Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

1

CHARACTERISATION OF ITALIAN CLAY SHALES FOR TUNNEL DESIGN

G. Barla, M. Barla, M. Bonini

Department of Structural and Geotechnical Engineering

Politecnico di Torino, Italy

giovanni.barla@polito.it

Abstract: This paper describes the characterisation studies carried out so far on Italian clay shales, involved

in the construction of significant tunnel lengths. Laboratory tests performed on cylindrical specimens, taken

from either cubic samples at the tunnel face or from borehole drilling, point out the characteristics of clay

shales: chaotic structure (tectonized and intensely fissured), sensitivity to ionic concentration of pore fluid,

swelling/squeezing behaviour. Numerical analyses have been performed in order to reproduce the response

of clay shales both at laboratory and in situ scale, in undrained and drained conditions. The difficulties in

assessing the design parameters based on laboratory testing are evidenced, thus pointing out the importance

of in situ observation and monitoring of the tunnel response during excavation.

Keywords: clay shales; rock characterisation; large size tunnels; full face excavation; monitoring.

1. INTRODUCTION

Tunnelling through the Apennines is presently

under way in Italy, in connection with the

construction and renewal of important

communication routes. Examples are the high

speed railway line between Bologna and Florence,

presently under construction, the A1 base tunnel

and the Sparvo tunnel, soon to be excavated.

Significant tunnel lengths are in a tectonized clay

shale formation known as “Chaotic Complex”.

Clay shales are the result of depositional or

post-depositional events of physical, chemical or

tectonic origin. They are classified as “soft rocks or

hard soils” and characterised by the following main

features:

•

high variability of physical properties and

mineralogical composition,

•

significant content of expansive clay

minerals,

•

presence of developed structure at different

scale levels,

•

low strength properties,

•

time-dependent behaviour.

It is the aim of this paper to give an overview of

the complex characteristics of clay shales with

reference to large size tunnel excavation and

construction.

2. EXCAVATION AND SUPPORT

METHODS

Current trends for construction of large size

tunnels (spans greater than 10 m and cross sections

of 100 m

2

or more) in difficult conditions, such as

represented by clay shales, involve the following

conventional construction methods (Barla G.,

2002):

•

side drift method,

•

top heading and benching down excavation,

•

full face excavation.

The first two methods of construction have been

widely applied in poor ground conditions as a mean

to reduce the cross section open in one stage, thus

reducing the potential of instability of the working

face. In particular, the second method permits a

high degree of mechanization for implementation

of stabilization measures, if required, and support

placement.

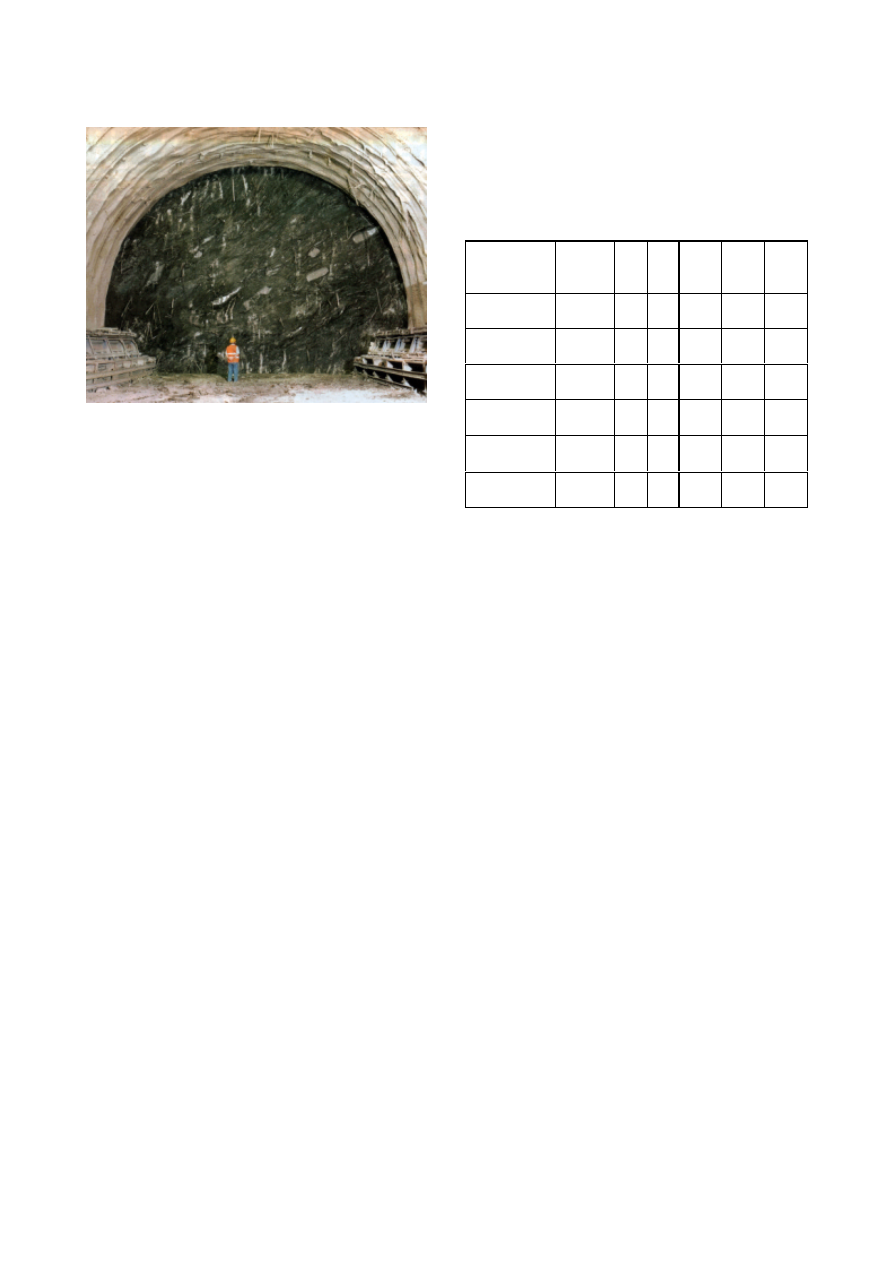

However, full face excavation (Fig. 1) is, at

present, the most appealing method and has been

applied with success in many cases (Barla G.,

2003). It was formerly introduced by Lunardi

(1995) and it is definitely being favoured by

designers from Italy with respect to other methods.

A significant advantage of this method is found in

the large working space available at the

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

2

Figure 1. Example of full face excavation method.

advancing face, so that large equipments can be

used effectively for installing support/stabilization

measures at the tunnel perimeter and ahead of the

face. However, the method makes it mandatory to

use a systematic reinforcement of the working face

and of the ground ahead.

Generally, the cross section is entirely open and

a primary lining (with steel fiber shotcrete and

heavy steel sets) with concrete invert (each

segment is cast within a very short distance from

the face) is installed as near the face as possible.

The face is reinforced by fiber-glass elements. The

concrete lining is completed at a distance not

greater than 3÷4 tunnel diameters behind the face.

3. CHARACTERISATION OF CLAY

SHALES

Cubic samples of clay shale are cut directly

from the tunnel face or, at the design stage,

cylindrical cores are obtained from borehole

drilling. Considering the presence in clay shales of

lithic components such as calcareous, marly and

arenaceous blocks in the form of disarranged

elements, cylindrical specimens (to be used in

laboratory tests) are often obtained with great

difficulty. The material in excess is used to

determine the physical properties and the

mineralogical contents as well as for oedometer

tests on reconstituted material.

3.1 Physical properties and

mineralogical composition

A common feature of clay shales is the

variability in grain size distribution. Silt and sand

may be present, although most significant is the

presence of clay particles. According to the

Plasticity Chart

, clay shales are in general

classified as “inorganic clays of low to average

plasticity” (Tab. 1).

Table 1. Triaxial tests performed*.

Tunnel

γ

d

[kN/m

3

]

G

s

[-]

w

n

[%

]

LL

[%]

PL

[%]

PI

[%}

S. Donato

22.1

22.

1

8.6

20-

30

13-

15

7-15

Raticosa

20.5

2.7

11.

5

40-

43

21-

22

≈

20

Osteria

21.7

2.7 7.0

34-

43

18-

20

14-

25

Sparvo

20.0

2.7

≈

1

0

26-

57

16-

25

10-

36

S. Vitale

18.5

18.

5

≈

1

7

25-

85

-

10-

55

Garbinogara

18.2

18.

2

20.

5

60.2

25.9

34.3

*

γ

d

= drained unit weight;

G

s

= grain specific

weight;

w

n

= natural water content;

LL = liquid

limit;

PL = plastic limit; PI = plastic index.

Based on X-ray diffraction analyses the clay

fraction is more than 50%. As the clay content

evaluated from the grain size distribution is less

than this quantity, one can infer that some of the

larger particles (more than 0.002 mm in diameter)

are made of attached clay grains. Expandable

minerals (i.e. smectite) may be present up to 40%

the clay composition.

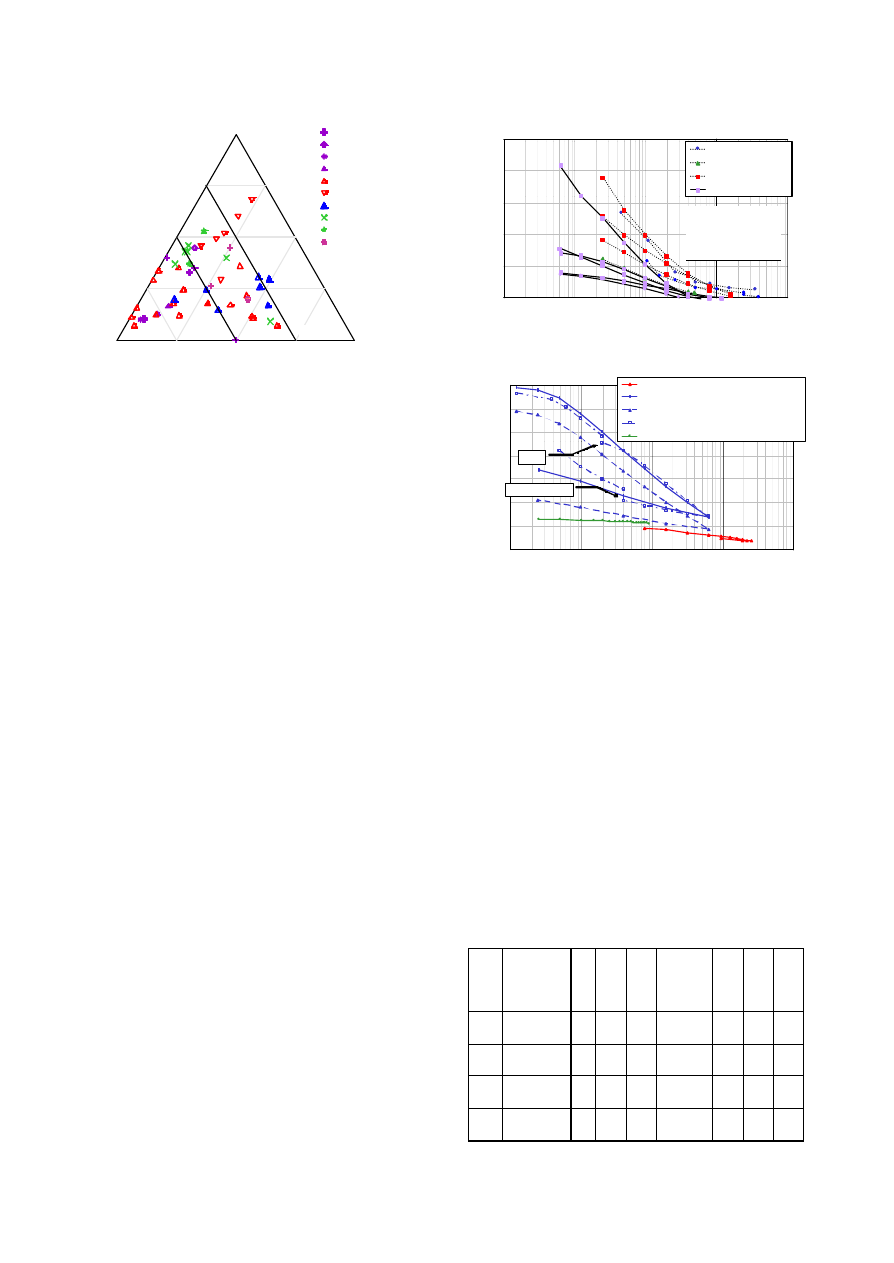

The swelling potential of clay shales is well

illustrated in Figure 2. Each point in the triangular

plot is defined by three percentages of clay

minerals, quartz and carbonate content,

respectively, as shown clockwise from 0 to 100%.

The diagram does not account for the effective

amount of swelling shown by the different clay

minerals (smectite, illite, etc.). An average to high

swelling potential is shown to characterize Italian

clay shales.

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

3

0

25

50

75

100

Carbonat e content [ %]

100

75

50

25

0

Q

ua

rtz

[%

]

100

75

50

25

0

C

la

y

m

in

e

ra

ls

[

%

]

A

B

C

A: high swelling potent ial

B: average swelling potent ial

C: low swelling pot ent ial

O steria clay shale

Rat icosa clay shale

Sparvo clay shale

S . Donato clay shale

V aricolori clay s hale

Terravecc hia clayst one

Caneva st iff c lay

Opalinus s hale

Lias Alpha shale

French marls

Figure 2. Swelling potential of Italian clay shales

compared to similar formations.

3.2 Oedometer tests

From a quantitative point of view, the swelling

potential can be investigated by means of the

Huder-Amberg modified oedometer test (Madsen,

1999). This allows for the determination of the

swelling coefficient

K on the diagram giving the

vertical strain versus the effective vertical stress as

shown in Figure 3.

The compressibility characteristics of clay

shales may be inferred by comparing oedometer

tests on natural and reconstituted samples. The

reconstitution, in fact, allows the determination of

the influence of structure and material intrinsic

properties. For the purpose of this study, the

Raticosa tunnel natural material was remoulded

with pestle and sieved through the ASTM sieves

nr. 10 and 40. Aggregates included in the matrix

were thus separated from the rest.

The materials were mixed at a water content

equal to 1.5 the liquid limit. Moreover, the

chemical composition of the pore fluid was

changed (i.e. adding NaCl and vice versa) in order

to check the sensitivity of expandable minerals

(Fig. 4). Chemical consolidation and swelling were

induced and the swelling index determined to be a

function of cation concentration.

0

5

10

15

20

25

0.001

0.01

0.1

1

10

Axial stress [MPa]

Swelling strain [%]

S. Donato tunnel

Raticosa tunnel

Osteria access adit

Sparvo tunnel

K [%]

S. Donato

2.9÷6.6

Raticosa

4.1

Osteria

4.9÷10.6

Sparvo

2.6÷11.6

Figure 3. Swelling tests with indication of K.

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.01

0.1

1

10

100

Vertical stress [MPa]

Void index [ - ]

Oed.: natural

Oed.: reconst. dist. water

Oed.: reconst. NaCl solution

Oed.: reconst. mixed test

Triaxial: natural isotropic comp. test

NaCl

Distilled water

Figure 4. Compression curves from oedometer

and triaxial tests.

3.3 Triaxial tests

Triaxial tests in closely controlled stress-path

conditions are a useful tool for the simulation of

the tunnel short- and long-term behaviour at

laboratory scale (Barla M., 1999). With reference

to the case of the Raticosa tunnel, a total of six

triaxial tests (Tab. 2) were performed by means of

the Soft Rock Triaxial Apparatus (SRTA) available

at the Politecnico di Torino (Bonini, 2003).

The stress-strain curves obtained for the

Raticosa tunnel (Fig. 5) exhibit an elasto-plastic

hyperbolic behaviour, clearly influenced by the rate

of axial displacement and saturation degree.

Table 2. Triaxial tests performed*.

Test

Type

B

[-]

B.P

.

[kP

a]

σ’

c

[kP

a]

a

ε&

[mm/mi

n]

t

max

[kP

a]

s’

m

ax

[kP

a]

∆u

[kP

a]

OS

T3

CID

-

0

90

0

0.0005

53

8

14

38

-

RT

C1

CIU

0.

81

400 48

6

0.001

17

0

55

5

-65

RT

C2

CIU+cr

0.

75

403 49

6

0.01

18

1

52

4

-28

RT

C3

CIU+cr

0.

77

399 49

7

0.005

14

8

48

0

18

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

4

RT

C4

CIU+cr

0.

80

404 48

8

0.005

94

45

3

31

RT

C5

Barla (1999) 0.

65

396 50

1

0.001

13

4

49

1

9

* B = Skempton’s parameter; B.P. = back

pressure;

σ

’

c

= consolidation effective stress;

= axial strain rate in the shearing phase;

t

max

= (

σ

v

-

σ

h

)

max

/ 2; s’

max

= (

σ

’

v

+

σ

’

h

)

max

/ 2;

∆

u = excess pore pressure.

0

0.1

0.2

0.3

0.4

0.0

1.0

2.0

3.0

4.0

5.0

External axial strain [%]

Deviator stress [MPa]

RTC1

0.001 mm/min

RTC2

0.01 mm/min

RTC3

0.005 mm/min

RTC4

0.005 mm/min

RTC5

0.001 mm/min

Figure 5. Stress-strain behaviour for different

axial strain rates.

Table 3. Strength parameters (mean values)*.

c

u

[kPa]

c

p

’

[kPa]

c

r

’

[kPa]

φ’

p

[°]

φ’

r

[°]

Tunnel

TX

TX

DS

T

X

D

S

T

X

D

S

TX

DS

S. Donato

-

35

-

10

-

24

34

20

24

Raticosa

100-900

16-540

16

-

16

-

Osteria

-

48

23

15

20 29

22

17

7

Sparvo

170-340

70

-

70

-

12

-

12

-

S. Vitale

-

-

28

-

0

-

26

-

20

Garbinogar

a

100-800

70

0

31

17

*

c

u

= undrained shear strength;

c

p

’, c

r

’ = peak

and residual cohesion;

φ’

p

,

φ’

r

= peak and residual

friction angle.

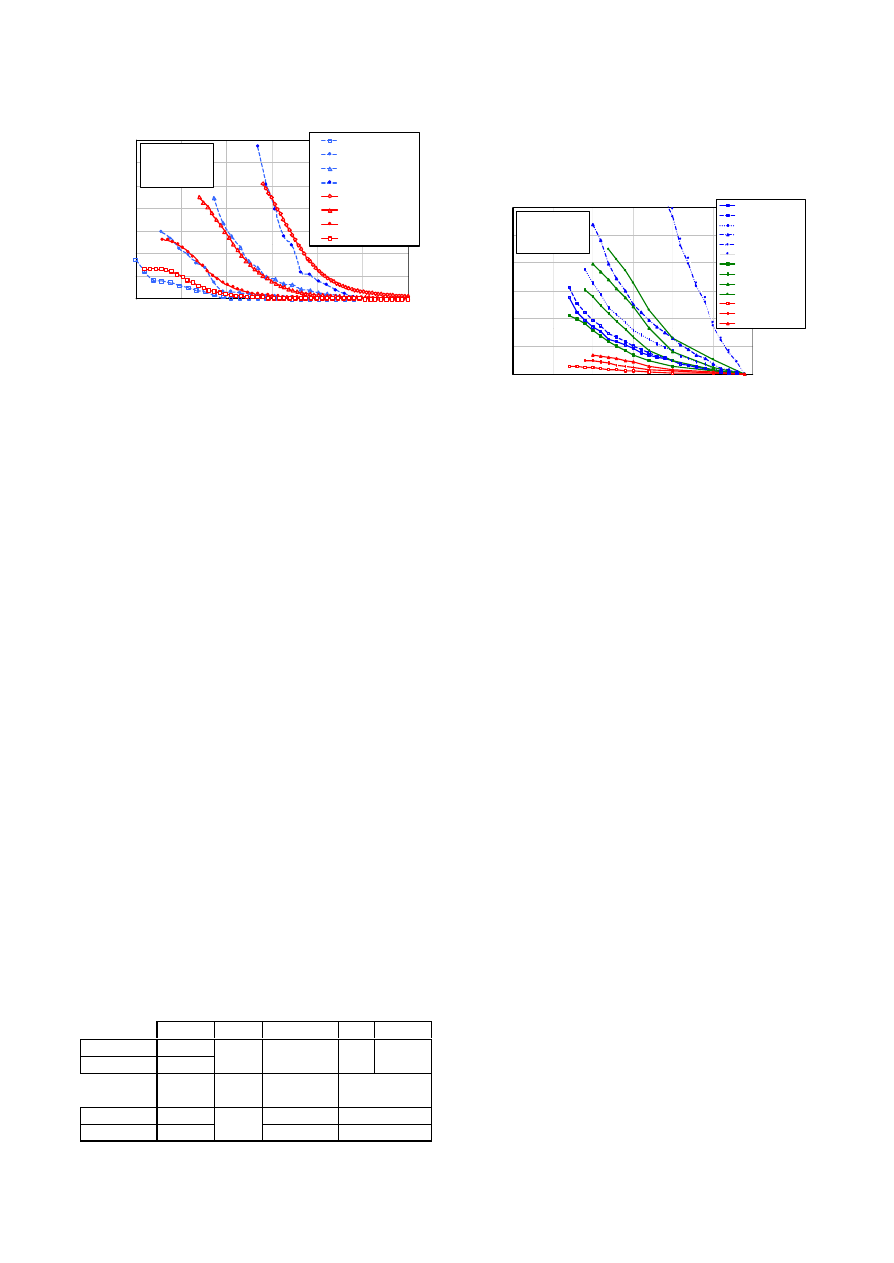

The mechanical behaviour of clay shales may

be inferred by comparing the results of triaxial tests

(TX) and direct shear tests (DS) in terms of

strength envelopes (Fig. 6) and strength parameters

(Tab. 3). These data together with the experience

gained during laboratory testing allow one to state

the following considerations.

•

The strength parameters are generally

influenced by structure (particle arrangement

and orientation of discontinuities), saturation

degree, loosening and stress release due to

sampling, etc.

•

Failure in TX tests often takes place along

planes on which fragments tend to align. The

development of a failure plane is free and

strength parameters are often influenced by

the direction of shearing.

•

The failure plane in DS tests is imposed so

that the strength parameters are higher than

those obtained by the TX tests.

Clay shales exhibit a time-dependent behaviour

as shown by the strain rate versus time plots

(Fig. 7). Time-dependent strains develop for a

mobilised strength nearly equal to 50% of the

failure value. Moreover, the strain rate is shown not

to increase significantly as the stress increases,

even if the failure deviator stress is attained.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0.0

0.5

1.0

1.5

2.0

Normal stress [MPa]

Shear strength [MPa]

Sparvo

S. Vitale

S. Donato

Garbinogara

Osteria

Raticosa

Figure 6. Shear strength envelopes.

0.000001

0.00001

0.0001

0.001

0.01

0.1

10

100

1000

10000

100000

Time [min]

Axial strain rate [%/min]

Sparvo SL=32%

Sparvo SL=50%

Sparvo SL=86%

Raticosa SL=55%

Raticosa SL=78%

Raticosa SL=87%

Raticosa SL=100%

Figure 7. Axial strain rate versus time obtained

for different stress levels (SL).

4. CASE STUDIES

The modern engineering approach to the design

of tunnels, as applied in full face excavation,

requires the following: definition of a realistic

geological and geotechnical model; prediction of

the ground behaviour by means of available

methods (previous experience, closed-form

solutions, numerical methods); selection of the

excavation sequence and support systems; final

design analyses; verification by observation and

monitoring.

For the purpose of the present paper it is of

interest to apply some of these tools to case studies,

in order to gain insights into the design parameters

a

ε&

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

5

of clay shales. For a circular tunnel (7.14 m radius)

subjected to a hydrostatic in situ state of stress (the

tunnel is at 100 m depth and the pore pressure is

taken to be 1.0 MPa), the ground reaction curve

can be obtained as shown in Figure 8.

The calculations have been performed by using

closed-form solutions, in terms of total (Ribacchi

and Riccioni, 1977) and effective stresses

(Labiouse and Giraud, 1998), and numerical

modelling by the Finite Difference Method (FDM)

and the Flac code (Itasca, 2000). Water flow is not

considered in the computations. Clay shales are

assumed to behave as an elastic perfectly plastic

0

20

40

60

80

100

0

2

4

6

8

10

12

14

16

18

20

Normalized radial displacement [%]

Normalized support pressure [%]

total stresses - closed-form solution

total stresses - numerical analysis

effective stresses - closed-form solution

effective stresses - numerical solution

range of allowed radial displcaments

analysis

Figure 8. Normalized ground reaction curve in

the case of Sparvo tunnel.

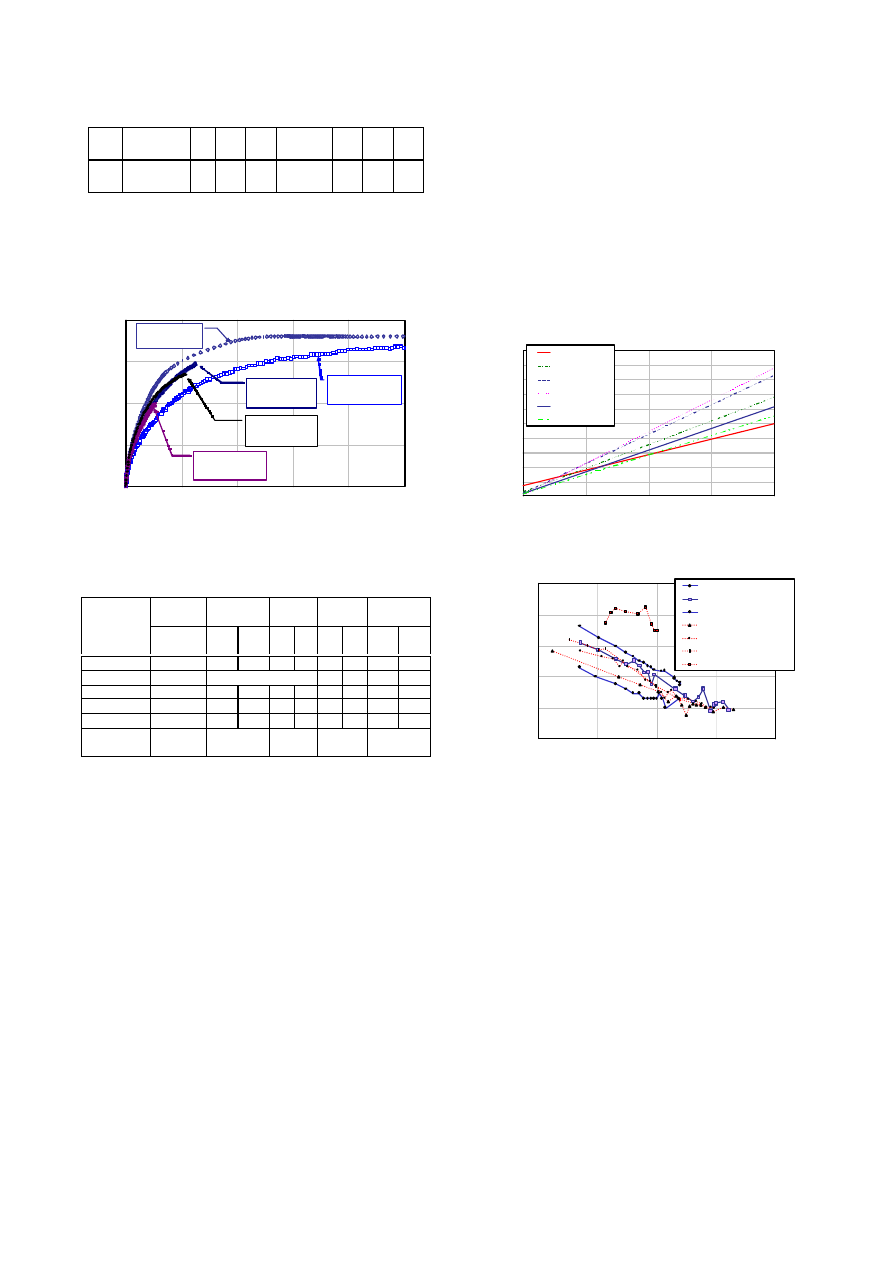

Figure 9. Sketch of the numerical model.

medium with the following parameters:

•

Undrained cohesion

c

u

= 340 kPa

•

Effective cohesion

c’ = 70 kPa

•

Effective friction angle

φ’ = 12 °

•

Young’s modulus

E’ = 40 MPa

•

Poisson’s ratio

ν = 0.35 -

•

Porosity

n = 0.25 -

•

Drained unit weight

γ

d

=

20 kN/m

3

which are typical values obtained from laboratory

tests carried out for the Sparvo tunnel at the design

stage (Tab. 3).

It is immediate to observe from the ground

reaction curve of Figure 8 that in order to keep the

normalized radial displacement below an

acceptable limit (say not greater than 1 to 2%), one

would need a support pressure of 60 to 80% of the

in situ state of stress (2.2 MPa). This is

significantly greater than the support pressure that

can be applied with a stabilization system at the

face and along the tunnel perimeter. However, it is

noted that, based on present experience derived

from excavation of large size tunnels in Italian clay

shales, although with some difficulties, these

tunnels have been excavated successfully. Should

one say that the prediction of tunnel performance

based on laboratory tests is not reliable?

To address this question, it is of interest to

consider the case of the Osteria access adit. This

tunnel (about 10.2 m span, 90 m

2

cross section), a

secondary access to the Raticosa tunnel (high speed

railway line Bologna-Florence), was excavated full

face through clay shales, under overburden depth

up to 200 m. With systematic reinforcement of the

tunnel face and heavy support at the heading, the

tunnel was completed reaching average

convergences of the tunnel cross section up to

46 mm and maximum longitudinal displacement

(“extrusion”) at the face of 137 mm.

Numerical analyses were performed by FDM

and an axi-symmetric coupled model reproducing

the full excavation sequence of an equivalent

circular tunnel (5.4 m radius) with the overburden

depth equal to 148 m (pore pressure 1.48 MPa).

The reinforcement was represented by a zone of

increased cohesion and Young modulus (150%)

while the support was simulated either with a

fictitious pressure or an equivalent lining (Fig. 9).

The results obtained are shown in Figure 10,

where the computed values are compared with the

observed values obtained from the longitudinal

displacements measured at the tunnel face by a

sliding micrometer. It is shown from Figure 10

that, independent of the many simplifications

introduced, the deformational response of the

tunnel, assuming a Mohr-Coulomb elasto-plastic

perfectly plastic law, is well represented. However,

in order to do this, the clay shales parameters

needed to be increased from the laboratory values

to the in situ values:

c’, from 20 kPa to 130 kPa;

E’, from 40 MPa to 200 MPa (dilatancy

ψ

= 0°).

60 m

0

10

20

30

40

50

Longitudinal

displacements

(sliding micrometer)

Radial

displacements

(optical targets)

Reinforced

ground

Primary

lining

9.5 m

7.0 m

A

A

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

6

0

20

40

60

80

100

120

140

45

50

55

60

65

70

75

Face advance [m]

Longitudinal displacement [mm]

04/07/98

05/07/98

07/07/98

08/07/98

Mohr-Coulomb

computed

values

0 5 10 15 20 25 30

Sliding

micrometer

installation (zero):

03/07/98

Mohr-Coulomb

computed

values

Figure 10. Longitudinal displacements at the face

of Osteria tunnel.

Another case of interest is the Raticosa tunnel

(high speed railway line Bologna-Florence), where

the excavation from the North side took place

through a paleo-landslide zone, in intensely

tectonized clay shales and under a limited

overburden (from few meters to 100 m). This

tunnel (about 14 m span, 160 m

2

cross section),

excavated full face with fiber glass dowels

reinforcement of the face and heavy support

systems installed in the heading, underwent

significant longitudinal displacements at the face as

shown typically in Figure 11, at a depth of 50 m

(pore pressure 0.4 MPa).

Also for this case numerical analyses were

performed with the FDM and an axi-symmetric

coupled model, in accordance with the same

procedure illustrated for the Osteria access adit. By

adopting a Mohr-Coulomb elasto-plastic perfectly

plastic law for the ground, the computed results

based on laboratory data gave once again

unrealistically high displacements around the

tunnel and an extent of the plastic zone such as to

make the tunnel unstable. However, by retaining

the same Mohr-Coulomb elasto-plastic model with

the ground parameters scaled up as shown in Table

4, the computed longitudinal displacements were

significantly underestimated with respect to the

measured values, as illustrated in Figure 11.

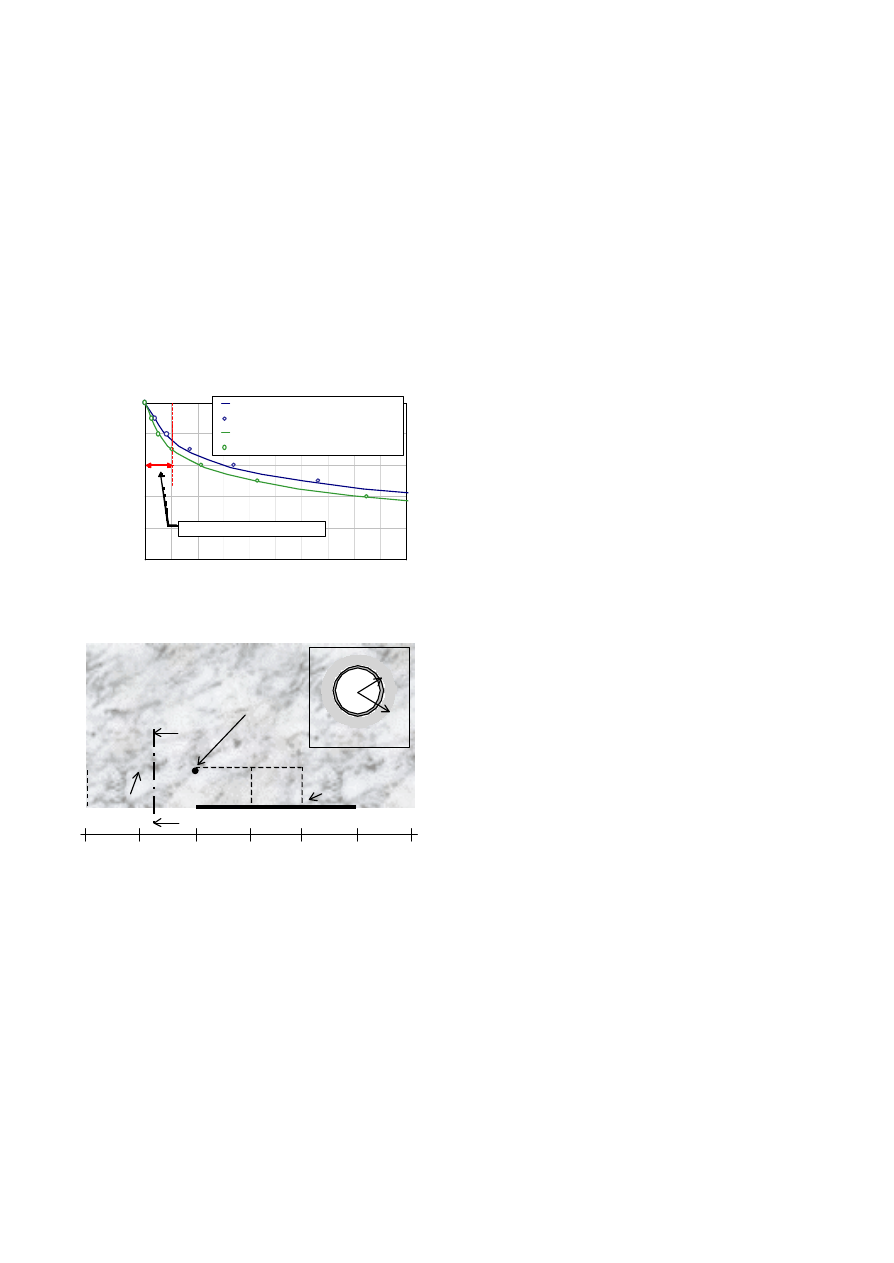

Considering the apparent time-dependent

behaviour influencing the tunnel response at the

face, as shown in Figure 11 for the longitudinal

Table 4. Raticosa tunnel parameters.

c’ [kPa]

φ’ [°]

ψ [°]

ν [-] σ

t

[kPa]

Laboratory

20

Tunnel

100

16

0

0.3

5.5

G

M

[MPa]

G

K

[MPa]

η

K

[MPa min]

η

M

[MPa min]

Laboratory

100

1.05

⋅

10

5

8.0

⋅

10

5

Tunnel

400

24.5

1.1

⋅

10

5

8.0

⋅

10

8

*

σ

t

= tensile strength;

G = shear modulus;

η

=

viscosity;

M

= Maxwell component;

K

= Kelvin

component.

0

20

40

60

80

100

120

0

5

10

15

20

25

30

Face advance [m]

Longitudinal displacement [mm]

04/07/98, h.13.00

04/07/98, h.20.00

05/07/98

06/07/98

15/07/98

16/07/98

CVISC

-

-

-

Mohr-Coulomb

-

-

Sliding

micrometer

installation (zero):

28/06/98

Figure 11. Longitudinal displacements at the face

of Raticosa tunnel.

displacement during excavation, it was decided to

adopt a visco-elastic plastic law (CVISC) available

with the Flac code. The results obtained are

illustrated in the same Figure 11, where the

computed values are compared with the monitored

data. It is shown that by invoking a time-dependent

behaviour for the ground, once again with the in

situ parameters scaled up with respect to the

laboratory values (Tab. 4), the tunnel response is

simulated satisfactorily.

5. CONCLUSIONS

The difficulties in characterisation of Italian

clay shales have been discussed with reference to

laboratory testing and large size tunnel excavation,

assisted by systematic performance monitoring

during face advance. It has been shown that, in

general, the laboratory data cannot be used directly

to assess the tunnel behaviour and that the

parameters need to be scaled up significantly in

order to obtain an appropriate prediction.

Possible lines of action to overcome these

difficulties are: (a) the use of experience gained

during the excavation of large size tunnels in clay

shales, as a guidance to assess the ground response;

(b) the use of a test section, where systematic

observation and monitoring during face advance

takes place in conjunction with back analysis.

6. ACKNOWLEDGEMENTS

The work described in this paper was carried

out with the financial support of the Italian

Ministry for University and Research as part of the

Research Programme “Mechanised excavation of

CVISC

computed

values

Mohr-Coulomb

computed

values

Paper 1B 05A — SINOROCK2004 Symposium

Int. J. Rock Mech. Min. Sci. Vol. 41, No. 3, CD-ROM, © 2004 Elsevier Ltd.

7

tunnels”, co-ordinated by Prof. Giovanni Barla.

The authors are grateful to Geodes (Turin) for the

technical support, to Rocksoil (Milan) for the

monitoring data and to Fiat Engineering (Turin) for

providing the cubic samples.

7. REFERENCES

Barla, G. 2002. Tunnelling under squeezing rock

conditions. In D. Kolymbas (ed.),

Tunnelling

Mechanics, - Eurosummerschool, Innsbruck,

2001. Rotterdam: Balkema.

Barla, G. 2003. Large span tunnels by full face

excavation in poor ground conditions. DS 5.3 –

Invited Discussion –

XIII ECSMGE, Prague.

Barla, M. 1999.

Tunnels in swelling ground –

Simulation of 3D stress paths by triaxial

laboratory testing. Ph. D. Thesis, Politecnico di

Torino.

Bonini, M. 2003.

Mechanical behaviour of Clay-

Shales (Argille Scagliose) and implications on

the design of tunnels. Ph. D. Thesis, Politecnico

di Torino.

Itasca, 2000. Flac, Fast Lagrangian Analysis of

Continua, Version 3.4. Itasca Consulting Group

Inc., Minneapolis.

Labiouse, V., Giraud, A. 1998. Analytical solutions

for the undrained response of a poro-elasto-

plastic medium around a cylindrical opening.

Proc. of the Biot conference on poromechanics.

Louvain la Neuve. Rotterdam: Balkema.

Lunardi, P. 1995. Progetto e costruzione di gallerie

secondo il metodo basato sull’analisi delle

deformazioni controllate nelle rocce e nei suoli.

Quarry and Construction.

Ribacchi, R., Riccioni, R. 1977. Stato di sforzo e di

deformazione intorno ad una galleria circolare.

Gallerie e Grandi Opere Sotterranee, 4.

Madsen, F. T. 1999. Suggested methods for

laboratory testing of swelling rocks. ISRM

Suggested Methods.

Int. J. Rock Mech. Min.

Sci. & Geomech. Abstr., 36.

Wyszukiwarka

Podobne podstrony:

Advanced Methods for Development of Wind turbine models for control designe

Design of a 10 kW Inverter for a Fuel Cell

Rindel Computer Simulation Techniques For Acoustical Design Of Rooms How To Treat Reflections

Design and construction of three phase transformer for a 1 kW multi level converter

Rewicz, Tomasz i inni Isolation and characterization of 8 microsatellite loci for the ‘‘killer shri

Recommendations for the Design of Bridges [Benson]

Principles of Sigma Delta Conversion for Analog to Digital Converters

100108 nmea 0183 sentences not recommended for new designs

Bartom NMT support concepts for tunnel in weak rocks

iraq book of iraq dodipp intelligence for military personnel 543NE5VSFEJ27BZY4ZHZFOZ3PIEZBN7S3XKQI7

Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying

Types of A V Aids and relevance for LT

Improved Characterization of Nitromethane, Nitromethane Mixtures, and Shaped Charge Jet

więcej podobnych podstron