

10k

100k

100k

1

1

10

10

100

100

1k

1k

10k

10k

100k

100k

136.82

0.00

50.00

100.00

136.82

0.00

50.00

100.00

44.85

-180.00

-135.00

-90.00

-45.00

0.00

44.85

-180.00

-135.00

-90.00

-45.00

0.00

f [Hz]

f [Hz]

[dB]

[deg]

Transfer characteristic of control system

10.00u

1.00

200.00u

2.00m

20.00m

1.00

100.00k

20.00 200.00 2.00k

2DGraphSel5

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

-3.14

3.14

0

1.00

100.00k

10.00 100.00 1.00k

2DGraphSel5

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

dq_ab...

GAIN

PHASE

Transfer characteristic of control system ( KP dependency)

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

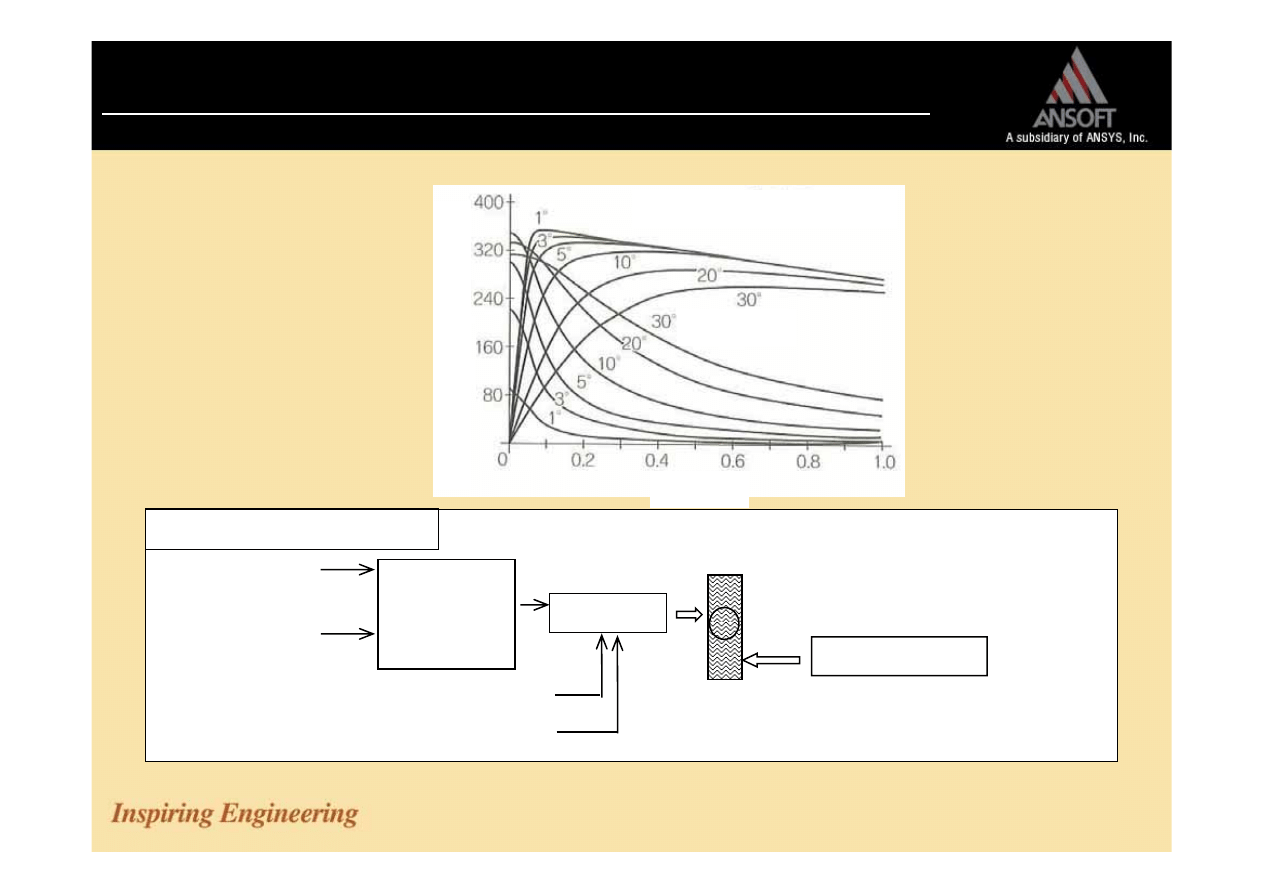

The modeling of side-force by a tire.

Slip rate

Side angle

Traction force, Side fo

rce [kgf]

Perpendicular load 380[kgf]

Side force

Slip rate

Slip

Vehicle speed

Slip angle

Rotational

Speed of tire

Load

Force of Rack F

Diagram of side force of Tire

Gap of a rack and rotational center : R

Sidewall equivalent radius : Rc

Ref. ISBN 4-381-08855-7

β

Fs

v

ω

v

V

mg

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

VHDL-AMS code

R

V

F

R

T

×

=

×

=

ω

)

,

(

/

)

(

β

µ

ω

β

ω

Slip

F

dt

V

V

Slip

lookup

v

v

v

=

=

−

=

∫

)

(

Fs

R

T

J

mg

Fs

×

−

=

⋅

=

ω

µ

&

begin

T == R * F ;

V == omg * R ;

if

(vv'dot <

0.0

)

use

slip_rate == (vv-ww)/vv ;

else

slip_rate == (ww-vv)/ww ;

end use

;

beta == omg'integ ;

mur == lookup_SideFC(slip_rate,

abs

(beta)) ;

Fs == mur * mass *

9.8

* sign(beta);

J * omg'dot == (T- Fs*R) ;

end architecture

beh ;

Slip rate

• VHDL-AMS model expresses definitional equations directly.

Friction Coeff.

Equations

Translation <> Rotation

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

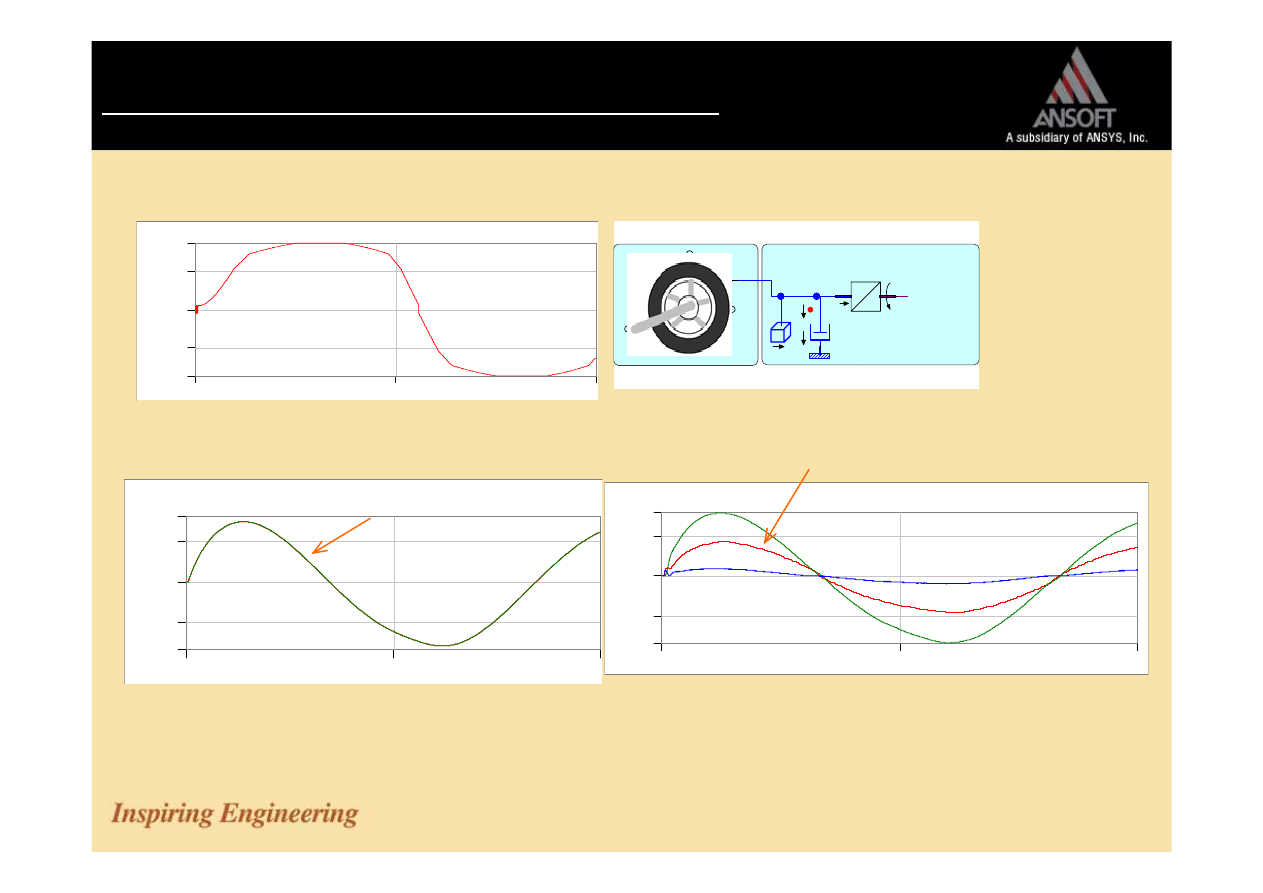

Nonlinear side force model

-4.20

4.00

0

0

1.00

500.00m

TBar.TORQUE [Nm]

SPRING_ROTB2.TORQUE [Nm]

-4.20

4.00

0

0

1.00

500.00m

トーションバー・トルク

TBar.TORQUE [Nm]

SPRING_ROTB2.TORQUE [Nm]

Motor.mi

-4.20

4.00

0

0

1.00

500.00m

トーションバー・トルク

TBar.TORQUE [Nm]

SPRING_ROTB2.TORQUE [Nm]

Motor.mi

TR1

ROT2

TSF

tra

Wheel_dynamics

-35.00

34.80

-20.00

0

20.00

0

1.00

500.00m

タイヤ横力 [kgf]

Steering torque = side force torque

Steering torque reduces as 1/2

• Nonlinear side force mapping.

• Confirm reducing steering force by assist motor.

w/o Power Assist

with Assist

Side force of Tire [N]

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

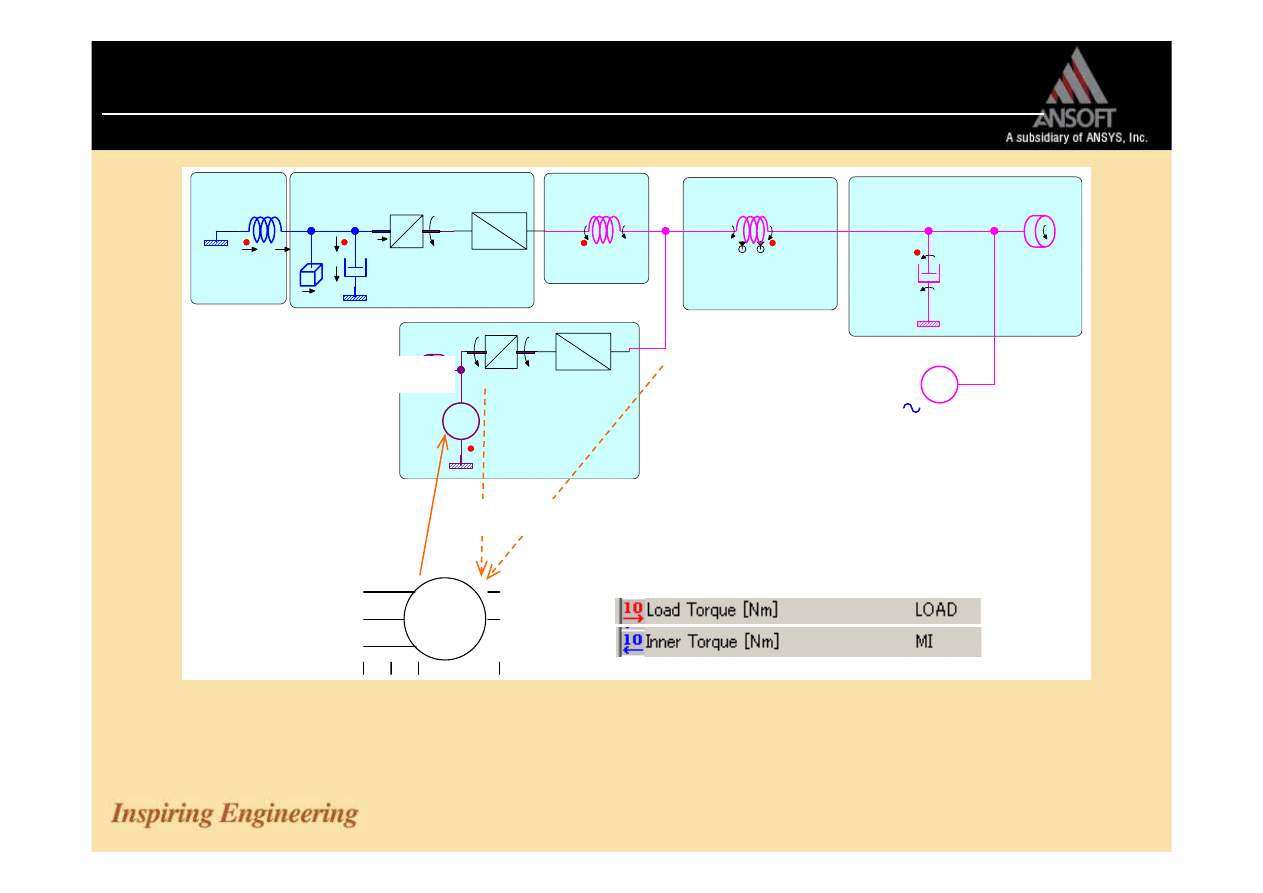

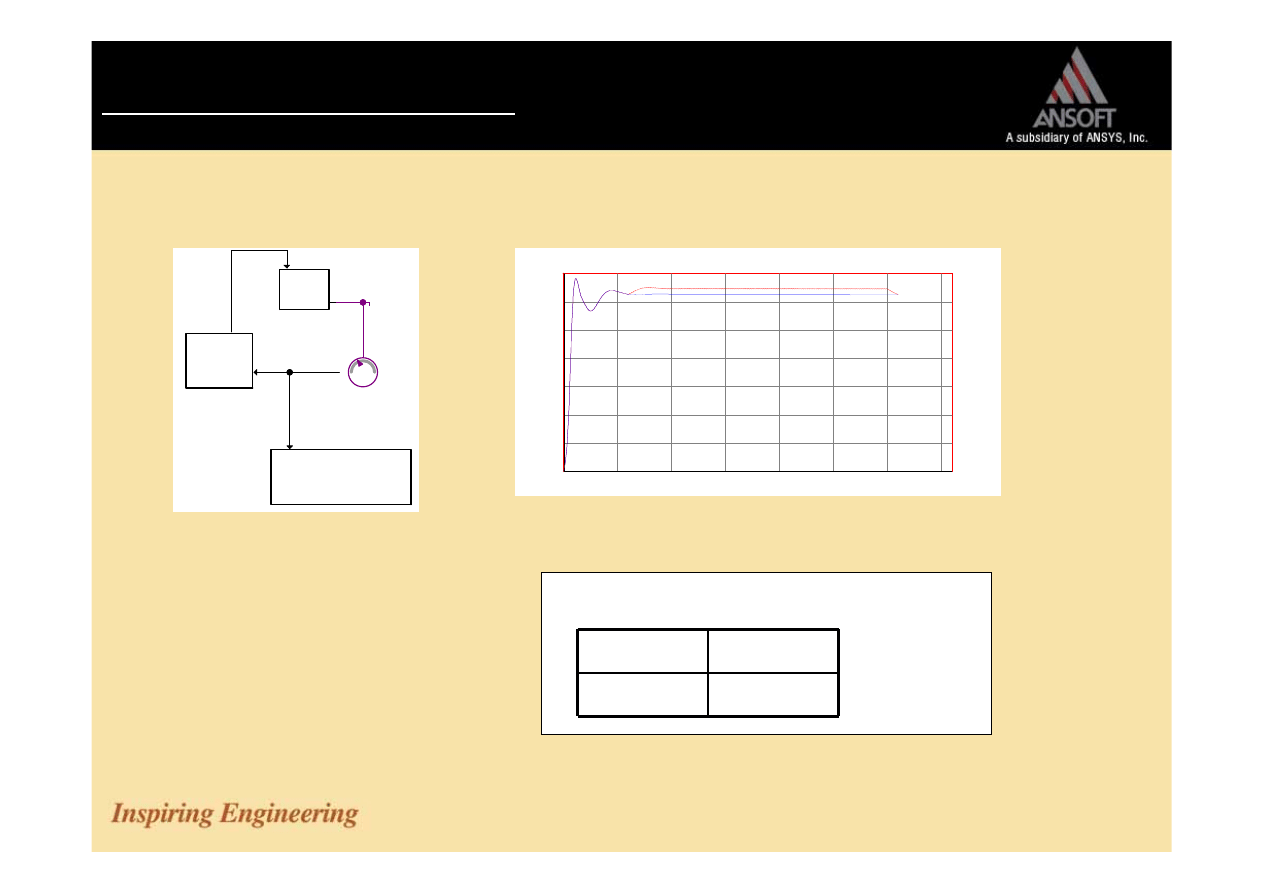

System Simulation

CONST

TRef

TBarAMS.m

TR1

ROT2

TSF

ROT1

ROT2

TSF

ROT

ROT_V

ROT

ROT_V

T

FM_ROT1

G(s)

ハンドル

操舵量

トーションバー

インタミ

ラック・ピニオン

反力

ピニオン

Φ

Φ

+

GAIN

1/2

AssistGain

W

+

WM_T

W

W

+

WM1

shaft

dcn

dcp

M

INV

Ave

~

Motor

tra

Tire

Y

t

GAIN

DATAPAIRS1

Battery

-

+

fp

fm

np

nm

SYM

PI

100 %

1

1

2

MRV

ω

ω

+

Pulley_ratio

Engine

VM_Eng

ECU

DCp

Fuel_Calc

Name

Value

Fuel_Calc.fc

9.7746m

DCp

Energy Balanced Model

Mechanics

Power supply

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

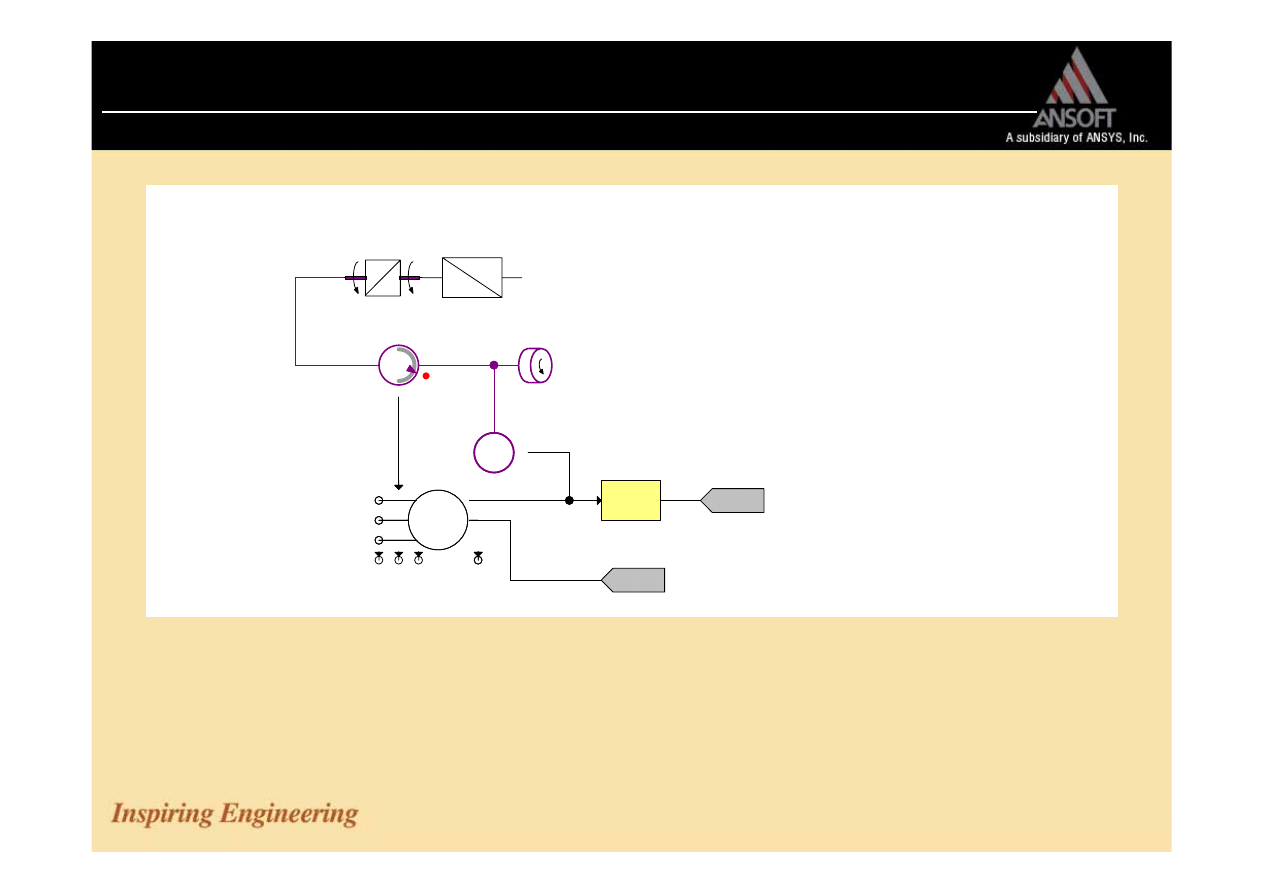

Components

•

Motor + Inverter

– Energy balanced model written by VHDL-AMS.

•

Power sources

– Battery : Automotive Library (Lead Acid battery)

– Alternator : Automotive Library (Averaged Model)

– Engine : Torque source (Throttle controlled torque source with

Torque-RPM lookup table)

– ECU : Analog PI control ( to keep RPM as idle )

MRV

T

X Y

Trq_per_ro

+

ω

+

AxWM

10

ThrPct

DAMP_ROT1

INPUT

Power

Motor Power OUT

Motor Losses

Inverter Losses

Engine model

RPM vs. Torque

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

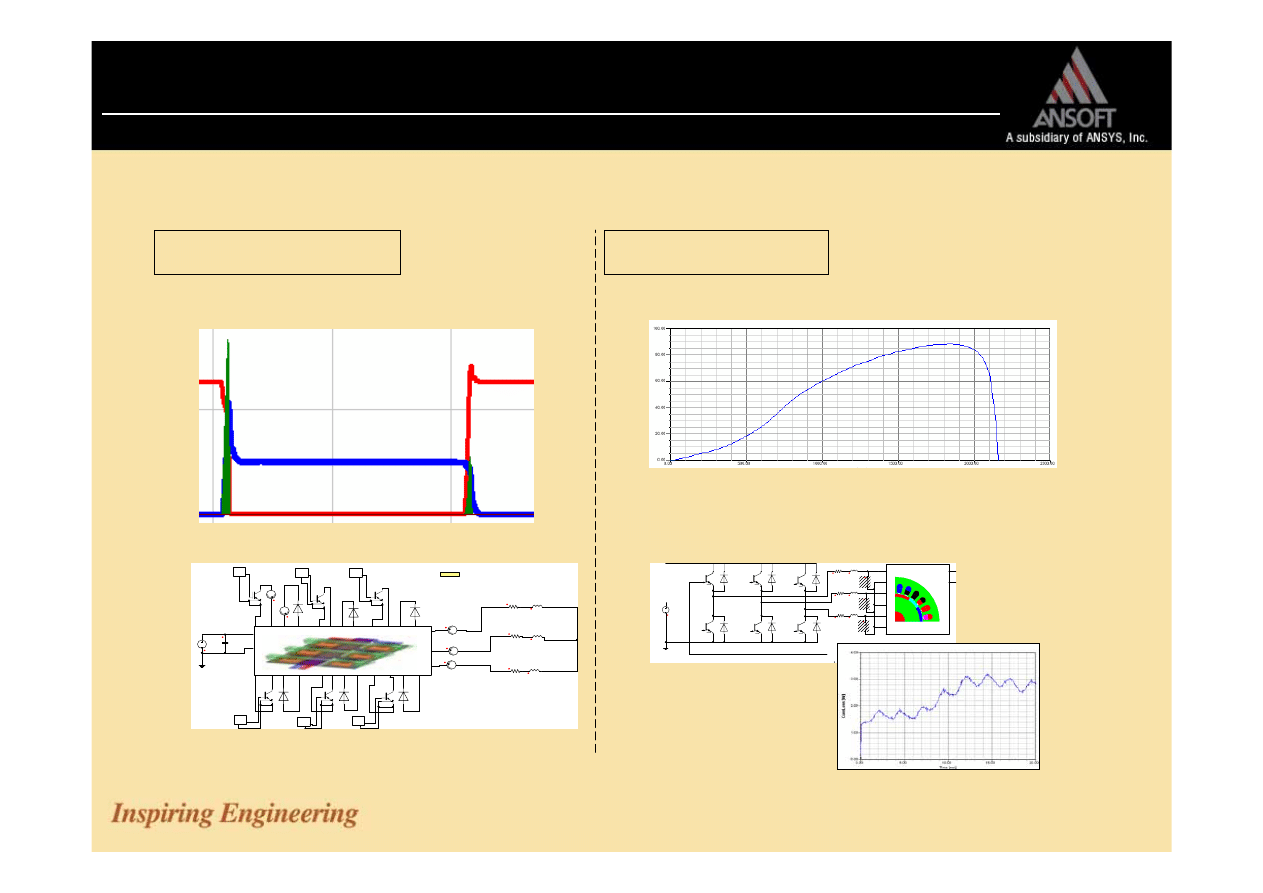

High Accuracy Estimation of Efficiency

for Inverter Losses

for Motor Losses

• Device Level IGBT and Diodes

• Easy estimation by

RMxprt

Ic

Vce

Loss:ON

Loss:Off

200

RA

LA

Lcoil

Rcoil

RC

Rcoil

RB

Rcoil

A

IA

A

IB

A

IC

ICA:

Rcoil := 178m

LB

Lcoil

LC

Lcoil

Lcoil :=2.46m

Pp := 4

Turns := 9

Pars := 2

500u

200

E

G

E

G

E G

E

G

E

G

E G

A

A

AMuIfw

AMuIC

WiHE

WdHA

WiHC

WdHC

ViHC

VdHC

UiHC

UdHC

ViHE

VdHA

UiHE

UdHA

w

VccP

V

u

VccN

WiLC

WdLC

ViLC

VdLC

UiLC

UdLC

WiLE

WdLA

ViLE

VdLA

UiLE

UdLA

Sheet7

• Parasitic LCR with

Q3D

• Core Loss from

Maxwell 2D/3D

Speed

Efficiency

FEA

sourceA1

sourceA2

sourceB1

sourceB2

sourceC1

sourceC2

Magnet01

Magnet02

Q1

Q2

Q3

Q5

Q4

Q6

400 V

RA Ohm

LL H

LDUM H

Core Loss vs. time

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

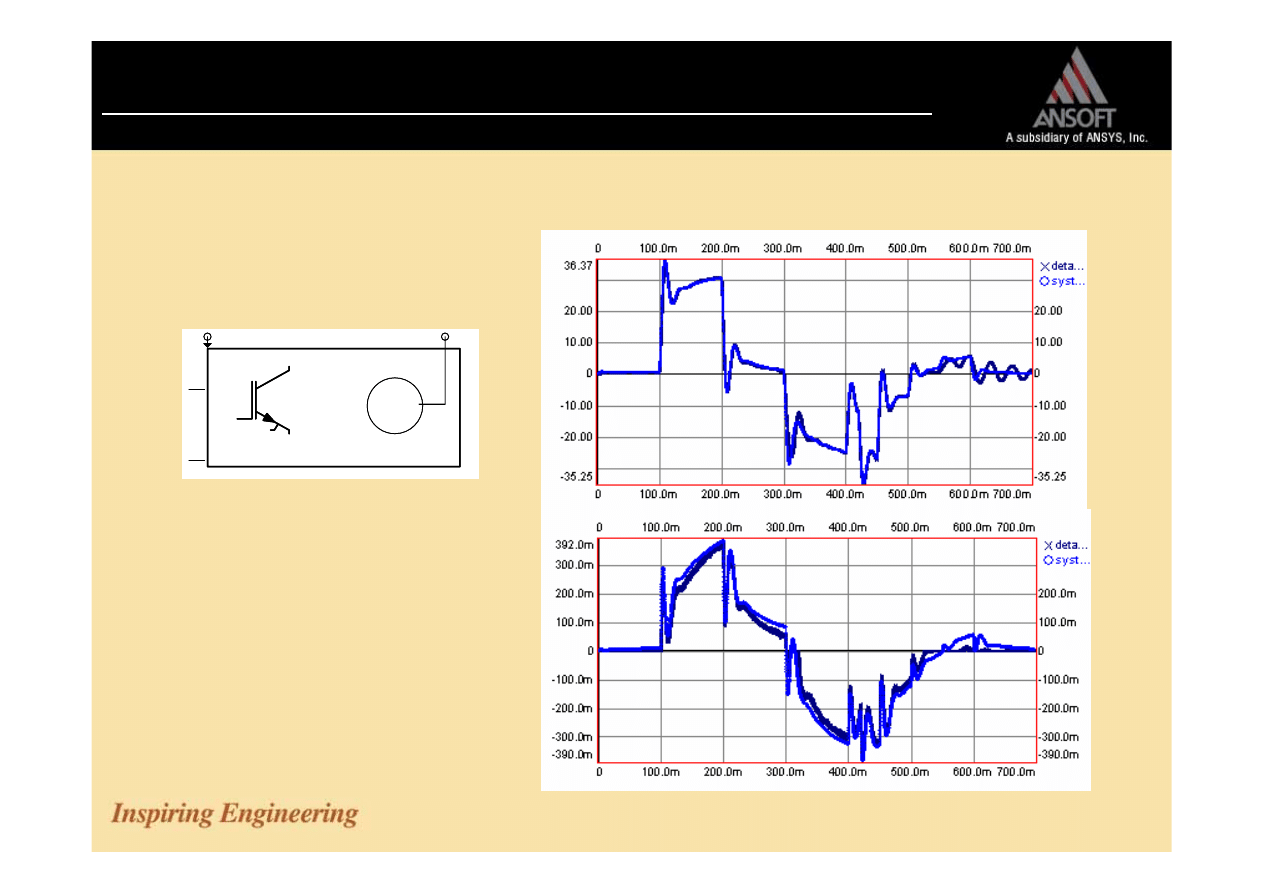

Energy Balanced model verification.

Motor Rotation Speed [RPM]

Motor Torque [Nm]

shaft

dcn

dcp

shaft

dcn

dcp

M

INV

Ave

~

Input :

Reference Torque

Equation

ω

η

η

⋅

=

⋅

⋅

T

I

V

inv

motor

T

T

J

ref

+

=

ω

&

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Simulation result : Battery Voltage

wEPS

woEPS

0

0

180.0

180.0

25.0

25.0

50.0

50.0

75.0

75.0

100.0

100.0

125.0

125.0

150.0

150.0

2.500

12.500

3.100

2.600

12.600

2.700

12.700

2.800

12.800

2.900

12.900

3.000

13.000

(1)

(2)

(1) : t= 30 : start EPS control

(2) : t=150 : end EPS control

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Simulation result : Engine Speed

wEPS

woEPS

0

0

180.0

180.0

25.0

25.0

50.0

50.0

75.0

75.0

100.0

100.0

125.0

125.0

150.0

150.0

0

0

700.0

100.0

100.0

200.0

200.0

300.0

300.0

400.0

400.0

500.0

500.0

600.0

wEPS

wo...

60.00

60.00

70.00

70.00

62.50

62.50

65.00

65.00

67.50

67.50

625.0

625.0

650.0

630.0

630.0

635.0

635.0

640.0

640.0

645.0

(1)

(2)

(1) : t= 30 : start EPS control

(2) : t=150 : end EPS control

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Fuel Consumption

wEPS

woEPS

0

0

180.0

180.0

25.0

25.0

50.0

50.0

75.0

75.0

100.0

100.0

125.0

125.0

150.0

150.0

0

0

700.0

100.0

100.0

200.0

200.0

300.0

300.0

400.0

400.0

500.0

500.0

600.0

MRV

ω

+

Engine

VM Eng

ECU

Fuel Calc

• 4 cycle engine

• Displacement : 1800[cc]

• ideal Air-Fuel ratio : 14.7

• Specific gravity : C

7.5

H

13.5

Engine rotational speed

Total Fuel consumption @2.5[min]

]

[

l

m

With EPS

26.8

WO EPS

26.1

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Summary

• The construction method of the mechanical load model by

using SIMPLORER.

• By using VHDL-AMS, modeling with high degree of

freedom or more was able to be made easily.

• In addition, it introduced the continuousness to the system

simulation of power consumption and components

simulation.

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

Conclusions

•

SIMPLORER can be as a communications tool that the designer of an

electric equipment and the designer of the regulating system guess the

function from the viewpoint of power consumption.

•

The equipment designer can optimize it by sharing the model under a more

concrete environment.

•

For a system designer, over-specked apparatus is presumed and the whole

cost can be reduced.

•

The model construction in standard language VHDL-AMS has a high ability

for such a demand, and the importance increases.

自動車工学入門 :野崎博路 著:山海堂 ISBN 4-381-08855-7

自動車工学 –基礎- :: (社)自動車技術会 ISBN 4-915219-30-5

車両システムのダイナミクスと制御:(社)日本機会学会:養賢堂: ISBN 4-8425-9901-4

電動機制御工学 〜可変速ドライブの基礎〜:松瀬貢規 著:電気学会/オーム社 ISBN 978-4-88686-255-6

© 2008 Ansoft, LLC All rights reserved.

Ansoft, LLC Proprietary

• Thank you

Wyszukiwarka

Podobne podstrony:

Modeling and Control of an Electric Arc Furnace

integration and radiality measuring the extent of an individuals connectedness and reachability in a

[Engineering] Electrical Power and Energy Systems 1999 21 Dynamics Of Diesel And Wind Turbine Gene

(WinD Power) Dynamic Modeling of Ge 1 5 And 3 6 Wind Turbine Generator {}[2003}

MODELING OF THE ACOUSTO ELECTROMAGNETIC METHOD FOR IONOSPHERE MONITORING EP 32(0275)

Home Power Magazine Issue 109 Extract pg22 Making Sense of Solar Electricity Costs

Whittaker E T On an Expression of the Electromagnetic Field due to Electrons by means of two Scalar

Haisch Update on an Electromagnetic Basis for Inertia, Gravitation, Principle of Equivalence, Spin

US Patent 511,560 System Of Electrical Power Transmission

US Patent 405,859 Method Of Electrical Power Transmission

Modeling of Polymer Processing and Properties

Pancharatnam A Study on the Computer Aided Acoustic Analysis of an Auditorium (CATT)

Hydrodynamic Modeling Of Sailing Yachts(1)

Sinners in the Hands of an Angry GodSummary

POWER STEERING

więcej podobnych podstron