PALLADIUM ON BARIUM SULFATE

1

Palladium on Barium Sulfate

1

Pd/BaSO

4

[7440-05-3]

Pd

(MW 106.42)

InChI = 1/Pd

InChIKey = KDLHZDBZIXYQEI-UHFFFAOYAH

(usually supported on BaSO

4

, or an appropriate form of carbon,

when used to catalyze the hydrogenation of acyl chlorides to alde-

hydes, the Rosenmund reduction;

2

useful catalyst for many other

hydrogenations

1b

–

l

)

Alternate Name:

Rosenmund catalyst.

Form Supplied in:

Pd-on-BaSO

4

and Pd-on-C are available com-

mercially or may be prepared.

3

Handling, Storage, and Precautions:

the catalysts may be stored

indefinitely in well-sealed containers.

1e

Although the unused

catalysts can be exposed to a clean atmosphere, they may ignite

organic solvent vapors; heating a Pd-on-C catalyst in a vacuum

drying oven at 115

◦

C for more than 48 h causes it to become

extremely pyrophoric.

4

After use, all catalysts are liable to con-

tain adsorbed hydrogen and may ignite when dried. The filtered

catalyst should be kept wet and away from combustible vapors

or solvents.

Traditional Rosenmund Procedures. The palladium-cata-

lyzed hydrogenation of an acid chloride to an aldehyde is known

as the Rosenmund reduction (eq 1). In the original procedure, hy-

drogen is bubbled through a heated suspension of the catalyst,

Pd/BaSO

4

, in a xylene or toluene solution of the acyl chloride.

2

The HCl formed is absorbed in water and titrated to monitor the

reaction’s progress. Although the procedure works well for many

acyl chlorides, for others the further reduction of the aldehyde

to the alcohol, and the consequential formation of esters, ethers,

and hydrocarbons, seriously lowers the yield of the aldehyde.

1

In initial experiments, it was reported that benzoyl chloride was

converted almost completely to benzaldehyde; however, repe-

tition of the same experiment, but with all reactants carefully

purified, gave none.

5

Seeking possible catalyst modifiers or reg-

ulators, it was found that quinoline-sulfur, a crude preparation of

thioquinanthrene, was most suitable.

5,6

Other regulators which

have been recommended are pure thioquinanthrene, thiourea, and

tetramethylthiourea.

5,7

The purity of the solvent, which is used in

much larger amounts than any of the reactants or the catalyst, is

a key to reproducible reductions.

8,9

Attaining the lowest temper-

ature at which HCl is evolved was reported to optimize the yield

of aldehyde.

1a

R

O

Cl

R

O

H

+

H

2

Pd/BaSO

4

+

HCl

(1)

toluene or xylene

In a 1948 review, it is claimed that ‘For accomplishing this

transformation, RCO

2

H → RCHO, the Rosenmund reduction is

probably the most useful method for application to a large number

of aldehydes of varied types’.

1a

This critical review describes the

scope and limitations of the reaction, the experimental conditions,

reagents, and procedures and includes tables recording the acid

chlorides whose reduction by the Rosenmund method had been

reported to November 1947.

Rosenmund described a simple apparatus for performing the

reduction.

5

A detailed description of a more elaborate appara-

tus and procedure used for the hydrogenolysis of β-naphthoyl

chloride (0.30 mol) in xylene catalyzed by 5% Pd/BaSO

4

and

regulated by quinoline-sulfur was given by Hershberg and

Cason (eq 2).

10

They recommended that a ‘poison’ always be

added to ensure controlled conditions. The hydrogenolysis of

mesitoyl chloride in xylene over unpoisoned Pd/BaSO

4

is des-

cribed in the same volume; vigorous stirring shortens the reaction

time by about one third.

11

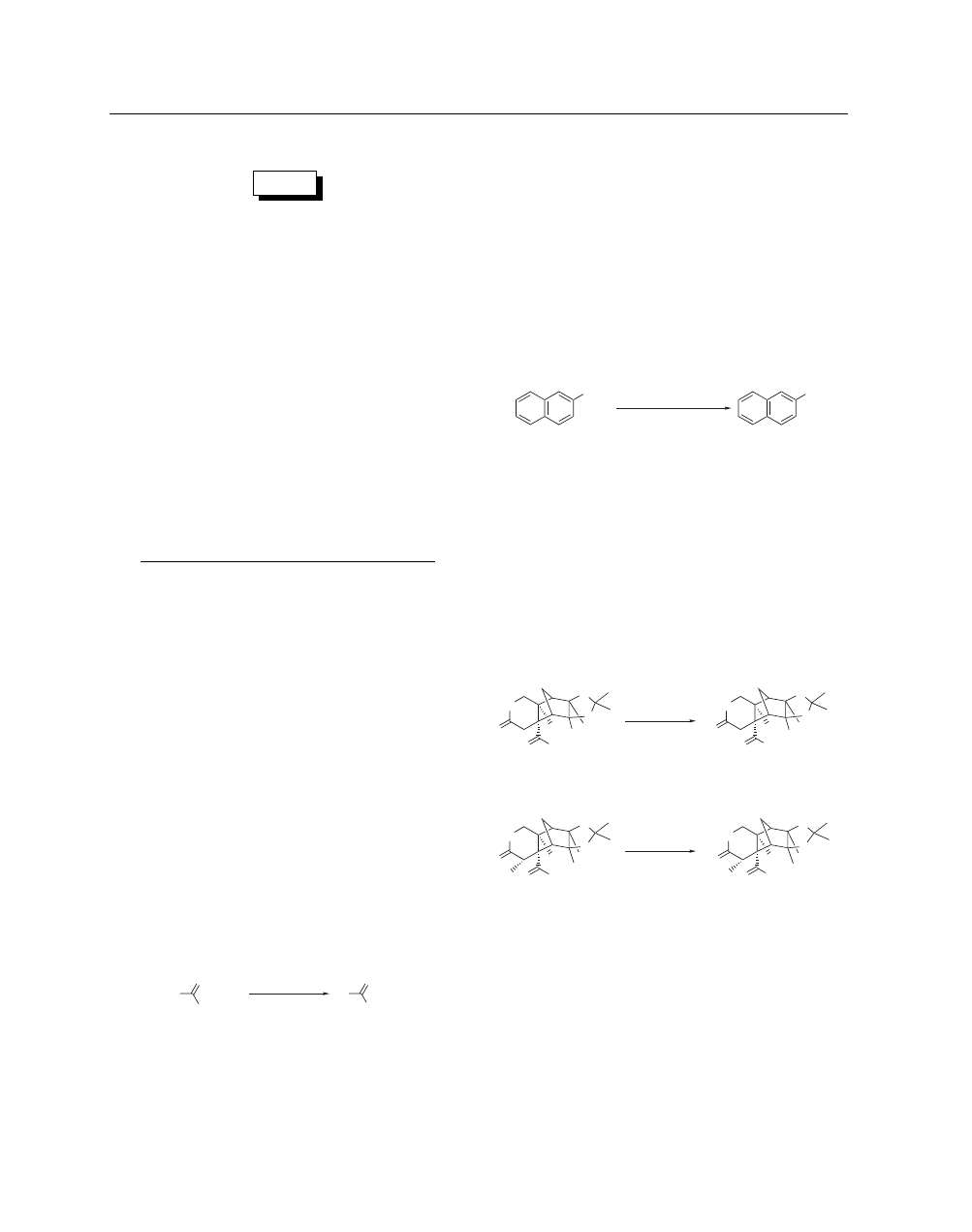

(2)

COCl

CHO

H

2

, 5% Pd/BaSO

4

quinoline-S, xylene, reflux

74–81%

The omission of catalyst poisons is common and the origi-

nal Rosenmund procedure

2

has been successful with acid halides

containing other functional groups, or condensed benzenoid or

heterocyclic systems.

1a

For example, discouraged by attempts to

obtain high yields with a variety of metal hydride reducing

reagents, Danishefsky et al. found that the original Rosenmund

procedure converts the acid chloride (eq 3) in an essentially quan-

titative yield.

12

The reduction of the related compound with a

methyl group proximate to the C(O)Cl group gave only a 49%

yield of the aldehyde (eq 4) (however, see below).

H

O

O

O

H

O

Cl

H

O

H

O

O

O

H

O

H

H

H

2

, Pd/BaSO

4

O

(3)

toluene, reflux

95%

H

O

O

O

H

O

Cl

H

O

H

O

O

O

H

O

H

H

H

2

, Pd/BaSO

4

O

(4)

toluene, reflux

49%

A procedure for the unpoisoned 10% Palladium on Carbon

catalyzed hydrogenation of α-phthalimido acid chlorides to the

aldehydes in benzene at 40

◦

C has been described.

13

To cause the

benzene to reflux at 40

◦

C, the pressure is lowered with a vacuum

pump which is attached to the outlet in a manner which allows the

collection and titration of the evolved HCl. This procedure was

suited particularly for the preparation of the phthaloyl methio-

nine aldehyde (eq 5) but the (±)-phenylalanine and (±)-alanine

derivatives gave yields of 93% and 94% respectively with benzene

refluxing at 1 atm. An almost identical low temperature (reduced

pressure) procedure was used to hydrogenate a diacid chloride to

the dialdehyde in 92–94% yield (eq 6).

14

Avoid Skin Contact with All Reagents

2

PALLADIUM ON BARIUM SULFATE

N

O

O

O

Cl

SMe

N

O

O

O

H

SMe

H

2

, 10% Pd/C

benzene, reflux, 38–40 °C

(5)

reduced pressure

90%

H

2

, 10% Pd/C

benzene, reflux, 30–35 °C

COCl

COCl

CHO

CHO

(6)

reduced pressure

92–94%

Rosenmund Reductions within Closed Systems. To avoid

the higher temperature and the hazard of free flowing hydrogen

of the classical Rosenmund procedure, particularly for large scale

preparations, an autoclave can be used for the Pd/C catalyzed

hydrogenolysis of 3,4,5-trimethoxybenzoyl chloride to the alde-

hyde (yield, 64–83%); the reduction was done at 35–40

◦

C and H

2

(4 atm) in toluene containing quinoline-S with anhydrous sodium

acetate as HCl adsorber (eq 7).

4,15

The same reaction has been

achieved repeatedly in 80–90% yields by the Rosenmund pro-

cedure without added regulators and either Pd/BaSO

4

or Pd/C

catalysts and either xylene or PhOMe as solvent.

1a

MeO

MeO

MeO

COCl

MeO

MeO

MeO

CHO

4 atm H

2

, 10% Pd/C

quinoline-S, toluene

(7)

NaOAc, 35–40 °C

64–83%

Sakurai and Tanabe were the first to report the use of a closed

system for the Pd/BaSO

4

catalyzed hydrogenolysis of an acyl

halide.

16

The reduction (H

2

, 1 atm) was conducted at rt in the

presence of a hydrogen chloride acceptor, N,N-dimethylaniline,

and acetone as solvent. N-Phthaloyl derivatives of (±)-α-amino

acid chlorides have been hydrogenated to the aldehydes using 10%

Pd/C in the solvent ethyl acetate (H

2

, 3 atm) in the presence of

dimethylaniline, with yields of over 90%.

13

The Sakurai and Tanabe procedure (5% Pd/BaSO

4

) gave

high yields of arachidaldehyde (72%) and stearaldehyde (96%);

for convenience, N,N-dimethylacetamide was used as the acid

acceptor to obtain excellent yields of palmitaldehyde (96%) and

decanaldehyde (96%).

17

Peters and van Bekkum chose ethyldi-

isopropylamine as HCl acceptor due to the competitive reduc-

tion of N,N-dimethylaniline, which obscured the end-point (vol

H

2

) of the hydrogenolysis of the acid chloride.

18

The mild

conditions converted the sterically hindered carbonyl chloride

function in 1-t-butylcyclohexanecarbonyl chloride to the alde-

hyde (78%), although t-butylcyclohexane was the sole product

of the original Rosenmund procedure (eq 8). Burgstahler and

Weigel also modified the Sakurai and Tanabe procedure by using

2,6-dimethylpyridine in place of N,N-dimethylaniline and THF as

solvent with either Pd/BaSO

4

or Pd/C as catalyst to obtain excel-

lent yields of 15 sensitive aliphatic and alicyclic aldehydes such

as hexanedial (74%) and (Z)-9-octadecenal (96%) (eq 9).

19

The

reaction temperature was lowered to 0

◦

C to convert dehydroabi-

etic acid chloride to the aldehyde (92%) (eq 10).

19

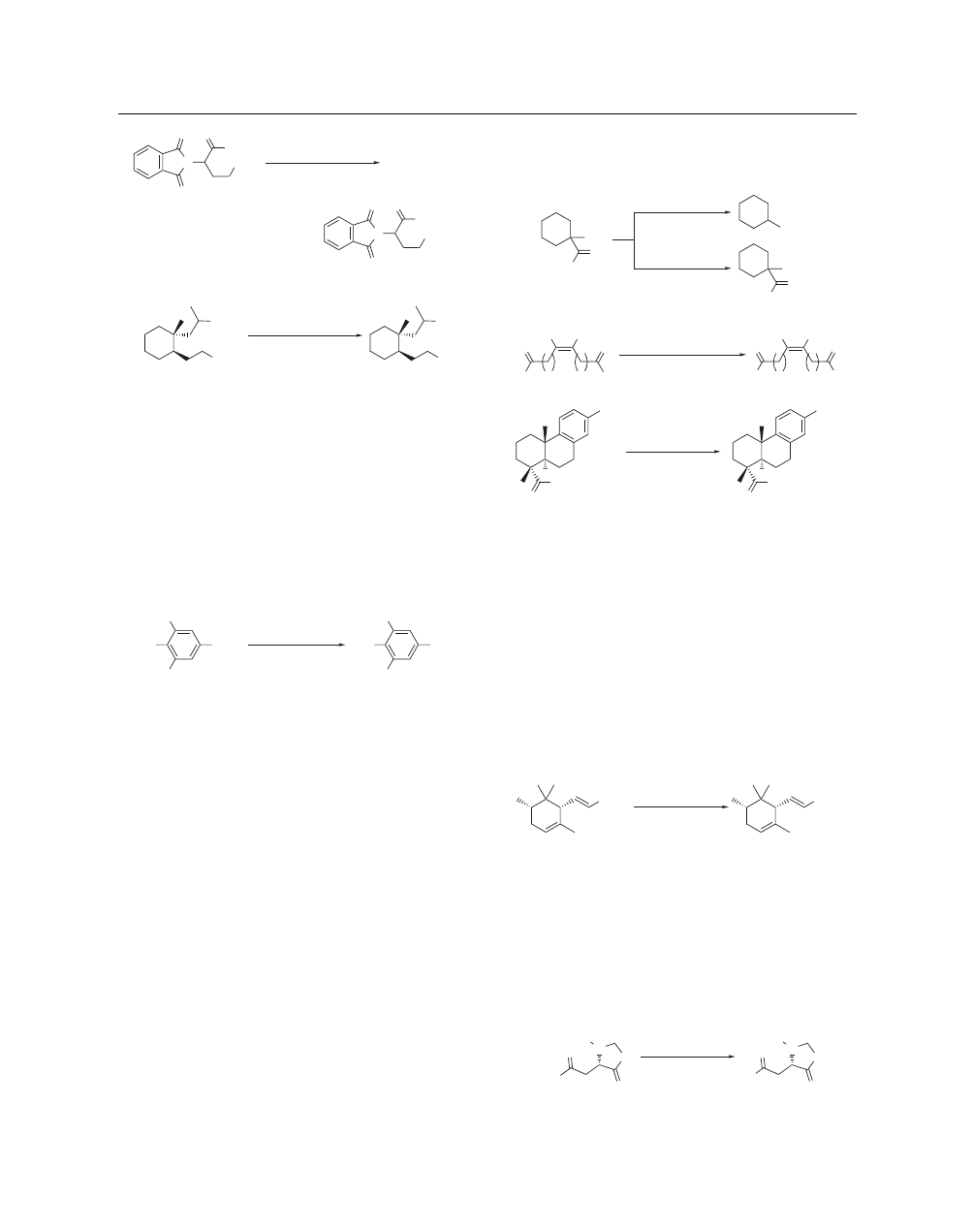

t

-Bu

Cl

O

t

-Bu

(8)

t

-Bu

H

O

1 atm H

2

, 10% Pd/C

acetone, i-Pr

2

NEt

+

CO

H

2

, 5% Pd/C

quinoline-S, toluene

reflux

25 °C

78%

H

H

Cl

O

Cl

O

H

H

H

O

H

O

7

7

7

1 atm H

2

, 10% Pd/C

(9)

7

THF, 2,6-lutidine, 25 °C

96%

1 atm H

2

, 10% Pd/C

2,6-lutidine

i

-Pr

H

O

Cl

i

-Pr

H

O

H

(10)

THF, 0 °C

93%

Both aliphatic and aromatic acid chlorides are reduced smoothly

at room temperature and atmospheric pressure to aldehydes with

10% Pd/C as catalyst, acetone or ethyl acetate as solvent, and

ethyldiisopropylamine as HCl acceptor.

20

The reaction proceeds

with high selectivity; over reduction is less than 1%, and nitro and

chloro substituents in benzoyl chlorides are unaffected, as is the

double bond in cinnamoyl chloride.

Recent Practice. Some more recent examples show that both

the older and the newer procedures are used successfully. As an

important step in the preparation of 10-nor-cis-α-irone, the clas-

sical Rosenmund reduction (H

2

, 5% Pd/BaSO

4

, toluene/reflux)

converted the acid chloride (1) to the product aldehyde in 93%

yield (eq 11).

21

H

2

, 5% Pd/BaSO

4

COCl

CHO

(11)

(1)

toluene, reflux

93%

The ‘semialdehyde’ derivatives of aspartic and glutamic acids

have been obtained in good yields and in higher purity than by

hydride reductions; acid-sensitive protecting groups are unaf-

fected.

22

The acid chlorides (2) and (3) (benzyloxycarbonyl (Z)

derivatives) were converted to the aldehydes using an unpoisoned

catalyst (5% Pd/BaSO

4

, boiling toluene, H

2

) (eq 12). The same

procedure was used to reduce the acid chloride (4), derived from

L

-alanine, to the aldehyde in 93% yield (eq 13).

23

N

O

Cbz

O

Cl

O

N

O

Cbz

O

H

O

H

2

, 5% Pd/BaSO

4

( )

n

(12)

( )

n

(2) n = 1

(3) n = 2

n

= 1, 87%

n

= 2, 82%

toluene, reflux

A list of General Abbreviations appears on the front Endpapers

PALLADIUM ON BARIUM SULFATE

3

N

O

MeO

2

C

O

Cl

O

N

O

MeO

2

C

O

H

O

(4)

H

2

, 5% Pd/BaSO

4

(13)

toluene, reflux

To protect the acid labile t-butoxycarbonyl protecting group

in acid chloride (5), the Burgstahler procedure (H

2

, 5% Pd/C,

2,6-lutidine, THF, 10–15

◦

C) converted (5) to the aldehyde

(eq 14).

19,22

1 atm H

2

, 5% Pd/C

2,6-lutidine

Cl

CO

2

-t-Bu

O

N(Boc)

2

H

CO

2

-t-Bu

O

N(Boc)

2

(14)

(5)

THF, 10–15 °C

78%

The quinoline-sulfur system was used to prepare methyl 4-

oxobutanoate from 3-methoxycarbonyl chloride as the first of a

three-step synthesis of a series of 5-vinyl γ-lactones.

10,24

Kinetics and Mechanism of the Rosenmund Reaction. The

kinetics of the amine-modified Rosenmund reduction has been

examined in detail.

20

In the absence of the tertiary amine, the

hydrogenolysis of 4-t-butylbenzoyl chloride proceeds beyond the

aldehyde stage to a complex mixture with bis(4-t-butylbenzyl)

ether as the main product. In the presence of the efficient HCl

acceptor zeolite NaA, most of the side reactions (acid catalyzed)

are suppressed, but reduction proceeds to 4-t-butylbenzyl alco-

hol. In the presence of the tertiary amine, the aldehyde is the sole

product. However, benzaldehydes subjected to the conditions of

the amine-modified reduction are hydrogenated to the alcohols,

but more slowly than in the absence of the amine and substan-

tially slower on a catalyst which has been used previously in a

hydrogenation of an acid chloride. The nature of the deactivation

is a subject of speculation.

20,25

The tertiary amine not only neutralizes HCl, but also acts as a

nucleophile which serves to moderate the reaction and enhance

the selectivity by competing with both the acid chloride and the

product aldehyde for active sites on the catalyst. A useful anal-

ogy is the effect of tertiary amines upon increasing the selectivity

of the hydrogenation of alkynes to alkenes on palladium

catalysts.

1b,26,27

The solvent also may compete for active sites;

for example, the rate constants for the Pd-catalyzed hydrogena-

tion of cyclohexene, corrected for the difference in the solubility

of H

2

in the solvents, are smaller in benzene and smaller still in

xylene, both commonly used in the Rosenmund reduction, than

in saturated hydrocarbons.

28

The presence of nucleophilic groups

elsewhere in the acid chloride may also act to moderate the re-

duction and affect selectivity in the absence of an added catalyst

poison.

Aliphatic acid chlorides generally are more easily hydrogen-

olyzed than are aromatic ones; however, the Peters and van

Bekkum paper contains the most direct comparison of relative

reactivities for some representative carbonyl chlorides (15 com-

pounds including 10 aromatic).

20

For benzoyl chlorides, electron-

donating substituents increase the reaction rate while electron-

withdrawing substituents have a retarding effect. The rates of

hydrogenation of aroyl chlorides generally are faster in the

solvents ethyl acetate or THF than in acetone.

The mechanism of the Rosenmund reduction has been dis-

cussed in relation to the characteristic reactions of transition metal

complexes.

29

It has been proposed that the acid chloride adds

oxidatively to the palladium metal, forming a complex which

gives rise to the observed products which depend upon the reac-

tion conditions, e.g. temperature, H

2

pressure, and solvent. Some

dissolution of the palladium when heated with an acid chloride at

about 100

◦

C was observed. However, exposing single crystals of

palladium to heptanoyl chloride in pentane and H

2

at room tem-

perature for 52 h did not change the (755) crystal surface which

had catalyzed the formation of the aldehyde.

25

A means of rep-

resenting catalytic processes on such crystal surfaces by analogy

with the reactions of transition metal complexes has been given

for catalytic hydrogenation.

26

Other Hydrogenations.

1b

–

e

Pd/BaSO

4

has also been used in

the conversion of alkynes to cis-alkenes.

30

In some cases, where

results of the reduction of alkynes to cis-alkenes with Lindlar cat-

alysts (see Palladium on Calcium Carbonate (Lead Poisoned))

are unsatisfactory, the use of Pd/BaSO

4

as the catalyst has been

effective (eqs 15 and 16).

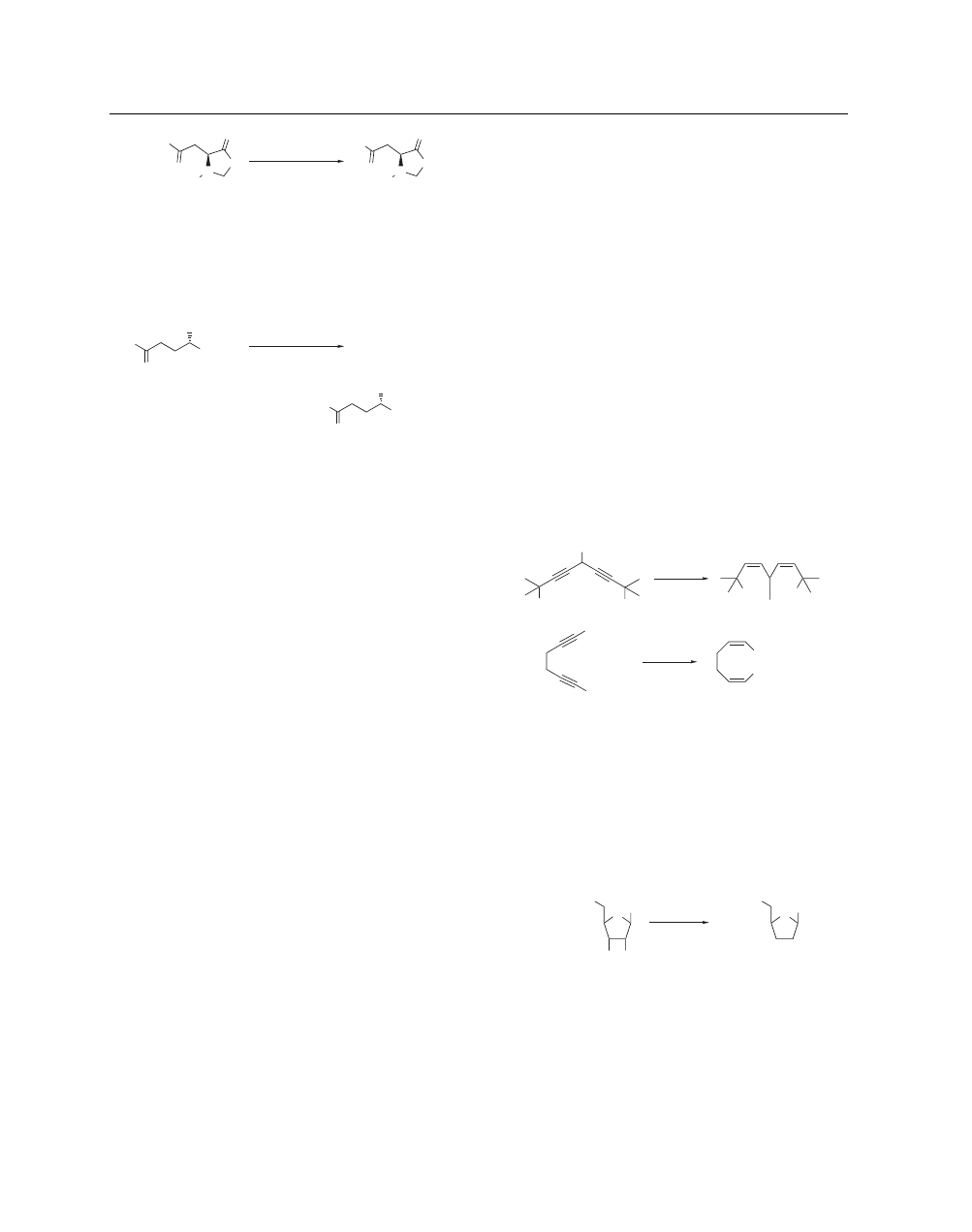

31

OH

OH

OH

OH

OH

HO

(15)

Pd/BaSO

4

quinoline

EtOH, H

2

95%

CO

2

Me

CO

2

Me

CO

2

Me

CO

2

Me

(16)

Pd/BaSO

4

quinoline

H

2

83%

The reverse has also been observed.

32

Interestingly, the satura-

tion of the trisubstituted alkene in humulinic acid B has also been

reported with this catalyst.

33

Hydrogenolysis of various functional groups has also been

reported with Pd/BaSO

4

. For example, the conversion of vinyl

epoxides to homoallylic alcohols,

34

α

-bromo-β-mesyluridines

to hydrocarbons (eq 17),

35

N,N

-dibenzylamino acids to

N

-benzylamino

acids,

36

and

the

enantioselective

mono-

dehydrohalogenation of α,α-dichlorobenzazepin-2-one

37

have

all been reported.

O

R

Br

MsO

PhCH

2

O

O

R

PhCH

2

O

Pd/BaSO

4

H

2

, NaOAc

(17)

36%

The maximum % ee observed for α-chlorobenzazepin-2-one

was 50%, but surprisingly the method was not effective for

other substrates, including α,α-dibromobenzazepin-2-one. eq 17

also shows the C–O bond of a benzyl ether was not cleaved

while the C–O bond of a mesylate and a C–Br bond were both

hydrogenolyzed.

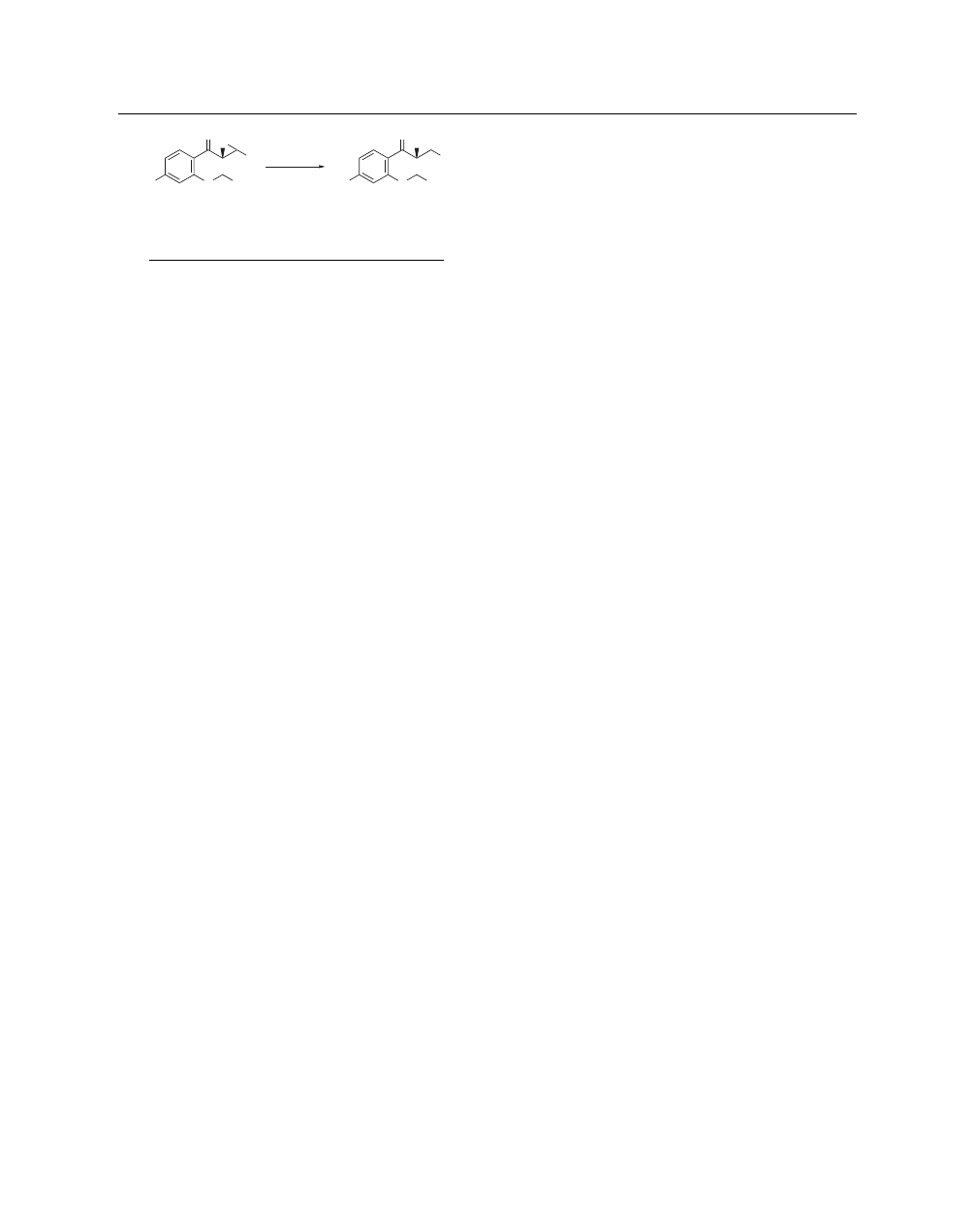

Regioselective opening of a 1,2-disubstituted epoxide was ob-

served with this catalyst (eq 18).

38

The benzylic ketone was not

reduced or hydrogenolyzed under the reaction conditions.

Avoid Skin Contact with All Reagents

4

PALLADIUM ON BARIUM SULFATE

O

OMe

Ph

MeO

O

O

O

OMe

Ph

MeO

O

OH

(18)

Pd/BaSO

4

H

2

92%

Related Reagents. Palladium on Carbon; Palladium–Graph-

ite; Palladium on Poly(ethylenimine).

1.

(a) Mosettig, E.; Mozingo, R., Org. React. 1948, 4, 362. (b) Kieboom, A.

P. G.; van Rantwijk, F. Hydrogenation and Hydrogenolysis in Synthetic

Organic Chemistry

; Delft University Press: Delft, 1977. (c) Fieser &

Fieser 1967

, 1, 975; 1974, 4, 367; 1979, 7, 275. (d) Rylander, P. N.

Catalytic Hydrogenation in Organic Syntheses

; Academic: New York,

1979. (e) Rylander, P. N. Hydrogenation Methods; Academic: New York,

1985. (f) Davis, A. P., Comprehensive Organic Synthesis 1991, 8, 286.

2.

Rosenmund, K. W., Chem. Ber. 1918, 51, 585.

3.

Mozingo, R., Org. Synth., Coll. Vol. 1955, 3, 181.

4.

Rachlin, A. I.; Gurien, H.; Wagner, D. P., Org. Synth. 1971, 51, 8.

5.

Rosenmund, K. W.; Zetzsche, F., Chem. Ber. 1921, 54, 425.

6.

Rosenmund, K. W.; Zetzsche, F.; Heise, F., Chem. Ber. 1921, 54, 638.

7.

Affrossman, S.; Thomson, S. J., J. Chem. Soc. 1962, 2024.

8.

Zetzsche, F.; Arnd, O., Helv. Chim. Acta 1926, 9, 173.

9.

Zetzsche, F.; Enderlin, F.; Flutsch, C.; Menzi, E., Helv. Chim. Acta 1926,

9

, 177.

10.

Hershberg, E. B.; Cason, J., Org. Synth., Coll. Vol. 1955, 3, 627.

11.

Barnes, R. P., Org. Synth., Coll. Vol. 1955, 3, 551.

12.

Danishefsky, S.; Hirama, M.; Gombatz, K.; Harayama, T.; Berman, E.;

Schuda, P. F., J. Am. Chem. Soc. 1979, 101, 7020.

13.

Foye, W. O.; Lange, W. E., J. Am. Pharm. Assoc. 1956, 45, 742.

14.

Johnson, W. S.; Martin, D. G.; Pappo, R.; Darling, S. D.; Clement,

R. A., Proc. Chem. Soc. 1957, 58.

15.

Wagner, D. P.; Gurien, H.; Rachlin, A. I., Ann. N. Y. Acad. Sci. 1970,

172

, 186.

16.

Sakurai, Y.; Tanabe, Y., J. Pharm. Soc. Jpn. 1944, 64, 25 (Chem. Abstr.

1951, 45, 5613).

17.

White, H. B. Jr.; Sulya, L. L.; Cain, C. E., J. Lipid Res. 1967, 8, 158.

18.

Peters, J. A.; van Bekkum, H., Recl. Trav. Chim. Pays-Bas 1971, 90,

1323.

19.

Burgstahler, A. W.; Weigel, L. O.; Shaefer, C. G., Synthesis 1976, 767.

20.

Peters, J. A.; van Bekkum, H., Recl. Trav. Chim. Pays-Bas 1981, 100,

21.

21.

Maurer, B.; Hauser, A.; Froidevaux, J-C., Helv. Chim. Acta 1989, 72,

1400.

22.

Bold, G.; Steiner, H.; Moesch, L.; Walliser, B., Helv. Chim. Acta 1990,

73

, 405.

23.

Hoffmann, M. G.; Zeiss, H-J., Tetrahedron Lett. 1992, 33, 2669.

24.

Perlmutter, P.; McCarthy, T. D., Aust. J. Chem. 1993, 46, 253.

25.

Maier, W. F.; Chettle, S. J.; Rai, R. S.; Thomas, G., J. Am. Chem. Soc.

1986, 108, 2608.

26.

Siegel, S., Comprehensive Organic Synthesis 1991, 8, 430.

27.

Steenhoek, A.; Van Wijngaarden, B. H.; Pabon, H. J. J., Recl. Trav. Chim.

Pays-Bas 1971

, 90, 961.

28.

Gonzo, E. E.; Boudart, M., J. Catal. 1978, 52, 462.

29.

Tsuji, J.; Ohno, K., J. Am. Chem. Soc. 1968, 90, 94.

30.

(a) Figeys, H. P.; Gelbcke, M., Tetrahedron Lett. 1970, 5139.

(b) Burgstahler, A. W.; Widiger, G. N., J. Org. Chem. 1973, 38, 3652.

(c) Johnson, F.; Paul, K. G.; Favara, D., J. Org. Chem. 1982, 47, 4254.

31.

(a) Burgstahler, A. W.; Widiger, G. N., J. Org. Chem. 1973, 38, 3652.

(b) Scheffer, J. R.; Wostradowski, R. A., J. Org. Chem. 1972, 37,

4317.

32.

Audier, L.; Dupont, G.; Dulov, R., Bull. Soc. Chem. Fr., Part 2 1957,

248.

33.

Burton, J. S.; Elvidge, J. A.; Stevens, R., J. Chem. Soc. 1964, 3816.

34.

Gossinger, E.; Graf, W.; Imhof, R.; Wehrli, H., Helv. Chim. Acta 1971,

54

, 2785.

35.

Furukawa, Y.; Yoshioka, Y.; Imai, K.; Honjo, M., Chem. Pharm. Bull.

1970, 18, 554.

36.

Haas, H. J., Biochemistry 1961, 94, 2442.

37.

Blaser, H.-U.; Boyer, S. K.; Pittelkow, U., Tetrahedron: Asymmetry 1991,

2

, 721.

38.

Augustyn, J. A. N.; Bezuidenhoudt, B. C. B.; Swanepoel, A.; Ferreira,

D., Tetrahedron 1990, 46, 4429.

Samuel Siegel

University of Arkansas, Fayetteville, AR, USA

Anthony O. King & Ichiro Shinkai

Merck & Co., Inc., Rahway, NJ, USA

A list of General Abbreviations appears on the front Endpapers

Wyszukiwarka

Podobne podstrony:

palladium on carbon eros rp006

catechol sulfate eros rc034

palladium triethylamine formic acid eros rp015

mercury II sulfate eros rm044

potassium permanganate copper II sulfate eros rp245

palladium II chloride eros rp007

palladium II acetate eros rp001

palladium graphite eros rp011

potassium on alumina eros rp192

More on hypothesis testing

więcej podobnych podstron