Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 1 of 12

ELECTRONICS

What is ESD?

ESD stands for Electro Static Discharge.

Static electricity is an everyday phenomenon - there can be few of us who have not

experienced a static shock after walking across a room and touching the door knob, or on

getting out of a car.

Other static nuisance effects include the cling of some fabrics to the body, the sticking of a

plastic document cover, or the attraction of dust to a TV or computer screen.

While we can feel some of these effects, static electricity is normally present at lower levels

that we cannot feel, hear or see, but may nevertheless damage sensitive electronic

components. It can build up rapidly on objects, in unexpected ways, to produce surprisingly

high voltages.

If two objects that have different voltages approach each other closely enough, charge may

pass from one object to the other in a fast electrostatic discharge. While this only lasts a

microsecond or less, the peak discharge current can be several Amps and the peak power

can be in the kilowatt range!

Why worry about ESD?

ESD can cause unseen damage to electronic components during manufacture of electronic

assemblies and equipment. If the damaged component fails immediately

(Catastrophic

Damage), the result can be a board that fail tests and requires rework. This represents lost

production and additional manufacturing costs.

Worse than this, a component may be partially damaged and weakened (Latent Damage). It

may suffer a change or drift in characteristics. It may remain within specification, but fail later

when in use by a customer. It has been estimated that 90% of damaged devices may be

discovered in this way. This is the most expensive type of failure, as it represents:

• Customer dissatisfaction, and the possibility of loss of product reputation and future

sales

• Customer service personnel and facility cost

• Engineers time, possibly for on-site repair with travel, and parts replacement

In manual assembly most ESD arises from charged personnel, if they are not grounded.

Most people do not feel an ESD shock unless they are charged to over 4000v, 2000V you can

visibly see

,

(the sensitivity threshold varies between people, and even over parts of the body!).

This voltage is quite common in the uncontrolled environment - how many of us have not felt

the occasional electrostatic shock in everyday life?

Low Humidity

The electrostatic properties of materials are very dependent on atmospheric humidity. A

controlled humidity of 50 %rh suits most circumstances. If humidity reduces below 20 %rh,

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 2 of 12

ELECTRONICS

ensure that selected materials and equipment will perform effectively under operational

conditions.

Clean room conditions

Some current materials and techniques in use for ESD protection are not suitable for use in

clean rooms (class 100 or tighter).

Where high voltages may be present

If high voltages greater than 250VAC or 500VDC are present then take particular care to

consider safety requirements.

Definitions

Antistatic

This can mean a wide variety of things, and is deprecated by the writers of 61340-5-1.

Although the term is widely used, it is better to avoid it if possible.

ESD

ElectroStatic Discharge. When the electric field strength in air becomes sufficiently high, its

insulating properties break down and charge can flow away in a rapid discharge. ESD can

have very short duration high current levels and and cause ignition of flammable materials or

damage to electronic components.

ESDS

ElectroStatic Discharge Sensitive device. An electronic component that could be damaged by

ESD.

Field work

Handling of ESDS within a temporary EPA, for example at the customer's site.

EPA

ESD Protected Area. An area in which static electricity is kept below levels that could cause

damage to electronic components handled within the area.

Intimate packaging

Packaging that makes contact with ESDS, for example the inner surface of an ESD protective

bag.

Proximity packaging

Material not making contact with ESDS but which is used to enclose one or more devices. For

example the outer surface of an ESD protective bag, or ESD packaging used to contain

ESDS already within other packaging.

Secondary packaging

Material used primarily to give additional physical protection to the outside of proximity

package e.g. cardboard boxes, padded bags, polythene wrap.

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 3 of 12

ELECTRONICS

Low charging

Packaging exhibiting properties which minimises any charge generation.

Conductive

The word "conductive" has a range of meanings within the context of different standards and

should be treated with care.

1.

any material that conducts electricity, i.e. not an insulator

2.

Within the 61340-5-1standard, "electrostatic conductive" packaging material has

surface resistance between 10

2

Ω and 10

5

Ω

3.

"conductive" has no specific meanings for other materials or equipment under 61340-

5-1 although it is often generally used to indicate materials having resistance values <

10

6

Ω

4.

specific meanings for other equipment are possible, e.g. "conductive footwear"

Dissipative

The word "dissipative" has a range of meanings within the context of different standards and

should be treated with care.

1.

Within the 61340-5-1standard, "electrostatic dissipative" packaging material has

surface resistance between 10

5

Ω and 10

11

Ω

2.

"dissipative" has no specific meanings for other materials or equipment under 61340-

5-1 although it is often generally used to indicate materials having resistance values <

10

12

Ω and > < 10

6

Ω

3.

specific meanings for other equipment are possible, e.g. "conductive footwear"

Electrostatic discharge shielding packaging

Packaging, barrier or enclosure that limits the passage of ESD current and attenuates the

energy resulting from an electrostatic discharge such that the maximum energy from 1000 V

HBM ESD applied to the outside of the packaging is less than or equal to 50 nJ measured

inside the packaging.

Surface resistance

This is the resistance of a surface measured by a concentric ring electrode test method

defined in 61340-5-1and IEC 61340-2-3: 2000. It is NOT the same as "surface resistivity" and

is typically about a factor of 10 less than surface resistivity as measured in the old EN100015

method.

Point-to-point resistance

The is the resistance measured between two electrodes placed on a surface, defined in

61340-5-1, IEC 61340-2-3: 2000 and ESD S11.11- 2001

Resistance-to-ground

This is the electrical resistance measured from a point to the ESD facility electrical earth

(usually mains power earth).

Key elements in an ESD Program

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 4 of 12

ELECTRONICS

Principles of electrostatic safe handling

There are two simple principles we can use to protect ESD sensitive components from ESD

damage:

•

Only handle sensitive components in an ESD Protected Area

(EPA) under

protected and controlled conditions

•

Protect sensitive devices outside the EPA

using ESD protective packaging

What is an EPA?

An EPA is an area that is maintained safe for handling static sensitive components by

keeping electrostatic fields and voltages to an insignificantly low level. An EPA should have

well defined boundaries so that it is clear where the safe area is entered and left.

Insulating materials are strong ESD sources and so they are excluded from the EPA where

possible. Where this is not possible special measures such as ionisers are used to neutralise

electrostatic charges.

All non-insulating and conductive objects are grounded, so that electrostatic charge cannot

build up on these. Most importantly, all personnel (people are conductive objects!) are

grounded so that they do not charge to high voltages. There are two ways in which people are

grounded:

• Using a grounded wrist strap (this is the preferred method)

• Using conductive footwear (conductive or dissipative shoes, or heel & toe straps on

both feet) in conjunction with a grounded conductive floor.

Three key elements of an effective ESD program

An effective ESD program requires three main parts:

•

The ESD Program.

This is a document that specifies the equipment used, and

procedures followed in order to ensure electrostatic safe handling.

•

The Training program.

This is required in order to make sure that everyone is aware

of, and understands the ESD Program, use of equipment and correct procedures.

•

The Audit program.

This is required in order to make sure that equipment remains

functional, and that the ESD Program procedures are correctly followed.

If any of these is absent, it is likely that the ESD prevention measures will eventually fail. A

fourth factor is also extremely important -

Management commitment.

If Management does

not provide the resources and authoritative support required, it is unlikely that the ESD

Program will succeed.

EPA design

Design philosophy

A primary objective of EPA design is that all personnel handling sensitive devices are

grounded. The preferred means of grounding personnel is by using wrist straps. If this is not

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 5 of 12

ELECTRONICS

practical, use compliant footwear or heel and toe straps with compliant flooring. Seated

personnel should be grounded via wrist straps - footwear grounding is not reliable in this case,

and grounding via the seat should not be considered a reliable option.

Any surfaces on which ESDS are placed must be connected to EPA ground, and have a

point-to-point resistance between 10

4

Ω and 10

10

Ω, and resistance-to-ground between

7.5x10

5

Ω and 10

9

Ω. The ESD Coordinator can authorise "hard grounding" (<10

4

Ω) of

surfaces when required.

General design

An EPA (Electrostatic Protected Area) is a region within which no item or activity must be able

to cause damage to a sensitive device. In the simplest case - a field work station - it may

consist of a dissipative mat, a wrist strap and common grounding facility for both. At the other

extreme it may consist of a large manufacturing area where all the measures of 61340-5-1

are implemented. In some cases the EPA may consist of a single bench work area, which

may not have an EPA floor.

The ESD Coordinator is responsible for determining EPA boundaries, construction, selection

of equipment and general appropriate design of EPA for their particular

application. Equipment used within the EPA must comply with the requirements of 61340-5-

1.

If possible, a group of EPA work stations should be combined into one large EPA, including

an EPA compliant floor. If this is not carried out and each work station forms an individual

EPA (which may not include an EPA floor), sensitive devices must then be packaged in ESD

protective packaging for transport between work stations.

Marking the EPA boundaries

Personnel must be able to see signs complying with 61340-5-1 before they enter the EPA.

Where appropriate (i.e. in a multistation EPA), compliant signs must also be visible within the

EPA, and exit signs should mark the boundary of the EPA.

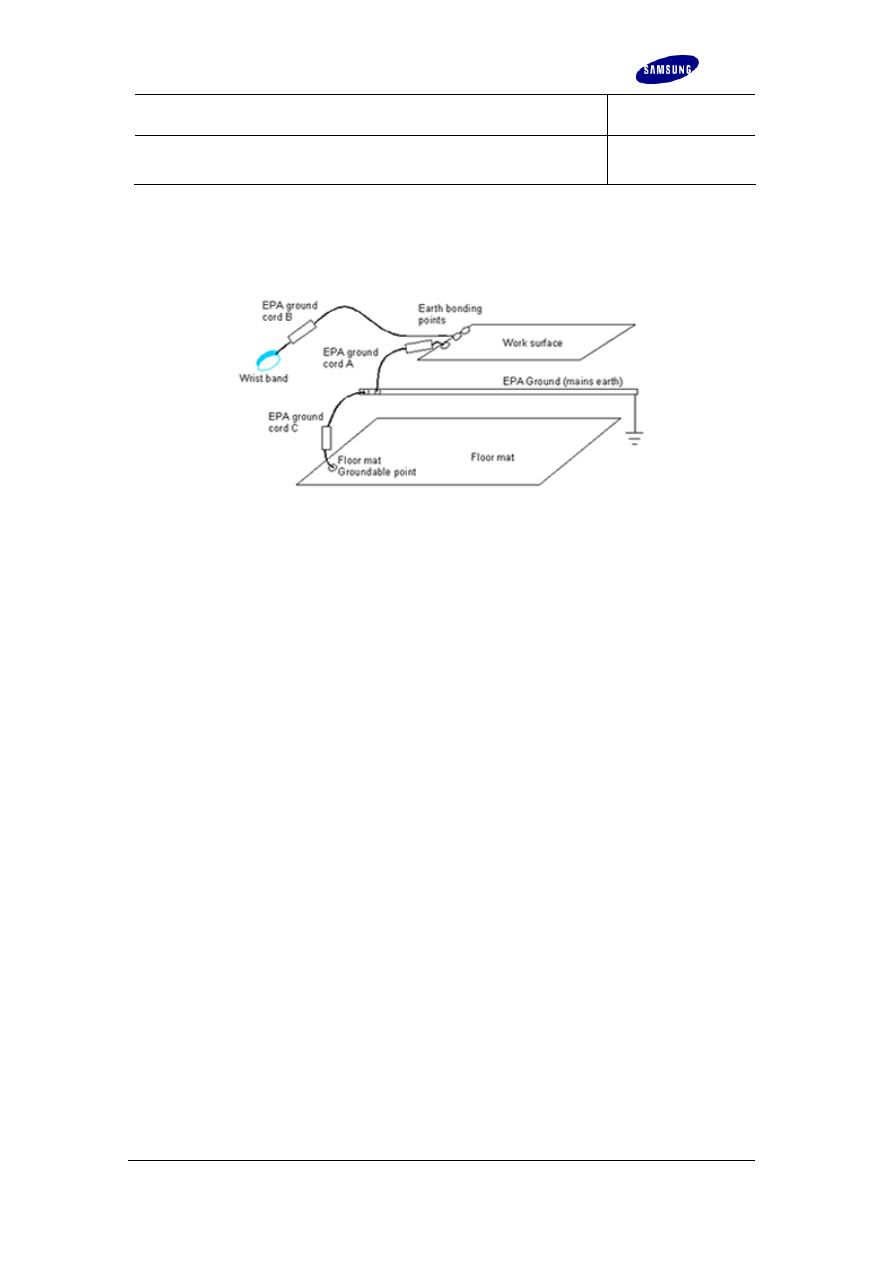

EPA ground system design

The EPA ground provides a low resistance path (<2

Ω) to ground, usually to mains protective

earth. A single EPA ground must be used within one EPA facility.

EPA ground bonding points (EBP) must be provided next to each working area or

surface. These are points to which wrist straps are connected, and must be clearly marked in

compliance with 61340-5-1. There must be sufficient EBPs to provide for operators and

visitors, and they must be accessible. EBP are connected to EPA ground through a

resistance of up to 10

6

Ω.

Surface to ground resistance values may be achieved by including discrete resistors in the

ground path, or by the resistance of the material which is directly grounded.

EPA ground cords are used to connect between groundable points and the EPA ground

facility. One or more resistor may be included in the ground cord to give the required

Service

ELECTRONICS

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 6 of 12

resistance to ground value. If a single resistor is used, it must be at the end of the cord at the

groundable point. If more than one resistor is included, the resistor at the end connected to

the groundable point must be at least half the total resistance in the cord. The ground cord

connections, if accessible, must be shrouded with insulating material.

The EPA ground connection system must not be compatible with any connecting system used

for any other purpose. The conducting parts of the connectors must be shrouded by insulating

material when a cord is connected to the bonding point.

Wrist straps

A wrist strap has a snugly fitting band worn around the wrist, and cord fitted with a quick

release connection. The resistance between the band inner surface and the groundable point

must be less than 10

5

Ω. The conducting parts of the connecting system must be shrouded

when connected. The strap ground cord must incorporate a resistor (7.5x10

5

Ω to 5x10

6

Ω ) at

the wrist end (see EPA ground cord B). The total resistance from hand to Earth Bonding Point

must be between 7.5x10

5

Ω and 3.5x10

7

Ω.

Certification of conformance

The ESD Coordinator must audit a new or modified EPA to ensure that compliance is

achieved, and must issue a Certificate of Conformance before the EPA is used.

Departures from the guidance of the 61340-5-1 Technical Report should be recorded on the

Certificate of Conformance, along with any extra equipment or procedures required to ensure

ESD protection.

Responsibilities of personnel

Responsibilities of all personnel

All personnel handling sensitive devices have responsibility to be aware of the ESD threat to

reliability of electronic products. They have prime responsibility to implement and maintain

ESD prevention measures. Any failure to do so should be reported to the ESD Co-ordinator.

All personnel are expected to inform the ESD Co-ordinator of any unsatisfactory measures,

and suggest improvements or corrective actions if appropriate.

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 7 of 12

ELECTRONICS

General Management responsibilities

61340-5-1 places responsibility for implementation of the guidelines of the Technical Report in

the hands of General Management. They are also ultimately responsible for making sure that

all aspects of ESDS handling are carried out, including;

• Maintaining a register of trained personnel

• Providing appropriate training for all personnel

• Ensuring

inspection,

supervision and maintenance of EPA facilities are carried out

The General Management bear the responsibility for

a

ppointment of the site ESD Co-

ordinator. A named ESD Co-ordinator is required for each site. They must be given total

Management back-up, and adequate resources and authority.

ESD Co-ordinator responsibilities

The ESD Co-ordinator is responsible to the Management for all site ESD matters. This

includes;

• Ensuring that a copy of the ESD Program or 61340-5-1 standard is available to all

relevant personnel

• Specifying and maintaining a list of ESD equipment

• Making sure ESD training is adequate and conforms to the requirements

• Maintaining a list of trained personnel

• Ensuring that all equipment and procedures conform to the standard

• Inspection, maintenance and verifying conformance of the EPA

• Making ESD program tailoring decisions when required

• Giving assistance when required

The ESD Co-ordinator has responsibility for making certain technical decisions in tailoring the

implementation of the ESD Program:

• Defining the boundaries of Electrostatic Protected Areas (EPA)

• Defining and selecting equipment for use within the EPA

• Construction and certification of EPAs

• Deciding which (if any) of the recommended measures are not required

• Deciding the frequency of certain audit actions

The ESD Co-ordinator can appoint deputies if required.

ESD Protective packaging

Definition of the types of packaging

61340-5-1 defines three types of packaging - intimate, proximity, and secondary packaging:

Term

Definition

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 8 of 12

ELECTRONICS

Intimate

packaging

Packaging material which may make contact with the ESDS

Proximity

packaging

Does not make contact with the ESDS, but may enclose one or more ESDS

Secondary

packaging

Mainly used to give physical protection, is kept away from ESDS and is not

allowed in the EPA.

Warning labels (compliant with 61340-5-1) must appear on all packages containing ESDS. If

removed for access, they must be replaced.

When unwrapping a package containing sensitive devices, it is important to remove

packaging as far as the ESD protective packaging layer that bears the ESD symbol. This

layer must only be removed within an EPA.

Secondary packaging, such as polythene bags, cardboard boxes, jiffy bags etc. must not be

taken into an EPA as they can be the source of electrostatic charge and ESD.

Packaging used in the EPA

Packaging brought into the EPA must not have an insulating outer surface. It must allow

charge to dissipate to EPA ground. Secondary packaging must not be brought into the EPA.

Packaging used to protect ESDS inside the EPA

Intimate packaging

Proximity packaging

Powered ESDS

Use low charging and

dissipative material

(> 10

8

Ω

)

Non-powered

ESDS

Use low charging and

conductive or dissipative

material.

Use low charging and shielding,

conductive or dissipative material.

Non-ESDS

Use packaging suitable for ESDS, or low charging.

If a material has a surface resistance of >10

9

Ω

, charge on the surface must decay, returning

the surface potential from 1000V to 100V in less than 2 seconds. Surface resistivity less than

10

4

Ω

("hard ground") is allowed at the discretion of the ESD Coordinator.

Packaging material resistances must be maintained to the highest and lowest humidities

expected under operational conditions.

All components, tools or materials that are not made of EPA compliant material, should be

packed in low charging and dissipative, or conductive, materials before transport into the EPA.

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 9 of 12

ELECTRONICS

Packaging used outside the EPA

An ESDS transported outside the EPA must be protected by a low charging and dissipative

(or conductive, if non-powered) layer of intimate packaging around the ESDS. This must be

further surrounded by shielding proximity packaging.

Some packaging such as shielding bags, combine the intimate and proximity shielding

packaging functions. At the time of writing, shielding bags are the only commonly available

packaging that has approved shielding characteristics for protection of ESD sensitive

components outside the EPA.

Packaging used to protect ESDS outside the EPA

Intimate packaging

Proximity packaging

Powered ESDS

Use low charging and dissipative material

(> 10

8

Ω

)

Non-powered ESDS

Use low charging and conductive or

dissipative material.

Use shielding

packaging.

Non-ESDS

Use packaging suitable for ESDS, or low

charging.

N/A

Definitions of packaging material types

In 61340-5-1 & 2, the following definitions apply to packaging materials:

Packaging

material

Definition

Low

charging

material

Material which has properties which minimise charge generation

Shielding

A barrier or enclosure which attenuates the energy from an electrostatic

discharge, reducing the energy transmitted from a 1000V human body model

test discharge to 50nJ or less.

Conductive

Packaging which has a surface resistance between 10

2

Ω

and 10

5

Ω

Dissipative

Packaging which has a surface resistance between 10

5

Ω

and 10

11

Ω

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 10 of 12

ELECTRONICS

Insulating

Packaging which has a surface resistance of 10

11

Ω

or greater

Auditing program

The 61340-5-1&2 documents are designed for use with quality systems such as ISO9000.

The requirements of 61340-5-1 should be treated as mandatory, while 61340-5-2 can be

considered recommendations.

Daily checks

It is most important to check conformance of wrist straps and their ground cords (as worn),

and heel & toe straps or ESD shoes before entering the EPA.

Visual check must be made of EPA and packaging, trolleys, excluded items, and ioniser

location & orientation. Documentation of these checks is optional.

Monthly checks

Check the continuity of equipment earth bonding on a sample basis, and the functionality of

ionisation systems.

Six-month checks

Check electrostatic fields <10kV/m, or alternatively potentials <100V. Check conformance of

signs and labels, and ESD garments.

Periodic audit

Periodic audit should be performed at not more than 12 month intervals. A follow-up audit

should be scheduled if appropriate and an Audit Report circulated.

Check:

• Wrist strap discipline and the conformance of wrist strap and footwear testers.

• EPA signs and labels

• Conformance of the resistance of floors, work surfaces, and seating.

• Conformance of tools.

• Conformance of packaging and disposal of discarded packaging and materials.

• Electrostatic

fields

<10kV/m,

or alternatively potentials <100V.

• Conformance of ionisers.

• High voltage area procedures

• Humidity control operation.

• Records and selection procedures

ESD Sensitivity of electronic devices

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 11 of 12

ELECTRONICS

As the human body was originally the most common and damaging source of electrostatic

discharge, the most common measurement of ESD sensitivity is by Human Body Model

(HBM) electrostatic discharge. In this test a charged 100pF capacitor is discharged into the

device via a 1500

Ω

resistor. The 100pF capacitor simulates charged stored on the average

human body, and the resistor simulates the resistance of the human body and skin. 61340-5-

1, if fully implemented, aims to protect devices down to 100V HBM sensitivity.

The ESD sensitivity of devices is given as an "ESD withstand voltage", which is the maximum

test voltage at which the device did not suffer damage.

Typical HBM withstand voltages of

various device technologies are given in the following table.

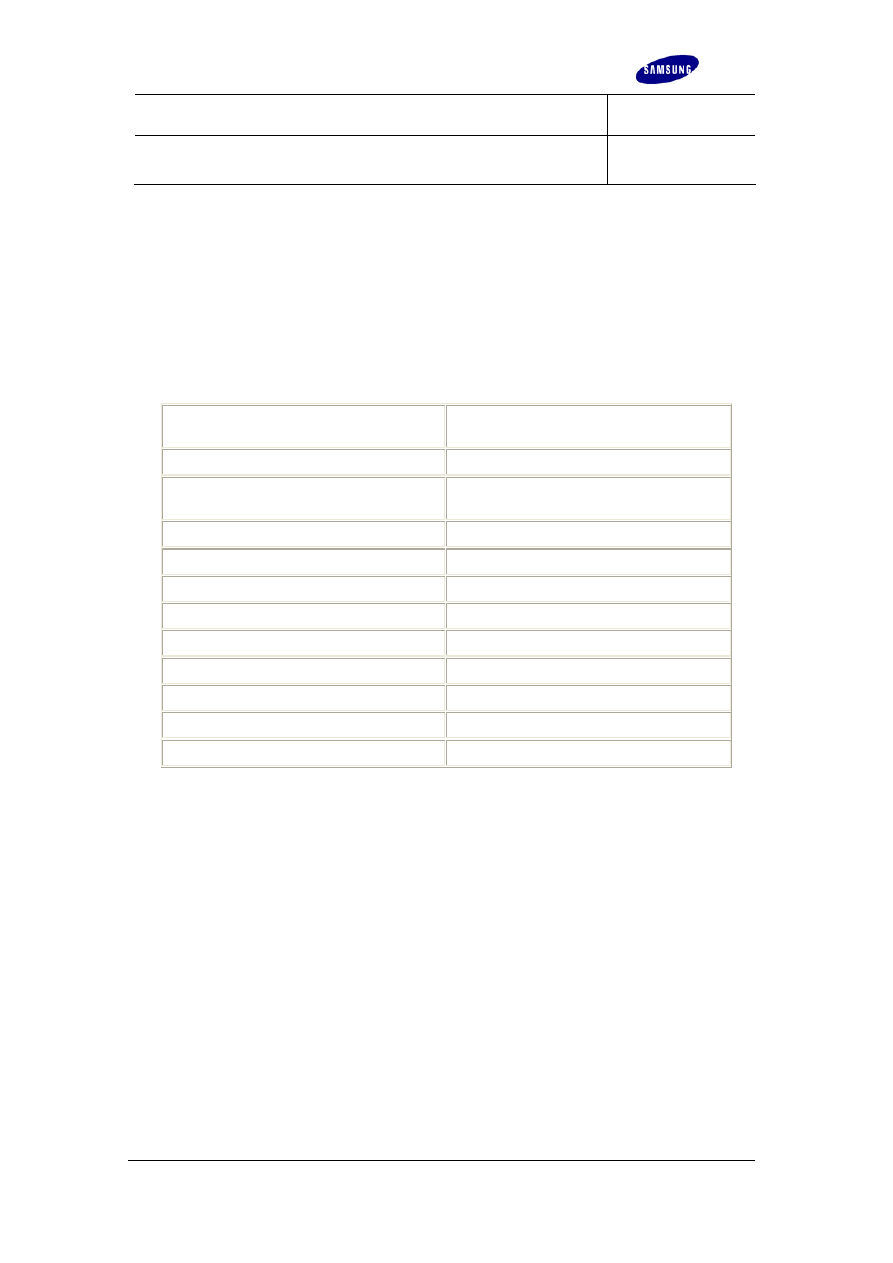

Device type

ESD withstand voltage sensitivity (V)

HBM

MR heads, RF FETs

10 - 100

Power MOSFETs

PIN diodes, laser diodes

100 - 300V

Pre - 1990 VLSI

400 - 1000V

Modern VSLI

1000 - 3000V

HCMOS

1500 - 3000V

CMOS B Series

2000 - 5000 V

Linear MOS

800 - 4000 V

Small geometry older bipolar

600 - 6000 V

Small geometry modern bipolar

2000 - 8000 V

Power bipolar

7000 - 25000 V

Film resistor

1000 - 5000 V

As component technology progresses, internal device sizes reduce and become more ESD

sensitive. Many modern components are protected by on-chip protection circuits, without

which they would be extremely sensitive. In most cases the design goal is to increase the

devices ESD withstand voltage to 2 kV. In some cases this goal cannot be met for various

reasons - there is often a trade off between ESD protection and device performance.

Overview of 61340-5-1 & 2

The IEC 61340-5-1 Technical Report Protection of electronic devices from electrostatic

phenomena – General Requirements was developed from earlier Standards including

EN100015. It is accompanied by a User Guide IEC61340-5-2, which gives a lot of additional

information to help the non-specialist implement IEC61340-5-1. As a IEC documents, they

have world-wide applicability and are planned to be developed into full world-wide IEC

standards in the future.

In Europe, the 61340-5-1&2 documents have been adopted by CENELEC to replace

EN100015. We recommend that the guidance given by the 61340-5-1 General Requirements

document is considered mandatory, while the additional guidance given by the 61340-5-2

User Guide may be considered to be recommendations.

Service

ECC

Issue 1

European Service

Guide to ESD

ECC G001

S

amsung

E

uropean

S

ervice

A

ward

Revised Date:

Page 12 of 12

ELECTRONICS

Parts of 61340-5-1 may be found on technical grounds to be unnecessary or irrelevant to a

particular installation or processes, and may be omitted. Where only partial compliance is

required in this way, this should be made clear to all who use or audit your ESD facilities. A

good way to achieve this would be to document it in an in-house ESD Programme or the EPA

Certificate of Conformance.

IEC61340-5-1 specifies general requirements for the design, use and control of a protected

area so that electrostatic sensitive devices (ESDS), having sensitivity of 100V (Human Body

Model test) or higher, can be handled with minimal risk of damage from procurement through

to end of life. The Technical Report covers:

• Signs and markings

• The electrostatic protected area (EPA) including requirements for protective

equipment, construction of the EPA, working practices, and field work

• Protective

packaging

• Training

requirements

• Quality

responsibilities

• Periodic Audit instructions

An Annex describes test methods to be used to verify the performance of equipment,

materials and packaging for use in protection of ESDS.

The Technical Report does not cover health and safety requirements, and compliance with

local regulations and practices should always be observed in this respect.

The Technical Report warns that special care may be required in implementing static damage

prevention measures under the following conditions:

Document Outline

- What is ESD?

- Key elements in an ESD Program

- EPA design

- Responsibilities of personnel

- ESD Protective packaging

- Auditing program

Wyszukiwarka

Podobne podstrony:

ECC G003 Guide to Repair Flow

ECC G002 Guide to RoHS

ECC G004 Guide Easy ESD

Herbs for Sports Performance, Energy and Recovery Guide to Optimal Sports Nutrition

Meezan Banks Guide to Islamic Banking

NLP for Beginners An Idiot Proof Guide to Neuro Linguistic Programming

50 Common Birds An Illistrated Guide to 50 of the Most Common North American Birds

Guide to the properties and uses of detergents in biology and biochemistry

Guide To Erotic Massage

A Guide to the Law and Courts in the Empire

10 Minutes Guide to Motivating Nieznany

A Student's Guide to Literature R V Young(1)

A Practical Guide to Marketing Nieznany

Guide To Currency Trading Forex

Lockpick Leif Mccameron'S Guide To Lockpicking(1)

J T Velikovsky A Guide To Fe A Screenwriter's Workbook id 22

Answer Key Guide to Reading

Jouni Yrjola Easy Guide to the Classical Sicilian (feat Richter Rauzer and Sozin Attacks)

21 Appendix C Resource Guide to Fiber Optics

więcej podobnych podstron