PROJECT PLAN - WALKING STICKS

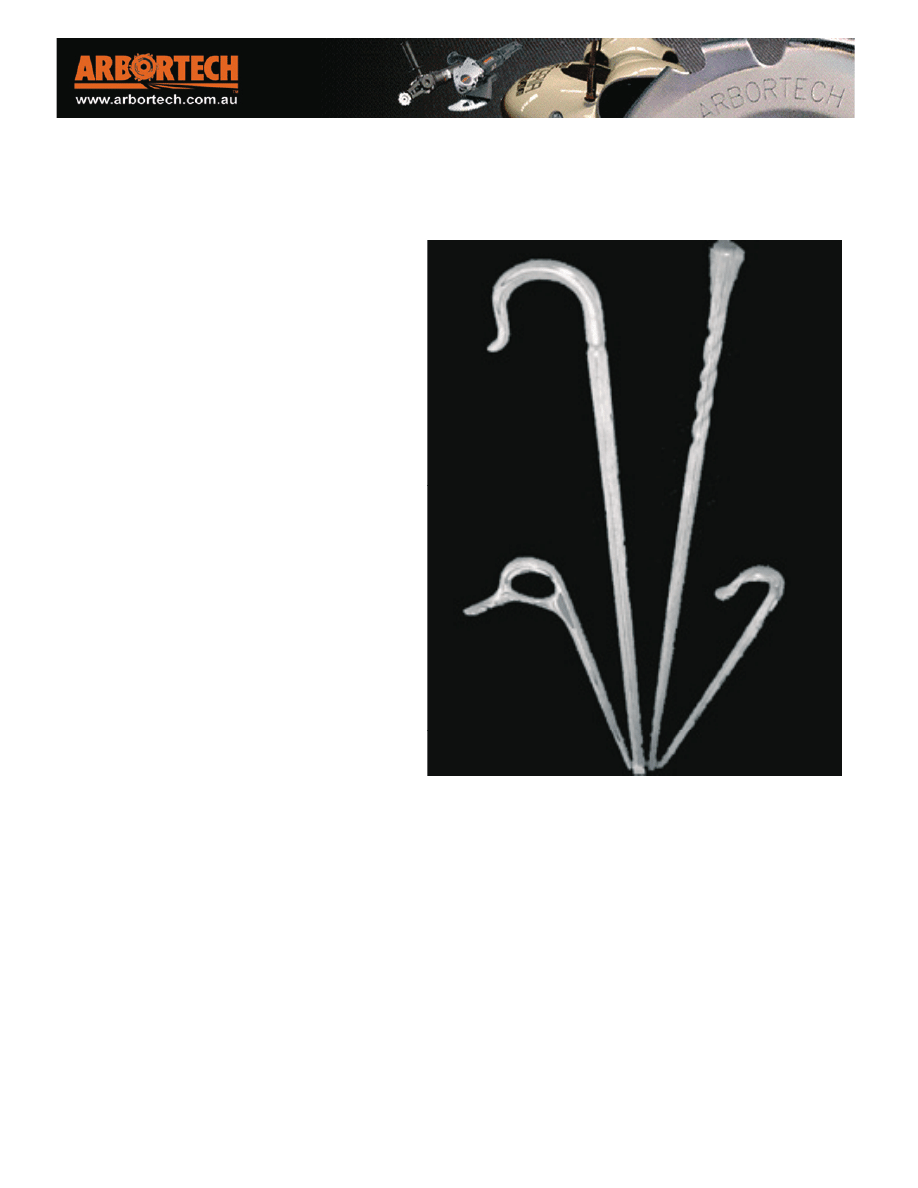

A relatively easy plan for the

beginner woodworker, these

walking sticks make wonderful

gifts. The designs shown are

simply ideas to get you started.

Your design can be as simple

or as intricate as your skills and

confi dence allow!

Arbortech tools needed :-

One or more of the following:-

+ Woodcarver Pro Kit

+ Industrial Pro Kit

+ Pro 3 Freestyle Kit

+ Pro Guard Mini Grinder

What else will I need?

ANGLE GRINDER: Suitable 4 inch (100mm) or 4-1/2 inch (115mm) angle grinder

WOOD: 2 pieces of ply wood 19 X 400 X 1000mm for sticks or 19 x 400 x 2000mm for staffs.

GLUE: White P.V.A. is adequate.

2-4 F CLAMPS

SAND PAPER FOR FINISHING (or Arbortech Grinder Sanding Pad)

FINISH: Options include using ArborWax or ArborOil, or a wax polish or brush applied varnish by

choice.

SAFETY: Safety glasses, ear plugs, dust mask & close fi tting clothes.

Copyright - Arbortech Industries Ltd - 2000

Page 1

METHOD

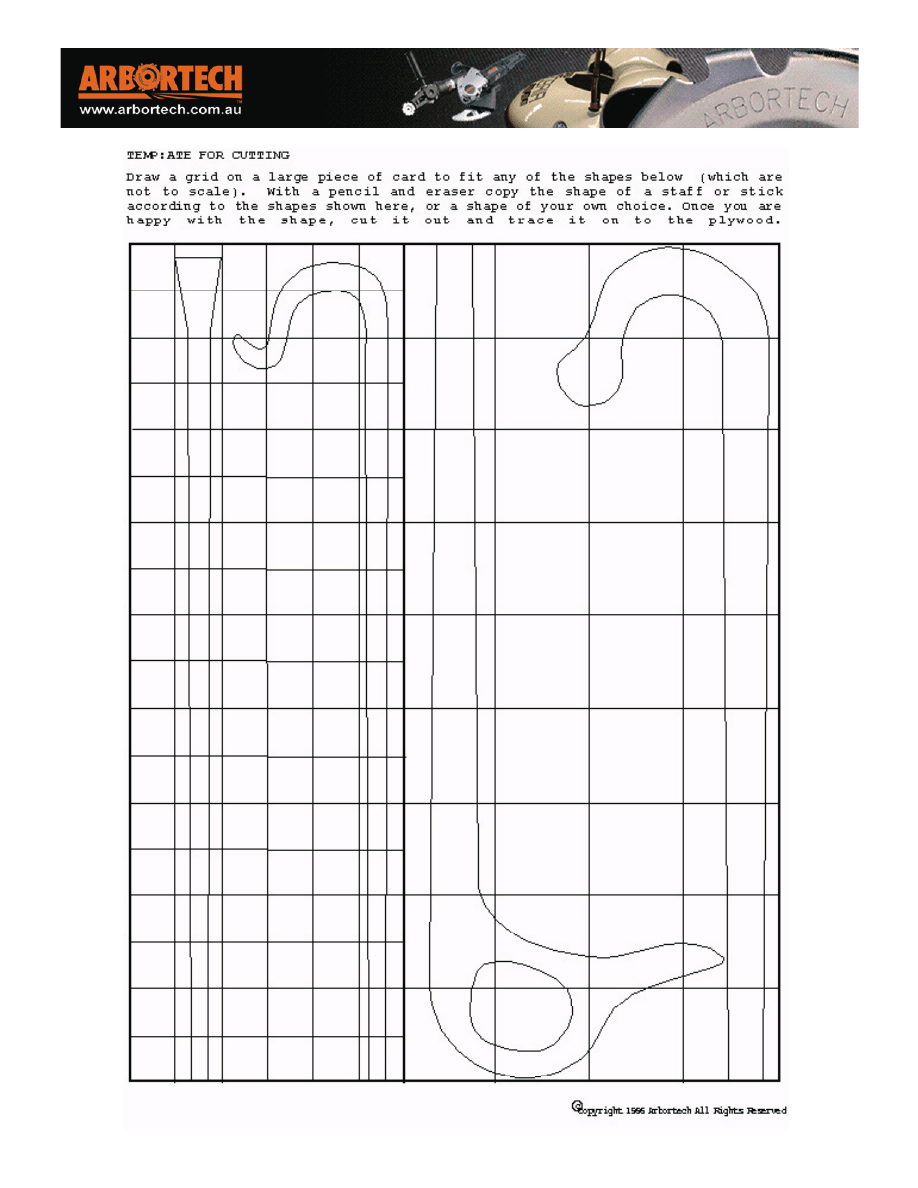

On the next page are scaled instructions to create a card template of various walking sticks and

staffs. All of which can be made as shown below. cut it out and trace it on the wood to create an

identical walking stick or staff shape. NB: To skip drawing a template you may draw a shape directly

onto the wood.

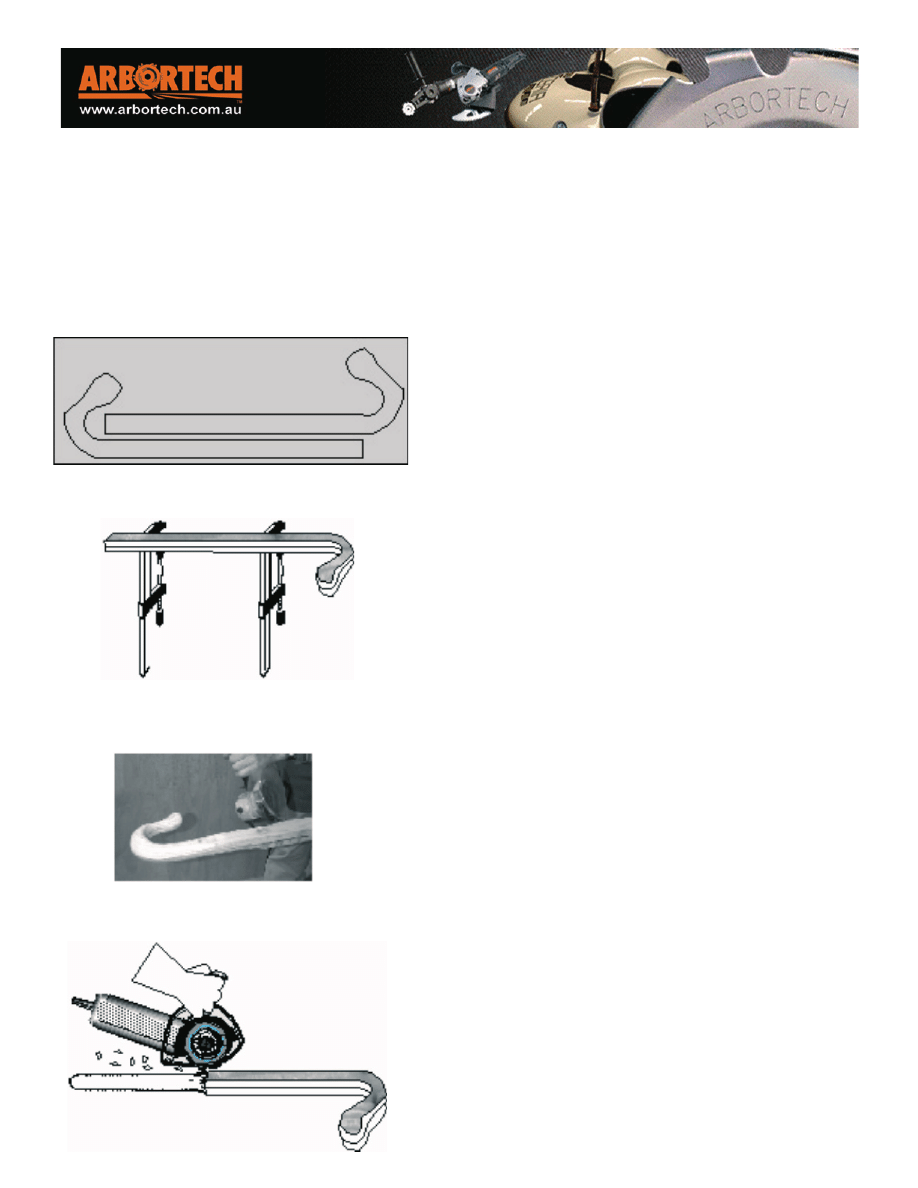

Figure 1

1. FIG 1 shows the lay up cutting plan a of basic

walking stick. The basic outline is traced from a

template. The shapes are cut out from the 19mm

plywood with a jig saw, to the near fi nished shape. NB.

Solid wood may be used but for strength any curves

must follow the natural grain.

Figure 2

2. Glue the two pieces of wood as shown in FIG 2 us-

ing the F clamps ie. 2 X 19mm = 38mm thick.

3. Once the glue has dried, then the squared edges

can be rounded using the Arbortech Woodcarver or

Industrial Woodcarver. FIG 3.

4. The Arbortech fl exible grinder sanding disk is used

towards the end of shaping and is used to cut away all

the tool marks and allow you to fi ne shape and adjust

the fi nal profi les. After 40 grit, use 80 grit and then

hand sand.

5. To obtain a good fi nish, fi rst seal the pores of the

wood with either a cellulose or oil sealing compound.

They are called grain sealers and obtainable from

woodworking suppliers. Apply a generous coat with a

rag. Allow this to dry and sand lightly with a fi ne sand

paper. Apply another sparing coat of sealer with a rag,

allow to dry. Apply polish or varnish fi nish.

FIGURE 1

FIGURE 2

FIGURE 3

Copyright - Arbortech Industries Ltd - 2000

Page 2

Copyright - Arbortech Industries Ltd - 2000

Page 3

Wyszukiwarka

Podobne podstrony:

Basic Fringe Tutorial

Basic Solid Edge v19 Tutorial

basic unix tutorial

[CMS, MAMBO] Basic Mambo4 5 Template Tutorial v2

3 ABAP 4 6 Basic Functions

Amadeus Basic Podręcznik szkoleniowy

bugzilla tutorial[1]

Basic Shed

freeRadius AD tutorial

BASIC MALTESE GRAMMAR AND DIC (G Falzon)

Alignmaster tutorial by PAV1007 Nieznany

free sap tutorial on goods reciept

ms excel tutorial 2013

Joomla Template Tutorial

basic model

Basic Radiation Physics

BASIC MILITARY REQUIREMENTS 24

ALGORYTM, Tutoriale, Programowanie

Basic Codes HTML

więcej podobnych podstron