Chemical Engineering Science, Vol. 53, No. 18, pp. 3189—3197, 1998

( 1998 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

PII: S0009–2509(98)00103–1

0009—2509/98/$—See front matter

Numerical study on

sublimation–condensation phenomena

during microwave freeze drying

Zhao Hui Wang* and Ming Heng Shi

Department of Power Engineering, Southeast University, Nanjing 210018, People’s Republic of

China

(Received 20 September 1997)

Abstract—A sublimation—condensation model is developed for freeze drying of unsaturated

porous media. The governing equations describing the drying process are solved numerically

with variable time step finite-difference method. The sublimation—condensation phenomena

during microwave freeze drying are studied numerically for different operating conditions

including electric field strength, sample thickness, and vacuum pressure. The results show that

the sublimation—condensation effects depend on different drying conditions. For larger electric

field strength, vapor transfer in sublimation—condensation region is more intensive and larger

part of the vapor is sublimated from this region, so the effect of sublimation—condensation

region on drying time is more significant. Too large electric field strength is not necessary for

microwave freeze drying. In case of larger sample thickness, the saturation change of the

sublimation—condensation region is larger, and the effect of sublimation—condensation region

on drying time is more significant. The effect of vacuum pressure on drying time is not so

significant in the observed range.

( 1998 Elsevier Science Ltd. All rights reserved.

Keywords: Drying; heat transfer; mass transfer; numerical analysis; porous media.

INTRODUCTION

In spite of the high cost, the demand for freeze-dried

products has been growing rapidly, and the freeze

dehydration has been applied as a key operation in

many new areas. In order to decrease the drying time

and increase the product quality, many ways to en-

hance the heat supply have been investigated.

The earliest work on heat and mass transfer mecha-

nism of freeze drying concentrated on the basic trans-

port phenomena. The transport properties such as

permeability, diffusivity, and thermal conductivity of

the materials dried were measured experimentally un-

der the conditions of low temperature and vacuum

pressure (Harper, 1962; Lusk et al., 1964; Massey and

Sunderland, 1967; King et al., 1968). In 1967, Sandall

et al. predicted the freeze drying rate with a pseudo-

steady model of heat and mass transfer, and Dyer and

Sunderland (1967) suggested a simple transient heat

transfer model for the freeze drying. As a significant

improvement, Fox and Thomson (1972) analyzed the

freeze drying process with an unsteady drying model

of coupled heat and mass transfer. Ma and Peltre

(1975) proposed an unsteady heat and mass transfer

model with internal heat generation for microwave

*Corresponding author. E-mail: zhwang@seu.edu.cn.

freeze drying. Numerical analysis was employed in

their research of freeze-drying process for the first

time.

After the Luikov’s theory (1975) of heat and mass

transfer in porous media was presented on the basis of

the irreversible thermodynamics, the study on heat

and mass transfer of freeze drying got to focus on the

solution to this model and the analysis of transport

mechanisms by using this model. Lin (1981, 1982)

obtained the analytical solutions in cases of constant

and variable temperature of sublimation front. Fey

and Boles (1987a, b) studied the effects of convection

heat transfer and compared the mass transfer between

the Darcy’s flow and the Fick’s diffusion with their

analytical solution.

All the models discussed above considering that

phase change of freeze drying at the sublimation inter-

face are called sublimation interface model. Fey and

Boles (1988) considered the frozen materials with

frozen water initially partially and fully filled and

proposed a model to describe the heat and mass

transfer in the unsaturated frozen region based on the

Luikov’s system. The water vapor recondensation

process in the frozen region was analyzed in this

model, but the saturation change of frozen region

caused by recondensation was not considered. The

transport coefficients in the model were also con-

sidered as constant.

3189

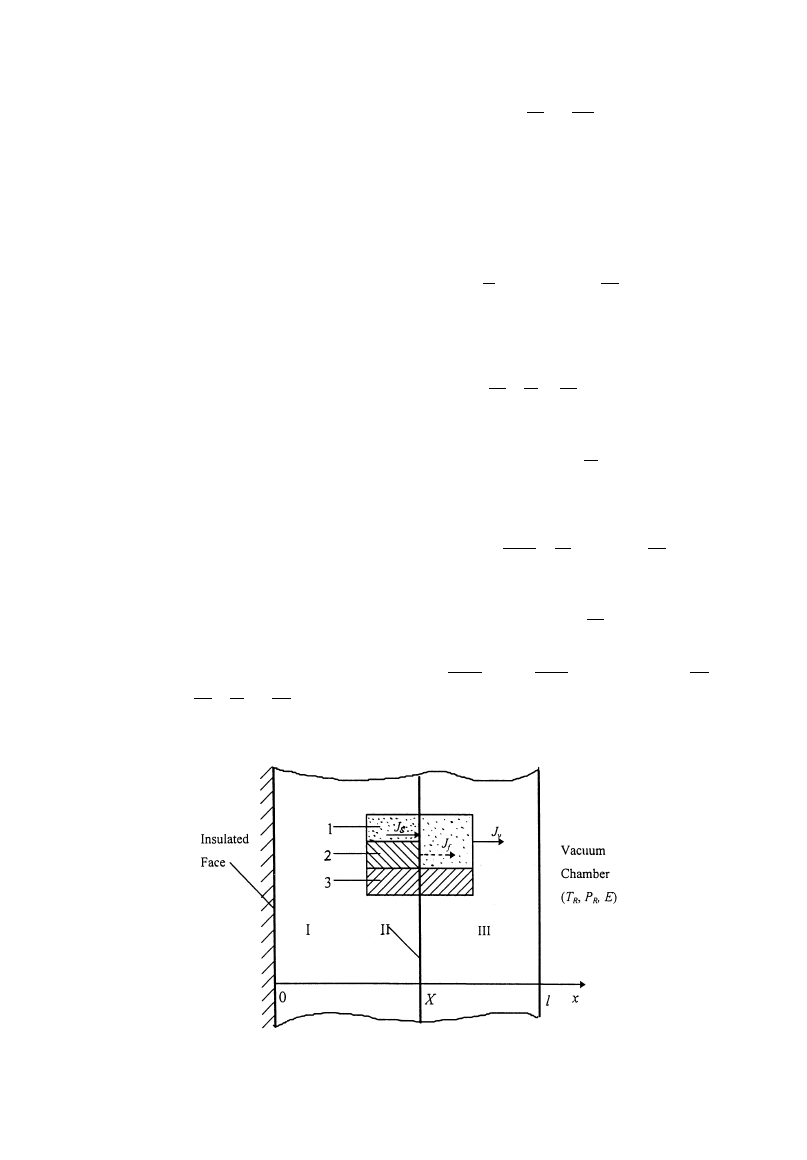

Fig. 1. Physical model of sublimation—condensation. I—Sublimation—condensation region; II—Sublima-

tion front; III-Dried region 1—vapor (

e(1!S)); 2—ice (eS); 3—solid body (1!e).

Based on the volume average theory for heat and

mass transfer in porous media by Whitaker (1977),

this paper developed a sublimation—condensation

model for freeze drying of unsaturated porous media.

The model considered the saturation change in frozen

region, which is called as sublimation—condensation

region in this article. Because the coefficients used in

our model are measurable, it is believed that this

model is more applicable in practice. Numerical simu-

lation of microwave freeze drying of unsaturated por-

ous media was conducted by using the variable time

step finite-difference method. The effects of operating

conditions including electric field strength, sample

thickness and vacuum pressure on the heat and mass

transfer in the sublimation—condensation region and

the drying time of the drying process were primarily

discussed.

MATHEMATICAL MODELING

Figure 1 illustrates an one-dimensional unsaturated

porous medium slab to be freeze-dried with micro-

wave heating. In the environment where the pressure

is below the triple point, the material includes

dried region and sublimation—condensation region

separated by a sublimation front. It is assumed

that water vapor is the only gas in the vacuum

chamber and ideal gas law is applicable. In addition,

the material is considered rigid, homogeneous, and

isotropy.

Dried region

The heat and mass transfer equations in the dried

region can be written as

Mass transfer

e

Lov

Lq

"

L

Lx

A

De

Lov

Lx

B

(1)

Heat transfer

oc

L¹

Lq

"

j

L2¹

Lx2

#

q

(2)

where q is microwave internal heat source.

According to the results of Dyer and Sunderland

(1968), convection heat transfer is neglected in the

energy equation of dried region.

Sublimation-condensation region

The vapor continuity equation can be obtained as

L

Lq

[(1!S)

eov]"!

LJS

Lx

#

I.

(3)

If the heat transfer caused by vapor convection is

neglected, the energy balance equation in sublima-

tion—condensation region changes to

oc

L¹

Lq

"

L

Lx

A

j

L¹

Lx

B

!

I

*H#q

(4)

The vapor source I in this region is defined as

I"!u4!5

LS

Lq

.

(5)

Based on the Darcy’s law and Fick’s law, the vapor

flow in this region can be written as

JS"!

KDKr

kv

ov

LP

Lx

!

(1!S)

eD

Lov

Lx

.

(6)

For saturated vapor of ideal gas, we have

JS"!KS

L¹

Lx

(7)

where

KS"

KDKr

kv

R

o2v#

C

KDKr

kv

R

ov¹#e(1!S)D

D

d

ov

d¹

.

(8)

3190

Z. H. Wang and M. H. Shi

Based on the fact that

eov

u4!5

(

ov

u4!5

;

1

(9)

the following equation can be obtained from eqs (3),

(5), and (7)

I"

e(1!S)

d

ov

d¹

)

L¹

Lq

!

L

Lx

A

KS

L¹

Lx

B

.

(10)

Replacing vapor source I by eq (10), eq. (4) becomes

[

oc]e

L¹

Lq

"

L

Lx

A

je

L¹

Lx

B

#

q

(11)

where

[

oc]e"oc#e(1!S)

d

ov

d¹

*H

(12)

je"j#*HKS.

(13)

Combining eqs (5), (10) and (11), we have

!

u4!5

LS

Lq

"!

L

Lx

A

KS

L¹

Lx

B

#

fT

L

Lx

A

je

L¹

Lx

B

#

fTq

(14)

where

fT"

e(1!S)

[

oc]e

)

d

ov

d¹

.

(15)

Equations (11) and (14) are the equations of heat

and mass transfer in sublimation—condensation re-

gion, respectively.

Sublimation front

If the vapor generated at the sublimation front is

formulated as

Jf"

A

!

u4!5S

dX

d

q

BK

x/X~

(16)

and the vapor flow in dried region is obtained as

Jv"!De

Lov

Lx

(17)

the mass balance equation at the front is

JvDx/X`!JSDx/X~"Jf

(18)

and the energy balance equation is

A

!

je

L¹

Lx

BK

x/X~

!

A

!

j

L¹

Lx

BK

x/X`

"

Jf *H. (19)

In order to quantify the contributions of JSDx/X~

and Jf to the drying rate per unit surface area, a new

parameter fJ is defined as

fJ"

JSDx/X~

JvDx/X`

(20)

where fJ represents the influence of sublimation phe-

nomena in sublimation—condensation region on heat

and mass transfer in the drying process.

Boundary conditions

Due to symmetry of the material, the boundary

condition at the center is

!

je

L¹

Lx

K

x/0

"

0.

(21)

The boundary conditions at the surface are

A

!

j

L¹

Lx

BK

x/l

"

a(¹ Dx/l!¹R)

(22)

ovDx/l"

PR

R¹

Dx/l

.

(23)

Initial conditions

¹

Dr/0"¹0

(24)

S

Dr/0"S0

(25)

X

Dr/0"l.

(26)

NUMERICAL PROCEDURE

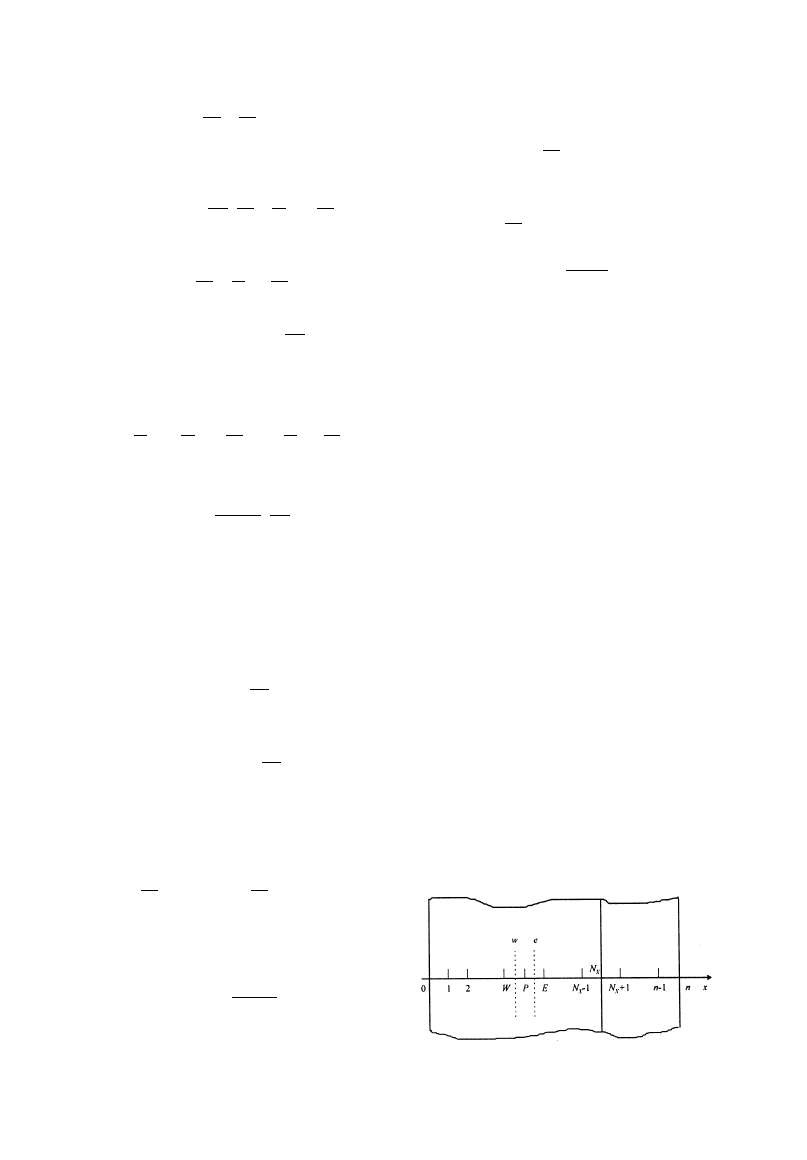

The governing equations, eqs (1), (2), (11), (14),

(16)—(19), and (21)—(26) were solved numerically by

using a variable time-step finite-difference method.

A control volume method was used to discretize the

equations uniformly and the grid nodes are located in

the centers of the control volumes as illustrated in

Fig. 2.

The discretization of the equations is given in the

appendix.

In principle, the temperature and ice saturation

profiles in the material can be obtained by solving the

matrix of the algebraic equations. Due to their nonlin-

earity, the temperature and saturation of the sublima-

tion front should be predicted at first in each iteration,

then the algebraic equation groups are solved for the

dried region and sublimation—condensation region

considering the sublimation front as the first kind of

boundary conditions.

In order to reduce the error caused by the explicit

format, a sufficiently fine grid was used. During the

program, test solutions for a typical operation were

obtained by utilizing different grid sizes to check the

grid independence. It was found that the difference of

drying time between the calculations of 200- and

250-grid is less than 0.1%. Thus, the 200-grid was

used in all subsequent computations. At each time

Fig. 2. Schematic for discretization of governing equations.

Sublimation—condensation study during freeze drying

3191

Table 1. Physical properties

Symbol

Value or expression

Unit

Reference

ci

2090

J/(kg °C)

Perry et al. (1992)

cs

1505

J/(kg °C)

calculated from Ma and Peltre

(1975)

D

2.51

]10~5](1.013]105/P)

m

2/s

Perry et al. (1992)

De

78.5

]10~4/(3.4#P/133.3)

m

2/s

Ma and Peltre (1975)

DH

2821500

J/kg

Perry et al. (1992)

KD

4

]10~8/P

m

2

Harper (1962)

Kr

1!S

—

—

u4!5

685

kg/m

3

Experiment

a

6.7

W/(m

2 °C)

Experiment

e

0.75

—

Experiment

ji

2.22

W/(m °C)

Perry et al. (1992)

js

0.2

W/(m °C)

Calculated from Ma and Peltre

(1975)

oi

913

kg/m

3

Perry et al. (1992)

os

320

kg/m

3

Calculated from Ma and Peltre

(1975)

ov

0.1

]exp(!53.7881#0.294552]¹

kg/m

3

Perry et al. (1992)

!

3.987875

]10~4]¹2)

increment, the solution is considered to have achieved

convergence if

K

¹P!¹0P

¹P

K

)

10

~5

(27)

and

K

SP!S0P

SP

K

)

10

~5.

(28)

The physical properties used in the calculation are

listed in Table 1.

The internal heat generation of microwave power

in eqs (2) and (11) is expressed as

q"kE

2

(29)

where k is obtained from Ma and Peltre (1975) for

dried beef and saturated frozen beef. The physical

properties of unsaturated frozen beef, such as dissipa-

tion coefficient, thermal conductivity, density, and

heat capacity, are calculated by volume-average

method.

RESULTS AND DISCUSSION

During microwave freeze drying of unsaturated

porous media, sublimation will take place not only at

sublimation front but also in sublimation—condensa-

tion region. In order to understand the drying mecha-

nism under various operating parameters in practical

freeze-drying process, the effects of those parameters

including electric field strength, vacuum pressure, and

sample thickness on the two kinds of sublimation are

discussed based on numerical calculation results.

A typical condition with initial saturation of S0"0.7

is

used.

The

reference

values

l"0.008 m,

E"120 V/cm, and PR"15 Pa are selected. In the

following calculations, only the parameters having

different values from reference are noted.

Heat and mass transfer in sublimation—condensation

region

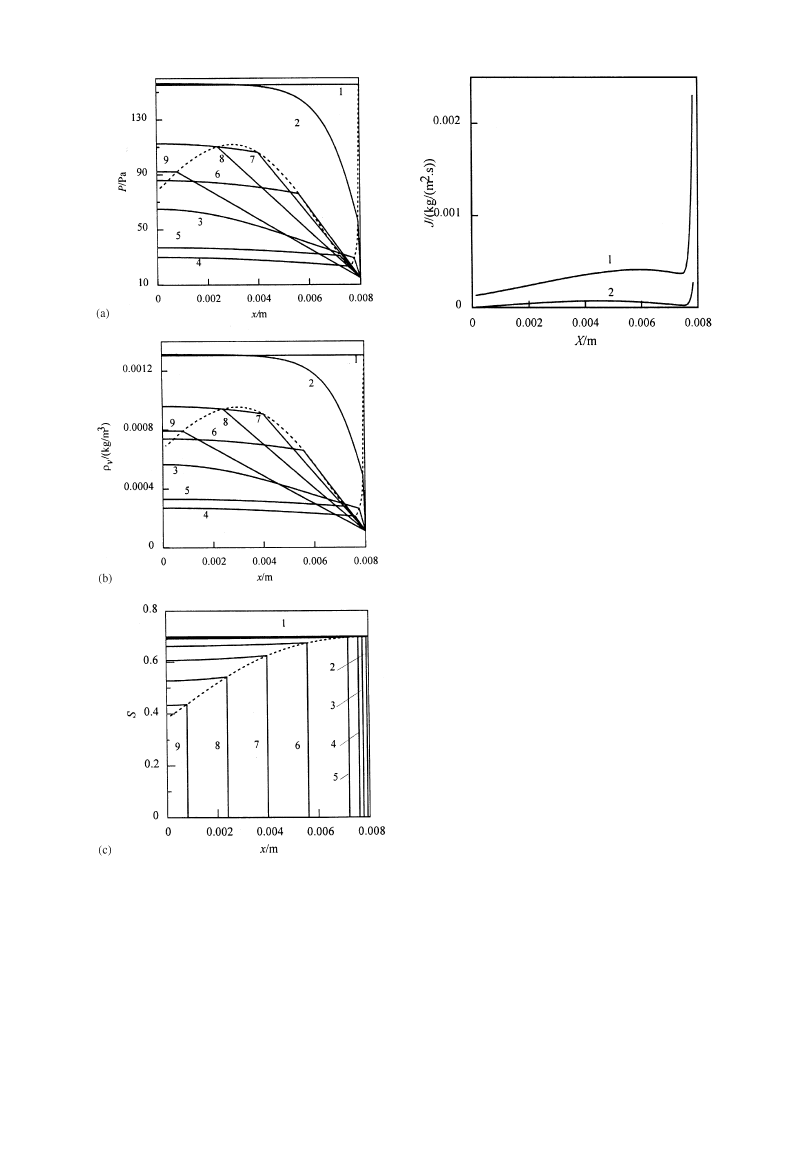

Figure 3 shows the distributions of pressure, vapor

density, and saturation in the material at different

times during drying. Figures 3(a) and (b) show that

the pressure and vapor density are of the similar

distributions. It can be seen that both the gradients of

pressure and vapor density in sublimation—condensa-

tion region are large in the initial period, then de-

crease and become less than those in dried region.

Though the gradients are much larger in dried region,

the vapor transfer exists in sublimation—condensation

region as expressed in eq. (6). The situation that the

pressure and vapor density decrease from the material

center to sublimation front as illustrated in Figs 3(a)

and (b) indicates that the vapor will be removed from

sublimation—condensation region. As a result, the ice

in sublimation—condensation region will sublimate

and the saturation in this region will decrease as

shown in Fig. 3(c). It can be seen that the saturation is

nearly in the uniform distribution in sublimation—

condensation region though it is larger near sublima-

tion front than in the center.

All the vapor sublimated in sublimation—condensa-

tion region joins the main flow in dried region. So the

drying rate in microwave freeze drying of saturated

porous media consists of the two flows attributed to

sublimation front and sublimation—condensation re-

gion. Figure 4 shows variation of the two vapor flows,

JSDx/X~ and JvDx/X`, illustrated in Fig. 1, with the

sublimation front at different positions. In fact,

JvDx/X` in the dried region is the drying rate per

unit surface area. JSDx/X~ is the vapor flow sub-

limated in the sublimation—condensation region while

JvDx/X`!JSDx/X~ is the vapor flow JfDx/X~ sub-

limated at the sublimation front. It can be seen

that both JSDx/X~ and JvDx/X` are large when the

3192

Z. H. Wang and M. H. Shi

Fig. 3. Profiles of pressure, vapor density, and saturation in

drying

q(s): 1—0; 2—0.1; 3—9; 4—76; 5—572; 6—2714;

7—4950; 8—7489; 9—10434. - - - Sublimation front.

sublimation front is near the surface. This is because

the mass transfer resistance is small in dried region for

the short mass transfer distance and pressure and

vapor density gradients are large in sublimation—con-

densation region when the temperature of sublima-

tion front is approaching wet bulb temperature of the

vacuum chamber at the beginning of drying. When

Fig. 4. Vapor flux at different positions of sublimation front.

1—JvDx/X`; 2—JSDx/X~.

the sublimation front shifts inside, the temperature of

sublimation front approaches wet bulb temperature

rapidly, the temperature distribution of sublimation

region becomes nearly a plateau, and the pressure and

vapor density gradients become small in sublima-

tion—condensation region as illustrated in Figs 3(a)

and (b). So JSDx/X~ decreases as shown in Fig. 4. In

the mean time, due to the increase of the mass transfer

resistance and the coupled effect of temperature,

JvDx/X` decreases. After the two flows pass the

smallest values in the initial period, they will increase

with the drying process. Then JvDx/X` becomes small-

er after X"0.0059 m while JSDx/X~ decreases after

X"0.0045 m.

Electric field strength

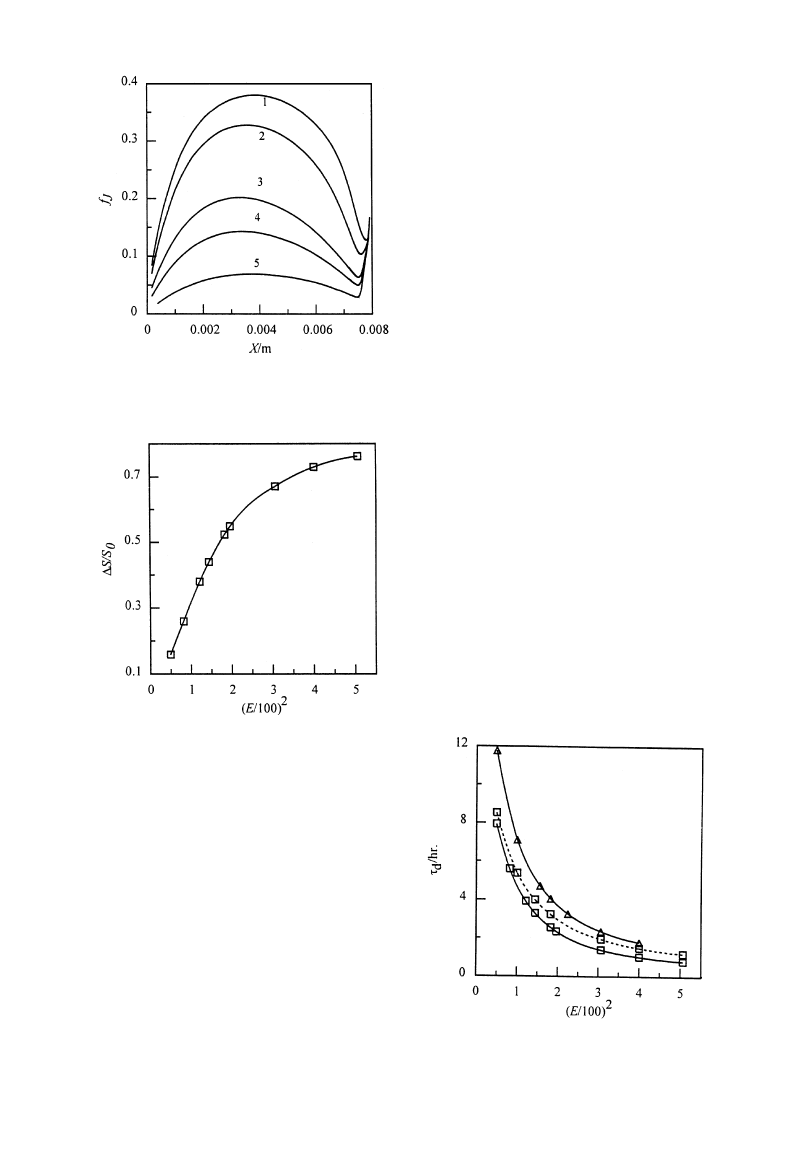

Effects on heat and mass transfer. Figure 5 illus-

trates the effect of electric field strength on fJ at

different sublimation front positions. It can be seen

that the curves are in the similar shape but fJ increases

with increasing electric field strength, E. As the elec-

tric field strength increases, the sublimation-conden-

sation region absorbs more energy and the average

temperature and temperature difference also increase.

Based on eq. (8), KS will increase exponentially with

the temperature in sublimation—condensation region,

resulting in the large vapor flow. There are significant

differences of fJ for different electric field strengths.

For example, the maximum fJ is 0.14 at E"100 V/cm

while 0.33 at E"175 V/cm except the initial period.

The sublimation will reduce the temperature differ-

ence in the sublimation—condensation region. This

means a more homogeneous heating in the sample

can be achieved and the probability of ice melting in

the frozen region of the material would be reduced at

higher electric field strength.

Due to the effect of electric field strength on vapor

transport, the sublimation phenomenon in sublima-

tion—condensation region is influenced by different

Sublimation—condensation study during freeze drying

3193

Fig. 5. Variation of fJ at different positions of sublimation

front E(V cm

~1); 1—225; 2—175; 3—120; 4—100; 5—70.

Fig. 6. Effects of E on sublimation—condensation region.

electric field strengths. Saturation change of sublima-

tion—condensation region for a complete drying pro-

cess is presented to illustrate the effect of electric field.

The calculation shows that the saturation distribution

in the sublimation—condensation region is a plateau

as shown in Fig. 3(c). Accordingly, the saturation of

sublimation front is applied to represent the satura-

tion variation of sublimation—condensation region

during the drying process. Figure 6 (in which,

*S"S0!S%/$) shows the relative difference of subli-

mation front saturation for the complete drying pro-

cess at different electric field strengths. The square of

electric field strength is used in abscissa axis of the

figure since the internal heat generation or the

strength of absorbed energy is in a square function of

electric field strength, E. The figure indicates that

a larger E value will cause a larger saturation change

of sublimation front. For example,

*S/S0 is about

44% for E"120 V/cm and 73% for E"200 V/cm. It

seems that increasing rate of

*S/S0 with (E/100)2 is

larger for lower electric field strength. The calculation

proves that melting phenomenon occurs ('!3°C)

when E*250 V/cm.

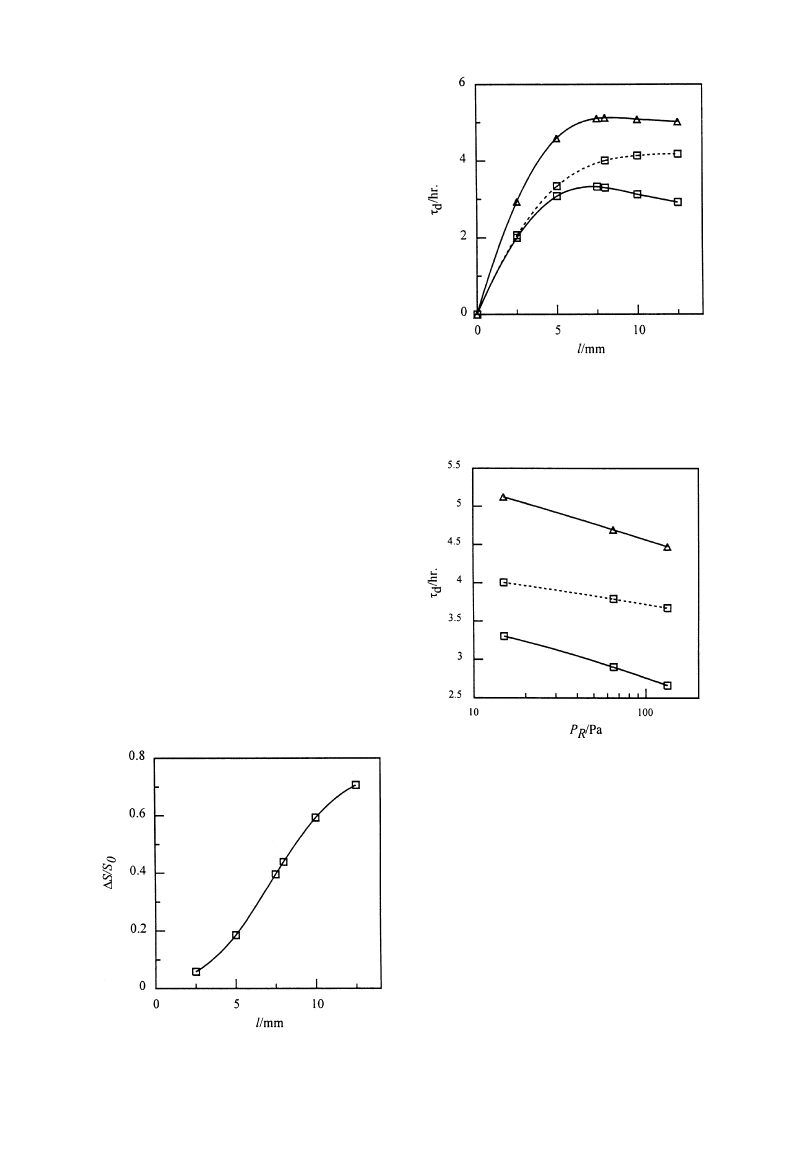

Effects on drying time. Figure 7 shows the drying

times at different electric field strengths under the

drying conditions of S0"0.7 and S0"1. In order to

study the effects of sublimation in sublimation—con-

densation region, the drying processes at S0"0.7 are

calculated by the sublimation interface model which

considers sublimation only at interface. The calcu-

lation results show that the difference of drying

time increases with E between the sublimation—

condensation and sublimation interface models. It

indicates that the influence of sublimation—condensa-

tion region on drying process is more significant for

larger E. This demonstrates that the sublimation—

condensation model is more applicable for practical

drying process.

Though no sublimation—condensation region exists

for saturated materials, the variation of drying time is

different from unsaturated materials. Simulation re-

sults show that drying time decreases with increasing

electric field strength for both initial saturation condi-

tions. However, the drying rates are different at differ-

ent S0. The drying times calculated from sublima-

tion—condensation model was used for S0"0.7. It

was observed that the ratio of the drying time at

S0"1 to that at S0"0.7 is about 1.48 for

E"70 V/cm and 2.0 for E"200 V/cm. As a result,

the advantage of using lower initial saturation is obvi-

ous for higher electric field strength. Unfortunately,

the melting phenomena occur at higher E value. The

calculation also shows that the critical E value of

melting is higher for lower S0. For example, the criti-

cal E value is about 225 V/cm for S0"1 while

Fig. 7. Effects of sublimation—condensation region on drying

time. (—) Sublimation—condensation model; (- - -) sublima-

tion interface model. S0: (K) 0.7; (n) 1.

3194

Z. H. Wang and M. H. Shi

250 V/cm for S0"0.7. Figure 7 also shows that de-

creasing rate of drying time becomes smaller when

electric field is strong, this means that the too large

electric field strength is not necessary for microwave

freeze drying.

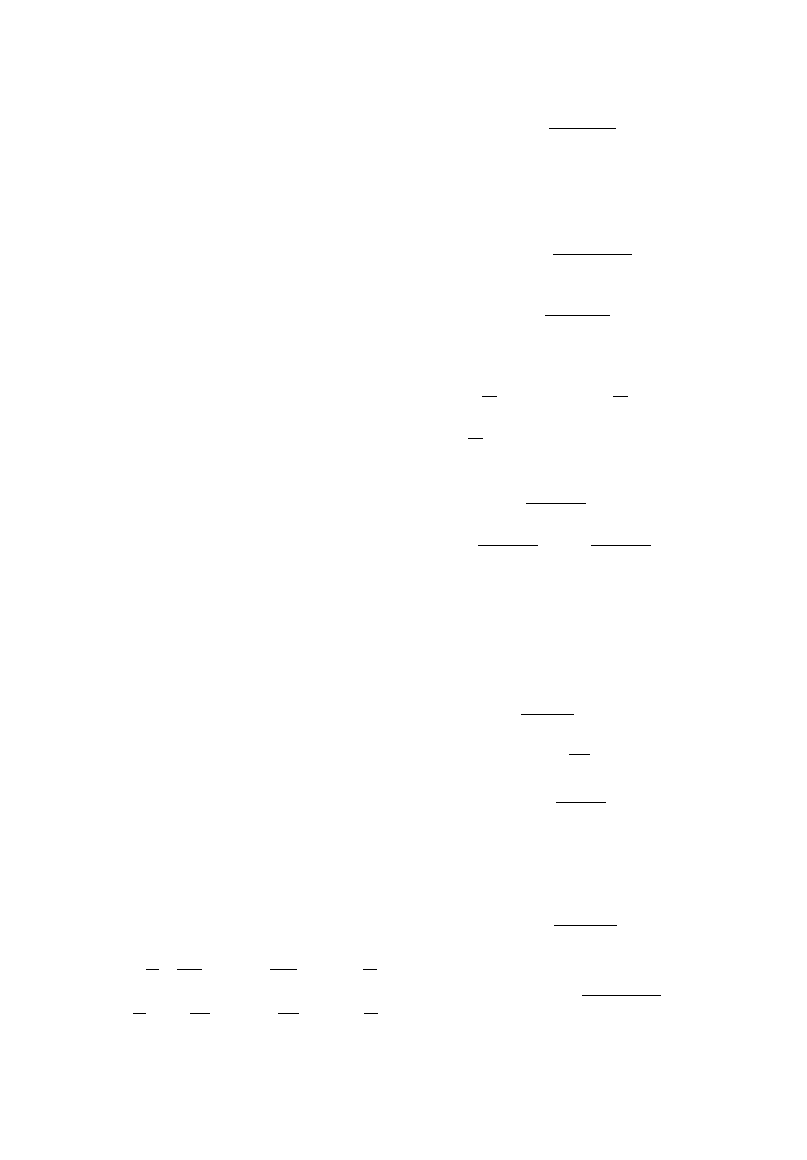

Sample thickness

Effects on heat and mass transfer. The calculations

show that more energy is absorbed by thicker samples

at a given electric field strength. On the other hand,

mass transfer resistance is greater for thicker samples.

Figure 8 shows the variation of

*S/S0 with half

sample thickness. In case of large sample thickness,

the influence of vapor sublimated from the sublima-

tion—condensation region is obvious, therefore the

saturation change of the sublimation—condensation

region is large. The figure also shows that

*S/S0

changes linearly with sample thickness and the change

rate is the largest in the range of l from 5 to 10 mm.

Thus, the

*S/S0 vs l plot is an ‘S’-shaped curve.

Effects on drying time. In order to compare the

effects of sublimation—condensation region on drying

process at different sample thicknesses, the calculated

drying times at S0"0.7 are illustrated in Fig. 9 from

sublimation interface and sublimation—condensation

models, respectively. It can be seen that the influence

of sublimation—condensation region on drying time

becomes more significant when sample thickness in-

creases. This indicates that the sublimation—conden-

sation region cannot be neglected in microwave freeze

drying of unsaturated porous media, especially for

larger scale samples. The drying time of saturated

material is also calculated for different sample

thicknesses as shown in Fig. 9. It shows that drying

time increases dramatically with sample thickness

increasing at 0 mm for both initial saturation condi-

tions. The drying times are almost independent of

sample thickness in case of l'5 mm. This is because

Fig. 8. Effects of half sample thickness on sublimation—con-

densation region.

Fig. 9. Effects of sublimation—condensation region on dry-

ing time. (—) Sublimation—condensation model; (- - -) subli-

mation interface model. S0: (K) 0.7; (n) 1.

Fig. 10. Effects of sublimation—condensation region on dry-

ing time. (—) Sublimation—condensation model; (- - -) subli-

mation interface model. S0: (K) 0.7; (n) 1.

the surface effects are more significant for thinner

sample.

The

melting

phenomena

occur

when

l'12.5 mm for S0"1, while l'15 mm for S0"0.7.

»

acuum pressure

Effects on heat and mass transfer. The sublimation—

condensation phenomena of unsaturated porous me-

dia were numerically studied at three vacuum pres-

sures. The calculation shows that the maximum

fJ increases from 0.2 at PR"15 Pa to 0.31 at

PR"133 Pa. This is because high vacuum pressure

causes high wet bulb temperature and high vapor

transfer resistance in the dried region, so the temper-

ature and vapor flow in sublimation—condensation

Sublimation—condensation study during freeze drying

3195

region are high. The numerical results also indicate

that

*S/S0 increases from 0.44 at PR"15Pa to 0.64 at

133 Pa. This means that higher vacuum pressure

causes greater effect on sublimation—condensation re-

gion and will produce greater effect on drying time.

Effects on drying time. Figure 10 shows the vari-

ation of drying time with vacuum pressure calculated

from sublimation interface model and sublima-

tion—condensation model. It can be seen that the

difference between the two models becomes larger

with increasing PR. However, high vacuum pressure

should be avoided in practical microwave freeze-dry-

ing operations because of melting and gas discharge.

The figure also shows the drying times at different

vacuum pressures and S0"1. It shows that the dry-

ing times decrease with increasing vacuum pressure at

both S0"0.7 and S0"1. Nevertheless, the effects of

vacuum pressure on drying process is not very signifi-

cant since the variation range of PR discussed here is

in the same order of magnitude.

CONCLUSIONS

The numerical calculations show that the sublima-

tion—condensation region plays an important role

in microwave freeze drying of unsaturated porous

media and the effects of sublimation—condensation

phenomena on drying process depend on operation

parameters. For larger electric field strength, vapor

transfer in sublimation—condensation region is more

intensive and larger part of the vapor is sublimated

from this region, so the effect of sublimation—conden-

sation region on drying time is more significant.

Smaller initial saturation is beneficial at higher elec-

tric field strength. However, too large electric field

strength is not necessary for microwave freeze drying.

In case of larger sample thickness, the saturation

change of the sublimation—condensation region is

larger, and the effect of sublimation—condensation

region on drying time is more significant. So sublima-

tion—condensation region cannot be neglected in

microwave freeze drying of unsaturated porous me-

dia, especially for larger scale samples. Though the

effect of vacuum pressure on sublimation—condensa-

tion region is significant a little more for higher vac-

uum pressure, the effect of sublimation—condensation

region on drying time is not so significant in the

observed range.

NOTATION

c

specific heat of the material, J/(kg °C)

D

diffusivity, m

2/s

De

effective diffusivity, m

2/s

E

electric field peak strength, V/cm

fT

source conversion coefficient from heat to

mass, kg/J

fJ

ratio of the vapor flux sublimated from sub-

limation—condensation region to the vapor

flux in dried region

*H

latent heat of sublimation, J/kg

J

mass flux, kg/(m

2 s)

Jf

mass flux of vapor sublimated at sublima-

tion front, kg/(m

2 s)

JS

mass flux of vapor in sublimation—conden-

sation region, kg/(m

2 s)

Jv

mass flux of vapor in dried region, kg/(m

2 s)

k

dissipation coefficient defined by eq. (29),

J/(s m

3) (V/cm)~2

KD

permeability of the dry material, m

2

Kr

relative permeability

KS

effective coefficient of nonisothermal vapor

motion in sublimation—condensation re-

gion, kg/(m s °C)

l

sample half thickness, m

P

pressure, Pa

PR

vacuum pressure, Pa

q

density of microwave power absorbed,

J/(s m

3)

R

water vapor gas constant, m

2/(s2 °C)

S

saturation of ice in sublimation—condensa-

tion region

¹

temperature, °C

u4!5

moisture content of the saturated porous

medium, kg/m

3

x

space coordinate, m

X

position of sublimation front, m

Greek letters

a

heat transfer coefficient, J/(s m

2 °C)

e

porosity

j

thermal conductivity, J/(s m °C)

k

viscosity, kg/(m s)

o

density, kg/m

3

q

time, s

qd

drying time, hr

Subscripts

0

initial value

d

of dried sample

D

in the dried region

i

ice

s

solid body

S

in sublimation—condensation region

v

vapor

Superscript

0

previous time step

REFERENCES

Ang, T. K., Ford, J. D. and Pei, D. C. T. (1977)

Microwave freeze-drying of food: a theoretical in-

vestigation. Int. J. Heat Mass ¹ransfer 20, 517—526.

Dyer, D. F. and Sunderland, J. E. (1967) The transient

temperature distribution during sublimation dehy-

dration. ASME J. Heat ¹ransfer 89, 109—110.

Dyer, D. F. and Sunderland J. E. (1968) The role of

convection in drying. Chem. Engng Sci. 23, 965—970.

Fey, Y. C. and Boles, M. A. (1987a) An analytical

study of the effect of convection heat transfer on the

sublimation of a frozen semi-infinite porous me-

dium. Int. J. Heat Mass ¹ransfer 30, 771—779.

3196

Z. H. Wang and M. H. Shi

Fey, Y. C. and Boles, M. A. (1987b) An analytical

study of the effect of the Darcy and Fick laws on the

sublimation of a frozen porous medium. ASME J.

Heat ¹ransfer 109, 1045—1048.

Fey, Y. C. and Boles M. A. (1988) Analytical study of

vacuum-sublimation in an initially partially filled

frozen porous medium with recondensation. Int. J.

Heat Mass ¹ransfer 31, 1645—1653.

Fox, E. C. and Thomson, W. J. (1972) Coupled heat

and mass transport in unsteady sublimation drying.

A.I.Ch.E. J. 18, 792—797.

Harper, J. C. (1962) Transport properties of gases in

porous media at reduced pressure with reference of

freeze-drying. A.I.Ch.E. J. 8, 298—302.

King, C. J., Lam, W. K. and Sandall, O. C. (1968)

Physical properties important for freeze-drying

poultry meat. Food ¹echnol. 22, 1302—1308.

Lin, S. (1981) An exact solution of the sublimation

problem in a porous medium. ASME J. Heat

¹

ransfer 103, 165—168.

Lin, S. (1982) An exact solution of the sublimation

problem in a porous medium. Part II—with an

unknown temperature and vapor concentration at

the moving sublimation front. ASME J. Heat

¹

ransfer 104, 808—811.

Luikov, A. V. (1975) Systems of differential equations

of heat and mass transfer in capillary-porous bodies

(Review). Int. J. Heat Mass ¹ransfer 18, 1—14.

Lusk, G., Karel, M. and Goldblith, S. A. (1964) Ther-

mal conductivity of some freeze-dried fish. Food

¹

echnol. 18, 1625—1628.

Ma, Y. H. and Peltre, P. (1975) Freeze dehydration by

microwave energy: Part I. theoretical investigation.

A.I.Ch.E. J. 21, 335—344.

Massey, W. M. Jr and Sunderland, J. E. (1967)

Measurement of thermal conductivity during

freeze-drying of beef. Food ¹echnol. 21, 408—412.

Patankar, S. V. (1980) Numerical Heat ¹ransfer and

Fluid Flow. Hemisphere, New York, U.S.A.

Perry, H. R., Green, D. and Maloney, J. O. (1992)

Perry’s Chemical Engineering Handbook, 6th Edn.

McGraw-Hill, New York, U.S.A.

Whitaker, S. (1977) Simultaneous heat, mass, and

momentum transfer in porous media: A theory of

drying. In Advances in Heat ¹ransfer, Vol. 13, pp.

119—203. Academic Press, New York, U.S.A.

APPENDIX

Equations (2) and (11) are in the same form of nonlinear

heat conduction equation with internal heat generation.

They can be expressed in the following implicit finite-differ-

ence format:

aP¹P"aE¹E#aW¹W#b

(A1)

where aP, aE, aW, are the coefficient matrix and b is the

source term, which are determined as in Patankar (1980).

By applying implicit format, eq. (14) is discretized as

SP"S0P#

*q

um

GC

(KS)e

*x

(¹E!¹P)!

(KS)w

*x

(¹P!¹W)

D

1

*x

H

!

*q

um

G

( fT)P

C

(

je)e

*x

(¹E!¹P)!

(

je)w

*x

(¹P!¹W)

D

1

*x

#

( fT)PqP

H

(A2)

where S

0P represents the value of SP of previous time step, and

the transport properties are obtained by arithmetic mean

(KS)e"

2(KS)E(KS)P

(KS)E#(KS)P

.

(A3)

(KS)w, (je)e, and (je)w are approximated in similar expres-

sions. According to the previous work (Ma and Peltre, 1975;

Ang et al., 1977), the vapor concentration in the dried region

is approximately in linear distribution. Therefore, eq. (1) can

be written in the following form:

Jv"!Dea

ovDx/l!ovDx/X

l!X

(A4)

where Dea is determined as

Dea"

(De)n#(De)N

X

2

.

(A5)

Based on eqs (18) and (19), the following equation of

energy balance at sublimation front is obtained:

C

Jv!

A

!

KS

L¹

Lx

BK

x/X~

D

*H"

A

!

je

L¹

Lx

BK

x/X~

!

A

!

j

L¹

Lx

BK

x/X`

.

(A6)

After discretization, it is replaced by

C

Jv#(KS)N

X~1@2

¹N

X

!¹N

X~1

*x

D

*H"!(je)N

X~1@2

¹N

X

!¹N

X~1

*x

#

(

j)N

X`1@2

¹N

X~1

!¹N

X

*x

(A7)

where (KS)N

X~1@2

, (

je)N

X~1@2

, and (

je)N

X~1@2

are calculated using

a formula similar to eq. (A3).

The finite-difference expression of SN

X

can be got in explicit

form by replacing the temperature and physical properties in

eq. (A2) with the corresponding values of previous time step.

The boundary conditions, eqs (21)— (23), can be discre-

tized as

¹1!¹2"

0

(A8)

!

jn

~1@2

¹n!¹n~1

*x

"

a(¹n!¹R)

(A9)

ovn"

PR

R¹n

(A10)

where

jn

~1@2

"

2

jnjn~1

jn#jn~1

.

(A11)

Since the complexity of the sublimation front, of which

temperature and saturation are intensively nonlinear func-

tions of time during microwave freeze drying, an explicit

method is employed to determine the time step of each

iteration as follows:

*q"!

*xum(SN

X~1

)

0

(Jf)0

(A12)

where

(Jf)0"(Jv)0!(JS)0

(A13)

(JS)0"!(KS)(¹)0N

0X

~

Ç

@

È

(¹)

0N

0X

!

(¹)

0N

0X

~

Ç

*x

(A14)

N

0X"NX#1

(A15)

and (KS)0N

0X

~1@2

is obtained by arithmetic mean similar to eq.

(A3).

Sublimation—condensation study during freeze drying

3197

Wyszukiwarka

Podobne podstrony:

A comparative study on heat pump, microwave and freeze drying of fresh fruits

Experimental study on drying of chilli in a combined Microwave vacuum rotary drum dryer (Weerachai K

Interruption of the blood supply of femoral head an experimental study on the pathogenesis of Legg C

Pancharatnam A Study on the Computer Aided Acoustic Analysis of an Auditorium (CATT)

Gemes Freud and Nietzsche on Sublimation

United States on the Pacific Front during World War II

An experimental study on the development of a b type Stirling engine

A REVIEW ON THE MATERIALS USED DURING

Interruption of the blood supply of femoral head an experimental study on the pathogenesis of Legg C

Pancharatnam A Study on the Computer Aided Acoustic Analysis of an Auditorium (CATT)

Comparative study on synteny between yeast ane vertebrates

On Bourdieu and Phenomenology

An experimental study on the drying kinetics of quince

A comparative study on conventional and orbital drilling of woven carbon

Energy Consumption and Colour Characteristics of Nettle Leaves during Microwave, Vacuum and Convecti

Effect of drying conditions on the quality of vacuum microwave dried potato cubes

więcej podobnych podstron