Effect of drying conditions on the quality of vacuum-microwave

dried potato cubes

Joanna Bondaruk

a

, Marek Markowski

a,*

, Wioletta Błaszczak

b

a

Department of Agri-Food Process Engineering, University of Warmia and Mazury in Olsztyn, Heweliusza 14, 10-718 Olsztyn, Poland

b

Division of Food Science, Institute of Animal Reproduction and Food Research, Polish Academy of Sciences, Tuwima 10, 10-747 Olsztyn, Poland

Received 1 August 2006; received in revised form 29 October 2006; accepted 29 October 2006

Available online 19 December 2006

Abstract

The influence of drying conditions on the color, starch content, sugar content, mechanical properties and microstructure of dried

potatoes was studied. Statistically significant differences between the color of raw and dried materials were observed for every drying

methods. It was observed that the vacuum-microwave drying technique prevents color damage during drying. Potato cubes dried in a

vacuum-microwave oven had lower starch and total sugar losses than those dried under forced convection conditions. The maximum

force values obtained from compression tests indicated statistical differences between samples dried in a microwave-vacuum drier and

a convection drier. The averaged force and energy required to cause 3 and 5.5 mm deformation were the highest for blanched and

hot-air dried (70

°C) potato cubes, and the lowest for vacuum-microwave dried material (24 kPa). The application of microwave energy

led to different physical changes in product microstructure, compared to those observed during hot-air drying. The extent of changes was

depended on the method and parameters of drying. In both cases the drying process caused deformation and disintegration of cell walls

and starch granules. Experiments show that in the case of hot-air drying the intensity of structural changes depends on drying temper-

ature. A higher temperature causes greater damage to the microstructure of potato cubes.

Microwave drying at 24 kPa ensured the shortest drying time and the best overall quality of dried potato cubes, and thus was chosen

as the most appropriate technique for potato drying.

Ó 2006 Published by Elsevier Ltd.

Keywords: Vacuum-microwave drying; Potatoes; Quality

1. Introduction

Hot-air drying has been to date the most common

drying method employed for food materials. However,

this method has many disadvantages, including poor

quality of dried products, low energy efficiency and a

long drying time. It has been reported that hot-air drying

of food materials, involving their prolonged exposure to

elevated drying temperatures, results in substantial deteri-

oration of such quality attributes as color, nutrient con-

centration, flavor and texture (

Durance, 1994; Maskan, 2000; Yongsawatdigul & Gun-

asekaran, 1996

).

Because of the low thermal conductivity of food mate-

rials in the falling rate drying period, heat transfer to the

inner sections of foods during conventional heating is

limited. The desire to eliminate this problem, to prevent

significant quality deterioration, as well as to achieve fast

and effective thermal processing has resulted in the

increasing use of microwaves for food drying. Micro-

waves have been used as a heat source since the 1940s

(

). This technique has been extensively

employed in the food and chemical engineering industries

(

Ayappa, Davis, Davis, & Gordon, 1991; Chatterjee,

0260-8774/$ - see front matter

Ó 2006 Published by Elsevier Ltd.

doi:10.1016/j.jfoodeng.2006.10.028

*

Corresponding author.

E-mail address:

(M. Markowski).

www.elsevier.com/locate/jfoodeng

Journal of Food Engineering 81 (2007) 306–312

). The energy supplied during

microwave heating reaches all the parts of dried material

at the same time. It enables to shorten dehydration time

and to control undesirable biological transformations.

The microwave drying technique has been used for dry-

ing herbs (

), raisins (

Kostaropoulos & Saravacos, 1995

), apples

and mushrooms (

Funebo & Ohlsson, 1998; Giri & Pra-

), carrots (

Litvin, Mannheim, & Miltz, 1998

)

and bananas (

). However, microwave dry-

ing is known to result in a poor-quality product when

applied improperly (

Vacuum-microwave

drying

is

a

novel

alternative

method of drying, allowing to obtain products of accept-

able quality. It permits a shorter drying time and a sub-

stantial improvement in the quality of dried materials,

in relation to those dried with hot air and microwaves

drying methods.

Drouzas, Tsami, and Saravacos (1999)

used the vacuum-microwave technique to investigate the

process of model fruit gel drying. They studied drying

kinetics under different levels of pressure and microwave

power.

Sunjka, Rennie, Beaudry, and Raghavan (2004)

dried cranberries using vacuum-microwave and micro-

wave-hot-air techniques, and demonstrated better quality

of the product obtained with vacuum-microwave drying.

studied carotenoid retention

of carrot slices and chlorophyll retention of Chinese chive

leaves dried under vacuum-microwave conditions. They

showed that the values of both indices were very close

or equal to those observed for materials dried by freeze-

drying and much higher than those recorded for hot-air

dried materials.

examined

temperature changes in carrots dried in a vacuum-micro-

wave oven and observed a uniform temperature distribu-

tion within the samples.

studied the influence of drying techniques

on the quality of osmotically dehydrated cranberries.

They demonstrated that vacuum-microwave drying is a

viable alternative to other foodstuff drying methods,

ensuring a short time of drying and high quality of dried

products.

The aim of the present experiments was to compare

selected quality attributes of potato cubes dried under vac-

uum-microwave conditions and with hot air.

2. Materials and methods

2.1. Materials

The experimental materials comprised potatoes (Sola-

num tuberosum cv Bryza) from a farm located near Wro-

claw

(SW

Poland),

stored

at

5

°C

until

sample

preparation. Two hours before drying the potatoes were

placed at ambient air temperature. Prior to the onset of

the experiments the potatoes were cut into 10 mm cubes.

Each sample was composed of several potato cubes, 80 g

of the total weight. In order to study the effect of pretreat-

ment on drying behavior, before drying several samples

were blanched in hot water (95

°C) for 4.5 min. The initial

moisture content of material was 4.0 ± 0.1 kg water/kg d.b.

2.2. Drying

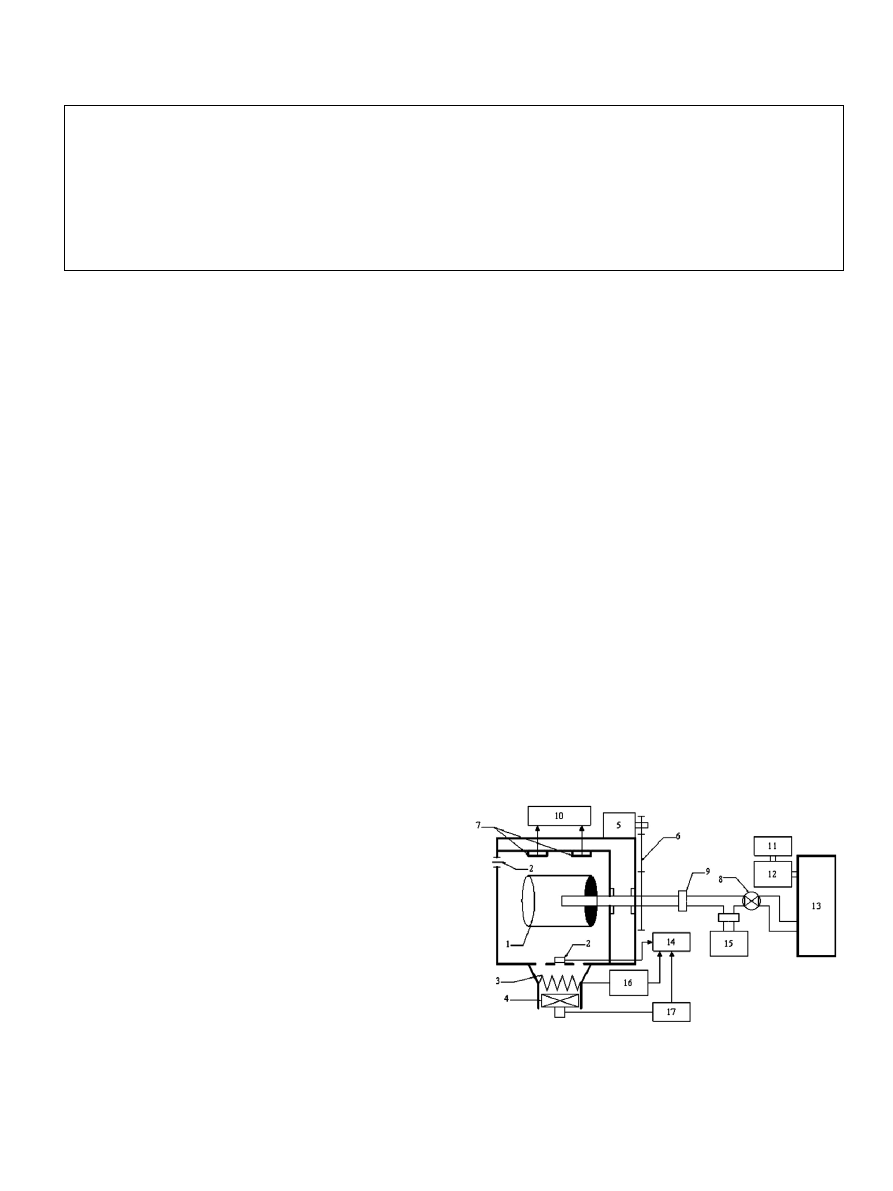

An experimental stand for vacuum-microwave drying is

shown in

. The vacuum-microwave drier is a horizon-

tal glass cylinder with a low dielectric loss coefficient. Elec-

tromagnetic fields are generated by two magnetrons of

1.2 kW maximum power output. Vacuum-microwave dry-

ing experiments were carried out at the Institute of Agricul-

Nomenclature

R

raw material, unblanched, not dried

RB

raw material, blanched, not dried

V6

vacuum-microwave dried material, 6 kPa

V12

vacuum-microwave dried material, 12 kPa

V18

vacuum-microwave dried material, 18 kPa

V24

vacuum-microwave dried material, 24 kPa

H50

raw material, unblanched, dried with hot air at

50

°C

H70

raw material, unblanched, dried with hot air at

70

°C

H50B

raw material, blanched, dried with hot air at 50

°C

H70B

raw material, blanched, dried with hot air at 70

°C

Fig. 1. Scheme of a vacuum-microwave drying experimental stand: 1 –

drying container, 2 – thermocouple, 3 – heaters, 4 – fan, 5 – motor, 6 –

gear, 7 – magnetron, 8 – valve, 9 – connector, 10 – magnetron power

control unit, 11 – vacuum pump control unit, 12 – vacuum pump, 13 –

compensating container, 14 – temperature control unit, 15 – pressure

measuring unit, 16 – heaters control unit, and 17 – fan control unit.

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

307

tural Engineering, Agricultural University in Wroclaw,

Poland.

Hot-air drying experiments were performed in a drier

that consists of three basic sections: air flow rate control,

heating control, and drying test compartment. The drying

compartment is a vertical cylinder, 0.2 m in diameter and

1 m in height. The supporting grid, which serves as a gas

distributor, has 4 mm squared orifices. Under the support-

ing grid there is a diverging cone (0.25 m in height) con-

nected with a pipe (0.065 m in diameter) supplying hot air.

Prior to vacuum-microwave drying the samples were

weighed on a laboratory scale and placed in a glass cylin-

der. In order to study the effect of vacuum levels on the

kinetics of potato cube drying under vacuum-microwave

drying conditions, several experiments were conducted at

the following pressure inside the drying chamber: 6, 12,

18, and 24 ± 2 kPa. The experiments were performed at

40% of maximum power (480 W). Only raw material was

used during microwave-vacuum drying experiments.

Moisture content d.b. and dry matter content were mea-

sured according to the

standards, using a

laboratory scale (WPE 600, RADWAG, Poland) to an

accuracy of ±0.01 g.

In order to show the effect of the inlet air temperature on

the kinetics of potato cube drying with hot air, the experi-

ments were carried out at air temperature of 50 and

70 ± 1

°C. The height of the layer of dried carrot cubes

was 5 ± 0.5 cm. During all drying experiments the air-flow

rate was 4.0 ± 0.4 m/s. Both raw and blanched potato

cubes were dried with hot air.

2.3. Sugar content and starch content

Sugar content was determined according to the Lane-

Eynon method (

). In order to determine reducing

sugar content, an alkaline solution of copper salt was sub-

jected to hot reduction by direct titration of a protein-free

solution, in the presence of methylene blue, without inver-

sion. Total sugar content was determined after inversion

with concentrated hydrochloric acid. Further procedures

were the same as in the case of reducing sugars.

Starch content was determined by the polarimetric

method (

). Starch hydrolysis was carried out

using concentrated hydrochloric acid, and the solution

was clarified with acid sodium phosphotungstate. Starch

content was determined on the basis of the angle of

polarization.

2.4. Color properties

Instrumental measurement of color was performed

using a MiniScan XE Plus spectrophotometer (HunterLab)

on the CIELab scale, at illumination D65, observer 10

° and

light diffusion 8

°. The color of potatoes was measured on

30 cubes selected randomly, and was described by three

coordinates in the color space: L

*

(lightness), a

*

(redness),

b

*

(yellowness), measured directly with a spectrophoto-

meter. CIE Tristimulus values and coefficients dependent

on the illuminant and observer were used to calculate the

yellowness index, YI313.

2.5. Compression tests

Quasi-static compression tests of single potato cubes

were performed. All the test were carried out using an

Instron Universal Testing Machine (High Wycombe,

Bucks, UK), model 4301, operating in the compression

mode, fitted with a parallel plate fixture for uniaxial com-

pression and a 100 N load cell. During compression exper-

iments cross-head speed was 2.5 mm/min. Before each

experiment a randomly chosen single potato cube dried

under the given conditions was placed on the bottom par-

allel plate and compressed. Compression experiments were

performed in 15 replications. The averaged force and

energy required to cause 3.0 and 5.5 mm deformation were

determined on the basis of force–deformation curves.

2.6. Microstructure

The microstructure of dried potato cubes was measured

according to the procedure described by

. The cubes were cut in half longitudinally along

the central pith. Small pieces revealing advanced lesions

were prepared for scanning electron microscopy studies

directly by freezing in liquid nitrogen followed by freeze-

drying. The dried samples were coated with gold in a vac-

uum evaporator JEE-144, and examined under a scanning

electron microscope JSM 5200 at an accelerating voltage of

10 kV.

2.7. Statistical analysis

The experimental data were verified statistically using

regression analysis, nonlinear estimation and ANOVA

technique in a completely randomized block design. The

significance of differences between treatments was deter-

mined by a one-factor analysis of variance using the Dun-

can multiple range test (p 6 0.05). The calculations were

performed using STATISTICA 7.1 (StatSoft Inc., USA)

software.

3. Results and discussion

As shown in

, the time required to decrease the

moisture content of potato cubes from the initial value to

Table 1

Time of drying required to reduce the moisture content of potato cubes to

a given level

Moisture content (kg/kg d.b.)

Time of drying (min)

V6

H50

H50B

H70

H70B

1.6

9

55

67

27

44

0.1

21

301

–

126

223

308

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

a level of 1.6 and 0.1 kg/kg d.b. depends on drying condi-

tions. It was also observed that if the microwave power

level remained constant the level of pressure inside the vac-

uum-microwave cave did not affect significantly (p 6 0.05)

the drying time. The reason may be that as the potatoes

were cut into 1 cm

3

cubes in the present experiments, the

drying rate was controlled by the heat dissipation rate.

Probably the value of latent heat of vaporization varied a

little and the drying rate was strongly impacted by micro-

wave power output while slightly by vacuum pressure. This

result is in agreement with the observations of

concerning carrot slices. It was found that the

time required to reduce moisture content to any level in

potatoes dried with hot air was dependent not only on

the drying conditions but also on pretreatment. A shorter

drying time was observed for unblanched potato cubes

dried under vacuum-microwave conditions while for those

blanched and dried with hot air the time of drying was sev-

eral times longer.

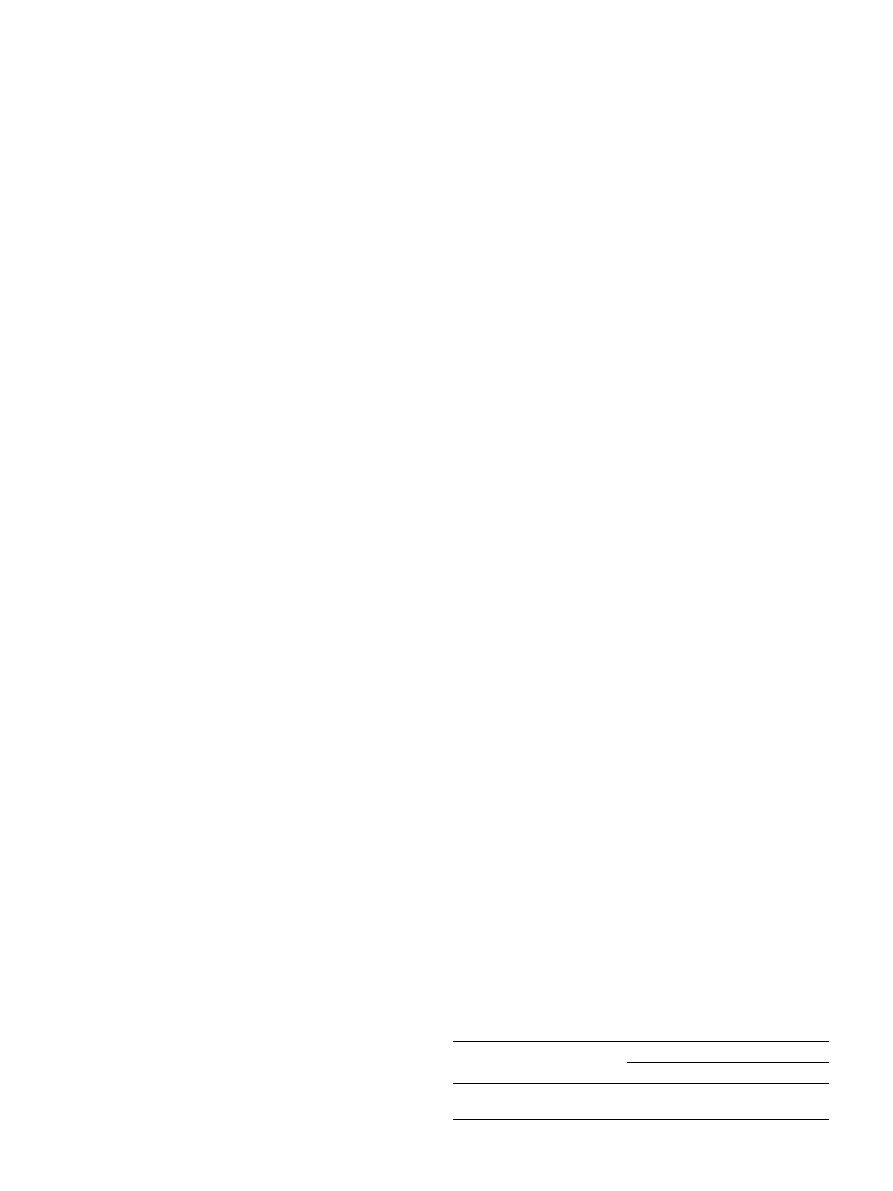

A two-term exponential model was used to describe the

kinetics of hot-air drying of potato cubes, while a linear

equation and a one-term exponential model were used in

the case of vacuum-microwave drying. Nonlinear regres-

sion analysis was used to fit models to experimental data.

Mathematical differentiation of the drying curves allowed

to calculate the drying rates (

). The drying rates of potato cubes dried with hot air

and in a vacuum-microwave oven are shown in

. Dur-

ing vacuum-microwave dehydration the rate of drying was

increasing for 0.28 min

1

and then stayed constant until

the initial water content of the material decreased to

60%, which was followed by a decreasing drying rate per-

iod. In hot-air dried material the drying rate decreased

gradually after the initial rapid rise. At all moisture con-

tents the rate of drying recorded under vacuum-microwave

conditions was higher, compared with the other drying

conditions.

The content of sugars and starch in raw and dried

potato cubes is presented in

. The results show that

following hot-air drying the starch content of unblanched

and blanched potato cubes was at a level of 90–93% and

90–96% of the initial value, respectively, compared to

95% observed after microwave-vacuum drying. The total

sugar content of hot-air dried potatoes and microwave-vac-

uum dried potatoes ranged from 84% to 91% and from

88% to 99% of the initial value, respectively. The concen-

tration of reducing sugars was 86–98% of the initial level,

irrespective of the drying method applied (

). Signifi-

cant differences (p 6 0.05) were observed between samples

dried under different conditions. If preventing starch and

sugar losses during potato drying was acknowledged

important while evaluating the drying process, it could be

concluded (based on the results in

) that vacuum-

microwave drying at 12, 18 and 24 kPa enabled to reduce

starch and sugar losses to a greater extent than other

techniques.

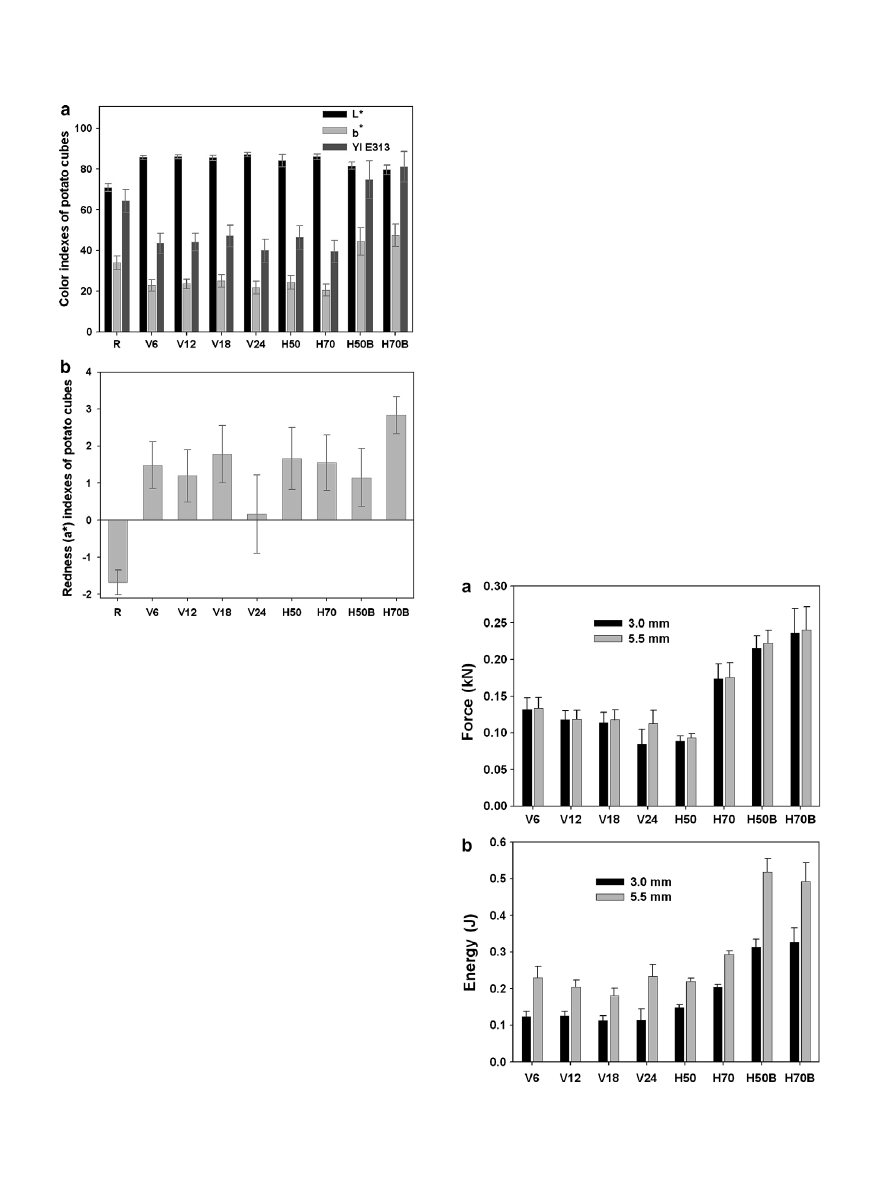

illustrates the results of color measurements of

raw and dried potato cubes. The lightness (L

*

) of dried

samples ranged from 80 to 87, redness (a

*

) from 0.2 to

2.8, and yellowness (b

*

) from 20 to 47. The results show

that drying caused an increase in lightness, L

*

, in compar-

ison with the reference sample. Furthermore, pretreatment

Fig. 2. Drying rates of potato cubes dried with hot air and the vacuum-

microwave.

Fig. 3. Content of sugar and starch in raw and dried potato cubes.

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

309

followed by air drying resulted in a darker color of potato

cubes (lower L

*

value), compared with the samples dried

without pretreatment. The highest value of lightness was

observed for potato cubes dried in a microwave oven at

24 kPa. The lowest L

*

index was observed for the reference

sample. The differences in lightness between potato cubes

dried in a microwave oven at 6, 12 and 18 kPa and

unblanched samples dried with hot air were found to be

non-significant (p 6 0.05).

There were significant differences (p 6 0.05) in a

*

values

between samples dried with hot air and with microwaves.

However, due to relatively small absolute values of a

*

observed for both drying methods and all conditions

applied, it can be assumed that the redness index, a

*

, did

not affect the overall color assessment of dried potato

cubes. Furthermore, unblanched samples dried with micro-

waves and with hot air showed lower values of b

*

, with the

lowest value observed for samples dried with hot air at

50

°C and with microwaves at 24 kPa. Pretreatment fol-

lowed by hot-air drying resulted in an increase in the b

*

index of potato cubes.

Differences in the b

*

index between dried samples were

significant (p 6 0.05). However, differences between sam-

ples dried with microwaves at 24 kPa and those dried with

hot air at 50

°C were non-significant. The fact that no sub-

stantial increase in a

*

and b

*

was observed for unblanched

samples dried at different conditions confirms that no enzy-

matic browning reactions occurred during drying. This can

be explained by fast inactivation of enzymes caused by the

sharp rise in temperature of samples during drying, and by

the relatively low temperature of the material during drying

which was not high enough to initiate the Mailard reac-

tions. As for the samples blanched before drying, a consid-

erable increase in the b

*

parameter was observed, which

suggests that enzymatic browning reactions were initiated

by the high temperature of water used for pretreatment.

It was found that blanching followed by drying with hot

air caused an increase in the yellowness index, YI E313, of

potato cubes. The highest value of this index, equal to 81,

was observed for blanched material dried with hot air at

70

°C, while the lowest (39) for unblanched ones dried with

microwaves at 24 kPa and with hot air at 70

°C. Significant

differences (p 6 0.05) were recorded in the YI E313 values

between samples dried with hot air and with microwaves.

However, differences in the yellowness index between

unblanched samples dried with microwaves at 24 kPa and

samples dried with hot air at 70

°C were non-significant

(p 6 0.05). The small values of a

*

, b

*

and YI E313 as well

as the high value of L

*

indicate that drying with micro-

Fig. 4. Color indices of raw and dried potato cubes. Means ± standard

deviations.

Fig. 5. Averaged force and energy required to cause 3.0 and 5.5 mm

deformation. Means ± standard deviations.

310

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

waves at 24 kPa resulted in the best color attributes of

dried potato cubes.

shows the averaged force and energy, respectively,

required to cause deformation of 3.0 and 5.5 mm during

the compression of dried potato cubes. It was found that

both blanched and unblanched samples dried with hot air

at 70

°C as well as blanched samples dried with hot air at

50

°C were characterized by the highest energy of deforma-

tion and the highest resistances at both deformation levels

(3.0 and 5.5 mm). Significant differences were observed

between the maximal compression forces of dried samples.

However, there were no significant differences (p 6 0.05)

between the maximal compression forces for samples dried

with hot air at 50

°C and for all samples dried with micro-

waves. Similar observations were made with respect to the

energy required to compress a sample, which suggests that

a vacuum level of 24 kPa ensures good texture parameters

of dried potato cubes and is most appropriate for potato

drying.

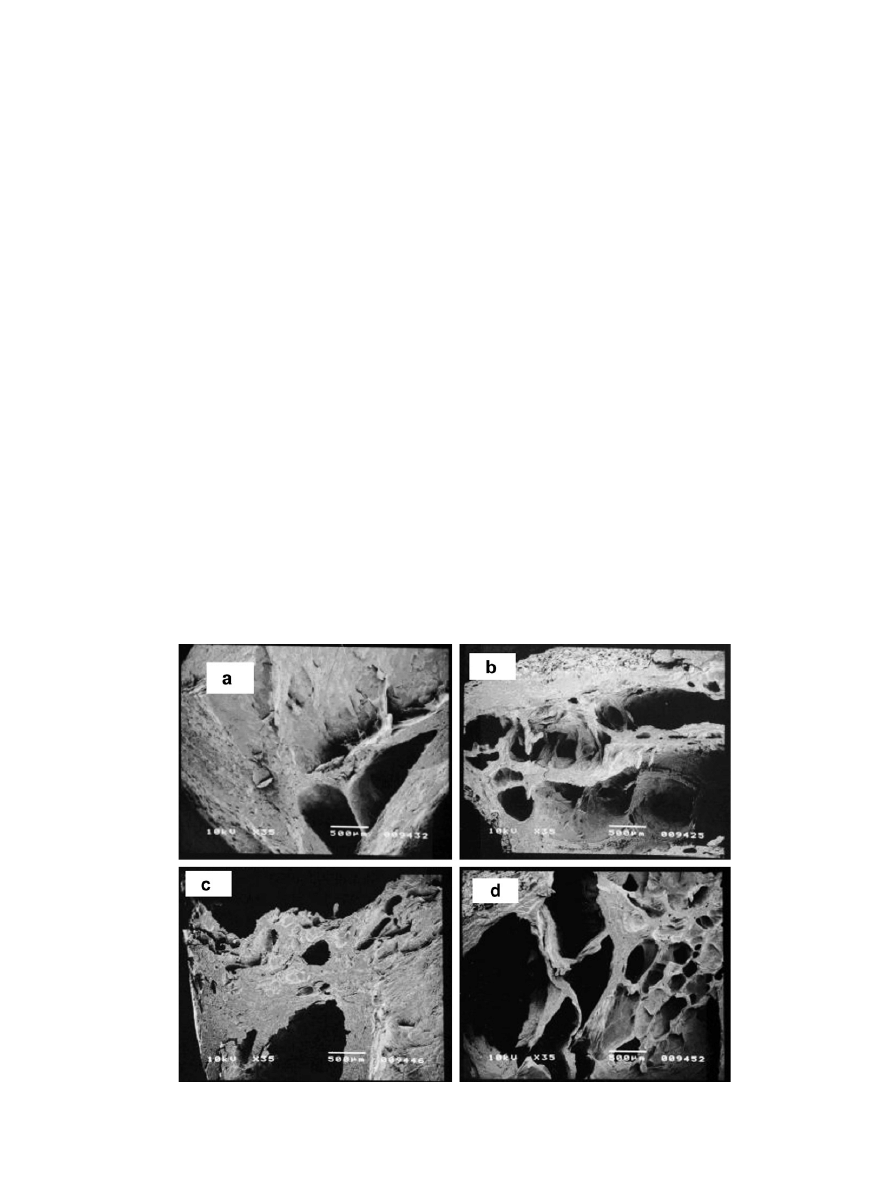

shows SEM (scanning electron microscopy)

images of the cross-sections of blanched and unblanched

potato cubes dried with hot air at 50 and 70

°C and in a

vacuum-microwave oven at 6 and 24 kPa. Well-preserved

structures of cell walls as well as whole cells filled with

starch gel were present in the inner regions of blanched

samples dried with hot air at 50

°C (

a). The micro-

structure of the interior part of a dried potato cube was

compact and the cells were tightly packed. Due to the

well-preserved cell structures, observed in

a, as well

as tight packing and strong connections between cells,

blanched and hot-air dried potato cubes were characterized

by higher mechanical resistance than unblanched samples.

The inner structure of unblanched potato cubes dried

with hot air at 70

°C (

b) is composed of a compact

starch–protein matrix containing diluted cell walls, residual

conductive bundles and starch grains. Despite considerable

porosity, the microstructure of potato cubes dried with hot

air at 70

°C showed higher mechanical resistance, com-

pared to samples dried at 50

°C. More advanced changes

in parenchyma microstructure were observed for potato

cubes dried at 70

°C.

As shown in

c and d, vacuum-microwave process-

ing caused more serious changes in the microstructure of

dried potato cubes in comparison with hot-air drying.

shows that regardless of the vacuum level applied,

dried material was characterized by strongly porous and

irregular structure. Drying at 6 kPa caused violent evapo-

ration of water in cells followed by a collapse of cell struc-

ture and partial disconnection of cells. Drying at 24 kPa

resulted in complete destruction of cell structure.

The phenomenon of more advanced destruction of

microstructure observed in dry potato tissue can be

explained by the fact that during vacuum-microwave dry-

ing the temperature of the material is strongly dependent

on the vacuum level. The lower the vacuum level during

drying the lower the temperature of the material. A higher

Fig. 6. SEM images of the cross-sections of potato cubes: (a) blanched and dried with hot air at 50

°C; (b) dried with hot air at 70 °C; (c) vacuum-

microwave dried at 6 kPa; (d) vacuum-microwave dried at 24 kPa.

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

311

temperature of the material could cause more violent evap-

oration of water as well as melting of starch granules,

which could weaken the starch–protein matrix. During vio-

lent evaporation of water in cells the pressure of vapor was

high, which could cause destruction observed in the micro-

structure of vacuum-microwave dried material. Differences

in the microstructure of dried potato cubes caused by dif-

ferent drying conditions during experiments (

) may

suggest that vacuum-microwave dried samples are charac-

terized by good reconstitution ability during rehydration,

which can be a consequence of their high porosity, com-

pared with those dried with hot air.

Measurements of the drying time and the quality attri-

butes of dried potato cubes indicated the advantage of vac-

uum-microwave drying over hot-air drying. The results of

this study suggest that a vacuum level of 24 kPa ensured

the best overall quality index of dried potato cubes, i.e.

slighter color changes of the product accompanied by its

higher ability to absorb water, good texture as well as a

high level of starch and sugar preservation.

4. Conclusions

Experimental data concerning the drying kinetics and

different quality attributes of blanched and unblanched

potato cubes dried by vacuum-microwave and hot-air tech-

niques were analyzed in the study. It was found that the

vacuum pressure affects the drying rate of potato cubes.

The time of drying needed to reduce moisture content from

the initial point to 0.1 kg/kg d.b., observed for potato

cubes dried in a vacuum-microwave oven at 6 kPa, was six-

fold shorter, compared with samples dried with hot air at

70

°C.

Experimental data show that almost all quality attri-

butes studied were dependent on the vacuum pressure level

applied during vacuum-microwave drying. It was also

observed that the drying technique strongly affected the

composition, color, mechanical properties and microstruc-

ture of dried potato cubes.

Microwave drying at 24 kPa ensured the shortest drying

time and the best overall quality index of dried potato

cubes, and thus was chosen as the most appropriate tech-

nique for potato drying.

Although modeling of the kinetics of vacuum-micro-

wave drying has been the subject of substantial research

over the last decade, further investigations should be per-

formed on modeling of the quality of vacuum-microwave

dried foods based on mass, heat and pressure transfer.

Acknowledgements

The authors are grateful for the financial support pro-

vided within the framework of Grant No. 2 P06T 052 29

of the Polish Ministry of Scientific Research. The authors

also thank Professor Marian Szarycz of Agricultural Uni-

versity in Wroclaw, Poland, for his helpful cooperation in

performing vacuum-microwave drying experiments.

References

AOAC. (1975). Official methods of analysis (12th ed.). Washington, DC.

Ayappa, K. G., Davis, H. T., Davis, E. A., & Gordon, J. (1991). Analysis

of microwave heating of materials with temperature dependent

properties. AIChE Journal, 37(3), 313–322.

Beaudry, C., Raghavan, G. S. V., Ratti, C., & Rennie, T. J. (2004). Effect

of four drying methods on the quality of osmotically dehydrated

cranberries. Drying Technology, 22(3), 521–540.

Błaszczak, W., Chrzanowska, M., Fornal, J., Zimnoch-Guzowska, E.,

Palacios, M. C., & Vacek, J. (2005). Scanning electron microscopic

investigation of different types of necroses in potato tubers. Food

Control, 16, 747–752.

Bouraout, M., Richard, P., & Durance, T. (1994). Microwave and

convective drying of potato slices. Journal of Food Process Engineering,

17, 353–363.

Chatterjee, A., Basak, T., & Ayappa, K. G. (1998). Analysis of microwave

sintering of ceramics. AIChE Journal, 44(10), 2302–2311.

Cui, Z.-W., Xu, S.-Y., & Sun, D.-W. (2004a). Effect of microwave-vacuum

drying on the carotenoids retention of carrot slices and chlorophyll

retention of Chinese chive leaves. Drying Technology, 22(3), 563–565.

Cui, Z.-W., Xu, S.-Y., & Sun, D.-W. (2004b). Microwave-vacuum drying

kinetics of carrot slices. Journal of Food Engineering, 65(3), 164–175.

Cui, Z.-W., Xu, S.-Y., Sun, D.-W., & Chen, W. (2005). Temperature

changes during microwave-vacuum drying of sliced carrots. Drying

Technology, 22(3), 563–565.

Drouzas, A. E., Tsami, E., & Saravacos, G. D. (1999). Microwave/

vacuum drying of model fruit gels. Journal of Food Engineering, 39(3),

117–122.

Funebo, T., & Ohlsson, T. (1998). Microwave-assisted air dehydration of

apple and mushroom. Journal of Food Engineering, 38, 353–367.

Giese, J. (1992). Advances in microwave food processing. Food Technol-

ogy, 46, 118–123.

Giri, S. K., & Prasad, S. (2007). Drying kinetics and rehydration

characteristics of microwave-vacuum and convective hot-air dried

mushrooms. Journal of Food Engineering, 78(2), 512–521.

Kostaropoulos, A. E., & Saravacos, G. D. (1995). Microwave pretreat-

ment for sun-dried raisins. Journal of Food Science, 60, 344–347.

Litvin, S., Mannheim, C. H., & Miltz, J. (1998). Dehydration of carrots by

a combination of freeze drying, microwave heating and air or vacuum

drying. Journal of Food Engineering, 36, 103–111.

Maskan, M. (2000). Microwave/air and microwave finish drying of

banana. Journal of Food Engineering, 48, 169–175.

Mermelstein, N. H. (1997). How food technology covered microwaves

over the years. Food Technology, 51(5), 82–84.

Pabis, S., Jayas, D. S., & Cenkowski, S. (1998). Grain drying. Theory and

Practice. New York, NY: John Wiley & Sons.

PCS. (1990). Fruit and vegetable products. Preparation of samples and

testing methods. Determination of sugar content and nonsugar extract.

PCS reference No. PN–90/A–75101.07. Warsaw, Poland: Polish

Committee for Standardization (in Polish).

Sunjka, P. S., Rennie, T. J., Beaudry, C., & Raghavan, G. S. V. (2004).

Microwave-convective and microwave-vacuum drying of cranberries:

A comparative study. Drying Technology, 22(5), 1217–1231.

Yongsawatdigul, J., & Gunasekaran, S. (1996). Microwave-vacuum

drying of cranberries: Part II. Quality evaluation. Journal of Food

Processing and Preservation, 20, 145–156.

312

J. Bondaruk et al. / Journal of Food Engineering 81 (2007) 306–312

Document Outline

Wyszukiwarka

Podobne podstrony:

Effect of vacuum microwave drying on selected mechanical and rheological properties of carrot

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

Drying kinetics and quality of vacuum microwave dehydrated garlic cloves and slices

Text which I chose is strongly connected with the economy and conditions on the market

Headspace Volatiles and Physical Characteristics of Vacuum microwave, Air, and Freeze dried Oregano

Effect of Drying Techniques and Storage on Mulberry (Morus alba) Quality

Effect of a novel physical pretreatment process on the drying kinetics of seedless grapes

31 411 423 Effect of EAF and ESR Technologies on the Yield of Alloying Elements

Effects of the Great?pression on the U S and the World

Effects of the Atomic Bombs Dropped on Japan

Effect of magnetic field on the performance of new refrigerant mixtures

76 1075 1088 The Effect of a Nitride Layer on the Texturability of Steels for Plastic Moulds

Curseu, Schruijer The Effects of Framing on Inter group Negotiation

A systematic review and meta analysis of the effect of an ankle foot orthosis on gait biomechanics a

71 1021 1029 Effect of Electron Beam Treatment on the Structure and the Properties of Hard

Effects of kinesio taping on proprioception at the ankle

Glińska, Sława i inni The effect of EDTA and EDDS on lead uptake and localization in hydroponically

Effecto of glycosylation on the stability of protein pharmaceuticals

Understanding the effect of violent video games on violent crime S Cunningham , B Engelstätter, M R

więcej podobnych podstron