Journal of Crystal Growth 260 (2004) 54–62

Resistivity control in unintentionally doped GaN films grown

by MOCVD

A.E. Wickenden*, D.D. Koleske

1

, R.L. Henry, M.E. Twigg, M. Fatemi

Electronics Science and Technology Division, Code 6800, Naval Research Laboratory, Washington, DC 20375-5320, USA

Received 28 April 2003; accepted 19 August 2003

Communicated by C.R. Abernathy

Abstract

The relationship of GaN resistivity to film microstructure and impurity compensation are investigated using

transmission electron microscopy, secondary ion mass spectroscopy, X-ray diffraction, and resistance measurements.

Unintentionally doped GaN films grown by MOCVD at varying pressures exhibit increased grain size, reduced carbon

and oxygen impurity incorporation, reduction in the density of threading dislocations (TDs) with an edge component,

and reduced resistivity with increasing growth pressure. Variation in resistivity over eight orders of magnitude is

observed as a result of varying the MOCVD growth pressure in a controlled experiment. Our results suggest that

disclocations play an important role in the resistivity of GaN. Evidence is presented of impurities segregating at TDs

having an edge component, and acting as compensating centers. The control of such compensation as a function of

MOCVD growth conditions is outlined.

Published by Elsevier B.V.

Keywords: A1. Compensation; A1. Impurities; A1. Threading dislocations; A3. Metalorganic vapor phase epitaxy; B2. Semicon-

ducting gallium nitride

1. Introduction

The III-nitride system is attractive for high-

power microwave applications due to the large

breakdown voltage of the wide band gap materi-

als, as well as their ability to realize high sheet

carrier densities in the two-dimensional electron

gas (2DEG) region formed at the AlGaN/GaN

interface. Highly resistive (HR) GaN is required to

facilitate device pinch-off and high frequency

operation. A large n

sheet

m product is required for

power applications, which further mandates high

electron mobility in the GaN film. We believe that

resistivity in heteroepitaxial GaN thin films, as in

many other III–V compounds, generally results

from compensation effects of deep level traps

rather than from the intrinsic wide band gap

nature of the material (e.g.

). Effects such as

persistent photoconductivity

and current col-

lapse

have been observed in GaN field effect

ARTICLE IN PRESS

*Corresponding author. Currently with US Army Research

Laboratory, AMSRL-SE-RL, 2800 Powder Mill Road, Adel-

phi, MD 20783-1197, USA. Tel.: +1-301-394-0094; fax: +1-

301-394-4562.

E-mail address:

awickenden@arl.army.mil

(A.E. Wickenden).

1

Currently with Sandia National Laboratory, Albuquerque,

NM 87185.

0022-0248/$ - see front matter Published by Elsevier B.V.

doi:10.1016/j.jcrysgro.2003.08.024

transistor (FET) and AlGaN/GaN high electron

mobility transistor (HEMT) devices having under-

lying HR GaN layers. Such effects degrade device

performance, and have been associated with

trapping centers in the HR GaN

. Evidence of

deep level centers have also been observed in HR

GaN UV detector structures

. The most desir-

able solution at present for optimized GaN growth

of device structures is to reduce background

donors and compensating acceptors to a mini-

mum, compensated level to achieve high resistivity

for device pinchoff, and low scatter in active device

regions for high mobility.

It is well known that heteroepitaxial growth of

GaN thin films on sapphire initiates as an

assemblage of crystallites, or grains, that coalesce

into a two-dimensional film

. These GaN films

have typical dislocation densities of 10

8

–10

10

cm

2

,

and the size and relative misorientation of the

grains are determined in part by the crystal growth

process parameters. GaN films and bulk crystals

are also known to contain relatively high levels of

background impurities

and point defects such

as vacancies

. In this investigation, we report on

the modification of GaN film resistivity through

microstructural and impurity control. Manipula-

tion of the growth conditions to tune the

concentration of defects which contribute to

GaN resistivity, and which also serve as scattering,

trapping and compensating centers in the con-

ducting regions of GaN films, has been observed

to result in significant improvements in device

performance. HEMT devices with 300 K sheet

carrier density of 1.3 10

13

cm

2

, mobility of

1500 cm

2

/Vs, and excellent pinchoff characteristics

have been demonstrated on such material.

2. Experimental procedure

2.1. Epitaxial growth

The microstructure of a heteroepitaxial GaN

film may be influenced in a number of ways,

including manipulation of the low temperature

nucleation layer (NL)

, the growth rate of

the epitaxial GaN film

, and the growth

pressure of the high temperature GaN film

For the results reported here, a series of unin-

tentionally doped (UID) GaN films was grown

using the metalorganic chemical vapor deposition

(MOCVD) technique, with growth pressure varied

from 40 to 500 Torr as the experimental control

variable. Each film was grown in a single-wafer

close spaced showerhead reactor, on a-plane

ð1 1 %2 0Þ sapphire substrates. An AlN NL of

approximately 250 (

A thickness was grown under

identical conditions for each film. The NL was

deposited at a temperature of approximately

700

C, at a chamber pressure of 40 Torr, using

1.23 mmol/min trimethylaluminum (TMA) and

0.089 mol/min ammonia (NH

3

) in a hydrogen

(H

2

) ambient. The GaN epilayer growth condi-

tions were held constant, using a growth tempera-

ture of approximately 1035

C, input reactant

fluxes of 21.5 mmol/min trimethylgallium (TMG)

and 0.071 mol/min NH

3

, in a H

2

ambient. Total

flows for both the NL and GaN epilayer were held

at 4 slm, and the MOCVD chamber pressure was

adjusted by varying the throttle valve setting on

the chamber exhaust. Growth pressure was ad-

justed immediately after NL growth, hence the

AlN NL was ramped up to the GaN growth

temperature at the pressure at which the GaN film

was subsequently grown. Seven UID-GaN films

were grown at pressures of 40, 65, 110, 130, 150,

300, and 500 Torr, respectively. A reduction in

GaN growth rate with increasing growth pressure

has been previously observed due either to the

decomposition of GaN in H

2

to form NH

3

,

or gas phase depletion of reactants

. The GaN

growth rate in this experiment varied nominally in

the range of 0.5–1.5 mm/h, with the lowest growth

rate observed at the highest growth pressure. In an

effort to maintain constant film thickness within

this experimental set, the time of each growth was

adjusted to yield a film thickness of approximately

1 mm. To independently investigate the contribu-

tions of microstructure and unintentional impurity

incorporation to the carrier compensation of the

GaN films, two additional films were grown. In the

first of these, the microstructure having approxi-

mately 0.5 mm grain size was established by the

initial growth of a 0.5 mm thick layer of GaN at a

pressure of 130 Torr. The growth was then stopped

for 2 minutes during which the chamber pressure

ARTICLE IN PRESS

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

55

was adjusted to 300 Torr, and an additional 1.5 mm

thickness of GaN was grown. In the second film,

the microstructure having approximately 2 mm

grain size was established by the initial growth of

a 0.5 mm thick layer of GaN at a pressure of

500 Torr. After stopping growth, the chamber

pressure was adjusted to 130 Torr, and an addi-

tional 1.5 mm thickness of GaN was grown. In the

following discussion, these bilayer films will be

referred to as 130/300 and 500/130, respectively, to

indicate the first film growth condition followed by

the subsequent film growth condition.

2.2. Characterization

The resistance of the UID GaN films was

measured by I =V characterization of squares

patterned on each sample, using large indium

stripe contacts to reduce measurement error

associated with contact resistance. Values of

resistivity, r; were derived using the relationship

r ¼ RA=L; where R is the resistance calculated

from the I =V measurements, A is the cross-

sectional area of the GaN film (1 mm GaN film

thickness 0.5 cm indium stripe length), and L is

the distance between contacts on the film surface

(approximately 0.3 cm). The experimental limit of

the resistivity measurement equipment was 10

10

O-

cm. Each of the films was measured at ambient

temperature, in the dark and with room light

illumination. The microstructure of the films was

investigated using transmission electron micro-

scopy (TEM) and X-ray diffraction analyses.

Cross-section TEM analysis was used to investi-

gate the grain size of the films, and plan-view TEM

imaging was used to measure dislocation densities.

X-ray diffraction analysis was performed in both

the symmetric {0 0 0 2} and asymmetric f1 0 %1 2g

modes, to investigate the contribution of edge,

screw and mixed-character threading dislocations

(TDs) in the films. Intrinsic impurity levels were

investigated in selected films with secondary ion

mass spectroscopy (SIMS)

. The films were

analyzed in a single SIMS experiment to ensure

equivalent background levels, and the SIMS

chamber was evacuated for >24 hours prior to

analysis to reduce the background of atmospheric

contamination in the SIMS chamber.

3. Results

3.1. GaN morphology

All of the GaN films in this study were

continuous and specular over the 2 inch wafer

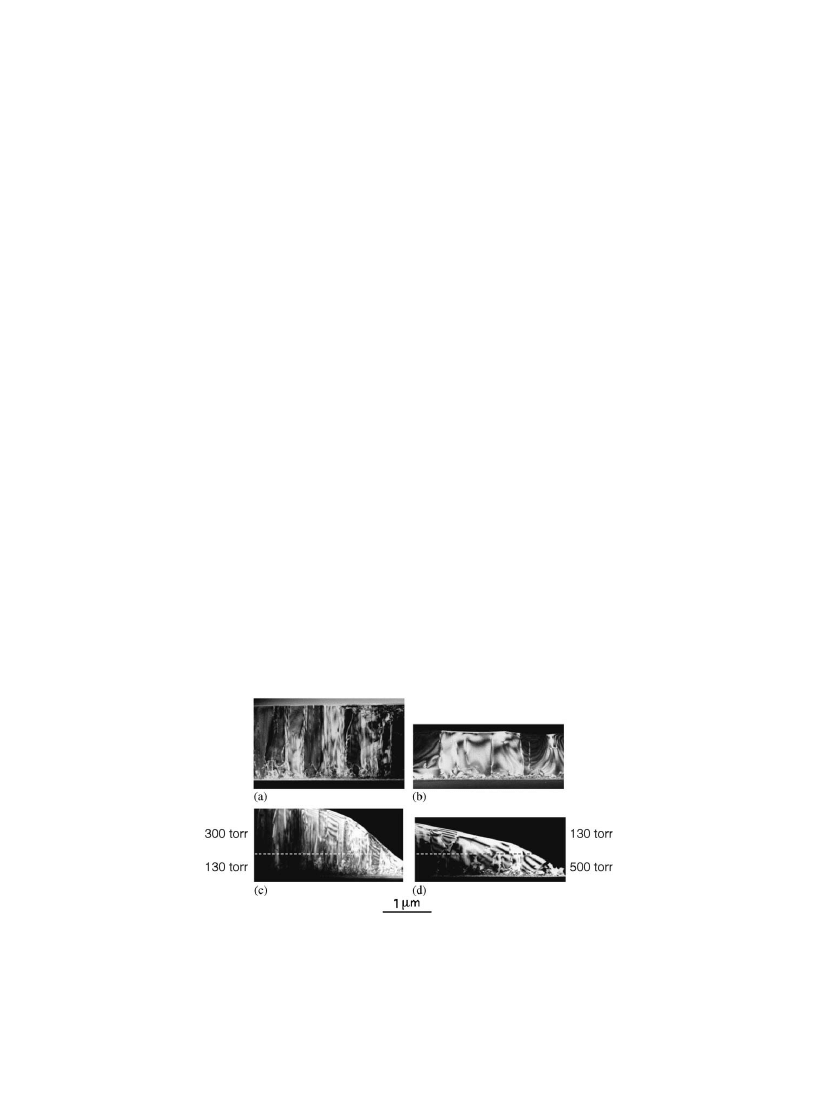

diameter. Cross-sectional TEM images of the 130

and 500 Torr single pressure films, and the 130/300

and 500/130 two-pressure films, are shown in

. The images clearly demonstrate increased

ARTICLE IN PRESS

Fig. 1. Cross-sectional TEM images of UID-GaN films, grown at pressures of: (a) 130 Torr, (b) 500 Torr, (c) 130/300 Torr, and (d)

500/130 Torr. The grain size is determined from the change in diffraction contrast due to slight misorientation of adjacent grains. The

grain size of films (b) and (d), established at the higher pressure, is approximately 2 mm, and the total dislocation density measured

using plan-view TEM analysis is 1 10

9

cm

2

. The grain size of films (a) and (c), established at the lower pressure, is approximately

0.5 mm, and the dislocation densities from plan-view TEM analysis are 4 10

9

cm

2

for both (a) and (c).

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

56

grain size with increasing growth pressure (

), a trend observed in previous studies

Further inspection of the two-pressure films

illustrates that the microstructure of an overgrown

GaN layer is determined by that of the initial

growth (

). Plan-view TEM analysis

revealed a total (edge, screw, and mixed) TD

density of 4 10

9

cm

2

in the 130 Torr and 130/

300 Torr films, 2 10

9

cm

2

in the 300 Torr film,

and 1 10

9

cm

2

in the 500 Torr and 500/130 Torr

films. The plan-view TEM images showed correla-

tion between TDs and the grain boundaries

observed in

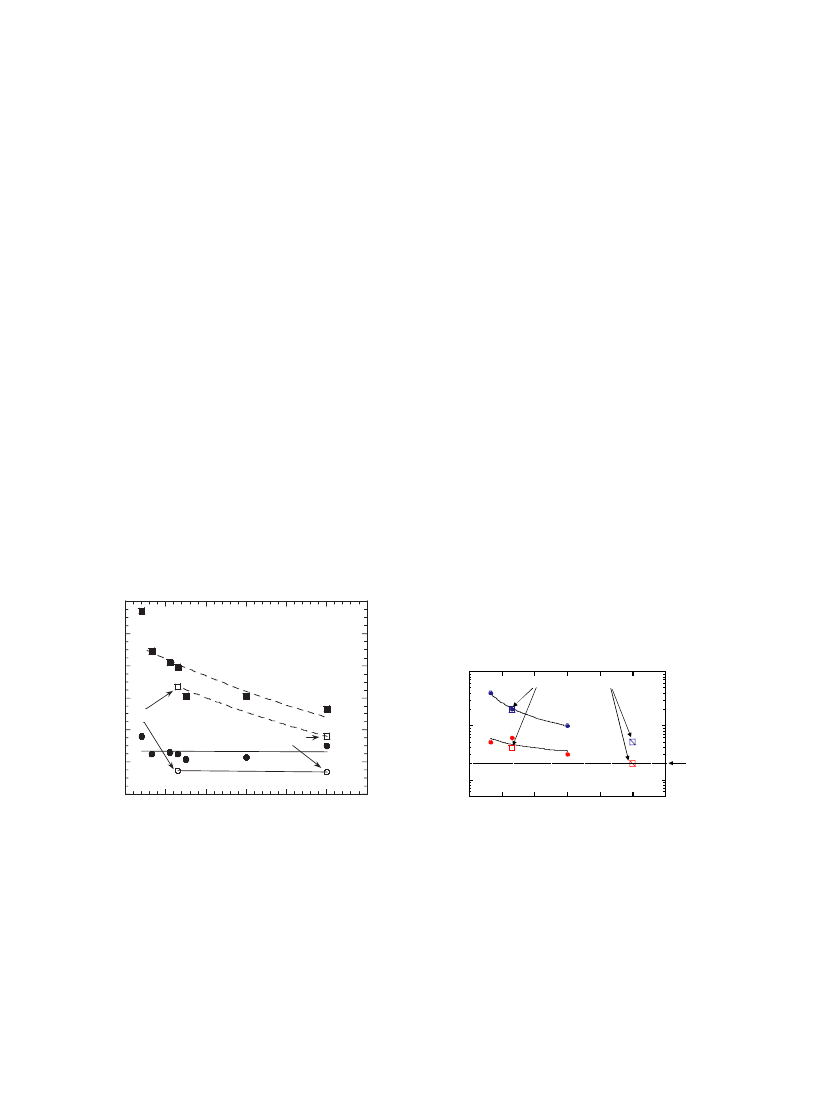

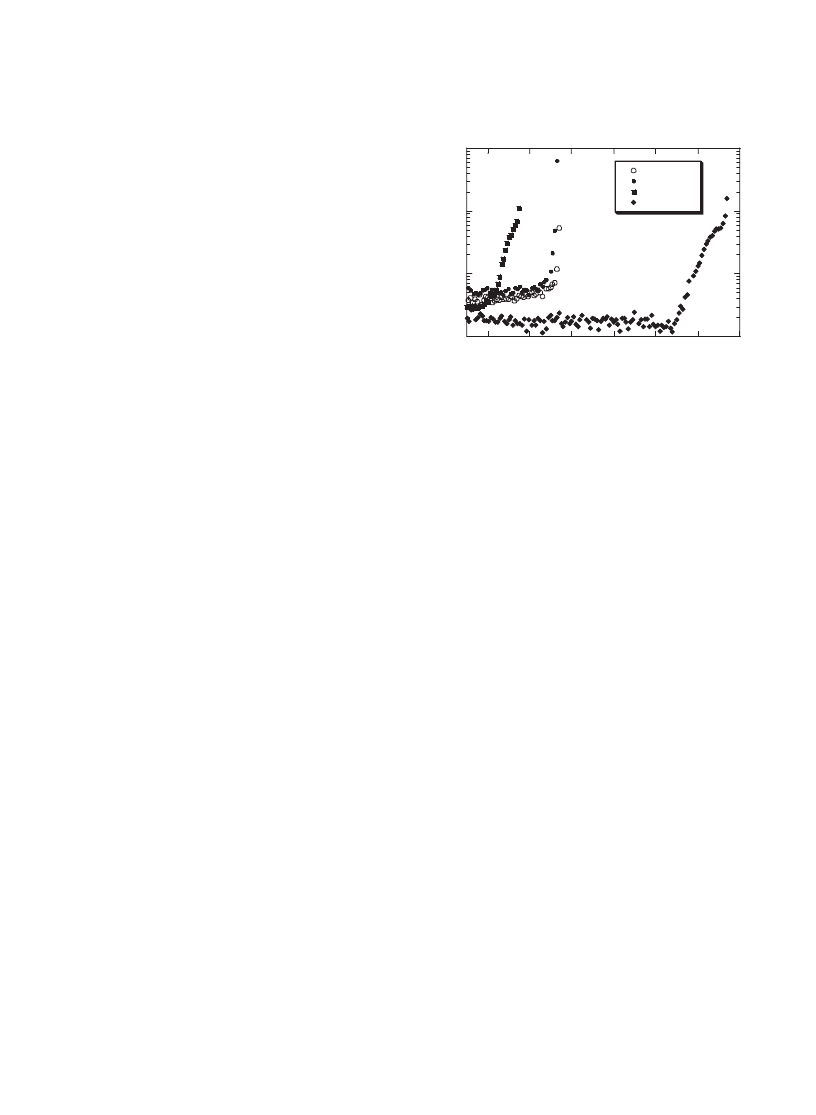

. X-ray diffraction data for the

films is shown in

. The general reduction of

FWHM values in the two-pressure films is

attributed to the fact that they are twice as thick

as the single-pressure films in the study. The X-ray

data for the thicker films is less subject to peak

broadening due to small sample volume, and less

influenced by the highly defective GaN interface

with the NL. The FWHM of the {0 0 0 2}

symmetric reflection, which is sensitive to screw-

type TDs

, appears to be insensitive to growth

pressure over a fairly broad pressure range. The

off-axis f1 0 %1 2g data, which is sensitive to screw

plus edge and mixed-character TDs, shows a

definite decreasing trend as a function of increas-

ing growth pressure. It is further observed from

the off-axis data that the two-pressure films appear

to follow the trend of the single-pressure films that

form the initial film growth. The X-ray diffraction

data is consistent with the plan-view TEM analysis

of TD density, and suggests that the ratio of edge-

type and mixed-character TDs to screw-type TDs

is decreasing with increasing growth pressure over

most of the pressure range investigated. Since

edge-type TDs are known to form at grain

boundaries to accommodate slight misorientation

between the grains

, the X-ray data is also

consistent with the increasing grain size observed

in the films grown with increasing growth pressure.

3.2. Background impurity analysis

SIMS data demonstrates an order of magnitude

decrease in the UID carbon concentration with

increasing growth pressure, from 4 10

17

cm

3

at

65 Torr to 5 10

16

cm

3

in the 500/130 Torr film,

as illustrated in

. The concentration of UID

oxygen decreases with increasing pressure by less

than a factor of three over the same pressure

ARTICLE IN PRESS

200

400

600

800

X-ray FWHM (arc-sec)

1000

1200

1400

0

100

200

300

400

500

600

Growth Pressure (torr)

500/130 torr

130/300 torr

Fig. 2. X-ray diffraction data for the GaN films in this study,

plotted as a function of growth pressure. Circles represent data

for the /0 0 0 2S reflection (sensitive to screw-type TDs), and

squares represent data for the 1 0 %1 2

reflection (sensitive to

total dislocations, including edge and mixed-character TDs).

Closed symbols represent data for single pressure GaN films,

and open symbols are data for two-pressure films, which are

plotted relative to the pressure of the underlying film since the

TEM data shows that the microstructure was fixed by the initial

film growth. The lines through data points are provided as a

guide to the eye.

10

16

10

concentration (cm

-3

)

17

10

18

0

100

200

300

400

500

600

GaN growth pressure (torr)

SIMS

detection

limit for C, O

130/300 torr film

500/130 torr film

Closed circles:

single pressure

films

Open squares:

Two-pressure films

carbon

oxygen

Fig. 3. SIMS analysis of carbon and oxygen for UID-GaN

films grown at MOCVD pressures of 65, 130, and 300 Torr

(closed circles), demonstrates the trend of reduced carbon and

carbon:oxygen ratio with increasing pressure. SIMS data for

the 130/300 Torr and 500/130 Torr UID-GaN films (open

squares) is plotted relative to the pressure of the underlying

film since the TEM data shows that the microstructure was

fixed by the initial growth. This plot demonstrates that the

impurity incorporation for this pressure range is associated with

TDs in the films. The lines through data points are provided as

a guide to the eye.

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

57

range, decreasing from 5 10

16

to 2 10

16

cm

3

.

Unexpectedly, carbon and oxygen levels were

constant through the depth of the two-pressure

films, at levels that corresponded to those expected

for the pressure used to grow the initial portion of

the films. The significance of the impurity profiles

of the two-pressure films will be discussed below.

The concentration of silicon, a donor impurity,

was not measured in these films, but SIMS analysis

of GaN films grown in this reactor under similar

process conditions have repeatedly demonstrated

UID silicon impurity concentrations below the

SIMS detection limit of 2 10

16

cm

3

. Simi-

larly, the concentrations of the acceptor impurities

magnesium and zinc were not measured, since the

precursors for these impurities are not used in this

MOCVD reactor, and previous analyses of films

grown in this reactor have shown the concentra-

tions of these impurities to be below the SIMS

detection limit.

3.3. Resistivity analysis

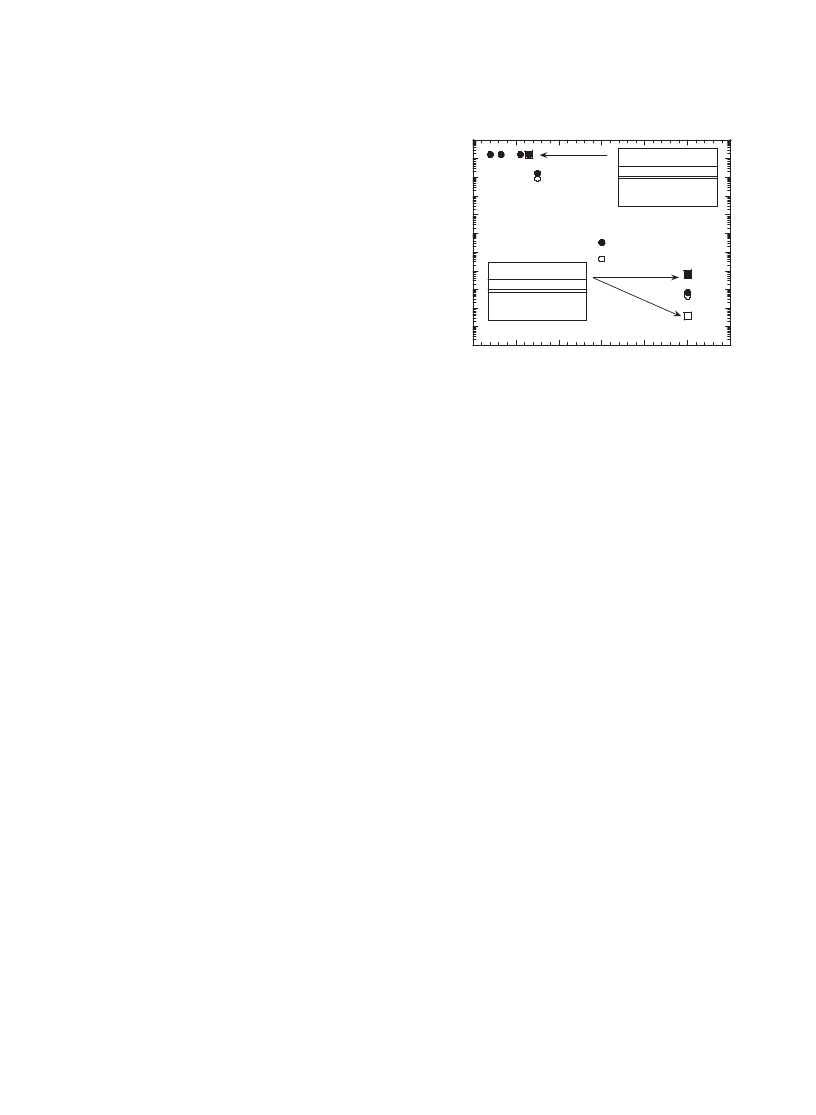

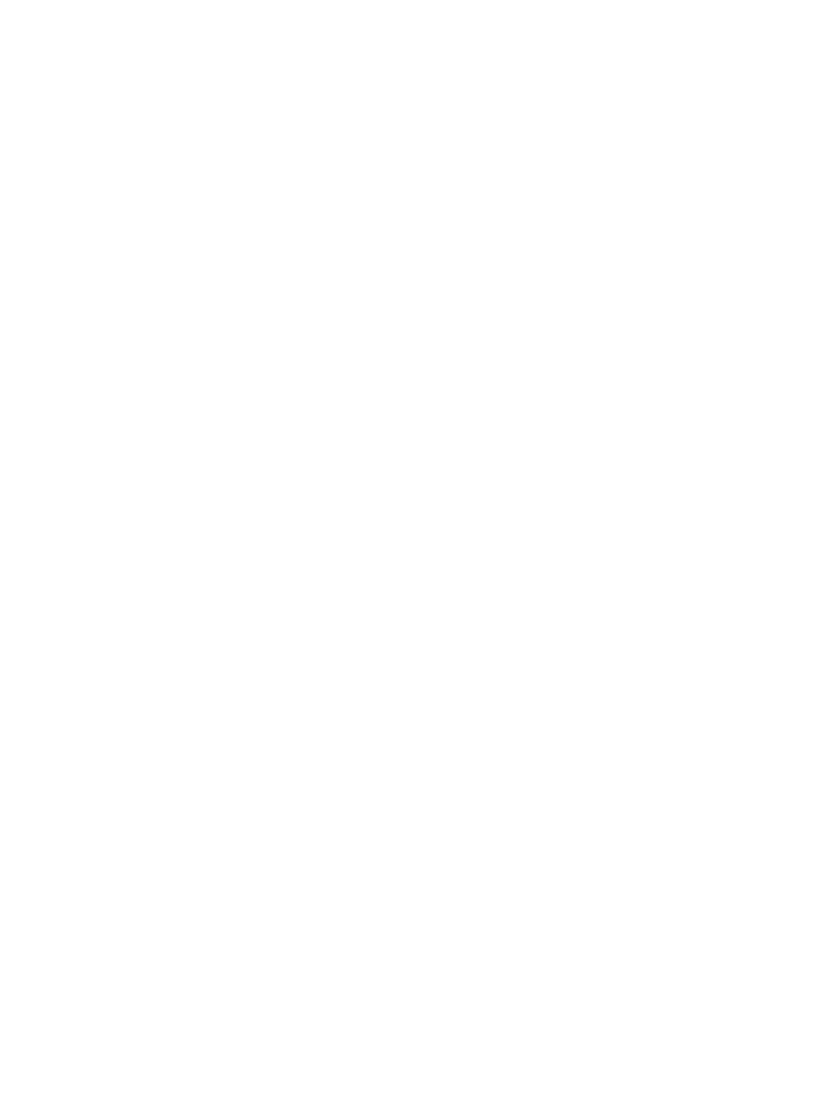

The resistivity of the single pressure UID-GaN

films is observed to decrease with increasing

growth pressure, varying over more than eight

orders of magnitude as illustrated in

. The

films in this series grown at pressures

p130 Torr

reached the experimental limit of measurable

resistance. The resistivity of films grown at

pressures >130 Torr decreases monotonically with

pressure, indicating an exponential relationship.

The measured resistivities of the 130/300 and 500/

130 Torr films are plotted relative to the growth

pressure of the underlying portion of these films,

which presents the most reasonable fit to data for

the single-pressure films. The significance of this

correlation will be discussed below. The difference

in light and dark resistivity measurements is

observed to become much more pronounced in

the films grown at higher pressures. The difference

in light and dark measured resistivity has been

associated with trapping states that are detrimen-

tal

to

device

performance

for

AlGaN/GaN

HEMTs. The discussion of this phenomenon is

beyond the scope of the current work, but is the

subject of ongoing investigation

4. Discussion

Carbon has been demonstrated to act as an

acceptor-type electron trapping center in GaN

, and substitutional oxygen impurities have

been predicted to act as donors

. Carbon and

oxygen are considered to be the primary back-

ground impurity acceptor and donor, respectively,

in the films in this study because of the low

concentrations of silicon donors and the absence

of zinc and magnesium acceptors in the growth

chamber. TDs have also been associated with

charge centers in GaN films, and must be

considered in the discussion of compensation

mechanisms governing the resistivity of UID

GaN films. Elsner and co-workers have modeled

both the open-core screw TD and the edge TD as

electrically inactive

, but predicted that the

stress fields surrounding the edge-type TD could

trap gallium vacancies, oxygen, and V

Ga

–O com-

plexes. These authors further suggest that the

Ga-vacancy and oxygen-related complexes act as

deep acceptors, with energy levels in the range of

0.3–0.8 eV above the valence band maximum

.

ARTICLE IN PRESS

10

0

10

2

10

4

10

6

10

8

10

resistivity (ohm-cm)

10

0

100

200

300

400

500

600

growth pressure (torr)

500/130 torr GaN

130/300 torr GaN

~1.5 µm GaN @ 300 torr

sapphire

~0.5 µm GaN @ 130

t

~2.0 µm GaN @ 130

sapphire

~0.5 µm GaN @ 500

t

Fig. 4. Resistivity of UID-GaN films as a function of epitaxial

growth pressure measured in the dark (closed symbols) and in

ambient room light (open symbols). The values were derived

from I=V characterization using indium stripe contacts on

squares patterned in the GaN films (see text). The experimental

limit of the resistivity analysis is reached at a level of 10

10

O-cm.

Data for the two-pressure films is again plotted relative to the

pressure of the underlying film. Inserts for the two-pressure

films illustrate the respective film structures.

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

58

Northrup has predicted the formation of Ga-filled-

core screw TDs under Ga-rich conditions, having

energy levels throughout the band gap and thus

being metallic, and predicted to serve as conduc-

tive pathways through the GaN film

. Recent

work by Krtschil and co-workers has suggested

decoration of TDs with impurities, contributing to

a charge on the dislocation core

.

Given substitutional incorporation of carbon

and oxygen on the GaN lattice, it may be

reasonable to assume that the reduction in the

C:O ratio observed with increasing growth pres-

sure (

) is related to reduced compensation in

the films in this study. In the case of the GaN film

grown at 40 Torr, impurity compensation and

scatter from crystalline disorder as evidenced by

high levels of both screw- and edge-type TDs

are also consistent with the measured high

resistivity. In separate multiple-pressure experi-

ments, we have observed carbon incorporation to

increase dramatically with decreasing growth

pressure for GaN films grown at pressures

o100 Torr, with carbon incorporation varying

over an order of magnitude in films where growth

rate varied by only 10%. In those experiments,

GaN films which were grown at very low pressures

(40–65 Torr) on films which had been grown at

higher pressures (130–300 Torr) exhibited sharp

distinctions in carbon impurity incorporation

corresponding to the interfaces between the GaN

films grown at the different pressures

. In the

present study, the two-pressure films were grown

using pressures >100 Torr, and no such distinc-

tions were observed in the SIMS data for either

sample. It is significant that the concentrations of

carbon and oxygen observed in

for the 130/

300 and 500/130 Torr films correspond to impurity

concentrations expected for the initial segment of

the GaN film growth (i.e., 130 and 500 Torr,

respectively) throughout the depth of the films,

rather than reflecting the levels for the respective

growth pressures of the single-pressure films. It is

also significant that the measured resistivity of the

two-pressure films corresponds to that of the

initial GaN growth that establishes the micro-

structure of the full film, rather than to that of the

film where the lower carbon level was anticipated

from the single-pressure film data. This unantici-

pated result demonstrates that compensation

effects are not related simply to a uniform

distribution of impurities in the bulk thin film as

a function of specific growth conditions, but that

under certain growth conditions may actually be

dominated by impurities that segregate on or near

TDs. The concentrations of TDs with an edge

component and carbon and oxygen impurities are

all observed to decrease as a function of increasing

growth pressure in this study. The carbon con-

centration varies exponentially with pressure for

growth pressures >100 Torr, and is higher than

expected from extrapolation of the plot in

for pressures

o100 Torr. This result is consistent

with the mechanism of carbon removal as a

function of hydrogen pressure

being dominant

except for carbon incorporation at sites near

dislocations with an edge component. The results

observed for the two-pressure films indicate that

for GaN films grown at MOCVD pressures

>100 Torr, the incorporation of C and O impu-

rities is dominated by the microstructure of the

GaN rather than by other kinetic growth mechan-

isms. A reduction of acceptor-type centers by

control of microstructure would be expected to

yield reduced compensation and thus decreasing

resistivity, consistent with the observed data of

. Our data would suggest that carbon

segregates at or near edge-type TDs in UID

GaN, and acts as a compensating acceptor. Our

data further suggests that carbon may incorporate

both in the lattice and near TDs with an edge

component in the pressure regime

o100 Torr, but

incorporates primarily near TDs with an edge

component for growth pressure >100 Torr.

The possibility of screw-type TDs having Ga-

filled cores as proposed by Northrup

, or

otherwise acting as sources of leakage current

must also be analyzed as a source of charge

reducing the resistivity of the UID GaN films. This

mechanism does not appear to be dominant in the

present study. The resistivity of the single-pressure

GaN films is observed to decrease dramatically

with increasing growth pressure, with almost no

variation in screw-type TD density over the range

of growth pressure investigated. Northrup’s model

suggests a crossover in the growth process where

Ga-filled-core screw-type TDs are energetically

ARTICLE IN PRESS

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

59

favored over open-core screw-type TDs as the

growth conditions become more Ga-rich. The

possibility of a change in character of the screw-

type TDs from open-core to Ga-filled core as

growth conditions are modified to yield a more

Ga-rich growth condition must be considered. In

earlier work

, we have demonstrated that for

pressures >100 Torr,

GaN decomposition

is

enhanced with increasing pressure, with nitrogen

removed from the GaN surface as NH

3

and

atomic or liquid Ga left behind. In both of the

two-pressure films in the present study, however,

the measured properties of the GaN films appear

to be related to the microstructure of the under-

lying GaN film, even though the local growth

environment of the film in direct contact with the

electrical probes had changed significantly. These

results are consistent with our analysis that the

TDs with an edge component, rather than

conductive screw dislocations, are the dominant

structural feature responsible for the resistivity

variation seen in the films.

Several groups have reported the presence of a

buried conductive layer (BCL) near the sapphire

substrate interface

. In all cases, the GaN

films under investigation were n-type conductive,

rather than resistive as are the films of the present

study. C=V analysis of the films in this study

observed evidence of a BCL in the film grown at

500 Torr, with an indicated electron concentration

of approximately 1 10

16

cm

3

at the interface,

which was determined to be near the detection

limit of the C=V analysis

and is close to the

UID concentration of oxygen in the film. No

evidence of BCL was observed in the 500/130 Torr

film or any of the other films grown at lower

pressures. The reduced data of

is the value

of the flat region of each SIMS profile, in the bulk

of the GaN thin film. A variation in the character

of the oxygen profiles near the sapphire substrate

interface is observed as a function of GaN growth

pressure, as illustrated in

. In lower pressure

growths (65 and 130 Torr), the oxygen concentra-

tion profile is flat with a sharp increase at the

substrate interface, but an oxygen shoulder is seen

in the data for the films where growth is initiated

at higher pressures (300 and 500 Torr). Under

higher pressure growth conditions, the GaN

growth rate is reduced and the coalescence time

is increased, possibly enhancing oxygen diffusion

from the sapphire substrate into the GaN film

until the film is fully coalesced. Upon coalescence

of the GaN film, however, an oxygen level due to

background impurities within the reaction cham-

ber is reached, which is the level plotted in

.

Oxygen impurities may be one of several sources

of interfacial conduction, but the presence of an

oxygen shoulder in the 300 Torr film, with no

observation of a BCL in the C=V analysis,

suggests that it may not be a dominant source of

conduction.

If a BCL is present, the resistance of the films

can be modeled with a simple parallel resistance

model, with the measured resistance, RðtotalÞ; is

given by

RðtotalÞ ¼ ½1=R

GaN; lateral

þ½1=ð2R

GaN; vertical

þ R

BCL

Þ

1

where R

GaN;lateral

is the resistance between the

indium contacts, R

GaN;vertical

is the resistance

through the GaN film between the indium contact

and the BCL, and R

BCL

is the resistance of the

ARTICLE IN PRESS

10

16

10

17

10

18

10

19

atomic concentration (cm

-3

)

1.0

0.80

1.2

1.4

1.6

1.8

2.0

O(65)

O( 130)

O( 300)

O(500 /1 30)

depth (micrometers)

Fig. 5. SIMS depth profiles of oxygen for four films in this

study, grown at pressures of 65 Torr (open circles), 130 Torr

(closed circles), 300 Torr (squares), and 500/130 Torr (dia-

monds). Note that the films grown at pressures of 130 Torr or

less show a sharp change in oxygen content at the GaN/

sapphire interface. In contrast, the films where growth was

initiated at 300 or 500 Torr exhibit an oxygen shoulder at the

interface, resulting in a nominally 200 nm thick layer with an

oxygen level between 2 10

16

and 8 10

17

cm

3

.

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

60

BCL. If we assume from the data of

a BCL

thickness of 2000 (

A, m

BCL

¼ 100 cm

2

/Vs, and an

electron concentration of 1.5 10

17

cm

3

, we

derive a reasonable value for r

BCL

¼ 0:42 O-cm.

If a constant BCL resistance is assumed to be

present for all the layers, the experimental results

of

can be fit only by allowing the resistivity

of the GaN film to vary from >10

10

O-cm at low

pressures to 10

3

O-cm at 500 Torr, still indicating a

broad range in compensation of the GaN films. If

oxygen impurities are indeed contributing to

interfacial conduction, a BCL should be present

only in the films grown at pressures >130 Torr in

this study. The observation of a BCL only in the

500 Torr film, with no BCL observed in the 500/

130 Torr film is significant. It suggests that the

BCL, if present, may not contribute significantly

to film conduction.

5. Conclusions

In this paper, we demonstrate that the resistivity

of UID GaN films may be controlled over more

than eight orders of magnitude by varying the

MOCVD growth pressure of the GaN film in a H

2

ambient. We show that with increasing growth

pressure, the GaN films exhibit increasing grain

size, decreasing density of TDs with an edge

component, decreasing carbon and oxygen con-

tent, and decreasing resistivity. The contribution

of a BCL to the measured total resistance is

analyzed and found to be too small to account for

the experimentally observed variations in resistiv-

ity. Our data demonstrates that TDs with an edge

component play a major role in the compensation

mechanisms of GaN, with carbon impurity segre-

gation at or near TDs with an edge component

resulting in compensating acceptor states. Carbon

acceptors are shown to incorporate both in the

lattice and near TDs with an edge component in

the pressure regime

o100 Torr, but incorporate

primarily near TDs with an edge component for

growth pressure >100 Torr. Substitutionally in-

corporated donors in the GaN lattice may

dominate carbon acceptors segregating at TDs

with an edge component as the concentration

of these TDs decreases, resulting in increased

conductivity consistent with the observed experi-

mental results.

Acknowledgements

The authors would like to thank L.T. Ardis for

expert TEM sample preparation and S.C. Binari

for C=V and I =V measurements. This work was

supported by the Office of Naval Research.

References

[1] R.N. Thomas, S. McGuigan, G.W. Eldridge, D.L. Barrett,

Proc. IEEE 76 (1988) 778.

[2] G. Beadie, W.S. Rabinovich, A.E. Wickenden, D.D.

Koleske, S.C. Binari, J.A. Freitas Jr., Appl. Phys. Lett.

71 (1997) 1092.

[3] S.C. Binari, K. Ikossi, J.A. Roussos, W. Kruppa, D. Park,

H.B. Dietrich, D.D. Koleske, A.E. Wickenden, R.L.

Henry, IEEE Trans. Electron. Dev. 48 (2001) 465.

[4] P.B. Klein, S.C. Binari, J.A. Freitas Jr., A.E. Wickenden,

J. Appl. Phys. 88 (2000) 2843.

[5] Z.C. Huang, J.C. Chen, D.K. Wickenden, J. Crystal

Growth 170 (1997) 362.

[6] K. Hiramatsu, S. Itoh, H. Amano, I. Akasaki, N. Kuwano,

T. Shiraishi, K. Oki, J. Crystal Growth 115 (1991) 628.

[7] I. Akasaki, H. Amano, Y. Koide, K. Hiramatsu, H.

Sawaki, J. Crystal Growth 98 (1989) 209.

[8] D.D. Koleske, A.E. Wickenden, R.L. Henry, M.E. Twigg,

J. Crystal Growth 242 (2002) 55.

[9] K. Saarinen, P. Seppala, J. Oila, P. Hautojarvi, C. Corbel,

Appl. Phys. Lett. 73 (1998) 3253.

[10] M.E. Twigg, D.D. Koleske, A.E. Wickenden, R.L. Henry,

M. Fatemi, J.C. Culbertson, Structural defects in nitride

heteroepitaxy, in: O. Manasreh (Ed.), III–V Nitride

Semiconductors: Electrical, Structural and Defect Proper-

ties, Gordon and Breach, London, 2000 (Chapter 15).

[11] D.D. Koleske, R.L. Henry, M.E. Twigg, J.C. Culbertson,

S.C. Binari, A.E. Wickenden, M. Fatemi, Appl. Phys. Lett.

80 (2002) 4372.

[12] A.E. Wickenden, D.D. Koleske, R.L. Henry, R.J. Gor-

man, M.E. Twigg, M. Fatemi, J.A. Freitas Jr., W.J.

Moore, J. Electron. Mater. 29 (2000) 21.

[13] D.D. Koleske, A.E. Wickenden, R.L. Henry, M.E. Twigg,

J.C. Culbertson, R.J. Gorman, Appl. Phys. Lett. 73 (1998)

2018;

D.D. Koleske, A.E. Wickenden, R.L. Henry, M.E. Twigg,

J.C. Culbertson, R.J. Gorman, Appl. Phys. Lett. 75 (1999)

1646.

[14] D.D. Koleske, A.E. Wickenden, R.L. Henry, J.C. Cul-

bertson, M.E. Twigg, J. Crystal Growth 223 (2001) 466.

[15] J.R. Creighton, W.G. Breiland, M.E. Coltrin, R.P.

Pawlowski, Appl. Phys. Lett. 81 (2002) 2626.

[16] SIMS analysis performed by Charles Evans West, Inc.

ARTICLE IN PRESS

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

61

[17] B. Heying, X.H. Wu, S. Keller, Y. Li, D. Kapolnek, B.P.

Keller, S.P. Denbaars, J.S. Speck, Appl. Phys. Lett. 68

(1996) 643.

[18] X.H. Wu, P. Fini, E.J. Tarsa, B. Heying, S. Keller, U.K.

Mishra, S.P. DenBaars, J.S. Speck, J. Crystal Growth 189/

90 (1998) 231.

[19] P.B. Klein, S.C. Binari, K. Ikossi, A.E. Wickenden, D.D.

Koleske, R.L. Henry, Electron. Lett. 37 (2001) 1550.

[20] H. Tang, J.B. Webb, J.A. Bardwell, S. Raymond, J.

Salzman, C. Uzan-Saguy, Appl. Phys. Lett. 78 (2001) 757.

[21] C.G. Van de Walle, J. Neugebauer, Mater. Sci. Forum 19

(1997) 258.

[22] J. Elsner, R. Jones, P.K. Sitch, V.D. Porezag, M. Elstner,

Th. Frauenheim, M.I. Heggie, S. .

Oberg, P.R. Briddon,

Phys. Rev. Lett. 79 (1997) 3672.

[23] J. Elsner, R. Jones, M.I. Heggie, P.K. Sitch, M. Haugk,

Th. Frauenheim, S. .

Oberg, P.R. Briddon, Phys. Rev. B 58

(1998) 12571.

[24] J.E. Northrup, Appl. Phys. Lett. 78 (2001) 2288.

[25] A. Krtschil, A. Dadgar, A. Krost, Appl. Phys. Lett. 82 (14)

(2003) 2263.

[26] N.G. Wiemann, L.F. Eastman, D. Doppalapudi, H.M.

Ng, T.D. Moustakas, J. Appl. Phys. 83 (1998) 3656.

[27] D.C. Look, J.R. Sizelove, Phys. Rev. Lett. 82 (1999) 1237

(and references therein).

[28] B.J. Ansell, L. Harrison, C.T. Foxon, J.J. Harris, T.S.

Cheng, Electron. Lett. 36 (2000) 1237.

[29] X.L. Xu, C.D. Beling, S. Fung, Y.W. Zhao, N.F. Sun,

T.N. Sun, Q.L. Zhang, H.H. Zhan, B.Q. Sun, J.N. Wang,

W.K. Ge, P.C. Wong, Appl. Phys. Lett. 76 (2000) 152.

[30] J.W.P. Hsu, D.V. Lang, S. Richter, R.N. Kleiman, A.M.

Sergent, R.J. Molnar, Appl. Phys. Lett. 77 (2000)

2873.

[31] M.G. Cheong, K.S. Kim, C.S. Oh, N.W. Namgung, G.M.

Yang, C.-H. Hong, K.Y. Lim, E.-K. Suh, K.S. Nahm, H.J.

Lee, D.H. Lim, A. Yoshikawa, Appl. Phys. Lett. 77 (2000)

2557.

[32] S.C. Binari, private communication.

ARTICLE IN PRESS

A.E. Wickenden et al. / Journal of Crystal Growth 260 (2004) 54–62

62

Document Outline

Wyszukiwarka

Podobne podstrony:

PHP Co nowego w PHP 5 (cz 3) 11 2004

1466205 2100SRM0735 (11 2004) UK EN

ogrody, Referat z antropologii-ogolny opis ogrodnictwa-25[1].11.2004, Referat z antropologii - 25

HTML hiperłącza 11 2004

11 2004 jak to dzialaid 12737 Nieznany (2)

1554636 8000SRM1080 (11 2004) UK EN

43 ROZ aprobaty techniczne [M I ] [8 11 2004][Dz U 2014

homework for 10 11 2004

W 12.11.2004. MNI, Studia, Pedagogika

MT 11 2004 Citroen Bucefał

W 05.11.2004 MNI, Studia, Pedagogika

1510469 2100SRM0986 (11 2004) UK EN

Bydgoszcz 11 5 2004 (1)

9 11 2004

argonauci zachodniego pacyfiku, antropologia referat-metoda badan-4[1].11.2004, REFERAT NA ĆWICZENIA

PHP Co nowego w PHP 5 (cz 3) 11 2004

Elementarz09 MI 11 2004

więcej podobnych podstron