POWDER METALLURGY

Mateusz Soja

Piotr Pabiańczyk

IM sem.3

16.11.2021

2

Introduction

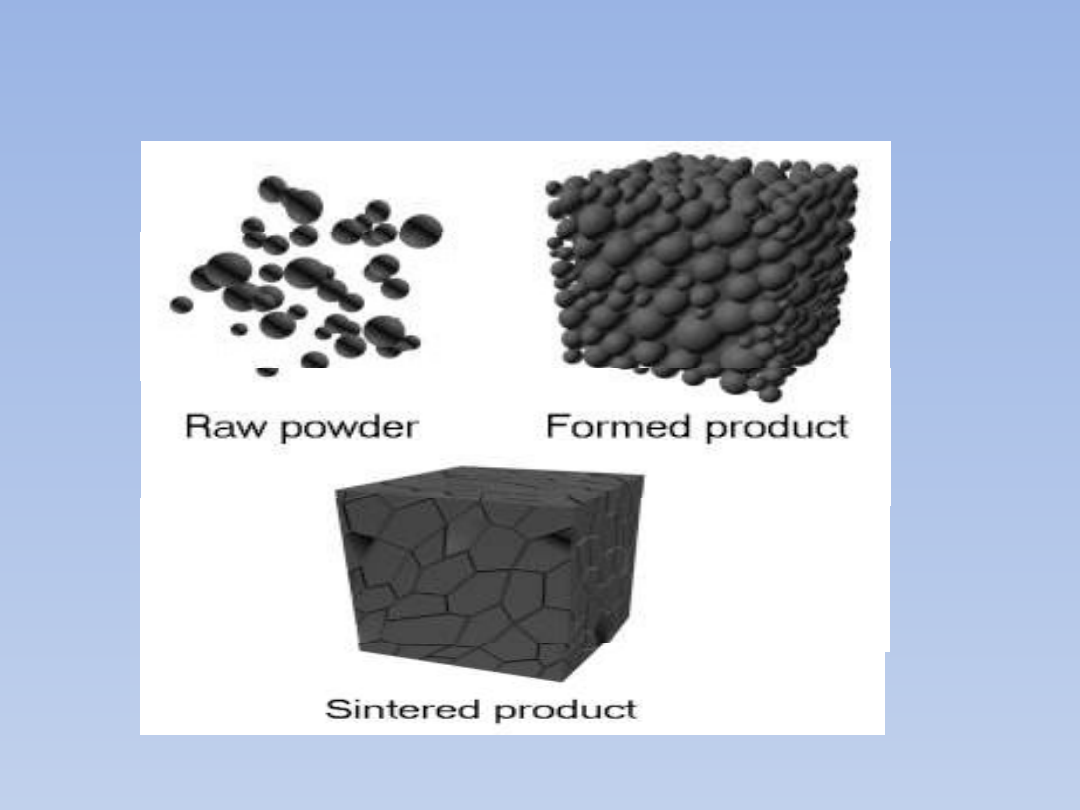

Powder metallurgy is a process for

forming metal parts by heating

compacted metal powders to just

below their melting points.

Powder metallurgy is the study of the

processing of metal powders, including

the fabrication and conversion of metal

powders into useful engineering

components.

Basic P/M Steps

• Raw Material/atomization,

• Mixing,

• Forming/Compaction,

• Sintering,

• Optional Operations,

• Finished Products.

Powder Compaction and

Sintering

POWDERS

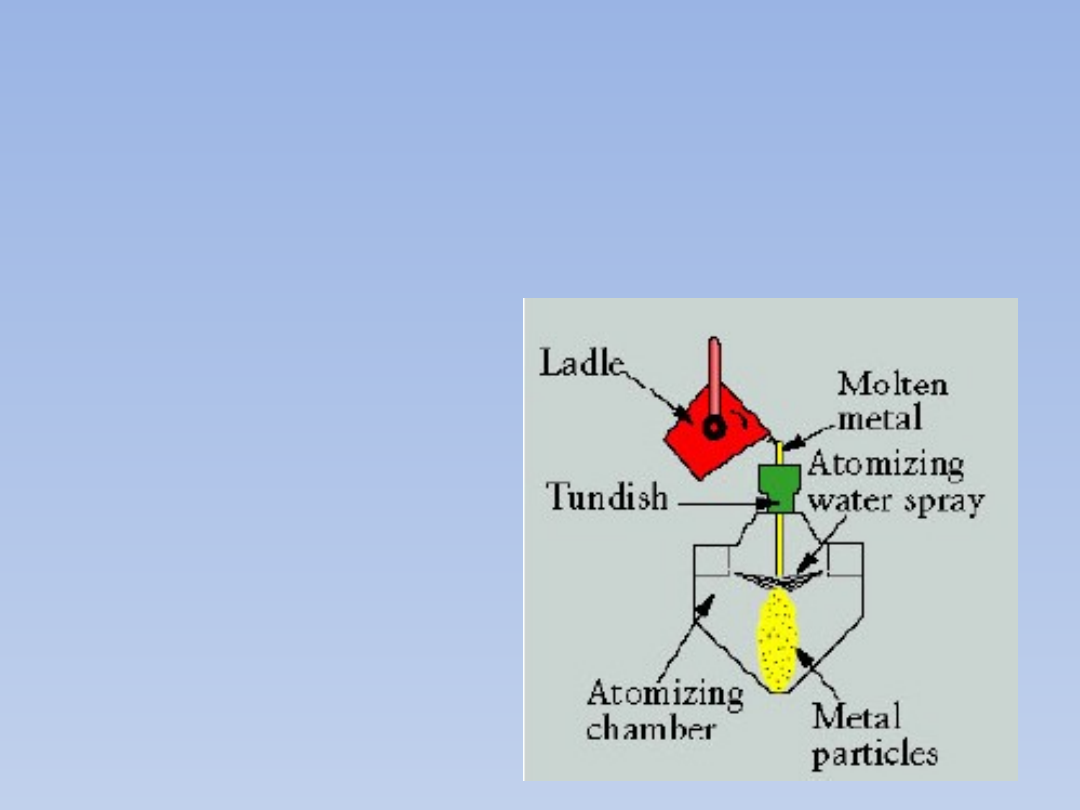

One method of metal-powder

production by melt atomization

Atomization is

accomplished by

forcing a molten

metal stream

through an orifice

at moderate

pressures.

MIXING

Elemental, partially alloyed or pre-alloyed

metal powders are first blended with

lubricants to produce a homogeneous mixture.

Cycyle of mixing:

1. Reduction of oxides,

2. Annealing,

3. Powder Weighings,

4. Adding lubricants,

5. Mixing.

FOMRMING/COMPACTION

Methods of compaction are:

• Pressing,

• Rolling,

• Extrusion,

• Injection molding.

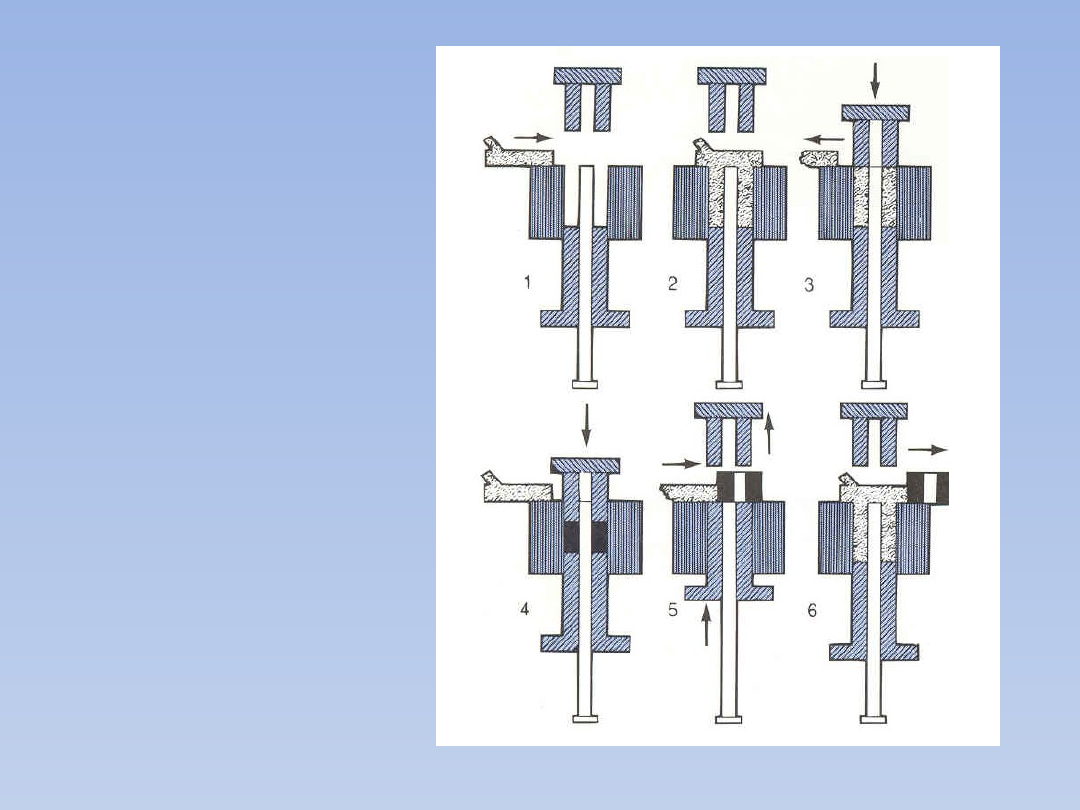

Pressing

Compaction Cycle:

1. Cycle Start

2. Charge die with

powder

3. Compaction

begins

4. Compaction

complete

5. Ejection of

compact

6. Recharging of die

MECHANICAL PRESS

SINTERING

The parts are heated below the

melting point of the base metal, held

at the sintering temperature, then

cooled.

Typical sintering temperatures for

based metals range from 1100 - 1150

celsius degrees

Standard cycle times range from 2-3

hours.

SINTERING FURNACE

Optional Operations

• Heat treatment,

• Impregnation of sintered,

• Machining,

• thermo-chemical treatment,

• Surface treatment of sintered.

Examples of typical parts made by

powder metallurgy processes.

Thx for your attention

Document Outline

- Slide 1

- Introduction

- Basic P/M Steps

- Powder Compaction and Sintering

- POWDERS

- MIXING

- FOMRMING/COMPACTION

- Pressing

- MECHANICAL PRESS

- SINTERING

- SINTERING FURNACE

- Optional Operations

- Slide 13

- Thx for your attention

Wyszukiwarka

Podobne podstrony:

16 197 208 Material Behaviour of Powder Metall Tool Steels in Tensile

Powder Metallurgy

Investigations of White Layer Formation During Machining of Powder Metallurgical Ni Based ME 16 S

Offenzellige Metallschaume

PowderedMetallurgy

Blacksmith The Origins Of Metallurgy Distinguishing Stone From Metal(1)

Metallica Discography Lyrics

Powder

Metallic Text Gimp

4 PIM Powder Injection Molding

METALLICA BLACK TEKSTY

metallica enter sandman level 2z5

Metallographic Methods for Revealing the Multiphase Microstructure of TRIP Assisted Steels TŁUMA

powdermeTALLURGY

Metallica Nothing Else Matters

Metall Alloys

Coating Methods, Powder Technology

Aluminum Metallurgy

więcej podobnych podstron