swiece uszkodzenia

Are Your Plugs Trying To Tell You Something?

CHAMPION

Glow Plugs for Diesel engines.

Possible causes

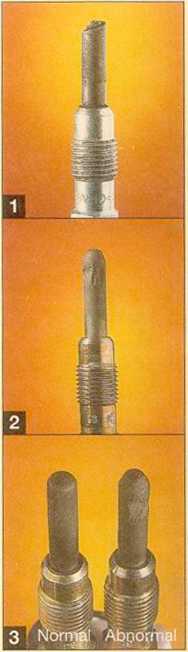

Q Melted or broken sheath

• Injectors (incorrect injection pressure, overadvanced injection, dripping nozzles). •Oil in the combustion chamber (overheating due to too high an oil level)

•Worn valve guides, broken piston rings

0 Corroded Sheath

• Electronic Control Relay Failure

• Incorrect system voltage

•Incorrect pług type fitted

• Thermal exchange regulation chamber compressed due to excessive torque on tightening of pług. A narrowed thermal exchange regulating chamber causes the sheath to overheat.

Corrective Action

• Recalibration of injection system •Correct engine oil level

• Replacement of piston rings/reboring of valve guides

• Check and/or replace Electronic Control Relay

• Check electrical system

• Check the pług type is correct for the vehicle

• The pług has to be mounted with care using a torque wrench, paying particular attention to the recommended torque levels

Q| Open circuit with apparently undamaged sheath

• Defective electrical system causing • Check electrical system

excessive voltage from battery

• Electronic Control Relay failure • Check and/or replace Electronic Control Relay

Spark Plugs for petrol engines.

Normal - Grey-brown deposits, lightly coated core nose. Plugs ideally suited to engine, and engine in good condition.

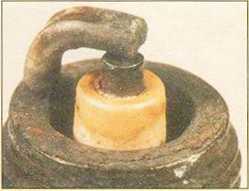

Oil Fouling - Wet, oily deposits. Fault: worn bores/piston rings or valve guides: sometimes occurs (temporarily) during running-in period.

Heavy Deposits - A build up of crusty deposits, light-grey sandy colour in appearance.

Fault: often caused by worn valve guides, excessive use of upper cylinder lubricant, or idling for long periods.

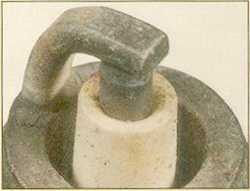

Overheating - Electrodes have glazed appearance, core nose very white - few deposits.

Fault: pług overheating.

Check: pług value, ignition timing, fuel octane rating (too Iow) and fuel mixture (too weak).

Lead Glazing - Pług insulator firing tip appears yellow or green/yellow and shiny in appearance.

Fault: often caused by incorrect carburation, excessive idling followed by Sharp acceleration. Also check ignition timing.

Electrode Damage - Electrodes burned away: core nose has burned glazed appearance.

Fault: pre-ignition.

Check: for correct heat rangę and as for ‘overheating’.

Carbon Fouling - Dry, black, sooty deposits.

Fault: over-rich fuel mixture. Check: carburettor mixture settings, float level. choke operation, air filter.

Split Core Nose - (May appear initially as a crack).

Fault: detonation or wrong gap-setting technique.

Check: ignition timing, cooling system, fuel mixture (too weak).

Wyszukiwarka

Podobne podstrony:

00439 57683fba1bad90493f04d56b521874a 444 Russell map movies can aid in uncovering a number of prob

htdctmw 061 Steps 4) and 5)—as if we have to tell you!—are on the next page... Weil, we know you’re

Sandland?7 p106 S TOP AUENĆINESSILENCE TH ISIS SH/BA. IHAVE SOMETHING TO TELL YOU .. BUTIN

1256069767 by WilliazashP0 I ve got something interesting to tell you... ...you wanna hear it ? wiw

Jane Austen Knits You must allow me to tell you how I and .

Sandland?7 p106 S TOP AUENĆINESSILENCE TH ISIS SH/BA. IHAVE SOMETHING TO TELL YOU .. BUTIN

angol4 Relacjonowanie wydarzeń Rozpoczynanie relacji Td like to tell you about... Chcę ci opowiedzie

image013 Tlł^NALYTięA^ABORATgg^ The AnLab is your chancc to tell us which storics you likc beat, and

Another valuable project would be trying to linę up Proof of Performance test dates, as all stations

075 (9) chapter five for the sewing room Here are some fun projects to twen up your sewing table. Th

więcej podobnych podstron