![]()

![]()

http://www.goldnscrap.com/index.php/gold

Oddzielenie kwasem solnym i

utlenienie miedzi do chydrochlorku miedzi.

Chlorek

miedzi(II),

CuCl2 – nieorganiczny

związek chemiczny, sól kwasu

solnego imiedzi na

+2 stopniu

utlenienia.

Dihydrat chlorku

miedzi(II) ma postać szmaragdowozielonych kryształów. W tej formie

występuje jako rzadki minerał eriochalcyt.

Otrzymać go można poprzez roztworzeniewęglanu

miedzi(II) w kwasie

solnym.

Bezwodny

chlorek miedzi występuje w postaci brązowego ciała stałego

(minerałtolbachit).

Można go otrzymać spalając miedź w nadmiarze chloru lub

poprzez odwodnienie dihydratu za pomocą stężonego kwasu

siarkowego.

Wodne roztwory chlorku

miedzi(II) są zielone, natomiast w dużym rozcieńczeniu mają barwę

niebieską.

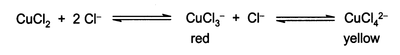

W

obecności nadmiaru jonów chlorkowych tworzy związki kompleksowe:

CuCl3-(czerwony) i CuCl42- (żółty)[4].

Pozostaje złoto, z którego

robimy wodę królewską, a potem z niej wytrącamy złoto.

Film z procesem (3 części):

http://www.youtube.com/watch?v=iCmXLXrAtto

http://www.youtube.com/watch?annotation_id=annotation_2862129675&feature=iv&src_vid=iCmXLXrAtto&v=Hv4CcaTVJqY#t=1m59s

http://www.youtube.com/watch?annotation_id=annotation_2194426549&feature=iv&src_vid=iCmXLXrAtto&v=0yOBdkxk1IE#t=3m39s

Złom elektroniczny

http://www.goldnscrap.com/index.php/scrap-cpu-a-chips

redukcja złota z wody

królewskiej za pomocą SMB ( pirosiarczyn sodu )

http://www.bimberhobby.pl/product.php?id_product=48

Before

explaining how to perform this process, it's probably be better if we

first talk about why use it in the first place.

As

you probably know, there are many reducing agents that will reduce

ionic gold into the metal, such as: SMB (Sodium MetaBisulfite),

copperas (Iron II Sulfate), Sulfur Dioxide Gas (SO2), Hydroquinone,

formaldehyde, hydrazine Sulfate and many more… each has its own

applications and pro's / con's.

The

Oxalic/Oxalate process is very selective for reducing Gold ions and

it is used when very high purity (9999 and higher) Gold is desired.

But due to the nature of this process which involves changing the

acidity of the solution (which may form oxides/hydroxides of base

metals and interfere the process), It is used almost exclusively as a

re-refining process, sometimes referred to as "polishing"

step. When in most cases the Gold will be reduced from an Aqua Regia

solution the 1st time with the use of SMB or SO2 Gas,

get washed and dissolved again, filtered and then reduced the

2nd with Oxalic Acid.

Important:

This is not a Recovery process, this is a final step of Refining.

High

purity Gold of 9999 and higher could be made with simple setup (as

you can view in the video below) that even a hobbyist refiner could

build himself, let alone a proper and well organized laboratory.

Who

needs this process and why?

Research

and processing labs can utilize this process to produce high purity

gold powder to be used either as is or as precursor for preparing

gold based catalysts. Considering the prices charged by large vendors

for precious metals powders, the cost saved by this process is

enormous.

Refiners

would rather use this process for producing small amounts of bullion

gold, amounts too small which doesn't justify setting up an

electrolytic refining cell (Wohlwill process).

The

use of Oxalic acid is also called for as a first refining step when

large amount of PGM's are in solution with the gold, such in the case

of dental gold.

WARNING:

The process described here involves highly corrosive and toxic

chemicals and should only be done outside or in a fume hood. Using

all the safety gear such as Gloves, goggles and a respirator is

mandatory.

The

process:

Gold

powder which had been refined once (dissolved and dropped out of

solution with SMB) was dissolved again by means of Aqua Regia in the

usual manner and filtered through a slow/medium speedFilter

paper .

This is the main Chloroauric Acid solution we will be working with in

this process.

.

This is the main Chloroauric Acid solution we will be working with in

this process.

-

The Gold solution is placed in a high quality borosilicate

beaker or

in a boiling

flask (with

tapered ground joint) and the flask is placed on a hot

plate/mantle on

medium heat. Make sure the solution level will not exceed two thirds

of the flask volume.

-

In another beaker, weight out Oxalic

acid (dehydrate).

The amount of Oxalic acid needed is 1.15

gram for

every 1

gram of

expected gold metal.

This ratio represents a 20% excess in Oxalic acid to ensure all of

the gold is reduced in case there's too much nitric acid left in the

original AR solution.

-

Add the Oxalic acid to the gold solution and turn up the heat of the

hotplate/mantle until a gentle boil has reached. A boiling flask with

tapered ground joints enables you to connect a condenser (Graham)

and an addition

funnel (see

video below), but if you are boiling the solution in an open mouth

beaker, you should cover it with a watch glass. The addition of

reagents will be done through the spout with a pipette.

-

Now prepare a concentrated Sodium

Hydroxide (NaOH)

solution in another beaker. Simply add some NaOH prills/powder and

dissolve it with warm water until no more is dissolved. Either by an

addition funnel or by manually adding it with a pipette, start adding

the NaOH solution to the gold solution. Remember you are adding a

strong base to a strong acid which produce a violent exothermic

reaction, thus the addition must be done SLOWLY

and DROPWISE.

You

may notice some precipitation of brown powder before you even add any

NaOH, but that's just about as far as it will go without pH

adjustments. At this point, you may also notice brown Nitrogen

Dioxide (NO2 – toxic gas) formed in the reaction vessel which is

the result of left over excess Nitric acid from the original Aqua

Regia solution. If the gas cloud formed is very thick, it's probably

a result of way too much Nitric being used and you might want to

consider adding more Oxalic acid and or even start over.

It

is pointless to try and determine just how much NaOH is needed, so

your main indicator for the reaction completion is the color of the

solution. As you add NaOH you will notice more and more

brownish/black suspension being formed that will slowly coagulate.

Keep adding NaOH solution until you can no longer notice the

yellow/orange hue of the solution and the bubbles.

-

Once the process is done and all of the gold had precipitated out,

the solution would normally be either colorless or with just a faint

color of blue/green. If there's a significant coloration to the

solution, then you probably should consider repeating the process all

together. Remember, this process is all about purity.

At this

point, the pH of the now barren mother liquor should fall anywhere

from 0-2.

-

If you used a boiling flask, it is recommended that you now transfer

the powder and the barren solution to an open mouth beaker so it will

be easier to wash. It is suggested that you will allow the gold

suspension to settle to the bottom first. It takes several hours…

Even better, let it to settle overnight.

-

The following day, slowly decant the barren waste solution either

through a filter or into a settling tank to be discarded later.

Washing

cycles are done in the usual manner:

-

Cover the gold powder with Hydrochloric acid (HCl 25-31%) and boil

for few minutes, let cool and settle, now decant and repeat two more

times at least.

-

Cover the gold powder with Ammonia solution (NH4OH 10-25%) and boil

for few minutes, let cool and settle, now decant and repeat one more

time at least.

-

Cover the gold powder with boiling hot Distilled Water

and swirl it around for few minutes, let cool and settle, now decant

and repeat 3-5 times.

You

can combine all of the above washes with the barren mother liquor and

filter it all at once just in case some gold powder slipped through.

Also, keep in mind that sometimes, the HCl washes may dissolve some

of the gold. You can precipitate it later with SMB.

Remember

you must make sure the combined washes solution is acidic, otherwise

you risk forming Ammoniacal gold complexes which can turn explosive.

You can test the solution with a simple pH test strips.

-

After the last distilled water wash is decanted, place the beaker on

a hot plate and set it on low heat until the gold powder is

completely dry. The color of the powder should be very light brown.

-

Depends on what you want to do, you can now use the gold powder as is

or melt your gold in a new and clean crucible.

-

Sit back, have a beer and enjoy your success :)