S5002315

204 MSockd 2ehrovico in Bohomin

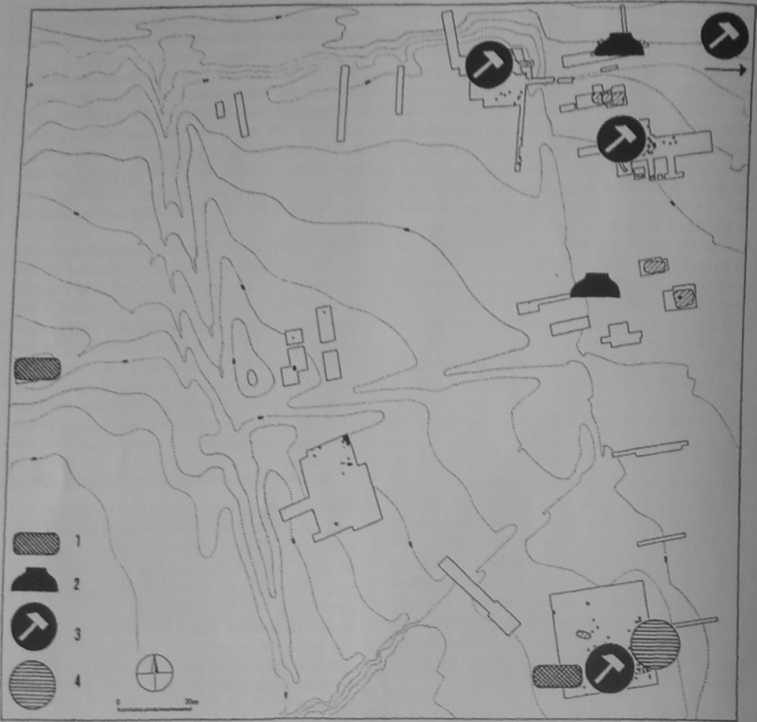

Fig. 109. Industrial features - • rccanstnictioa. 1 roasting pit, 2 bloomery workshop, 3 reheating hearth, 4 feature of undotemiined funcdan.

oval or circular shape with the diameter between 60-80 cm.

The presence of a smali ąuantity of bloomery slag in feaiures used evidently for pyrotechnological Processing might in di ca te the reheating of raw bloom (features 5/80 and 11/86 - shallow circular pits, 100x115 cm and 120x130 cm in diameter). A smali amount of tiny fragment* of bloomery slag need not be indicative of local iron making, as it is also a by-product of raw bloom Processing (cf. Pleiner 1993. 248).

The processing of raw bloom is also evidenced by two large non-homogeneous slag conglomerates, each consisting of up to six lumps of slag melted together, which were of different testu re and showed solidified flows or drops of different direc-tions (Fig. 14). The conglomerates size makes it

possible to attempt an estimate of the dimensions of the reheating hearths. The dimensions of the slag lump from trench 11G were 46x42x34 cm, the other conglomerate, a surface find from the area east of feature 1/79, was 40x34x36 cm. This indi-cates a pit at least 70-80 cm in diameter. Both aggregates correspond in size to the aggregate from the bloomery workshop in Mśec, measuring 36x33x46 cm and comprising three lumps of slag, which was found lying in a pit with burnt bottom and walls, 100x80 cm in size, 20 cm dcep (Pleiner • Princ 1984, 147, Abb.7). Reheating hearths are not very freąuently found on La Tfene or Roman period bloomery sites. K. Bielenin (1984, 35) de-scribed several examples of similar hearths - one of them 80 cm in diameter - in the immediate ricinity of a bloomery workshop, others as far as

fALEllA f

Industrial settlcment, LT B2-C1 185

100 m away. He explains their relntlvc scardty by only be uaed as an appnnimate basie for further

sui:in'Hting the poaaibility that the reheating of considerations. If we aaaume the weight of slag

the raw bloom took place directly in the area of produced by one smelt in MSeckć 2ehrovice to

the bloomery workshop, and the sraithing took reach 10 kg, then 560 kg of slag would represent

place on the terrain surfacc, where it did not leave 55 smelts; if the propoaed weight of slag was 15

any archaoologically identifiable traccs. kg, then it could havc been 37 smelts.

Lumpa of bloomery slag occurred in various den- The nuraber of smelts can also be calculated from

aitiee outaide the above-deocribed featurea aa we 11 the amount of iron produced by one smelt. This ia (ef. Chapter 12). . auppoaed to have reached in Mftec c. 2.5 kg of raw

The bloomery slag on the aite (including the frag- bloom (Pleiner - Princ 1984). According to this,

ments of fu mace lining), gained by the excava- the 132 kg of raw bloom inMAeckć2ehrovice would

tions, roached a to tal weight of c. 580 kg. Of that, eorrespond to c. 53 smelts, which ia a figurę not

feature 1/79 and i ta immediate surroundings, in- very different from the previous calculation. These

cluding the ploughsoil finda, contained 285 kg of numbers are very rough estimates, undoubtedly

slag, the accumulatian in trench 3 99 kg, feature at the Iower end of the scalę of actual output an

11/86 745 kg, and the conglamerate from trench the aite, as we are working with just a sample of

llO 20 kg. Together with the earlier surface find the whole find complex, the real volume of which

of the conglomerate of 525 kg. the total of c. 630 is unknown.

kg of bloomery slag originated from the aite so far. It is possible to infer from the number of smelts

This quantity represents but a fragment of the performed, the manpower and time reąuired for

total volume of slag from the aite (not induded iron-making on a aite. UBscfaenlohr and YSer-

aree.g. the finda of slag from systeraa tic field walk- neels (1991,106) calculate the manpower needed

ing of the present author. 1993-1995), and all the for the indńridual actmties connected with iron-

estimates of local iron production represent the making aa foliowa:

minimal possible quantitłes. reduction of iron in the furnace: 1 smelt = 25

According to the estimate by R. Pleiner bssed on man/days,

the investigations and ezperiments conducted so eztraction, washing, and roasting of 40 kg of iron far, 630 kg of slag and lining corresponds to e. are = 1 man/day,

550 kg of slag proper, which in tum corresponds production of 100 kg af charcoal = 1 man/day.

to c. 99 to 165 kg (on average 132 kg) of raw bloom According to this estimate, the 46 smelts in Mtec-

actually produced, i.e. 49.5 to 82J> kg of ber iron. ki 2ehrovice (if the aeerages from the Iower es-Although it is not known how large a portion af timates of production are uaed. <£ also Table 28) the site’s total find potendal is araflaUe far the would reąaire 115 man/Uąys, 1185 kg af charcoal

estimation, the total local iron production on the 12 man/days, and 1320 kg af iron are (according site may be estimated in the order of hundreds of to K. Bielenin iron are : raw bloom = 10 : 1) 33

kg. This volume of production might not seem to man/days, which ia a total af 160 man/days for the

be too large, and it certainly does not bear eon- whole estimated output at the kwest end of the

parison with the tons of iron produced by the large scalę. Although Eschenlohr and Semeels (1991)

bloomery districts of la ter periods (cf. the Holy uaed for the estimate of manpower requirements

Cross Mountains in Pol and. Bielenin 1992). how- a morę sophisticated furnace with a much higher

ever, it was suffident for the manufacture of a volume tfaan could be angectured for MAecke

great number ofartefaets. 66 kg ofhar iron, which Żebrowce, their results seem to be generally

is an average of the above-mentioned estimate applicable even for much sunpter sunken fur-

of the minimum output on the site, would be naces of a smaller rolume. The esperiment by

enough to make for ezampte 88 sword blades or P. Crew and C. Sałter (19931 demonstzated a total

132 lance heads, 66 axe heads or 1320 medium requirement of 25 man/hours (25 man/days?)

knives (weights of the olgecfcs after Pleiner 1994, for the production of 1 kg of bar iron including

183). the ore and charcoal Processing, etc. If the mini-

R. Pleiner (Pleiner - Princ 1984. 161-162) can- mam eotume of bar iron produced in MSeckć

sidered the weight of slag błock from a furnace in Żehrowce has been estimated as 66 kg, then,

the bloomery workshop in Mdec to be 10-15 kg according to the results reached by Crew and

although the slag hlock found in situ in furnace 1 Salter. this would mean that 165 man/days

weighed only 6 kg. It should be potnted out that were reąuired. This result is very near to the

this weight is the minimum weight, as the slag 100 man/days calculated using the estimates by

found in the furnace can represent only part af Eschenkhr and Semeels. For the operation of

the original błock. Tłua estimate ia rahd for a dif- a btoomery furnace, and for the work preceding

ferent type of furnace than the one presumed to and foUmiog the smelt itoełf, at least 3 persona

be used at MSeckć 2ehrovke, and therefore it can K-schenkhr - Semeels 1991.106) were esseniial.

Wyszukiwarka

Podobne podstrony:

S5002311 170 Mdeckć Źohrovico in Bohomin A boad mado from colourless glnss (Fig. 73:7) fbund in feat

S5002313 180 MSeckó 2ohrovico in Bohomia The tools, i.o. iron chisels and knivos, were not fbund in

S5002311 170 Mdeckć Źohrovico in Bohomin A boad mado from colourless glnss (Fig. 73:7) fbund in feat

S5002311 170 Mdeckć Źohrovico in Bohomin A boad mado from colourless glnss (Fig. 73:7) fbund in feat

S5002312 178 Mdeckó 2ehrovice in Bohcmin chisel. A massive ąuadrangular artefact, from fea-ture 9/81

S5002321 260 MSeckć Żehrovicc in Bohemia Fig. 2. Interpretation of the ground plan ofbuilding 0/87-1

S5002312 178 Mdeckó 2ehrovice in Bohcmin chisel. A massive ąuadrangular artefact, from fea-ture 9/81

S5002317 188 MAockó 2chrovico in Bohomin Raw iron bloom weight - minimal 132 kg Raw iron bloom woi

54573 S5002312 178 Mdeckó 2ehrovice in Bohcmin chisel. A massive ąuadrangular artefact, from fea-tur

51654 S5002318 190 MSeckó 2ehrovice in Bohemia and wool. The smali proportion of neo-natal and non-a

397 (13) 370 Dress Accessońes piąte were held securely in position (fig 247). A further feature of t

więcej podobnych podstron