CCI20140507�30

-54-

Method for Remoyal of Insecticides

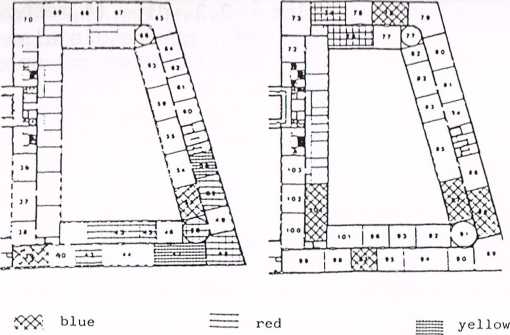

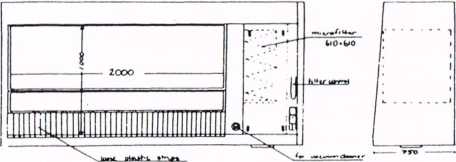

Because of the obvious health-hazard while handling the objects, it was decided to remove the insecticide dust in an especially constructed fume-cupboard by means of pressu-rized air.

2900

On the drawing you can see the dimensions of the fume cup-board. In the front there is a removable window. The loose plastic strips secure the necessary vacuum in the working chamber. The air exchange chamber. The air exchange is 800 cubical meters per hour. There are three filters in the cupboard: a microfilter absorbing particles down to one micrometer, a filter to take the odours which consists of potassium permanganate and finally one morę microfilter.

A filter control indicates time for filter change. The fumecupboard is lackered with acid-resistant paint because of the presence of corrosive insecticides.

Remoyal of Insecticides, Safety and Working Procedurę

When the cleaning of the objects for the new storerooms at the Museum was stopped, because of the discovery of DDT, the objects in ąuestion were put into plastic bags which were then put into acid-free cardboard boxes. These were sent to an interim storę room attached to the conservation workshop, while we worked on a treatment solution.

Safety

We discussed our own safety risks a lot when starting this work. Naturally we wanted to minimize the spreading of dust from the objects to ourselves and our surroundings.

We decided upon a working routine for two persons - one movable and the other stationary. One did the carrying, registration and after-treatment-packing. The other did the work in the fume cupboard - that means taking the objects out of the plastic bags, removing any stuffing paper and treating the objects with pressurized air. Ali this was done inside the fume cupboard. Al the rubbish was put into plastic bags which were marked "DDT" and safely stored, and later in bigger portions sent to salt mines in Germany.

Safety Eguipment

To protect ourselves we used lightwear polyethylen suits with hood, microdust masks, vinyl gloves, and a hearing protector because of the noise of the fume cupboard and the airpressure pistol. The suits were changed every second day, the gloves and masks every day.

A yacuum cleaner with micro filter was used for keeping the room and the fume cupboard free of dust. Its outlet went via a tubę into the fume cupboard. In addition the cabin walls, the window and the plastic curtain were cleaned with water (containing an antistatic medium) and absorbent disposable paper towels.

Wyszukiwarka

Podobne podstrony:

m850 possibly by only some of the latter: it was never as common as we are given to believe. Only a

Back ♦ ♦ ♦YOU CAH rfEVER,PR£DICT Abbey Shore never intended to be the savior of the world; it was ju

00055 ?8eb8f33682dd4ffedb872005d8a4b1 54 Hembree & Zimmer quite a while for discussion of the K

Weronika DZIKOWSKA It is necessary to develop methods for transfer of results obtained by testing sa

image002 For morę of the best M/M romance, visit www.dreamspinnerpress.com

img2 Y> %eM For morę of the best M/M romance, visit www.dreamspinnerpress.com

placecards HOLIDAY PLACE CARDS GLUE AREA 1, Cut out pattem for base of the tree; and tracę it on col

Isolation An essential ingredient of any safe system of work is the method and integrity of the isol

i. Introduction CCT diagrams are used for detennination of the phase structure and hardness of steel

490 for evaluation of the synergy effect in the case of ihe fusion of enterprises and intangible res

9 Zastosowania rachunku różniczkowego w ekonomii Zadanie 9.7. For each of the given cost functions f

więcej podobnych podstron