SealInstallationTecTips8.5x11 8/19/03 8:21 AM Page 1

Composite

C

M

Y

CM

MY

CY CMY

K

WELCOME TO TECHTIPS. Maximizing bearing performance and life remains an objective throughout The Timken Company,

from design teams to manufacturing associates to our field sales team and distributors. TechTips helps you install and maintain

Timken

®

bearings, seals and components to maximize the life and performance of your bearings and the systems in which they

operate. For more information regarding Timken automotive products and services, visit timken.com or contact your local

Timken distributor.

VOLUME 1 • ISSUE 2

SOLUTIONS FOR THE

AUTOMOTIVE INDUSTRY

SOLUTIONS FOR THE

AUTOMOTIVE INDUSTRY

SOLUTIONS FOR THE

AUTOMOTIVE INDUSTRY

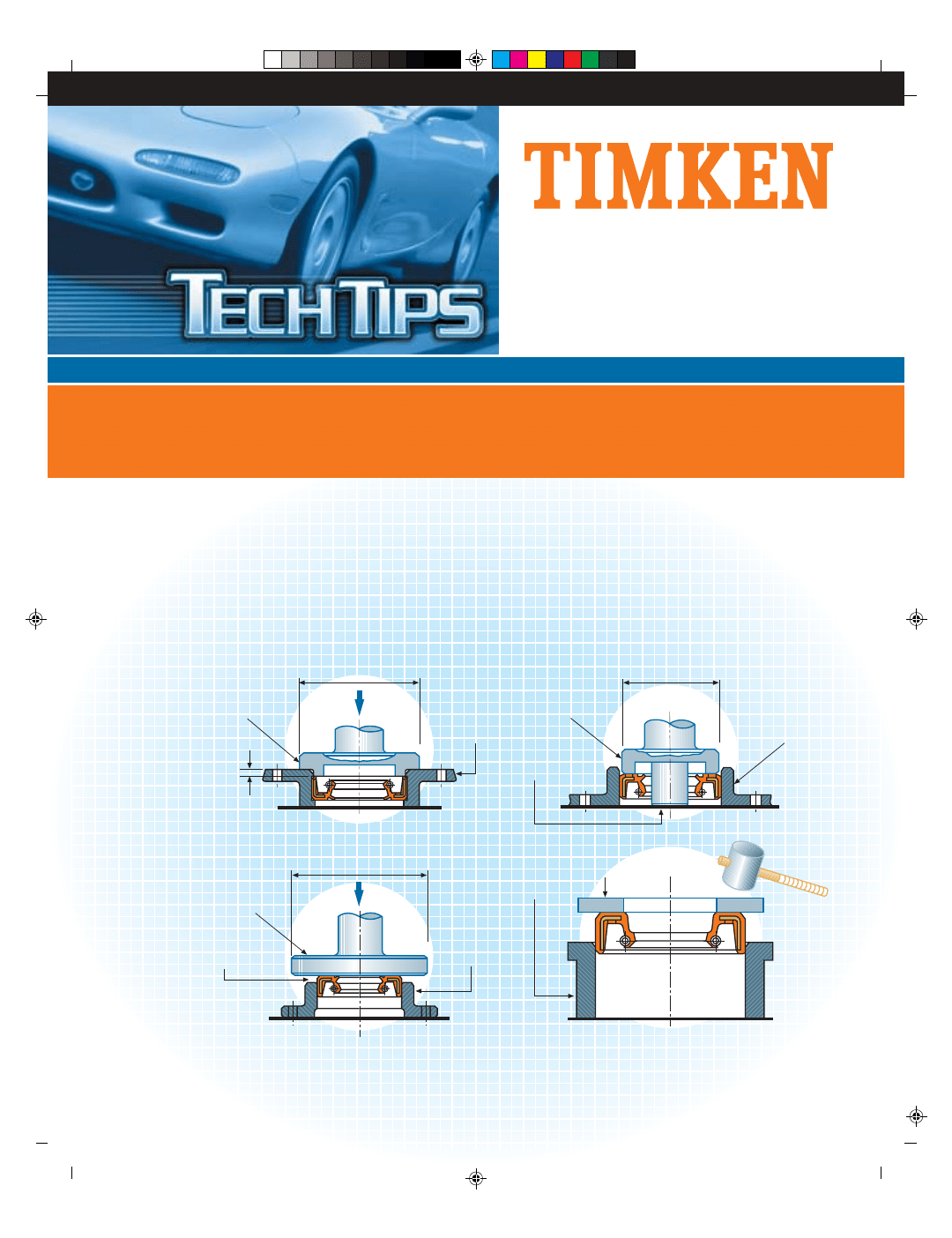

INSTALLATION TOOL

HOUSING

E

TOOL STOPS

AGAINST

SUPPORT

SURFACE

SEAL AND SHAFT INSTALLATION PROCEDURES

The subject of installation is commonly overlooked when selecting an oil seal for an application. Possibly, this is one of the major

causes of premature seal failure. To assist the installation, the seal should be prelubricated with grease or oil to reduce sliding friction

of contact surfaces. This also helps protect the seal lips during initial run-in. An installation tool should always be used when installing

an oil seal. Using a tool improves ease of installation and reduces the possibility of seal cocking (non-perpendicular to shaft). A

hydraulic or pneumatic press is advised to supply necessary force to install the seal. Following are examples of both recommended

and improper installation methods.

ACCEPTABLE METHOD OF SEAL INSTALLATION

MINIMUM DIAMETER .20 TO .40 LARGER THAN SEAL O.D.

DIAMETER .020 TO .040 LESS THAN BORE DIA.

INSTALLATION TOOL

HOUSING

STRIKE PLATE

HOUSING

WIDTH "E" = TO CHAMFER WIDTH PLUS .020

TOOL STOPS AGAINST HOUSING FACE

In each preferred method, installation load is absorbed by either housing or bottom plate to prevent seal damage and to assist in

locating the seal properly within the bore.

MINIMUM DIAMETER .20 TO .40 LARGER THAN SEAL O.D.

SURFACE

STOPS TOOL

INSTALLATION TOOL

HOUSING

SealInstallationTecTips8.5x11 8/19/03 8:21 AM Page 2

Composite

C

M

Y

CM

MY

CY CMY

K

© 2003 The Timken Company

Printed In the U.S.A.

70M-08-03-7 Order No. 7549

Timken® is the registered trademark of

The Timken Company.

www.timken.com

WARNING: Proper maintenance and handling practices are critical. Follow the equipment manufacturer’s installation instructions.

Failure to follow installation instructions and to maintain proper lubrication can result in equipment failure and could lead to a risk

of serious bodily harm.

WORLDWIDE LEADER IN BEARINGS AND STEEL

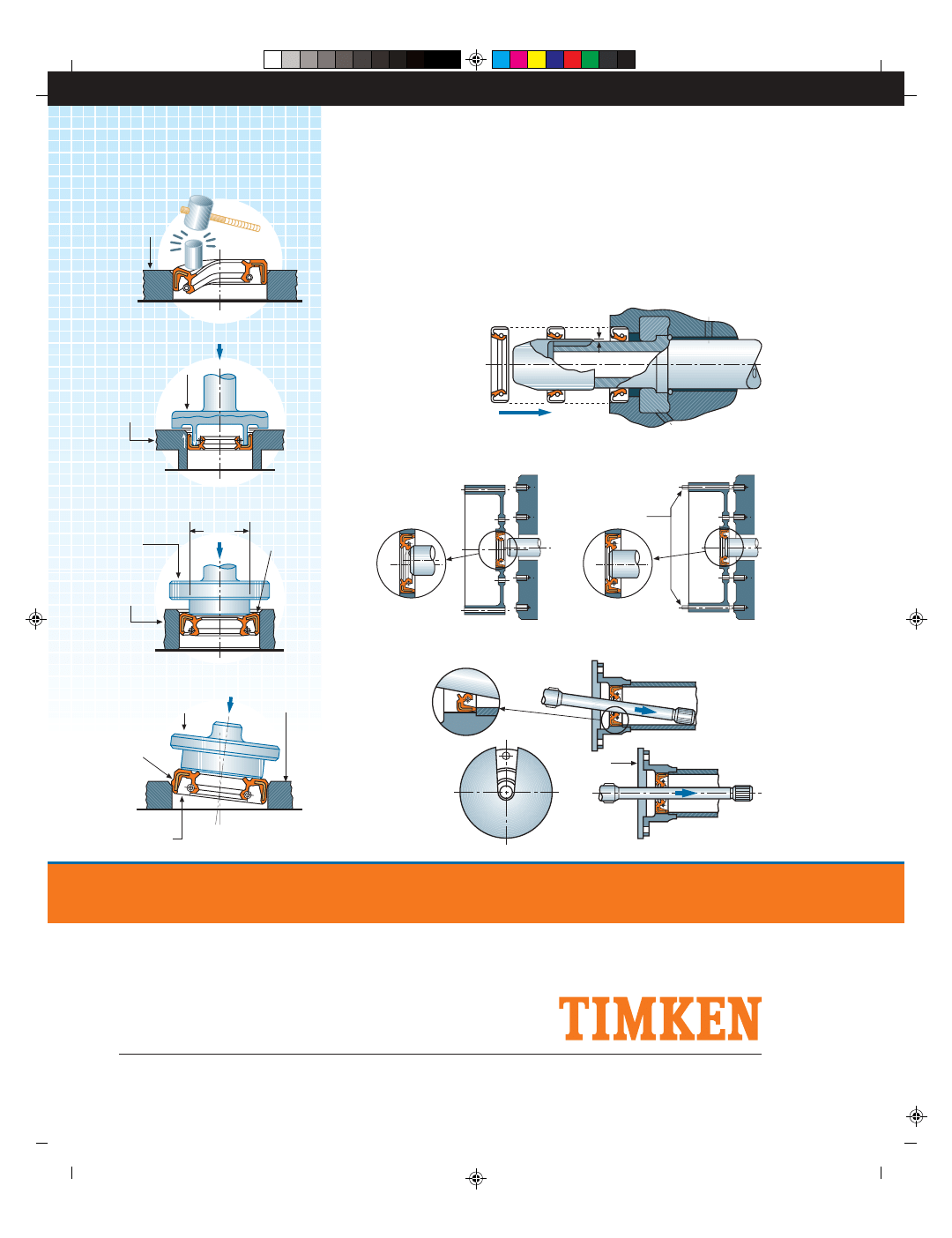

IMPROPER METHOD

OF SEAL INSTALLATION

SMALL

DIA.

HOUSING

INSTALLATION TOOL

HOUSING

MISALIGNMENT ERRORS

INSTALLATION

TOOL

HOUSING

DEFORMED

SEAL

INSTALLATION TOOL

COCKED SEAL

O.D.

PEELING

HOUSING

SEAL INSTALLATION

OVER SHAFT SPLINES

LONG SHAFT

HEAVY WEIGHT

HOUSING

A) BAD

B) GOOD

GUIDE PLATE

SHAFT INSTALLATION

The advisable sequence of installation is to install the seal over the shaft and then into

the housing bore. Exercise care to not damage or deform the seal lip. The proper

chamfer angle minimizes this problem. When installing over a keyway or spine, employ

a sleeve or bullet to protect the seal lip from cuts.

Where the shaft must be installed through the seal, centering guides for the shaft

prevent lip deformation and dislodging of the spring. When possible, the shaft should

be rotated as it passes through the seal to reduce sliding friction.

0.02 MAX

BAD

LOCATING PIN

GOOD

All technical information and illustrations in this Seal and Shaft Installation TechTips were provided

by and printed with the permission of Freudenberg-NOK.

© Freudenberg-NOK 2000

TechTips is not intended to substitute for the specific recommendation of your equipment suppliers.

Wyszukiwarka

Podobne podstrony:

TimKen com Wheel Bearing Replacement Tips

MA Skills Com Mount And Hamme

DiceElectronics com Audi iPod Interface Install

CCI and Turbo CCI Tips and Nuances

microsoft microsoft outlook and exchange server tips and tricks FWWF6QVBJHAJ3XOZIQG3OOK3PXKVZKIW3KW

=erico com LENTON and CADWELD Bar to Bar Connections

MA Skills Com Mount And Hamme

(Ebook Business) 030216 Job Interview Question And Answser English Tips

Focus and Concentration Some Tips For Getting Your Players Back

VAG COM 512 4 USB Driver Installation Instructions

Flooring Solid Hardwood Plank and Strip Installation (18898)

The main press station is installed in the start shaft and?justed as to direction

Boiler installation and commissioning tips

Fringe Tips and Ideas

Glow Worm installation and service manual Hideaway 70CF UIS

więcej podobnych podstron