016

GERM/UUY'S PANTHER TANK

associated equipment Due to the large space needed to mount the GG400 auxiliary generator set. ammumtion stow-age for the main gun was reduced to 64 rounds The coaxial machinę gun and its mount were not mstalled The aperture m the gun mantlet was sealed with an armor pług.

The Sd.Kfz.267 was outfitted with a FuG 8 (30 watt trans-mitter with medium wave length receiver. operated m the fre-quency band 0 83 to 3 MHz) and a FuG 5 (10 watt transmit-ter with ultra short wave length receiver. operated in the fre-quency band 27.2 to 33.4 MHz). The Sd.Kfz.267 can be iden-tified by an Antennenfuss Nr.1 (antenna base. 104 mm base diameter) mounted on an msulator protected by a large ar-mored cylinder fitted on the rear deck A Sternantenne D (star antenna) for the FuG 8 was fitted to this base. A2-meter Stabantenne (rod antenna) for the FuG 5 was mounted on nght rear of the turret roof.

The Sd.Kfz.268 was outfitted with a FuG 7 (20 watt trans-mitter and ultra short wave length receiver. operated m the frequency band 42 1 to 47.8 MHz) and a FuG 5 The Sd.Kfz.268 can be identified by the 1 4 meter Stabantenne for the FuG 7 mounted on the left side of the rear deck with a 2 meter Stabantenne for the FuG 5 mounted on the right rear of the turret roof

Additional spare antenna rods were carried in three tubes mounted below the large camster for the gun cleaning rods on the left superstructure side 2 2 PROŁUCIfOM

An imtial order for 1000 Panther Ausf.D was placed by In 6. Contracts for assembly of the Panthers were awarded to the firms of M A.N. (Maschinenfabrik Augsburg-Nuernberg m Nuernberg). D.B. (Daimler-Benz in Berlin-Marienfelde). MNH (Maschinenfabrik Niedersachsen Hannover) and Henschel (Henschel & Sohn in Kassel). M.A.N.. D.B., and MNH as-sembled both chassis and turrets Henschel only assembled chassis. Turrets were assembled by Wegmann in Kassel and delivered in operating condition for Henschel to mount on their completed chassis.

Pnor to completion of the first Panther Ausf.D. the pro-duction order was reduced to 850. The actual number pro-duced fell short of 850. when M A.N. was ordered to provide 12 Panther chassis without turrets for use as Berge-Panther recovery vehicles These 12 Berge-Panther with Fgst.Nr in the rangę from 210125 to 210136 were completed by M.A.N. in early June 1943

TABLE 2.2: PANTHER AUSFUEHRUNG D PRODUCTION

M.A.N. D.B. Henschel MNH

|

Month |

No |

Fgst.Nr |

No. |

Fgst.Nr |

No. |

Fgst.Nr. |

No. |

Fgst.Nr. |

|

Jan43 |

4 |

210004 |

0 | |||||

|

Feb43 |

11 |

210015 |

6 |

211006 |

0 |

1 |

213001 | |

|

Mar43 |

25 |

210040 |

14 |

211020 |

10 |

212010 |

19 |

213020 |

|

Apr43 |

0 |

210040 |

19 |

211039 |

26 |

212036 |

39 |

213059 |

|

May43 |

68 |

210108 |

60 |

211099 |

25 |

212061 |

41 |

213100 |

|

Jun43 |

31 |

210151 |

40 |

211139 |

25 |

212086 |

36 |

213136 |

|

Jul43 |

58 |

210209 |

65 |

211204 |

19 |

212105 |

48 |

213184 |

|

Aug43 |

38 |

210247 |

26 |

211230 |

15 |

212120 |

36 |

213220 |

|

Sep43 |

7 |

210254 |

20 |

211250 |

10 |

212130 | ||

|

Total: |

242 |

250 |

130 |

220 = |

842 |

2 3 MODIFICATIONS fNTBOPUCEP PURING PRODUCTION

As with all senes of German Panzers, modifications were fre-quently introduced during production runs. These modifica-tions were prompted by a desire for. 1

The modifications are listed in the chronological order m which the changes first appeared on completed Panthers leav-ing the assembly plants In some cases. several months elapsed between the first appearance of a modification ana the time that it was present on all new production Panthers This was due to four different assembly plants each with nu-merous suppliers of major and minor components all initiat-mg modifications at different times and also by “first in. last out' tendencies This was caused when the older stockpiled parts were covered. buried, or madę maccessible by stonng shipments of newer parts The newer parts. bemg easier to obtam. were used first until their removal allowed access to the older parts

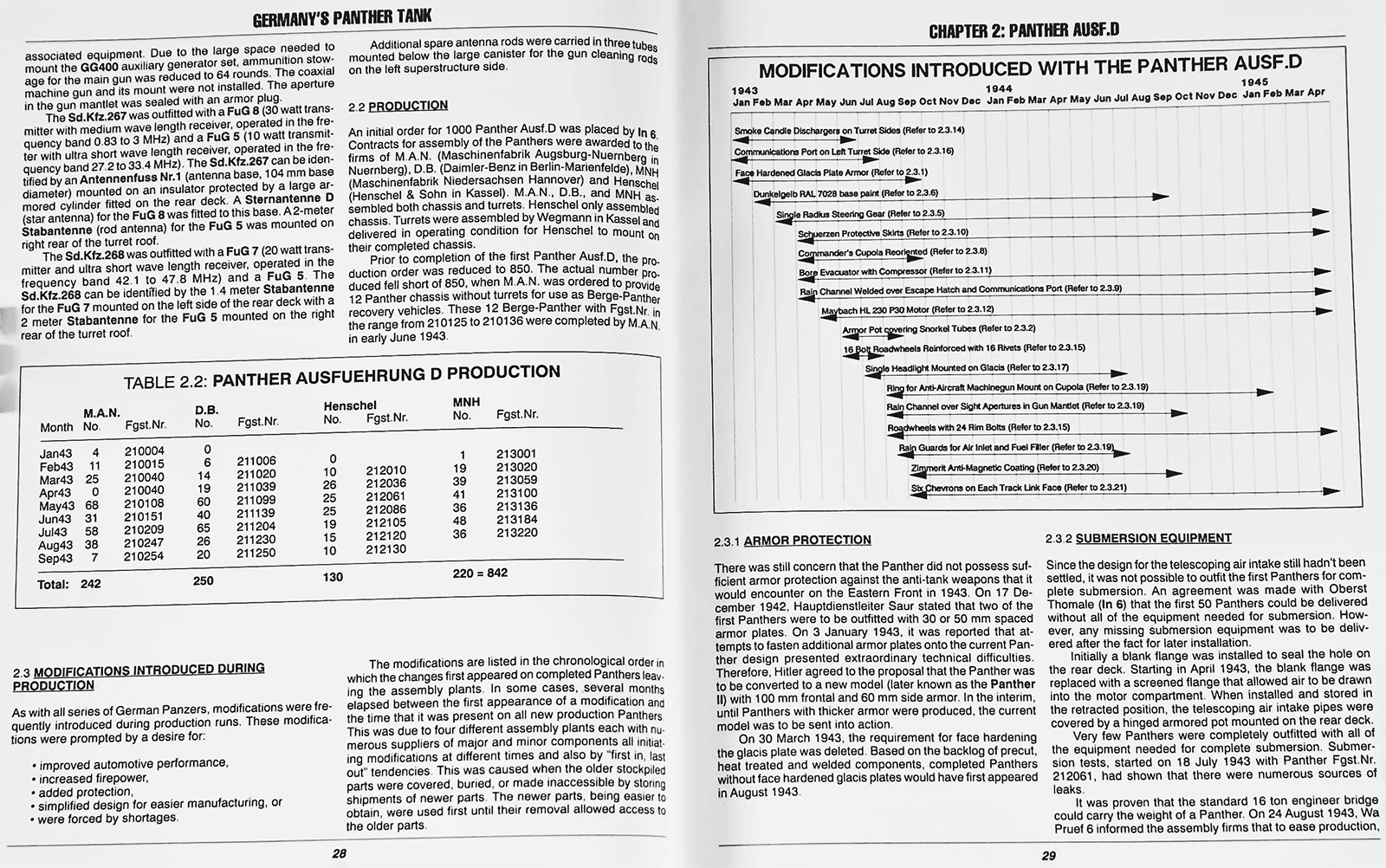

1943 1944 1945

Jan Fab Mar Apr May Jun Jul Aug Sap Oct Nov Dac Jan Fab Mar Apr May Jun Jul Aug Sap Oct Nov Dac Jan Fab Mar Apr

|

Snx1o GaocHo Dtochargers on Turret Sidcs (Retor to Z3.14) CommunlcaUona Port on Left Turret Side (Rcler to 2.3.16) | |

|

Face Ha/doned Glacis Plato Armor (Retor to 2.3.1) | |

|

Durjcelgelb RAL 7028 baso paint (Retor to 23.6) | |

|

Single Radka Stec ring Gear (Retor to 2.3.5) | |

|

Sehuerzen ProtectMe Sfclrtj (Rotor to 2.3.10) | |

|

Coymander1s Cupola Reort^cod (Retor to 23.8) Boy Evacustor w«h Compreasor (Retor to 2 3.11) | |

|

Rajn Channel Welded over Escape Hatch and Communications Port (Retor to 239) | |

|

Mjyfcach HL230P3O Motor (Refer to 25.12) | |

|

Arryy Pot t^yęrlng Snorkol Tubes (Retor to 233) l6jk>^taadwhoeis Rctoforced with 16 Rwets (Reter to 23.15) | |

|

Stopie Headlight Mounted on Glacis (Refer to 23.17) Rtop for And-Air era ft Machtoegun Mount on Cupola (Retor to 23 19) | |

|

Rato Channd over Sight Apertures to Gun MantJct (Retor to 23.19) | |

|

Rojdwheełs wtth 24 Rim 8otts (Retor to 23.15) | |

|

Rajp Guards lor Air Inkrt and Fud Filer (Refer to 2319)^ Ztoynerit And-Magnetlc Coattog (Retor to 2330) | |

|

Sb^hevTons on Each Track Unk Face (Retor to 2.331) | |

2.3.1 ARMOR PROTECTION

There was still concern that the Panther did not possess suf-ficient armor protection against the anti-tank weapons that it would encounter on the Eastern Front m 1943. On 17 De-cember 1942. Hauptdienstleiter Saur stated that two of the first Panthers were to be outfitted with 30 or 50 mm spaced armor plates. On 3 January 1943. it was reported that at-tempts to fasten additional armor plates onto the current Panther design presented extraordmary techmcal difficulties. Therefore. Hitler agreed to the proposal that the Panther was to be converted to a new model (later known as the Panther II) with 100 mm frontal and 60 mm side armor. In the interim, until Panthers with thicker armor were produced. the current model was to be sent mto action.

On 30 March 1943. the requirement for face hardenmg the glacis piąte was deleted Based on the backlog of precut. heat treated and welded components. completed Panthers without face hardened glacis plates would have first appeared in August 1943

2 3 2 SUBMERSION EOUIPMENT

Since the design for the telescoping air intake still hadn't been settled. it was not possible to outfit the first Panthers for com-plete submersion. An agreement was madę with Oberst Thomale (In 6) that the first 50 Panthers could be delivered without all of the equipment needed for submersion. How-ever, any missing submersion equipment was to be deliv-ered after the fact for later installation.

Initially a blank flange was installed to seal the hole on the rear deck. Starting in Apnl 1943. the blank flange was replaced with a screened flange that allowed air to be drawn into the motor compartment When installed and stored in the retracted position. the telescoping air intake pipes were covered by a hmged armored pot mounted on the rear deck.

Very few Panthers were completely outfitted with all of the equipment needed for complete submersion. Submersion tests. started on 18 July 1943 with Panther Fgst.Nr. 212061. had shown that there were numerous sources of leaks

It was proven that the standard 16 ton engineer bridge could carry the weight of a Panther. On 24 August 1943. Wa Pruef 6 mformed the assembly firms that to ease production.

29

improved automotive performance.

• mcreased firepower.

• added protection.

• simplified design for easier manufacturmg. or

• were forced by shortages

Wyszukiwarka

Podobne podstrony:

GERMANYS PANTHER TANK As an expedient to mcrease protection against strafing aircraft and splinters

GERMANY S PANTHER TANK Drawmg No H-Sk A 86176 dated 7 November 1943 shows a machmegun mount for a Pa

GERMANYS PANTHER TANK 4 3 13 WATERTLGHT SEALS BEHINB THE GUN MANTLET On 16 March 1944 MNH was mforme

GERMAN Y S PANTHEH TANK was almost completed. A model of the motor was complete and was to be sent t

i «GERMANY S PANTHER TANK Panther Ausf D. Tacticai Nr 203 (Fgst Nr 211213) was compieted at Daimler-

GERMANY S PANTHER TANK I Befehls-Panther Ausf D. Tactical Nr 155. possessed the last changes madę to

GERMANYS PANTHER TANK succeed in producmg a single 1 32 m rangefmder before the end ot ihe war Devel

GERMANYS PANTHER TANK STATUS OF OPERATIONAL PANTHERS Oparallon ZHadada from 5 to 17 Juty 1043 ICO 10

GERMANYS PANTHER TANK PANTHERS SENT TO THE WESTERN FRONT 344 STATUS OF PANTHERS ON THE WESTERN

GERMAIMY S PANTHER TANK "Sgt Ameth Anderson, Tank Commander “In our tanks we have not the ar mo

00161 d9d6ad9473daaf2c66ca66aa7e86e2 162 McWilliams constrain the solution by placing an upper bou

00175 Sf44c966c95fb915bf72191bd27e4aa 176 McWilliams To understand the wide rangę of cost penalties

00226 ?ff5d9dd7f87bcdc11138bd181d09bc 228 Baxlcy Figurę 7. Esample of Modified Shewhart Control Lar

00317 ?8ddf873a508f535a2304aca8bc776b 320 McCarville & Montgomery units will be rejected due to

00322 ?b73d4dcbb3956a7a53bceacac34fb9 Optimizing Defect Levels and Losses from Gage Errors 325 Figu

00323 ?85e6f46f7f32f30fdf82adebd3e7fe 326 McCarviIle & Montgomery Figurę 10. The Defect Level D

00329 ?f4634893f39e8884db8751e17aa760 332 McCarville & Montgomery 0.136772. This becomes a pote

więcej podobnych podstron