Service

ELECTRONICS

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 1 of 6

ESD Guidelines

This process defines the ESD protection of staff, workstations and repair equipment.

Marking EPA (Electrostatic Protected Area) boundaries

The boundaries of the EPA must be clearly marked.

This can be done by using an area which is separated from other areas by the

way it is built or by putting up clear floor markings (Picture 1).

Additional signs must be put up within the EPA (Picture 2).

ATTENTION

ESD PROTECTED AREA

OBSERVE SAFETY

MEASURES WHEN

HANDLING DEVICES

WHICH ARE SENSITIVE

TO ELECTROSTATIC

CHARGES!

Picture

1

Picture

2

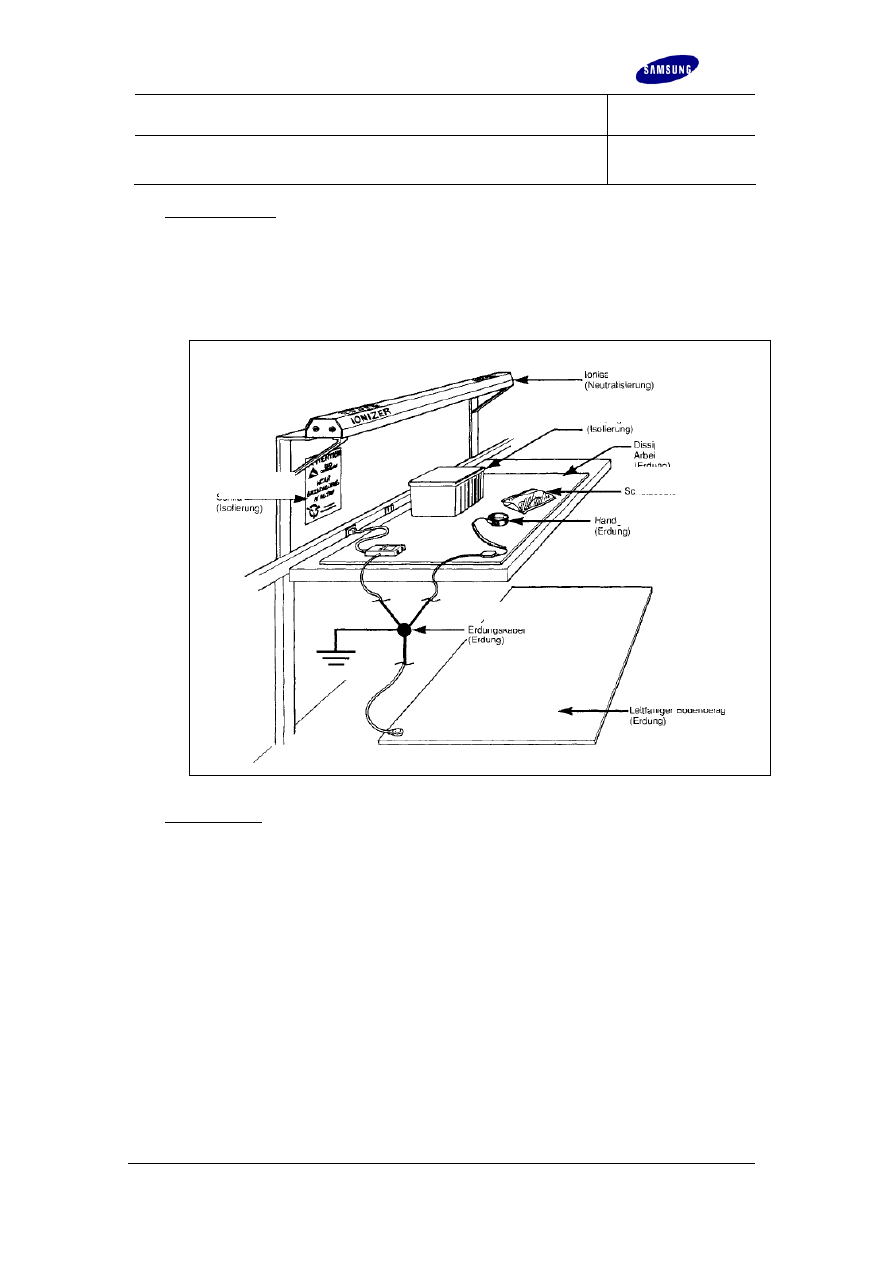

The EPA must be furnished and equipped as shown in Picture 3.

Picture 3

10

Trolley grounding

11

Ankle and toe straps (footwear)

12 Ionisers

13 Dissipating

desk

surface

14 ESD

chair

15 Dissipating

flooring

16 ESD

garment

17 Dissipating

shelves

18 EPA

sign

1 Dissipating

wheels

2 Dissipating

surfaces

3

Wrist strap tester

4 Footwear

tester

5 Footwear

electrode

6

Grounding wrist strap with

grounding

cable

7 Grounding

line

8 Grounding

9 Grounding

point

Service

ELECTRONICS

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 2 of 6

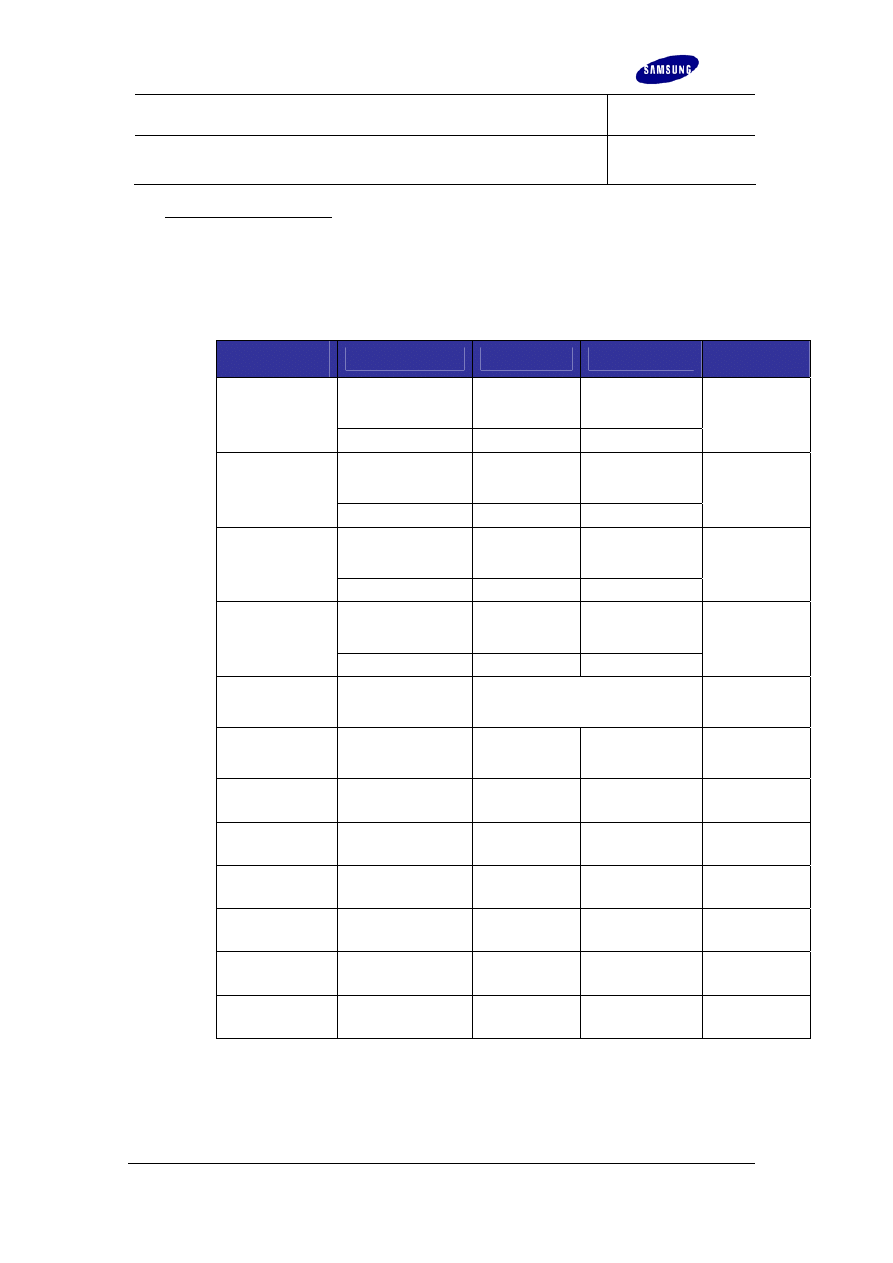

ESD workstation

SAMSUNG mobile phones must be repaired at workstations which are protected

against electrostatic charges.

ESD workstations must be equipped as shown in Picture 4.

Ioniser

(neutralizing)

Conductive container

(insulation)

Dissipating

worktop

(grounding)

Protective bag

(insulation)

Sign

(insulation)

Wrist strap

(grounding)

Grounding cable

(grounding)

Conductive flooring

(grounding)

Picture 4

ESD garments

Any person in the EPA must wear dissipating and closed garments when

repairing SAMSUNG mobile phones.

When working on SAMSUNG mobile phones in the EPA, the following garments

must be worn:

Service

ELECTRONICS

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 3 of 6

1.

ESD

smock

3.

ESD

footwear

2.

ESD

shirt

4.

ESD

gloves

ESD personal grounding devices

Any person in the EPA must use personal grounding devices such as wrist straps

or footwear grounding.

ESD tools

Any tool used for repairing SAMSUNG mobile phones such as screw drivers,

tweezers, soldering irons etc. must comply with the ESD guidelines.

Soldering irons must have grounded tips.

Tools should not have insulating handles and must be marked with an ESD sign

(Picture 5).

Picture 5

Service

ELECTRONICS

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 4 of 6

Storing and transporting ESD sensitive devices

For transporting and storing ESD sensitive devices, use trays, stands, containers

and bags made from conductive, dissipating or insulating materials only.

When transporting individual components, use conductive foam pads. Due to

their low electrical resistance, this ensures that all connectors have the same

potential level.

For assemblies and PCBs, use conductive or dissipating boxes, containers,

stands or trays.

When using shelves with wheels, a static charge can be generated which is

conducted to the transported part. For this reason, ESD shelves are made from

dissipating/conductive materials and are equipped with dissipating/conductive

wheels. If the flooring is not conductive, a transport trolley must be grounded

using grounding connections when loading or unloading sensitive components.

Visitors and ESD protection

In areas with conductive flooring, visitors must wear ESD footwear or disposable

ankle or toe straps.

In addition, visitors must wear an ESD smock and a grounded wrist strap when

handling PCBs or components.

No eating, drinking or smoking

In ESD areas (EPA), it is strictly forbidden to eat, drink or smoke.

This rule must be indicated by signs in the EPA.

Cleaning of EPA

ESD surfaces must not be cleaned with ordinary household cleaners because

they can leave an insulating layer on the cleaned surface. Use special cleaners.

Surfaces should be cleaned at least once a week.

Humidity

Each EPA must be equipped with a humidity and temperature measuring device.

The information stored by the measuring device can help to analyze any mistakes.

Humidity should always be over 30 %.

For lower humidity values, it is recommended to use ionisers.

Service

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 5 of 6

ELECTRONICS

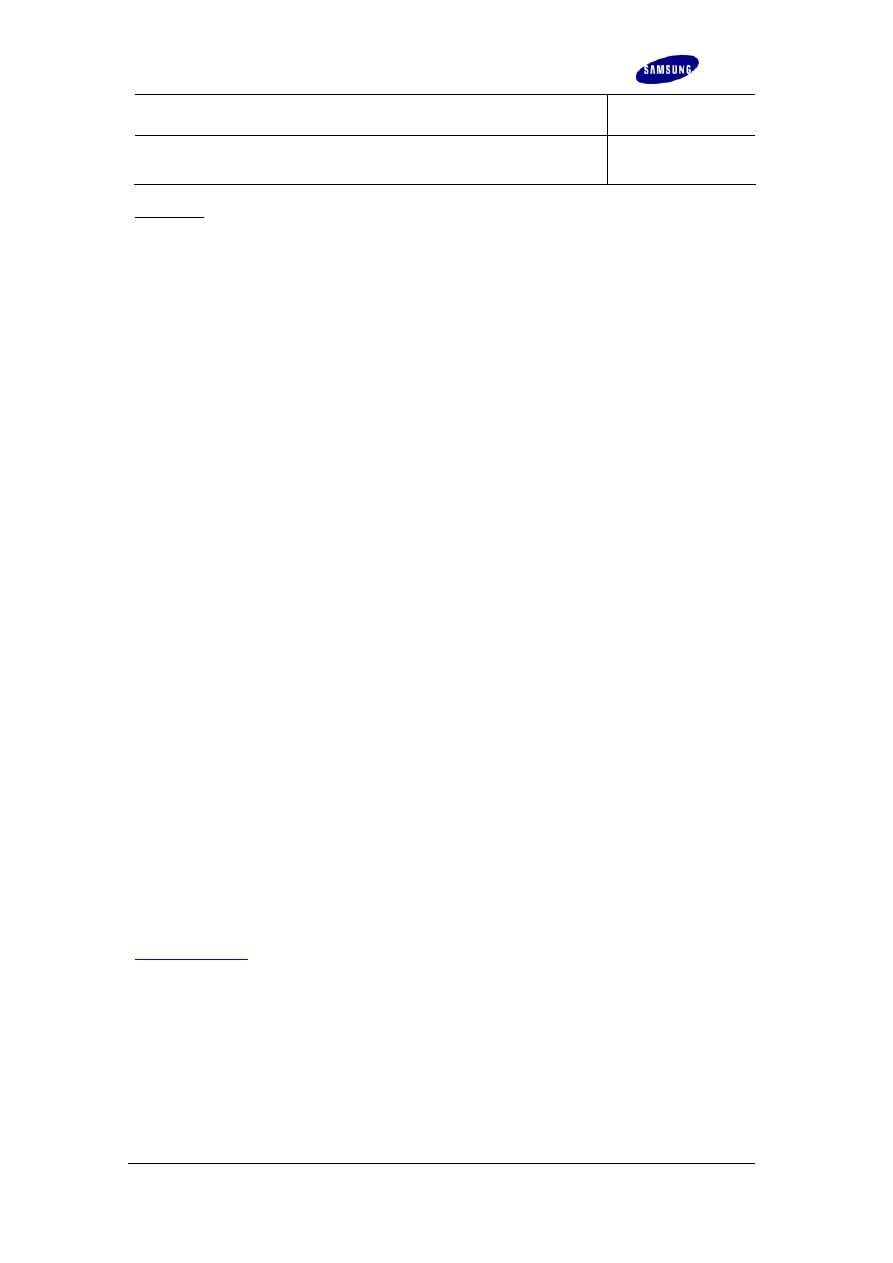

Checking ESD protection

ESD protective equipment such as wrist straps, footwear grounding straps, ESD

worktops and flooring must be checked regularly. The results of these checks

must be documented by the ESD officer.

Checking intervals and limiting values are defined as follows:

ESD protective

product

Checking parameter

Lower limit

Upper limit

Checking

interval

Dissipating resistance

to protective

conductor

7.5 * 10

5

Ω

1.0 * 10

9

Ω

ESD flooring

Surface resistance

7.5 * 10

4

Ω

1.0 * 10

9

Ω

Quarterly

Dissipating resistance

to protective

conductor

7.5 * 10

5

Ω

1.0 * 10

9

Ω

ESD worktop

Surface resistance

7.5 * 10

4

Ω

1.0 * 10

9

Ω

Monthly

Dissipating resistance

to protective

conductor

7.5 * 10

5

Ω

1.0 * 10

9

Ω

ESD transport

trolley

Surface resistance

7.5 * 10

4

Ω

1.0 * 10

9

Ω

Monthly

Dissipating resistance

to protective

conductor

7.5 * 10

5

Ω

1.0 * 10

9

Ω

ESD chair

Surface resistance

7.5 * 10

4

Ω

1.0 * 10

9

Ω

Monthly

ESD wrist strap

and spiral cable

(unused)

(Inner) surface to

ground resistance

1.0 * 10

5

Ω Daily

ESD wrist strap

and spiral cable

(unused)

Surface resistance

7.5 * 10

5

Ω

3.5 * 10

7

Ω Daily

ESD shoes

Dissipating resistance

to worn shoe

1.0 * 10

5

Ω

3.5 * 10

7

Ω Daily

ESD garment

Surface resistance

7.5 * 10

5

Ω

1.0 * 10

12

Ω Monthly

ESD gloves

Surface resistance

7.5 * 10

5

Ω

1.0 * 10

12

Ω Monthly

ESD tool

Surface resistance

7.5 * 10

5

Ω

1.0 * 10

12

Ω Monthly

Service

ECC

Issue 1

European Service

ESD Easy Guide

ECC G004

S

amsung

E

uropean

S

ervice

A

ward

Author: Torsten Heiner

Revised Date:

Page 6 of 6

ELECTRONICS

Reference

It is recommended to use the following international standards as a guideline:

IEC 61340-5-1 Electrostatics Part 5-1:

Protection of electronic devices from electrostatic phenomena

- General requirements

IEC 61340-5-2 Electrostatics Part 5-2:

Protection of electronic devices from electrostatic phenomena

- User guide

IEC 61340-4-1 Ed. 2.0 Electrostatics Part 4-1:

Standard test methods for specific applications

- Electrostatic behaviour of floor coverings and installed floors

IEC 61340-4-3 Electrostatics Part 4-3:

Standard test methods for specific applications

- Footwear

IEC 61340-4-5 Electrostatics Part 4-5:

Test method for the characterization of electrostatic protective footwear and flooring in

combination with a person

IEC 61340-2-1 Electrostatics Part 2-1:

Measurement methods

- Ability of materials and products to dissipate static electric charge

IEC 61340-2-3 Electrostatics Part 2-3:

Test methods for determining the resistance and resistivity of solid planar materials used to

avoid electrostatic charge accumulation

IEC 61340-3-1 Electrostatics Part 3-1:

Methods for simulation of electrostatic effects:

Human body model (HBM) component testing

IEC 61340-3-2 Electrostatics Part 3-2:

(2003-02) Methods for simulation of electrostatic effects: Machine model (MM)

component testing

These standards can be purchased from the following suppliers:

Or national standards bodies

Wyszukiwarka

Podobne podstrony:

ECC G001 Guide to ESD

ECC G003 Guide to Repair Flow

ECC G002 Guide to RoHS

Jouni Yrjola Easy Guide to the Classical Sicilian (feat Richter Rauzer and Sozin Attacks)

Diy Japanese Garden Easy Step By Step Guide To Make

Jouni Yrjola Easy Guide to the Classical Sicilian (feat Richter Rauzer and Sozin Attacks)

Autogenic Training a practical guide in six easy steps Karl Hans Welz

guide camino aragones pl

Herbs for Sports Performance, Energy and Recovery Guide to Optimal Sports Nutrition

Meezan Banks Guide to Islamic Banking

10 Easy Steps to Turning Dreams into Reality!

NLP for Beginners An Idiot Proof Guide to Neuro Linguistic Programming

freespan spec guide

Eaton VP 33 76 Ball Guide Unit Drawing

Herbs to Relieve Headaches Keats Good Herb Guide

50 Common Birds An Illistrated Guide to 50 of the Most Common North American Birds

Configuration Guide WAN Access(V100R006C00 02)

więcej podobnych podstron