Service

ELECTRONICS

ECC

Issue 1

European Service

RoHS Guidelines

ECC G002

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 1 of 2

1. General

This process describes how to handle RoHS compliant and non-compliant spare parts as well

as labelling and handling of repair equipment for RoHS compliant components.

2. RoHS

Guidelines

2.1

Handling new spare parts

RoHS compliant spare parts must be stored separately from RoHS non-compliant

spare parts.

Both types, RoHS compliant and RoHS non-compliant spare parts, must be

clearly labelled.

An example for clearly labelled spare parts is given in Picture 1 and Picture 2.

RoHS

non-

compliant

spare parts

RoHS compliant

spare parts

Picture 1

Picture 2

2.2

Handling defective spare parts

RoHS compliant defective parts must be stored separately from RoHS non-

compliant defective parts.

Both types, RoHS compliant and RoHS non-compliant defective parts, must be

clearly labelled.

An example for clearly labelled defective parts is given in Picture 3 and Picture 4.

RoHS

non-

compliant

spare parts

RoHS compliant

spare parts

Picture 3

Picture 4

Service

ELECTRONICS

ECC

Issue 1

European Service

RoHS Guidelines

ECC G002

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 2 of 2

2.3

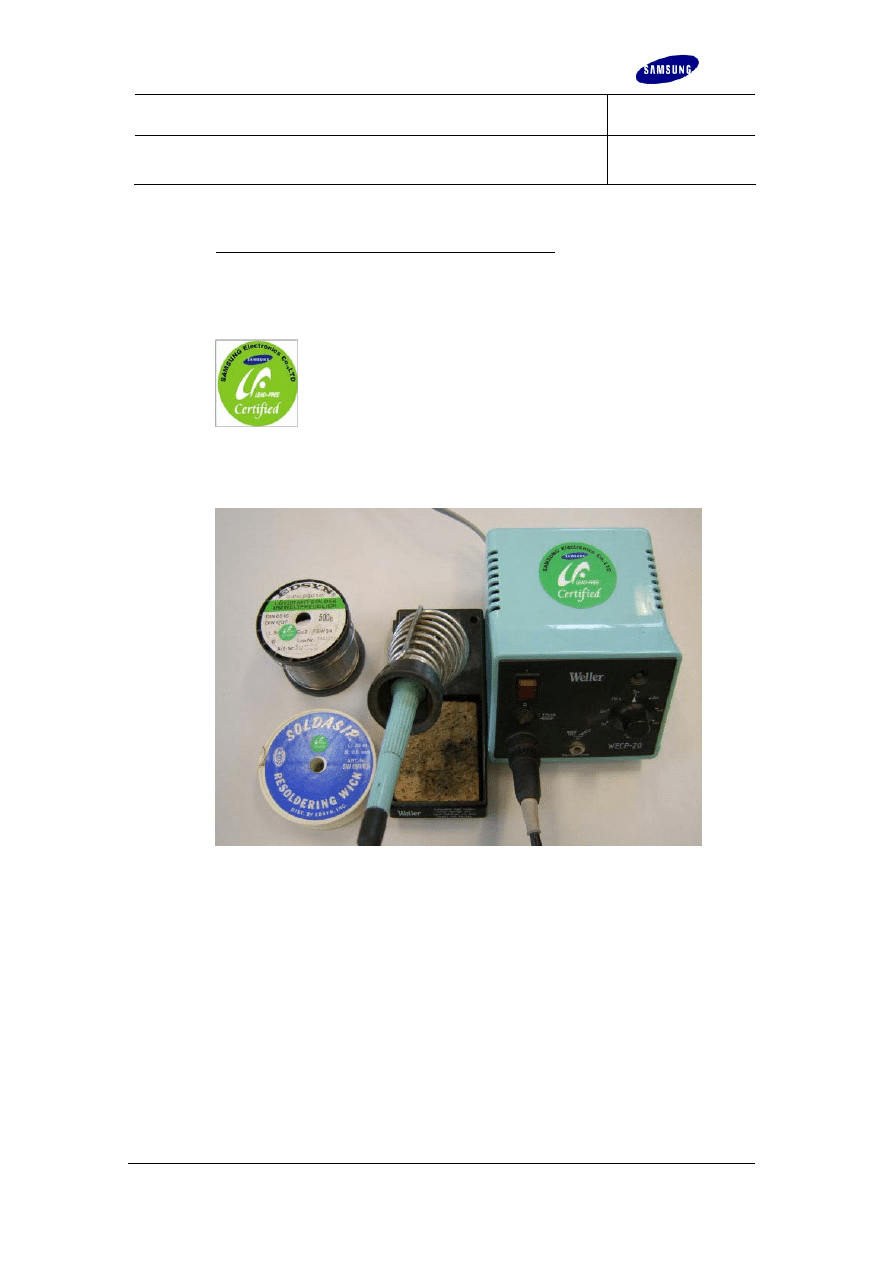

Repair equipment for RoHS compliant components

Repair equipment such as soldering irons, BGA soldering devices, resoldering

wick etc. for RoHS compliant components must be marked with the SAMSUNG

L/F logo (Picture 5). This equipment must be used on a separate workstation.

Picture 5

An example for repair equipment labelled in the described way is given in Picture

6.

Picture 6

Wyszukiwarka

Podobne podstrony:

ECC G003 Guide to Repair Flow

ECC G001 Guide to ESD

Herbs for Sports Performance, Energy and Recovery Guide to Optimal Sports Nutrition

Meezan Banks Guide to Islamic Banking

NLP for Beginners An Idiot Proof Guide to Neuro Linguistic Programming

50 Common Birds An Illistrated Guide to 50 of the Most Common North American Birds

Guide to the properties and uses of detergents in biology and biochemistry

Guide To Erotic Massage

A Guide to the Law and Courts in the Empire

10 Minutes Guide to Motivating Nieznany

A Student's Guide to Literature R V Young(1)

A Practical Guide to Marketing Nieznany

Guide To Currency Trading Forex

Lockpick Leif Mccameron'S Guide To Lockpicking(1)

J T Velikovsky A Guide To Fe A Screenwriter's Workbook id 22

Answer Key Guide to Reading

Jouni Yrjola Easy Guide to the Classical Sicilian (feat Richter Rauzer and Sozin Attacks)

21 Appendix C Resource Guide to Fiber Optics

więcej podobnych podstron