Zakłady Aparatury Chemicznej CHEMET S.A.

ul. Sienkiewicza 47

42-600 Tarnowskie Góry

tel.: (+48 32) 39 33 300

fax: (+48 32) 39 33 301

e-mail: info@chemet.com.pl

www.chemet.com.pl

Tabela Nr. 1.

Tłoczenie den elipsoidalnych stalowych wg PN-64/M-35411 oraz PN-75/M-35412

Wg PN-64/M-35411 |

|||||||||||||||||

D |

h |

Grubość dna g w mm |

|||||||||||||||

|

|

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

24 |

25 |

|

|

Normalna wysokość h |

|||||||||||||||

|

|

20 |

30 |

40 |

60 |

90 |

|||||||||||

|

|

Średnica krążka/ciężar krążka w kG |

|||||||||||||||

33,5 |

8,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

38 |

9,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

44,5 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

57 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

76 |

19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

89 |

22 |

|

|

146 |

|

|

|

145 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0,53 |

|

|

|

1,04 |

|

|

|

|

|

|

|

|

|

108 |

27 |

|

|

170 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0,7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

133 |

33 |

|

|

200 |

200 |

206 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0,98 |

1,22 |

1,55 |

|

|

|

|

|

|

|

|

|

|

|

159 |

40 |

|

|

|

234 |

242 |

|

242 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,7 |

2,15 |

|

3,6 |

|

|

|

|

|

|

|

|

|

194 |

49 |

|

|

|

276 |

285 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2,3 |

3,0 |

|

|

|

|

330 |

|

|

|

|

|

|

219 |

55 |

|

|

306 |

306 |

312 |

312 |

312 |

|

|

7,2 |

|

|

|

|

|

|

|

|

|

|

2,3 |

2,9 |

3,6 |

4,2 |

4,8 |

|

|

|

425 |

|

|

|

|

|

273 |

69 |

|

|

374 |

374 |

378 |

378 |

378 |

|

|

|

15,6 |

|

|

|

|

|

|

|

|

|

3,4 |

4,3 |

5,3 |

6,1 |

7,1 |

|

|

|

497 |

|

|

|

|

|

324 |

81 |

|

|

435 |

435 |

440 |

440 |

440 |

466 |

466 |

|

21 |

|

|

|

|

|

|

|

|

|

4,7 |

5,8 |

7,1 |

8,3 |

9,5 |

12,1 |

13,5 |

|

|

|

|

|

|

|

356 |

89 |

|

|

472 |

472 |

480 |

|

480 |

505 |

505 |

|

|

|

|

|

|

|

|

|

|

|

5,5 |

6,9 |

8,5 |

|

11,4 |

14,1 |

16,8 |

|

|

|

|

|

|

|

406 |

102 |

|

|

535 |

535 |

540 |

|

540 |

565 |

565 |

565 |

|

600 |

|

|

|

|

|

|

|

|

7,1 |

8,8 |

10,8 |

|

14,4 |

17,7 |

19,7 |

23,4 |

|

35,5 |

|

|

|

|

457 |

115 |

|

595 |

595 |

595 |

602 |

602 |

602 |

626 |

626 |

626 |

|

|

|

|

|

|

|

|

|

5,3 |

8,7 |

11 |

13,4 |

15,6 |

18 |

21,7 |

25,2 |

29,5 |

|

|

|

|

|

|

508 |

127 |

662 |

|

656 |

656 |

662 |

|

662 |

687 |

687 |

687 |

|

700 |

|

|

|

|

|

|

5,3 |

|

10,6 |

13,3 |

16,2 |

|

21,8 |

26 |

29 |

35 |

|

49 |

|

|

|

|

|

|||||||||||||||||

Wg PN-75/M-35412 |

|||||||||||||||||

D |

h |

Grubość dna g w mm |

|||||||||||||||

|

|

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

25 |

|

|

Normalna wysokość h |

|||||||||||||||

|

|

40 |

60 |

90 |

|||||||||||||

|

|

Średnica krążka/ciężar krążka w kG |

|||||||||||||||

600 |

150 |

|

|

830 |

830 |

830 |

830 |

|

830 |

830 |

865 |

865 |

865 |

865 |

|

|

|

|

|

|

|

21,2 |

25,5 |

29,7 |

34 |

|

42,5 |

51 |

64,5 |

73,7 |

83 |

92,2 |

|

|

|

700 |

175 |

|

|

|

940 |

940 |

940 |

|

940 |

940 |

975 |

975 |

975 |

|

997 |

997 |

|

|

|

|

|

|

32,7 |

38,1 |

43,6 |

|

54,5 |

65,4 |

82 |

93,7 |

105,5 |

|

134,6 |

169 |

|

800 |

200 |

|

|

1070 |

1050 |

1050 |

1050 |

|

1050 |

1050 |

1050 |

1080 |

1080 |

|

1130 |

1130 |

|

|

|

|

|

35 |

40,8 |

47,6 |

54,4 |

|

68 |

61,6 |

100,8 |

115 |

129,6 |

|

169,4 |

184,8 |

|

Tabela Nr. 2.

Tłoczenie den okrągłych stalowych wg DIN-28011

Wg PN-64/M-35411 |

||||||||||||||||||

D |

R |

r |

Grubość dna g w mm |

|||||||||||||||

|

|

|

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

24 |

25 |

|

|

|

Normalna wysokość h |

|||||||||||||||

|

|

|

20 |

25 |

35 |

45 |

50 |

60 |

70 |

80 |

90 |

|||||||

|

|

|

Średnica krążka/ciężar krążka w kG |

|||||||||||||||

101,6 |

101,6 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

108 |

108 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

114,31 |

114,31 |

11 |

|

|

|

|

165 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,1 |

|

|

|

|

|

|

|

|

|

|

|

133 |

133 |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

139,7 |

139,7 |

14 |

|

|

|

|

190 |

190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,3 |

1,4 |

|

|

|

|

|

|

|

|

|

|

159 |

159 |

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

168,3 |

168,3 |

17 |

|

235 |

|

235 |

|

|

255 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1,0 |

|

1,7 |

|

|

3,2 |

|

|

|

|

|

|

|

|

|

193,7 |

193,7 |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

219,1 |

219,1 |

22 |

|

|

306 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2,2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

244,5 |

244,5 |

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

273 |

273 |

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300 |

300 |

30 |

|

|

|

410 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5,2 |

|

|

|

|

|

|

|

|

|

|

|

|

310 |

310 |

31 |

|

|

|

420 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5,4 |

|

|

|

|

|

|

|

|

|

|

|

|

315 |

315 |

32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323,9 |

323,9 |

32 |

|

|

435 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4,6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

355,6 |

355,6 |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

400 |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

406,4 |

406,4 |

41 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

457,2 |

457,2 |

46 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

500 |

50 |

|

|

|

|

656 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15,8 |

|

|

|

|

|

|

|

|

|

|

|

508 |

508 |

51 |

|

|

|

|

662 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16,2 |

|

|

|

|

|

|

|

|

|

|

|

550 |

550 |

55 |

|

|

|

|

785 |

|

785 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22,6 |

|

30,2 |

|

|

|

|

|

|

|

|

|

600 |

600 |

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

609,6 |

609,6 |

61 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

650 |

650 |

65 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

700 |

70 |

|

|

|

|

920 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32,5 |

|

|

|

|

|

|

|

|

|

|

|

711,2 |

711,2 |

71 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

750 |

750 |

75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

800 |

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

812,8 |

812,8 |

81 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

850 |

85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

900 |

90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tabela Nr. 3.

Tłoczenie den okrągłych stalowych wg DIN-28013

Wg PN-64/M-35411 |

||||||||||||||||||

D |

R |

r |

Grubość dna g w mm |

|||||||||||||||

|

|

|

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

24 |

25 |

|

|

|

Normalna wysokość h |

|||||||||||||||

|

|

|

20 |

25 |

35 |

45 |

50 |

60 |

70 |

80 |

90 |

|||||||

|

|

|

Średnica krążka/ciężar krążka w kG |

|||||||||||||||

101,6 |

81 |

15,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

108 |

86 |

16,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

114,31 |

92 |

17,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

133 |

106 |

20,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

139,7 |

112 |

21,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

159 |

125 |

24,5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

168,3 |

135 |

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

193,7 |

155 |

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

219,1 |

175 |

34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

244,5 |

196 |

38 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

273 |

218 |

42 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300 |

240 |

46 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

310 |

248 |

48 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

315 |

252 |

49 |

|

445 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3,6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323,9 |

254 |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

355,6 |

284 |

55 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

320 |

61 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

406,4 |

325 |

62 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

457,2 |

365 |

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

400 |

77 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

508 |

406 |

78 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

550 |

440 |

85 |

|

|

|

|

|

|

|

|

720 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32,6 |

|

|

|

|

|

|

|

600 |

480 |

92 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

609,6 |

488 |

94 |

|

|

|

|

|

|

|

|

830 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

42,5 |

|

|

|

|

|

|

|

650 |

520 |

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

560 |

110 |

|

|

|

|

|

|

920 |

|

920 |

|

940 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

43,6 |

|

54,1 |

|

79 |

|

|

|

|

|

711,2 |

569 |

110 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

750 |

600 |

115 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

640 |

125 |

|

|

|

|

|

|

1050 |

|

1050 |

1050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

54,4 |

|

67,5 |

81,6 |

|

|

|

|

|

|

812,8 |

650 |

125 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

680 |

130 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

720 |

140 |

|

|

|

|

|

|

|

|

1175 |

|

|

|

|

1175 |

|

|

|

|

|

|

|

|

|

|

|

|

|

85,2 |

|

|

|

|

213,2 |

|

|

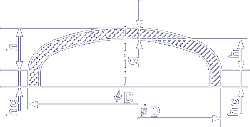

Nazwa elementu |

Rysunek poglądowy |

Zakres wyoblania |

Dna stożkowe wyoblane |

|

Średnica wewnętrzna |

|

|

Grubość blachy: stal węglowa do 12 mm; stal kwasoodp. do 10 mm |

|

|

Promień wyoblenia R = 10 ¸ 60 mm |

|

|

Wysokość części cylindr. |

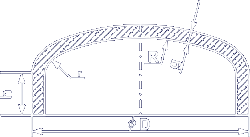

Dna płaskie wyoblane |

|

Średnica wewnętrzna |

|

|

Grubość blachy: stal węglowa do 12 mm; stal kwasoodp. do 10 mm |

|

|

Promień wyoblenia R = 10 ¸ 60 mm |

|

|

Wysokość części cylindr. |

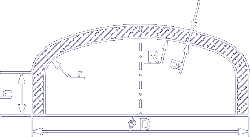

Półsoczewki kompensatorów wyoblane |

|

Średnica wewnętrzna max. |

|

|

Średnica wewnętrzna min. |

|

|

Grubość blachy od g = 3 ¸ 8 mm |

|

|

Promień wyobleń R = 30, 40, 50 mm |

|

|

Wysokość półsoczewki. h = (2xR) + g |

Wyszukiwarka

Podobne podstrony:

dna-plaskie-wyobl-NB, Konstrukcje metalowe-zbiorniki

blachy-Steel, Konstrukcje metalowe-zbiorniki

zaporow-zwrotne-b-h-Toszek, Konstrukcje metalowe-zbiorniki

zawory-oddech-Biuro-Handl-Toszek, Konstrukcje metalowe-zbiorniki

cieczowskazy-biuro Handl-Toczek, Konstrukcje metalowe-zbiorniki

wlazy-ITALINOX, Konstrukcje metalowe-zbiorniki

zaw-bezp-biuro-Handl-Toczek, Konstrukcje metalowe-zbiorniki

konstr-cylindr, Konstrukcje metalowe-zbiorniki

dna-stozkowe-NB, Konstrukcje metalowe-zbiorniki

Zaw-bezp-propor, Konstrukcje metalowe-zbiorniki

zbiorniki-poziome-dwupl-paliw, Konstrukcje metalowe-zbiorniki

armatura-spoz-farm-Italinox-1, Konstrukcje metalowe-zbiorniki

więcej podobnych podstron