6355787698

Diagnostyka’ l(45)/2008 13

RYBCZYŃSKI, Maps ofTolerable Misalignments of Bearings Applicable...

in steady State and nominał operation conditions, at the speed equal to 3000 rev/min and fuli power output 211 MW [10, 12].

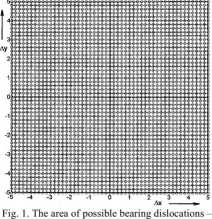

grid 51x51 points for which calculations were carried out

It was decided to study the response of this machinę to dislocations of all bearings in all directions, and to record this response in the form of vibrational symptoms observed in all bearings. For this purpose a piane of possible bearing dislocations was defined, the centre of which is the basie, designed position of the bearing with respect to other bearings. Assuming this position as a base is justified by the fact that bearing dislocations reveal random naturę, as a result of which dislocation of an arbitrary bearing in arbitrary direction is eąually possible. Performed were systematic, detailed calculations of the effects of bearing dislocations within the ranges:

-5mm < Ax < 5 mm, with 0,2mm step in horizontal direction,

-5mm < Ay < 5mm, with 0,2mm step in vertical direction.

It was assumed that simultaneous dislocations in vertical and horizontal direction are possible. Conseąuently, a 51 x 51 grid was defined on the dislocation piane, which gave 2601 possible positions of the bearing centre. The distribution of the calculation points within the 10x10 mm sąuare is schematically shown in Fig. 1.

For each point marked with a smali circle on the dislocation piane in the Fig. 1, the calculations were performed using the programme package MESWIR. For the purposes of the present publication the following quantities were calculated and analysed:

- amplitudes of relative vibrations in two directions Ax, Ay, perpendicular to each other

- RMS velocities of absolute vibrations in two directions Vx, Vy, perpendicular to each other. The reported research is of typical theoretical

and numerical naturę. All calculations were

performed using a set of Computer codes composing the system MESWIR [1, 12, 15]. The system was developed and is in use in IF-FM for calculating the dynamics of rotors supported on oil bearings. The rotors are modelled using finite elements. Bearing characteristics (reactions, stiffness and damping properties) are obtained as the numerical solution of the two-dimensional Reynolds equation with the Reynolds boundary conditions. The main codę package is written in FORTRAN. The work consisted in calculating the dynamie State of the machinę with the simulated misalignment of a selected bearing from its base position. The misalignment defect was introduced to the base model of the machinę as the dislocation of a relevant node representing the bearing, in the form of dislocation components: Ax in the horizontal direction and Ay in the vertical direction. An arbitrary bearing dislocation is the geometrie sum of the above elementary dislocations. The results of calculations are sequences of instantaneous positions of selected system nodes as a function of time, which makes it possible to calculate vibration amplitudes and velocities, and draw trajectories of those nodes.

In order to determine the areas of permissible bearing dislocations with respect to allowable bearing vibrations, the limits of vibrations were assumed [10, 11]. When these limiting values were exceeded, the technical State of the turboset was considered unacceptable. The following vibration criteria were assumed:

A < A,fm = 165 pm,

where A/im is the limit of relative journal-bush vibrations, expressed by the p-p dislocation amplitudę in two directions inclined by 45° to the perpendicular,

VRMS < VRMS lim =7,5 mm/s, where Vrms Hm is the limit of absolute bearing vibrations, expressed by RMS vibration velocities in the horizontal and vertical directions.

The vibration limits were taken from the standards: ISO 7919-2 for relative vibration and from ISO 10816-2 for absolute vibration. The limits correspond to the machinę warning State.

It is worth stressing that for the machinę to be considered ready for operation as a whole, all these two conditions are to be simultaneously met in all bearings, and not only in the bearing in which the defect was recorded. In case any of these limits is exceeded, the turboset should be stopped from operation. There should be also underlined that type of vibration and location of points where the vibration are analysed in the machinę model correspond to those measured by the diagnostic system in the real machinę. That is why these maps are compatible with the recordings of the machine’s diagnostic system and can be easily compared with the vibrations recorded by the system. Thus they can be used by the diagnostic system.

Wyszukiwarka

Podobne podstrony:

Diagnostyka’ l(45)/2008 15 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

Diagnostyka’ l(45)/2008 17 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

Diagnostyka’ l(45)/2008 19 RYBCZYŃSKI, Maps ofTolerable Misalignments of Bearings

12 Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps ofTolerable Misalignments of Bearings

14 Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

16 Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps offolerable Misalignments of Bearings Applicable...MAPS OF

20 Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps ofTolerable Misalignments ofBearings

Diagnostyka’ 4(48)/2008 13 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

18 Diagnostyka’ l(45)/2008 _RYBCZYŃSKI, Maps ofTolerable Misa/ignments ofBearings

10 Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSKI, Small-Sized Test Bedfor

Diagnostyka’ l(45)/2008 Spis treści Joanna IWANIEC - AGH

Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSKI, Small-Sized Test Bedfor

Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSKI, Small-Sized Test Bedfor Diagnosing... broader

Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSKI, Small-Sized Test Bedfor Diagnosing... into

Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSKI, Small-Sized Test Bedfor

Diagnostyka’ l(45)/2008 GUMIŃSKI, JASIŃSKI, RADKOWSK1, Small-Sized Test Bedfor Diagnosing... Fig. 4.

:ACTM Acta Sci. Poi, Medicina Veteriiiaria 7(4) 2008, 13-20 SAFETY AND QUALITY OF MILK PRODUCTS FROM

Diagnostyka’ 4(48)/2008 11 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

więcej podobnych podstron