essentÊrving°95

-

C A R V I N G A COMMONPLACE OBJECT IN H I G H R; : .H

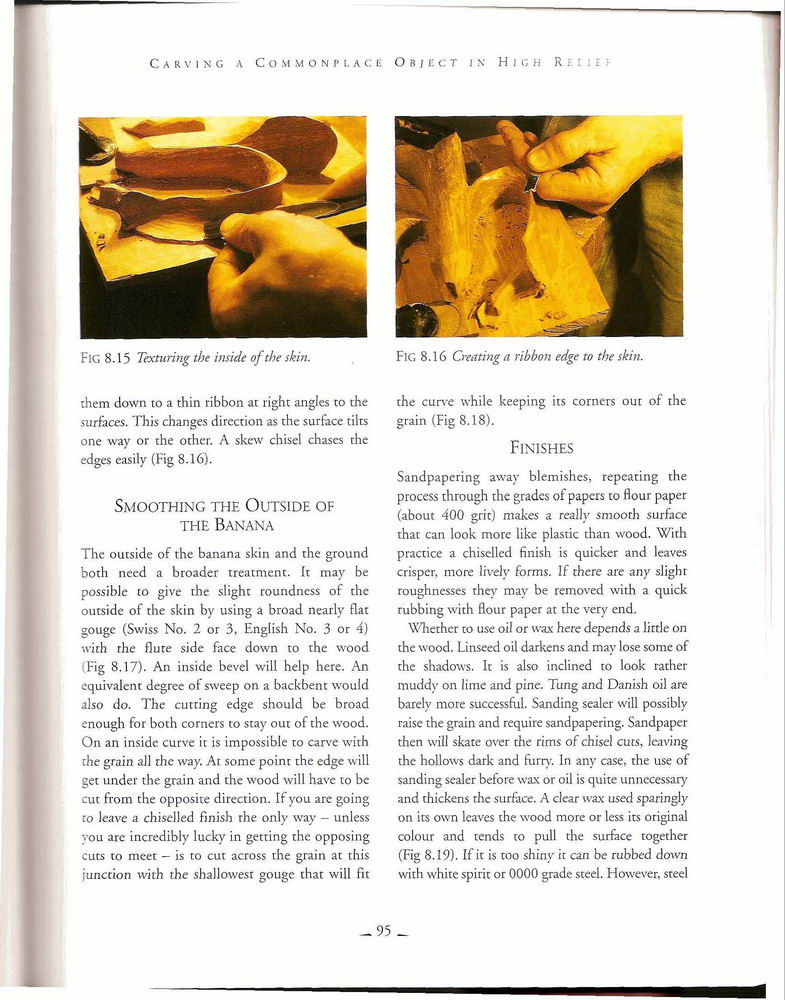

Fig 8.15 Texturing the inside of the skin.

Fig 8.16 Creańng a ribbon edge to the skin.

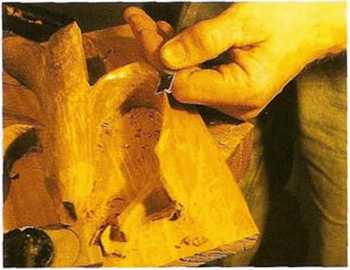

them down to a thin ribbon at right angles to the surfaces. This changes dircction as the surface tilts one way or the other. A skew chiscl chascs the edges easily (Fig 8.16).

SMOOTHING THE OUTSIDE OF the Banana

The outside of the banana skin and the ground both need a broader treatment. It may be possible to give the slight roundness of the outside of the skin by using a broad nearly fiat gouge (Swiss No. 2 or 3, English No. 3 or 4) wirh rhc flure sidc face down to the wood Fig 8.17). An inside bevel will help here. An equivalcnt degree of sweep on a backbent would also do. The cutring edge should be broad enough for both corners to stay out of the wood. On an inside curve it is impossiblc to carvc with the grain all rhc way. Ar somc point the edge will get under the grain and the wood will havc to be cut from the oppositc direction. Ifyou are going to leavc a chiselled finish rhe only way - unless you arc incrcdibly lucky in getting the opposing cuts to mect - is to cut across the grain at this itinction with the shallowesr gouge that will fit the curve while keeping its corners out of the grain (Fig 8.18).

Finishes

Sandpapering away blemishcs, repeating the proccss through the grades of papers to flour paper (about 400 grit) makes a really smoorh surface that can look morÄ™ like plastic than wood. With practice a chiselled finish is quicker and lcaves crisper, morÄ™ Iively forms. If rhere are any slight roughnesses they may be removed with a quick rubbing with flour paper at the verv end.

Whcther to use oił or wax here depends a lirtle on the wood. Linseed oil darkens and may lose some of the shadows. It is also inclined to look rather muddy on limę and pinc. Tung and Danish oil are barcly morę succcssful. Sanding sealer will possibly raisc the grain and require sandpapering. Sandpaper then will skatc over rhc rims of chisel cuts, leaving the hollows dark and furry. In any case, the use of sanding sealer before wax or oil is quite unnccessary and thickens rhc surface. A elear wax used sparingly on its own lcaves the wood morę or less its original colour and tends to puli the surface together (Fig 8.19). If it is too shiny it can be rubbed down with white spirit or 0000 grade Steel. Howcver, Steel

-95 -

Wyszukiwarka

Podobne podstrony:

essent?rving?89 C A R V I N G A COMMONPLACE OBJECT IN H I G H R E L I F. F Making a Model and CHOOSI

essent?rving?88 CHAPTER 8 CARYING A COMMONPLACE OBJECT IN HIGH RELIEF Finding Interest IN

essent?rving?93 C A R V I K G A COMMONPLACE OBJECT IX HlCII R F. L 1 F F FlG 8.9 The skin is morÄ™ de

jff 116 DIGEST OF GENERAL RULES FOR JUDO CONTEST It is commonly reÄ…uired in Judo contest that the pl

â–¡ NATIONAL GEOGRAPHIC The Milky Way arcs overa mountain lakÄ™ in California. From ourvantage point in

infrared body?tector INFRA-RED BODY DETECTOR - M3)T SffWTMn) THE circuit in Fig.2 can detect any lar

essent?rving?59 Car ved Mo u l dix g s Fig 4.12 After the rim ofthe cup has been stabbed in, a chip

essent?rving?68 E S 5E NTI A L W O O D C A R VIN G TECHNIQLES Fig 5.6 The gouge can removeplenty of

essent?rving?05 C A R V 1 N c, IN T H F. R O L N D Fig 9.19 Using a rijfler to shape the stew of th

essent?rving?21 C A R V 1 N G A N Ani M AL IN THE R O l N D Fig 11.5 Rear view. The saw cnts facilit

essent?rving?70 Es S E N TI A L W O O D C A R VING TeCHXIQUE$ Fig 15.23 The fishtail cutting the end

Icad iFig. 1A»; remoce rł»e vibrntor «md bridge ihr eonnortion as shown in Fig. II?. The 6.3-vo

Y CORTEX RAIN) % Fig. 7. Some connections in th« atcending pathways o( the auditory nerroui

Theoretical and Methodological Problems 15 The growing interest in ecosystem services in cities and

P1130049 1.3.4 Uterine pathology 1.3.4.1 Embryonic death In the horse embryonic death occurs in 4 to

więcej podobnych podstron