Service

ELECTRONICS

ECC

Issue 1

European Service

Guide to Repair Flow

ECC G003

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 1 of 5

1. General

This process describes special repair guidelines which must be observed during the repair

procedure.

2. Repair

Guidelines

2.1

Mobile phone software update

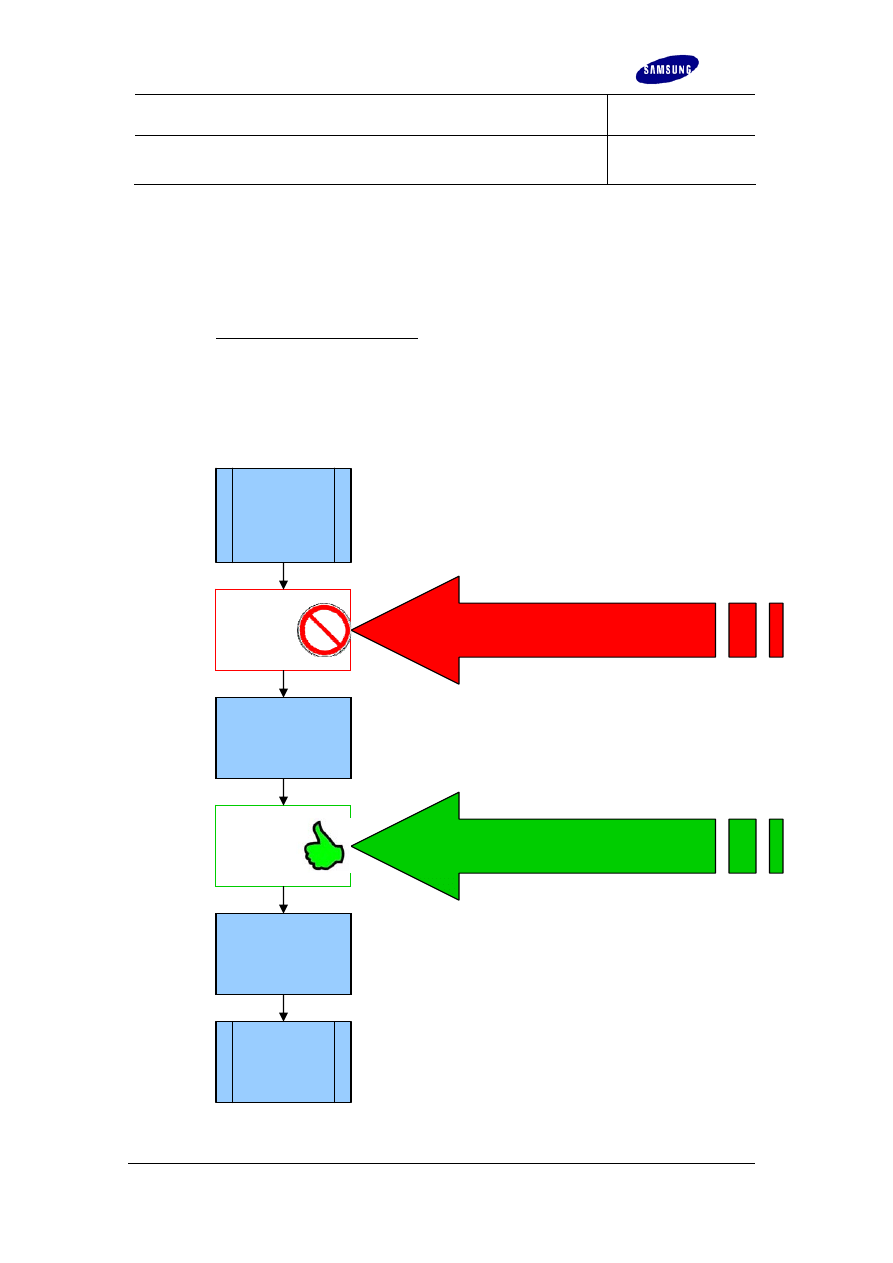

Do not carry out a software update before repairing a unit!

If a software update is executed before a technician examines a defective phone,

it is virtually impossible to find out whether a phone with an NDF diagnosis (No

Defect Found) is correctly labelled NDF, or whether the original defect was

eliminated with the software update.

Incoming

defective phone

Software

update

Do not carry out a software update before

repairing a unit!

A software update can be carried out

during or after repair of a unit.

Software

update

(if

necessary)

Trouble shooting

and repair of

defective phone

Final test

Repaired

phone returned

to customer

Service

ELECTRONICS

ECC

Issue 1

European Service

Guide to Repair Flow

ECC G003

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 2 of 5

2.2

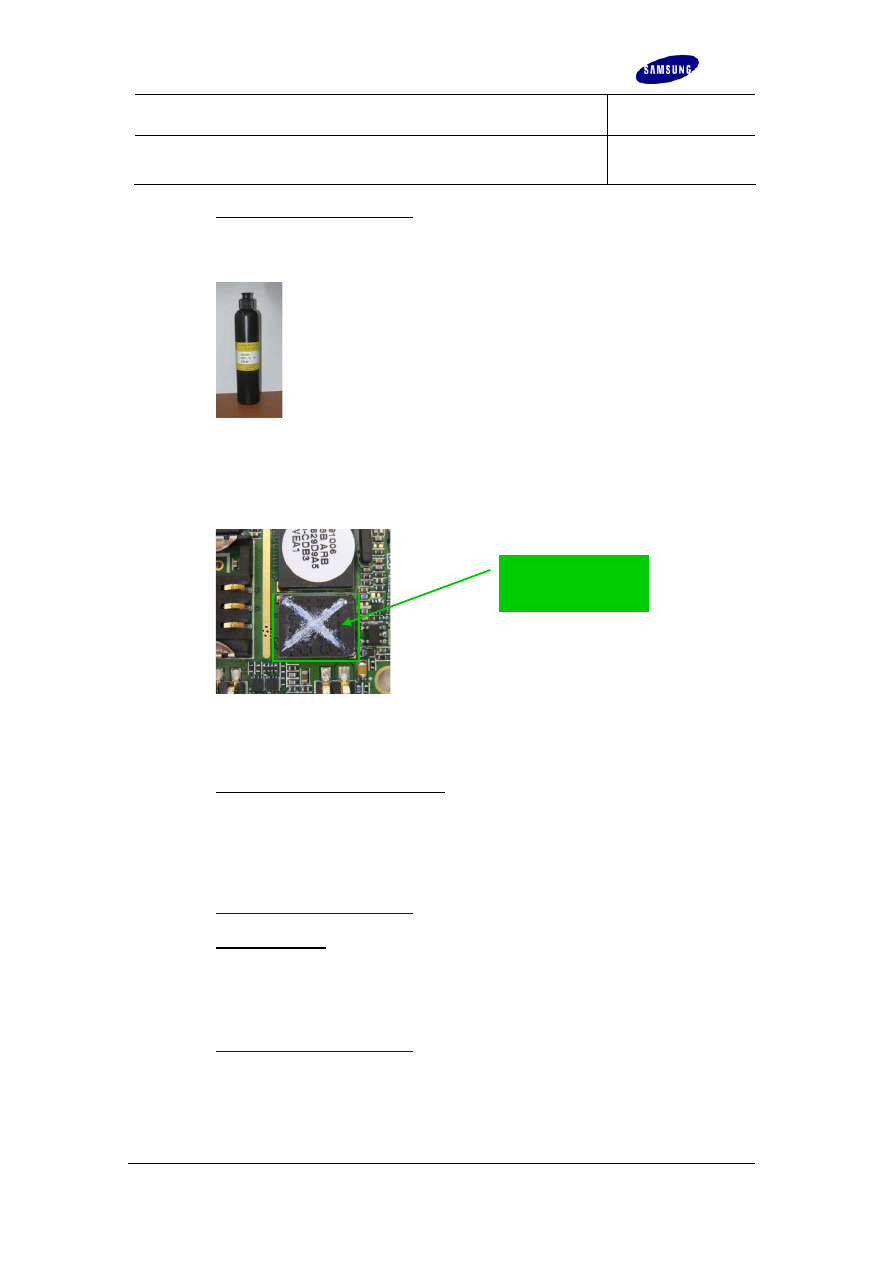

Replacing uBGA components

New uBGA components must be re-glued with the BGA adhesive recommended

by Samsung after soldering the component.

Loctite 5313

The same uBGA component can be replaced only once; for this reason, the

exchanged uBGA component must be market with a cross (Picture 1). A

maximum of two µBGA’s per PCB to be changed.

Exchange uBGA

component

Picture

1

For this purpose, a high-tech marker from EDDING, type XXX, colour XXX, must

be used.

2.3

Latest software tools and firmware

The latest version of any software tools and of the phone firmware must be used

when repairing mobile phones.

It can be downloaded from the following website:

2.4

Service bulletins

The service bulletins published by SAMSUNG must be observed.

The bulletins can be downloaded from the following website:

Service

ECC

Issue 1

European Service

Guide to Repair Flow

ECC G003

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 3 of 5

ELECTRONICS

2.5

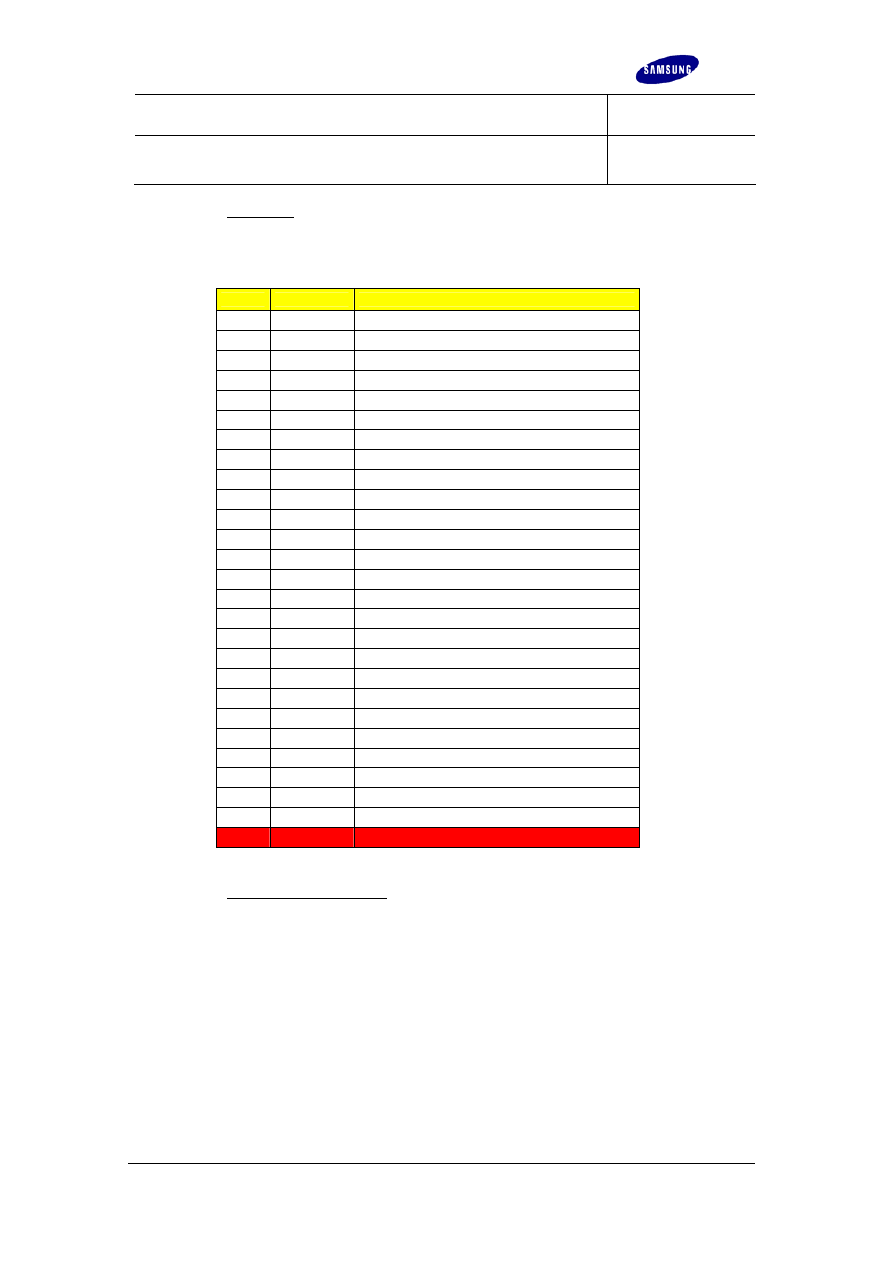

NDF units

Units for which no defect could be found (NDF units) must be marked with the

condition code „X“ in the IRIS code.

Code

Abbreviation Description

1 Condition

PERMANENTLY

PRESENT

2 Condition

TEMPORARILY

PRESENT

3

Condition

AFTER SOME TIME

4 Condition

AFTER

WARMUP

5

Condition

IN COLD CONDITION

6 Condition

WHEN

POWER

ON/SWITCHING

7

Condition

CAUSED BY SHOCK

8 Condition

IN

HUMID/WET

ENVIRONMENT

9

Condition

IN DRY ENVIRONMENT

A

Condition

DAMAGE CAUSED BY FALLING

B

Condition

DAMAGE CAUSED BY WATER, LIGHTNING

C Condition

ONLY

CERTAIN

STATIONS/CDs/TAPES

D

Condition

ONLY FOR CERTAIN STANDARDS

E Condition

ONLY

ONE

CHANNEL

F Condition

ONLY

CERTAIN

INPUTS

G Condition

ONLY

CERTAIN

OUTPUTS

H

Condition

IN POSITION STANDBY/OFF

I

Condition

IN EDIT MODE

K

Condition

WHEN CONNECTED TO OTHER DEVICES

L

Condition

IN INSERT MODE

M

Condition

IN ASSEMBLE MODE

N Condition

RIGHT

CHANNEL

O Condition

LEFT

CHANNEL

P Condition

SPARE

PARTS

PROBLEM

S

Condition

FOR SECOND HAND PROCESSING

V Condition

FOR

SCRAPPING

X

Condition

NO DEFECT FOUND

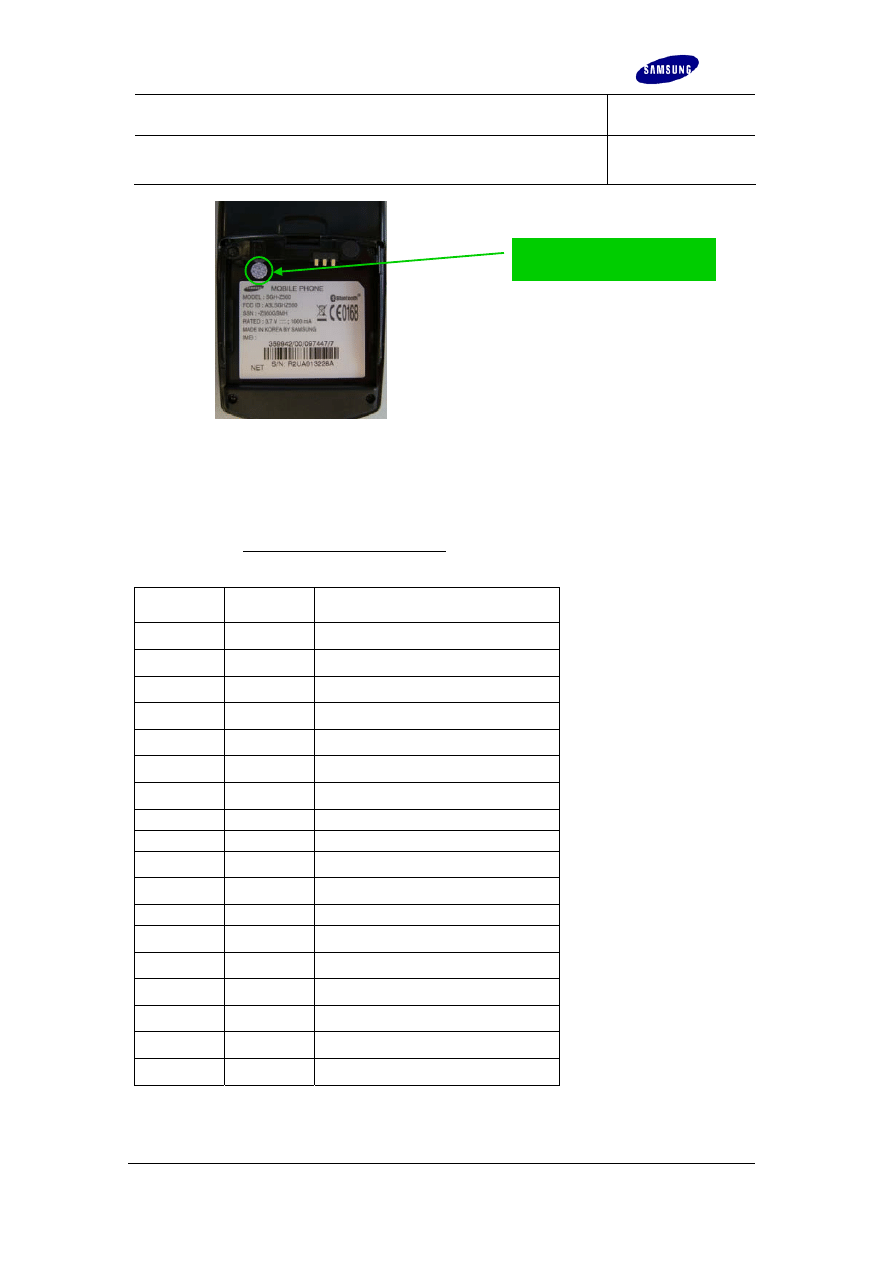

2.6

Liquid damage indicator

Every unit must be equipped with a liquid damage indicator, if not yet in place

(Picture 2).

This liquid damage indicator must be placed near the battery contacts or the SIM

card reader.

Service

ELECTRONICS

ECC

Issue 1

European Service

Guide to Repair Flow

ECC G003

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 4 of 5

Liquid damage indicator

Picture

2

2.7

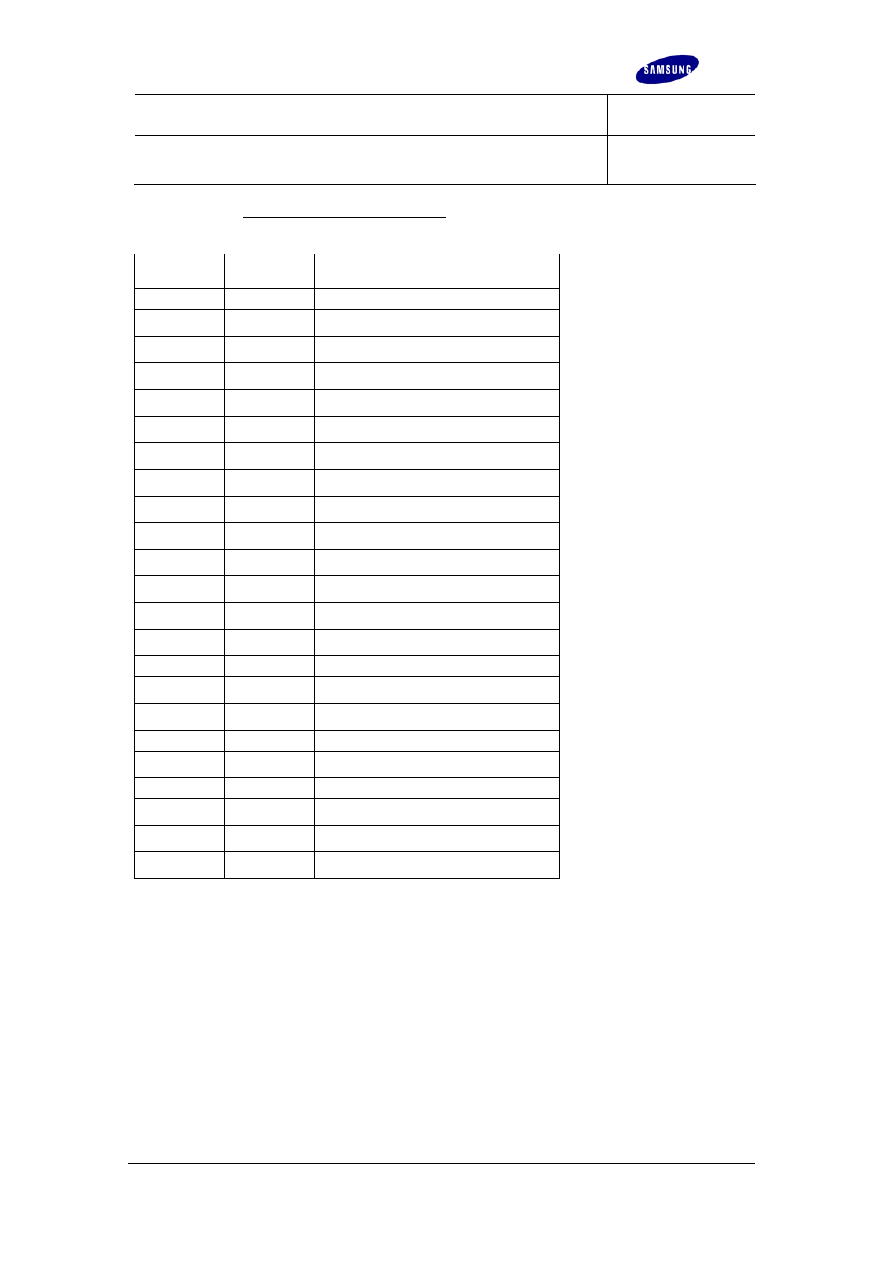

Typical Screw Torque Settings

Model

Start

Month

Torque

E370

06/04 1.0±0.1

kgf.㎝

P900

06/04 0.8~1.2

kgf.㎝

X160

06/04 1.3±0.1

kgf.㎝

X461

06/04

1.2 ± 0.1 kgf.㎝

X650

06/04

1.1 ± 0.1 kgf.㎝

C130

06/05

0.9 ~ 1.1 kgf.㎝

E900

06/05 1.0±0.1

kgf.㎝

P910

06/05

1.2 ± 0.1 kgf.㎝

P920

06/05

1.6 ± 0.1 kgf.㎝

X500

06/05 1.0±0.1

kgf.㎝

X820

06/05

0.9 ~ 1.1 kgf.㎝

Z220

06/05

1.6 ± 0.1 kgf.㎝

E380

06/06 1.5±0.2

kgf.㎝

X680

06/06

0.9 ~ 1.1 kgf.㎝

Z400

06/06 1.6±0.1

kgf.㎝

Z560

06/06

1.2 ± 0.1 kgf.㎝

D830

06/07 1.0±0.2

kgf.㎝

D840

06/07

1.2 ± 0.1 kgf.㎝

Service

ECC

Issue 1

European Service

Guide to Repair Flow

ECC G003

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 5 of 5

ELECTRONICS

2.7

Typical Screw Torque Settings

Model

Start

Month

Torque

P200

06/07

1.1 ~ 1.3 kgf.㎝

X630

06/07

0.9 ~ 1.3 kgf.㎝

Z710

06/07

1.2 ± 0.1 kgf.㎝

S501I

06/08

1.2 ± 0.1 kgf.㎝

X510

06/10 1.1±0.1

kgf.㎝

X530

06/10 1.0±0.1

kgf.㎝

X830

06/10

0.8 ~ 1.0 kgf.㎝

C300

06/11 0.8~1.2

kgf.㎝

E250

06/11 0.9±0.1

kgf.㎝

E420

06/11

0.9 ~ 1.1 kgf.㎝

E570

06/11

1.0 ± 0.1 kgf.㎝

E690

06/11 1.1±0.1

kgf.㎝

P310

06/11

1.3 ± 0.1 kgf.㎝

X520

06/11 1.0±0.1

kgf.㎝

Z360

06/11

1.2 ± 0.1 kgf.㎝

Z630

06/11

1.1 ± 0.1 kgf.㎝

Z720

06/11 0.9±0.1

kgf.㎝

E390

06/12

1.0 ~ 1.2 kgf.㎝

E480

06/12 1.0~1.2

kgf.㎝

P940

06/12

0.7 ~ 0.8 kgf.㎝

C140

07/01 1.65±0.05

kgf.㎝

E490

07/01 1.0±0.1

kgf.㎝

X540

07/01

0.9 ~ 1.1 kgf.㎝

Wyszukiwarka

Podobne podstrony:

ECC G002 Guide to RoHS

ECC G001 Guide to ESD

Herbs for Sports Performance, Energy and Recovery Guide to Optimal Sports Nutrition

Meezan Banks Guide to Islamic Banking

NLP for Beginners An Idiot Proof Guide to Neuro Linguistic Programming

50 Common Birds An Illistrated Guide to 50 of the Most Common North American Birds

Guide to the properties and uses of detergents in biology and biochemistry

Guide To Erotic Massage

A Guide to the Law and Courts in the Empire

10 Minutes Guide to Motivating Nieznany

A Student's Guide to Literature R V Young(1)

A Practical Guide to Marketing Nieznany

Guide To Currency Trading Forex

Lockpick Leif Mccameron'S Guide To Lockpicking(1)

J T Velikovsky A Guide To Fe A Screenwriter's Workbook id 22

Answer Key Guide to Reading

Jouni Yrjola Easy Guide to the Classical Sicilian (feat Richter Rauzer and Sozin Attacks)

21 Appendix C Resource Guide to Fiber Optics

więcej podobnych podstron