SysVar 08.02.03 en

1 of 170

SOFTWARE

KR C...

System Variables

KUKA System Software (KSS)

Issued: 05 Jul 2005

Version: 03

2 of 170

SysVar 08.02.03 en

e

Copyright

KUKA Roboter GmbH

This documentation or excerpts therefrom may not be reproduced or disclosed to third parties without the express permission of the publishers.

Other functions not described in this documentation may be operable in the controller. The user has no claim to these functions, however, in

the case of a replacement or service work.

We have checked the content of this documentation for conformity with the hardware and software described. Nevertheless, discrepancies

cannot be precluded, for which reason we are not able to guarantee total conformity. The information in this documentation is checked on a

regular basis, however, and necessary corrections will be incorporated in subsequent editions.

Subject to technical alterations without an effect on the function.

3 of 170

SysVar 08.02.03 en

Contents

1

How to use this documentation

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

A

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

B

29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

C

34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

D

41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

E

53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

F

63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

G

66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

H

68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

I

70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

J

77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

K

78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

L

81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

M

85

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

N

92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

O

95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

P

100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

R

115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

S

124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

T

139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

U

158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

V

159

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

W

166

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

Z

170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Variables

4 of 170

SysVar 08.02.03 en

1

How to use this documentation

5 of 170

SysVar 08.02.03 en

1

How to use this documentation

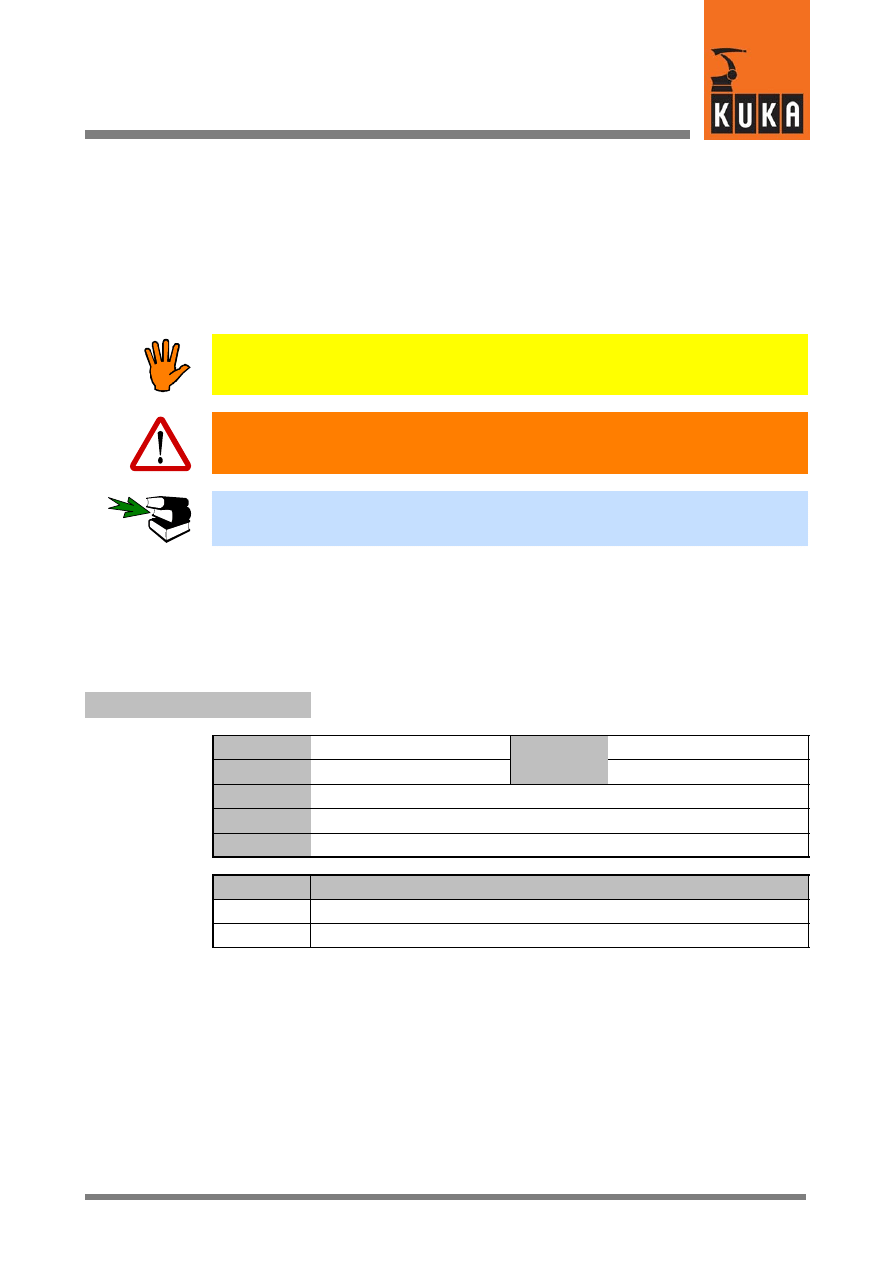

This tabular summary of the system variables is intended to serve as an aid for programmers

with good knowledge of the functions of the KUKA robot system and the KR C... controller,

and who are thoroughly familiar with programming.

Many variable values are preset by the manufacturer (default values) and should not be

changed without a compelling reason. If changes are nevertheless necessary, they can be

carried out using the variable modification function or by editing the files.

Change the values of variables only if you have sufficient knowledge of the func-

tions of the system variables and their effects!

The manufacturer accepts no liability and provides no warranty whatsoever

for damage of any kind arising from improper modification of variable

values or their modification for a purpose other than the intended one.

Please also observe the chapter [Safety] in the handbook.

Please note:

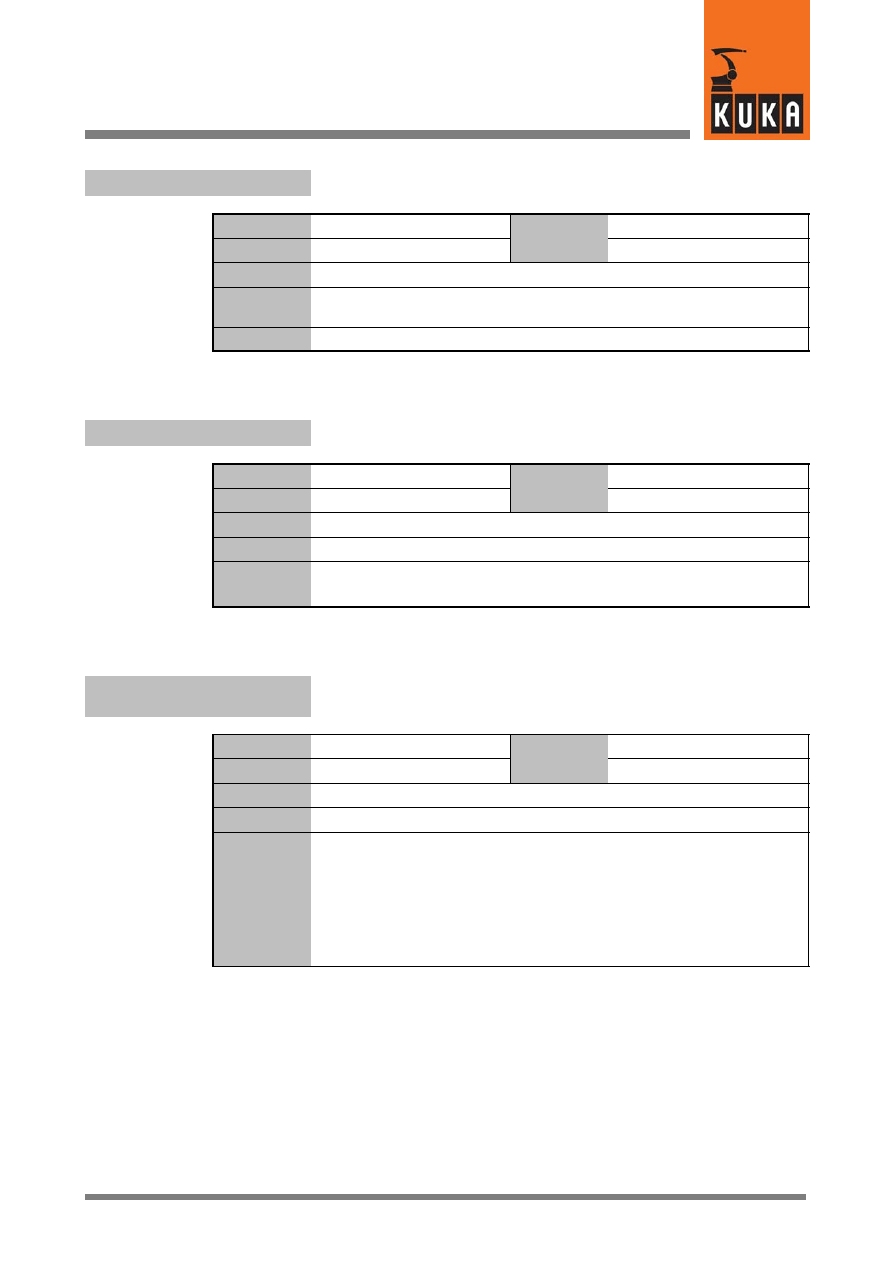

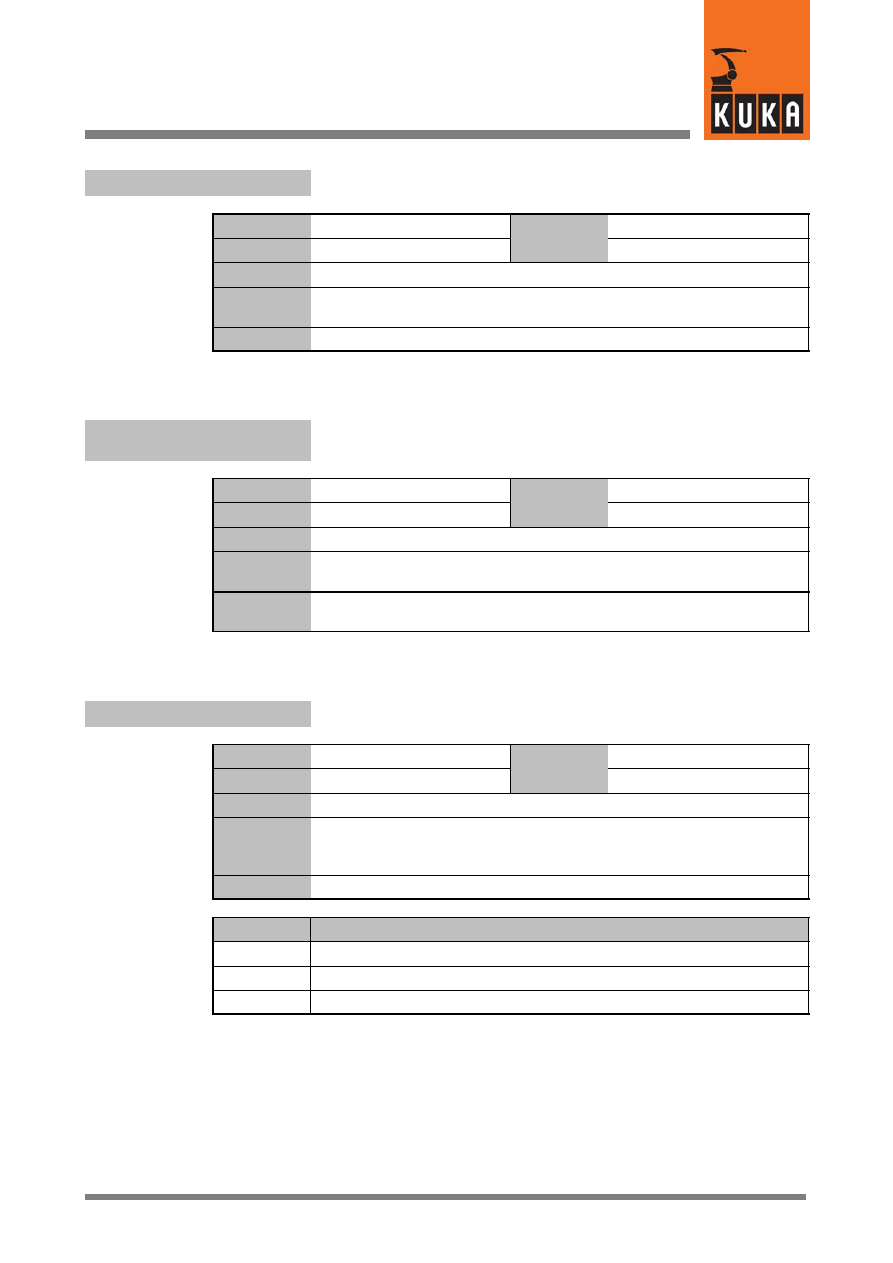

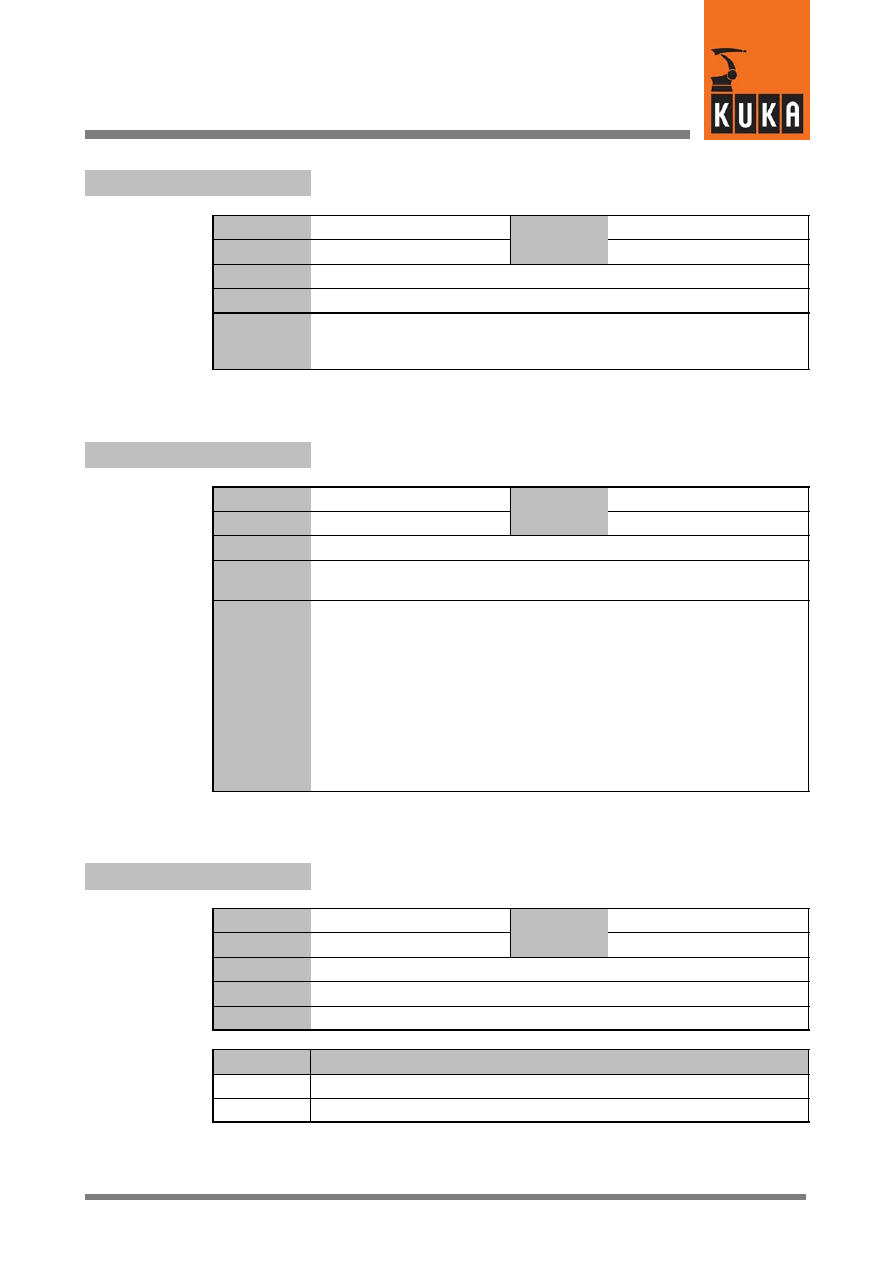

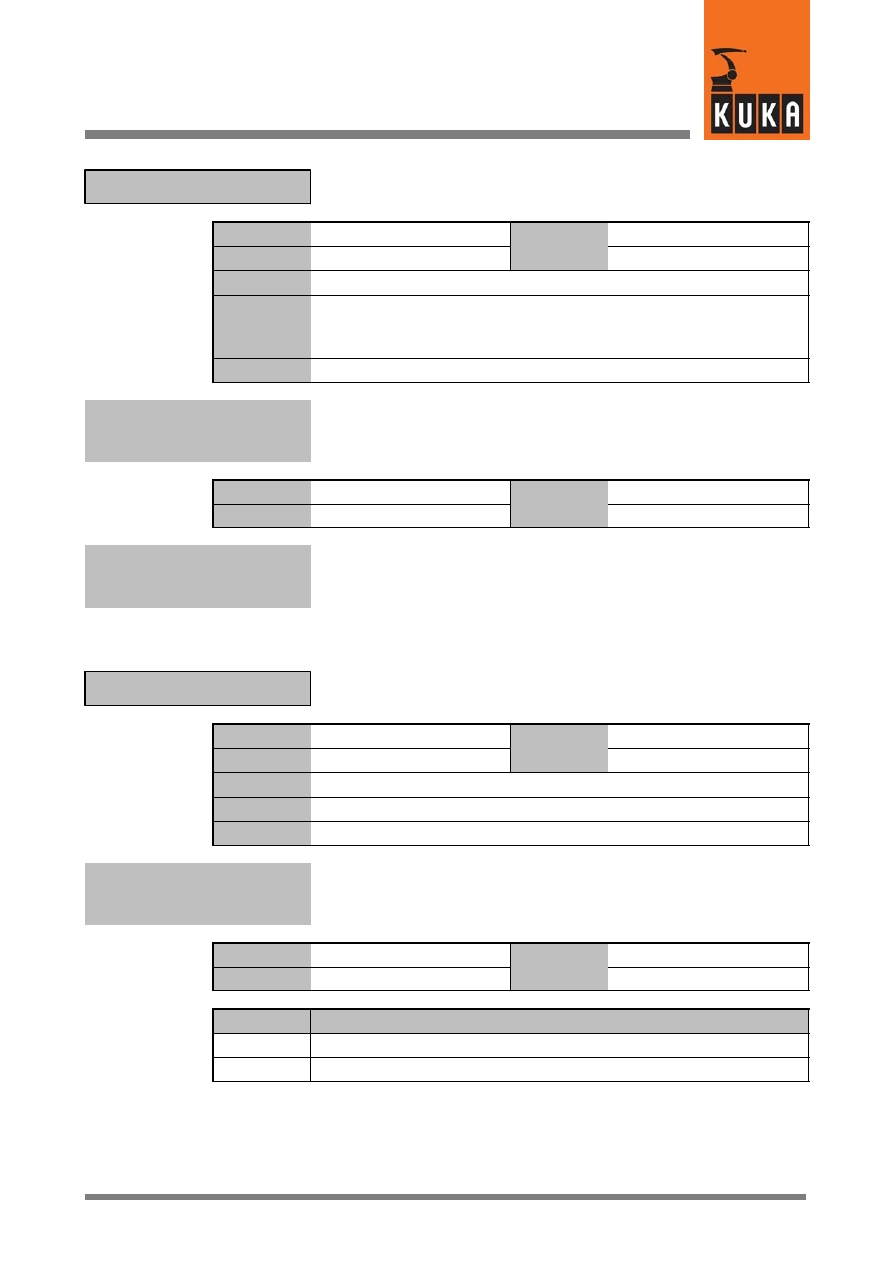

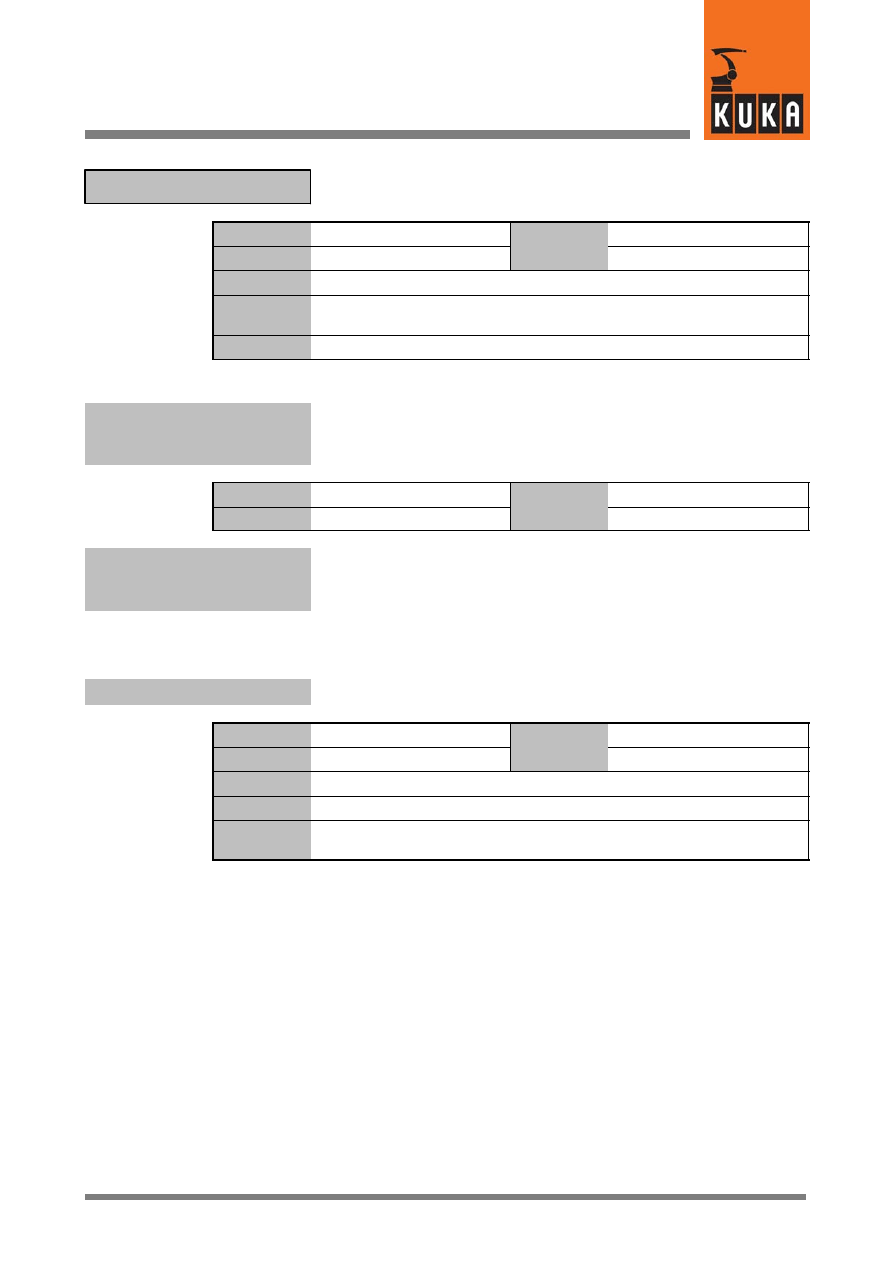

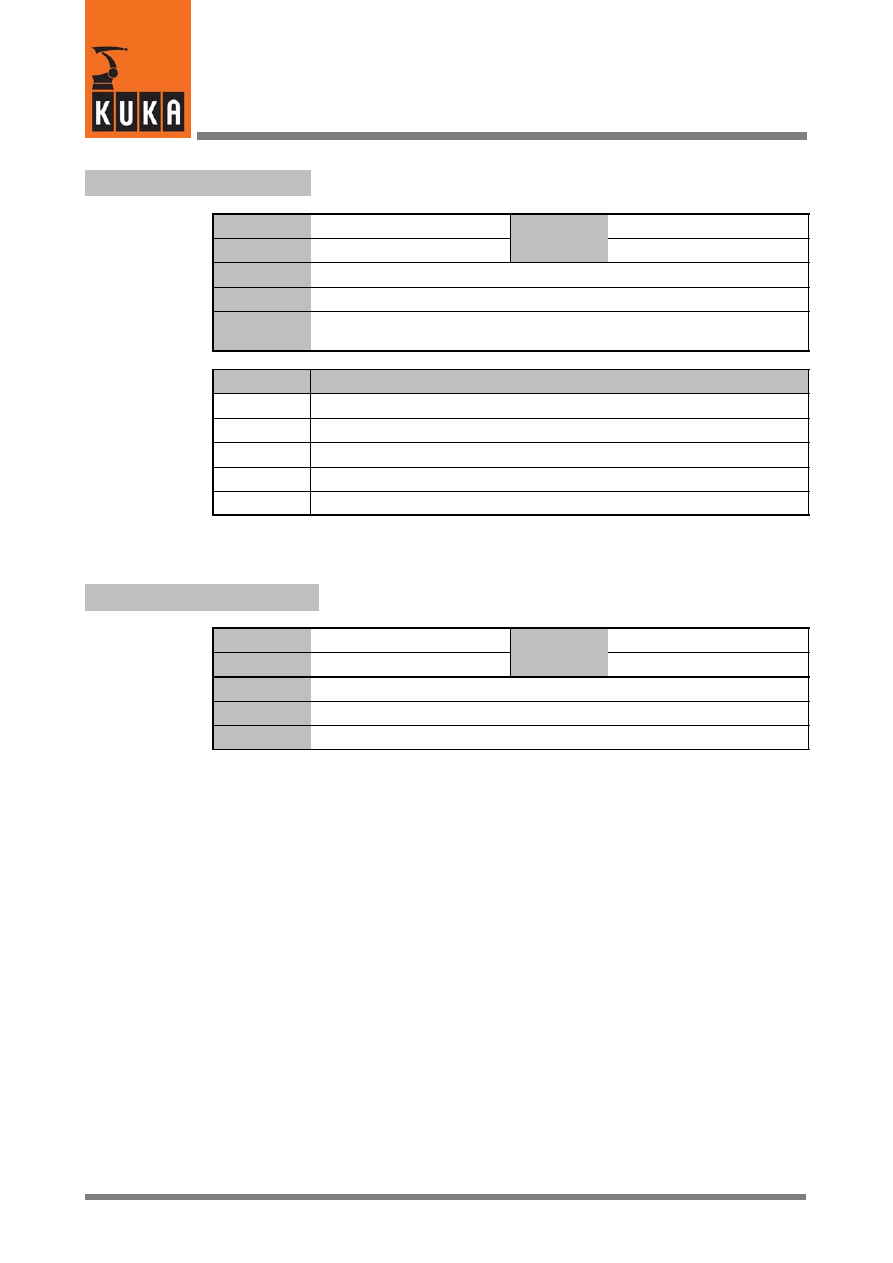

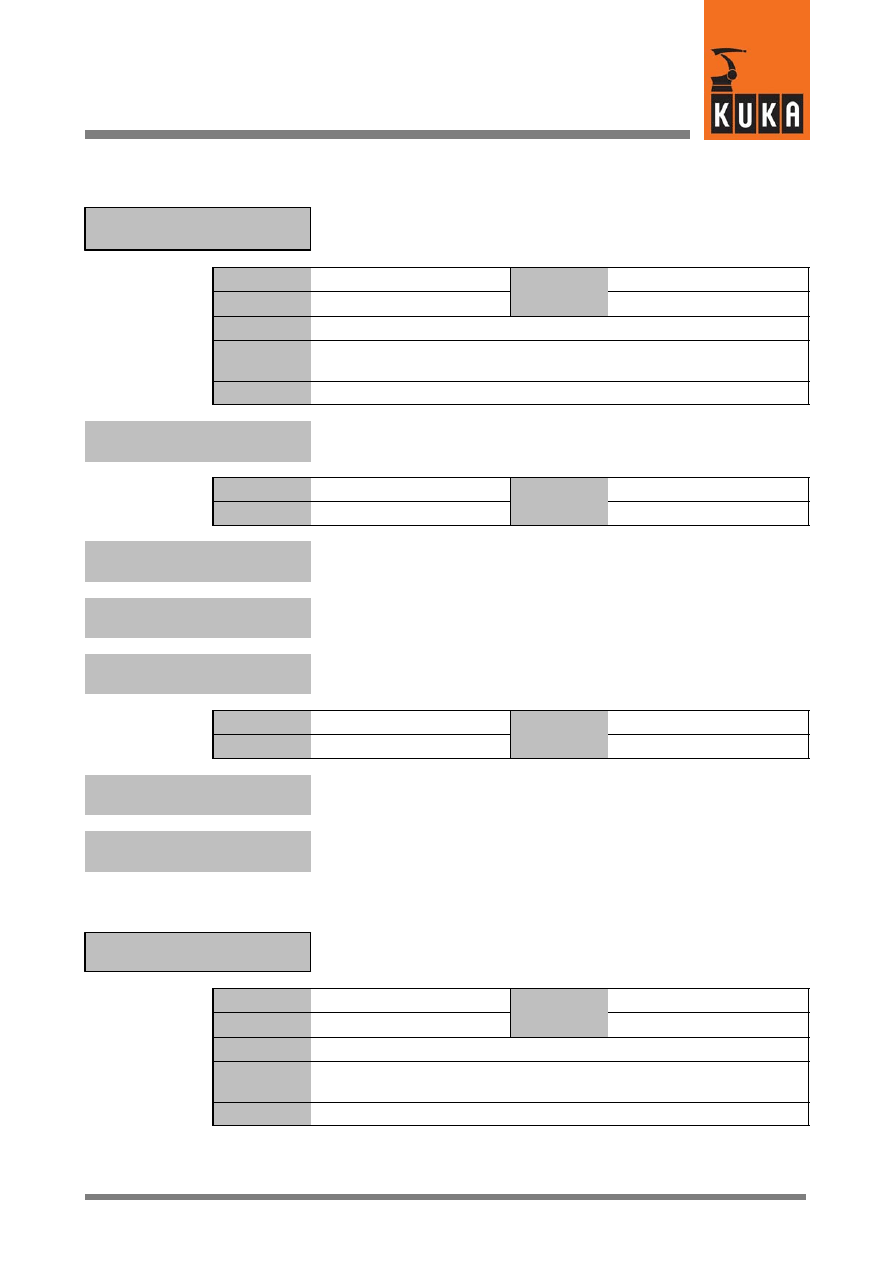

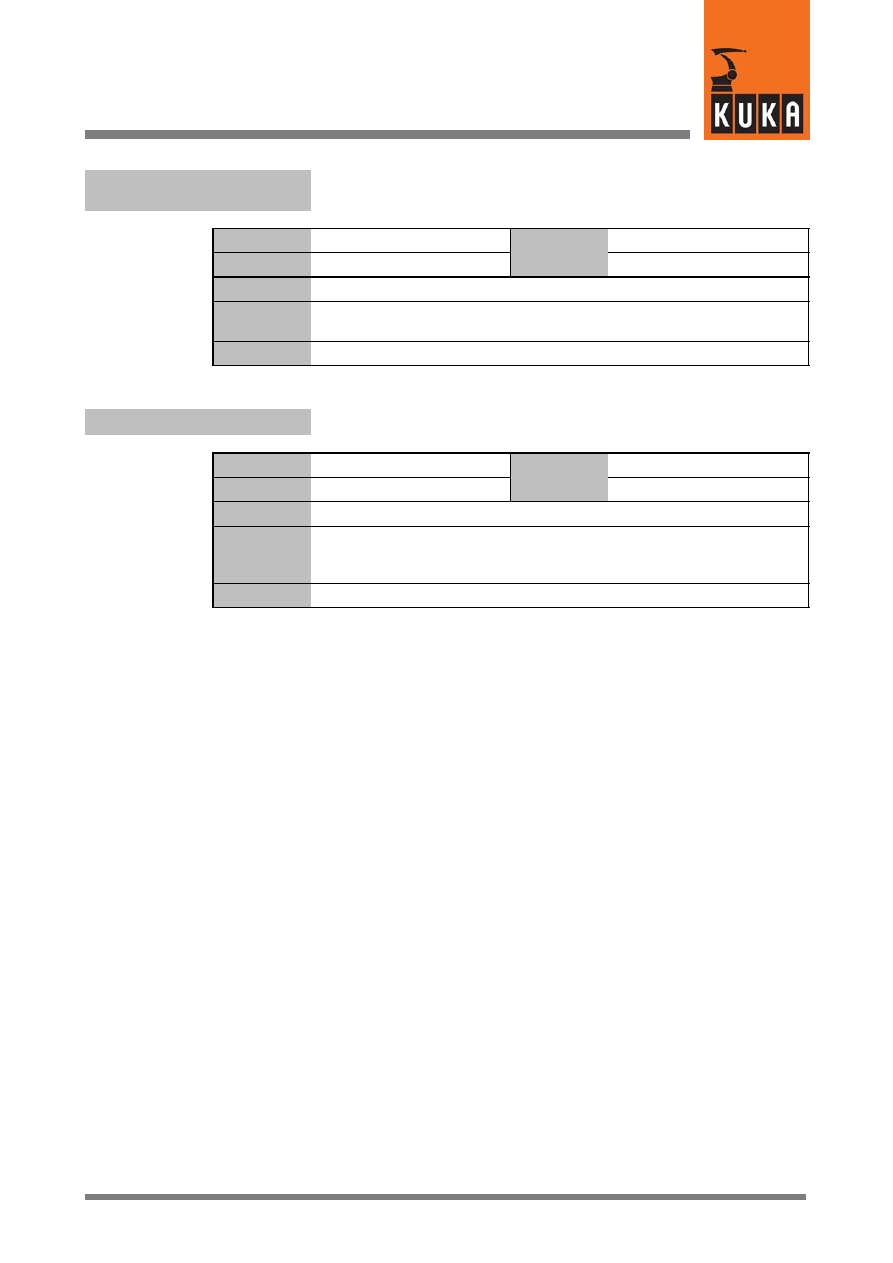

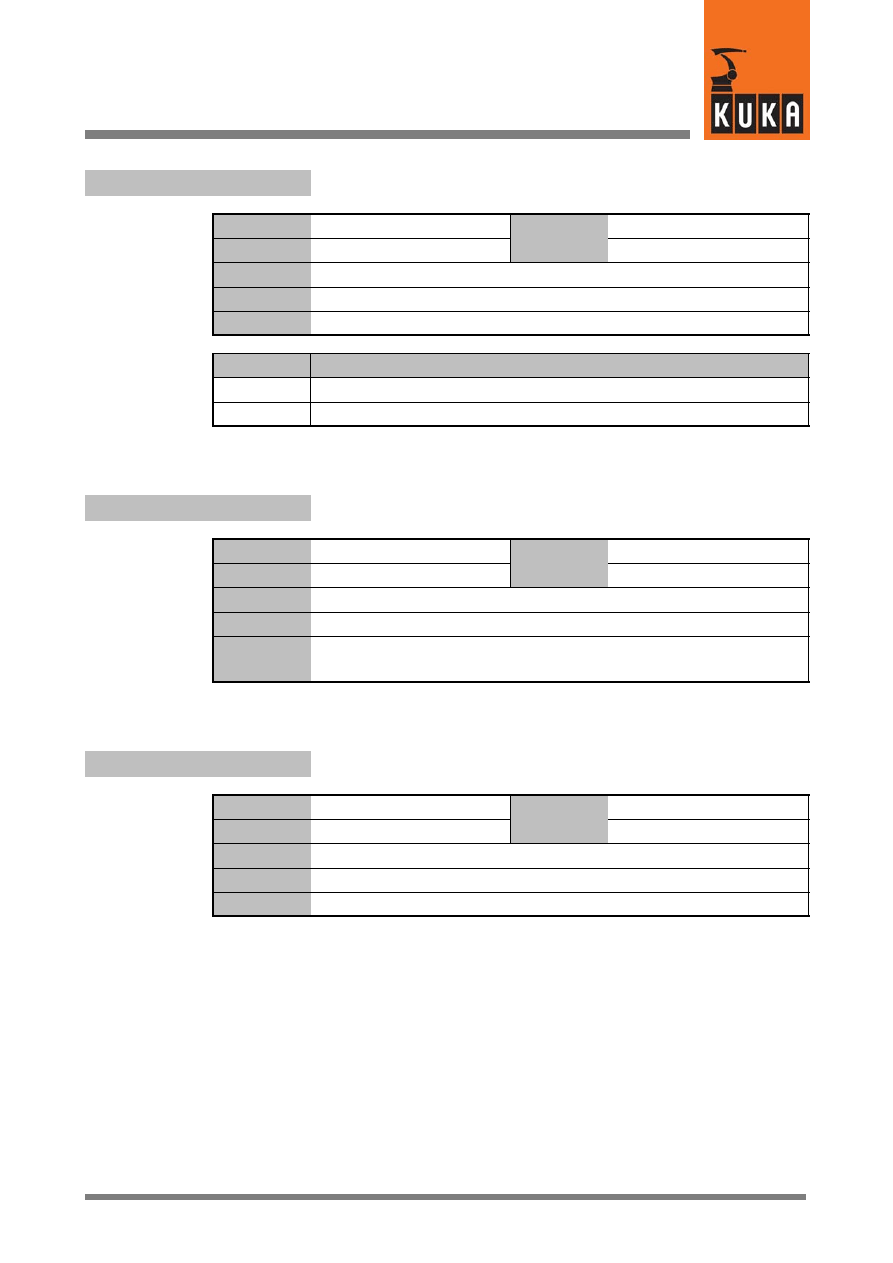

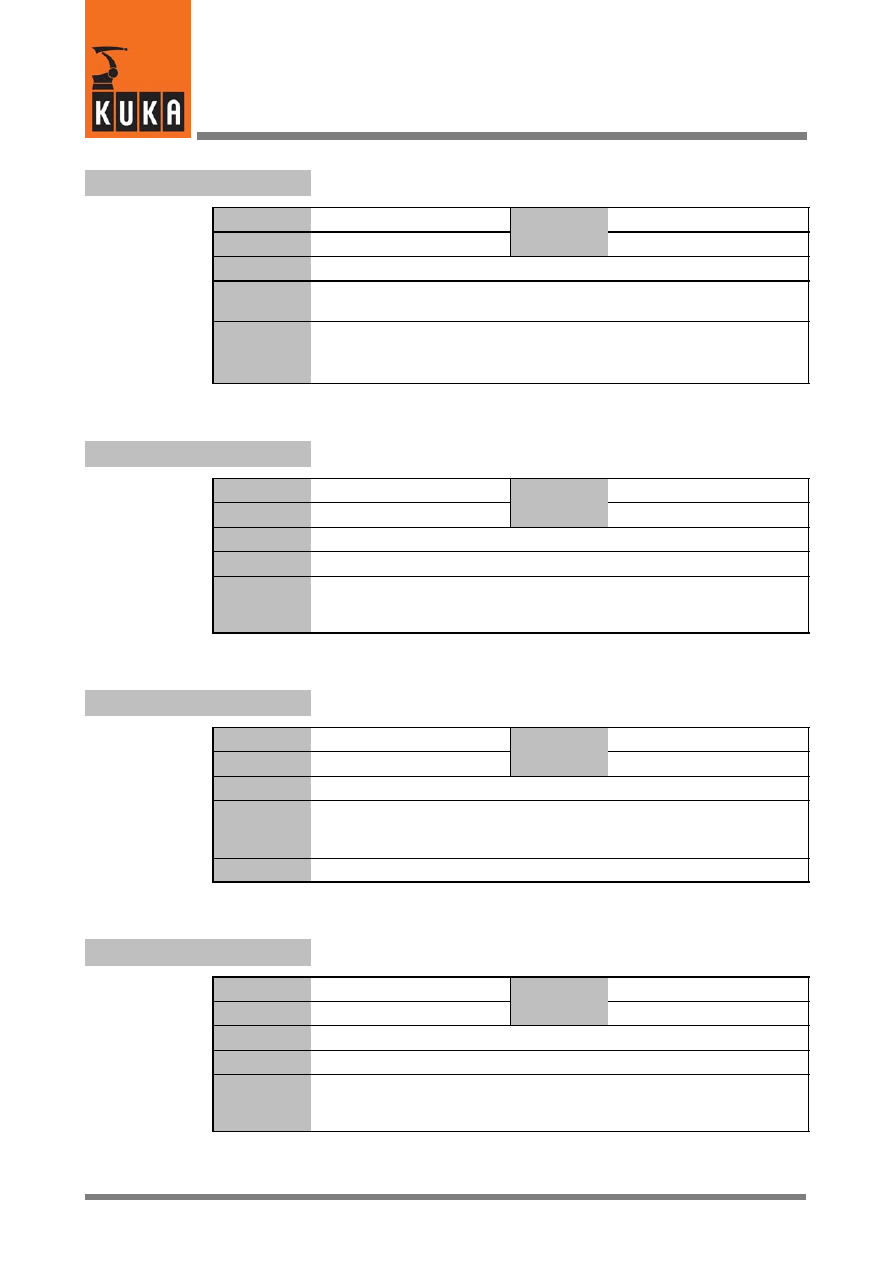

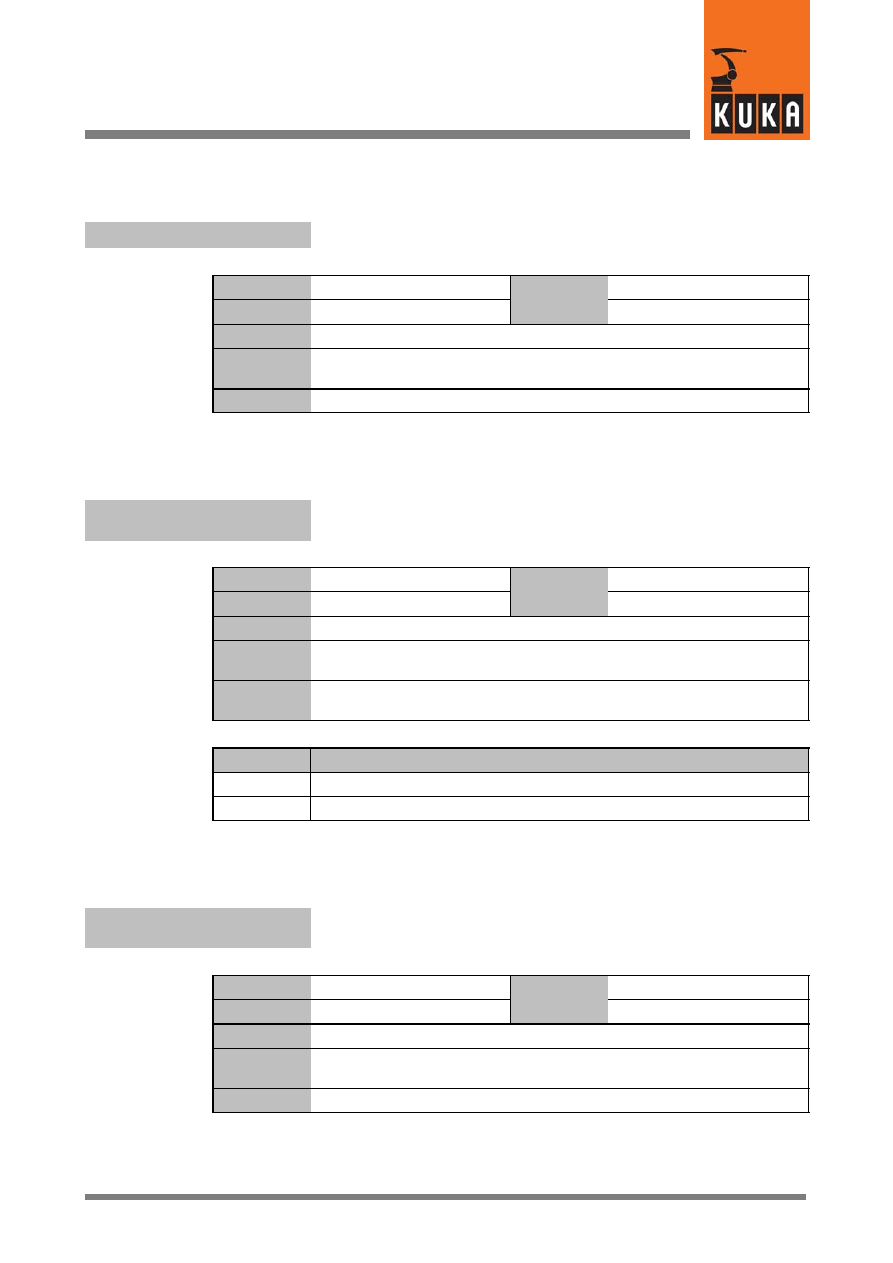

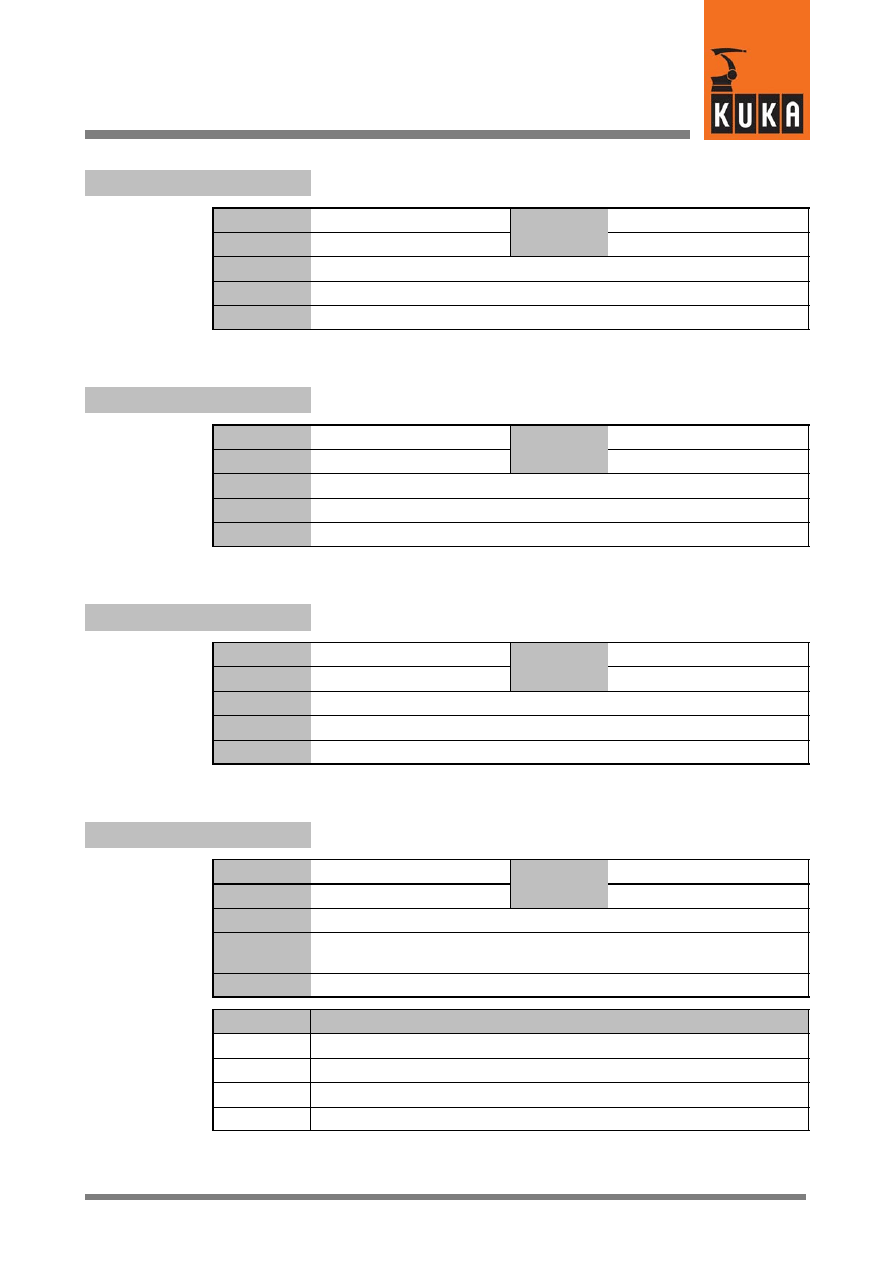

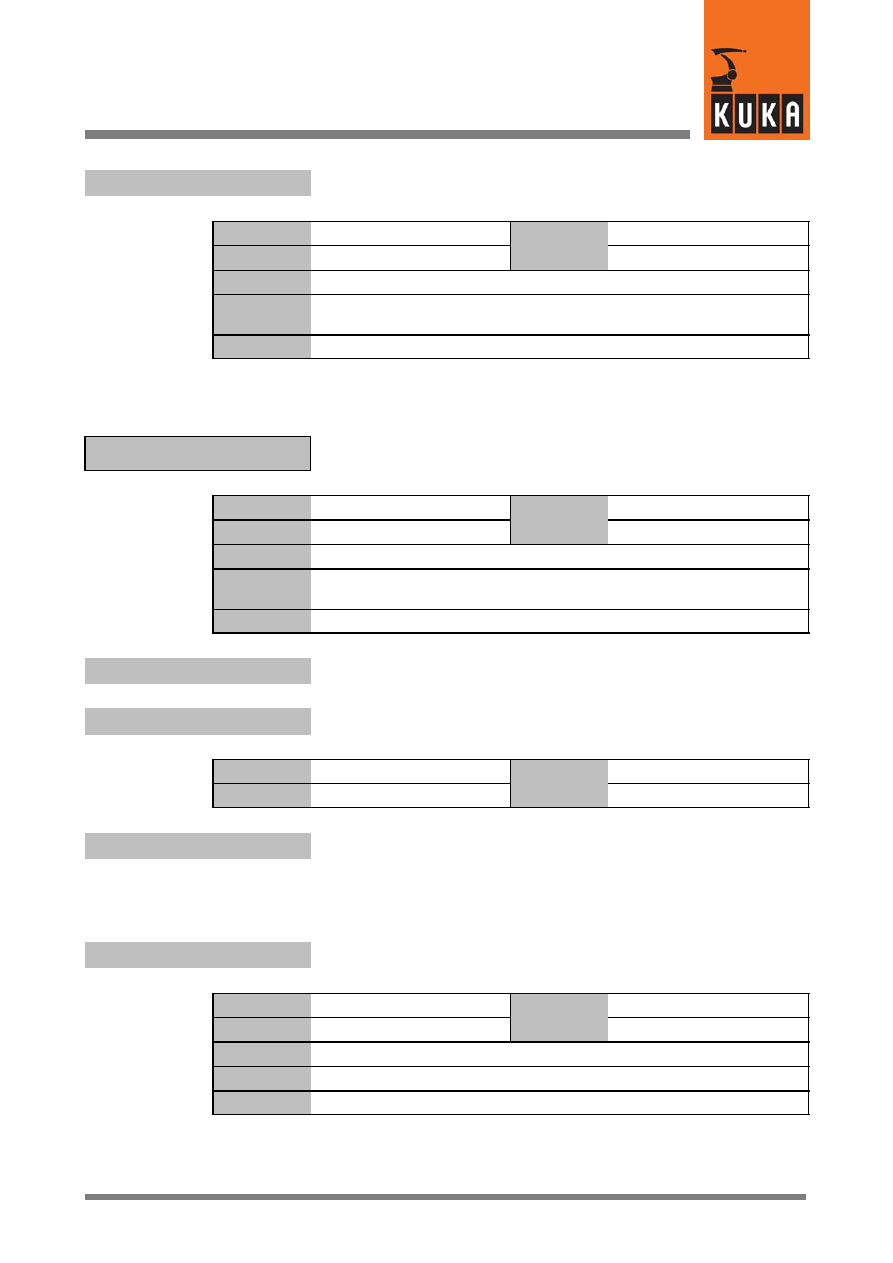

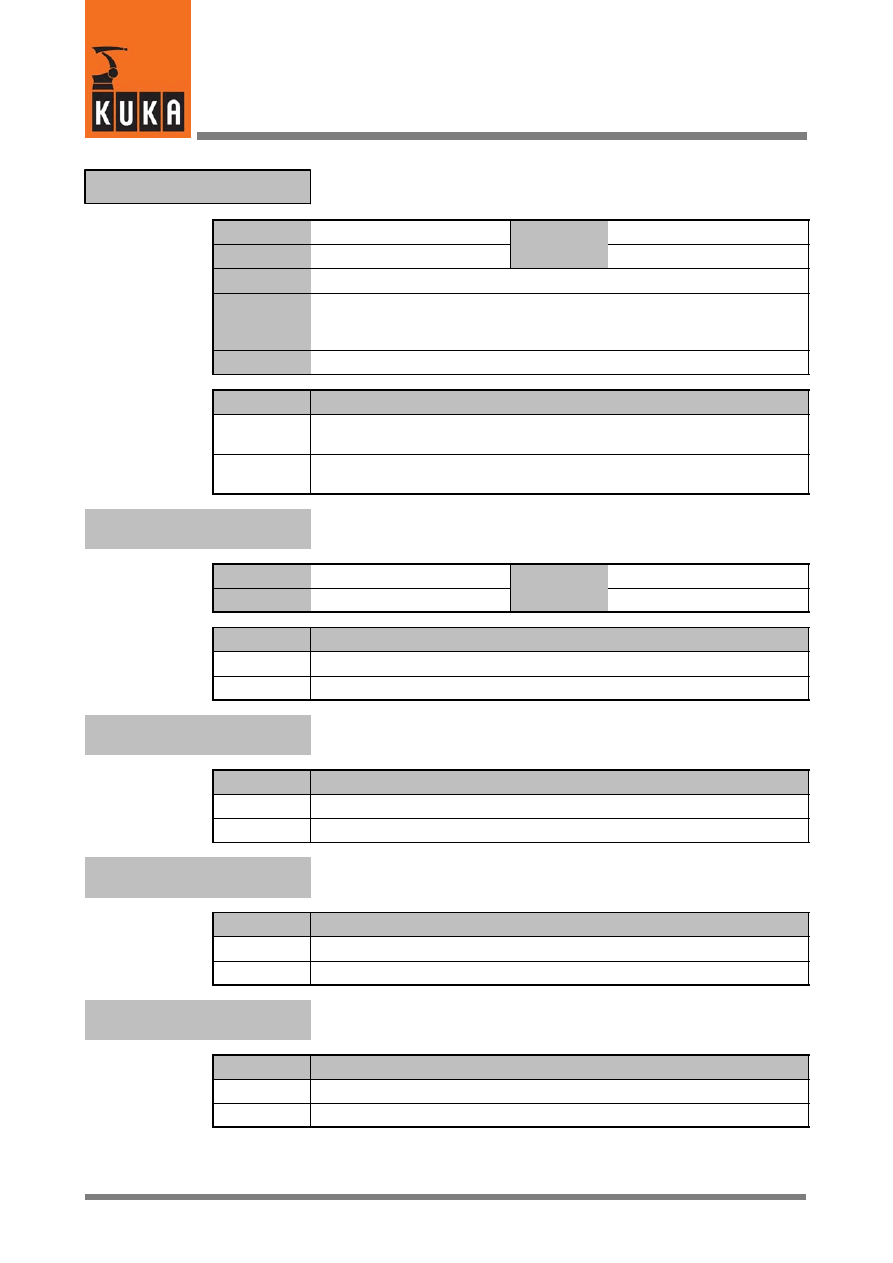

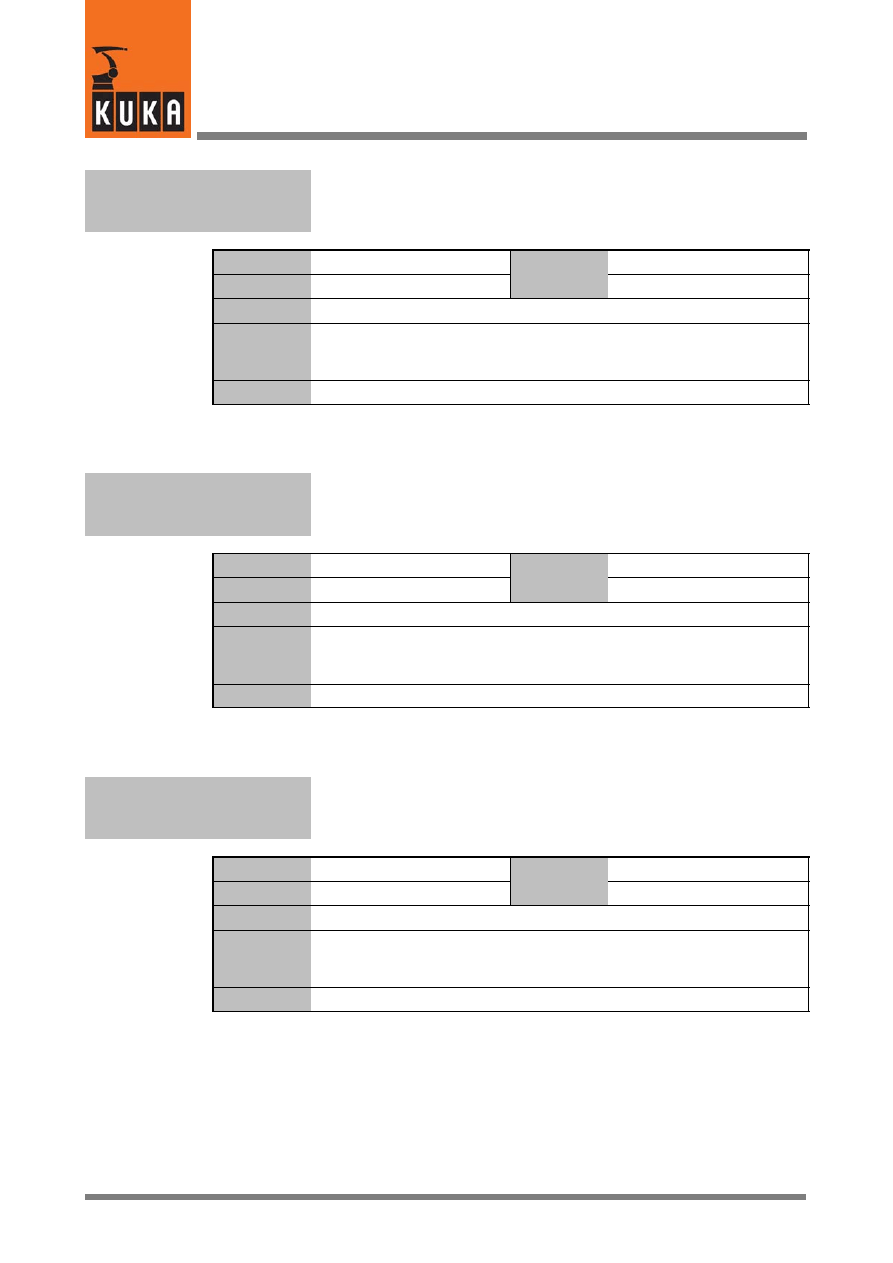

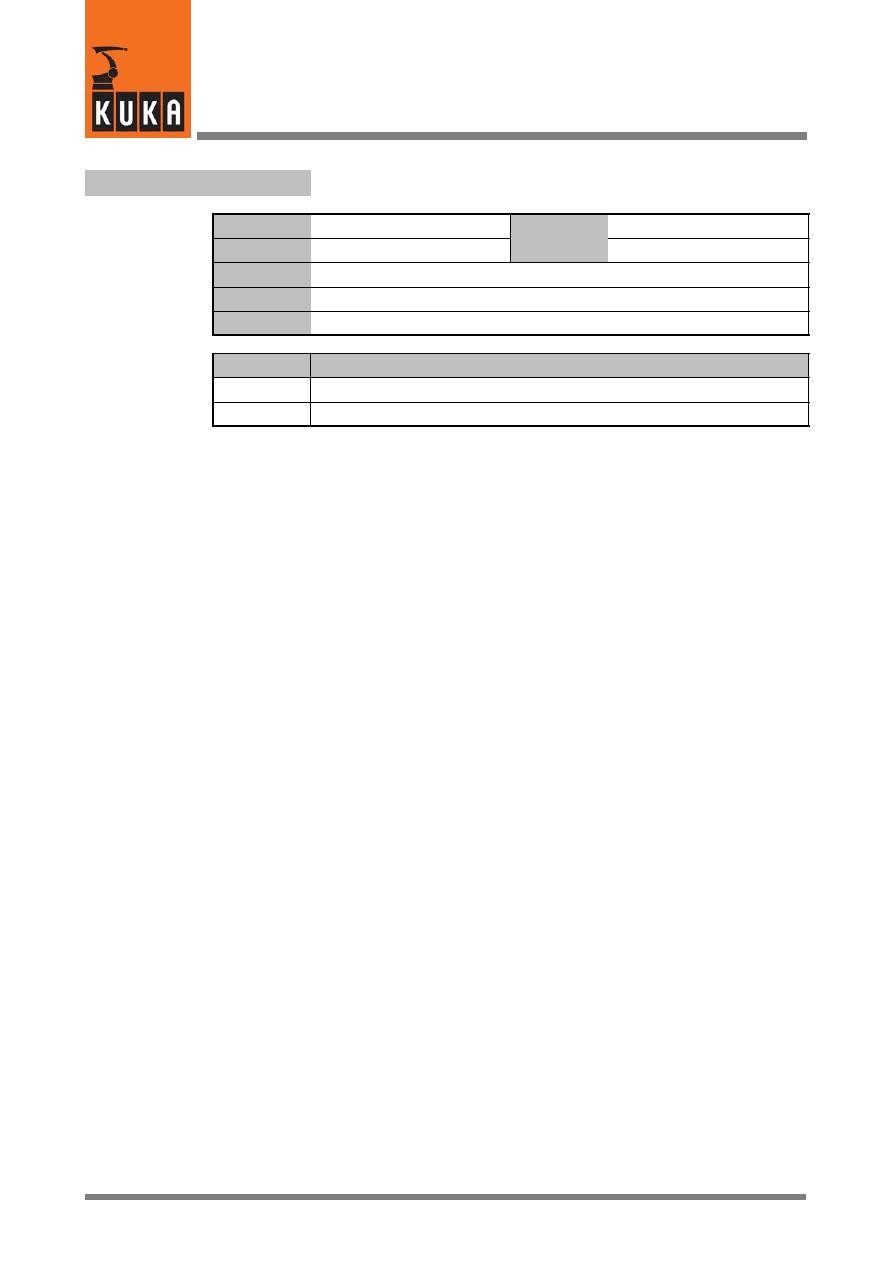

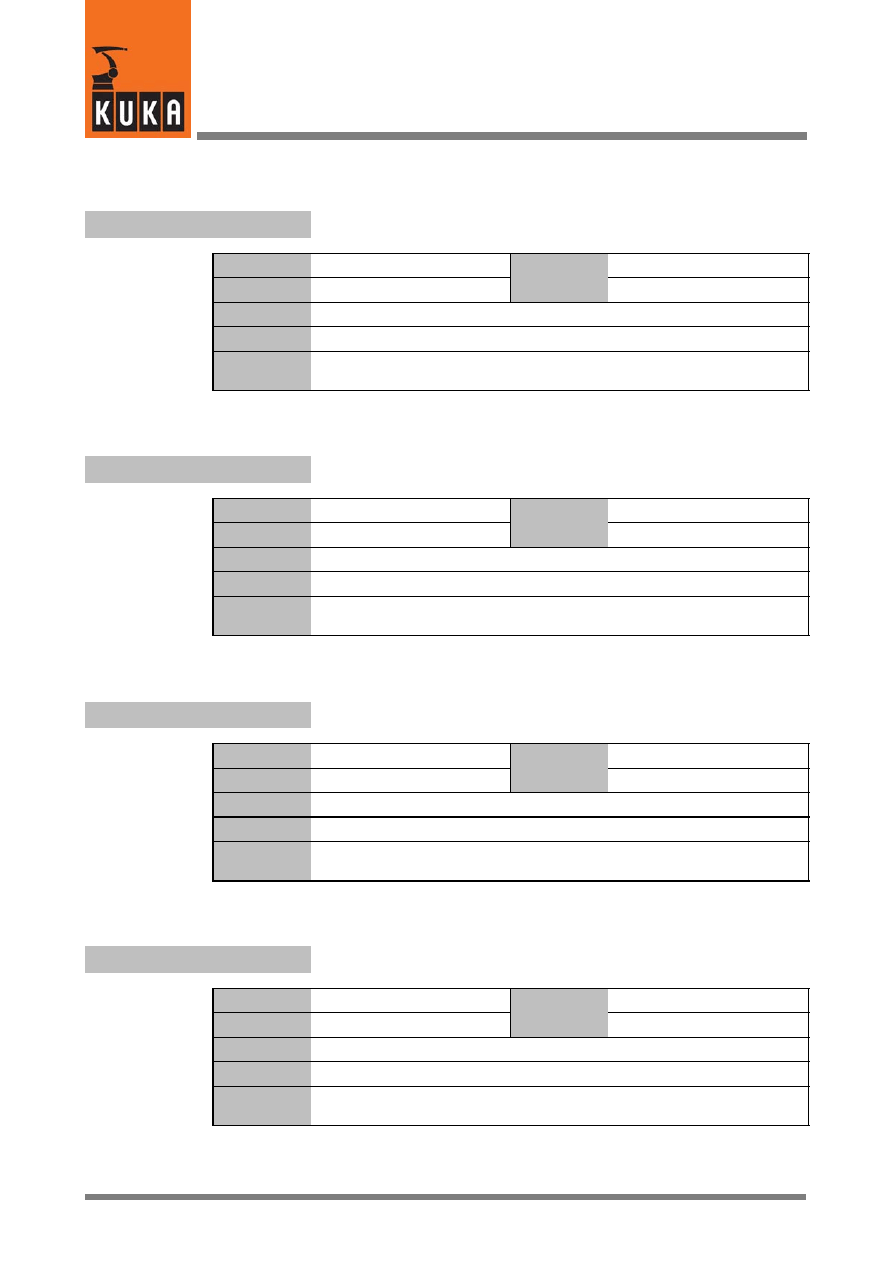

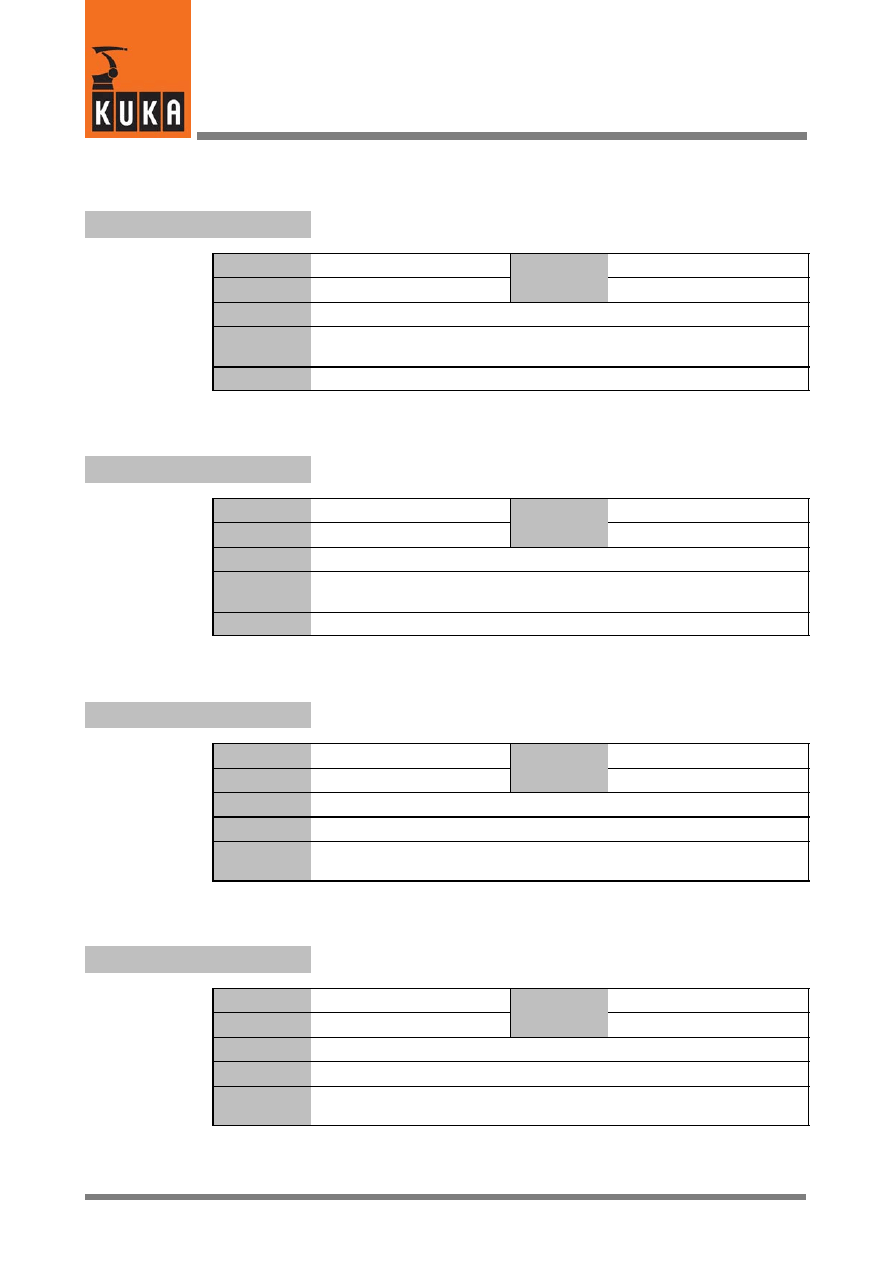

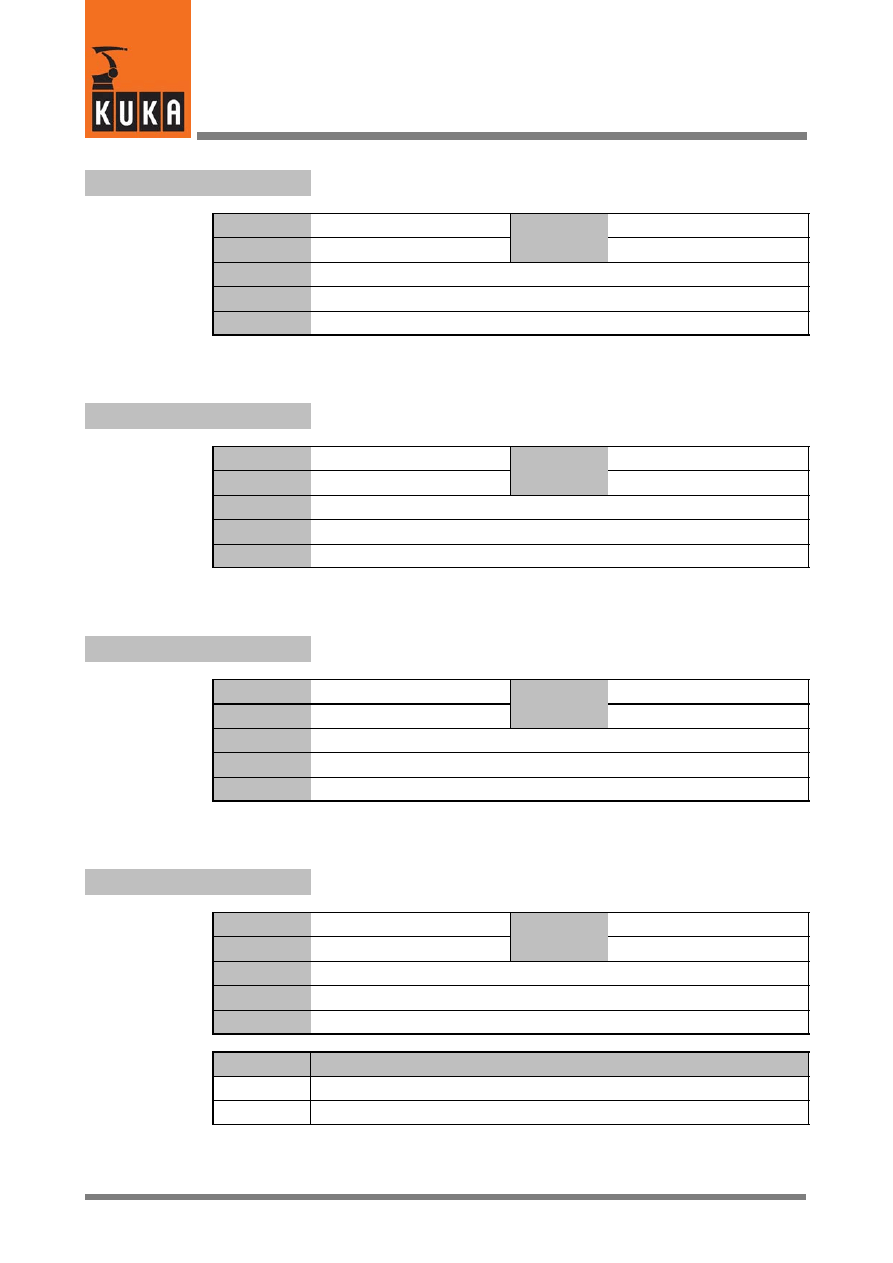

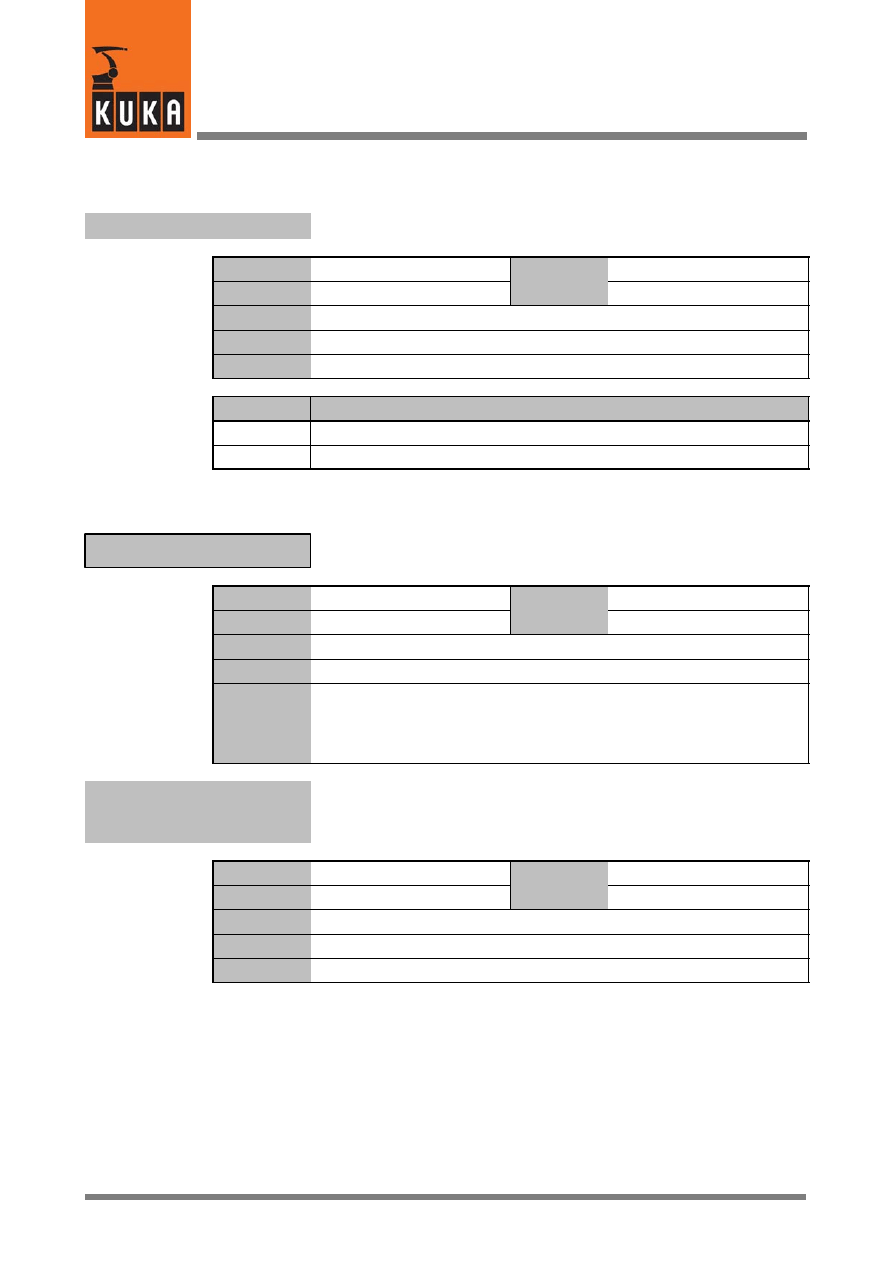

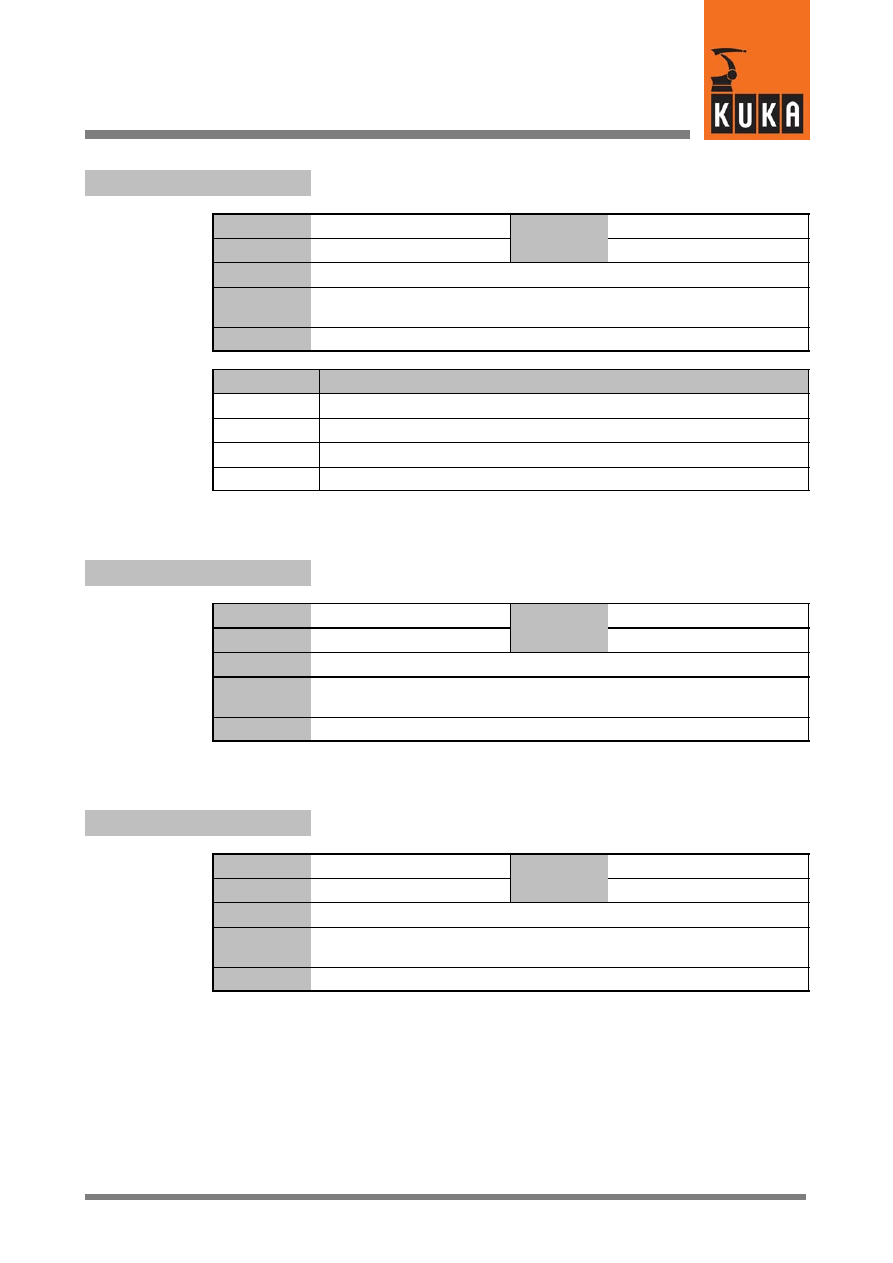

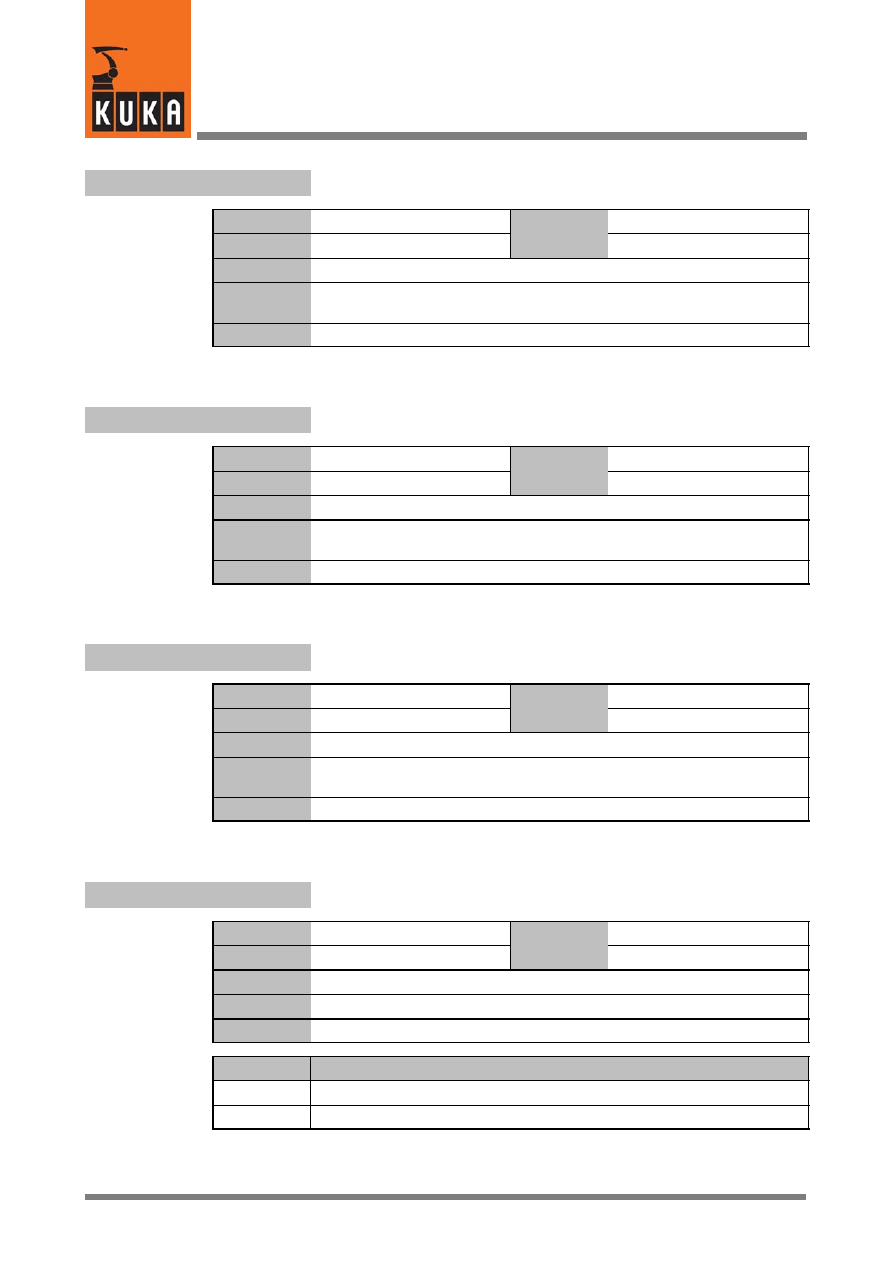

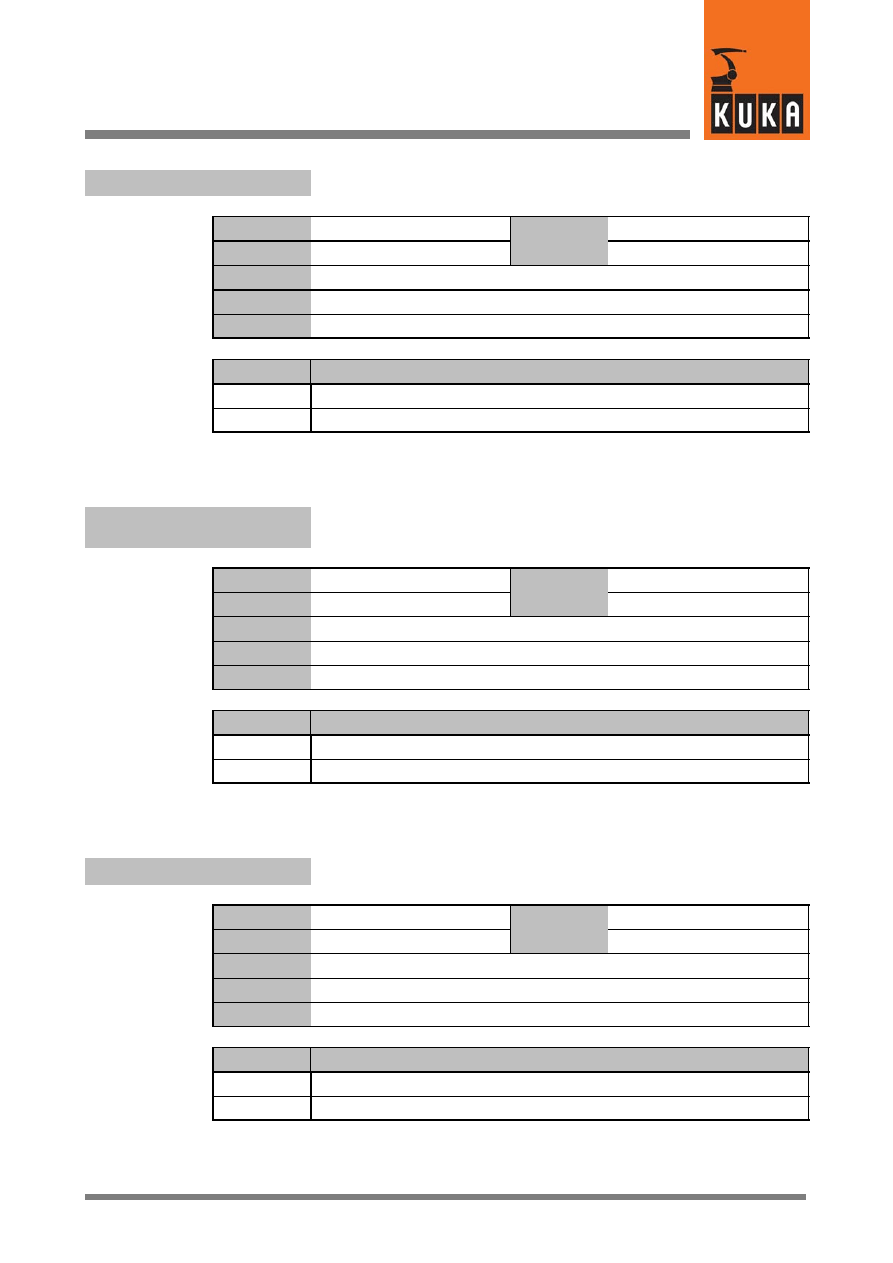

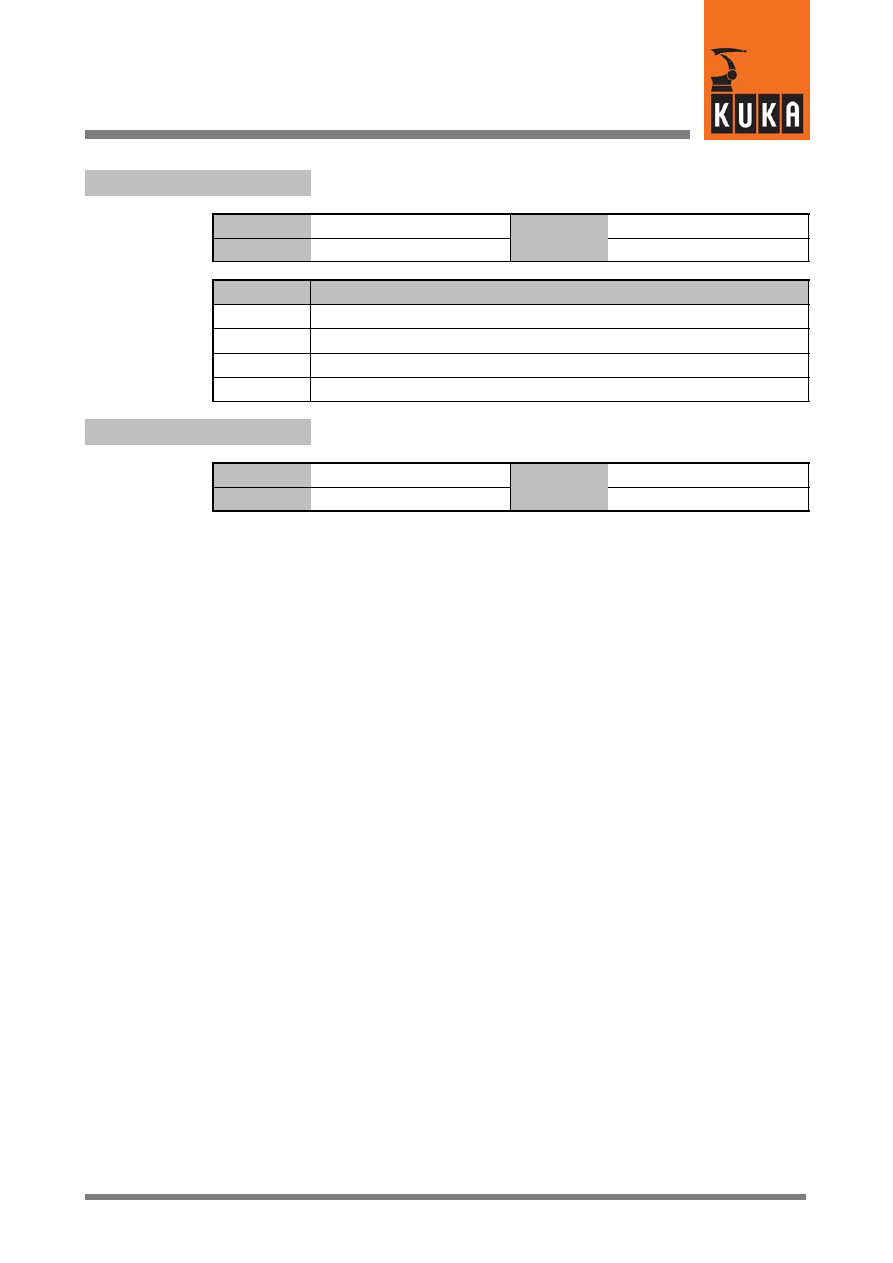

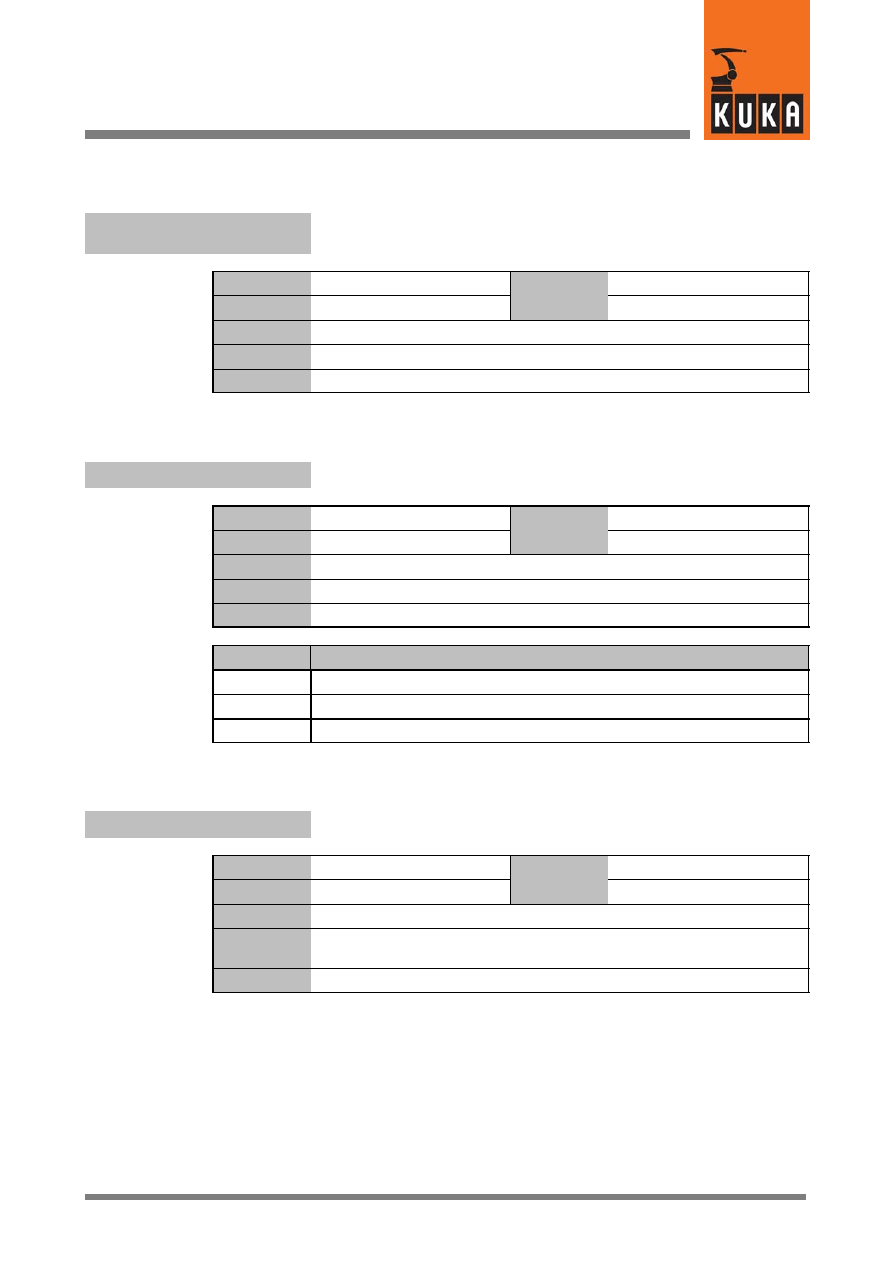

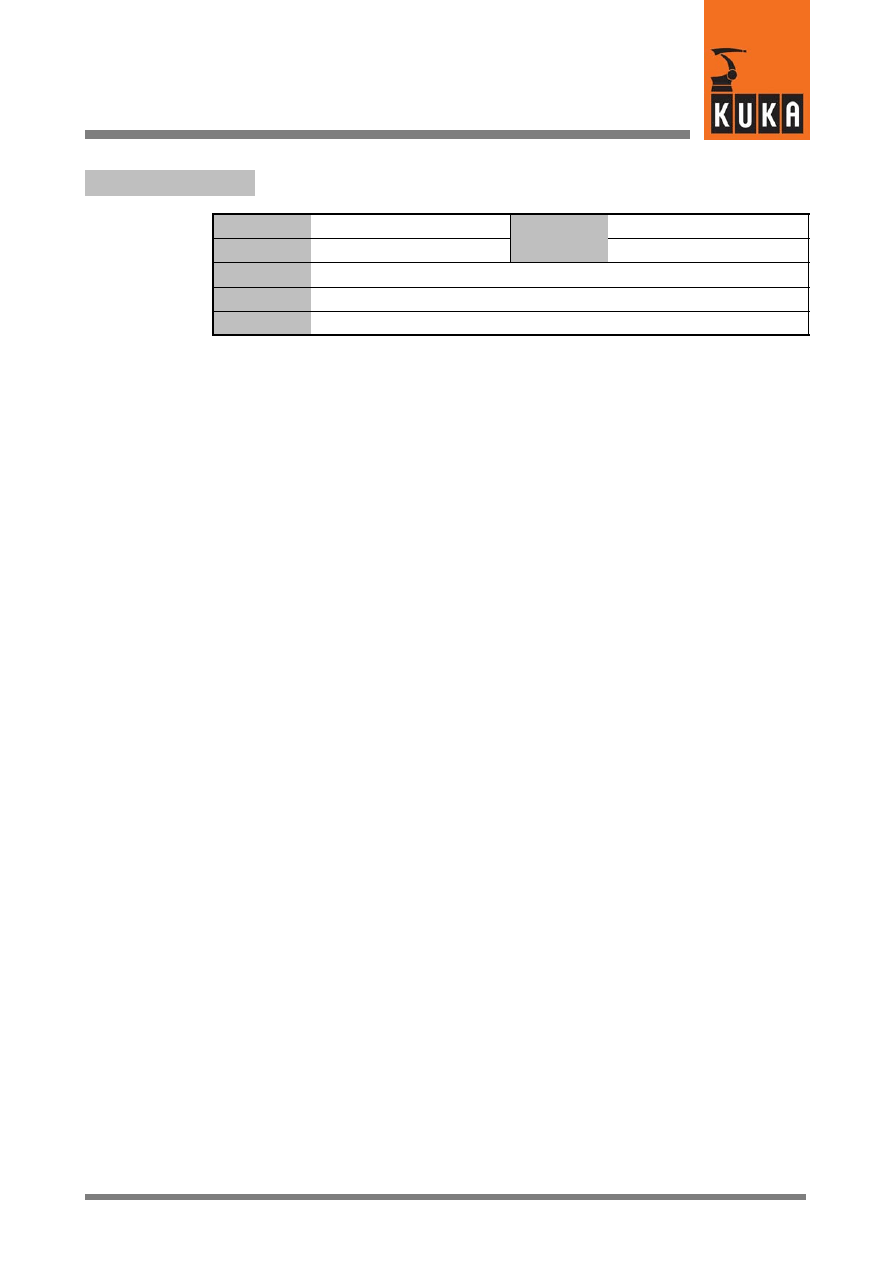

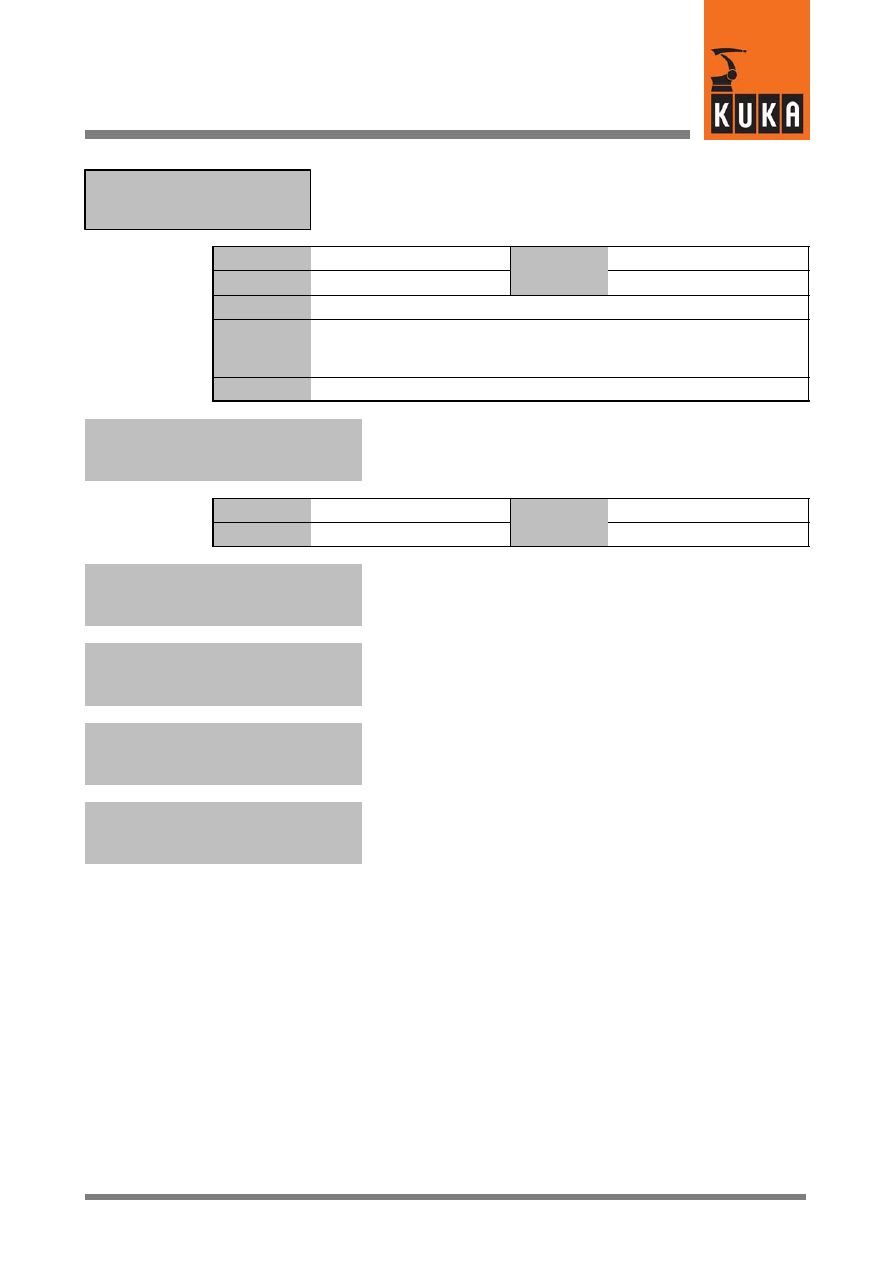

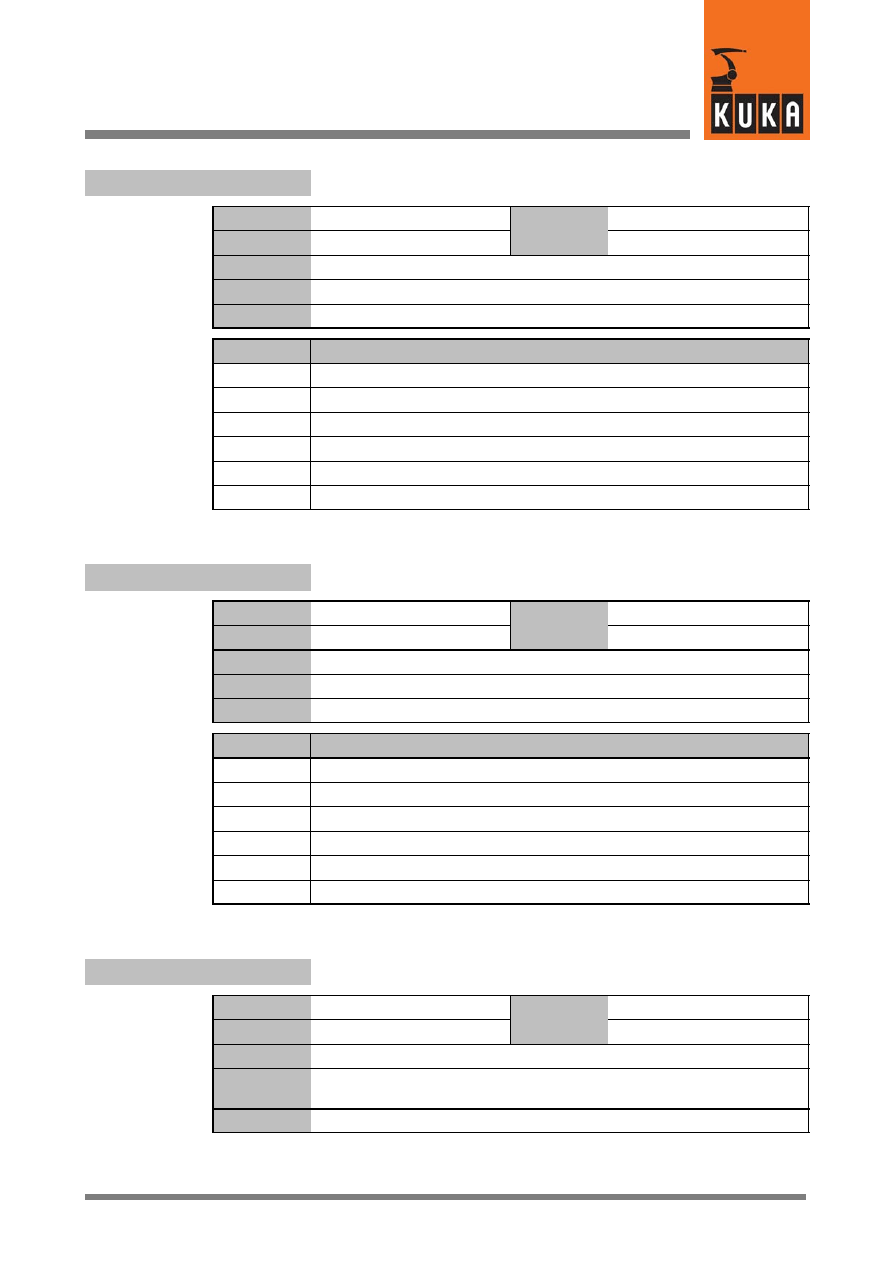

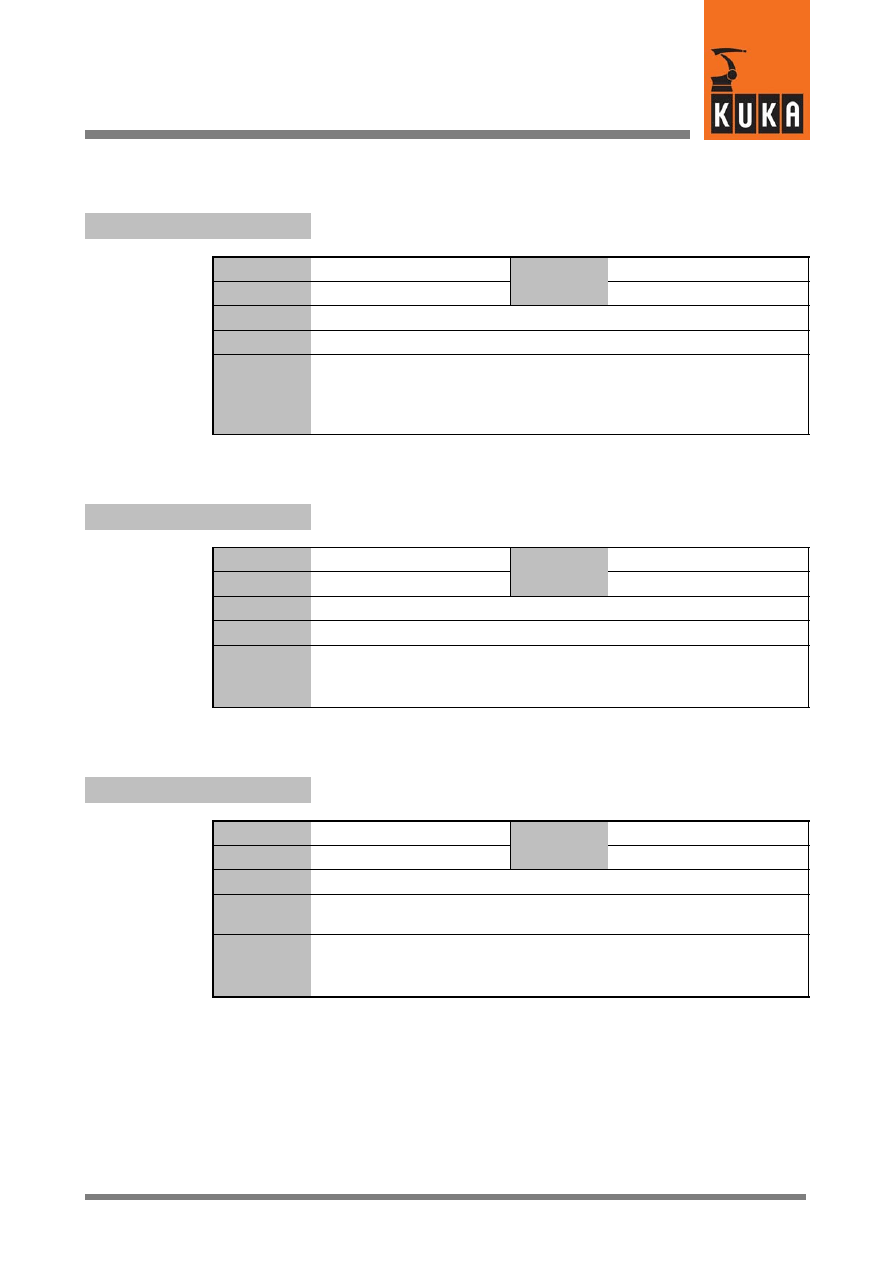

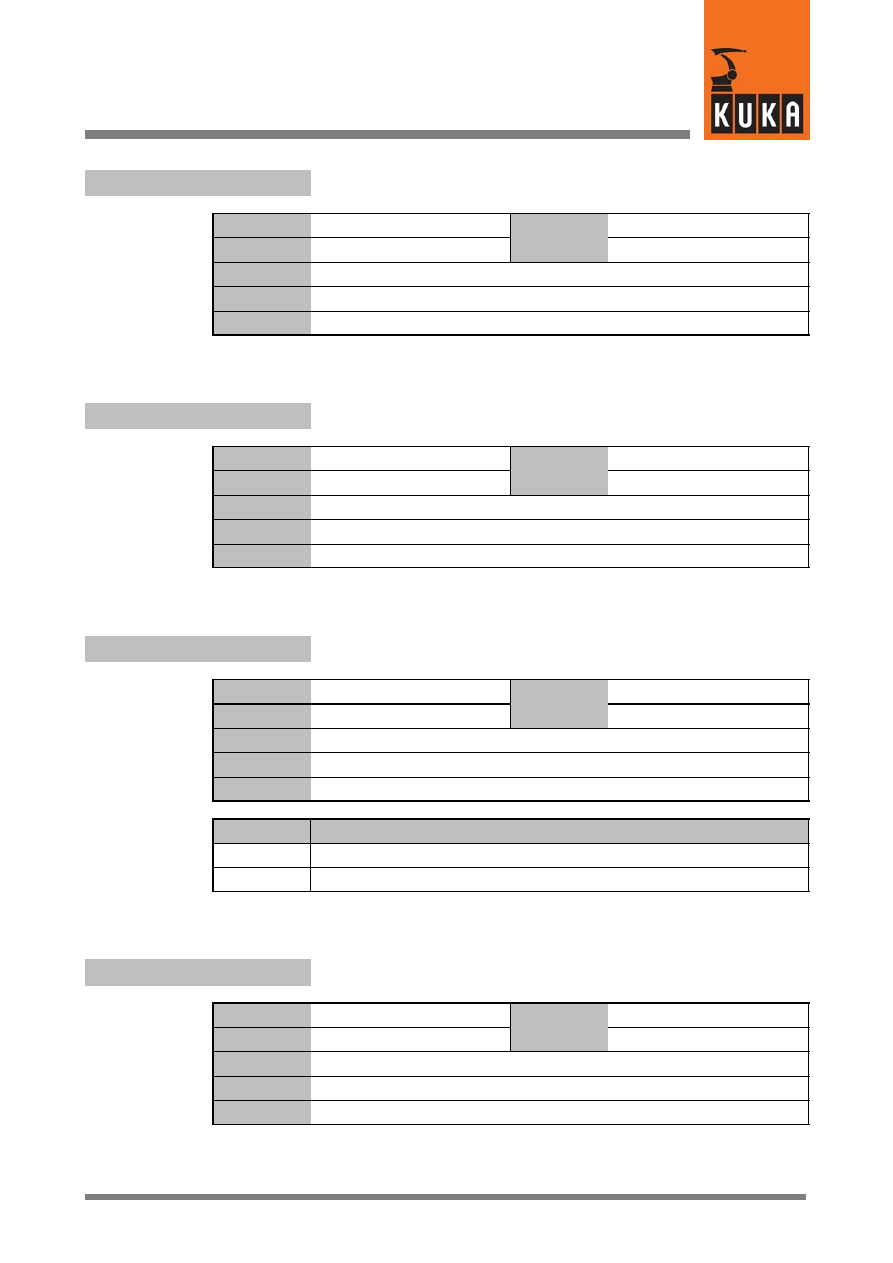

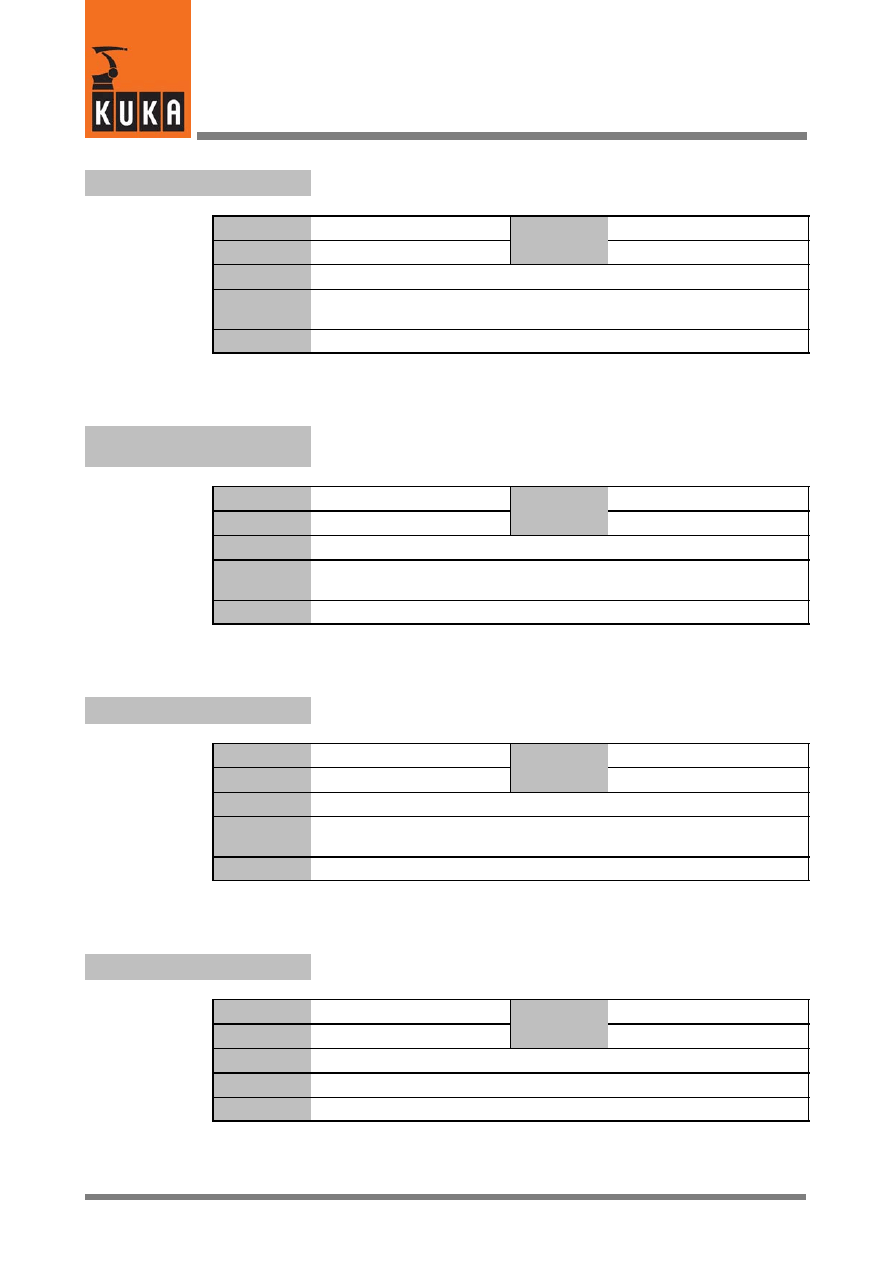

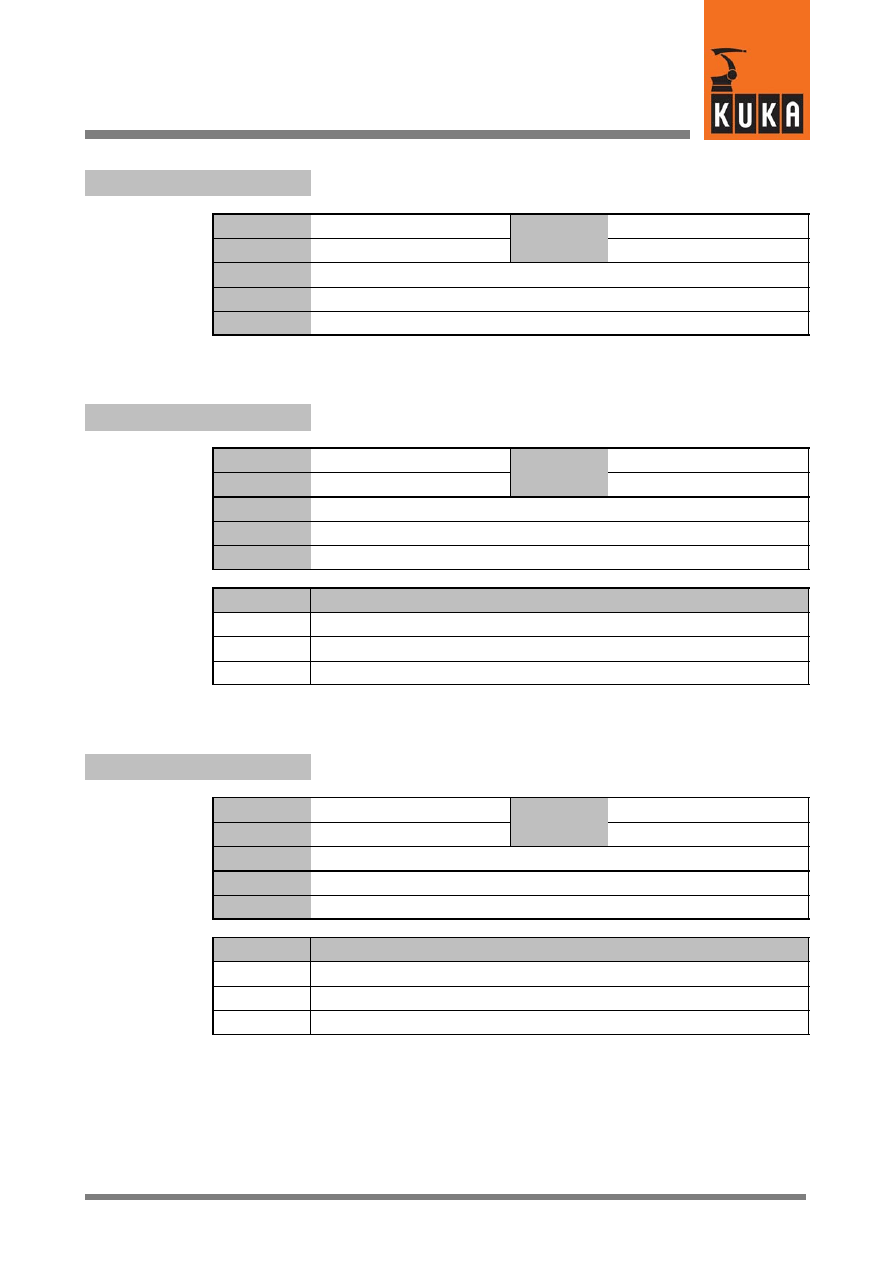

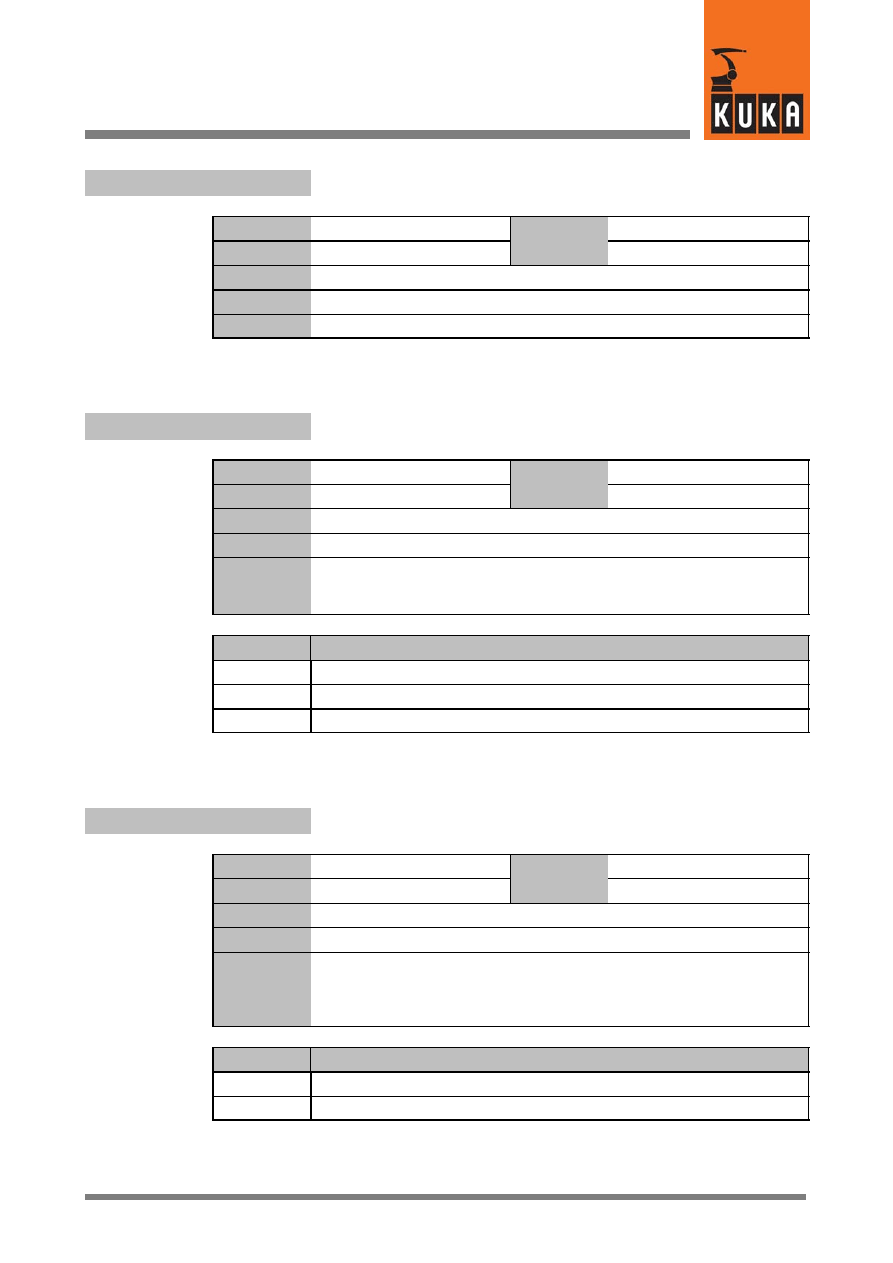

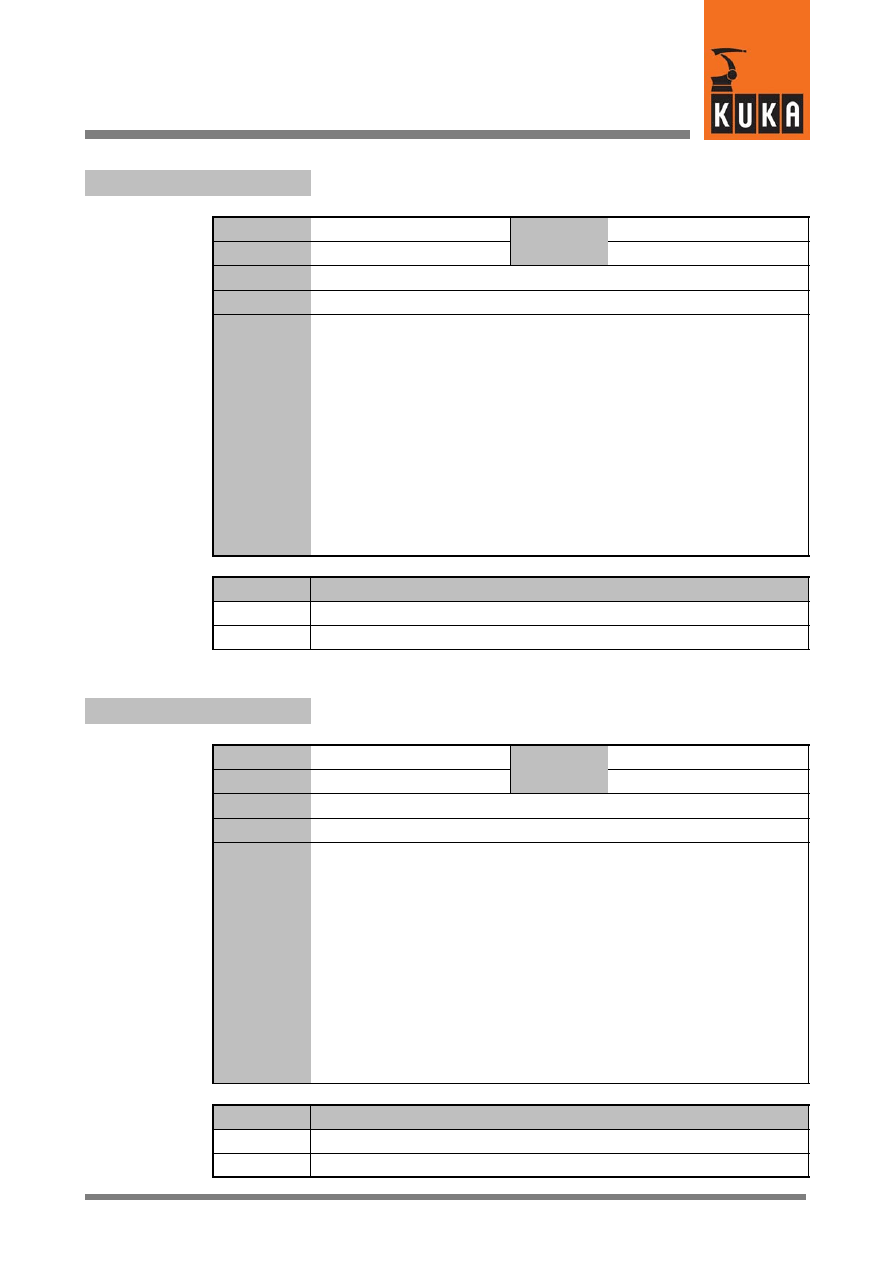

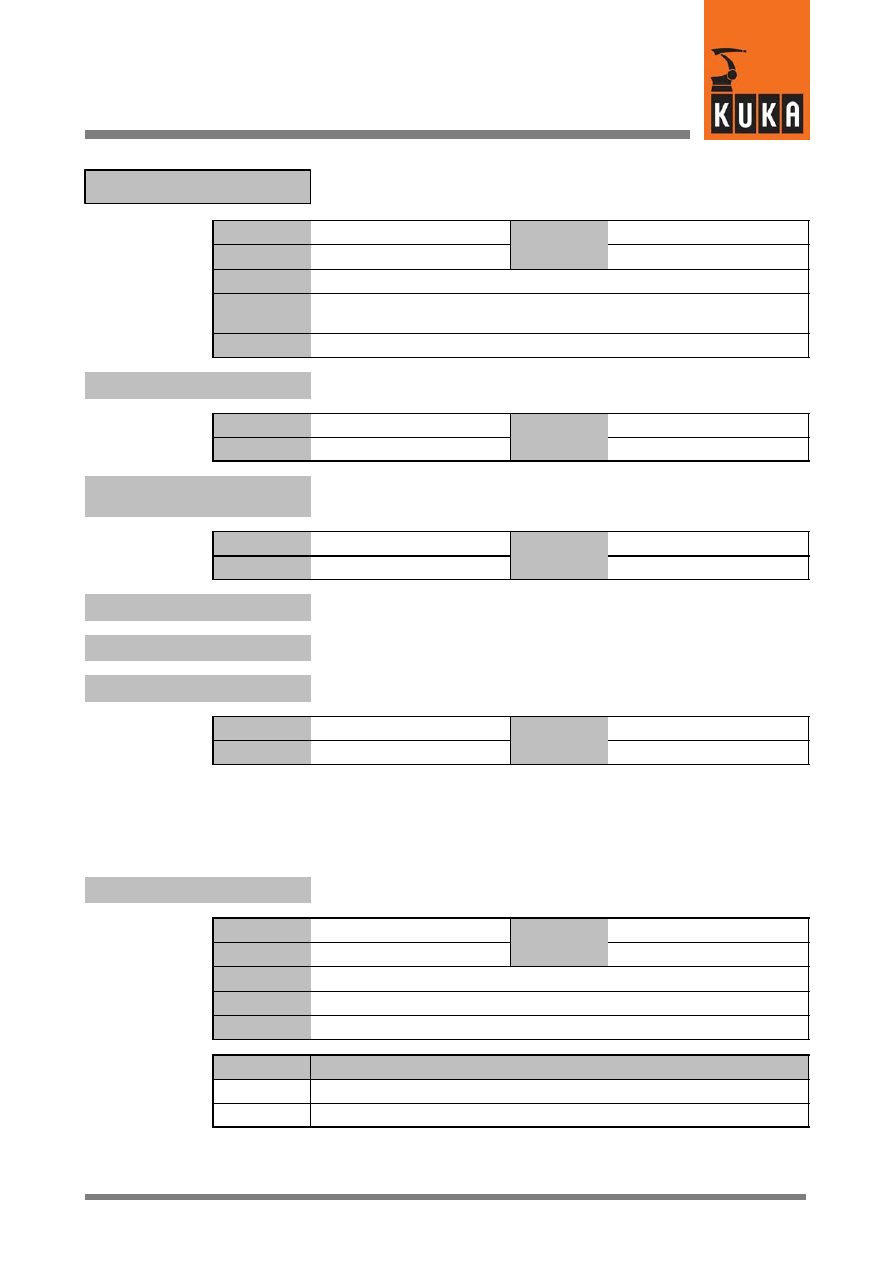

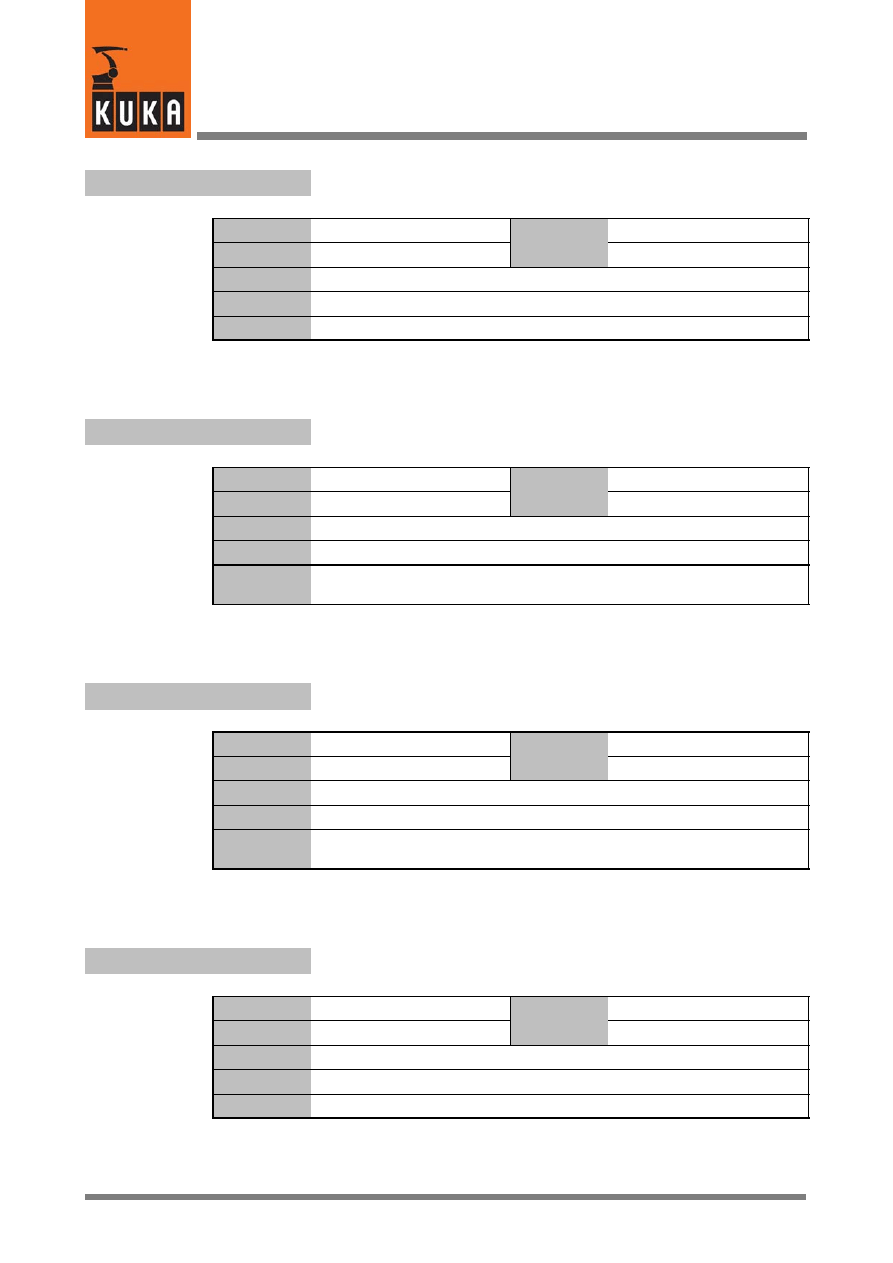

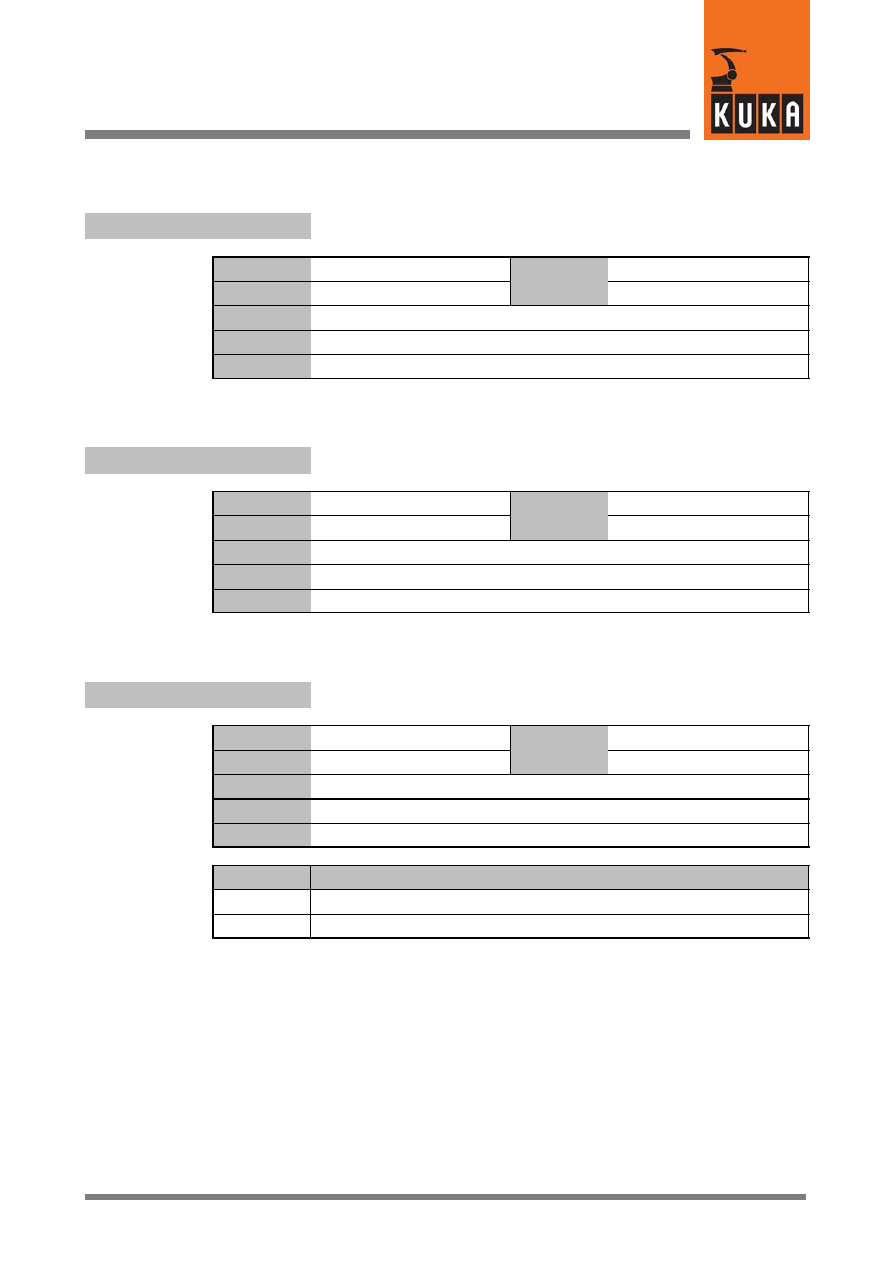

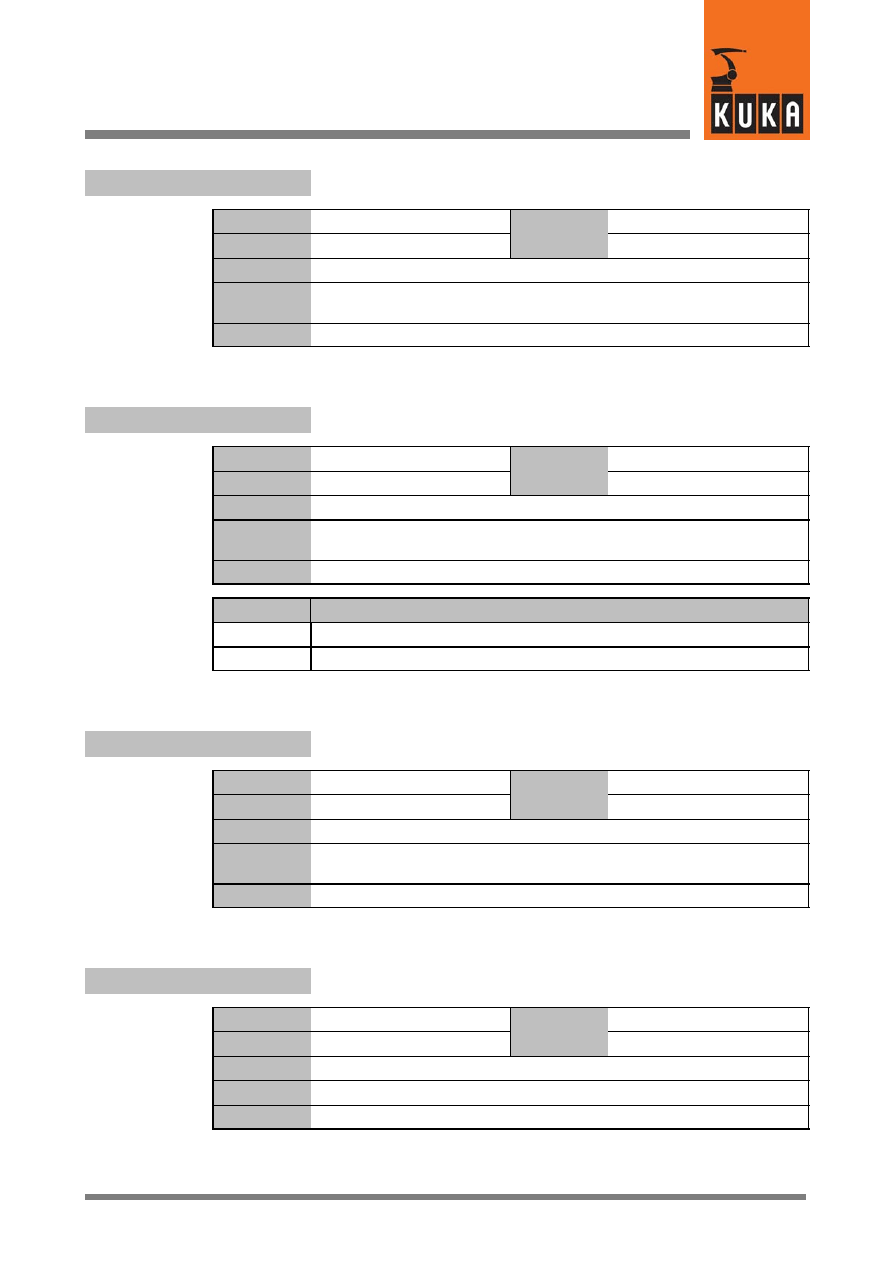

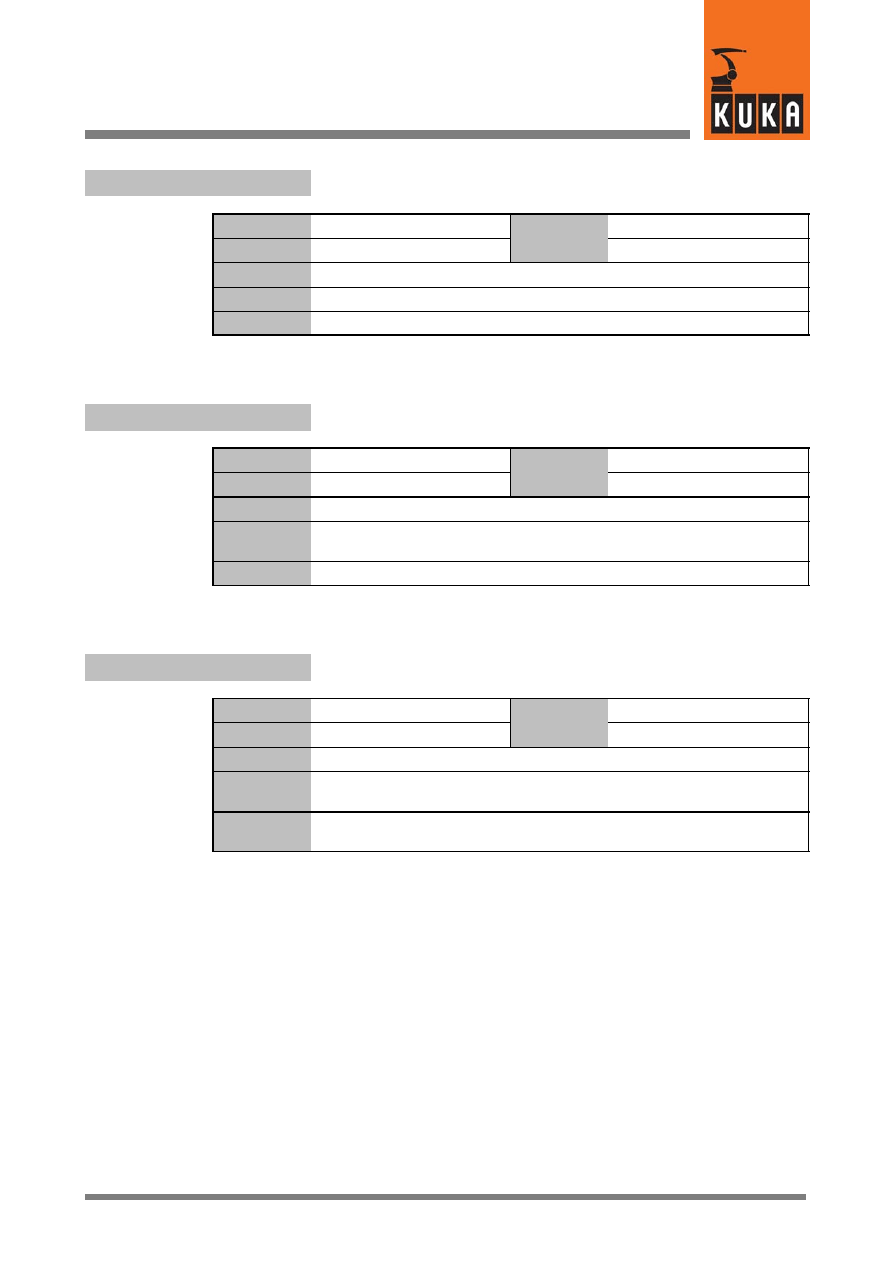

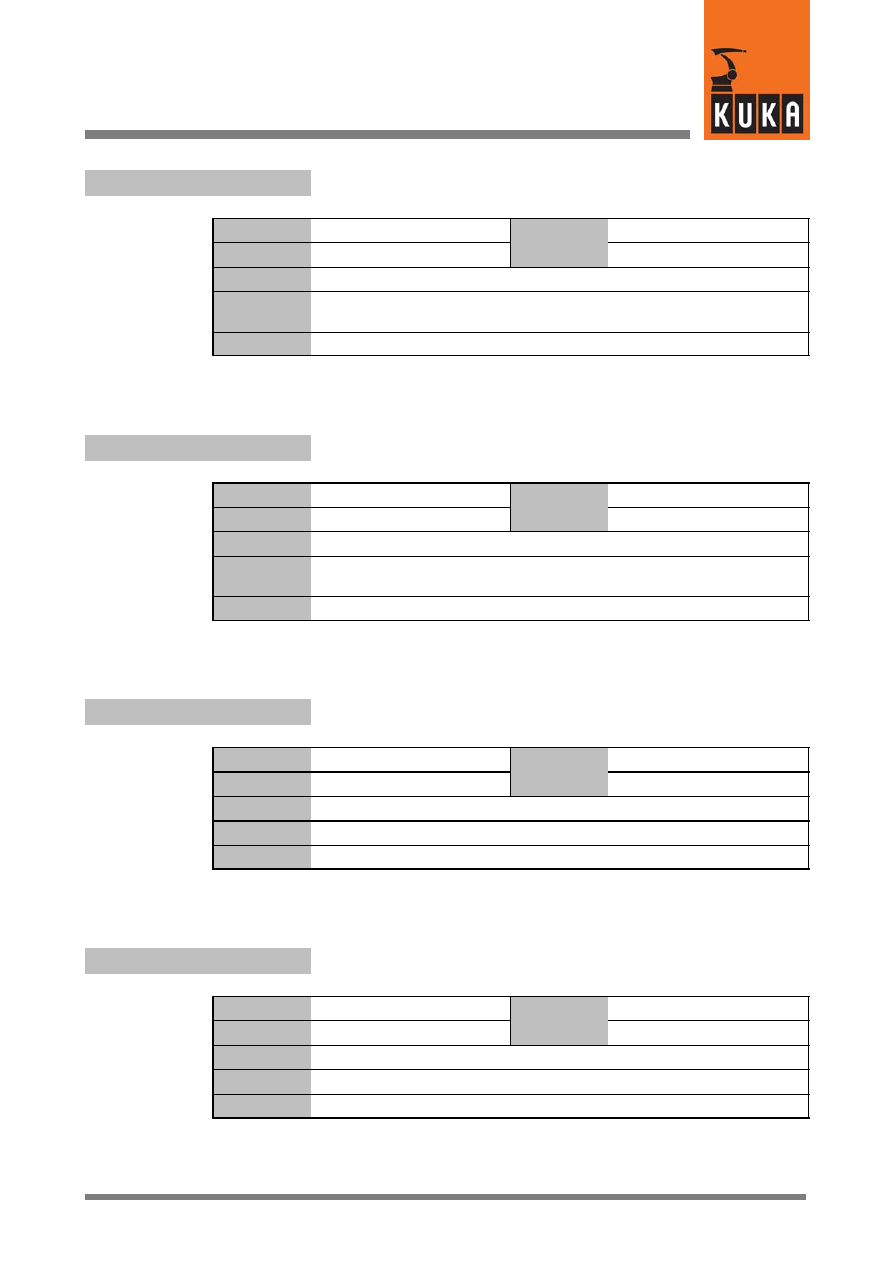

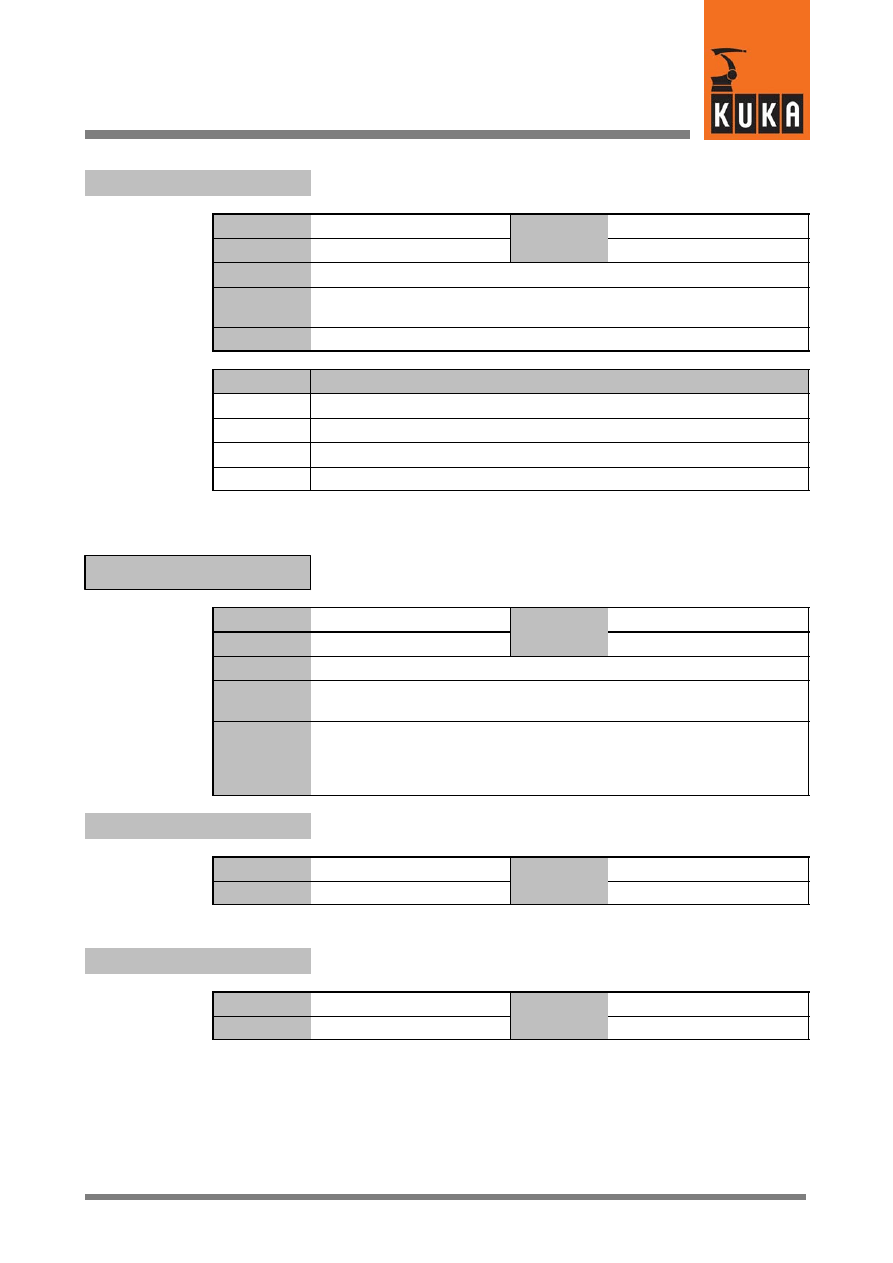

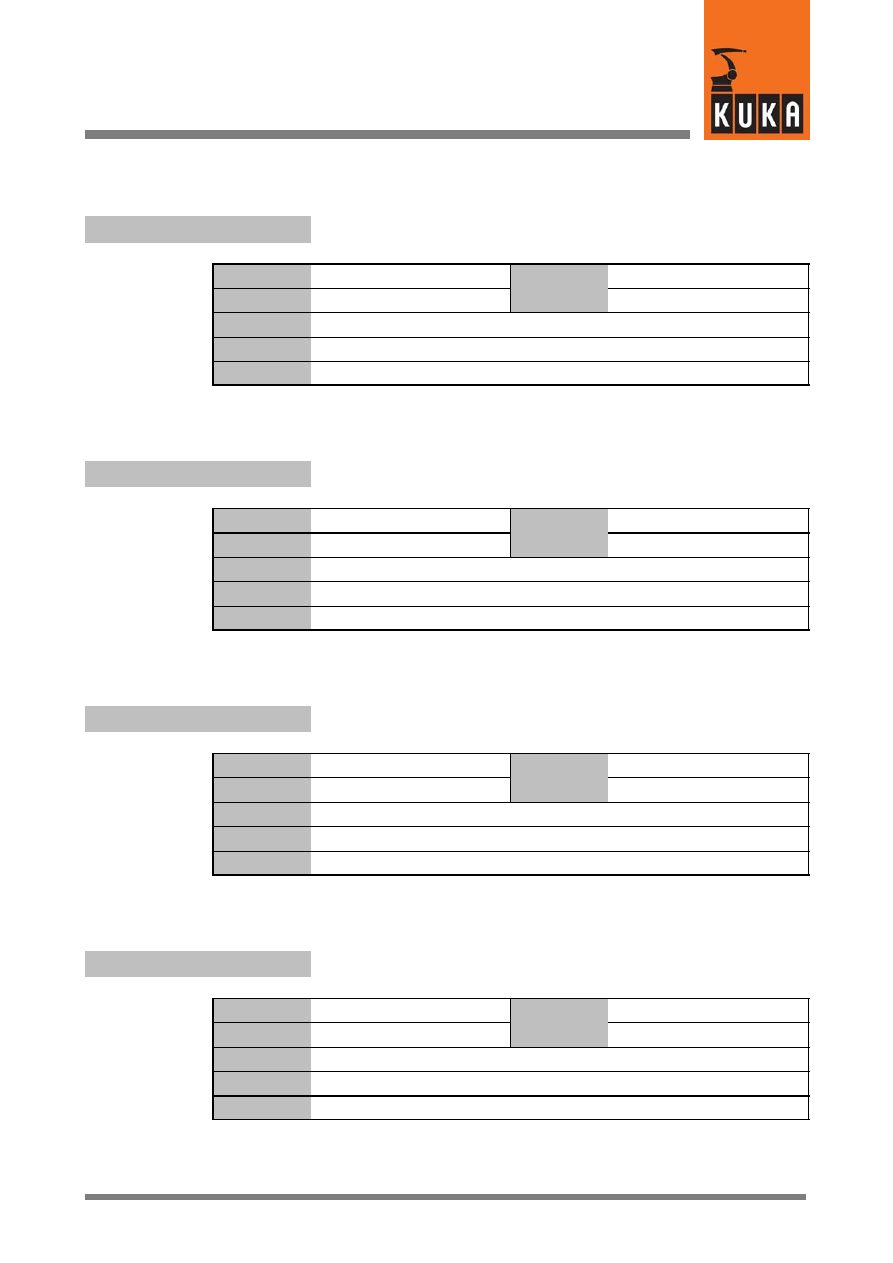

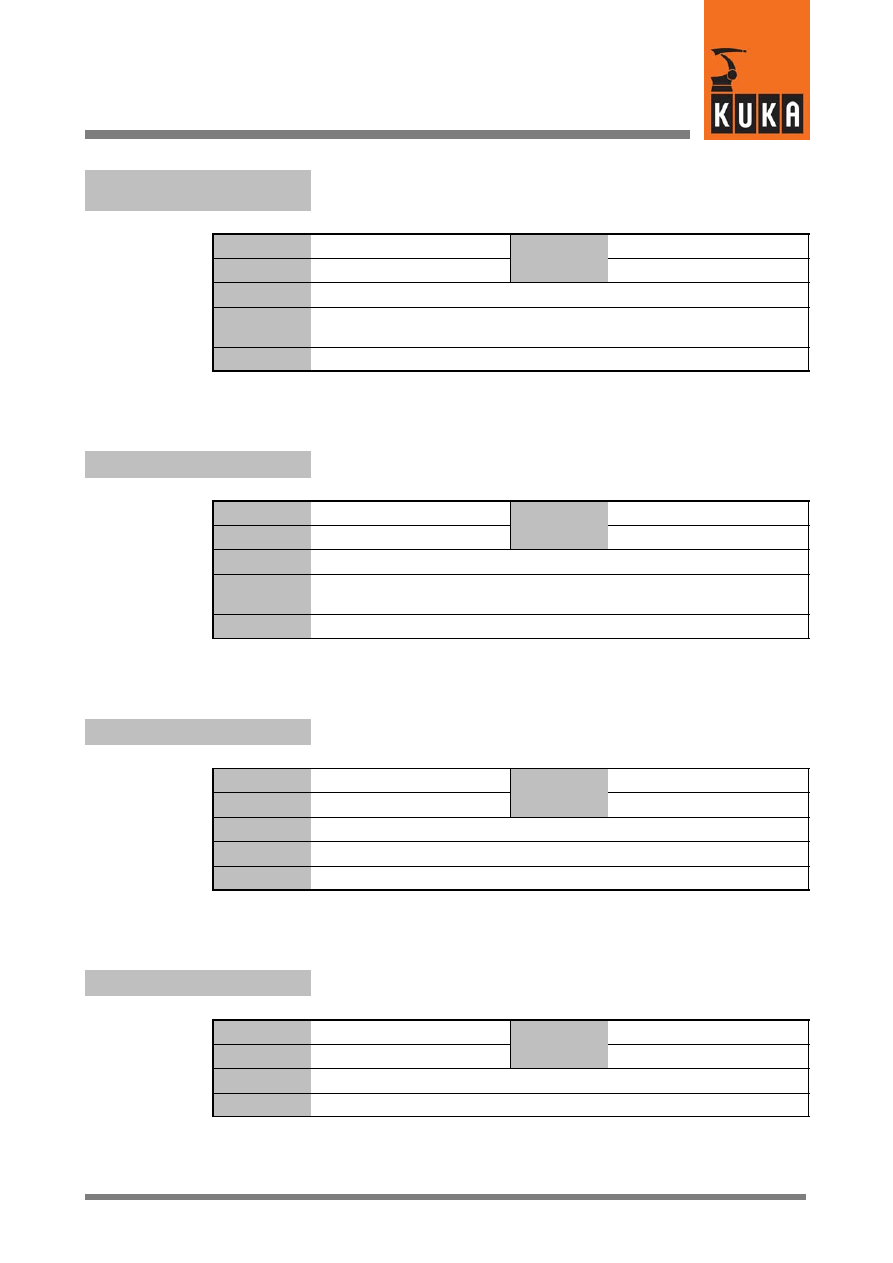

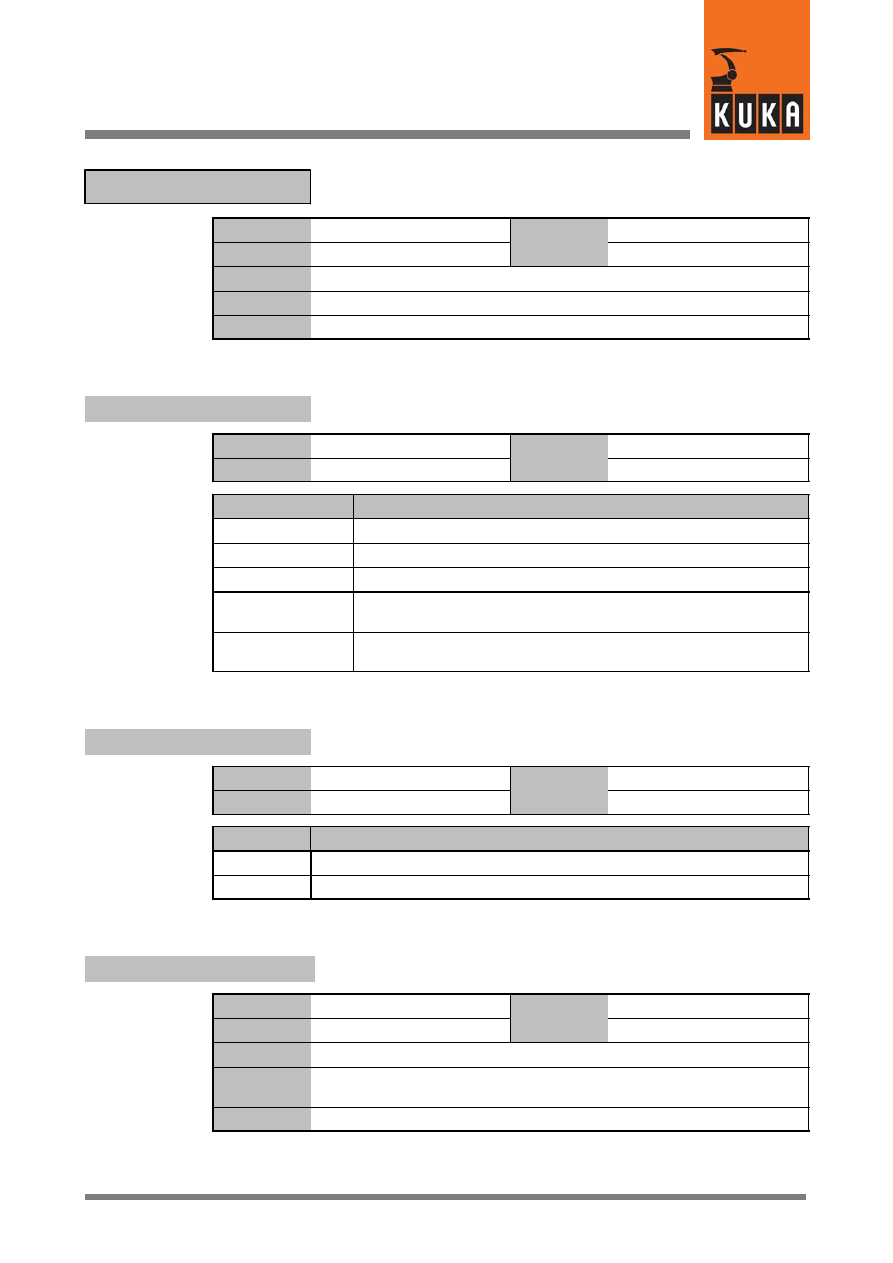

Each table is preceded by a title with the name and function of the system variable, e.g.:

Variable name

Function of the variable

Data type

Value

min.

Unit

Value

max.

In file

Original line

Comments

Options

Effect

If no Options are specified, then the second table is omitted.

System Variables

6 of 170

SysVar 08.02.03 en

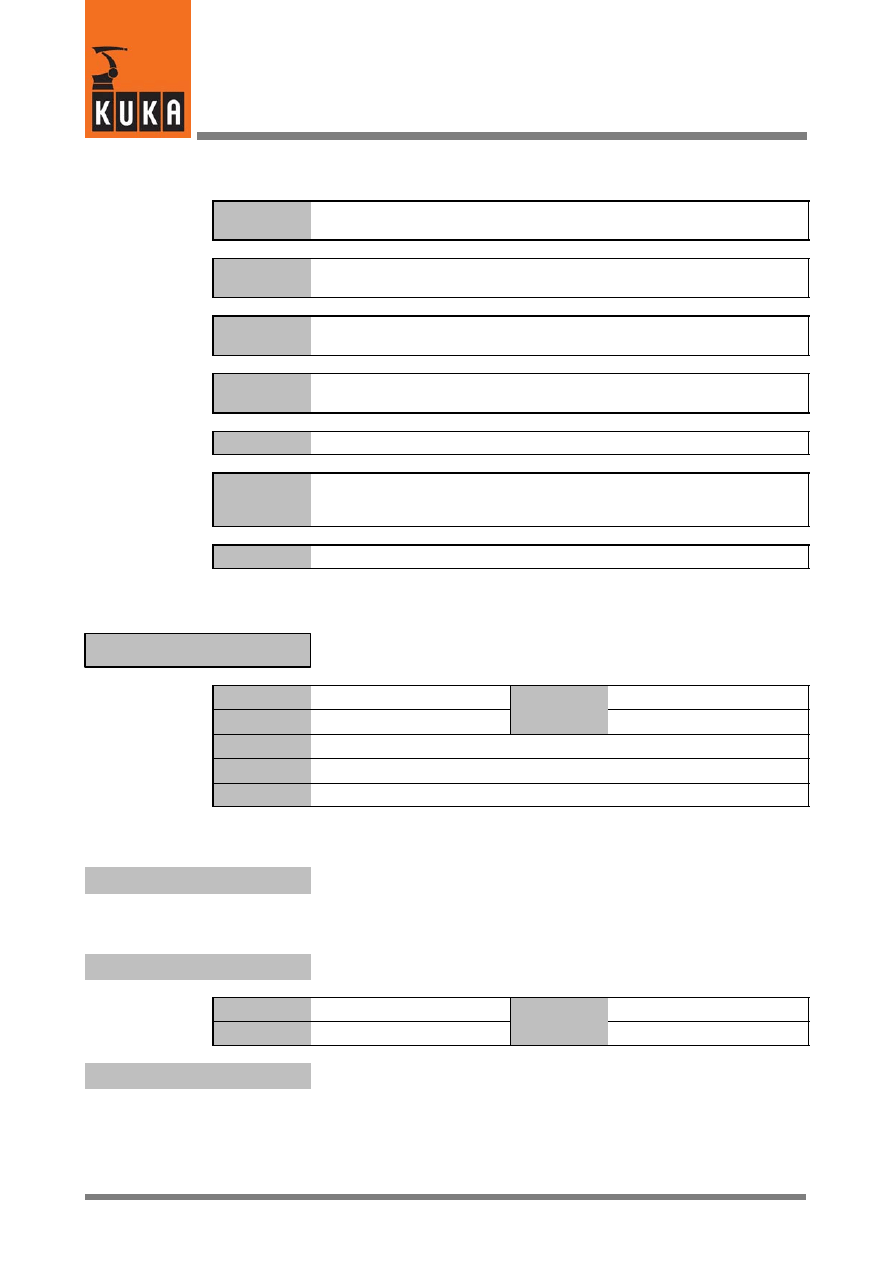

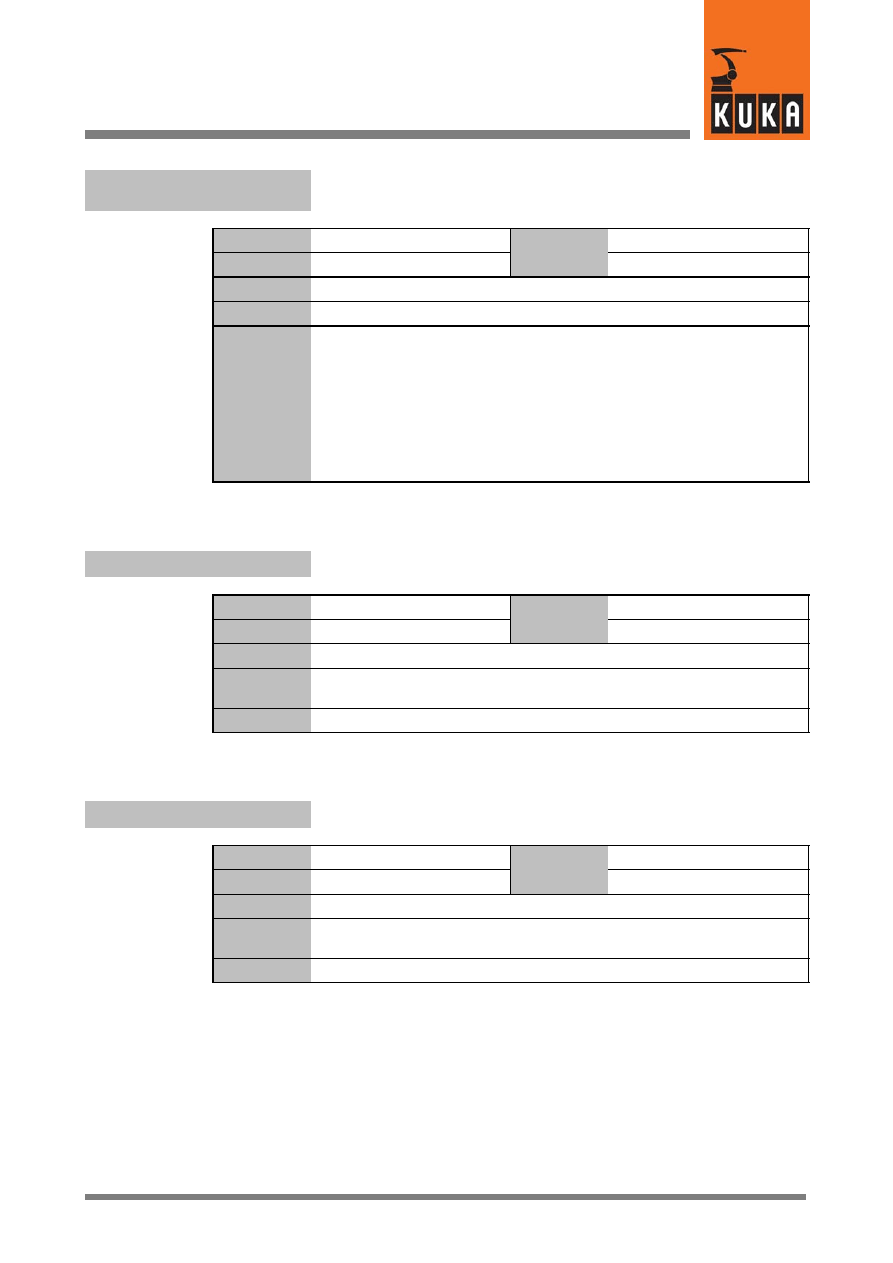

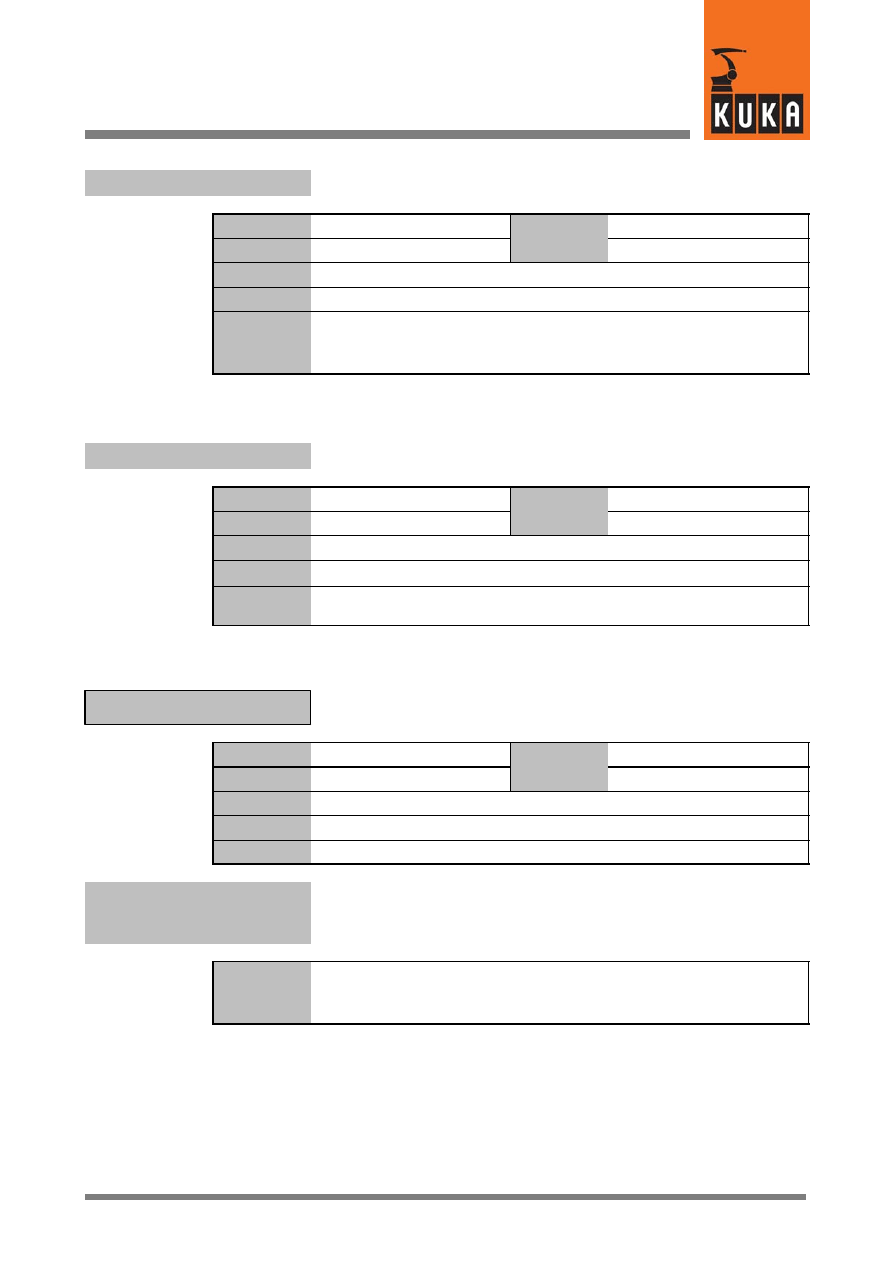

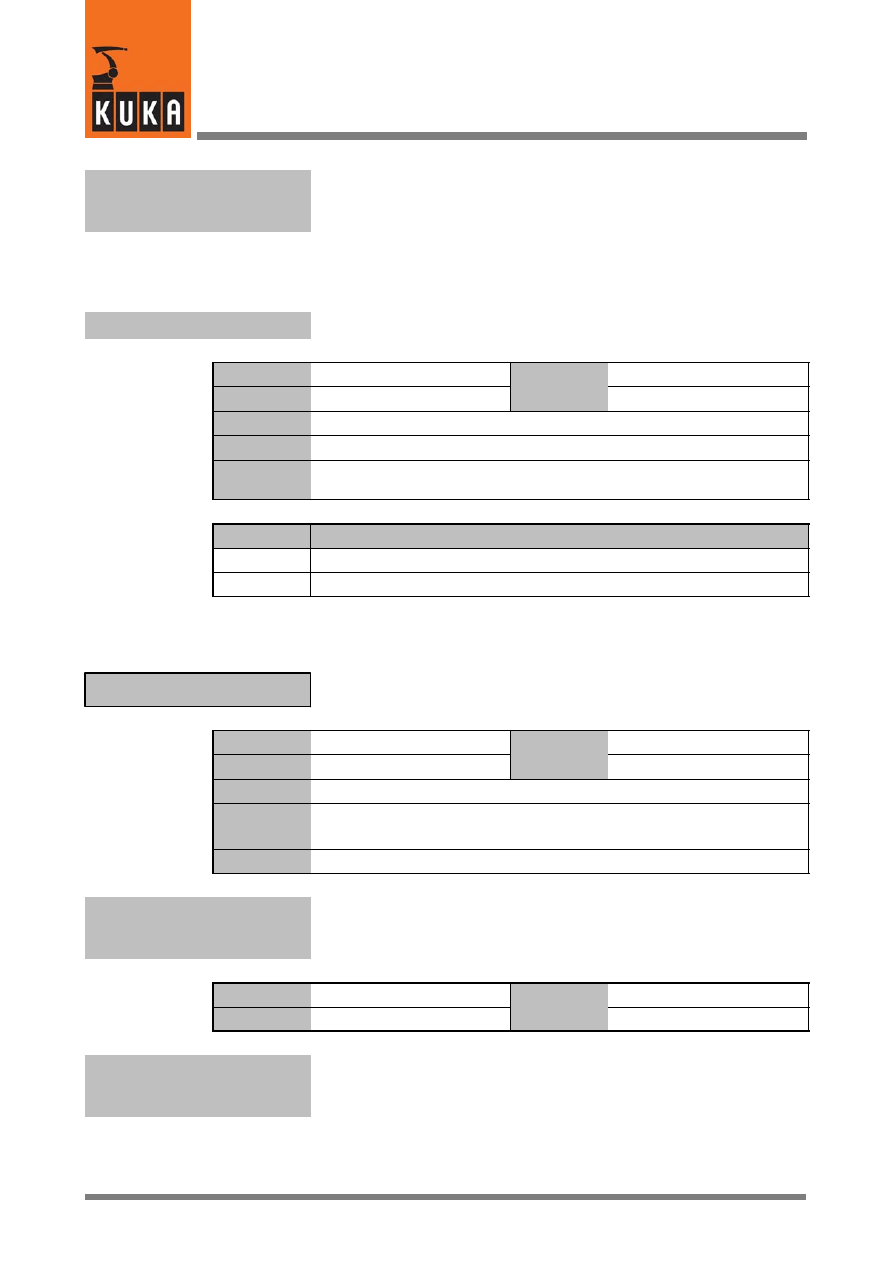

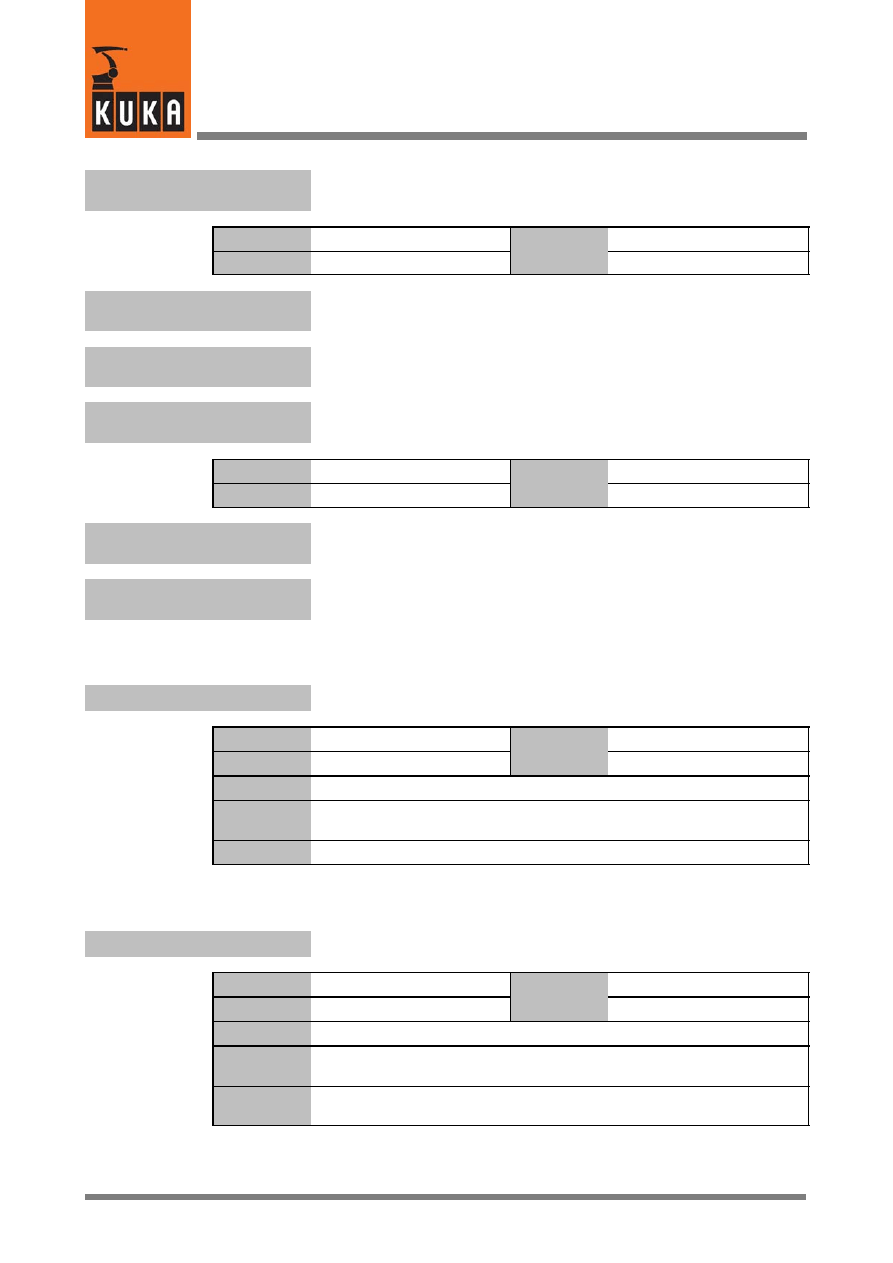

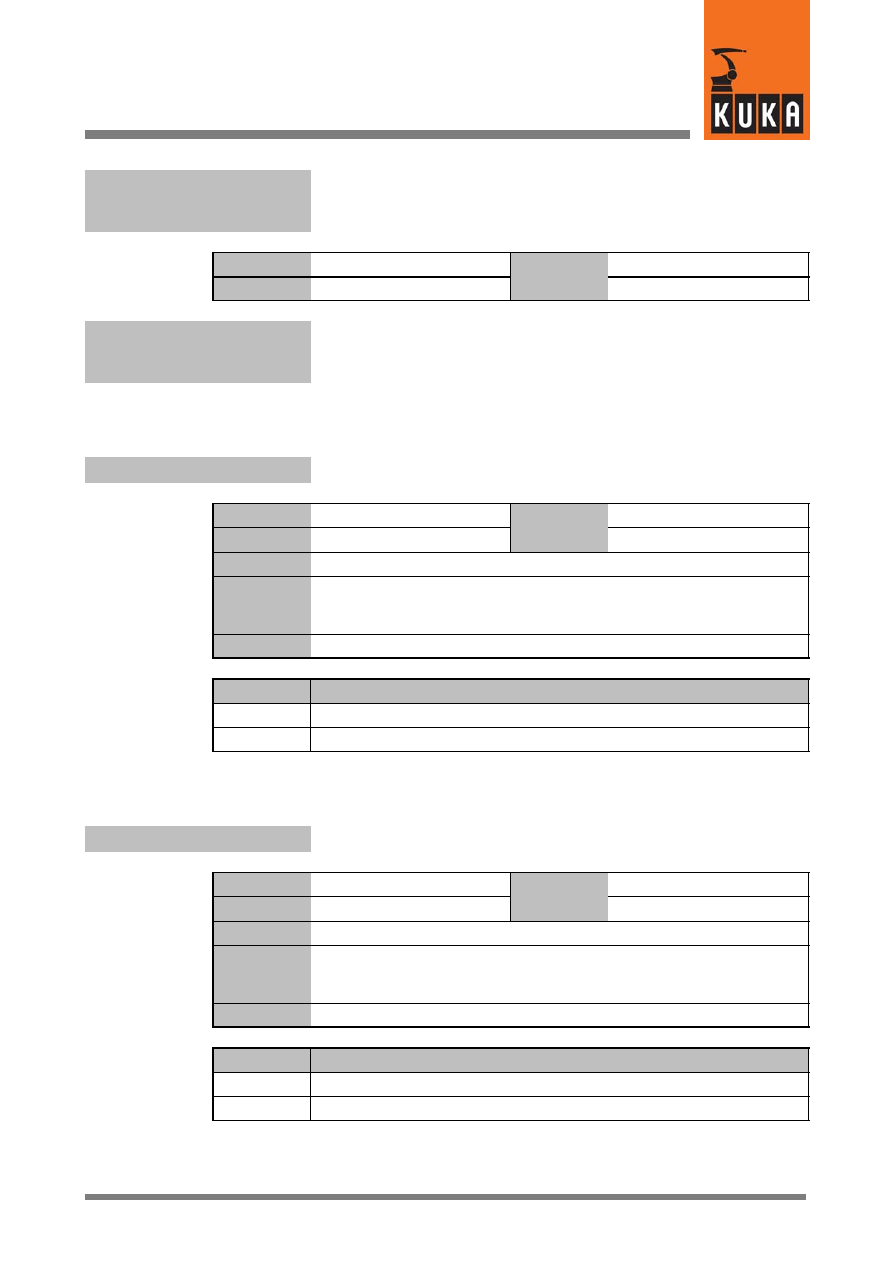

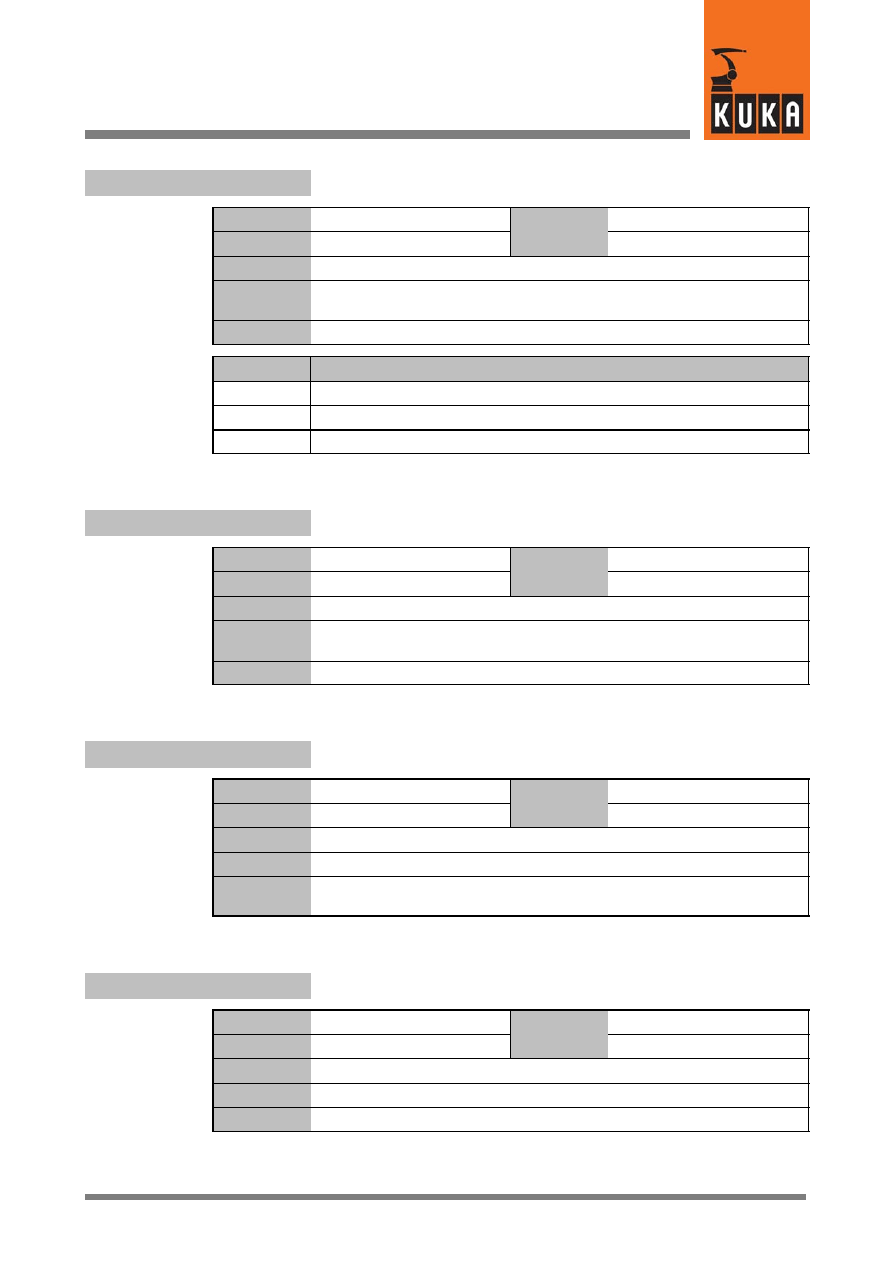

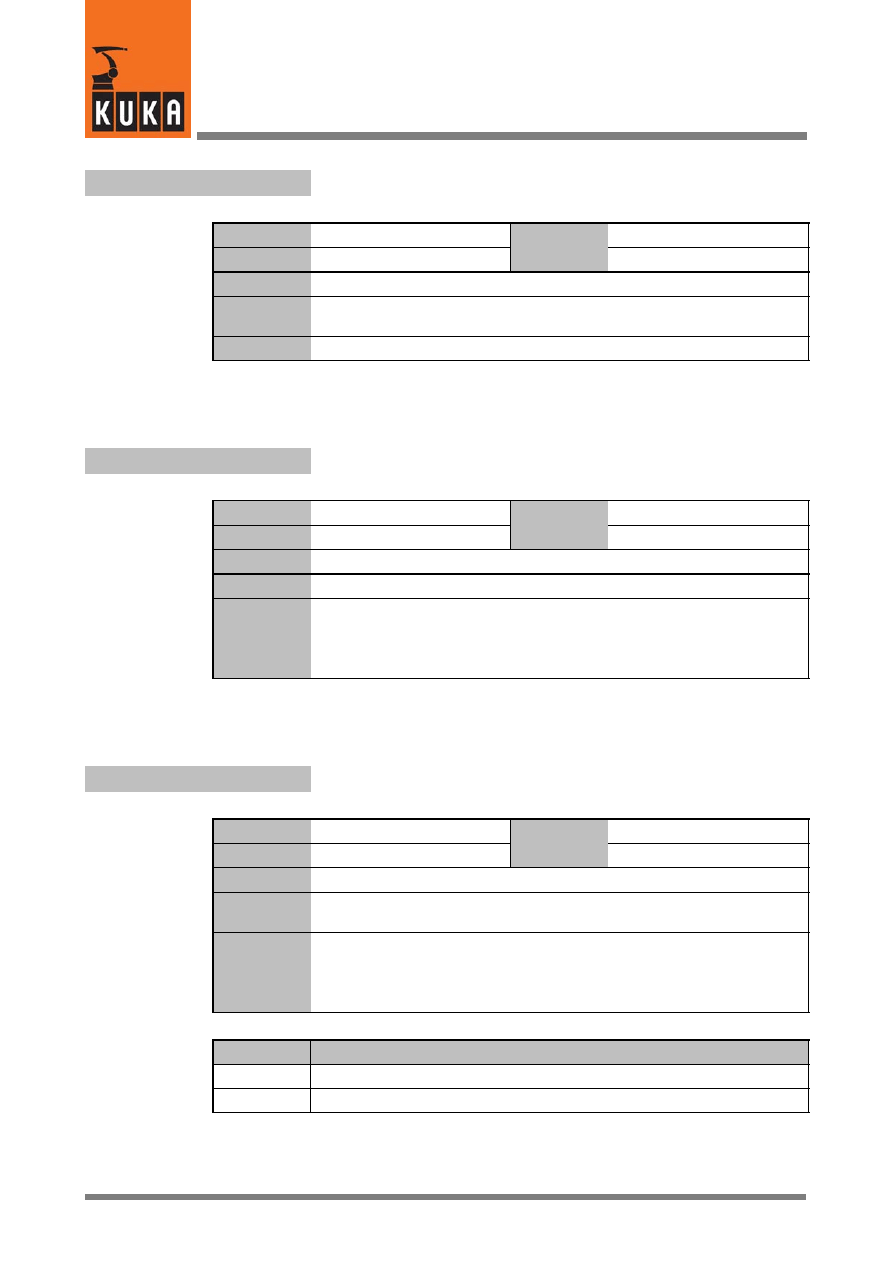

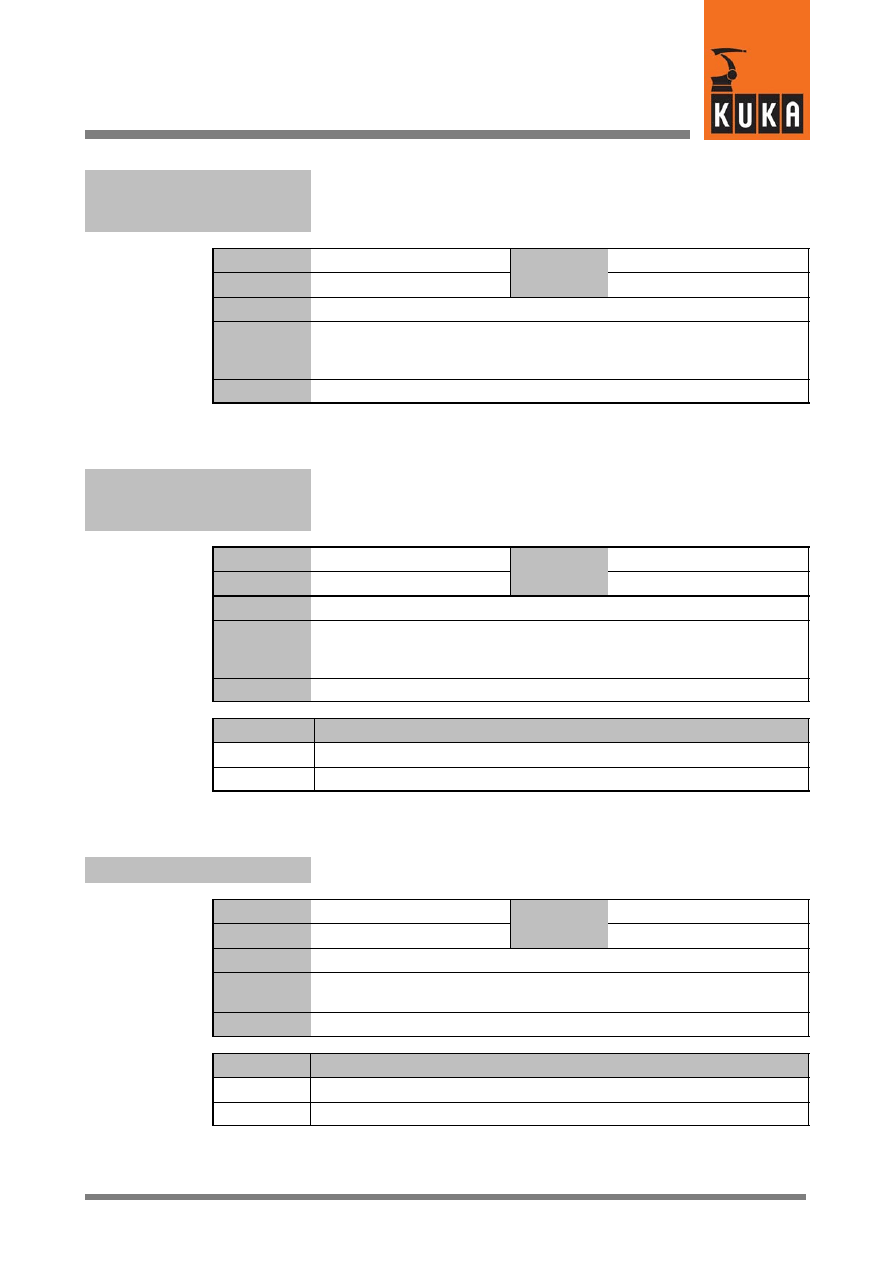

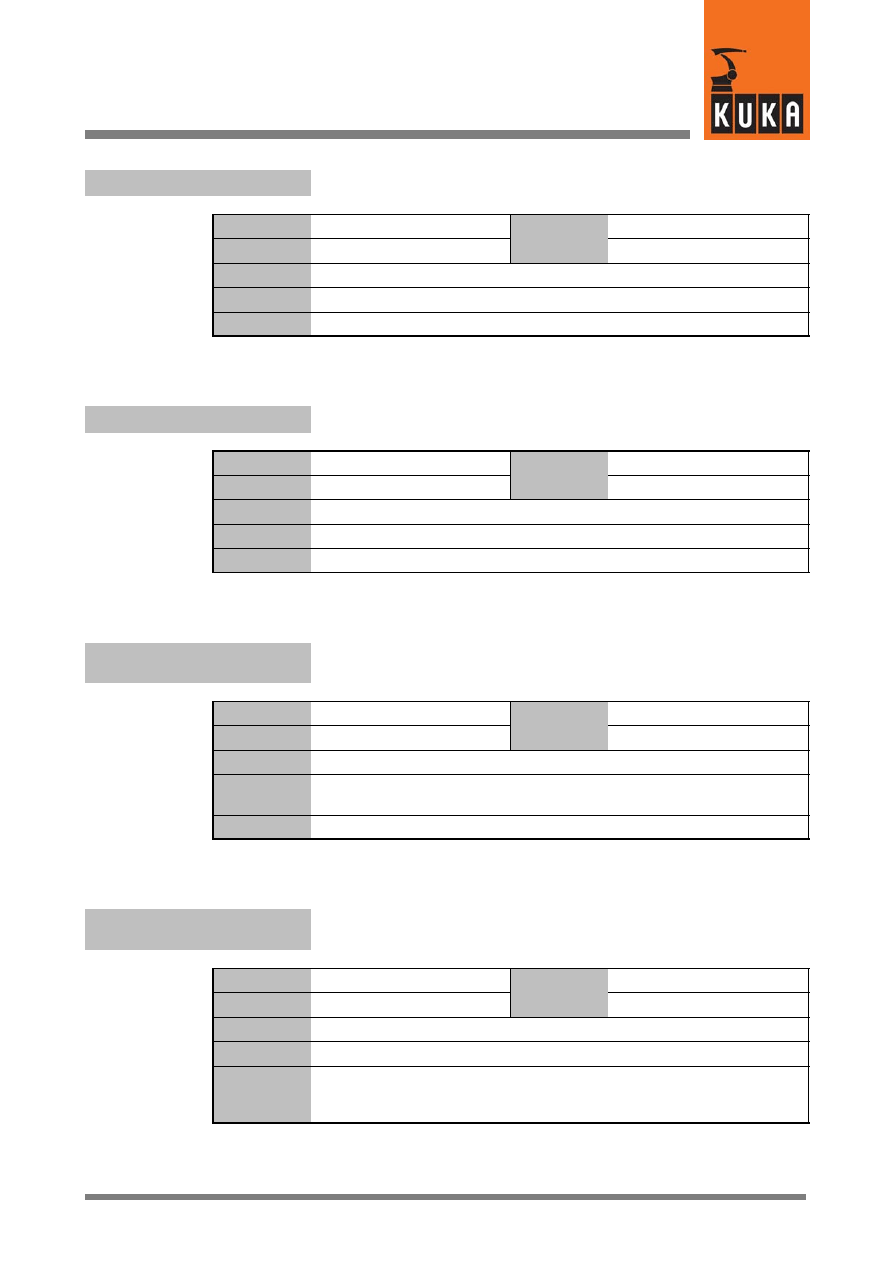

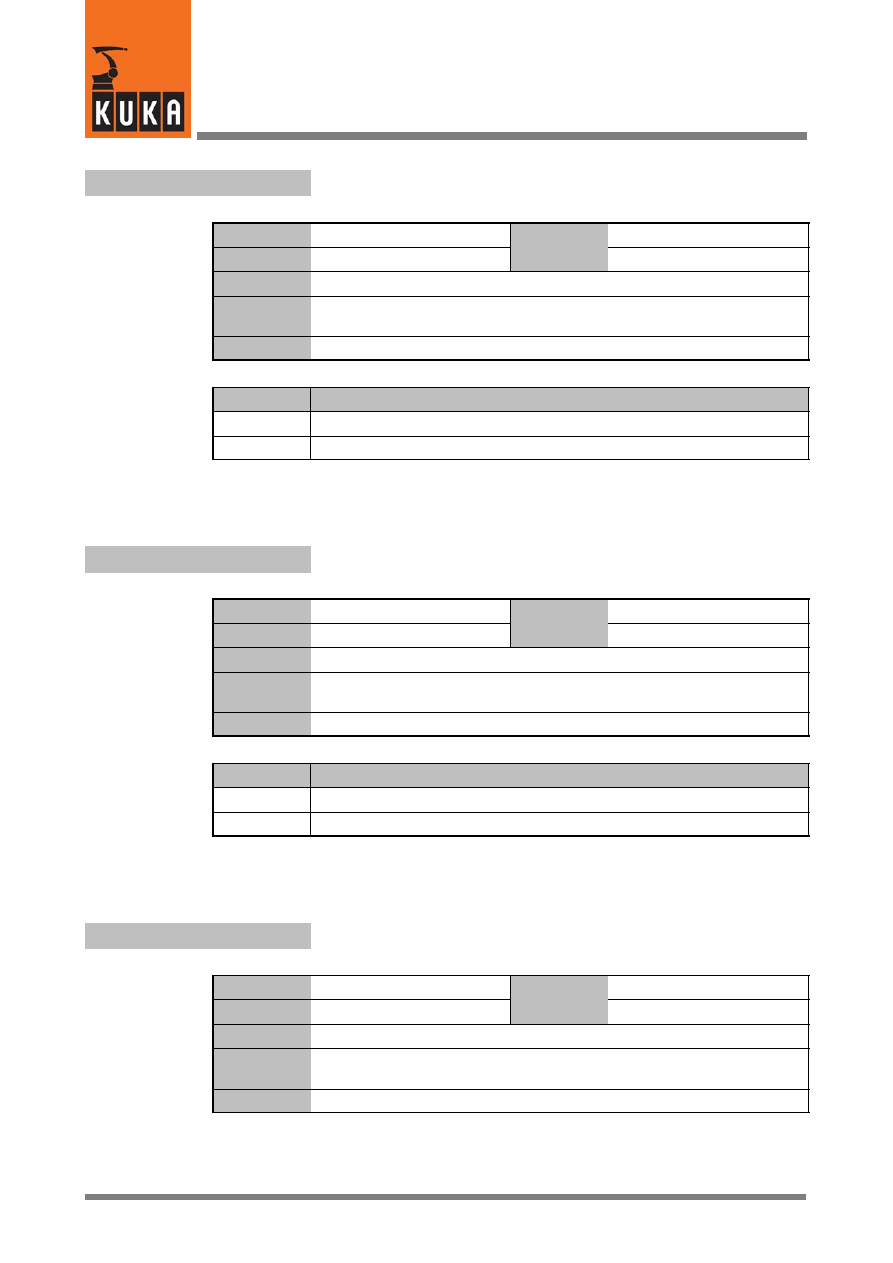

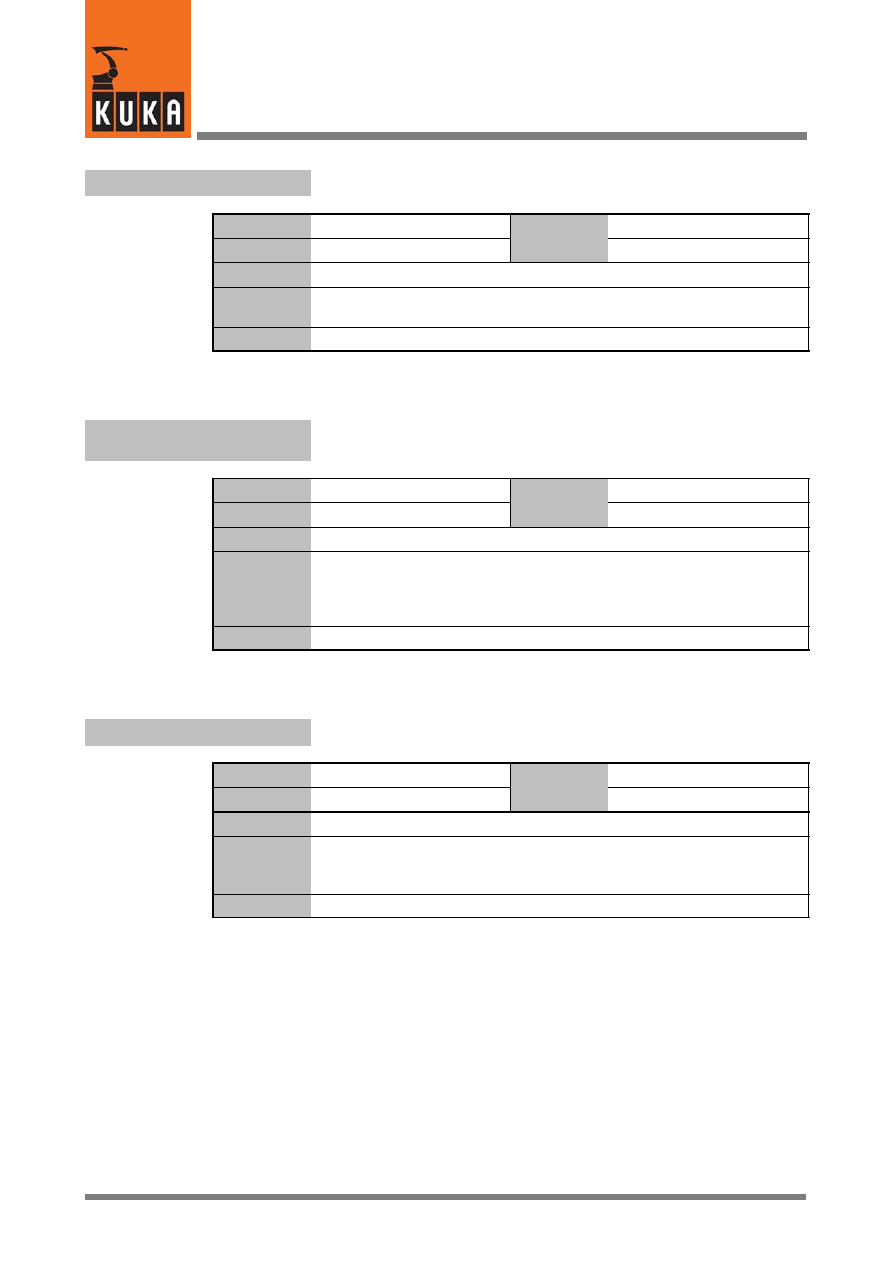

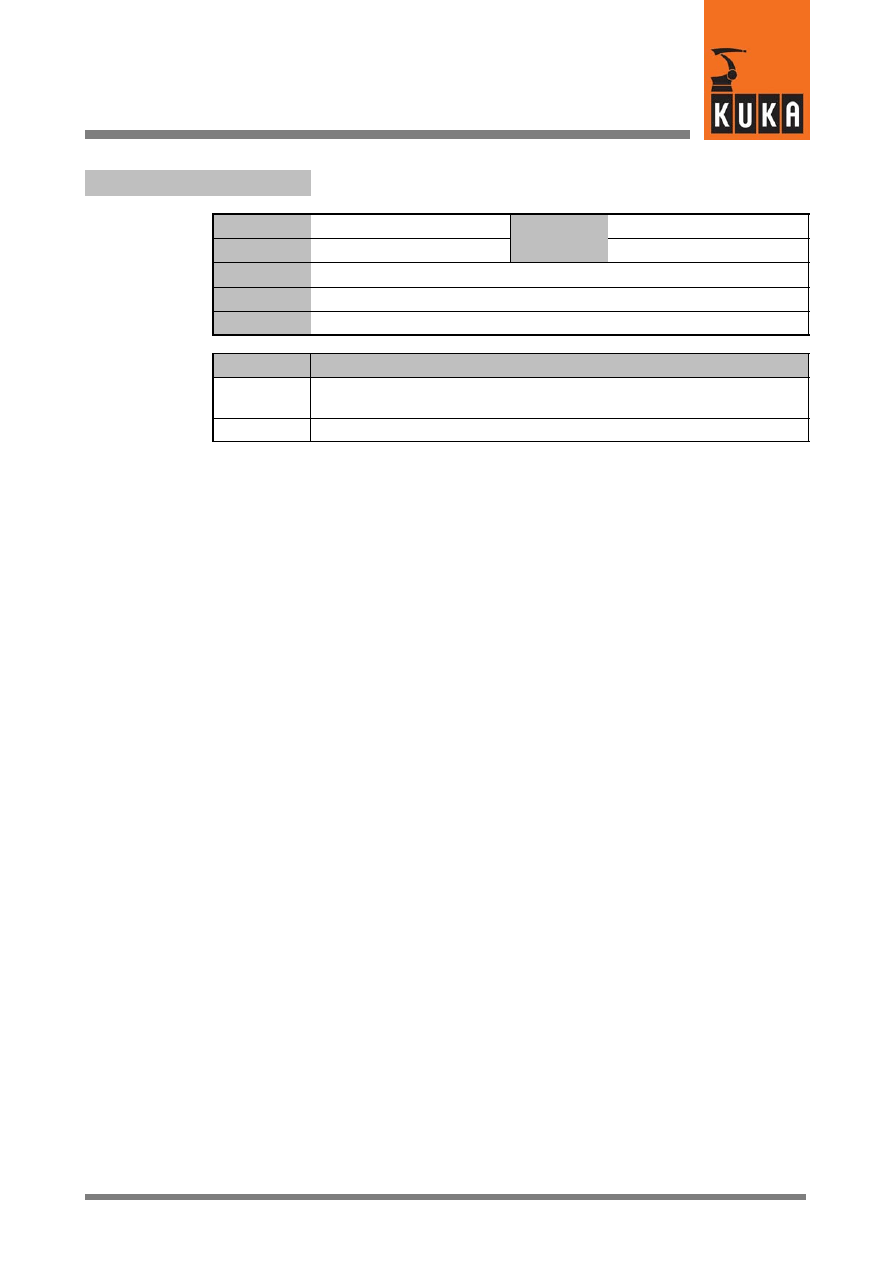

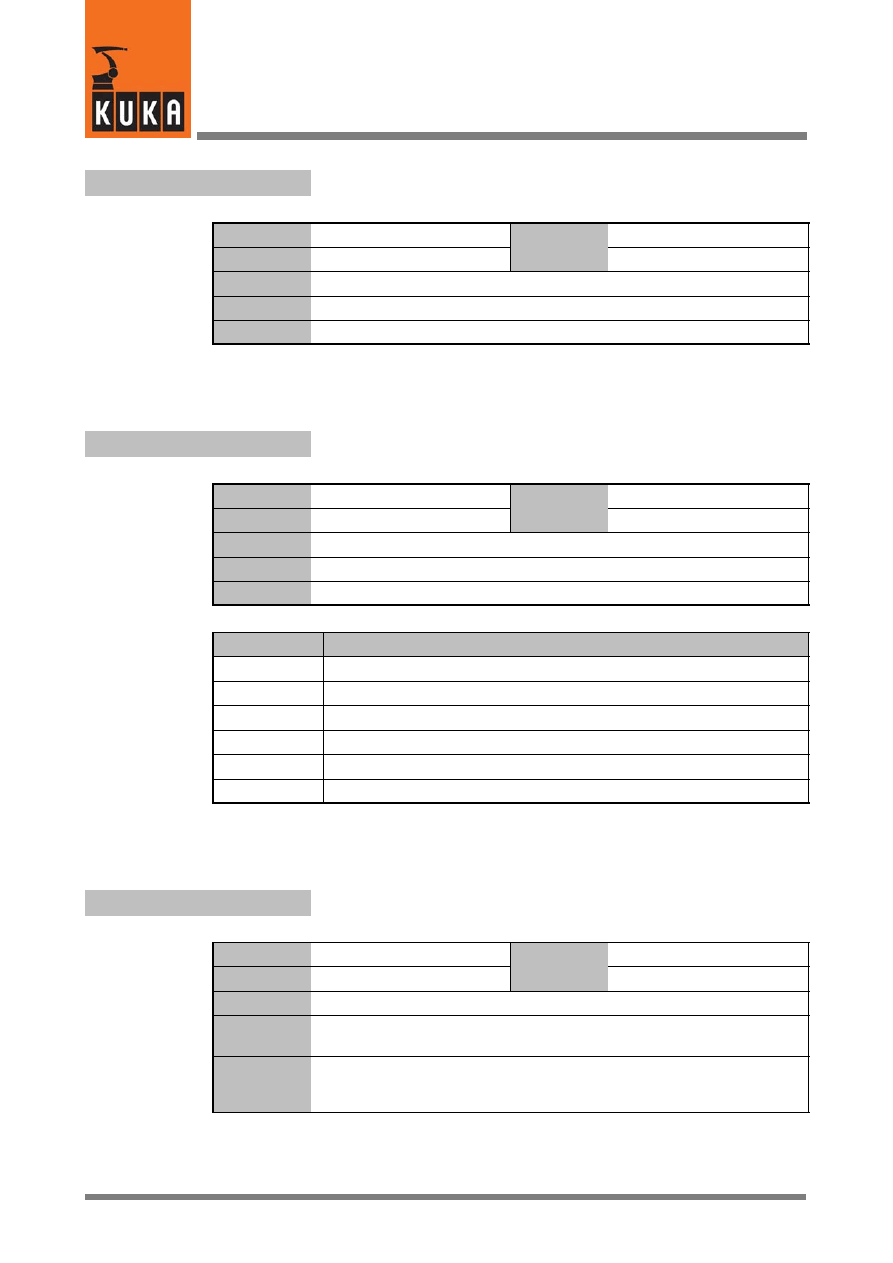

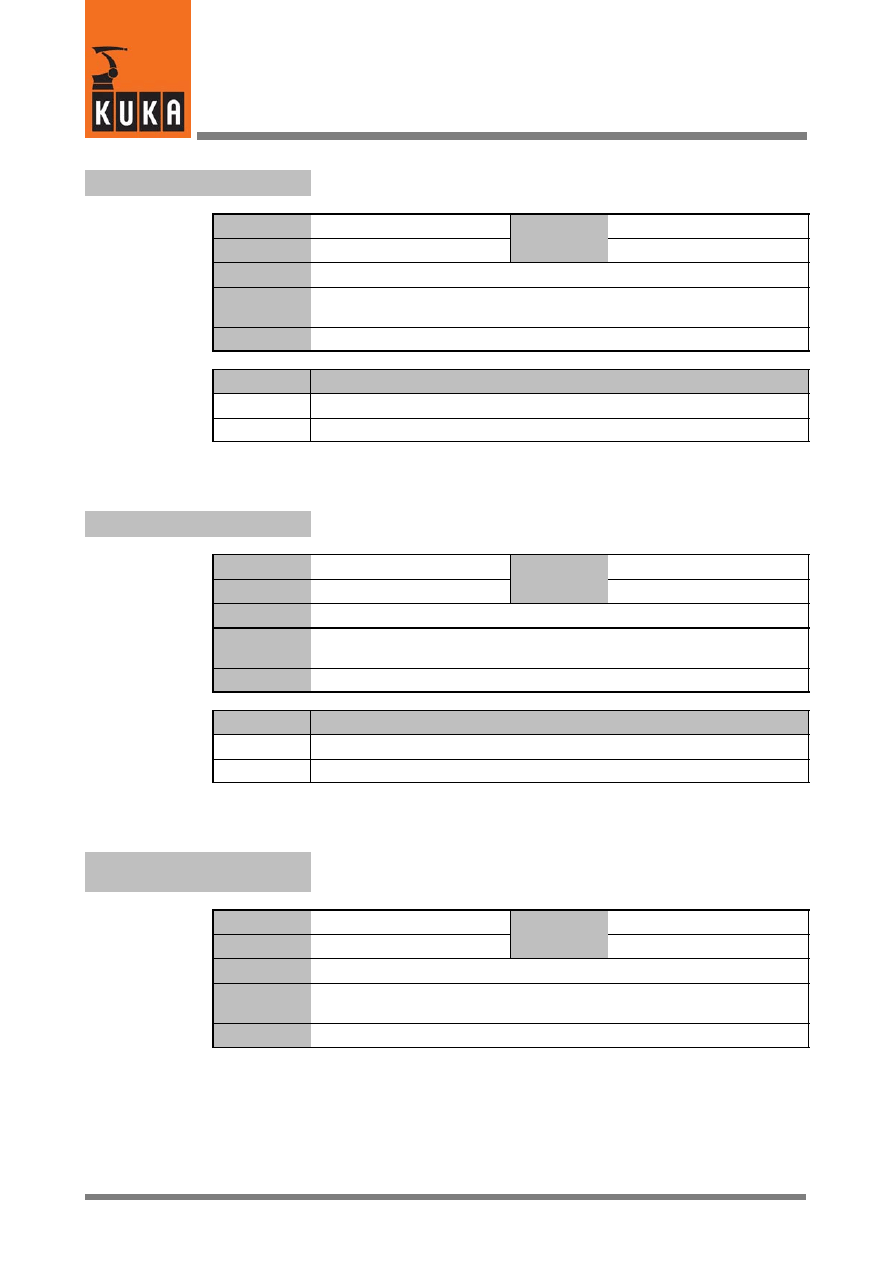

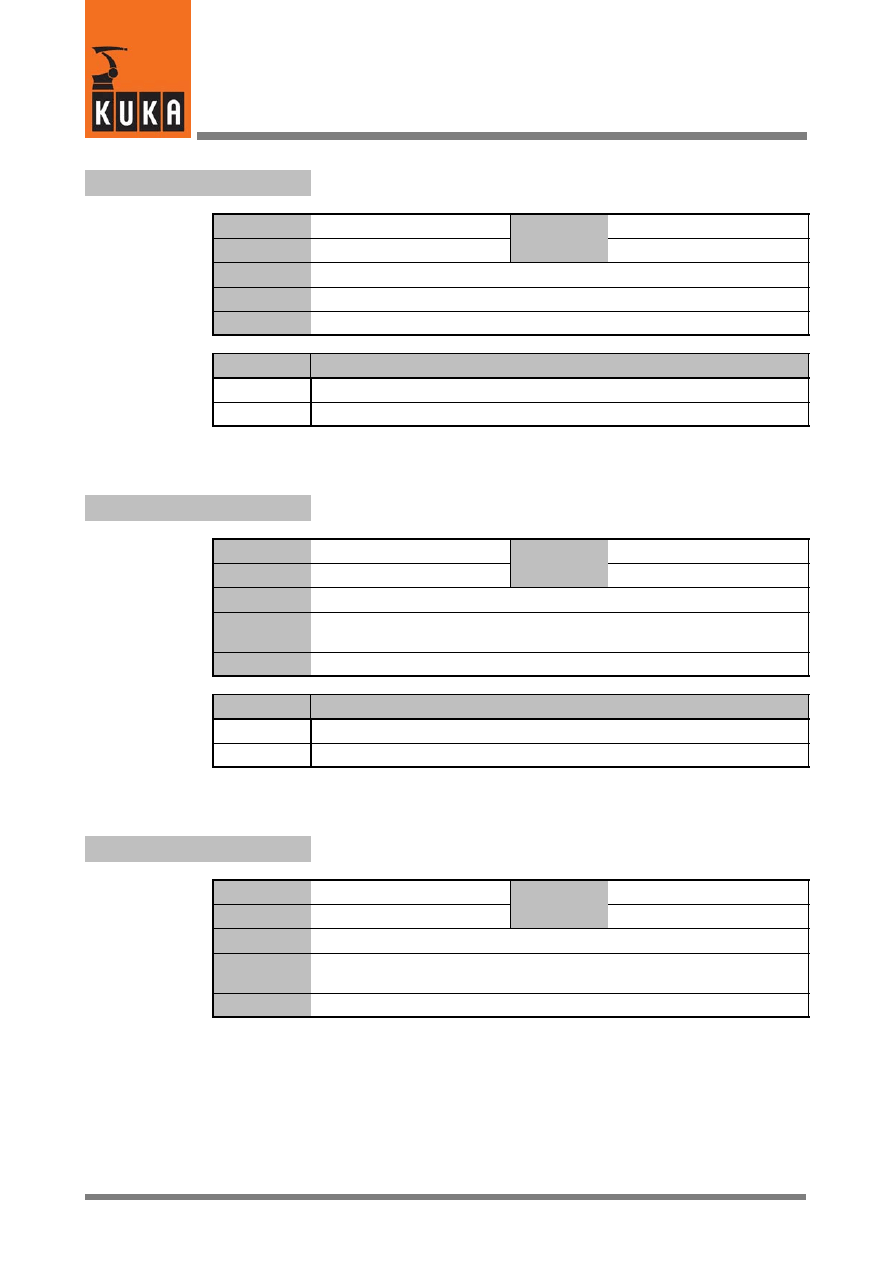

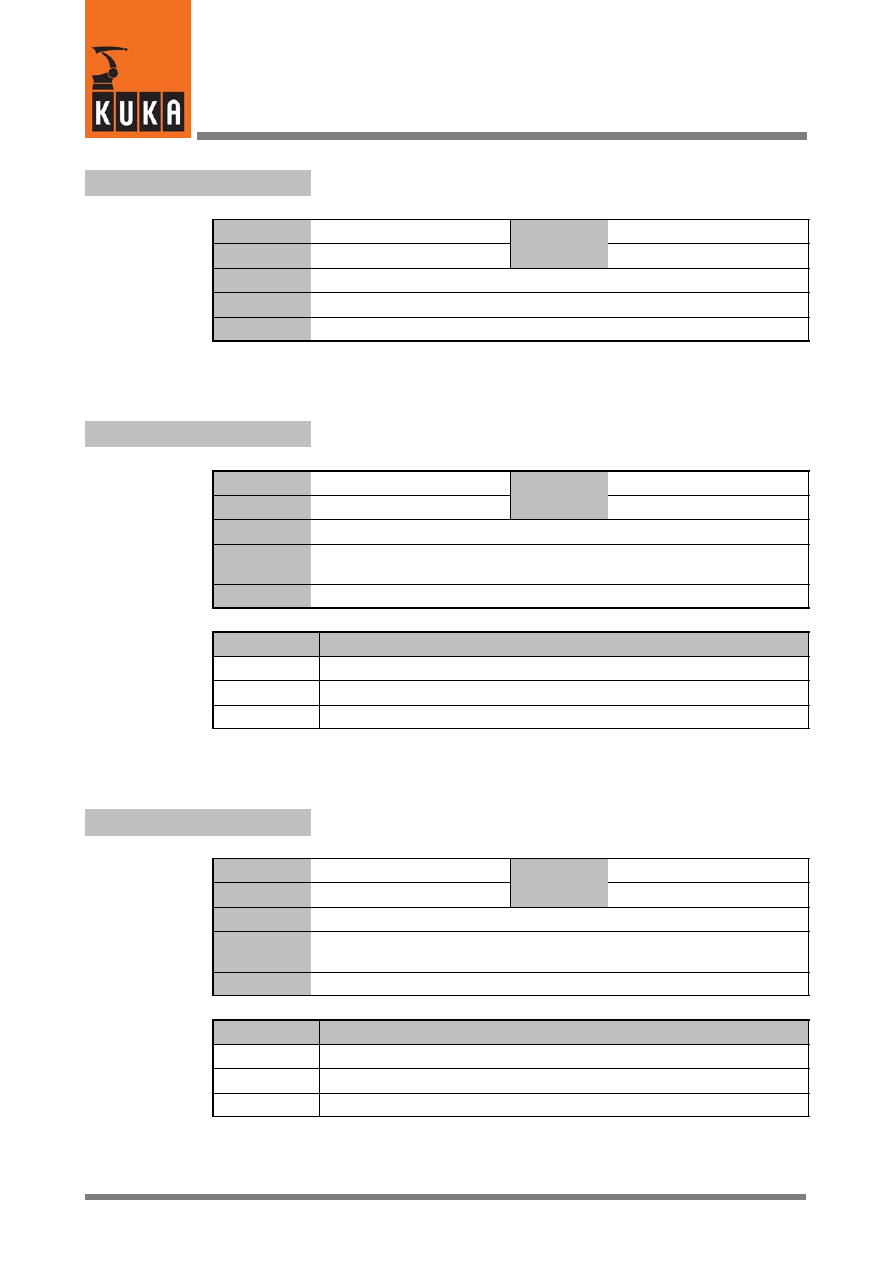

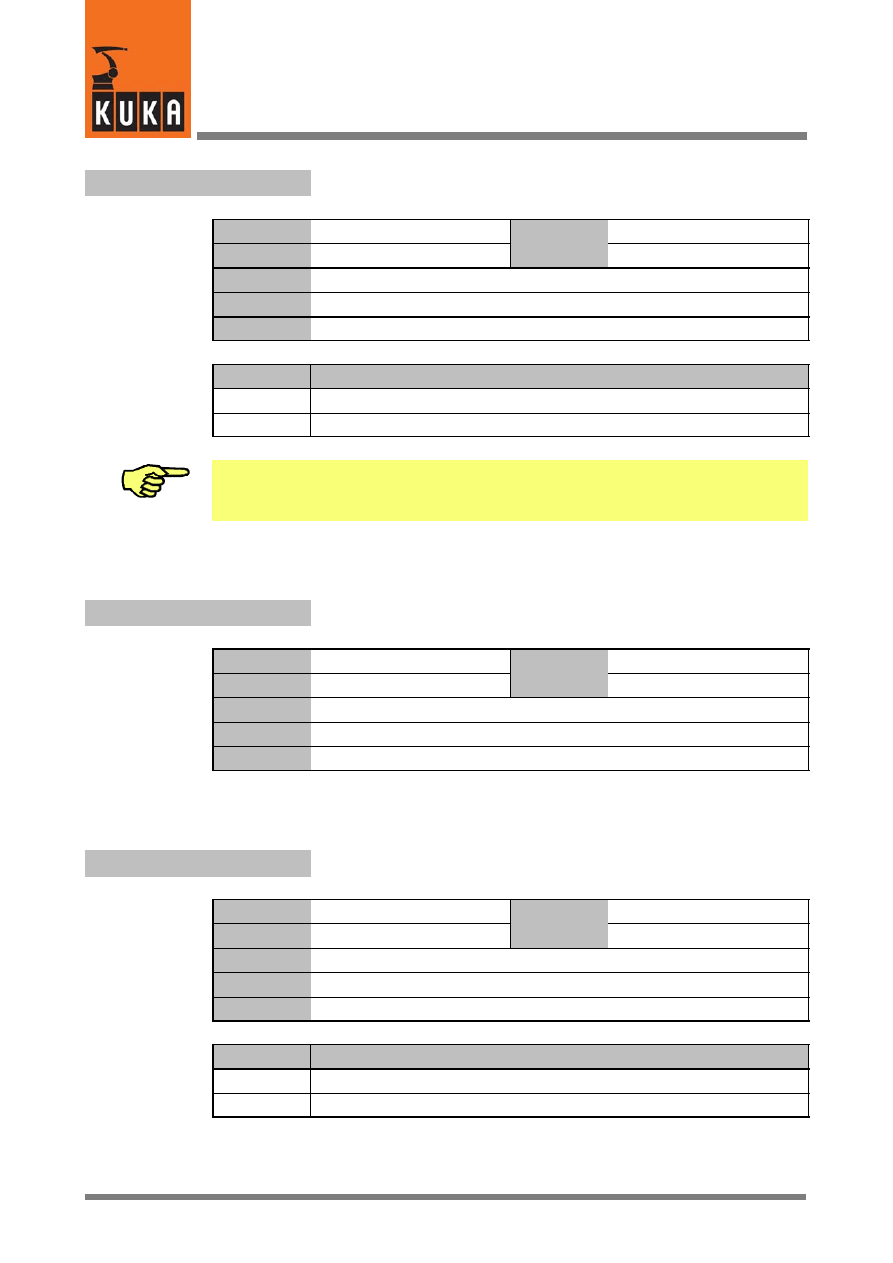

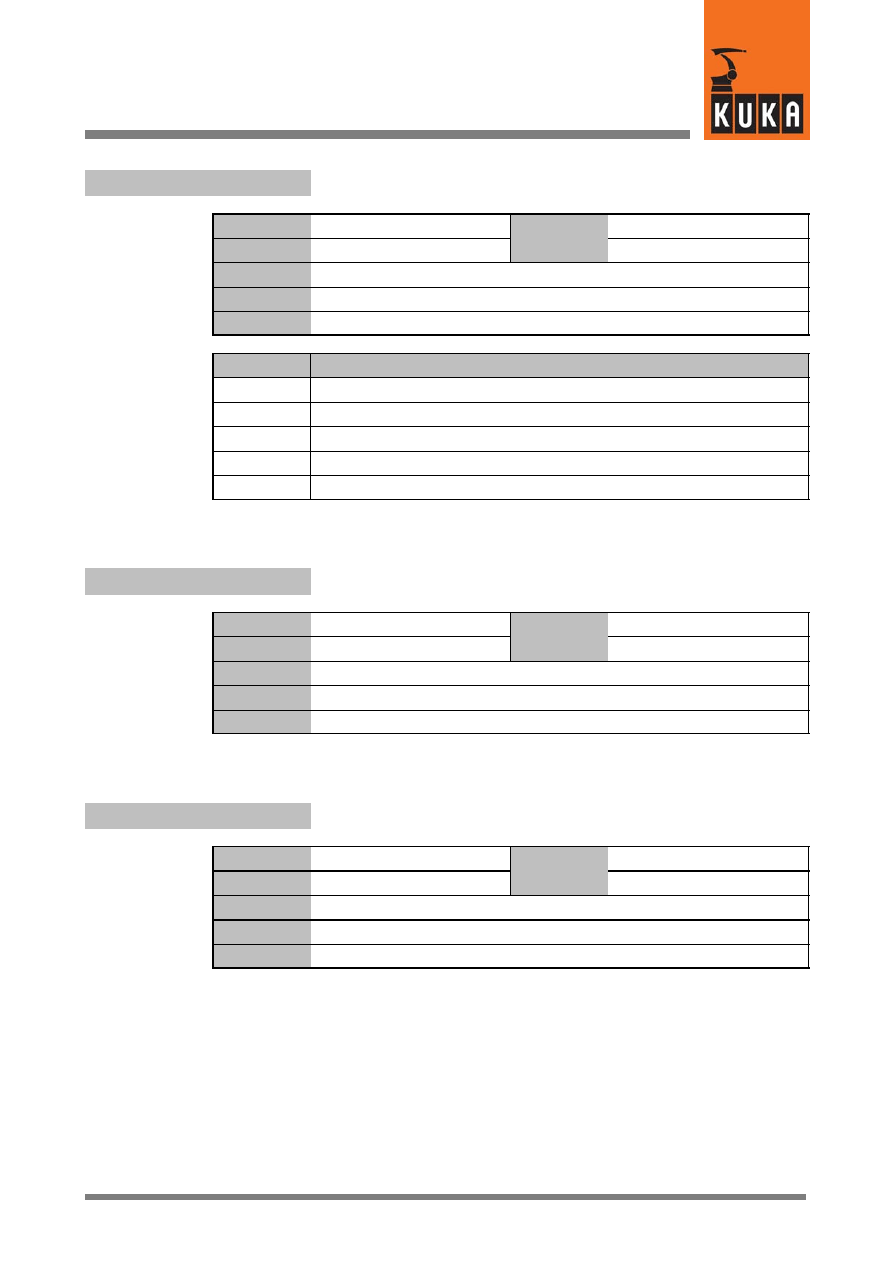

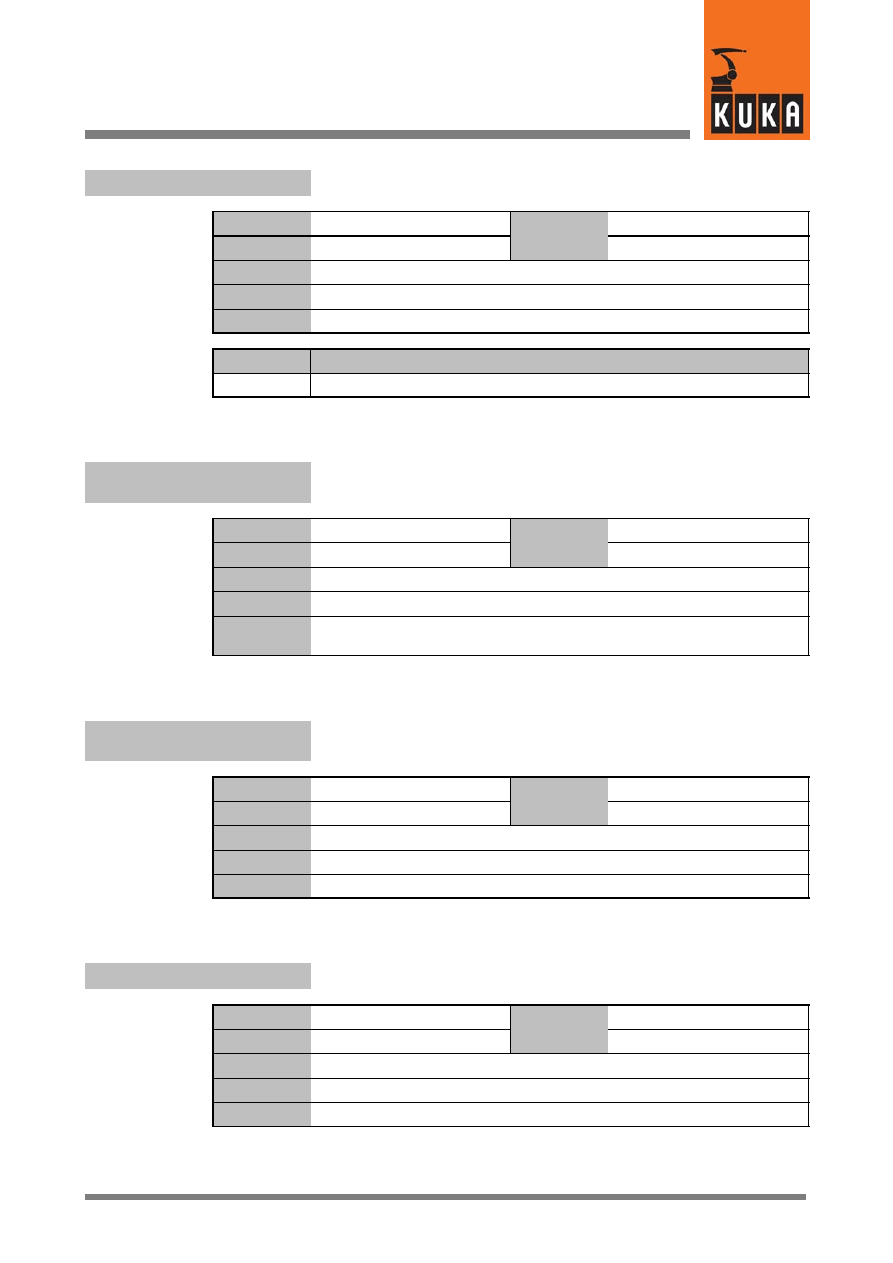

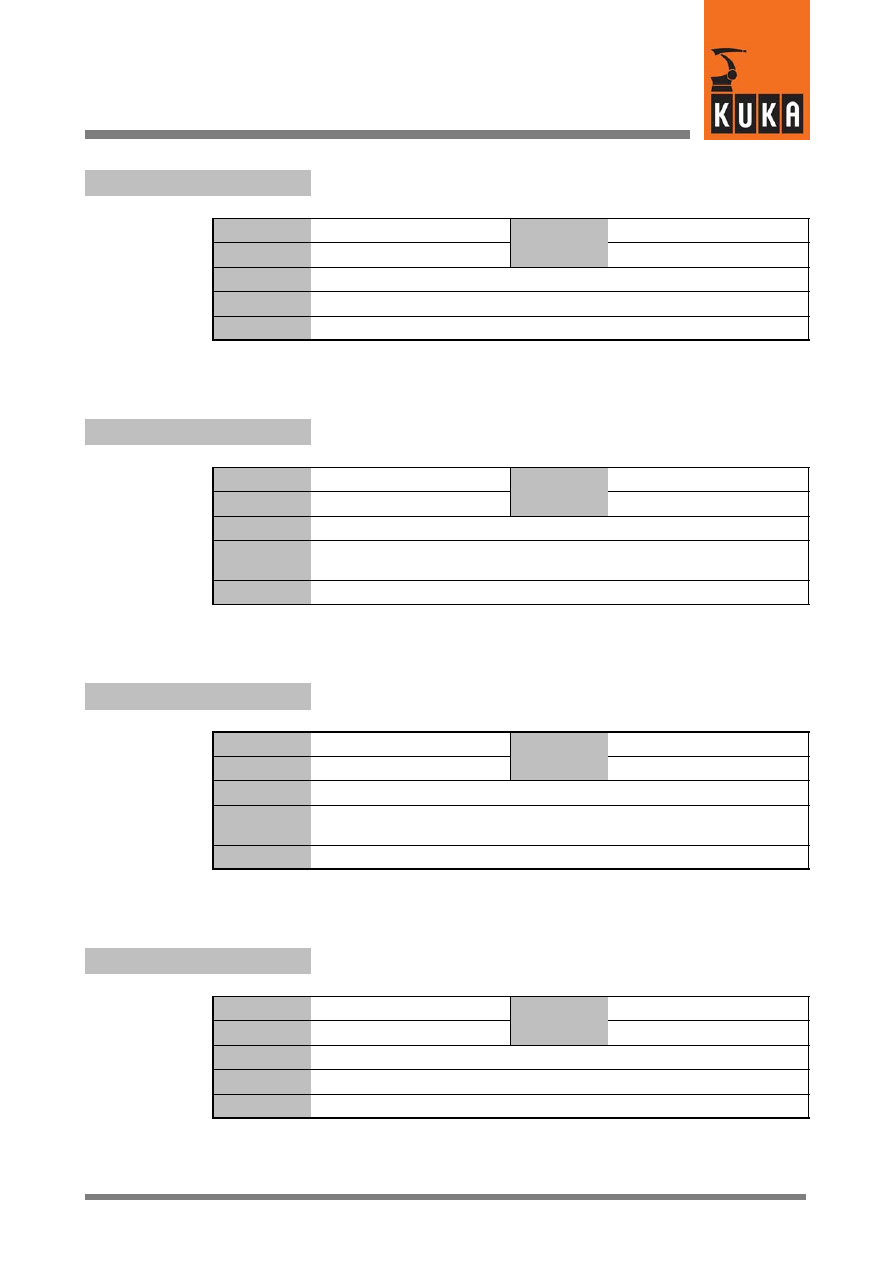

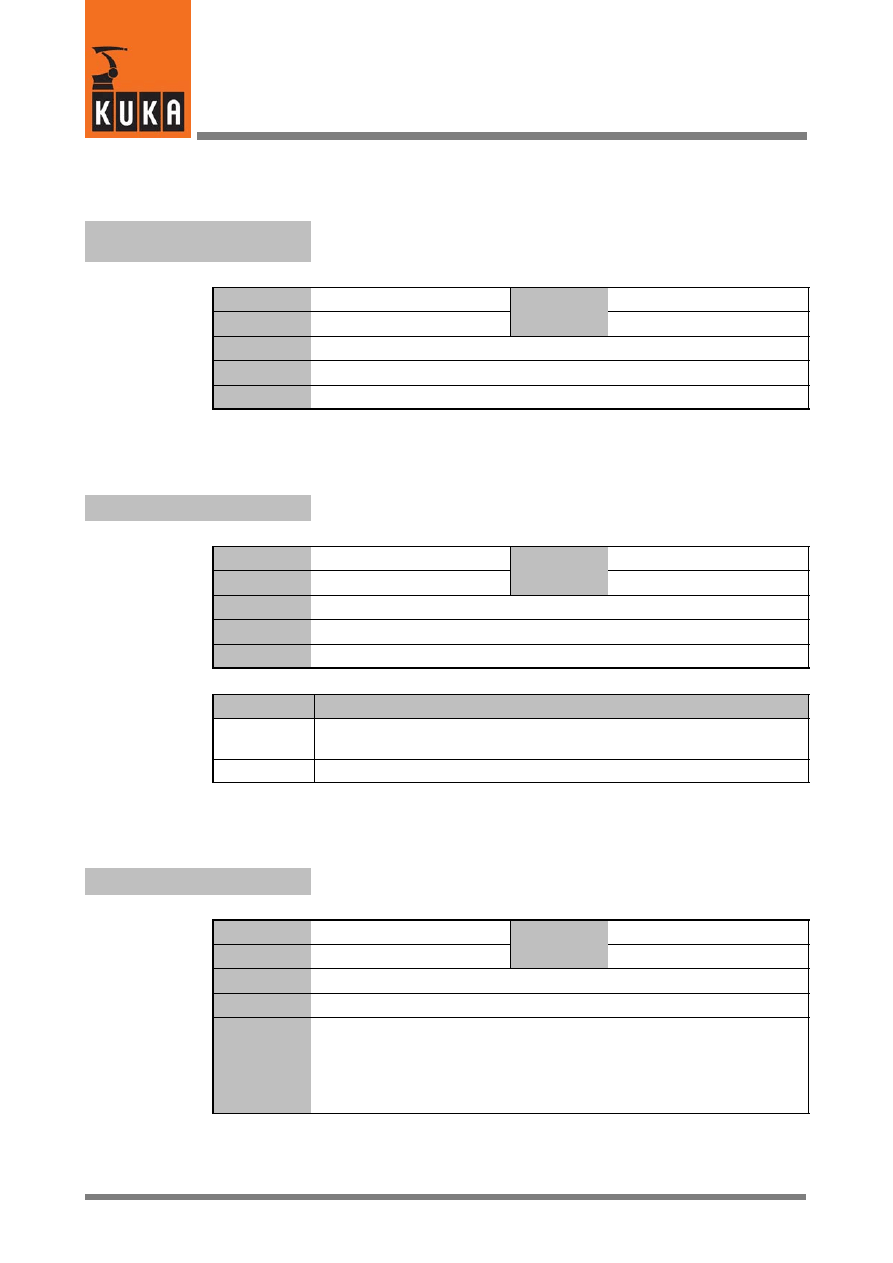

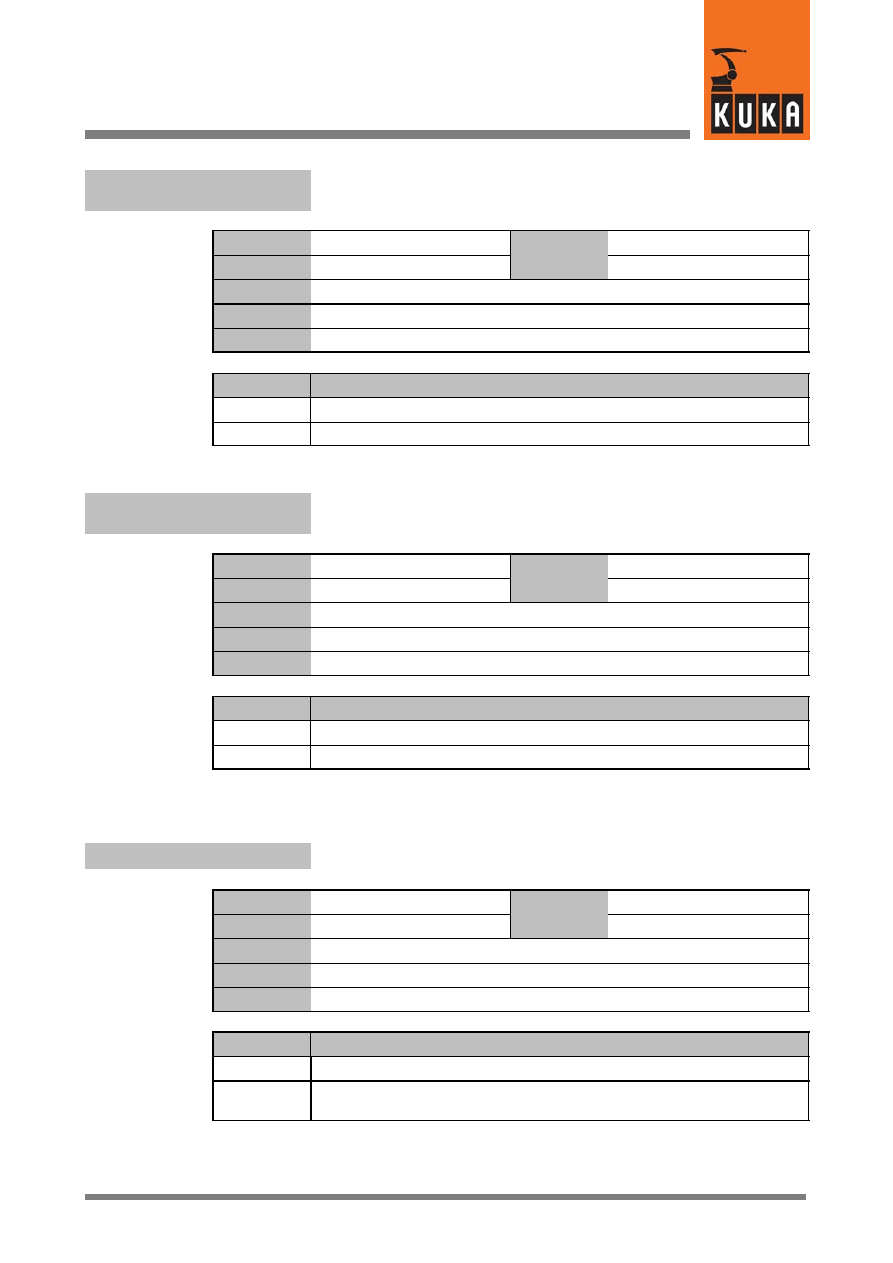

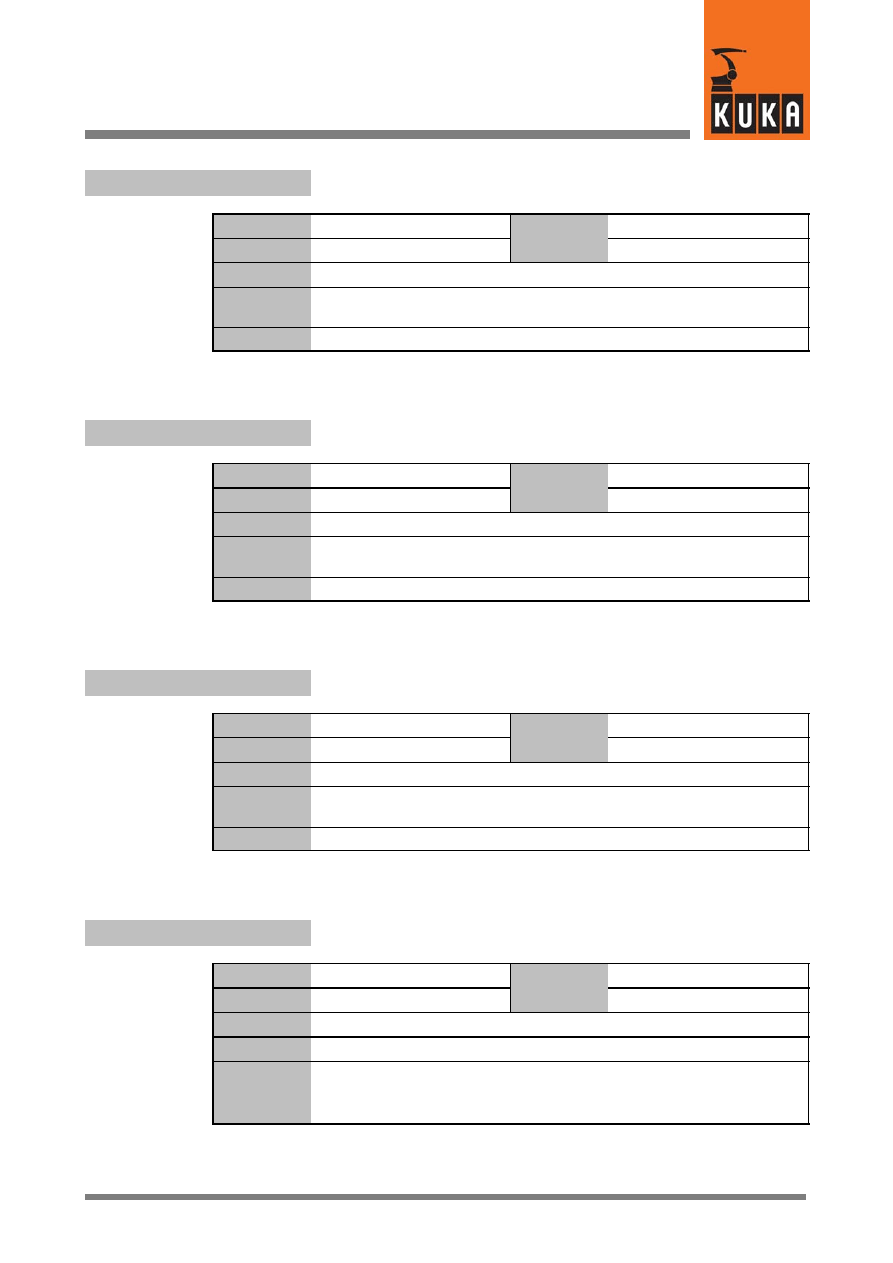

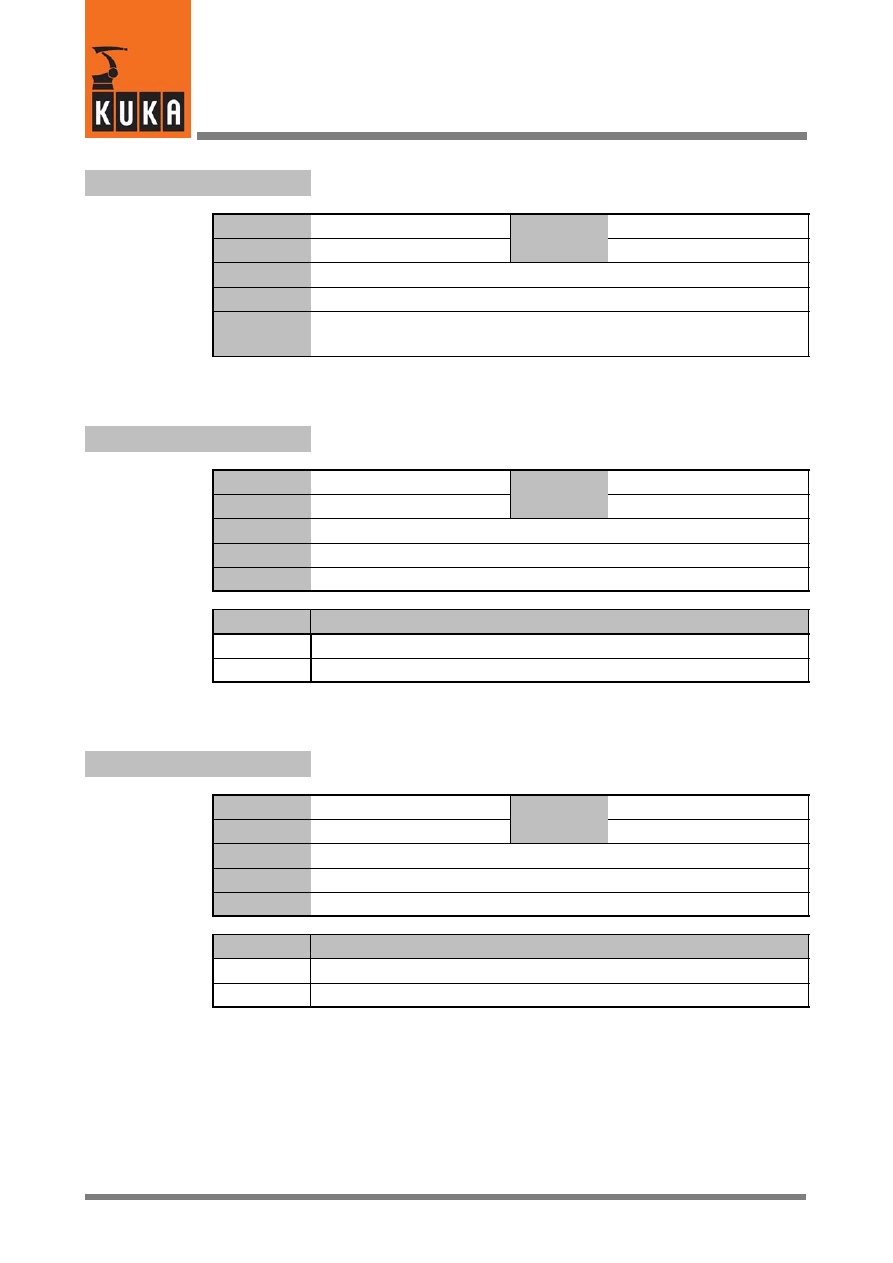

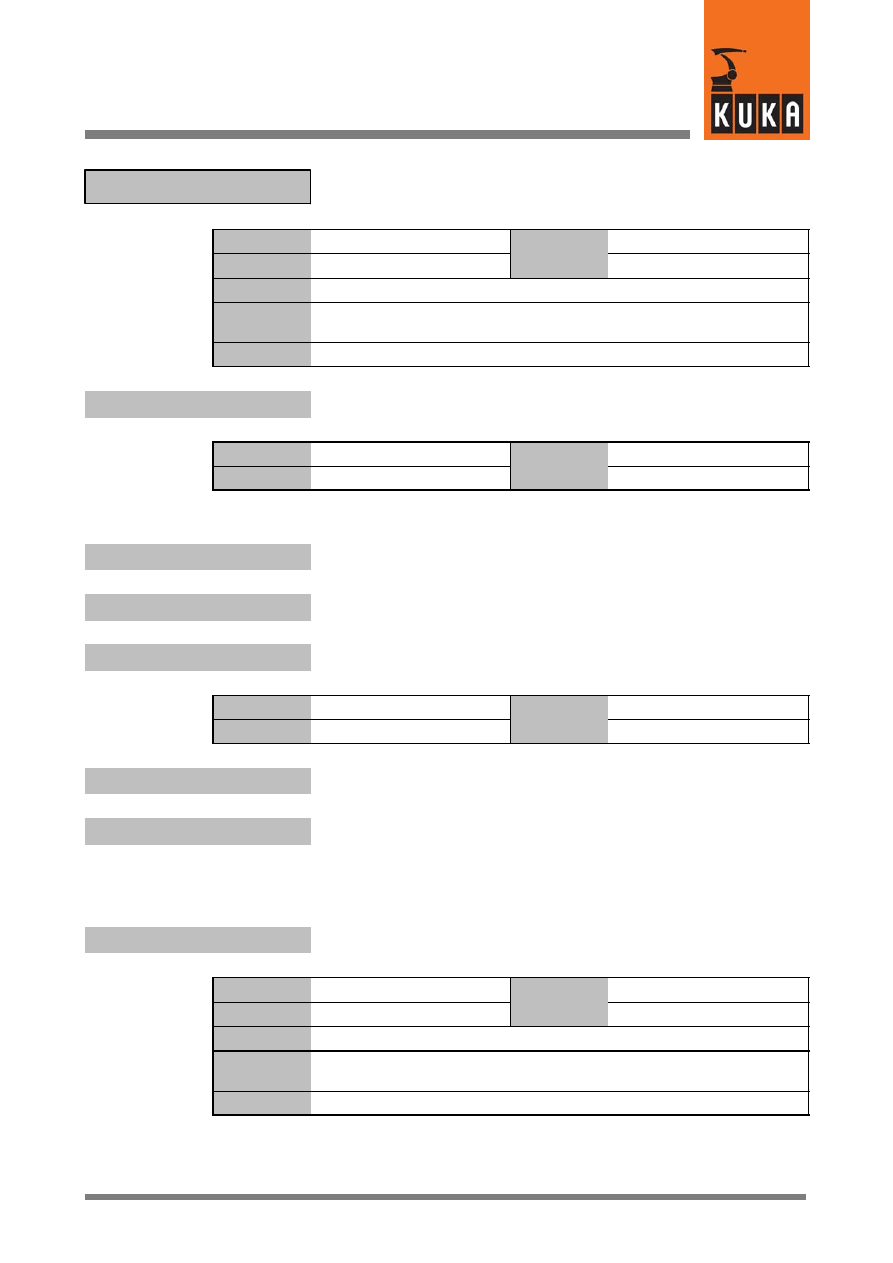

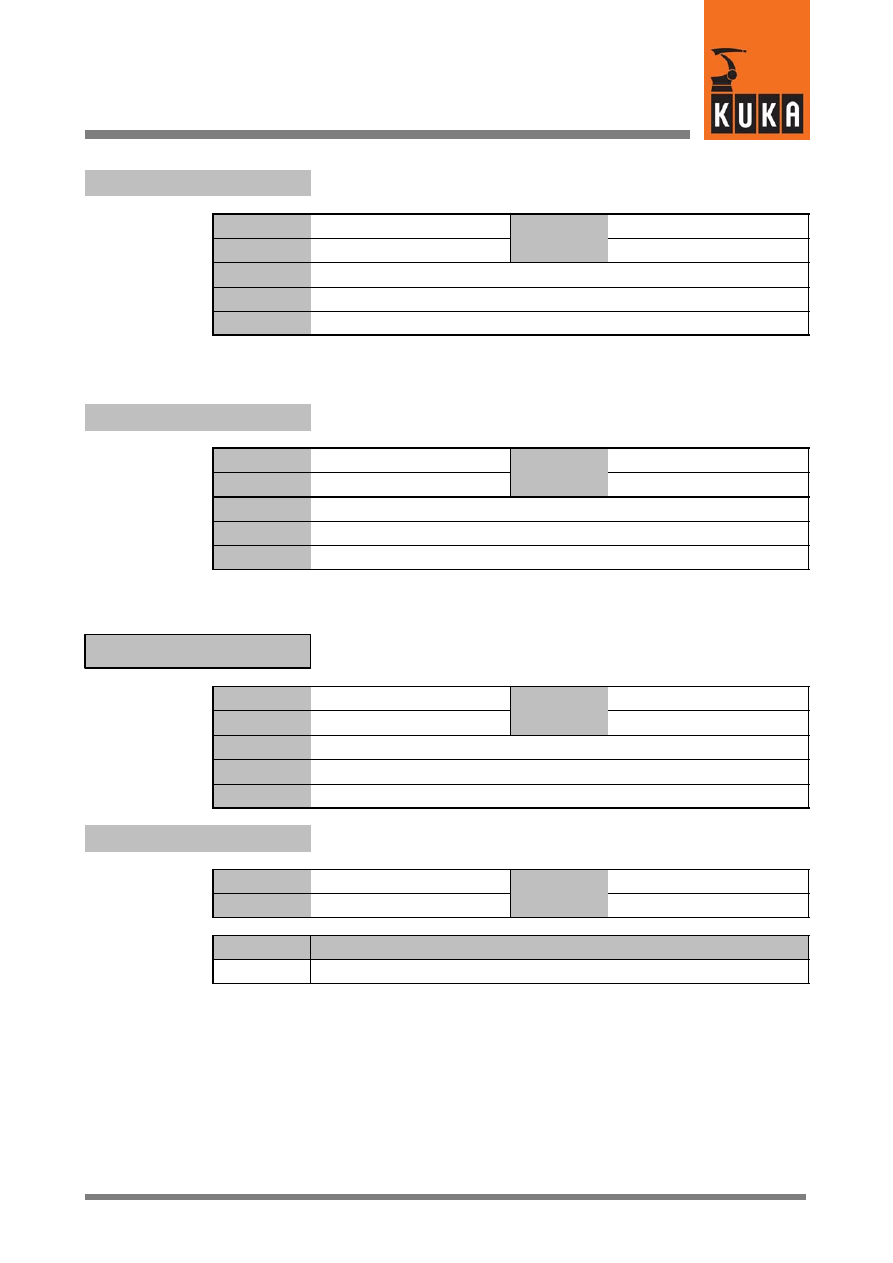

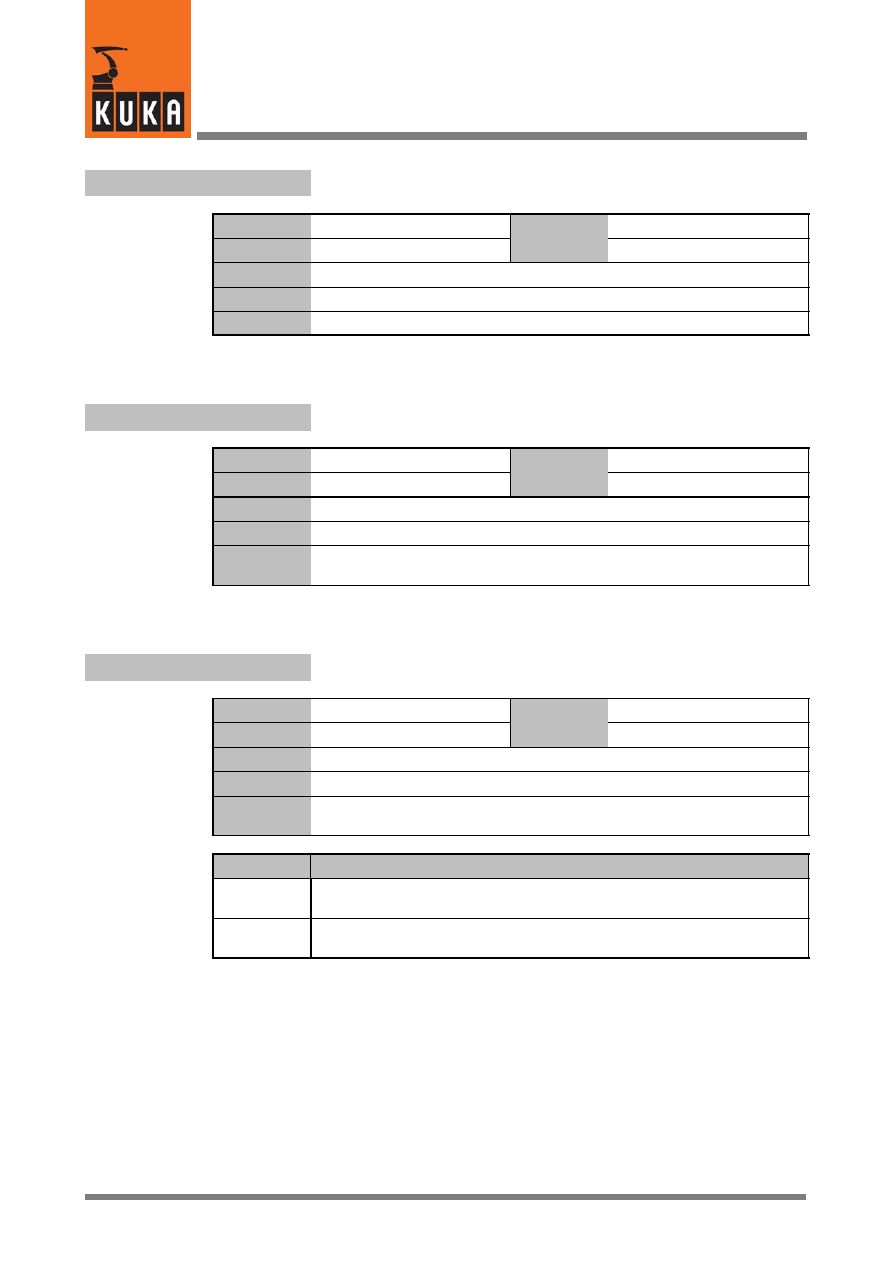

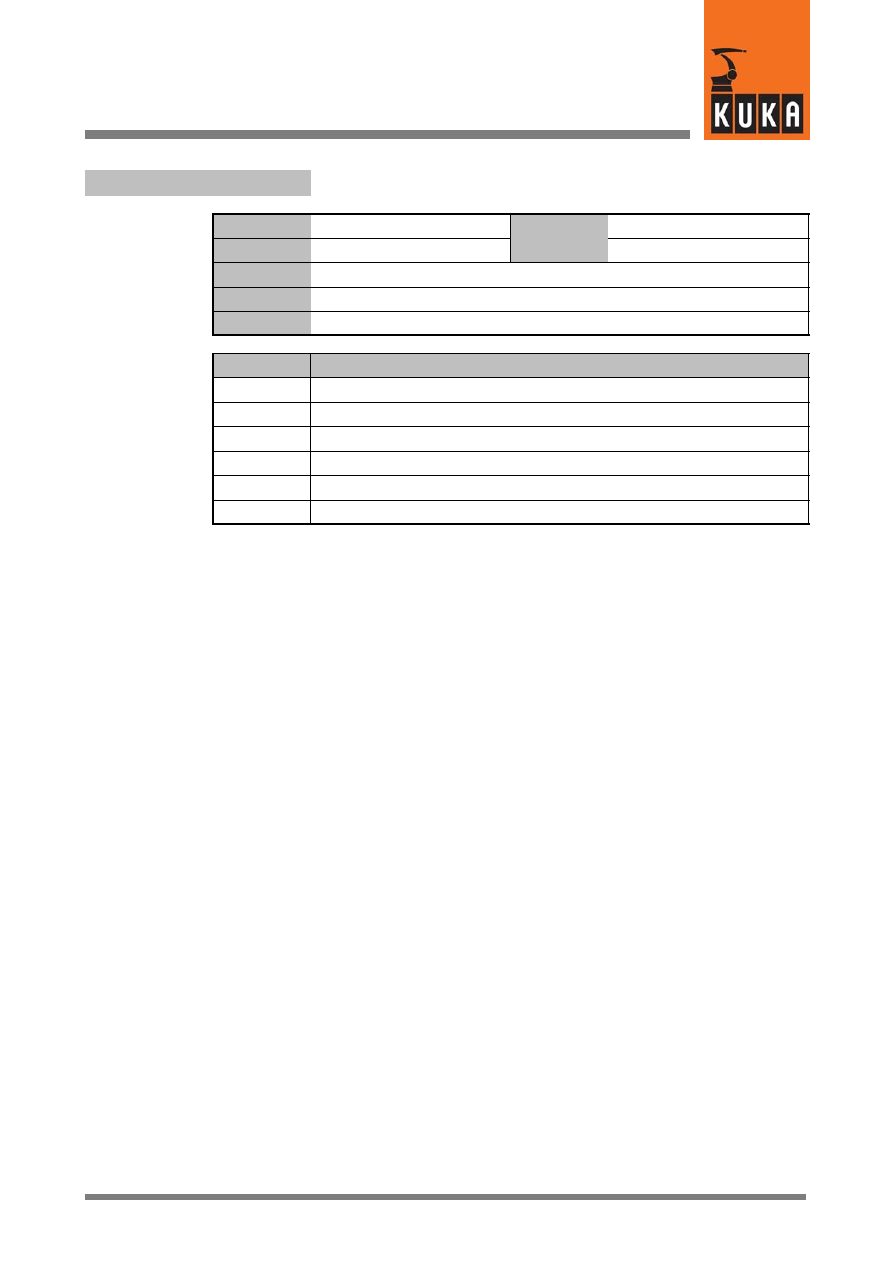

Table entries:

Data type

Real, Integer, Boolean, Character, Structure, Signal declaration, Enum,

Frame, Array

Unit

ms, mm, m/s

2

, s, °, %, V, A, increments, bits, bit sequence, motion

instructions

In file

KRC\Roboter\KRC \R1\Mada\...

...

\Steu\Mada\...

Original line

Source text

;Comment

Comments

Functional description

Value min.

max.

Minimum and maximum values depending on the specific data type

Option

Options depending on the data type (TRUE, FALSE, 1, 2, etc.)

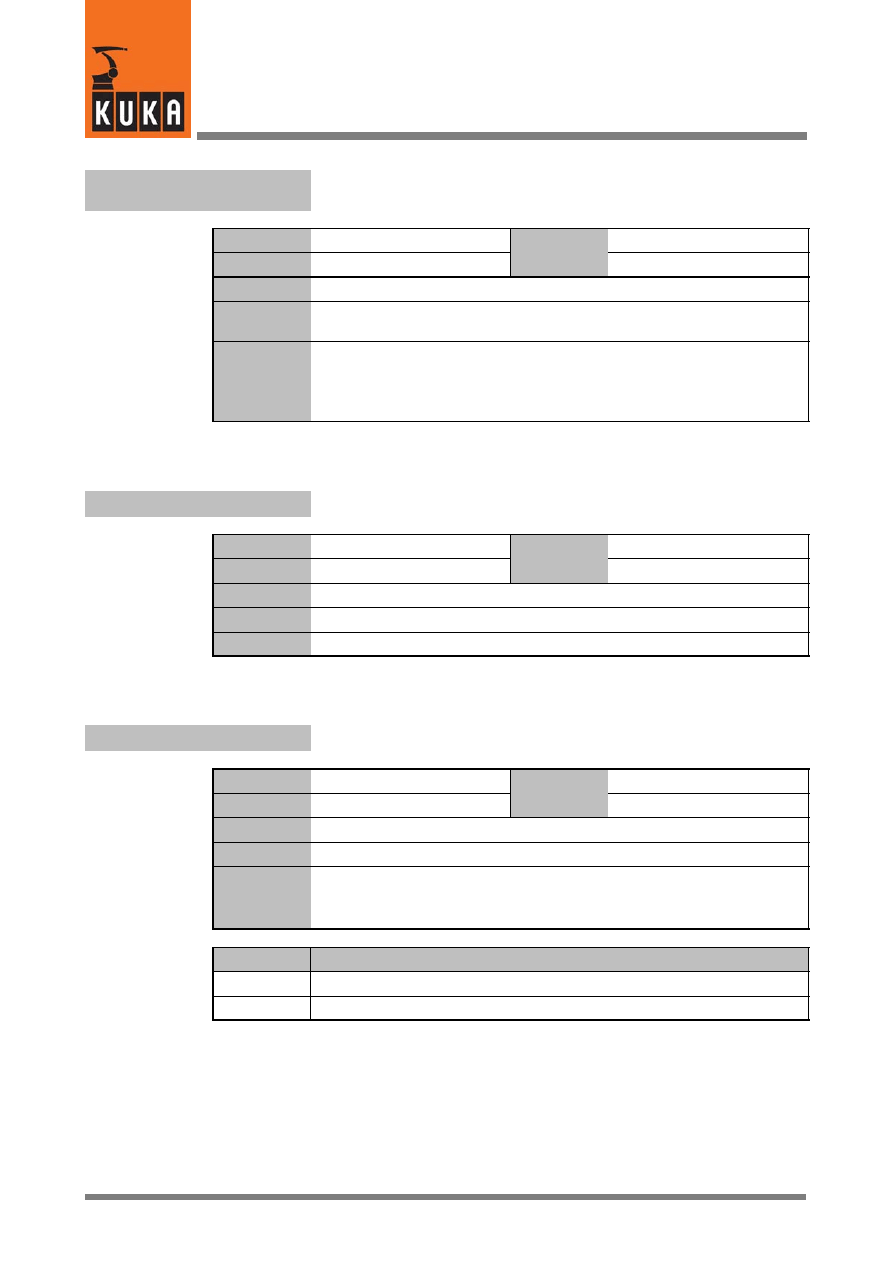

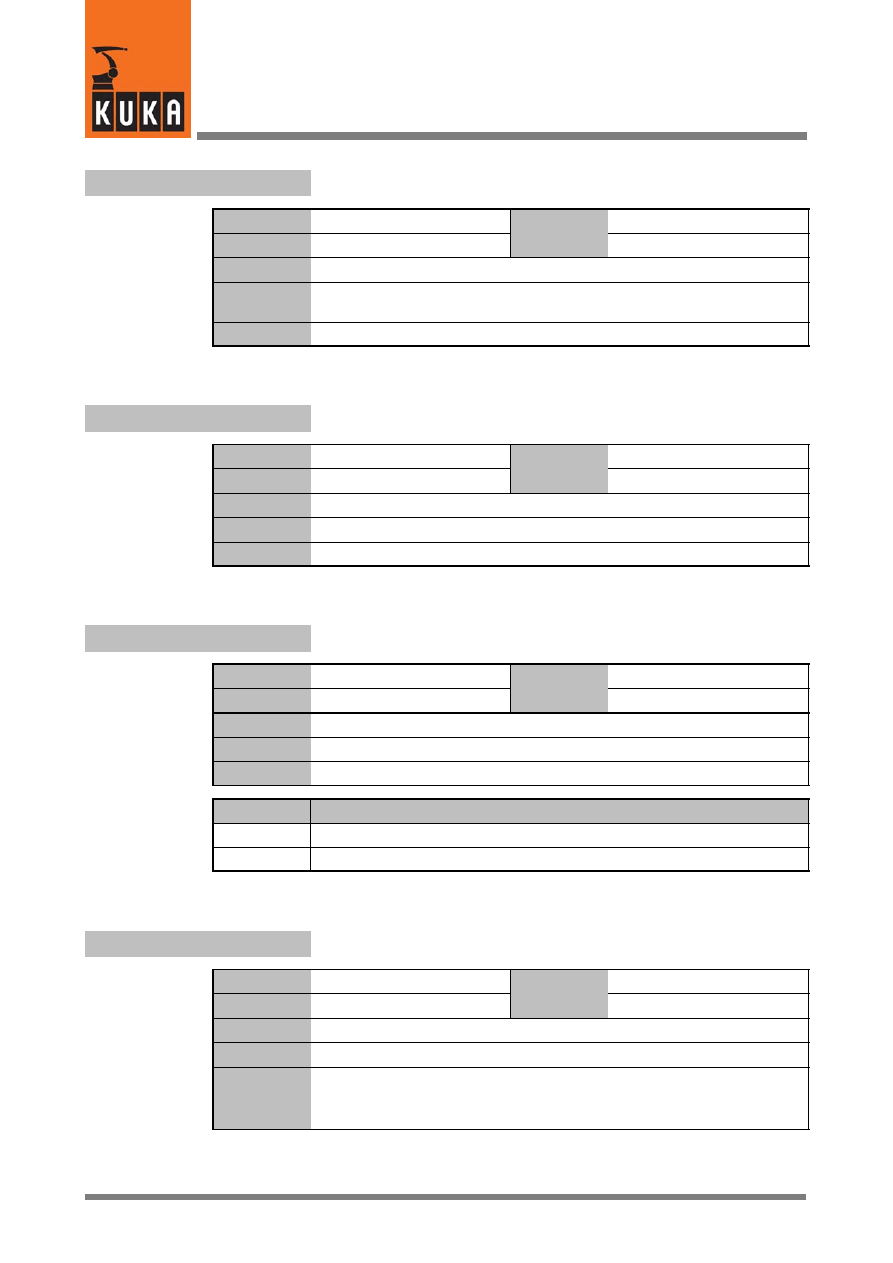

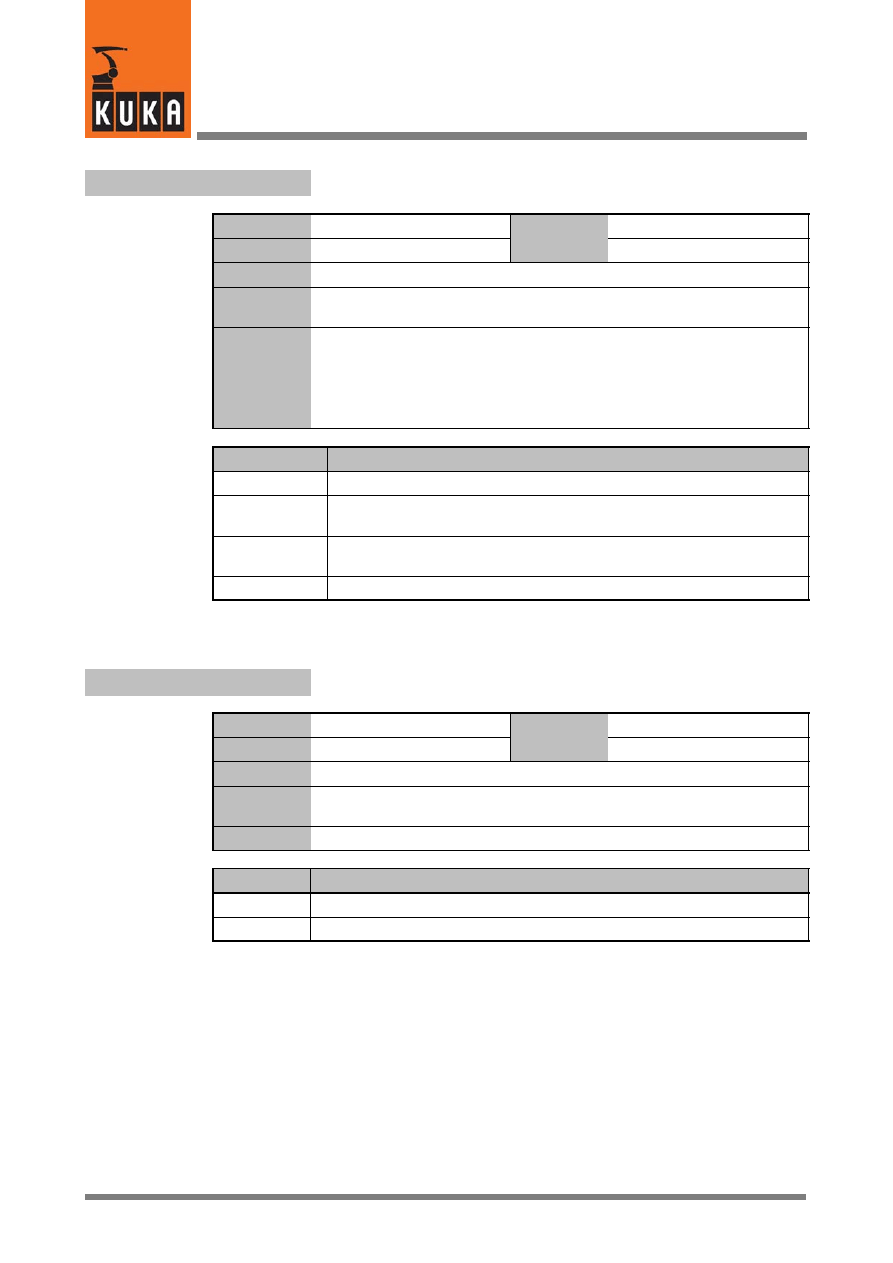

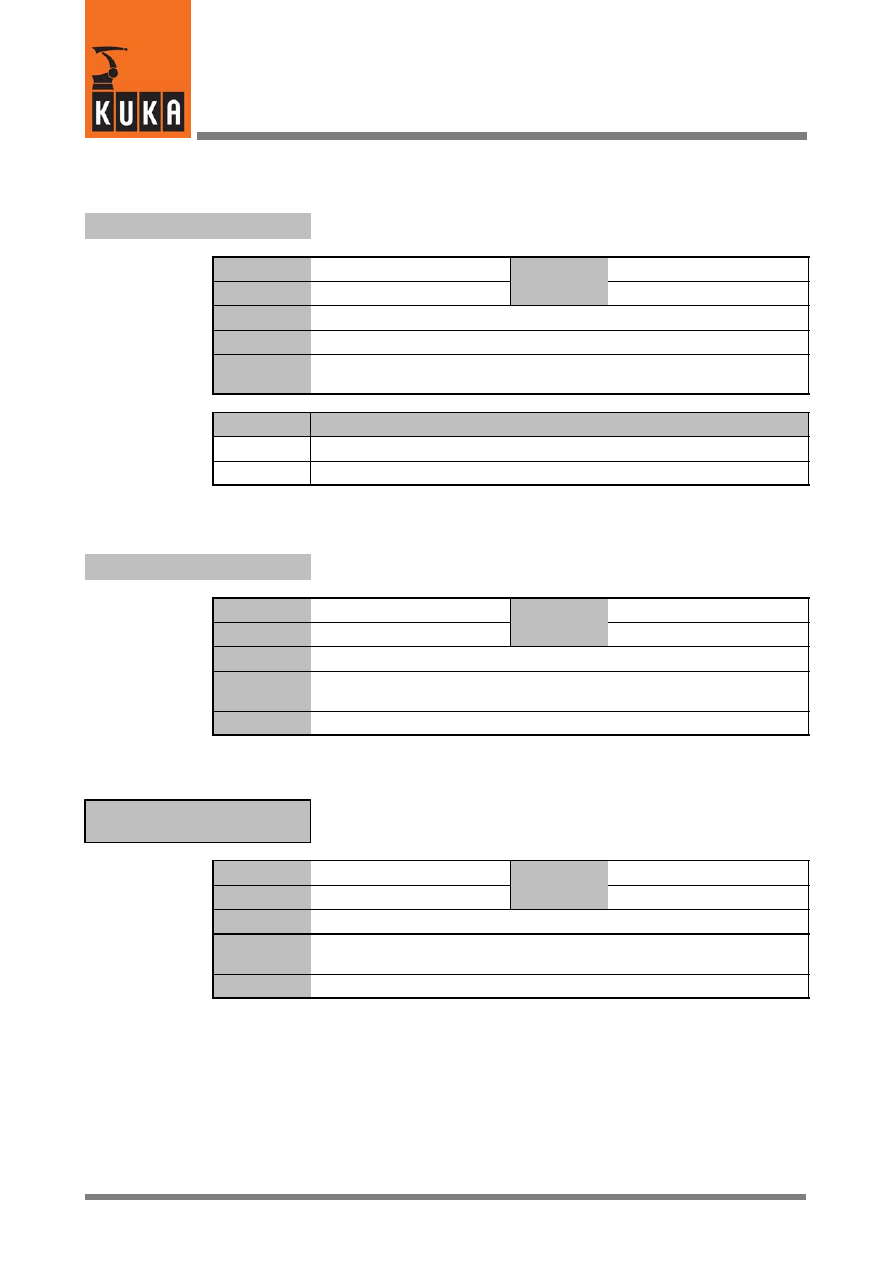

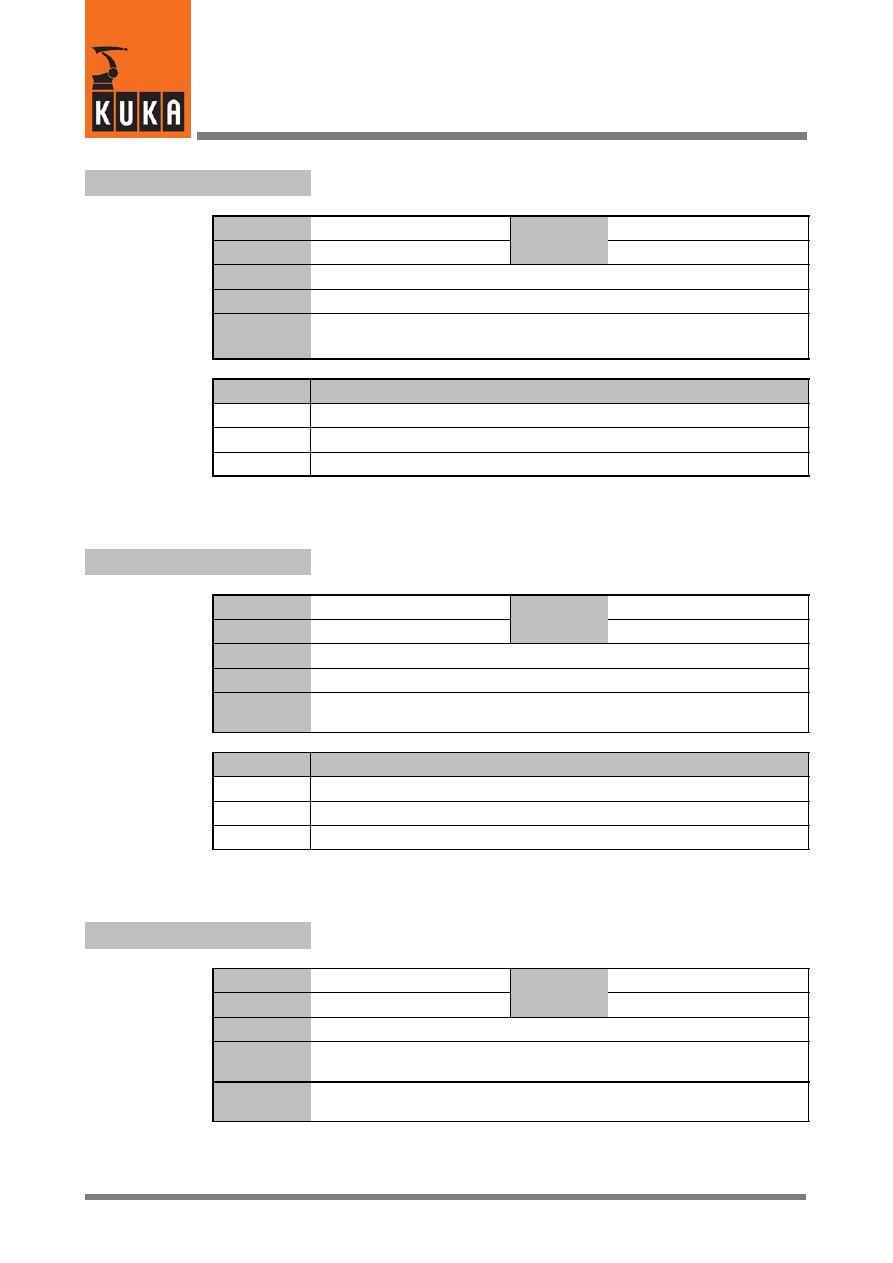

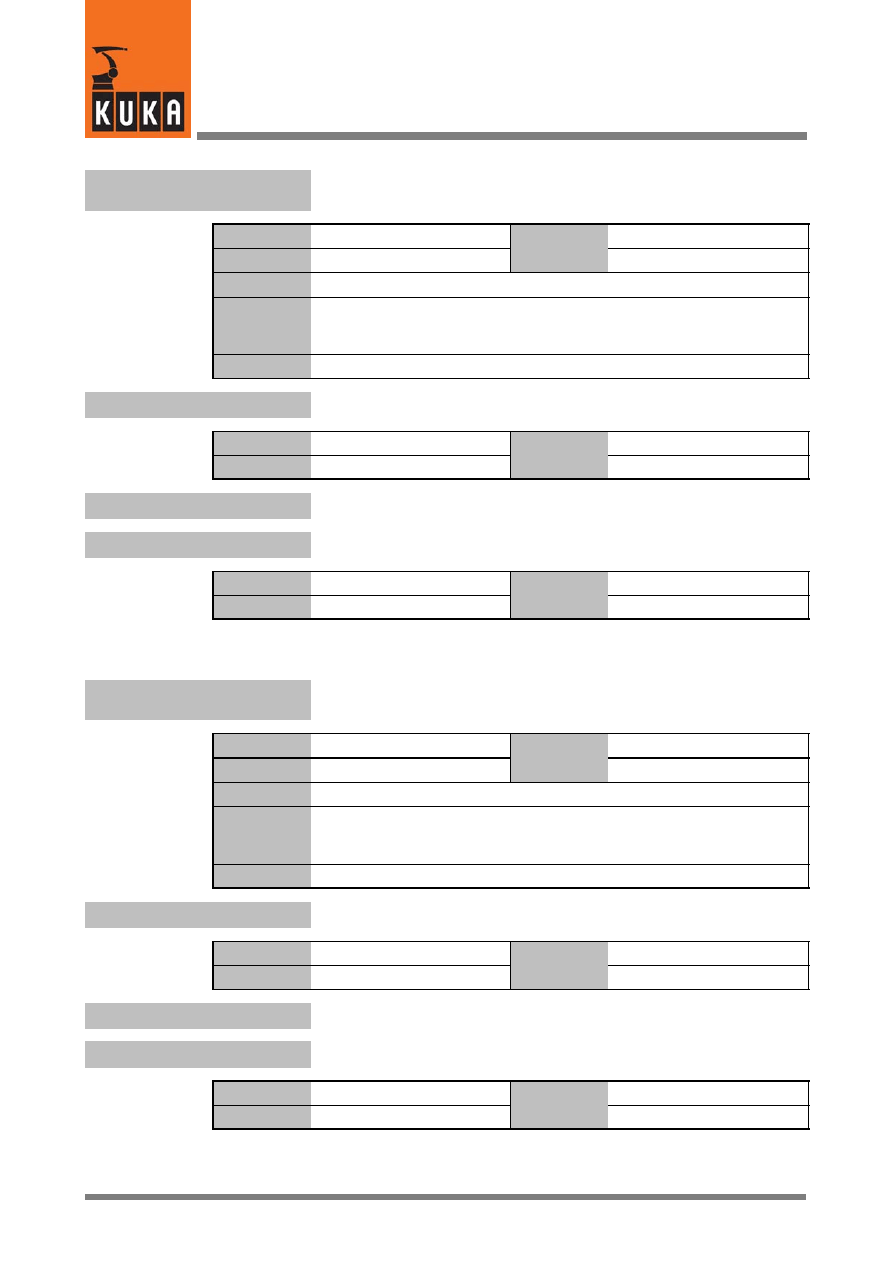

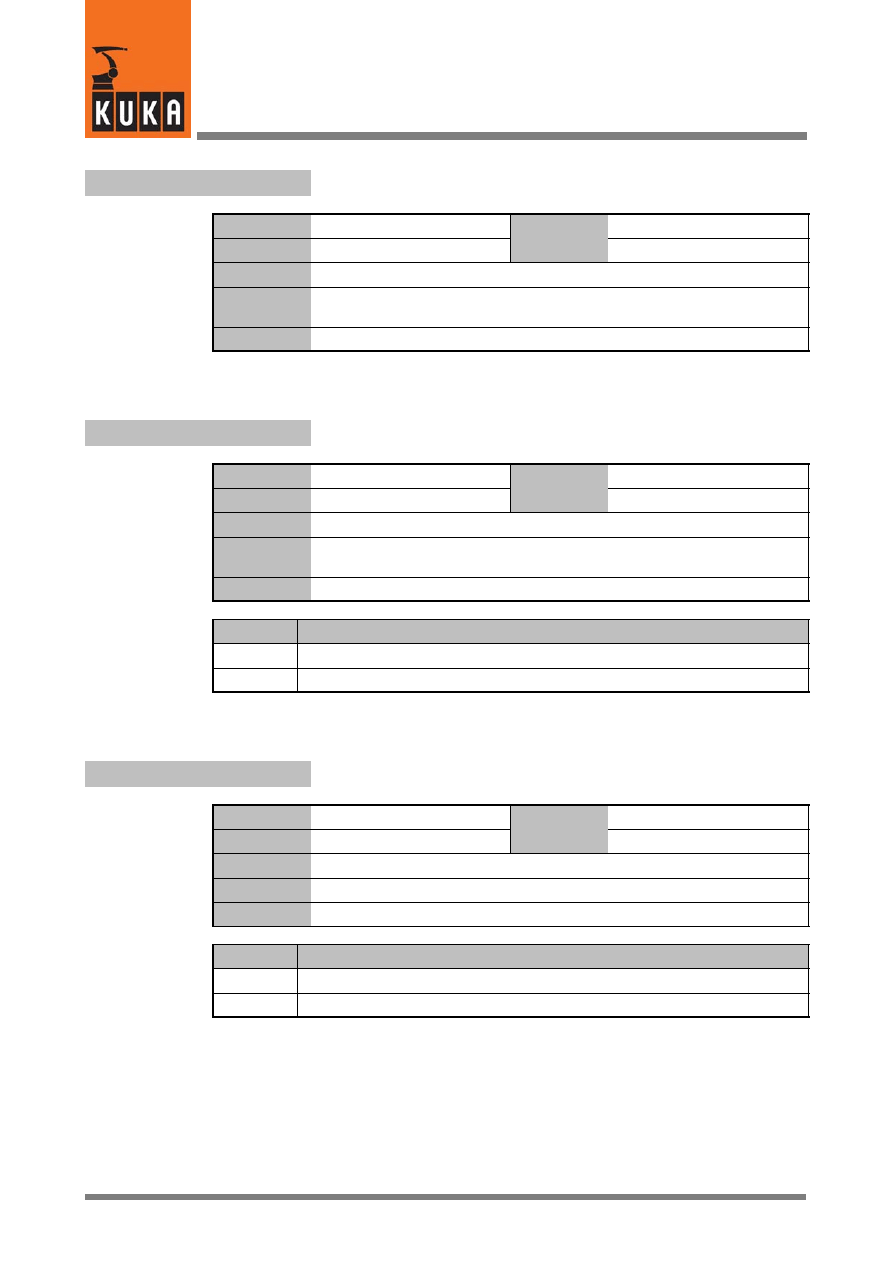

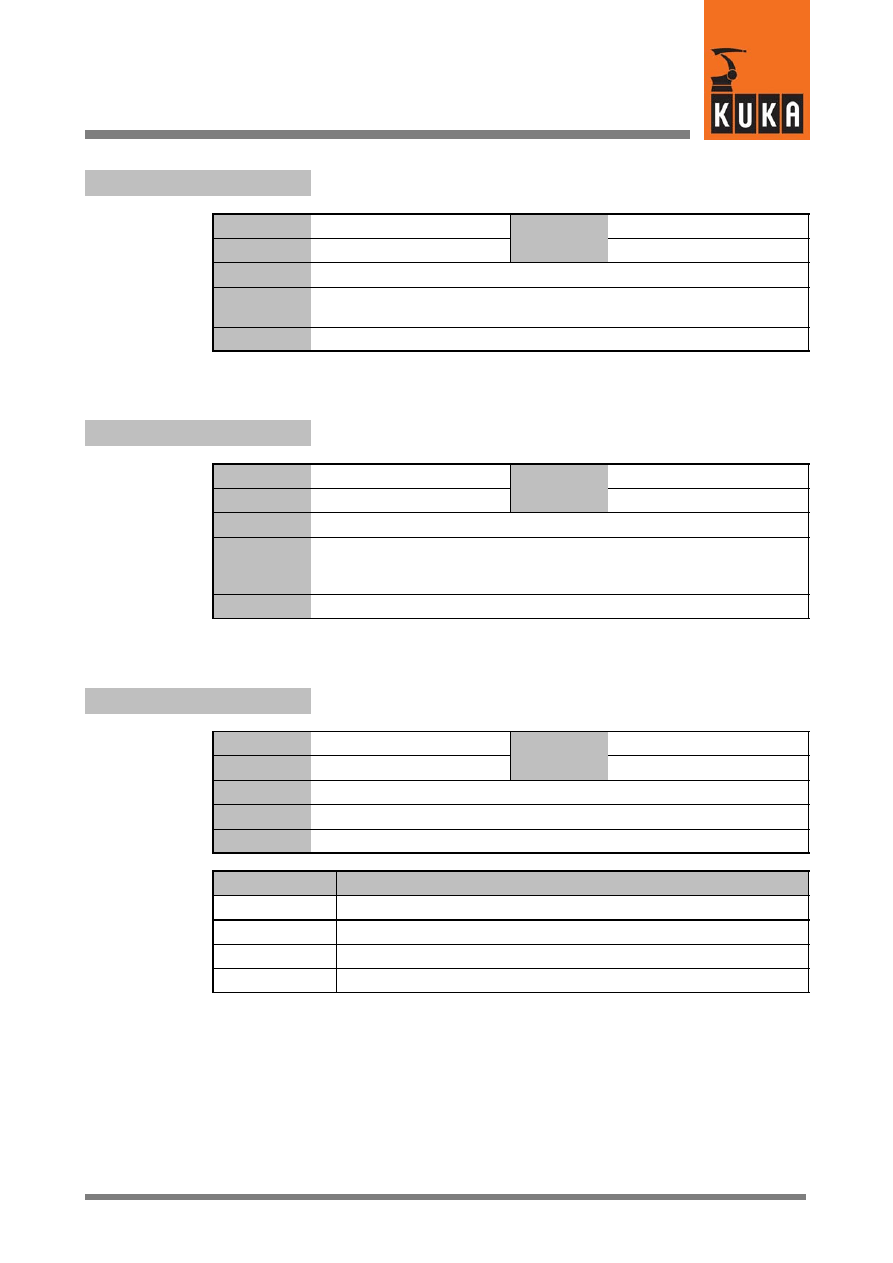

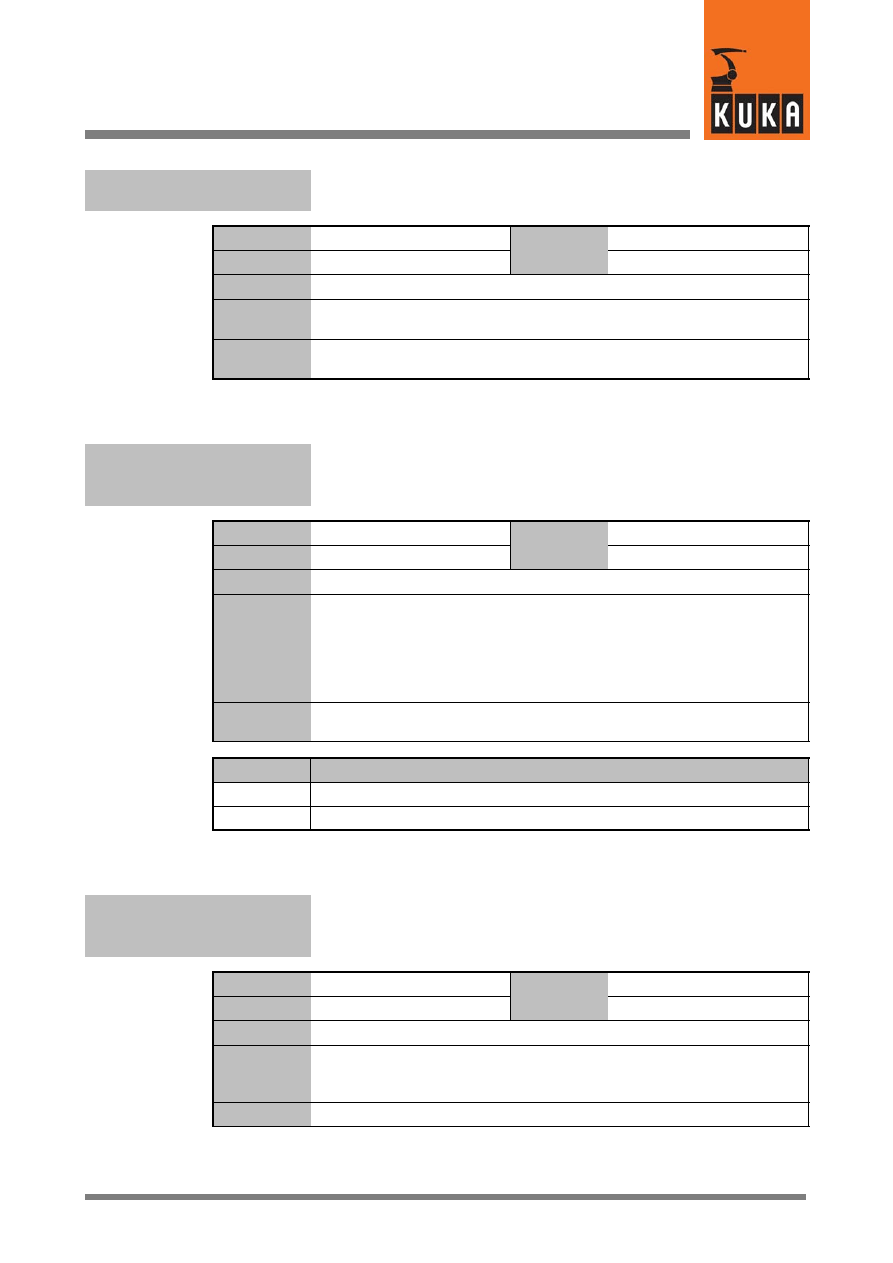

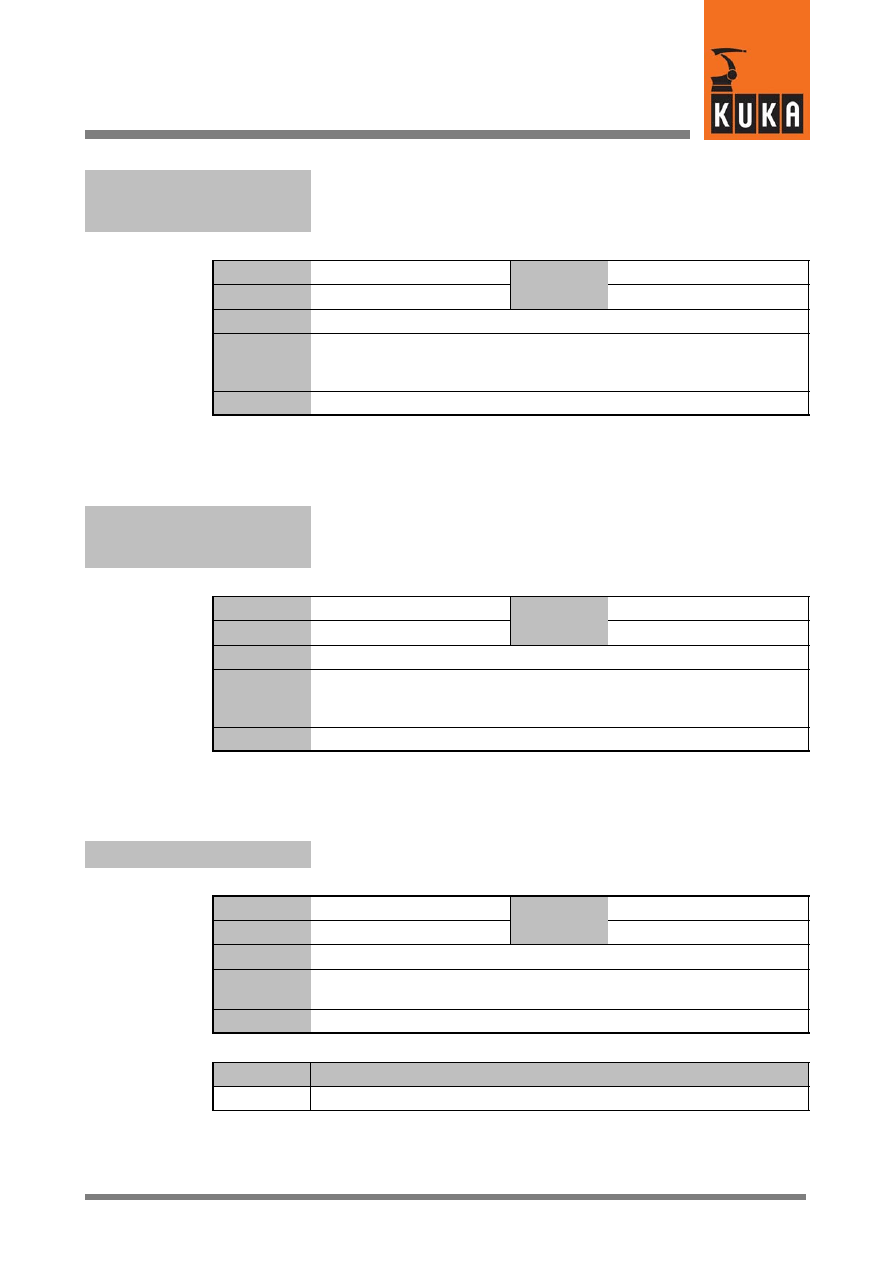

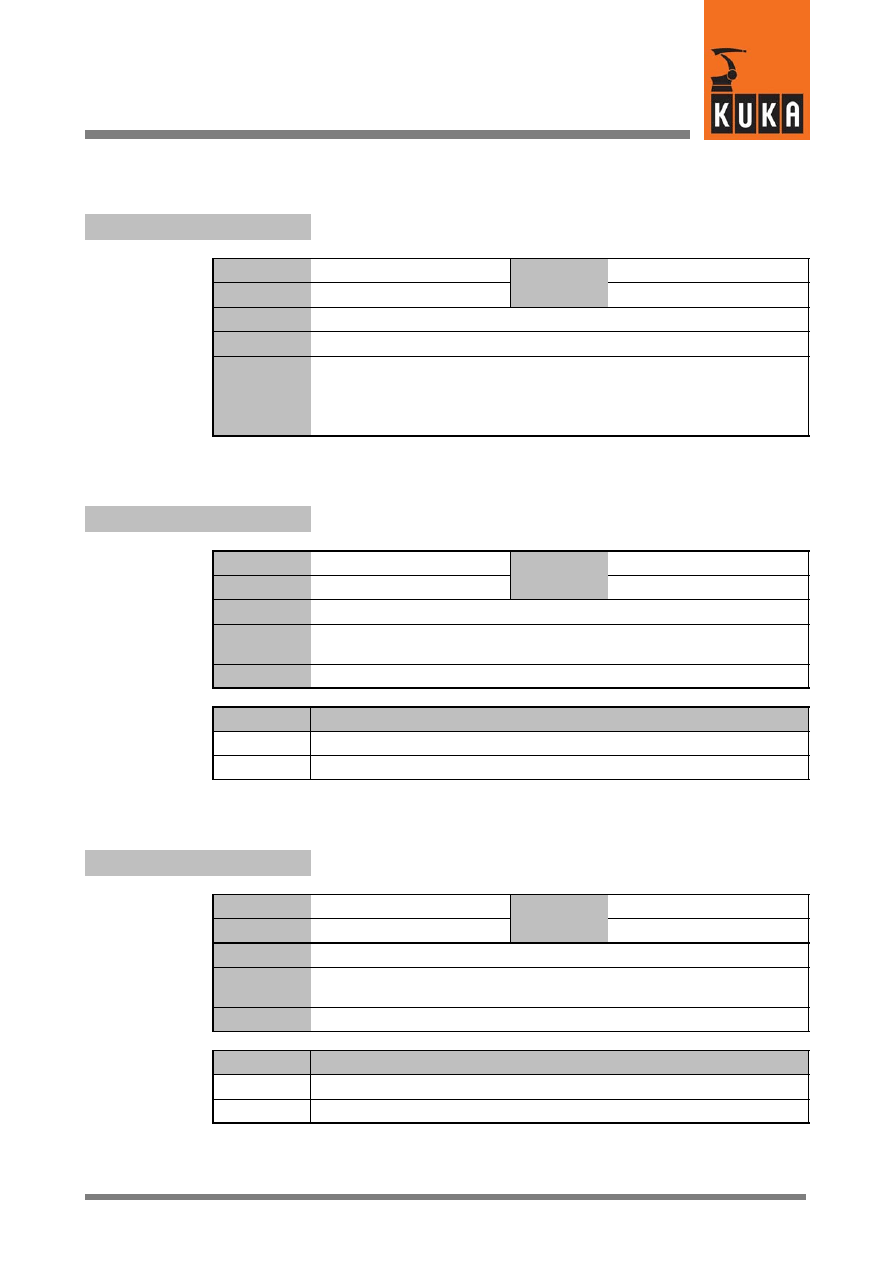

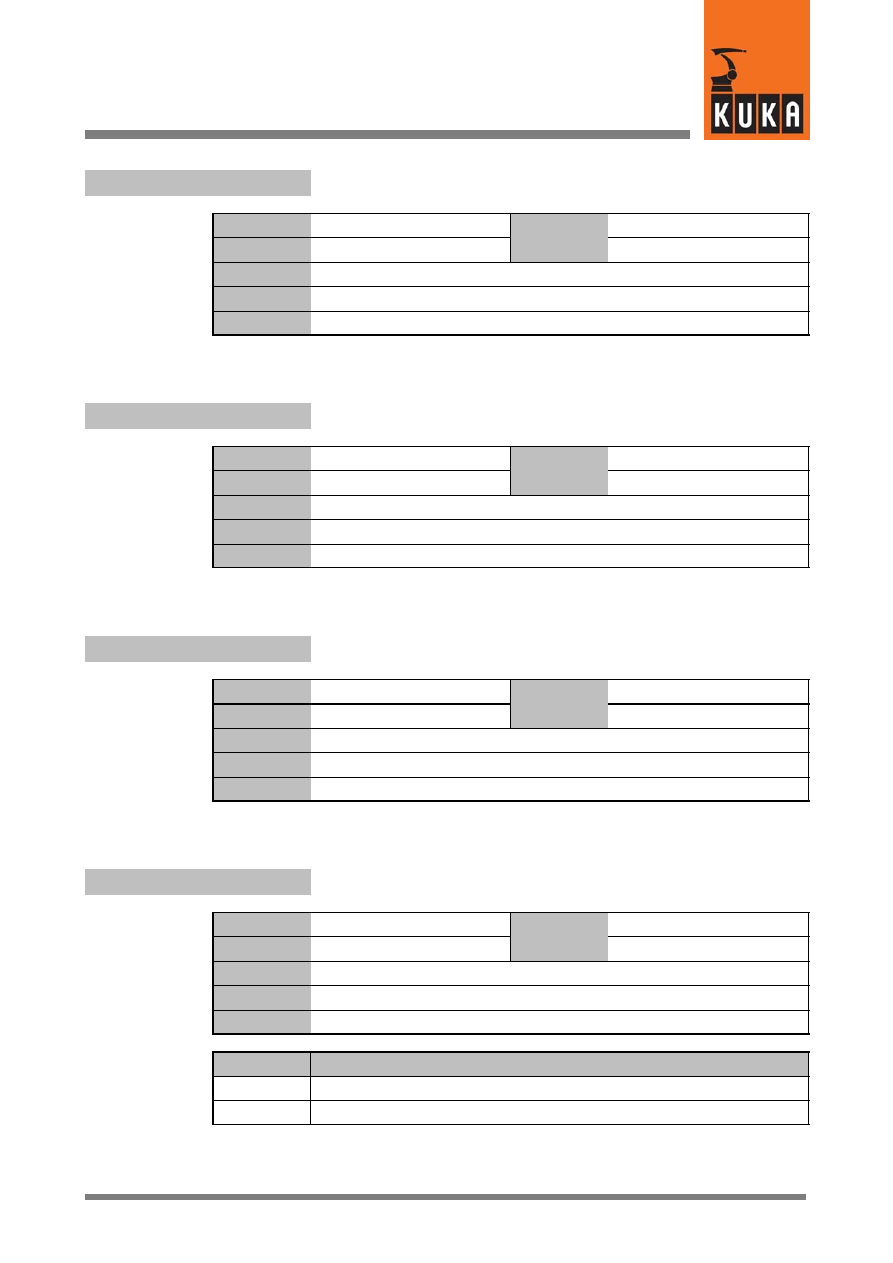

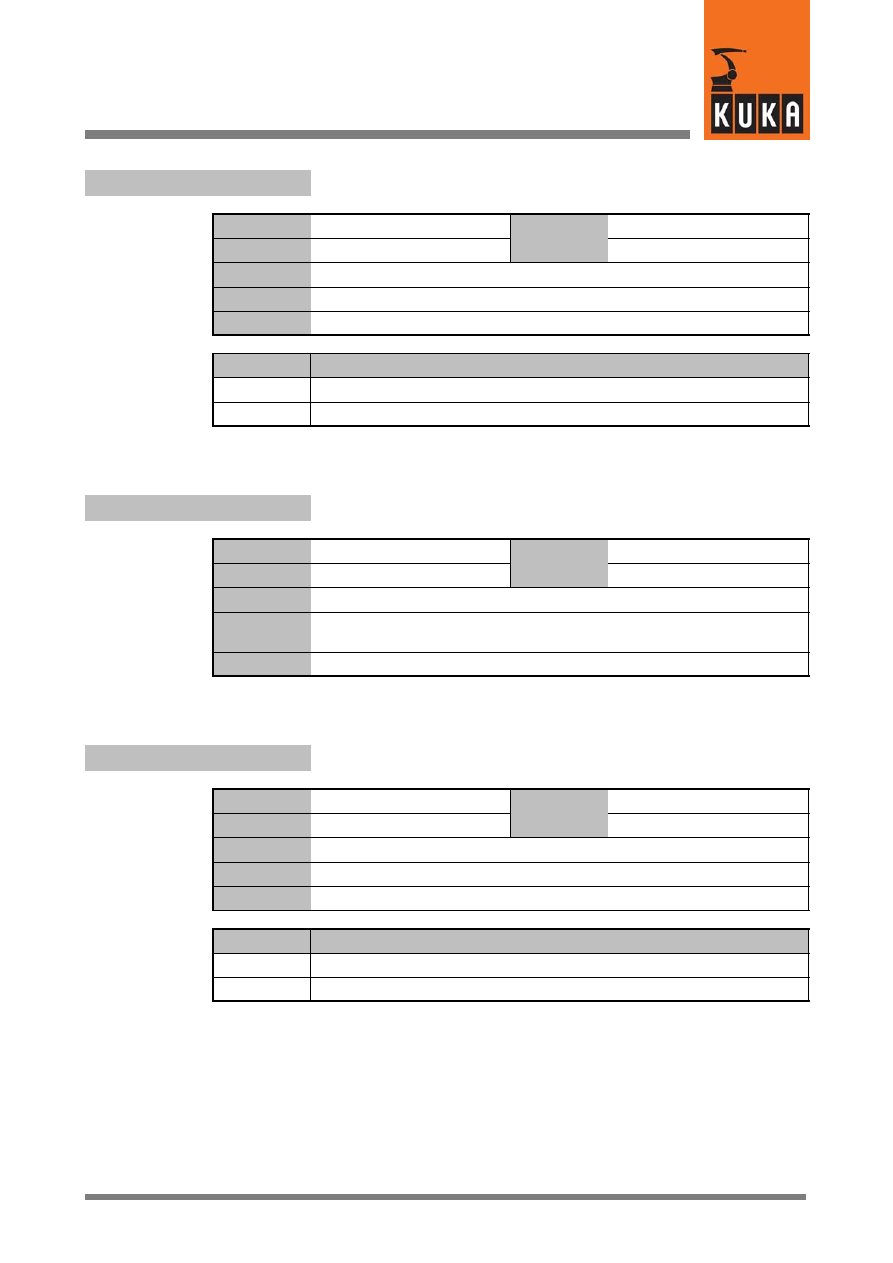

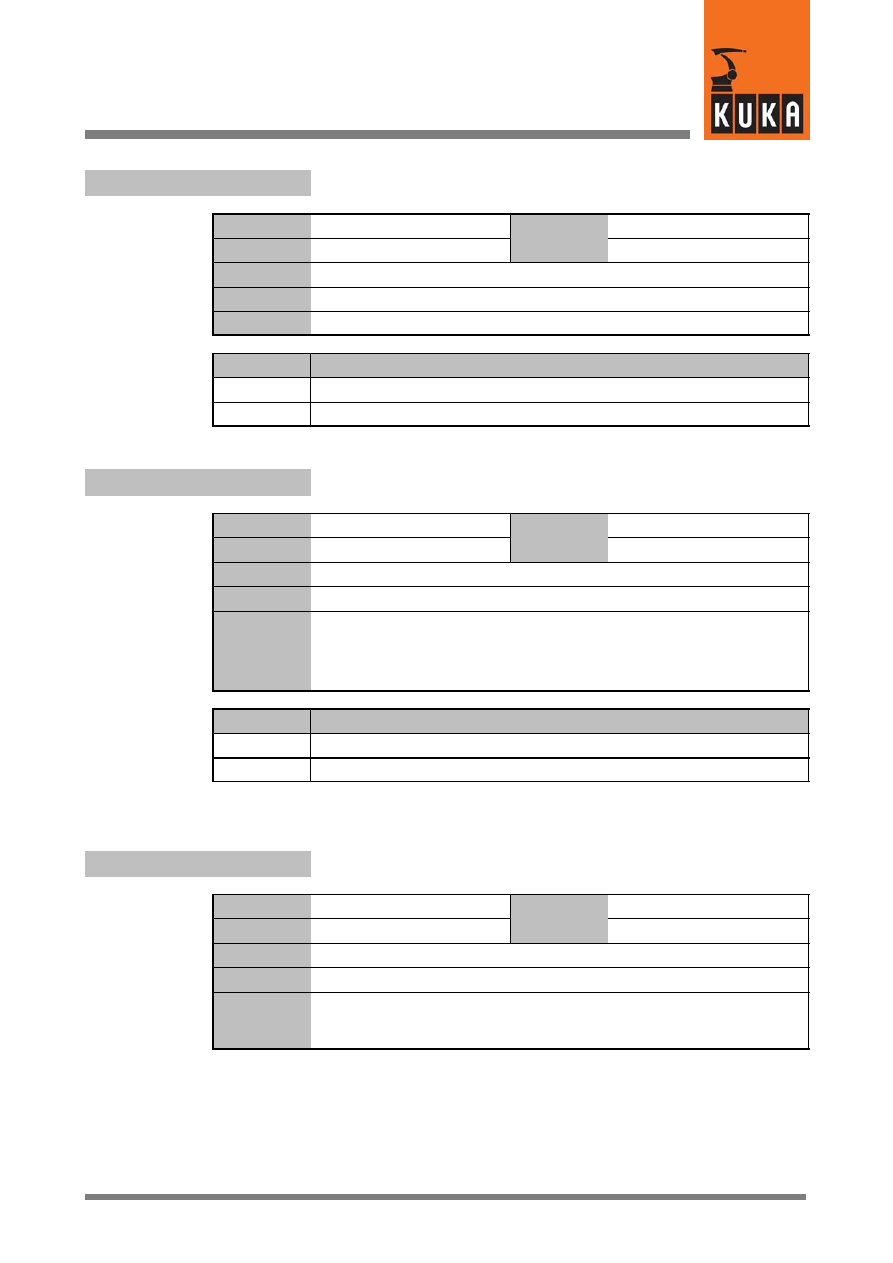

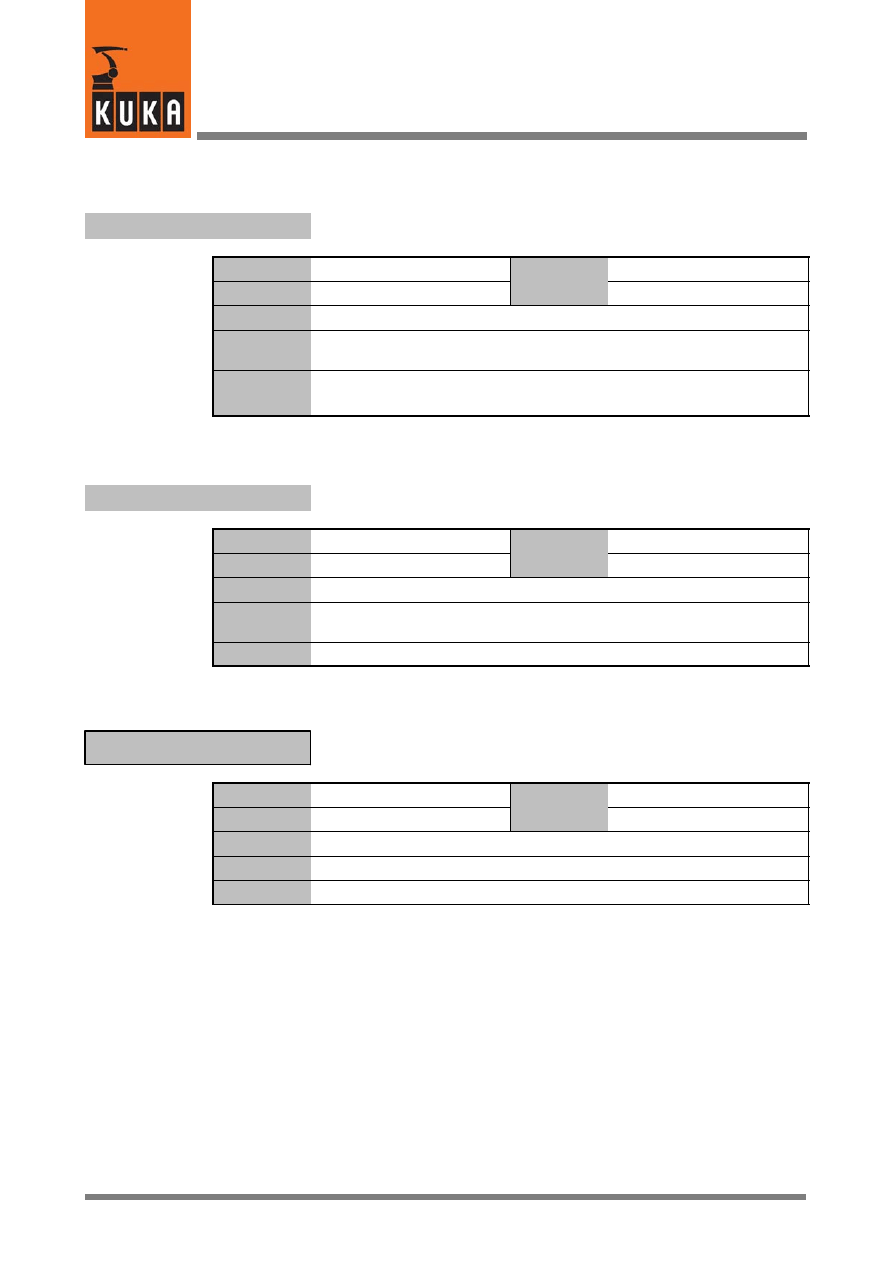

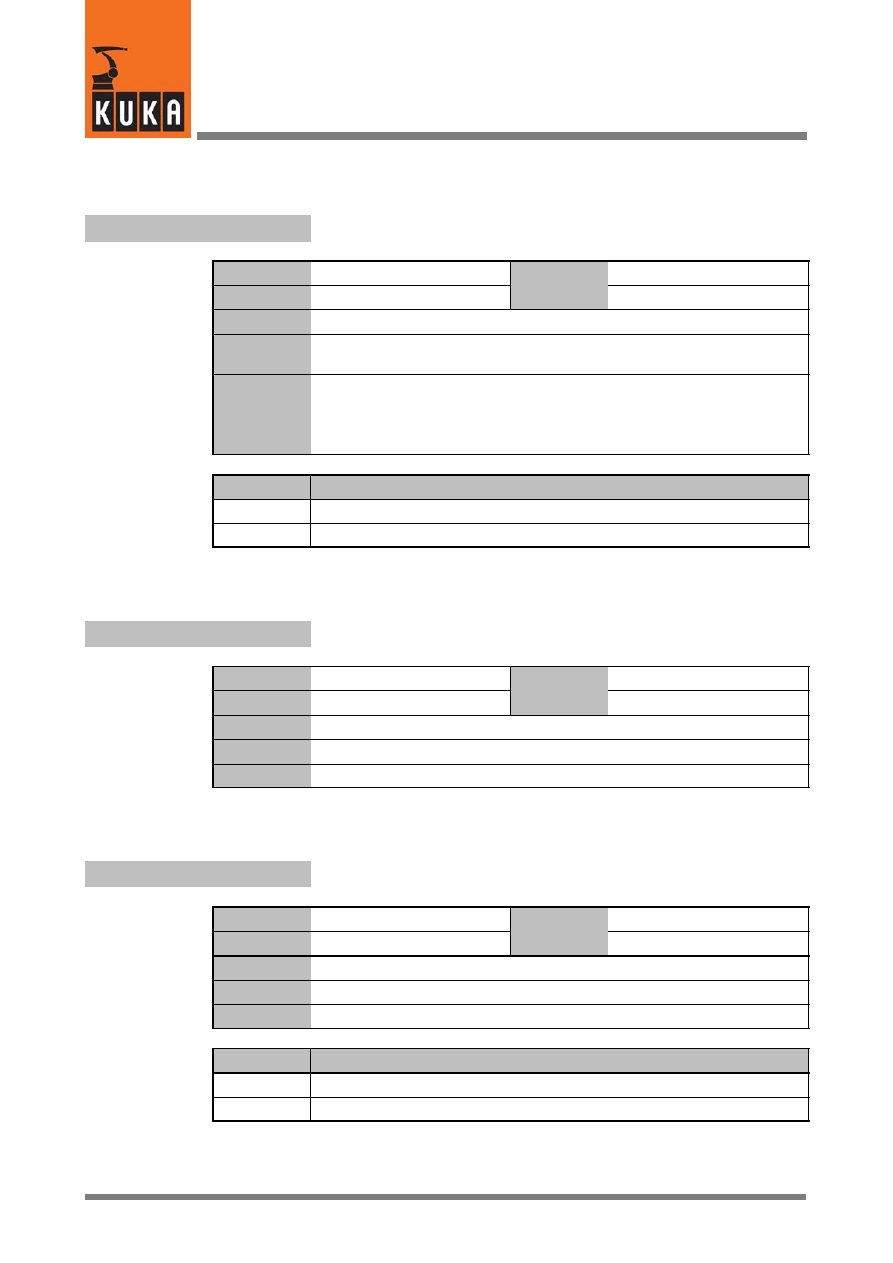

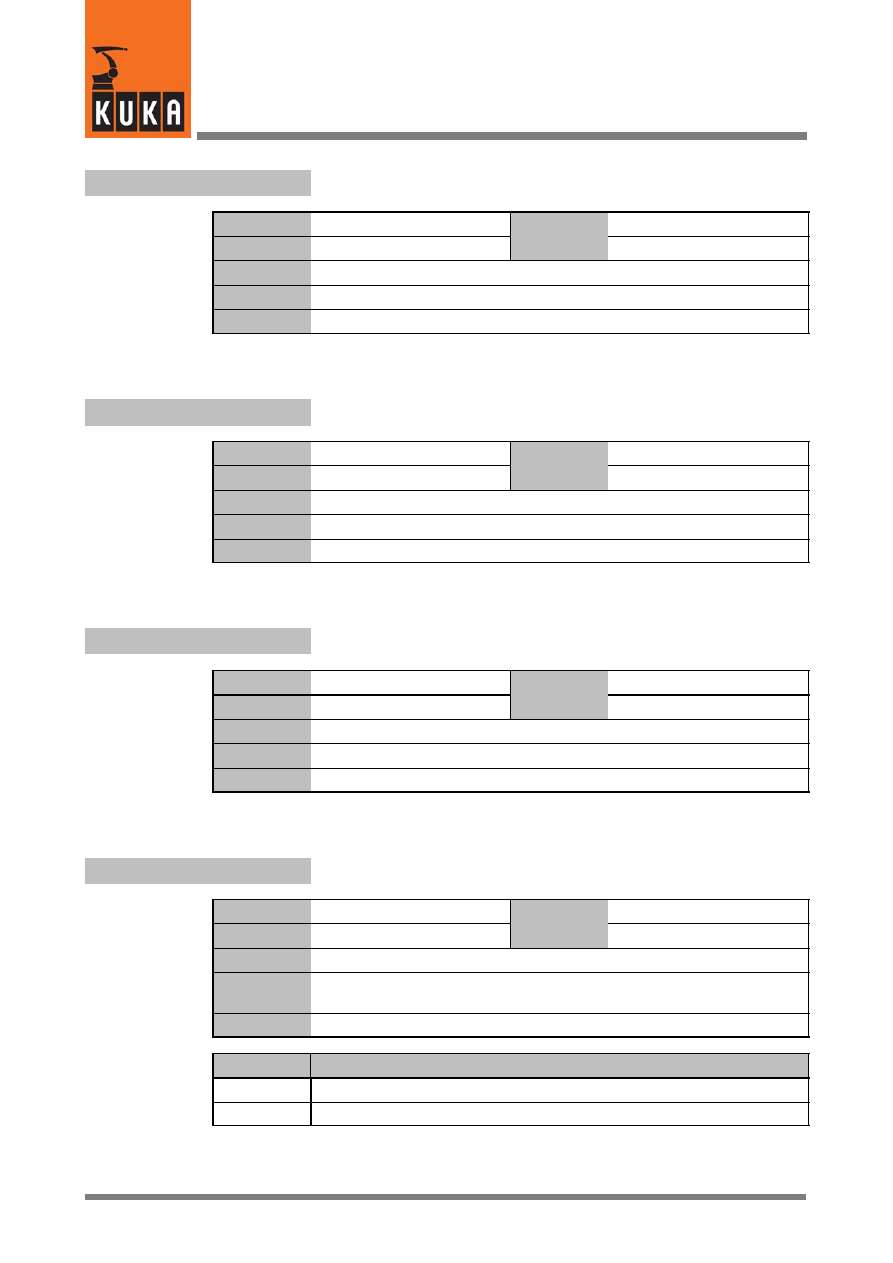

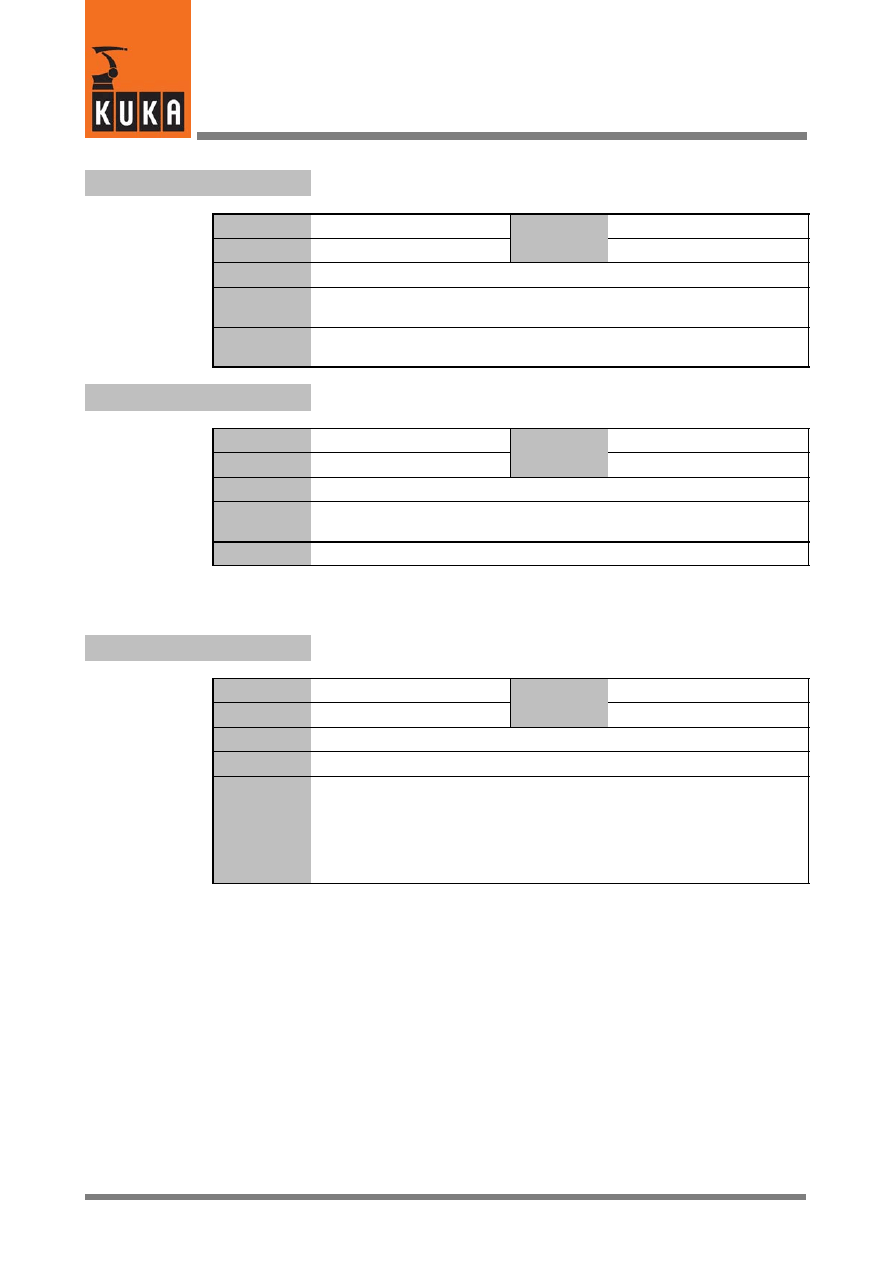

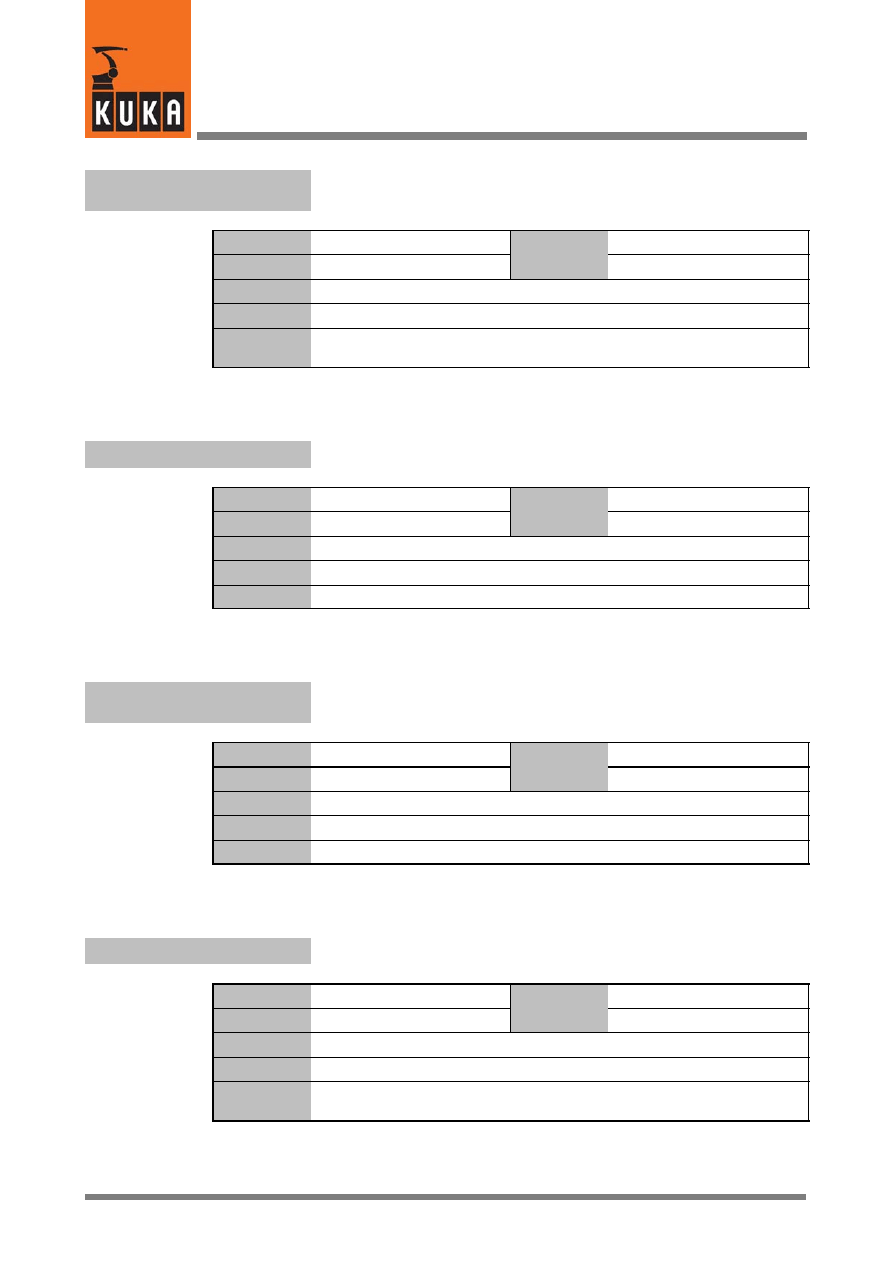

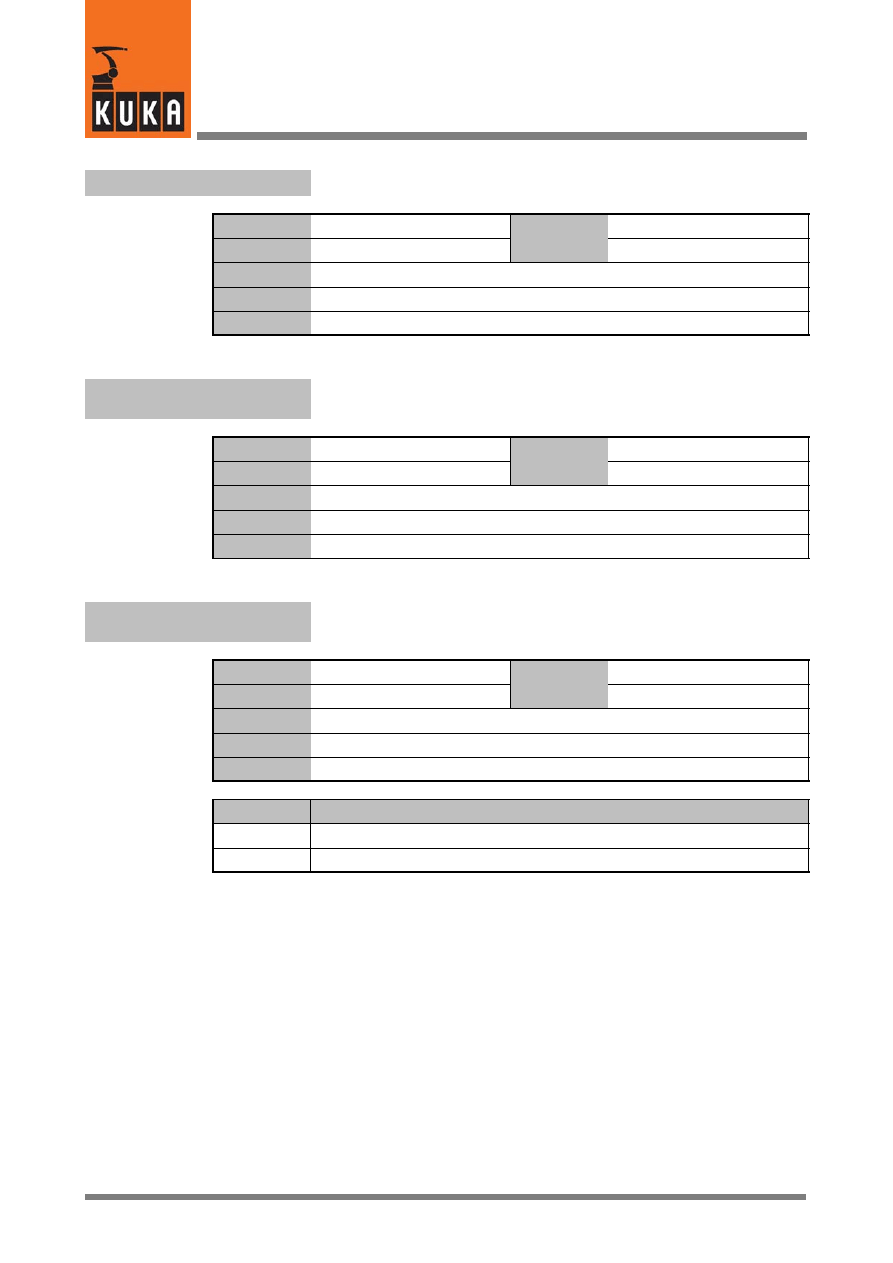

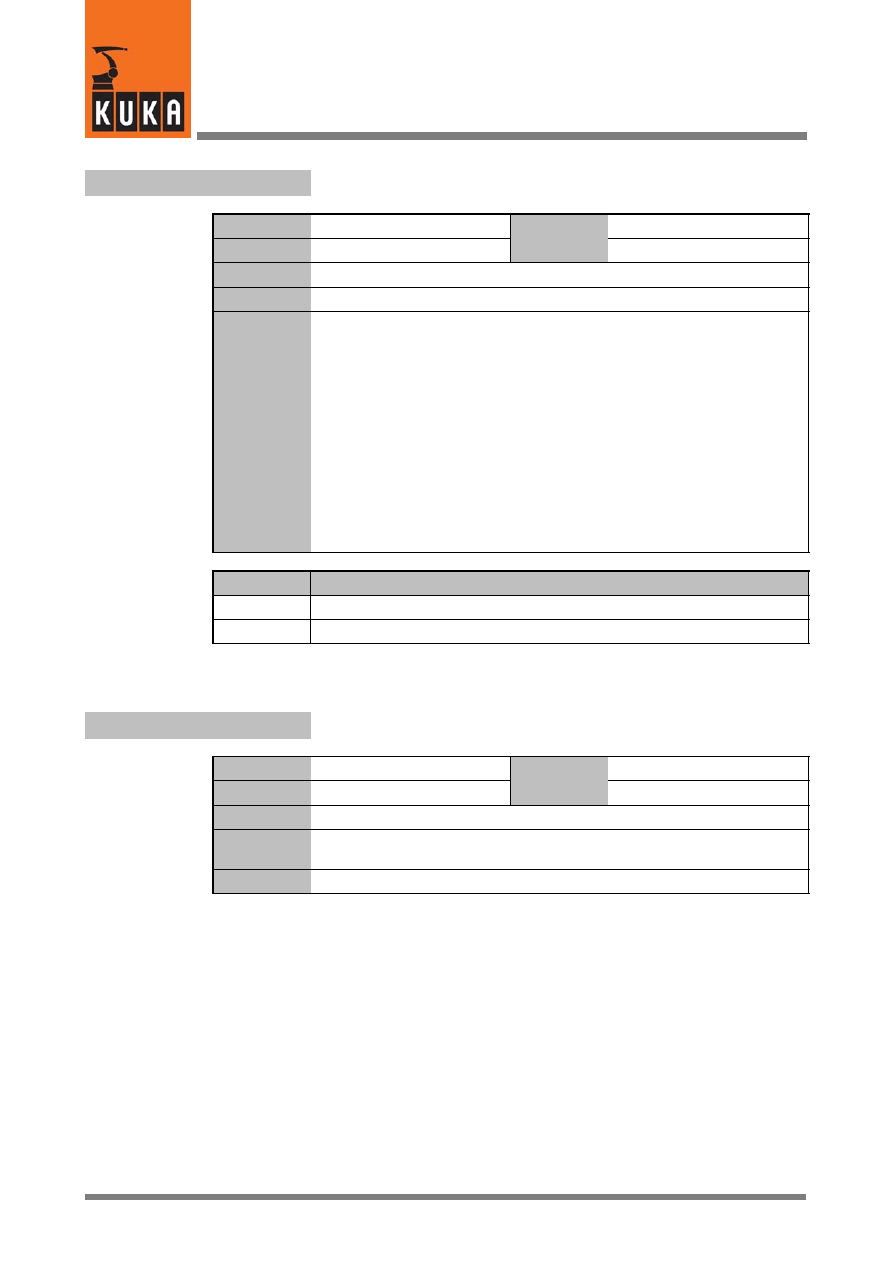

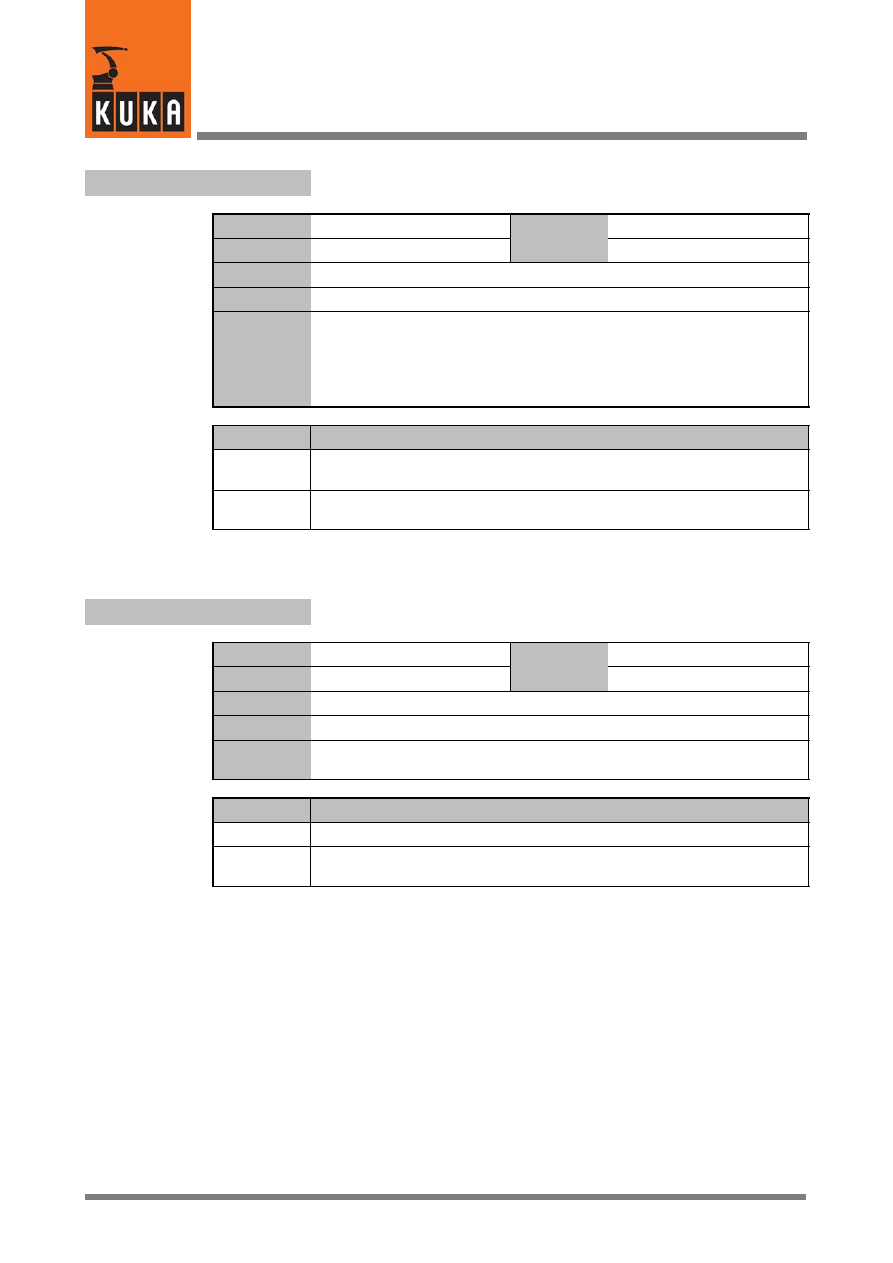

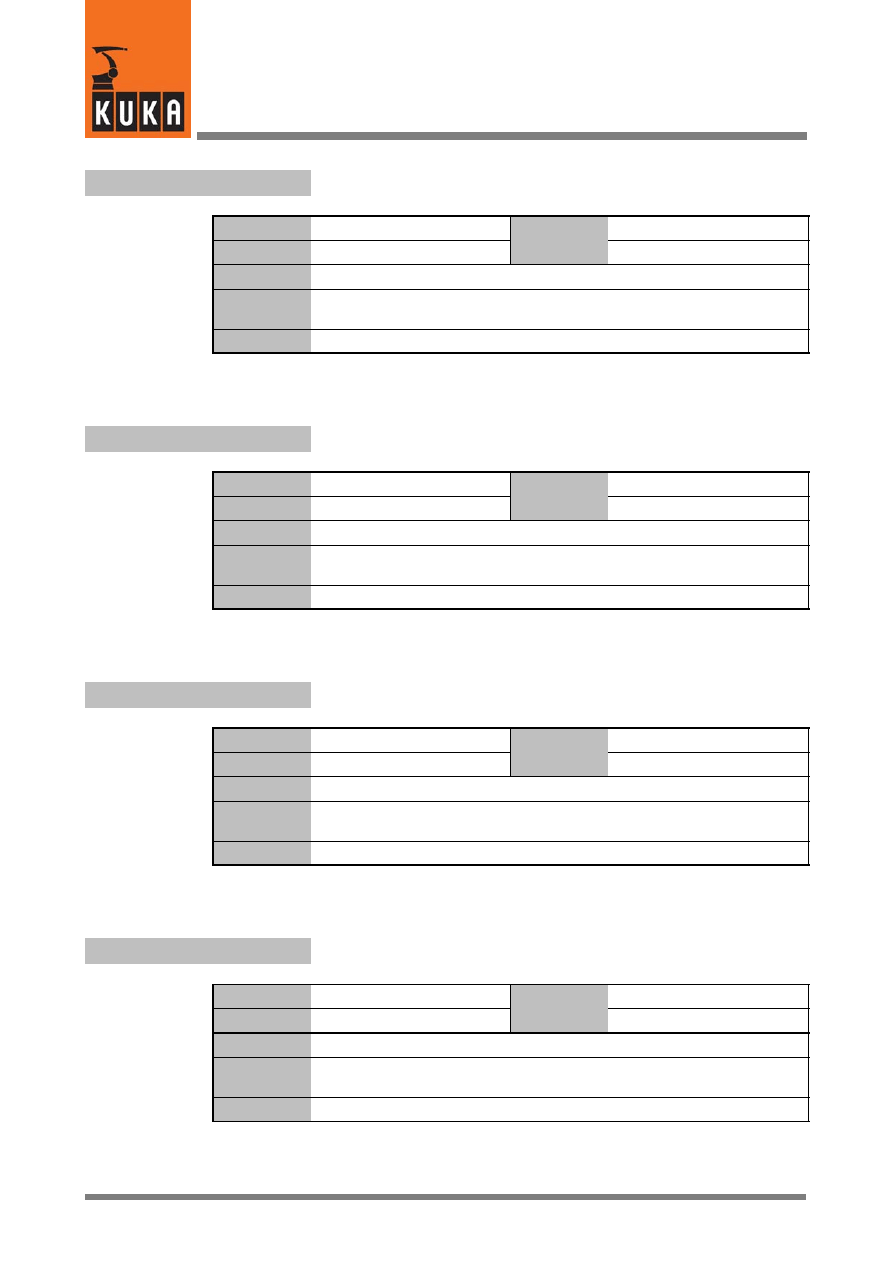

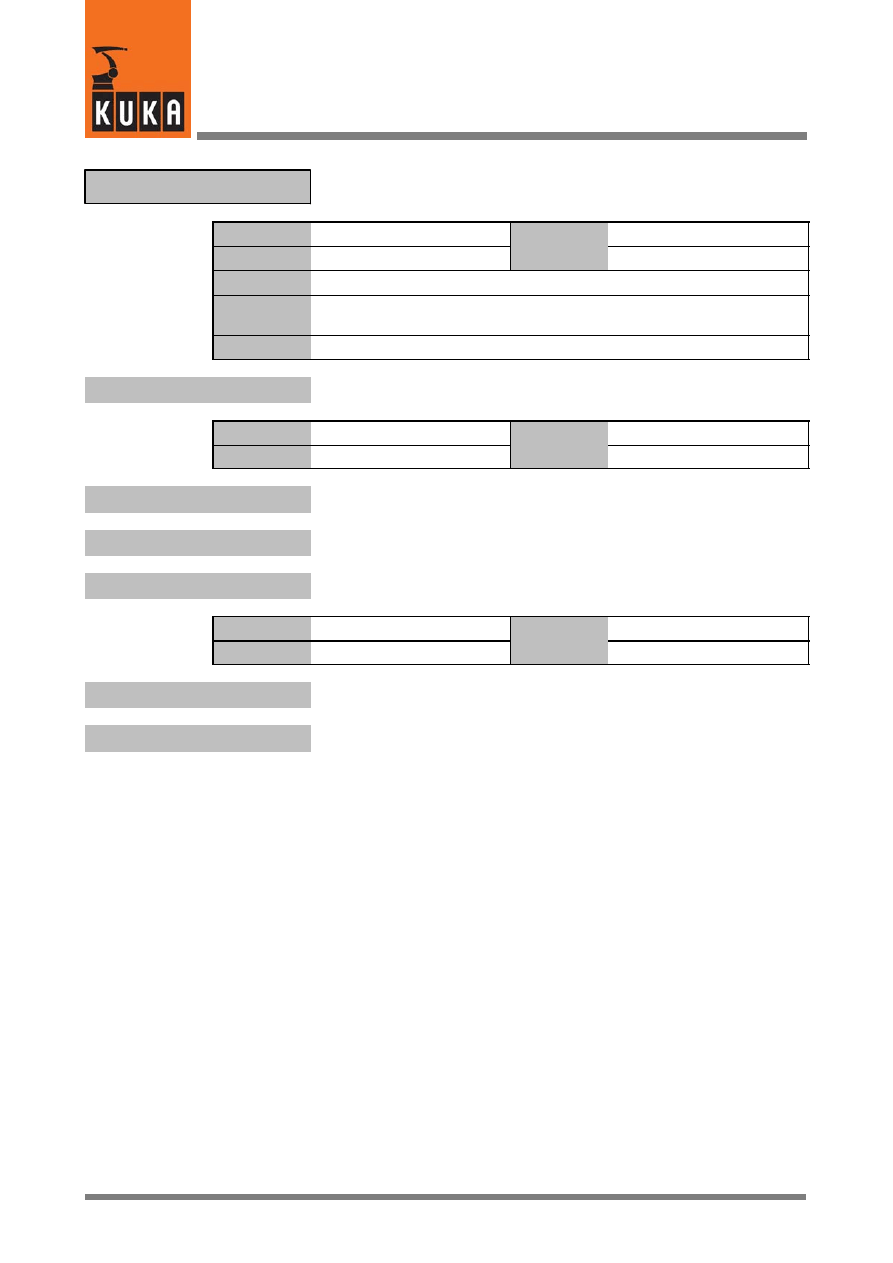

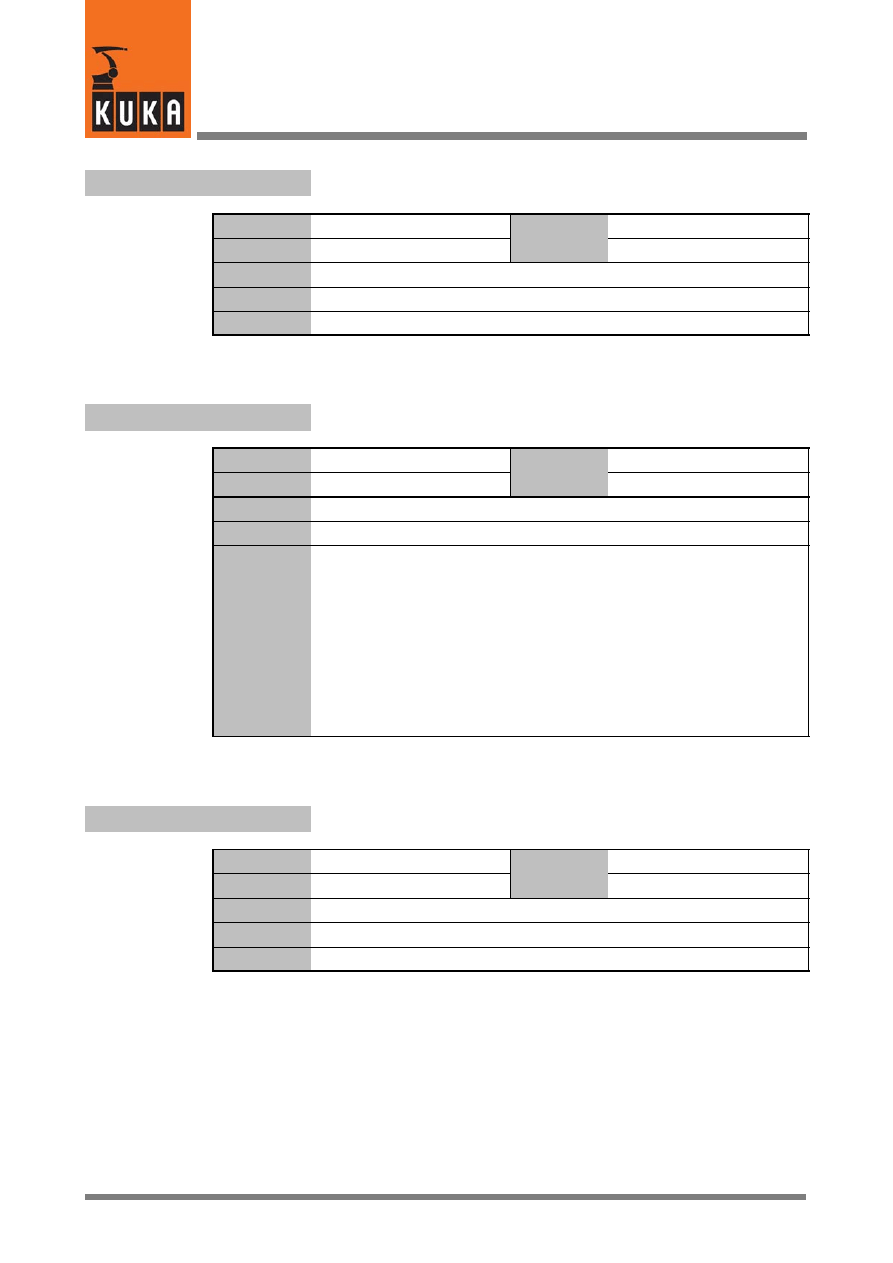

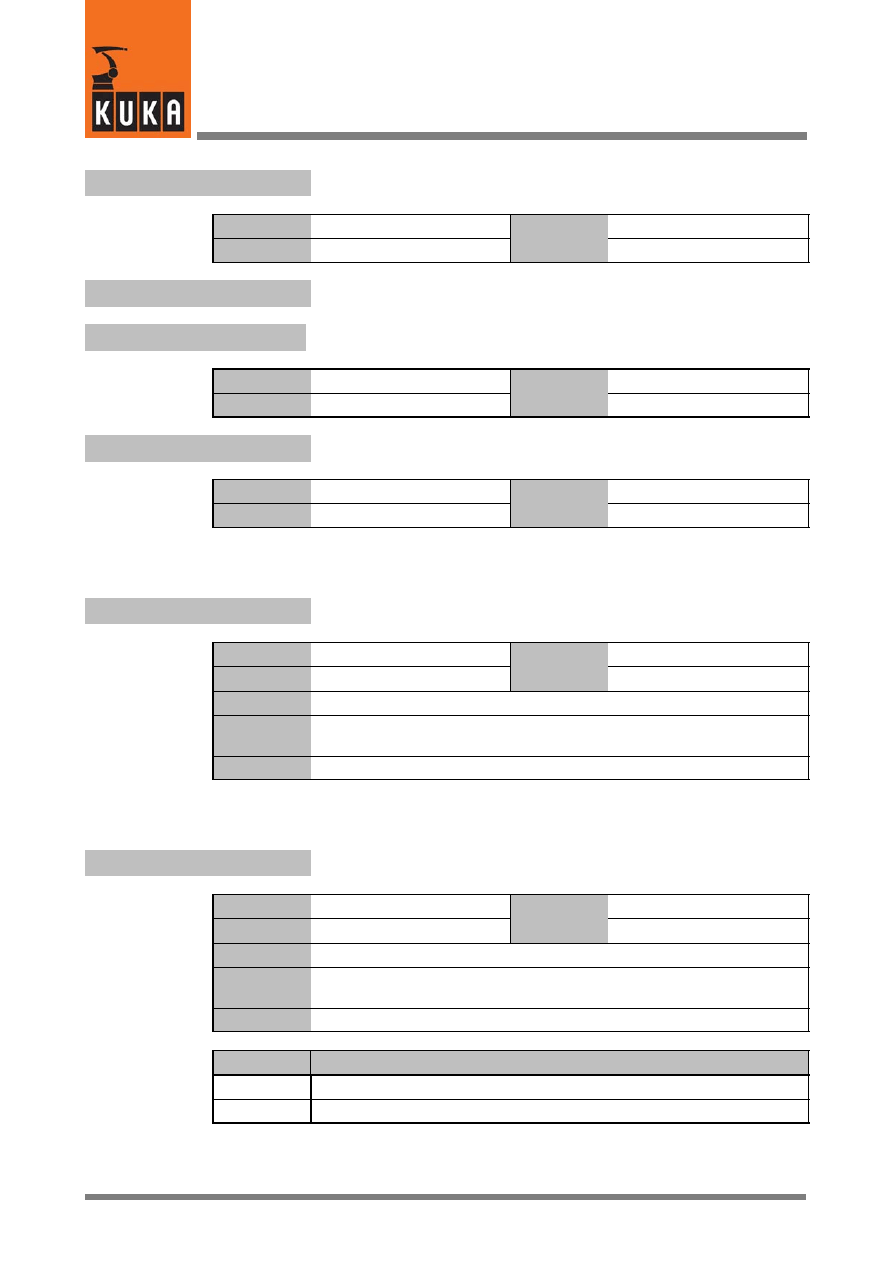

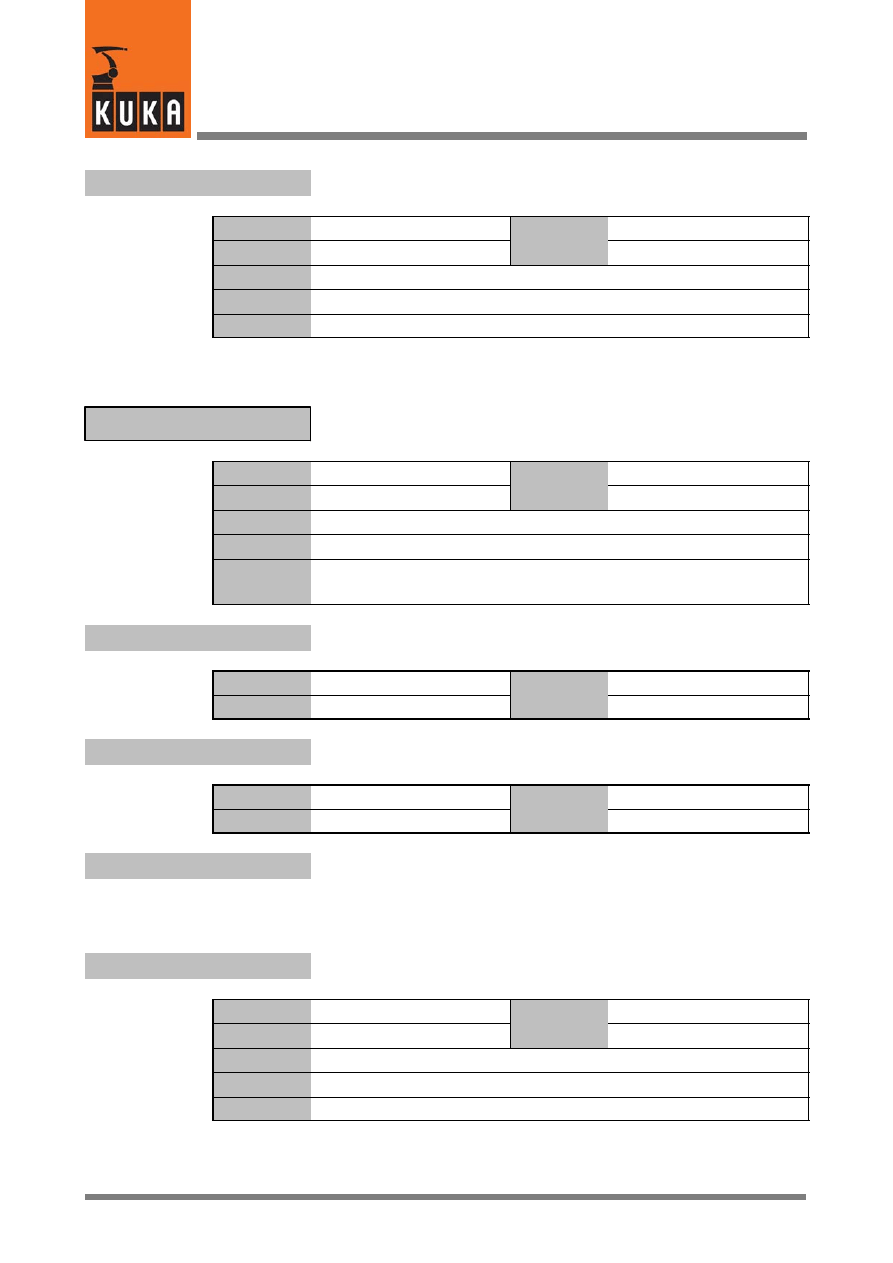

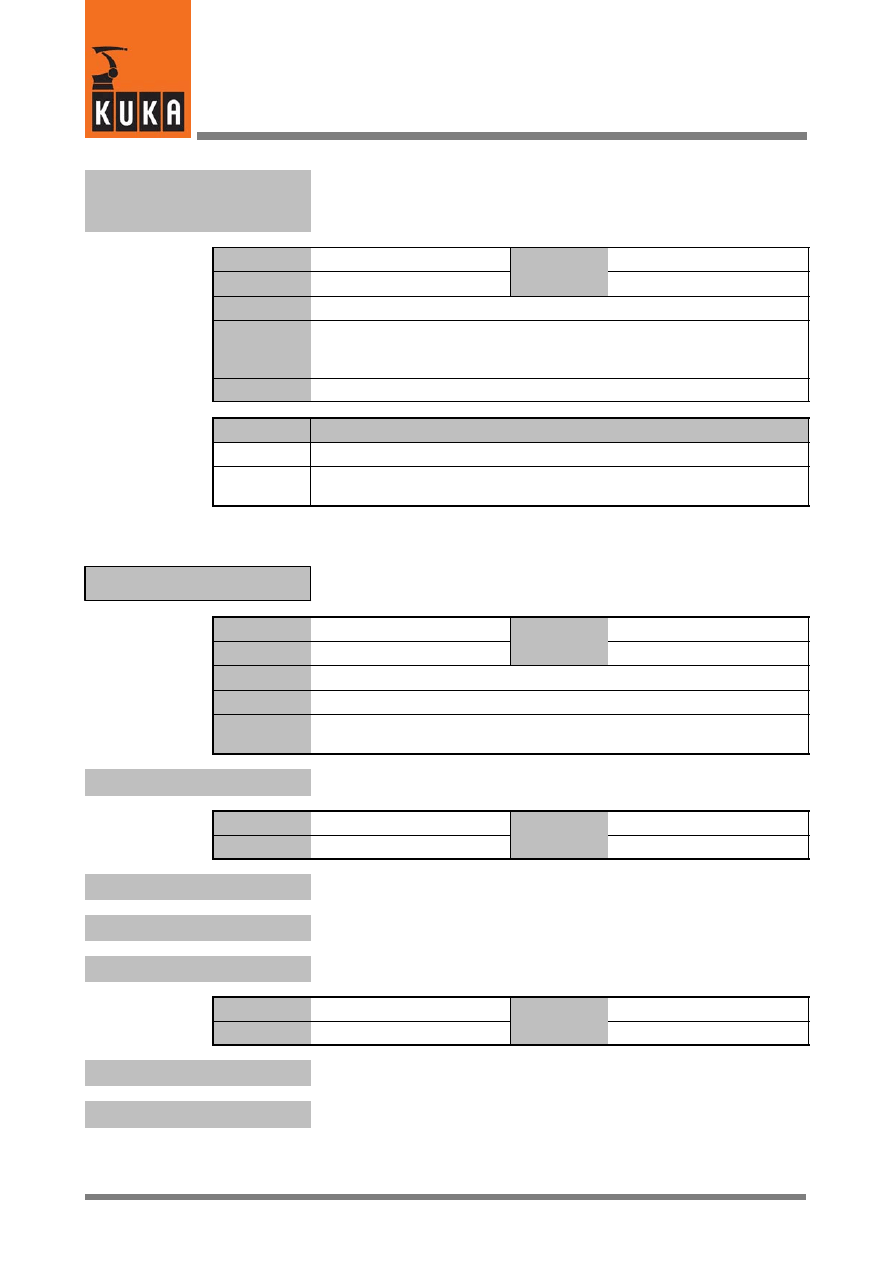

A group of system variables is indicated at the beginning with a framed name box:

Function of the variable

Variable name

Data type

Structure

Value

min.

Unit

Value

max.

In file

Original line

Comments

If the description contents of subsequent system variables remain the same, only their title

lines are displayed.

Variable name.1

Function of the variable

If there is a change, the corresponding section of the table is shown under the title line. This

change then applies to all subsequent variables of the group.

Variable name.2

Function of the variable

Data type

Real

Value

min. 0

Unit

mm, °

Value

max.

Variable name.3

Function of the variable

2

A

7 of 170

SysVar 08.02.03 en

2

A

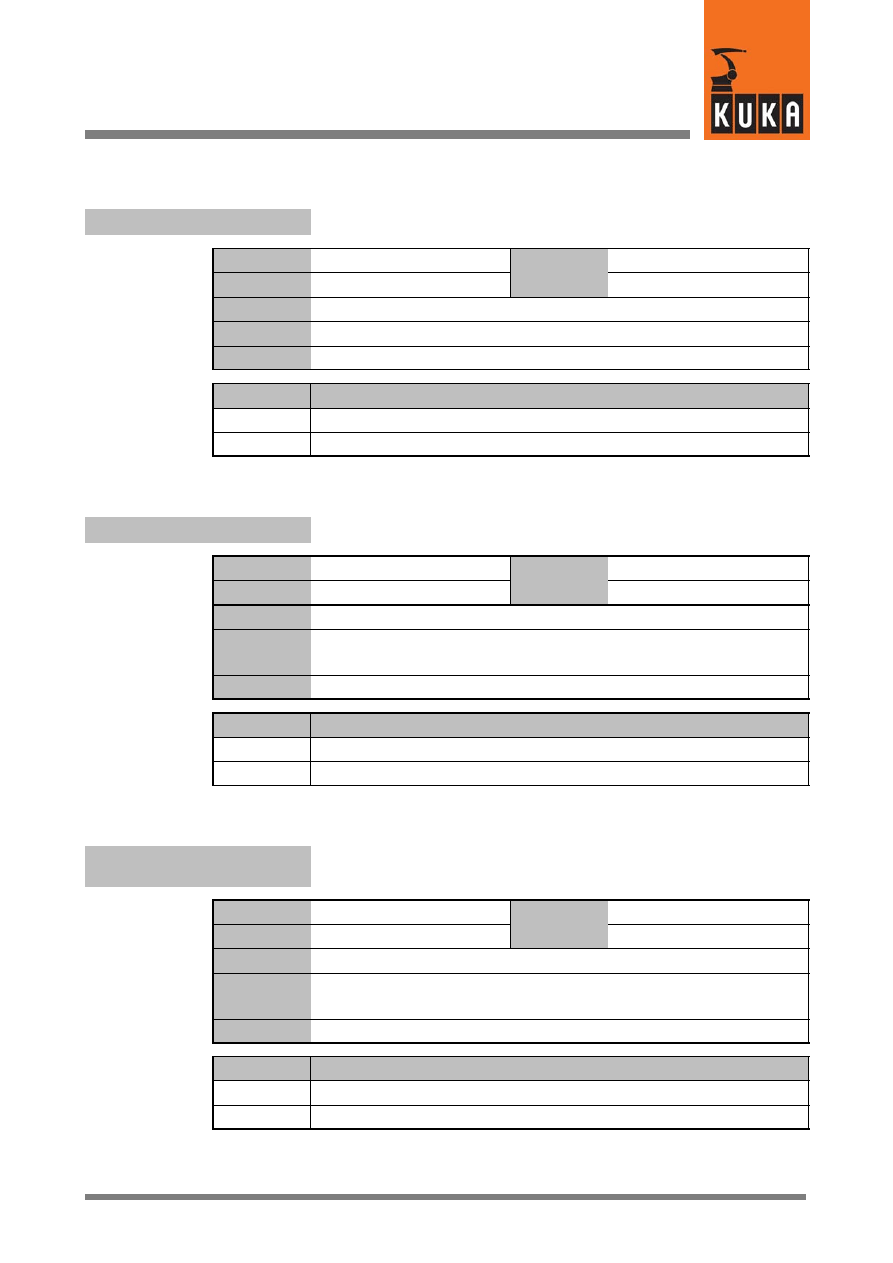

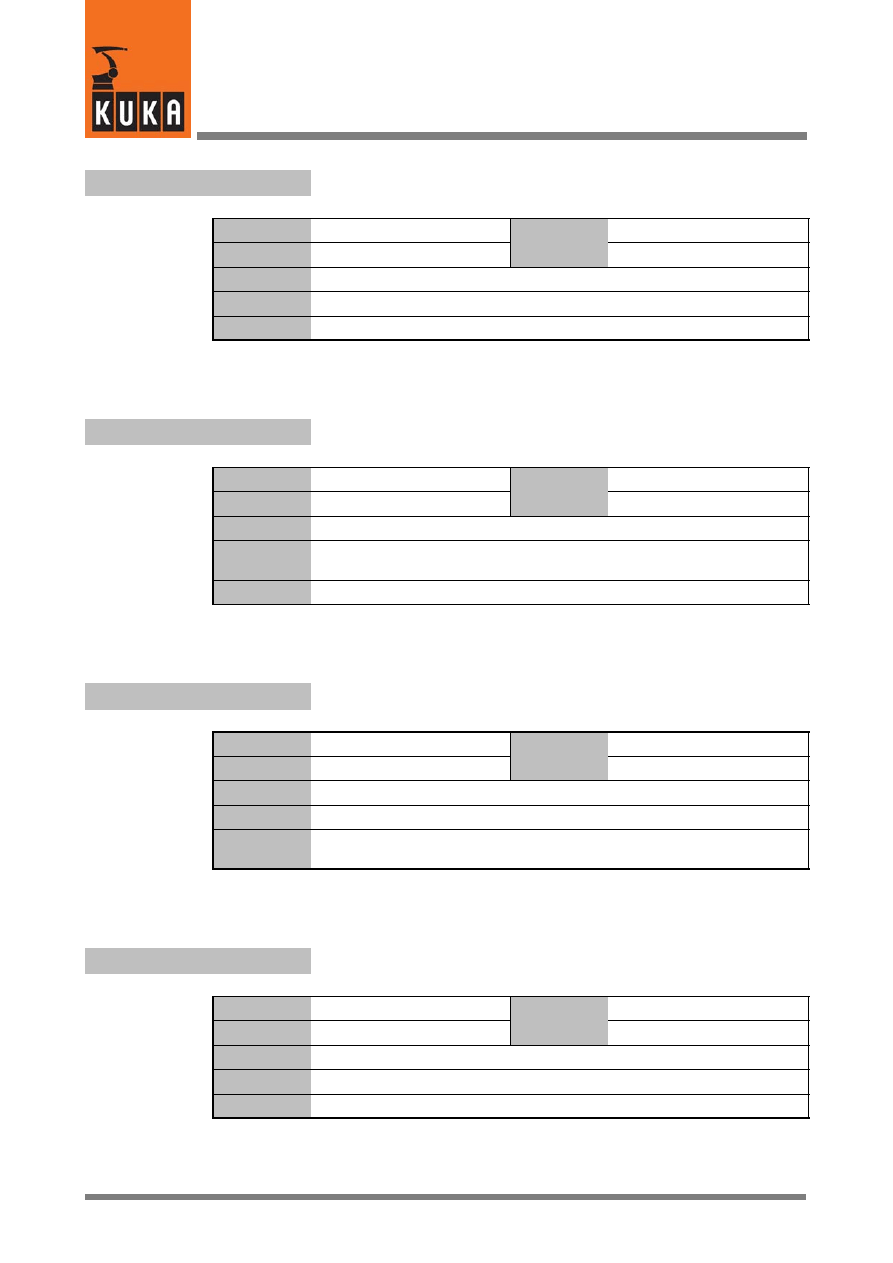

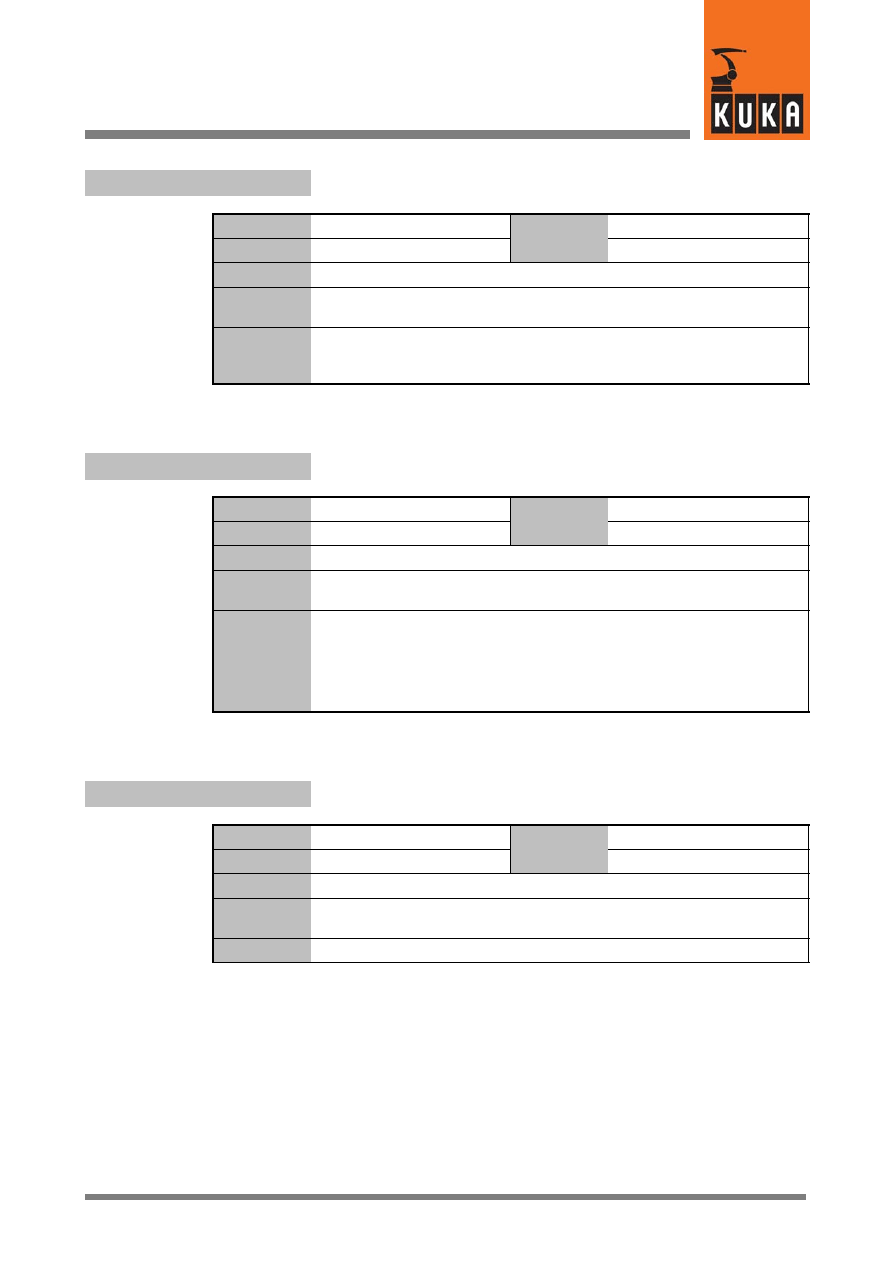

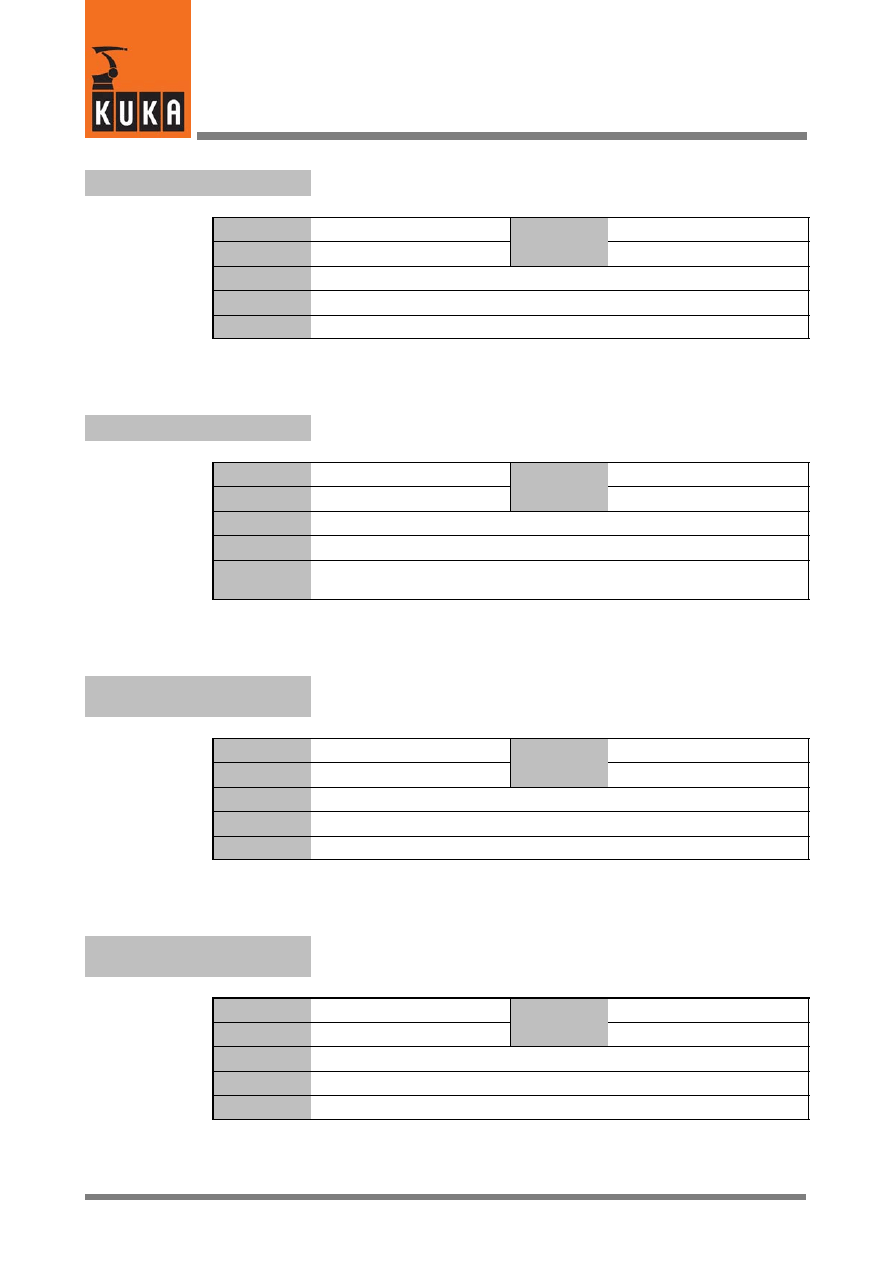

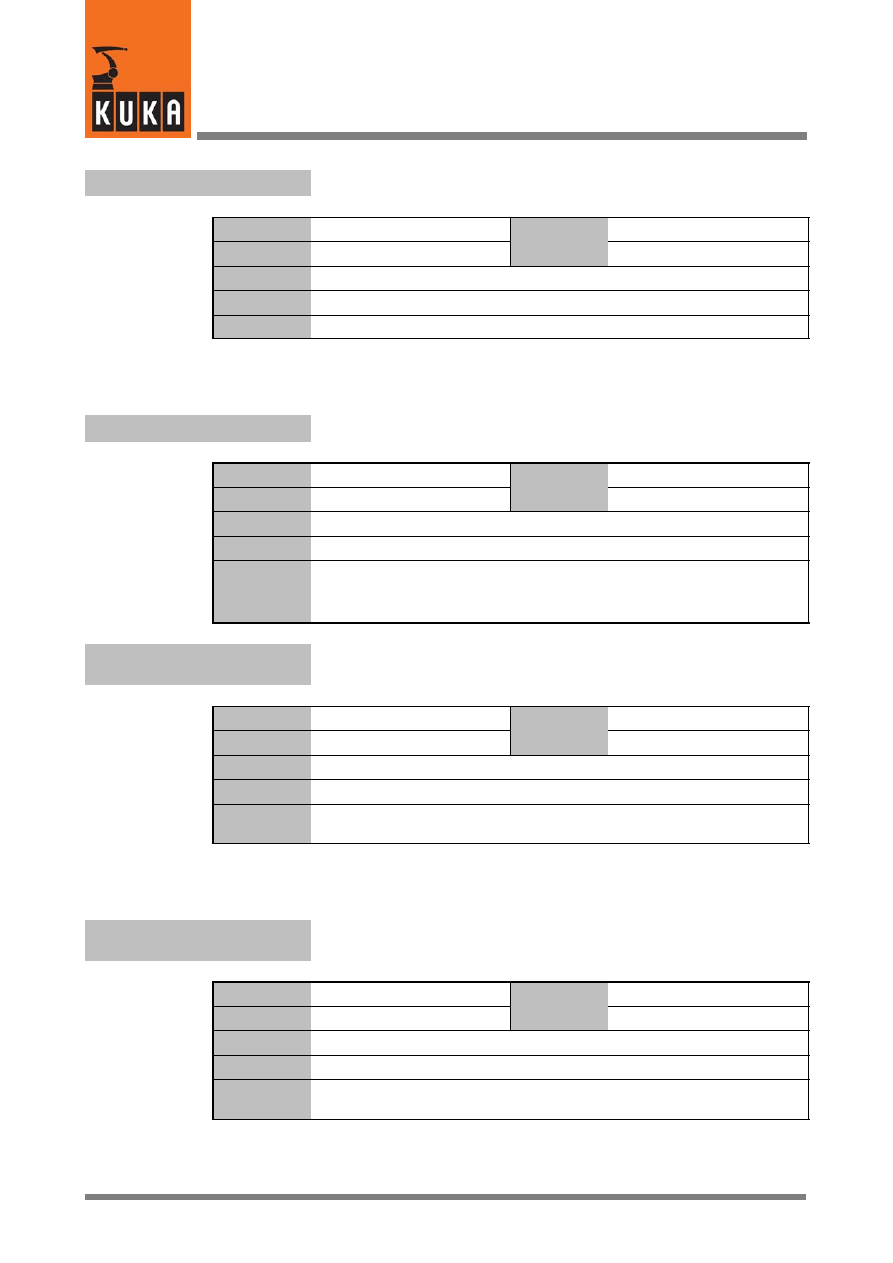

$A4PAR

Set axis 4 parallel to the last rotational main axis

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $A4PAR

Comments

Options

Effect

0

Not set

1

Set

$ABS_ACCUR

Switch absolutely accurate robot model on/off

Data type

Boolean

Value

min.

Unit

Value

max.

In file

------

Original line

BOOL $ABS_ACCUR=FALSE

;Absolutgenaues Robotermodell

Comments

Options

Effect

TRUE

Switched on

FALSE

Switched off

$ABS_CONVERT

Conversion of point coordinates into absolutely accurate robot

model

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$custom.dat

Original line

BOOL $ABS_CONVERT=FALSE

;Konvertierung der Punktkoordinaten

Comments

Options

Effect

TRUE

FALSE

System Variables

8 of 170

SysVar 08.02.03 en

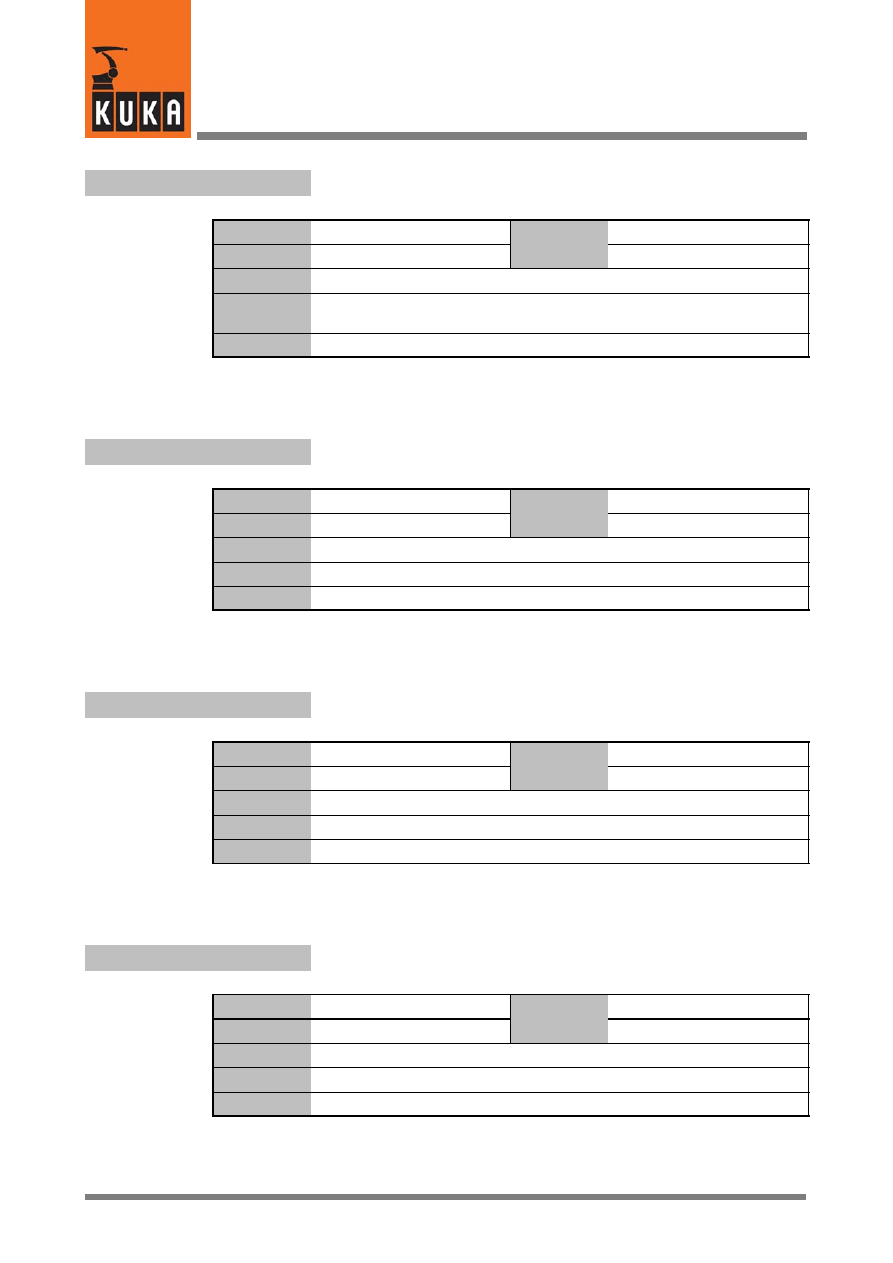

$ABS_RELOAD

Reload absolutely accurate robot model

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$operate.dat

Original line

BOOL $ABS_RELOAD

Comments

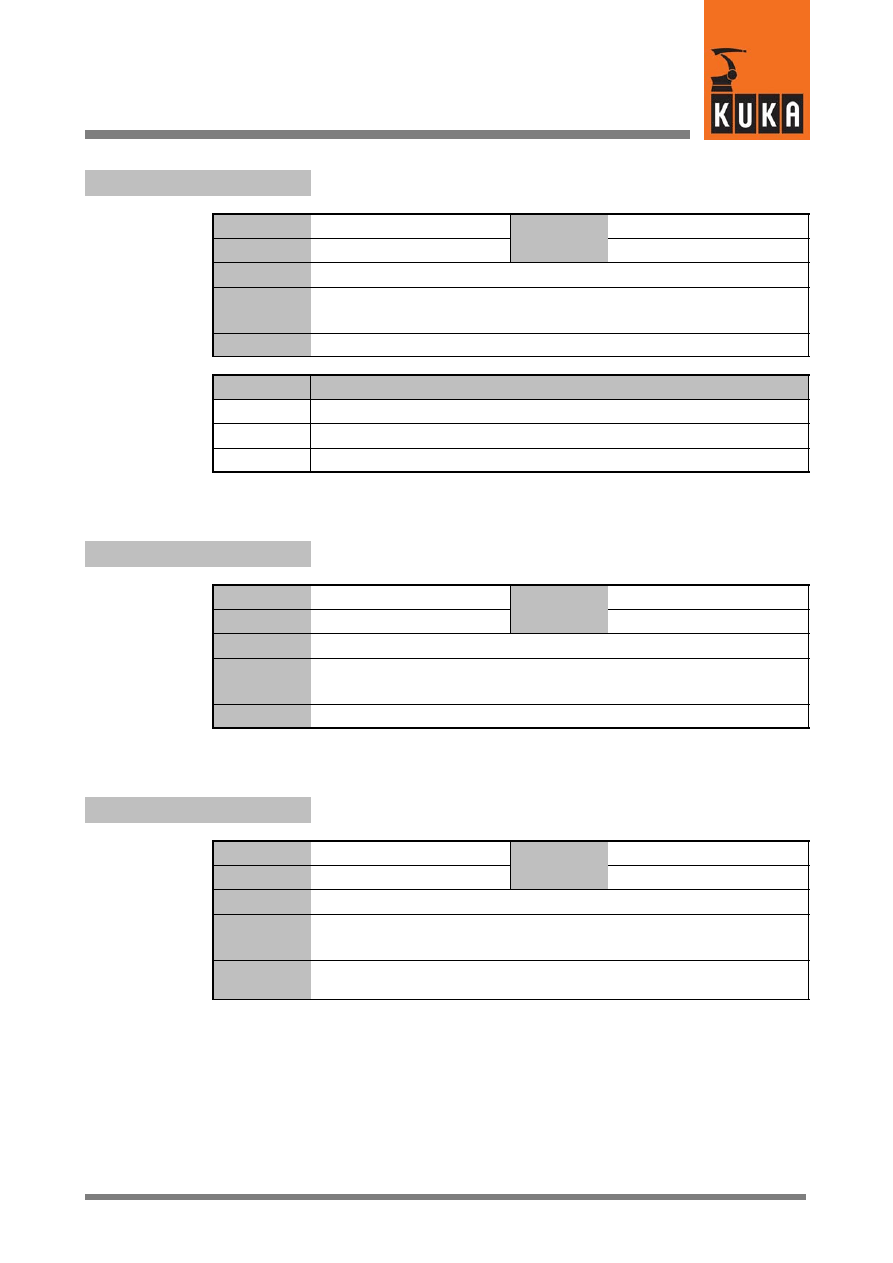

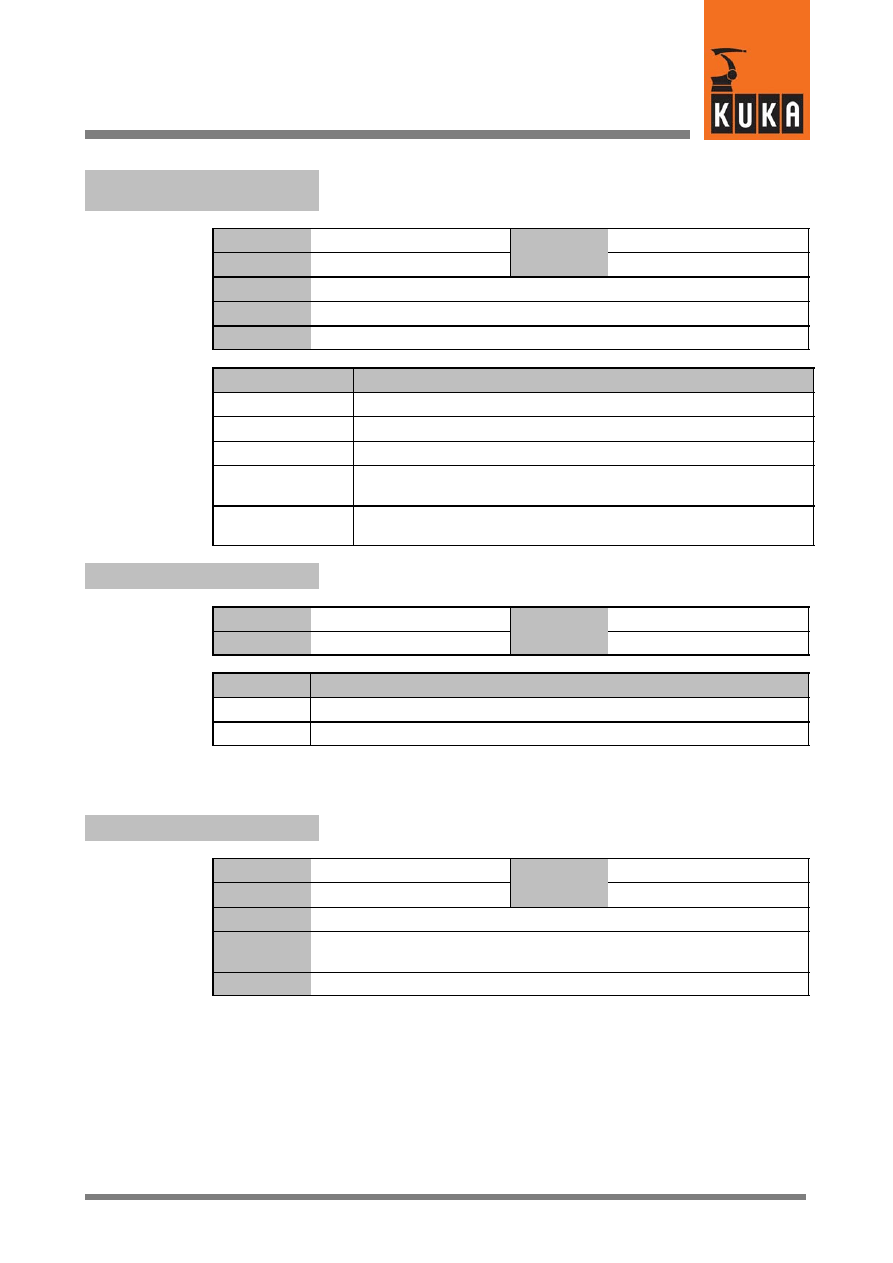

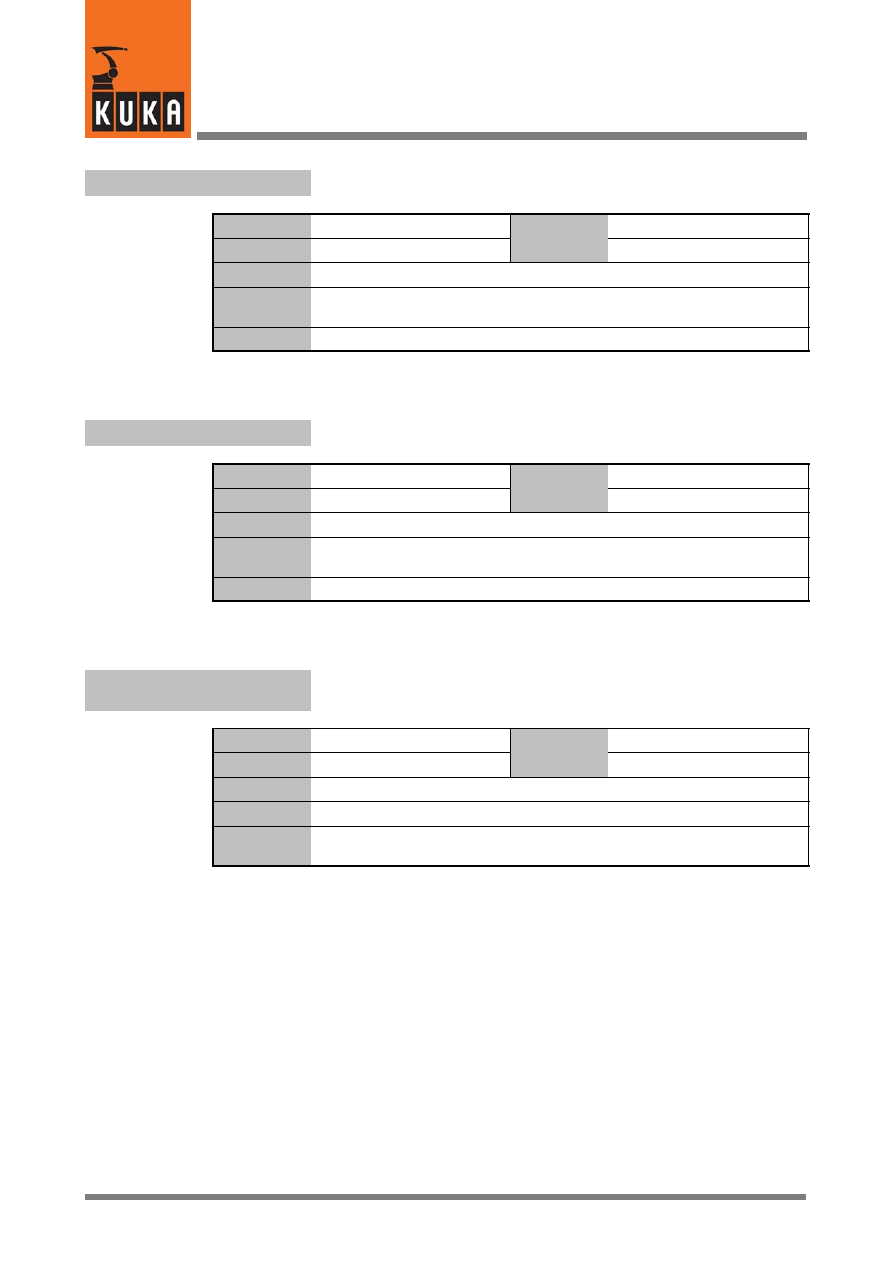

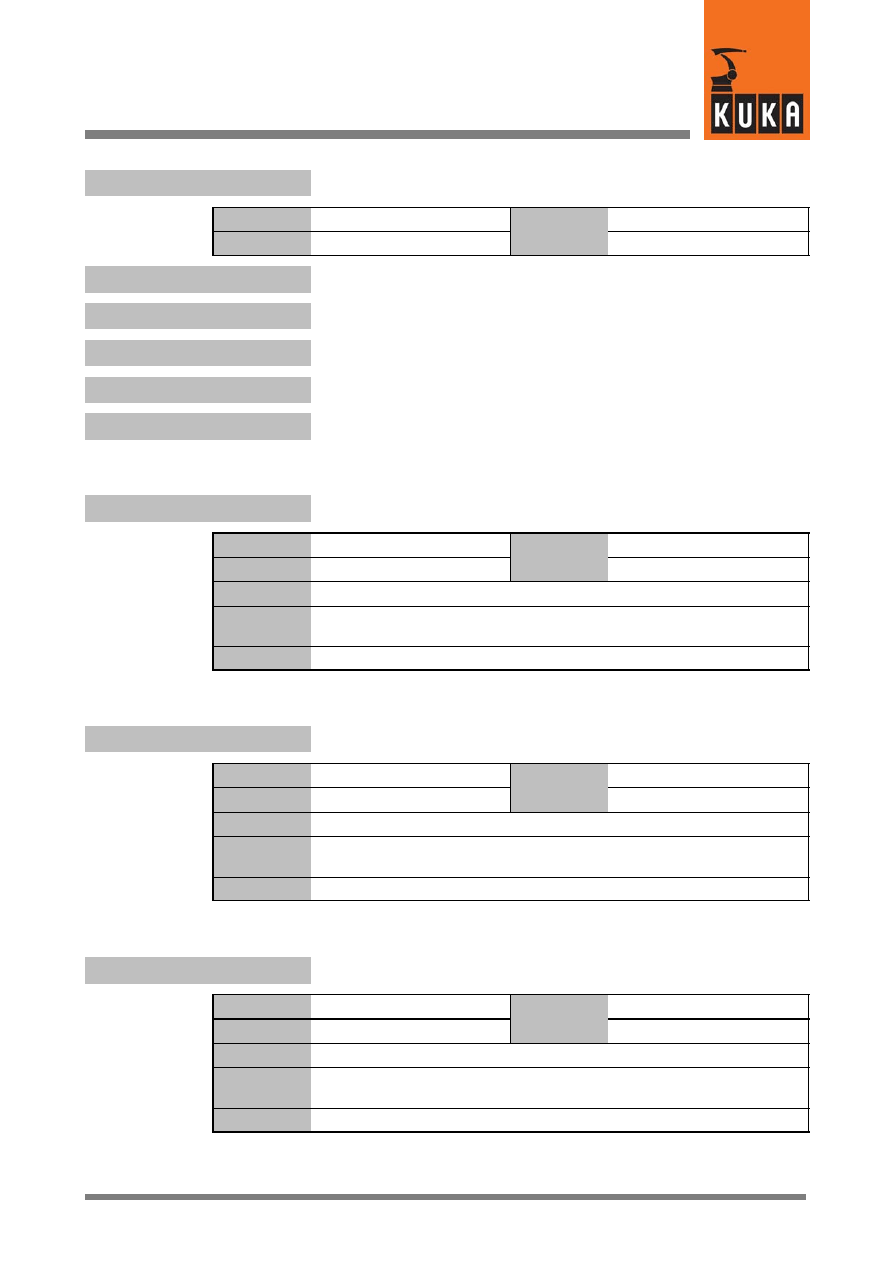

$ACC

Path, swivel and rotational accelerations in the advance run

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL CP $ACC

Comments

Accelerations in the advance run

CP = m/s

2

, ORI1 = °/s

2

, ORI2 = °/s

2

$ACC_ACT_MA

Limit value of axial command acceleration

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $ACC_ACT_MA=250

;Grenzwert Sollbeschleunigung [%]

Comments

$ACC_AXIS[n]

Acceleration of the axes in the advance run

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

------

Original line

INT $ACC_AXIS[n]

Beschleunigung der Achsen [%] Vorlauf

Comments

[n] = [1] ... [6] axes A1 ... A6

2

A (Fortsetzung)

9 of 170

SysVar 08.02.03 en

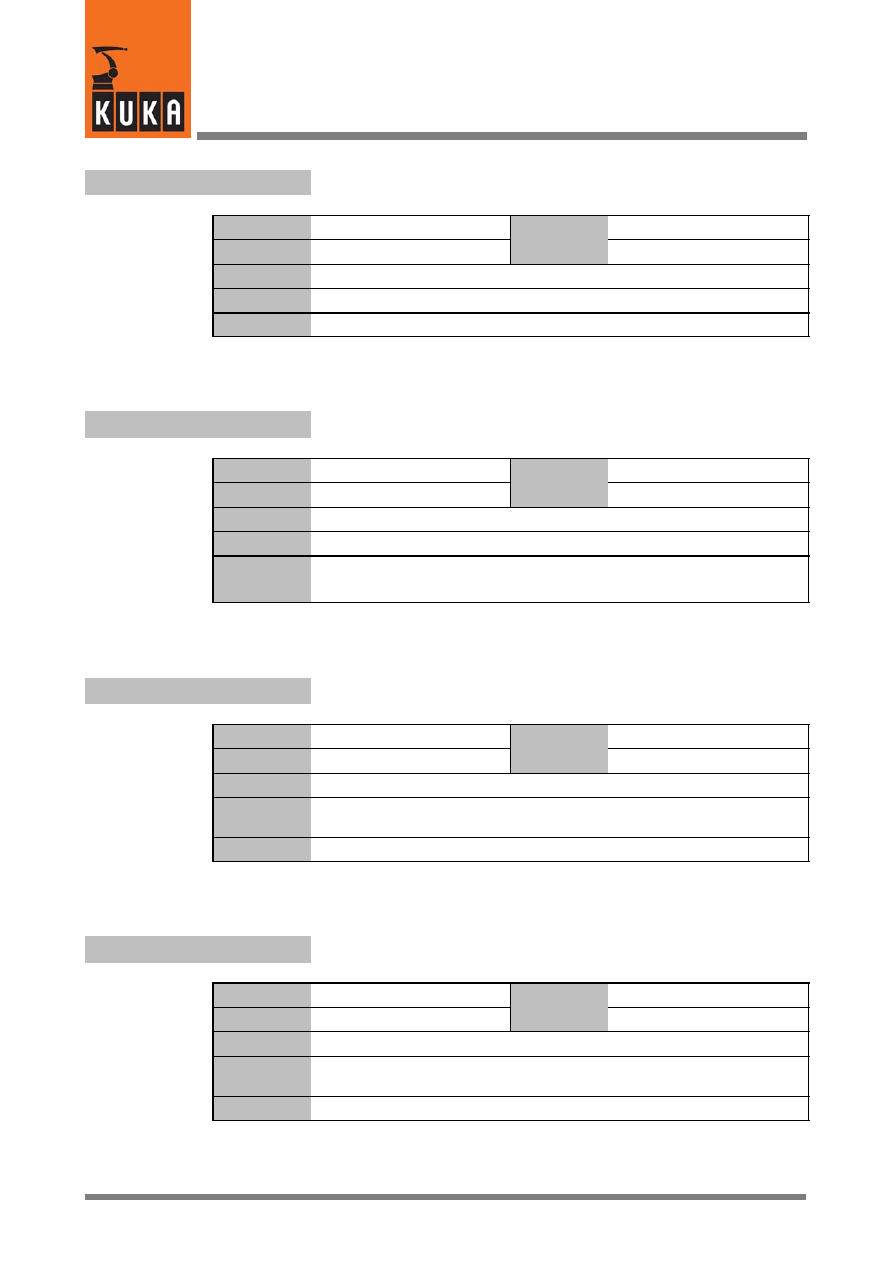

$ACC_AXIS_C[n]

Acceleration of the axes in the main run

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

R1\Mada\$operate.dat

Original line

INT $ACC_AXIS_C[n]

Beschleunigung der Achsen [%] Hauptlauf

Comments

[n] = [1] ... [6] axes A1 ... A6

$ACC_C

Path, swivel and rotational accelerations in the main run

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$operate.dat

Original line

DECL CP $ACC_C

Comments

Accelerations in the main run

CP = m/s

2

, ORI1 = °/s

2

, ORI2 = °/s

2

$ACC_CAR_ACT

The current values of the acceleration components and the total

acceleration

Data type

Frame

Value

min.

Unit

m/s

2

Value

max.

In file

R1\Mada\$operate.dat

Original line

DECL ACC_CAR $ACC_CAR_ACT

Comments

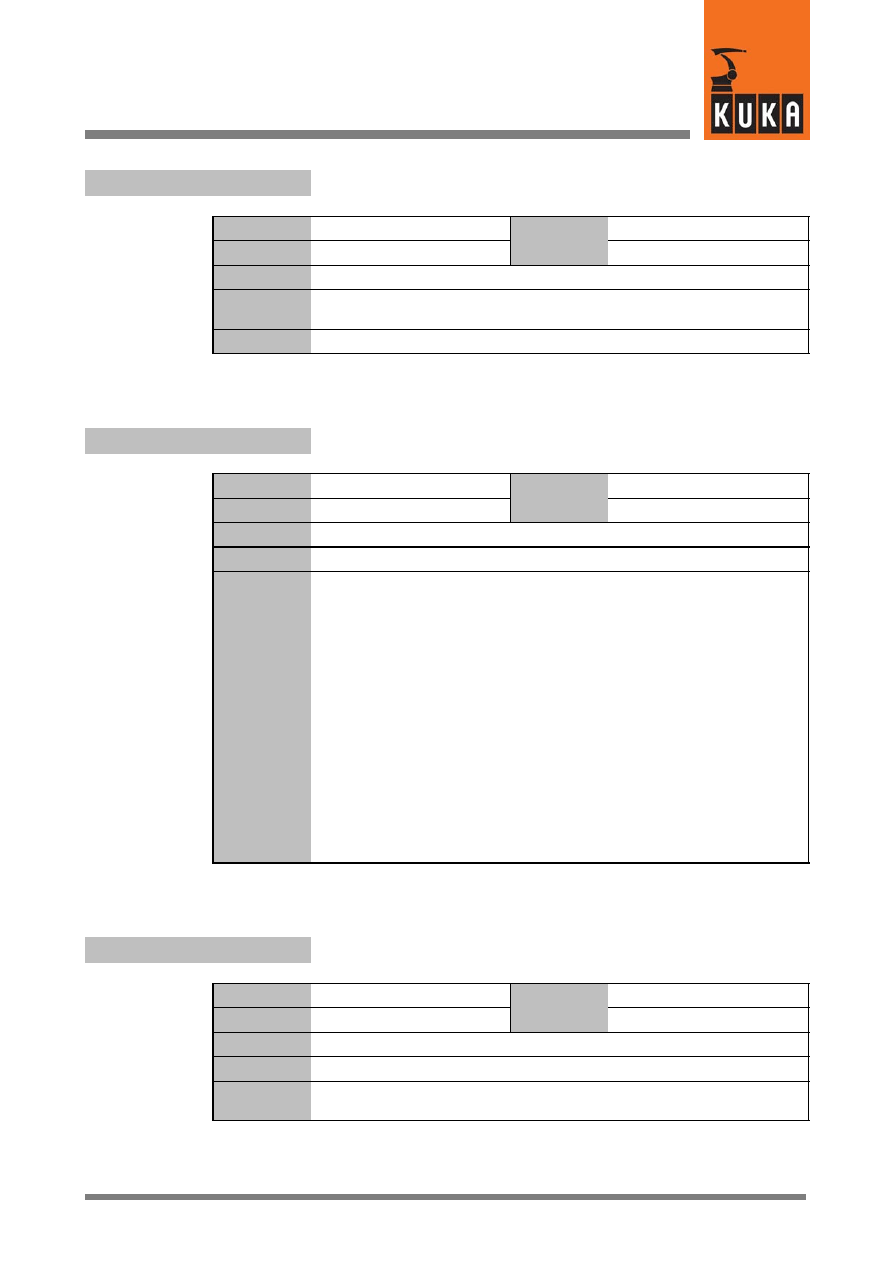

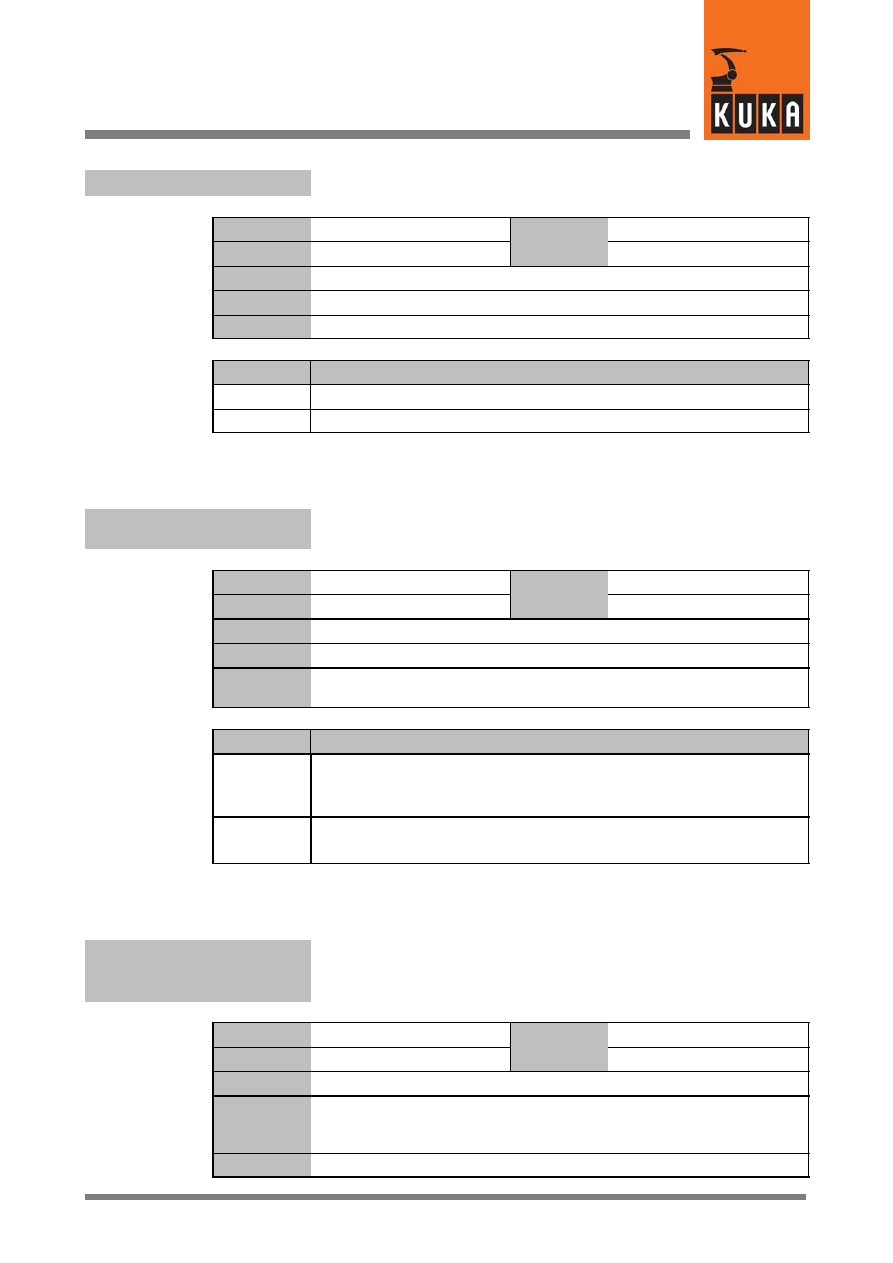

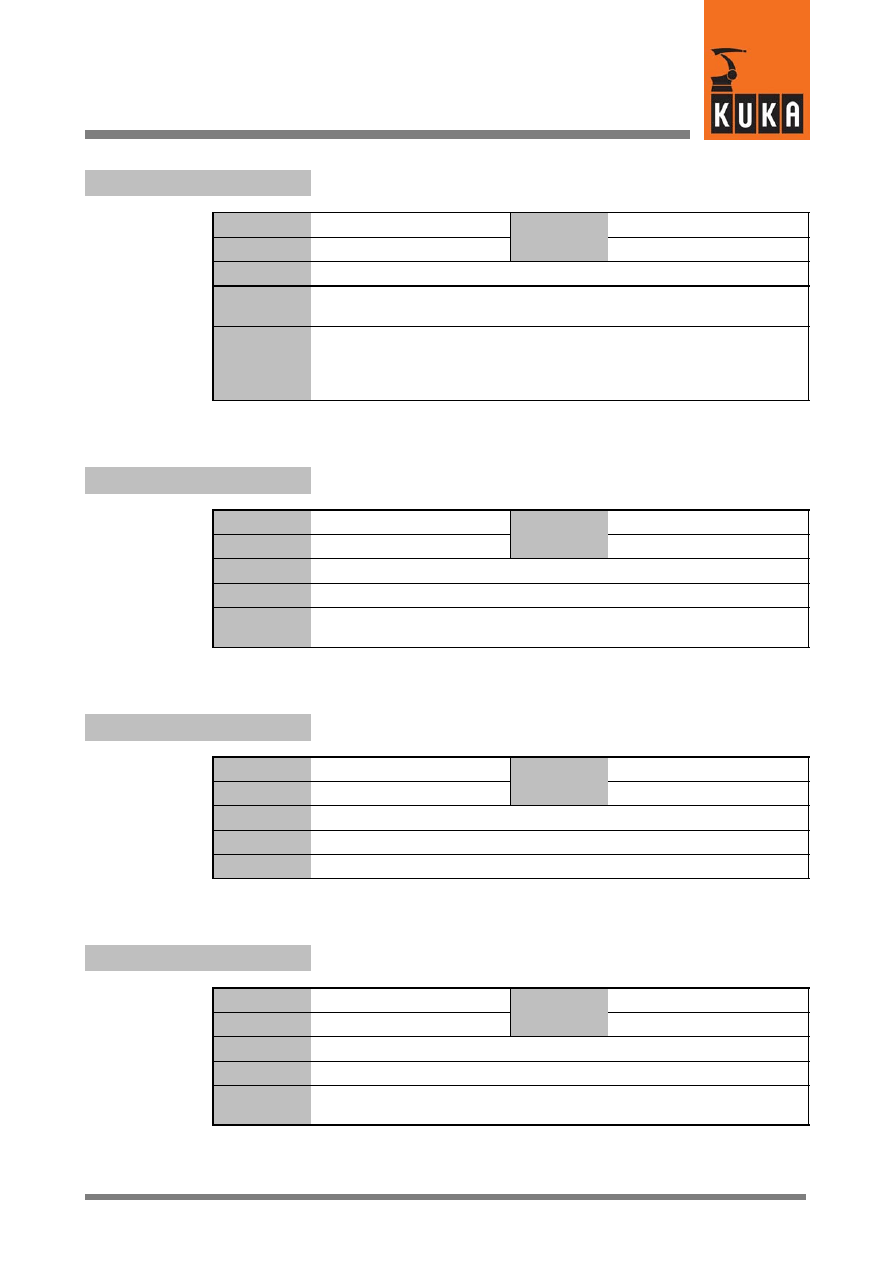

The X, Y and Z components of “$ACC_CAR_ACT” contain the acceleration

components along the axes of “$ACC_CAR_TOOL”. “$ACC_CAR_

ACT.ABS” contains the associated total acceleration value. Components A,

B and C are each set to “0”.

This variable is write--protected.

Acceleration due to gravity (9.81 m/s

2

) is automatically calculated into the

acceleration caused by the motion.

System Variables

10 of 170

SysVar 08.02.03 en

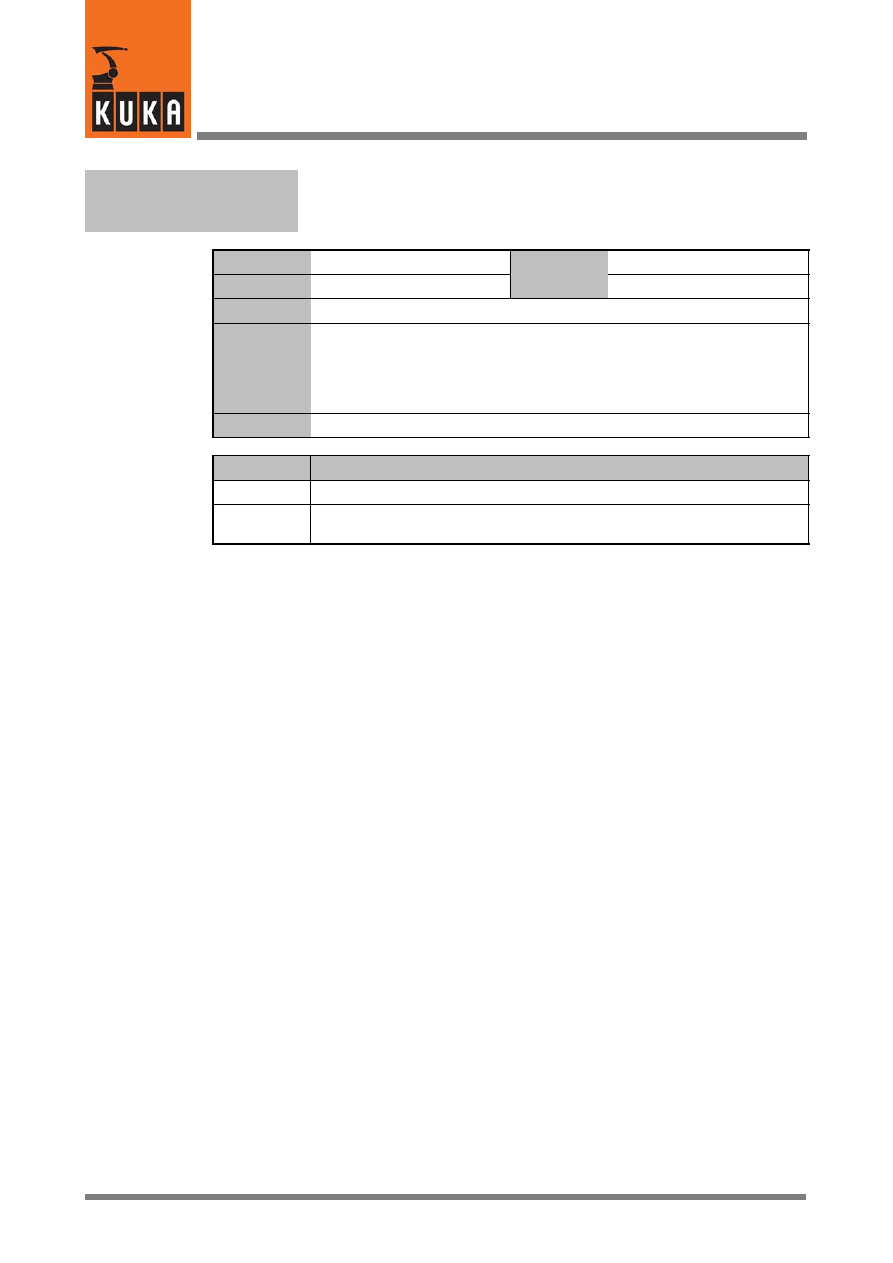

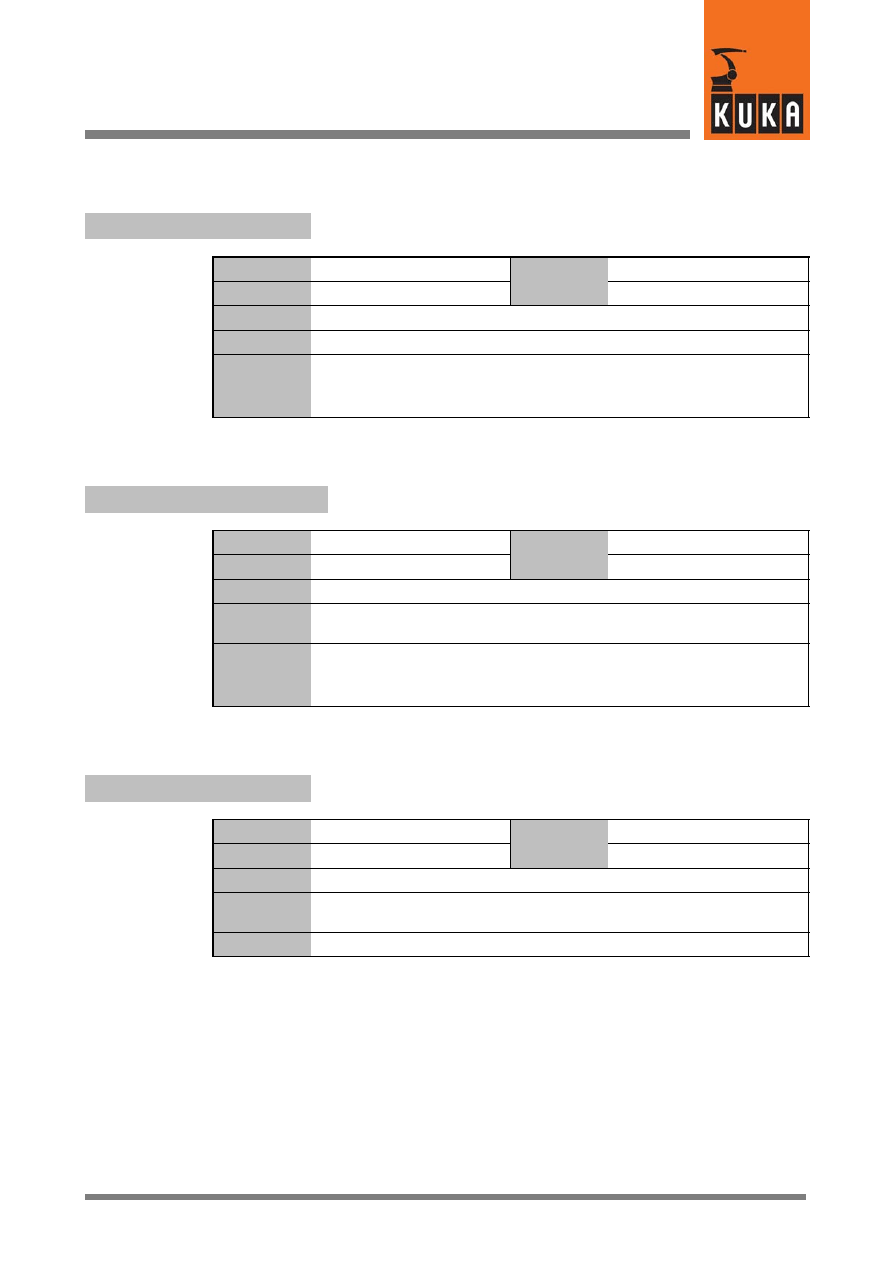

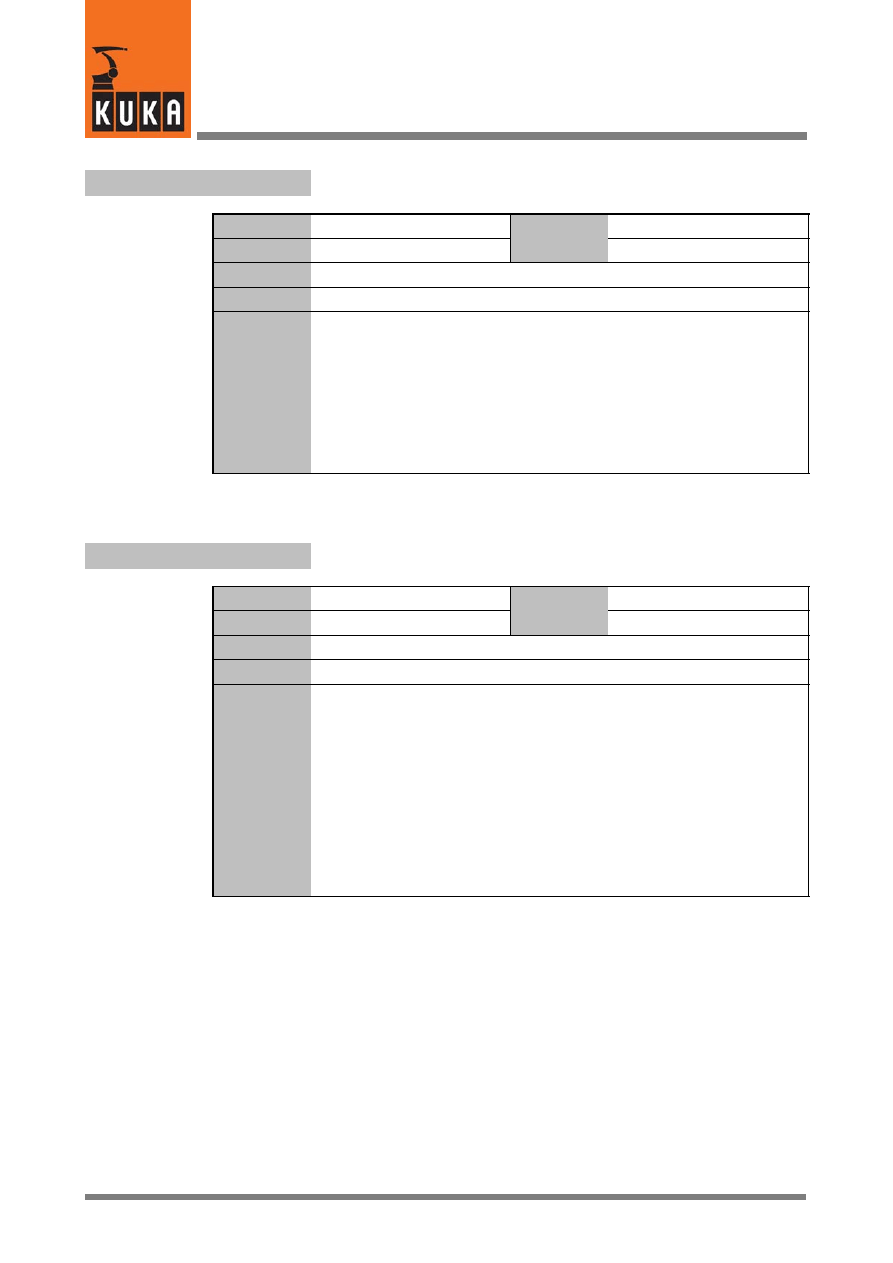

$ACC_CAR_LIMIT

Used to set the maximum permissible value for the acceleration

components and the total acceleration

Data type

Frame

Value

min.

Unit

m/s

2

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL ACC_CAR $ACC_CAR_LIMIT={X 0.0,Y 0.0,Z 0.0,A 0.0,B 0.0,C

0.0,ABS 0.0}

Comments

If the variable “$ACC_CAR_STOP” is set to “TRUE”, then if the acceleration

value is exceeded the robot is stopped (ramp--down braking) and an

acknowledgement message is generated.

The values can only be modified by editing the machine data.

$ACC_CAR_MAX

Saves the greatest absolute values of “$ACC_CAR_ACT”

Data type

Frame

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL ACC_CAR $ACC_CAR_MAX

Comments

This variable can be set to “0” to determine the maximum values.

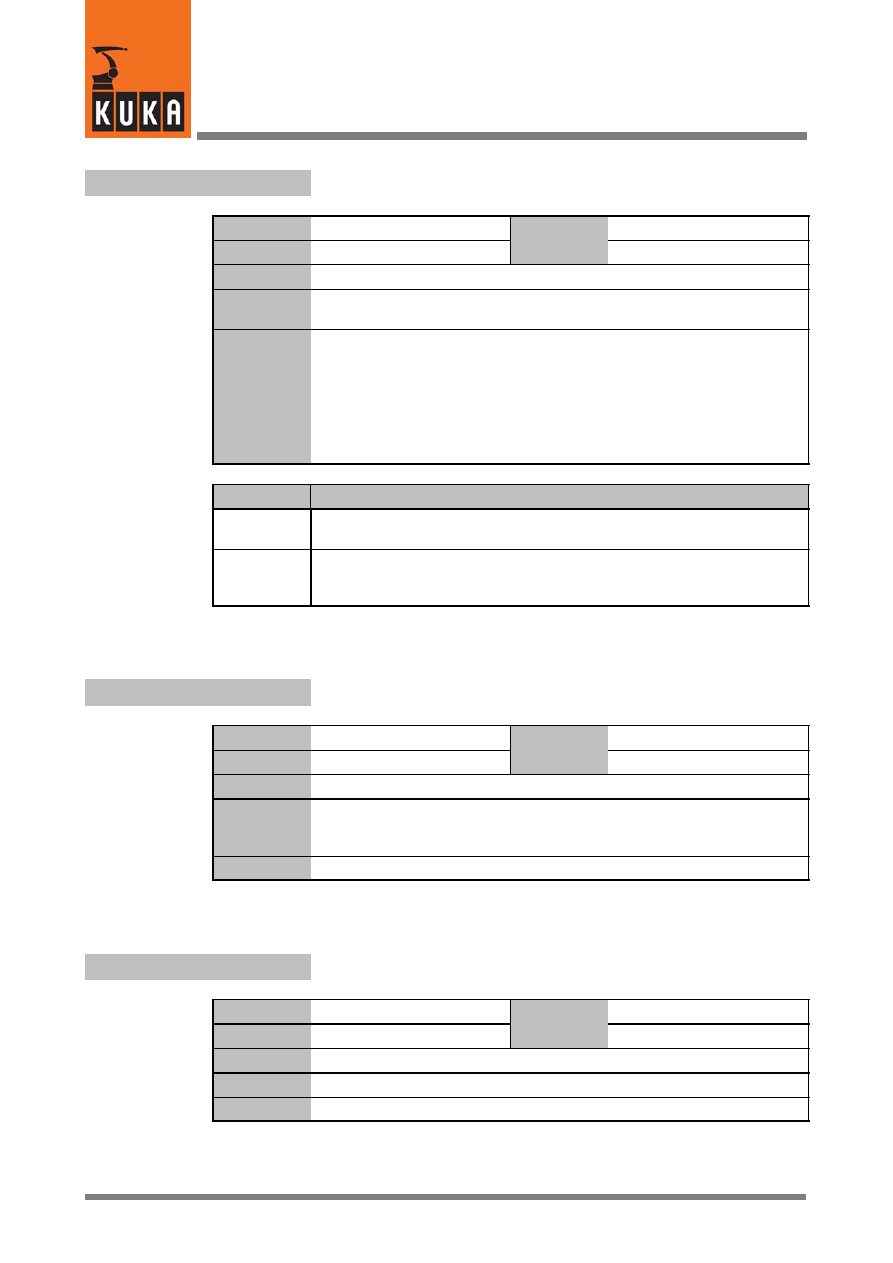

$ACC_CAR_STOP

The robot can be stopped if “$ACC_CAR_LIMIT” is exceeded

Data type

Boolean

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

BOOL $ACC_CAR_STOP=FALSE

Comments

Activates or deactivates the stop reaction when the value specified in

“$ACC_CAR_LIMIT” is exceeded.

The values can only be modified by editing the machine data.

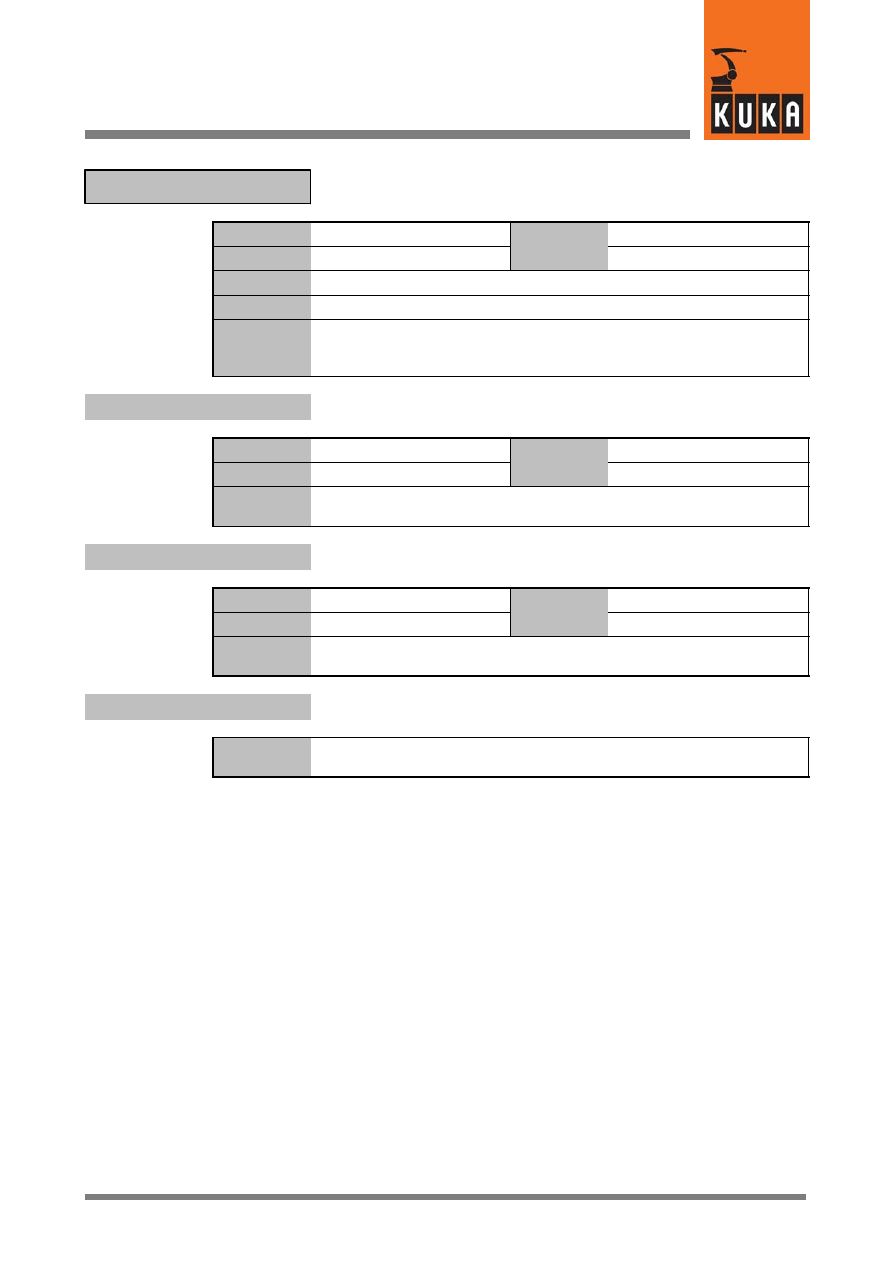

Options

Effect

TRUE

Stop reaction is activated.

FALSE

Stop reaction is deactivated.

2

A (Fortsetzung)

11 of 170

SysVar 08.02.03 en

$ACC_CAR_TOOL

A point on the tool mounted on the robot at which the current

effective acceleration is measured

Data type

Frame

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

FRAME $ACC_CAR_TOOL={x 0.0,y 0.0,z 0.0,a 0.0,b 0.0,c 0.0}

Comments

In the same way as “$TOOL”, $ACC_CAR_TOOL is also specified relative

to the flange by means of the X, Y and Z coordinates. The angles of rotation

A, B and C indicate the positions of the 3 axes of the coordinate system in

which the acceleration components are then specified. The individual

acceleration components and the total acceleration are all evaluated

cyclically.

Acceleration caused by gear unit torsion or flexion of the robot is not taken

into consideration. These values can only be modified by editing the

machine data.

$ACC_EXTAX[6]

Acceleration of the external axes in the advance run

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

------

Original line

INT $ACC_EXTAX[6]

;Beschleunigung der externen Achsen [%] Vorlauf

Comments

$ACC_EXTAX_C[6]

Acceleration of the external axes in the main run

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

------

Original line

INT $ACC_EXTAX_C[6]

;Beschleunigung der externen Achsen [%] Hauptlauf

Comments

System Variables

12 of 170

SysVar 08.02.03 en

$ACC_MA

Maximum values for path acceleration, swivel acceleration and

rotational acceleration

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL CP $ACC_MA={CP 4.6,ORI1 200.0,ORI2 200.0}

Comments

CP

= Max. path acceleration [m/s

2

],

ORI1 = Max. swivel acceleration [°/s

2

],

ORI2 = Max. rotational acceleration [°/s

2

]

When calculating the values, make sure that no axis goes to current

limitation.

$ACC_OV

Data for acceleration with changes of override

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL CP $ACC_MA={CP 4.6,ORI1 200.0,ORI2 200.0}

Comments

CP

= Path acceleration with change of override [m/s

2

],

ORI1 = Swivel acceleration with change of override [°/s

2

],

ORI2 = Rotational acceleration with change of override [°/s

2

]

$ACT_BASE

Number of the current BASE system

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $ACT_BASE

;Aktuelle Base--Nummer

Comments

$ACT_EX_AX

Number of the current external base kinematic system

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $ACT_EX_AX

;Aktuelle externe Kinematik

Comments

2

A (Fortsetzung)

13 of 170

SysVar 08.02.03 en

$ACT_TOOL

Number of the current tool coordinate system

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $ACT_TOOL

;Aktuelle Toolnummer

Comments

$ACT_VAL_DIF

Max. permissible difference of encoder actual values when switching

on system

Data type

Integer

Value

min.

Unit

Increments

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $ACT_VAL_DIF

;Geberistwertdifferenz [Inkr]

Comments

If the limit values are exceeded, the message “Perform mastering”

appears.

$ADAP_ACC

Activation of acceleration adaptation

Data type

Enum

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

DECL ADAP_ACC $ADAP_ACC=#STEP1

;Beschleunigungsanpassung

(#NONE, #STEP1 )

Comments

*) #STEP1 and #STEP2 require valid dynamic data ($DYN_DAT)

Options

Effect

#NONE

Not activated

#STEP1

Dynamic model without kinetic energy *)

#STEP2

Dynamic model with kinetic energy *)

System Variables

14 of 170

SysVar 08.02.03 en

$ADVANCE

Specification of the advance run (max. 5 motion blocks)

Data type

Integer

Value

min. 0

Unit

Motion blocks

Value

max. 5

In file

------

Original line

INT $ADVANCE

;Vorlauf [max. 5 Bewegungssätze]

Comments

$ALARM_STOP

Signal declaration for short--circuit braking (dynamic braking)

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $ALARM_STOP $OUT[1013]

Comments

$ANA_DEL_FLT

Analog output filter

Data type

Enum

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL SW_ONOFF $ANA_DEL_FLT=#OFF

Comments

Options

Effect

#ON

Switched on

#OFF

Switched off

$ANIN[n]

Analog inputs

Data type

Real

Value

min. --1.0

Unit

V

Value

max. +1.0

In file

------

Original line

REAL $ANIN[n]

Comments

[n] = [1] ... [8]

--1.0 ----> --10 V

+1.0 ----> +10 V

2

A (Fortsetzung)

15 of 170

SysVar 08.02.03 en

$ANOUT[n]

Analog outputs

Data type

Real

Value

min. --1.0

Unit

V

Value

max. +1.0

In file

------

Original line

REAL $ANOUT[n]

Comments

[n] = [1] ... [16]

--1.0 ----> --10 V

+1.0 ----> +10 V

$APO_DIS_PTP[n]

Maximum approximation distance for PTP axis[

n

]

Data type

Real

Value

min.

Unit

mm, °

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $APO_DIS_PTP[

n

]

Comments

[n] = [1] ... [6]:

axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

Motion input for asynchronous external axes E1 -- E6,

negative or positive direction

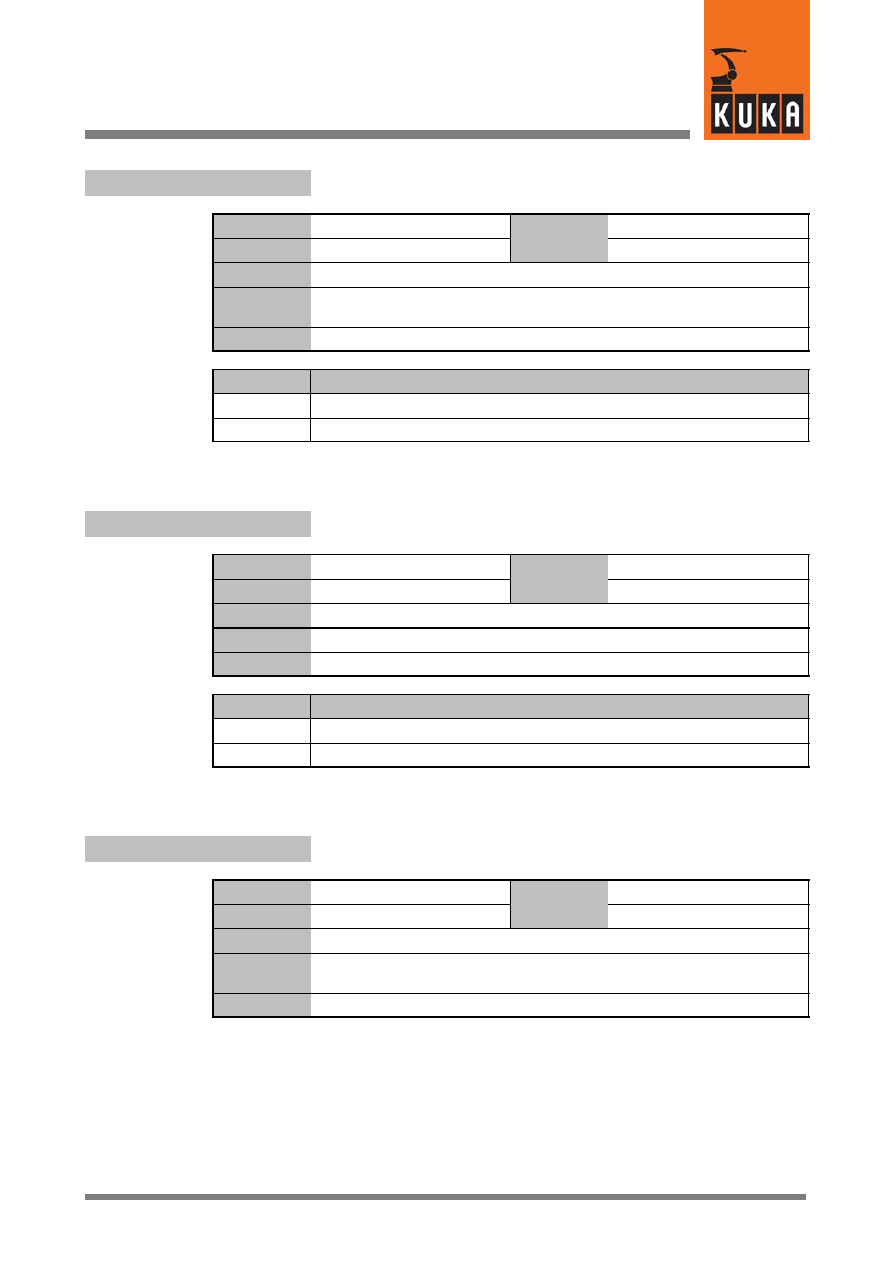

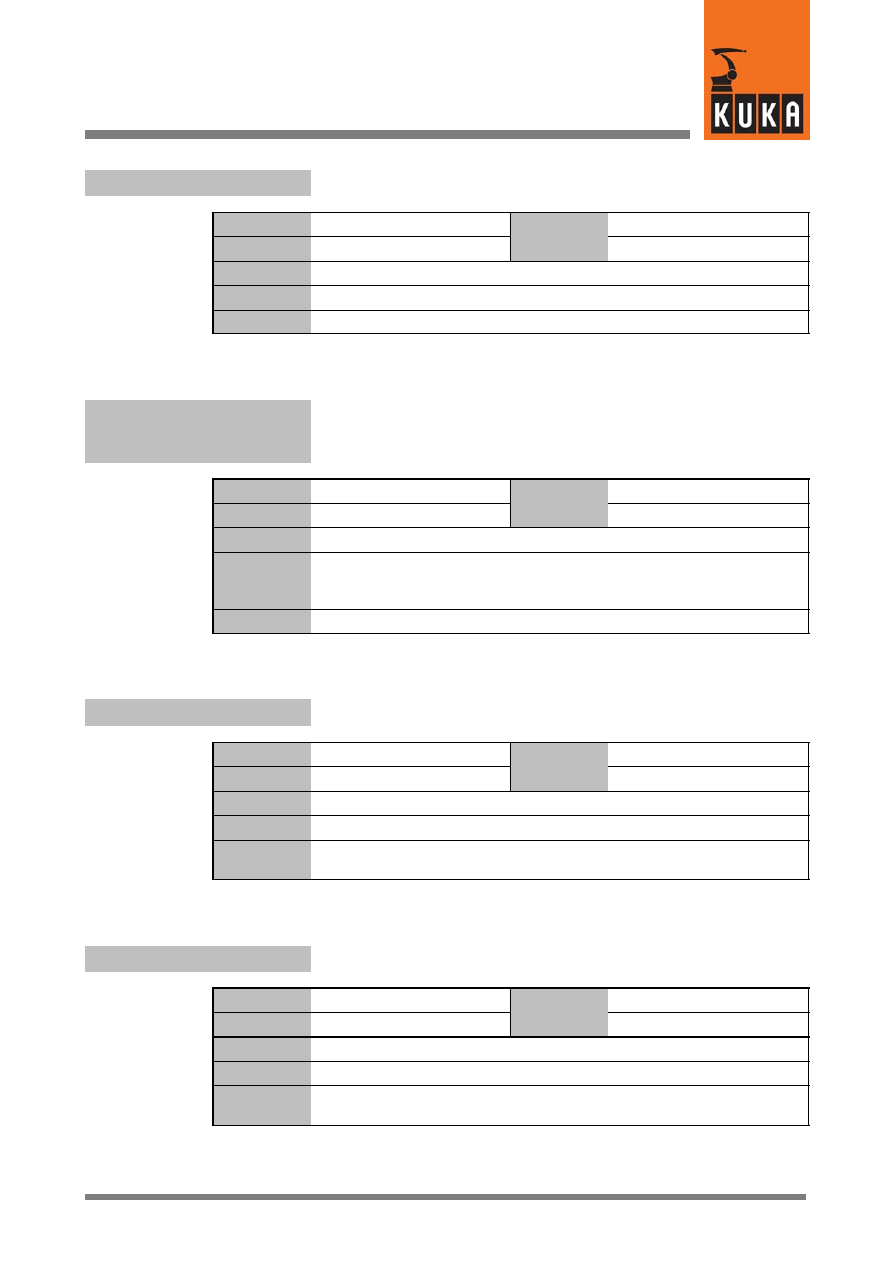

$ASYNC_AX

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

Comments

$ASYNC_AX1_M

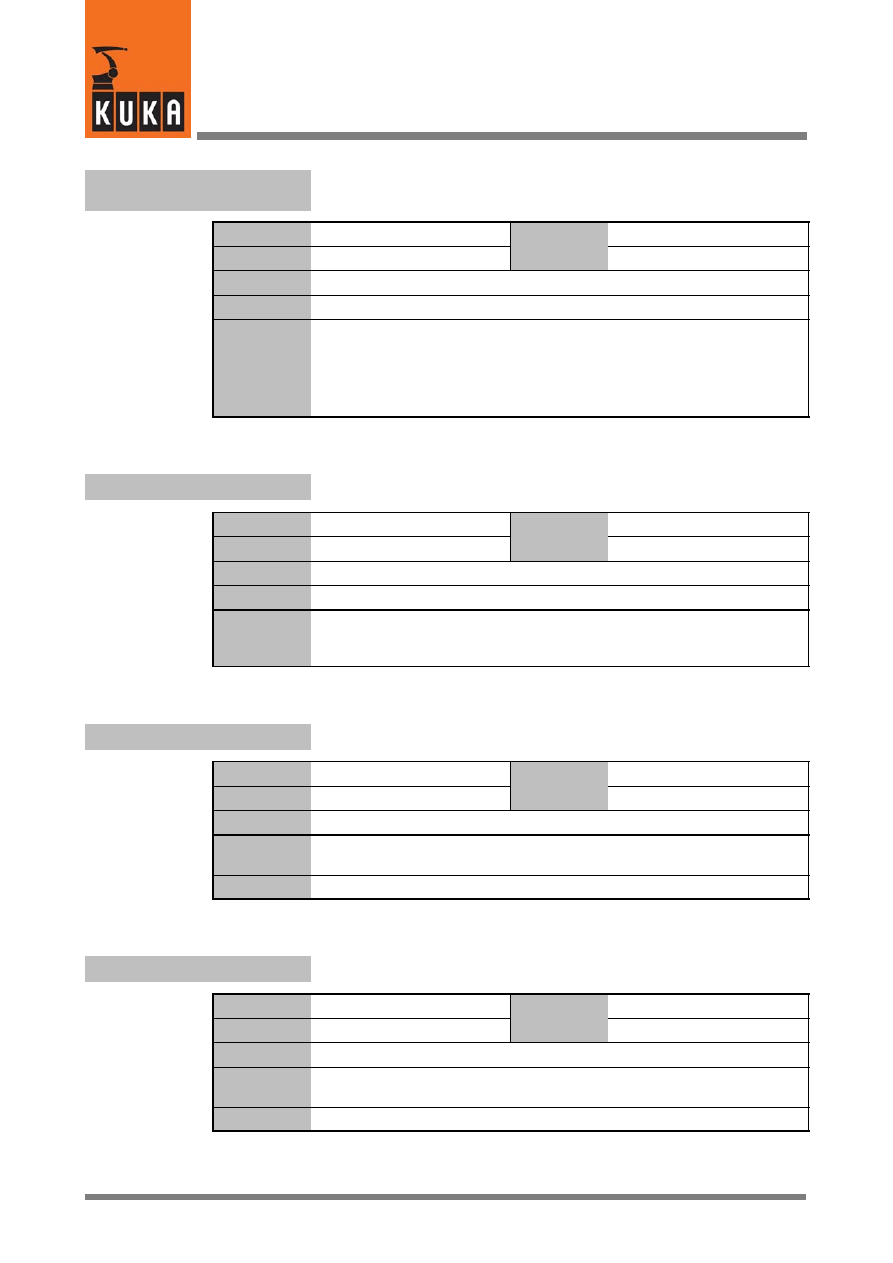

...

$ASYNC_AX6_M

Motion input for asynchronous external axes E1 -- E6,

negative direction

Original line

SIGNAL $ASYNC_AX1_M $IN[1026]

...

SIGNAL $ASYNC_AX6_M $IN[1026]

System Variables

16 of 170

SysVar 08.02.03 en

$ASYNC_AX1_P

...

$ASYNC_AX6_P

Motion input for asynchronous external axes E1 -- E6,

positive direction

Original line

SIGNAL $ASYNC_AX1_P $IN[1026]

...

SIGNAL $ASYNC_AX6_P $IN[1026]

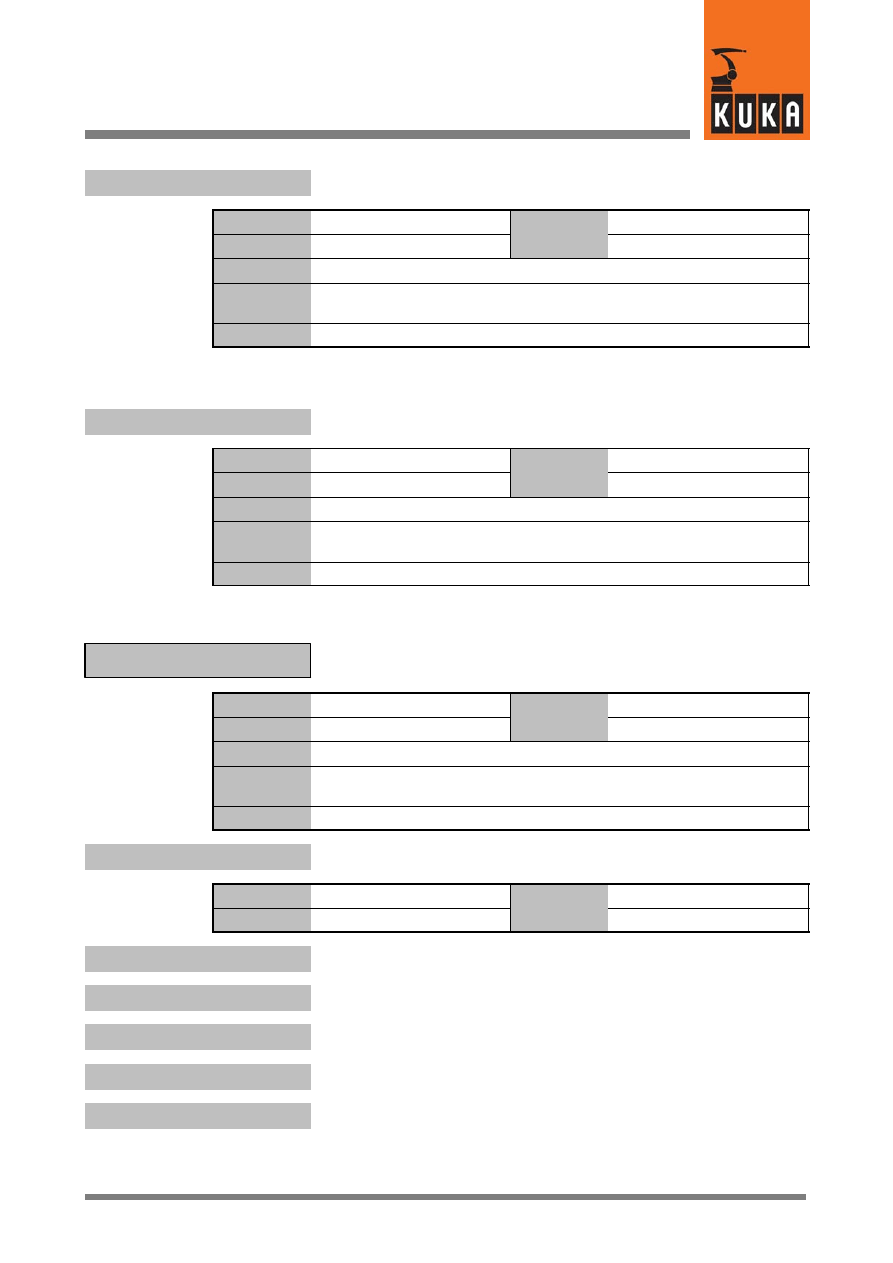

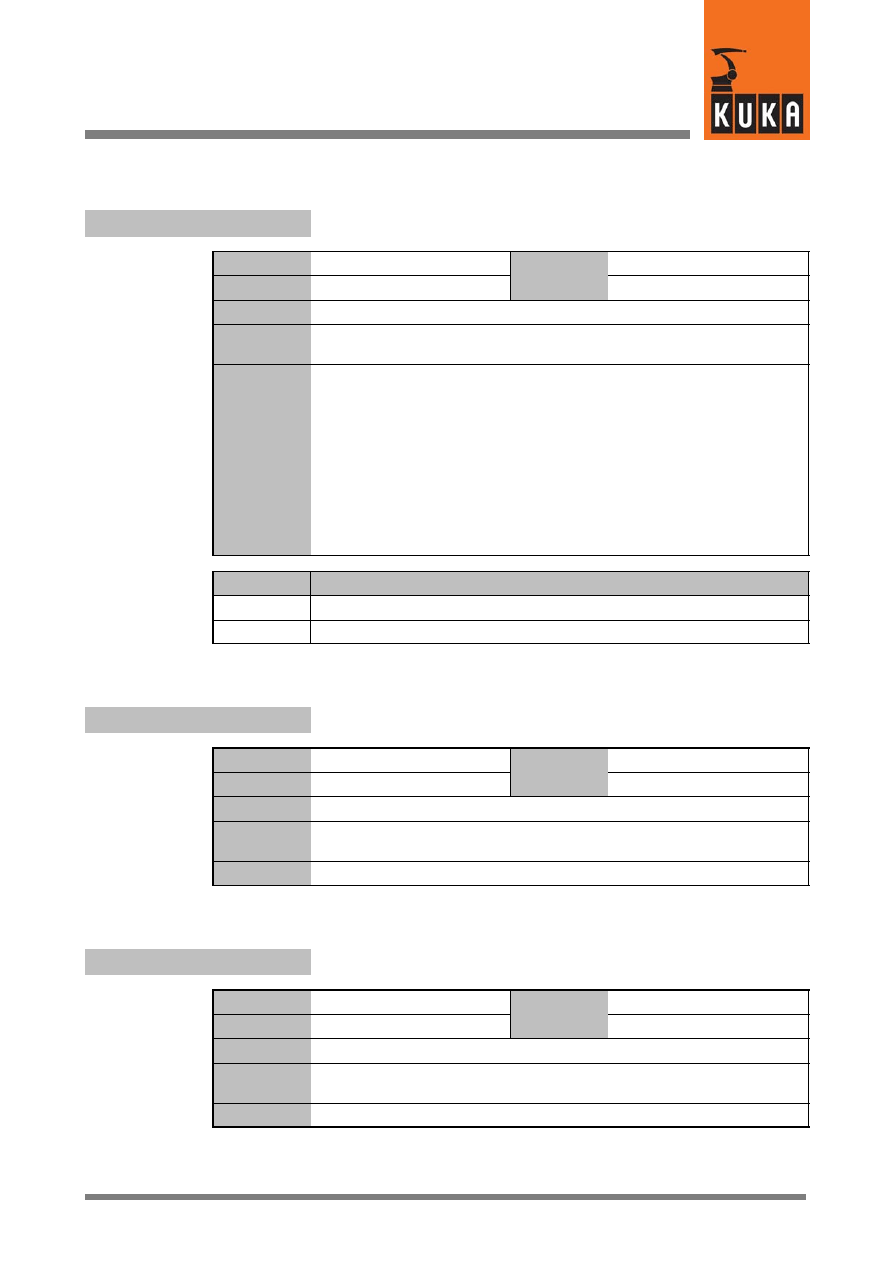

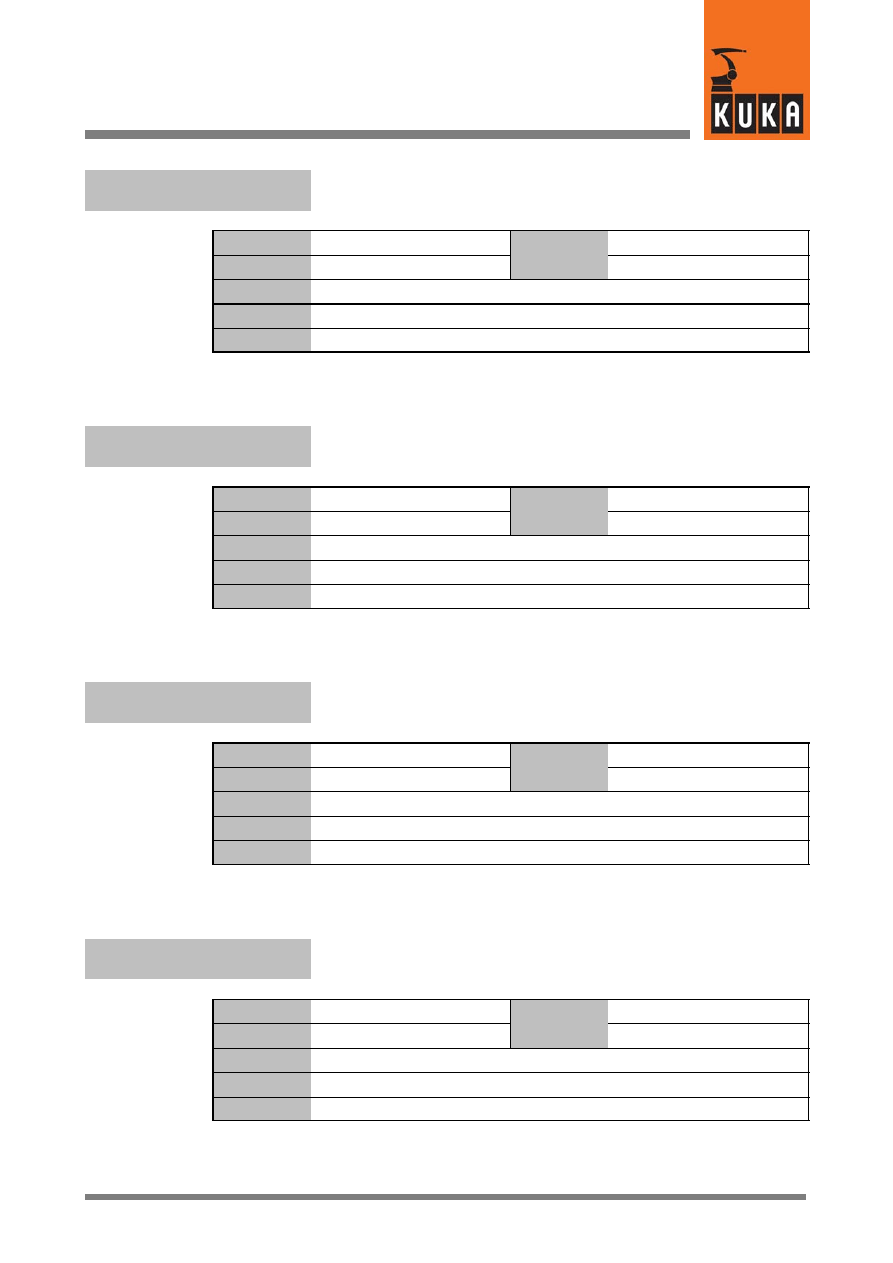

$ASYNC_AXIS

Bit arrays to switch external axes to asynchronous mode

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $ASYNC_AXIS

;Aktive asynchrone Zusatzachsen

Comments

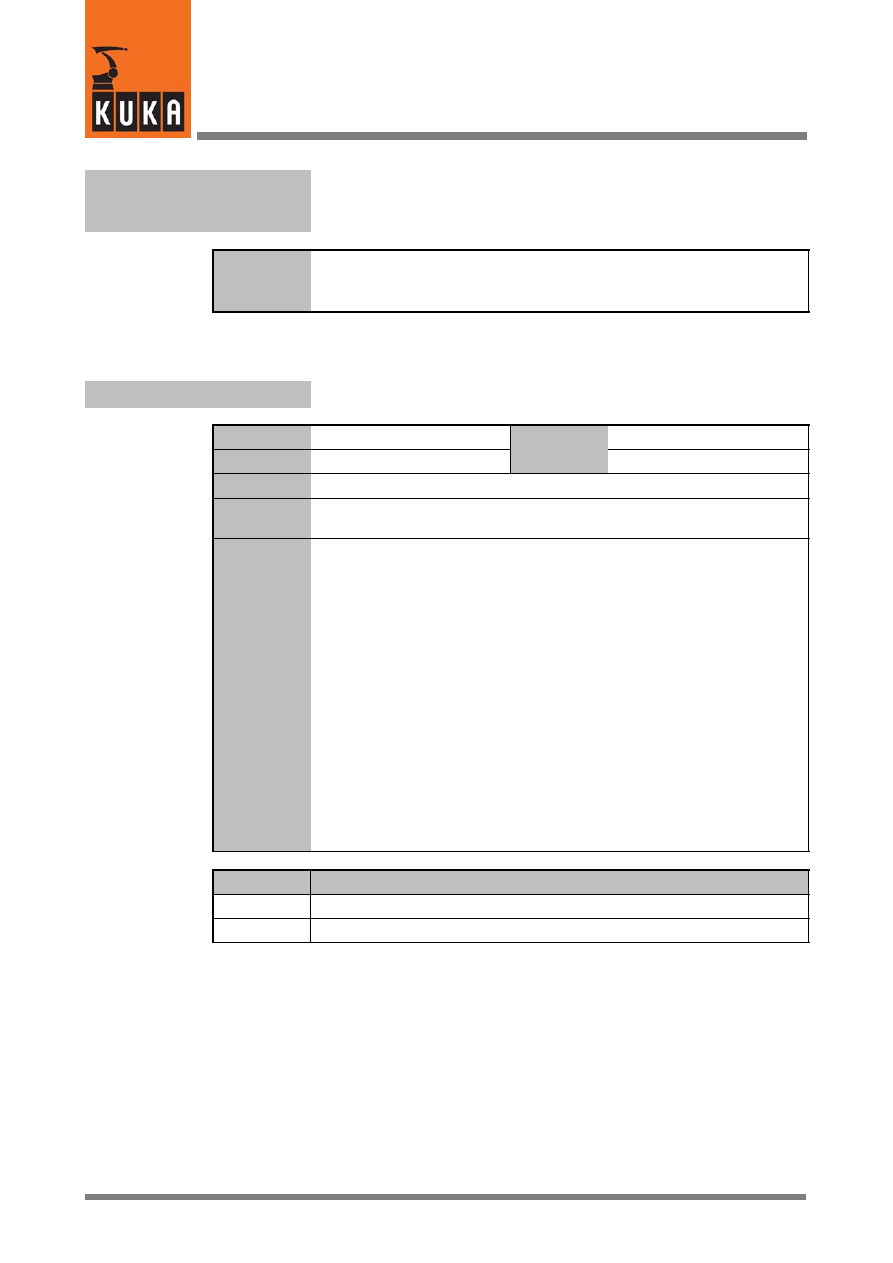

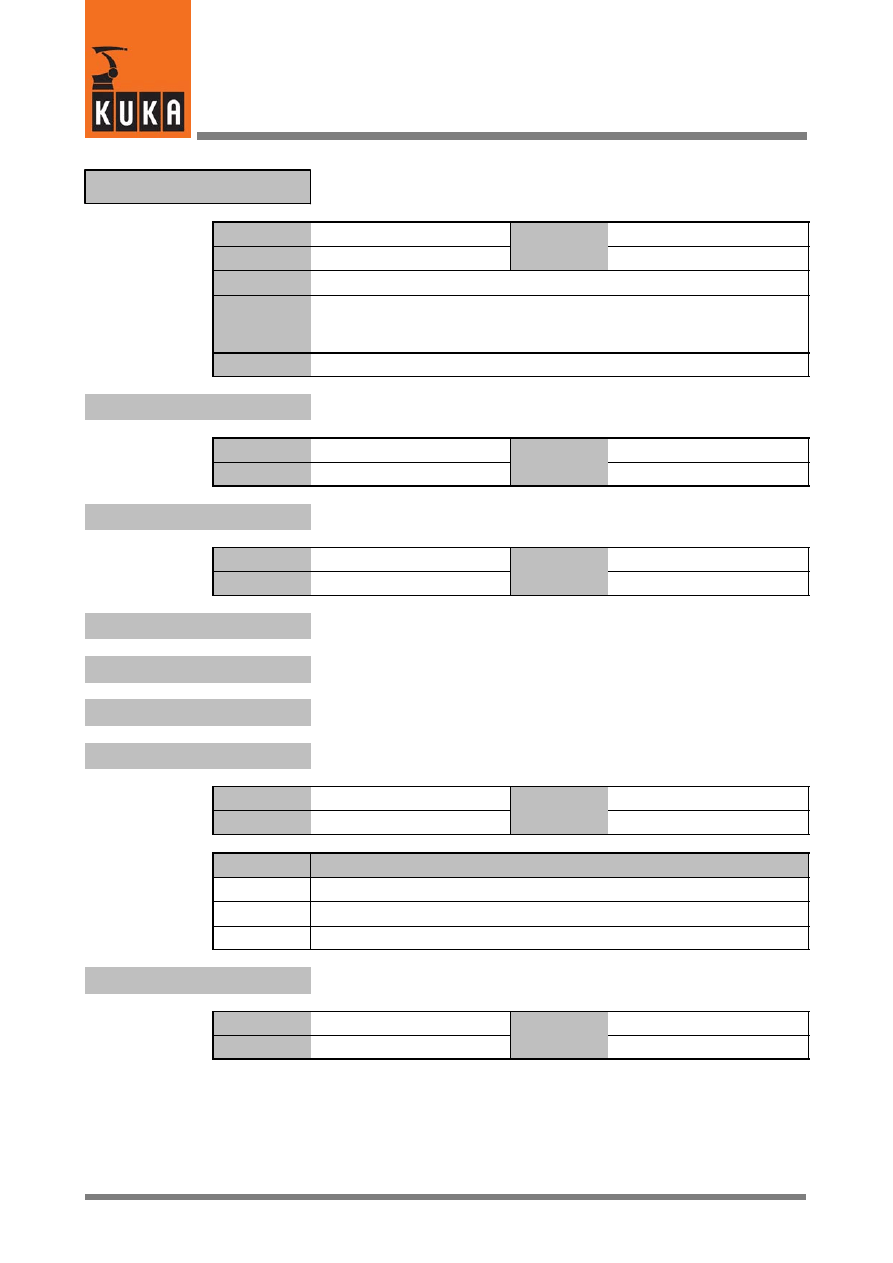

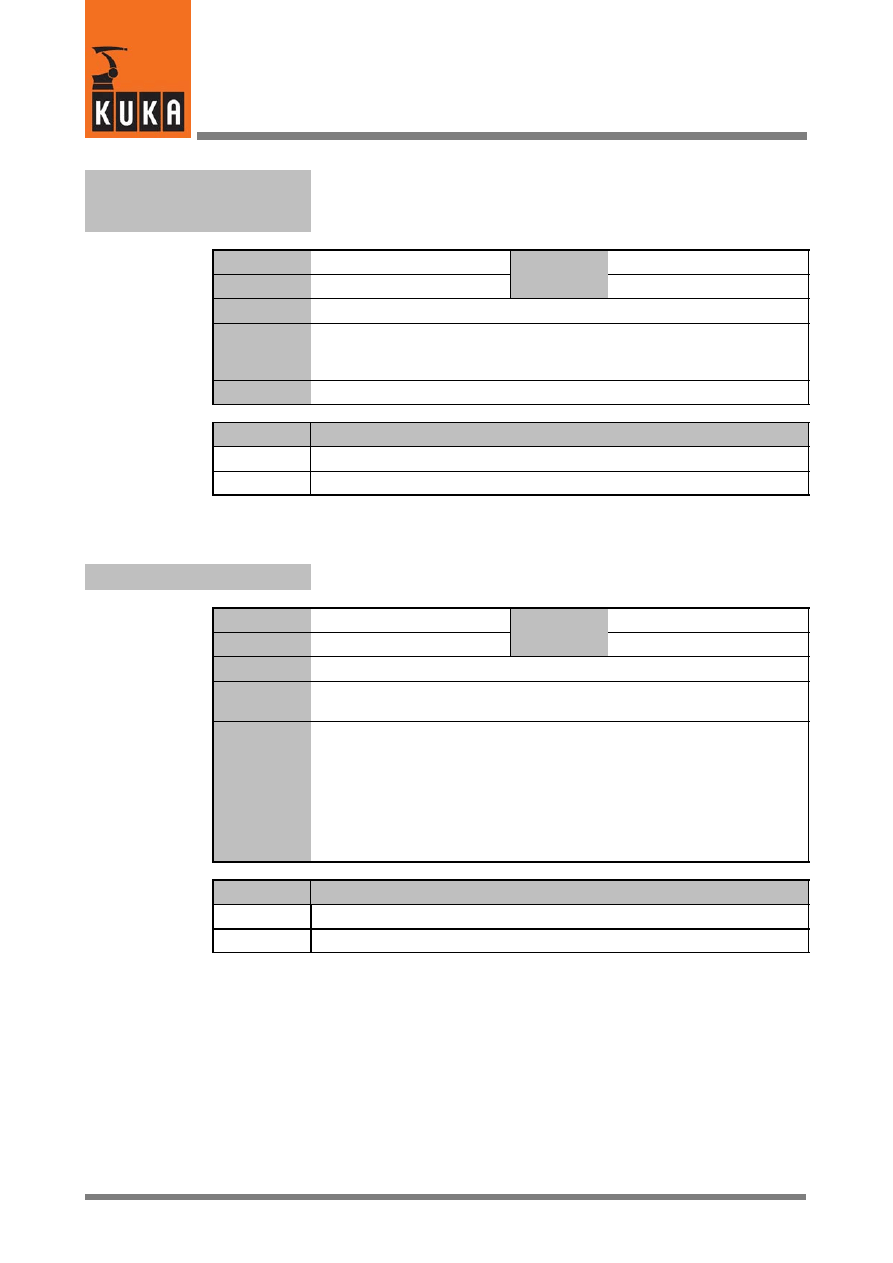

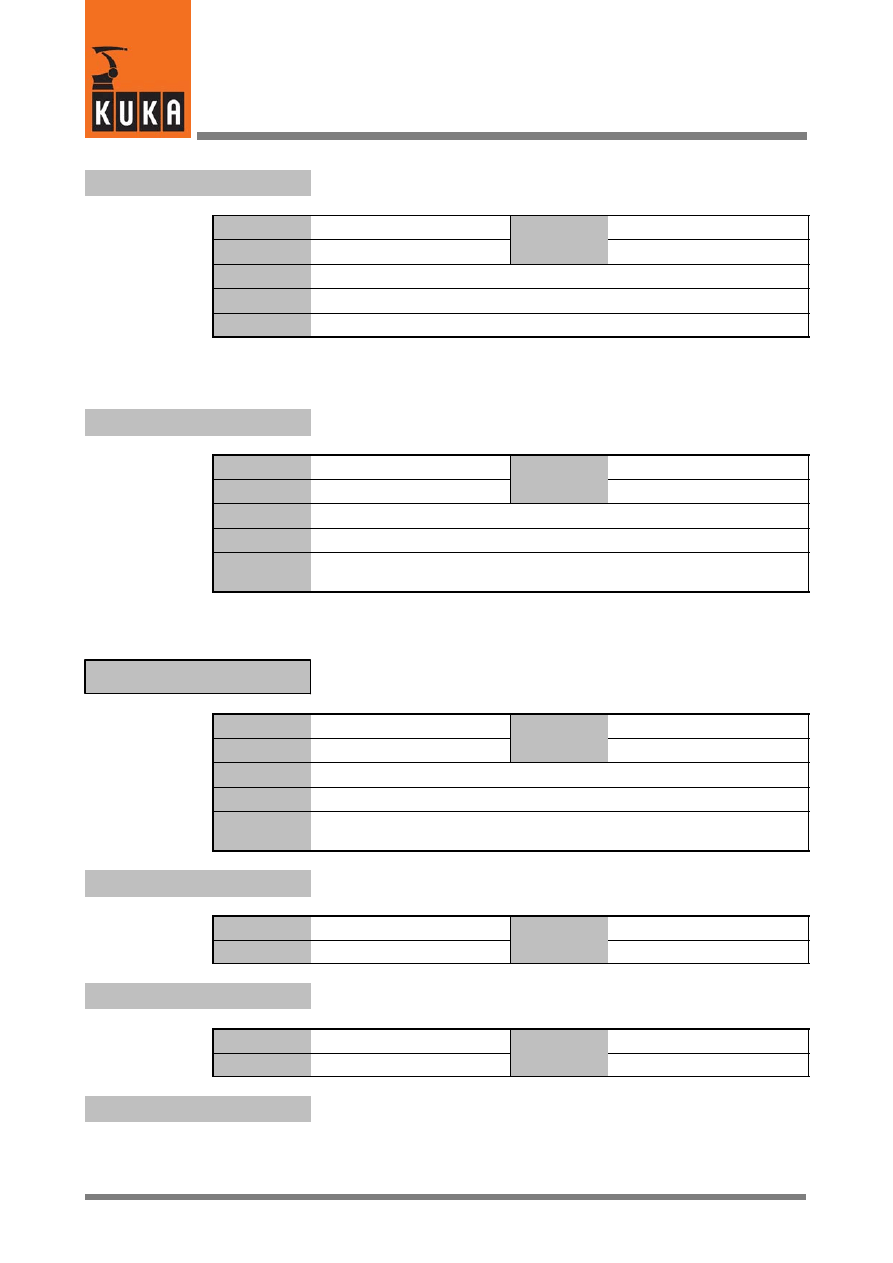

When $ASYNC_AXIS is assigned in a KRL program, the newly--defined

asynchronous axes are valid from this position until a new assignment is

made.

When $ASYNC_AXIS is defined, the advance run will be stopped if the va-

lue of $ASYNC_AXIS changes. Before a new value of $ASYNC_AXIS is

saved, the system will wait until all synchronous motions (through advance

run stop) and all asynchronous motions have been completed, and all axes

are in position. Thus the instruction “$ASYNC_AXIS=...” can be used –

along with the system variable $ASYNC_STATE – to synchronize in time

synchronous and asynchronous motions.

$ASYNC_AXIS can only be modified in the KRL program, and not in the in-

terrupt or in the SUBMIT interpreter.

The bits correspond to the external axes in ascending order:

Bit 0 = external axis 1,

Bit 1 = external axis 2, etc.

If the bit is set, the external axis will be switched to asynchronous mode; if it

is reset, the external axis will be switched back to synchronous mode.

Options

Effect

Bit = 1

The corresponding external axis is switched to asynchronous mode

Bit = 0

The corresponding external axis is switched to synchronous mode

2

A (Fortsetzung)

17 of 170

SysVar 08.02.03 en

$ASYNC_FLT

Filter for asynchronous external axes

Data type

Integer

Value

min. 0

Unit

ms

Value

max. 16

In file

------

Original line

INT $ASYNC_FLT

Comments

The value of $ASYNC_FLT is the filter length in milliseconds for all asyn-

chronously coordinated motions; it corresponds to the system variable

$FILTER for synchronous motions.

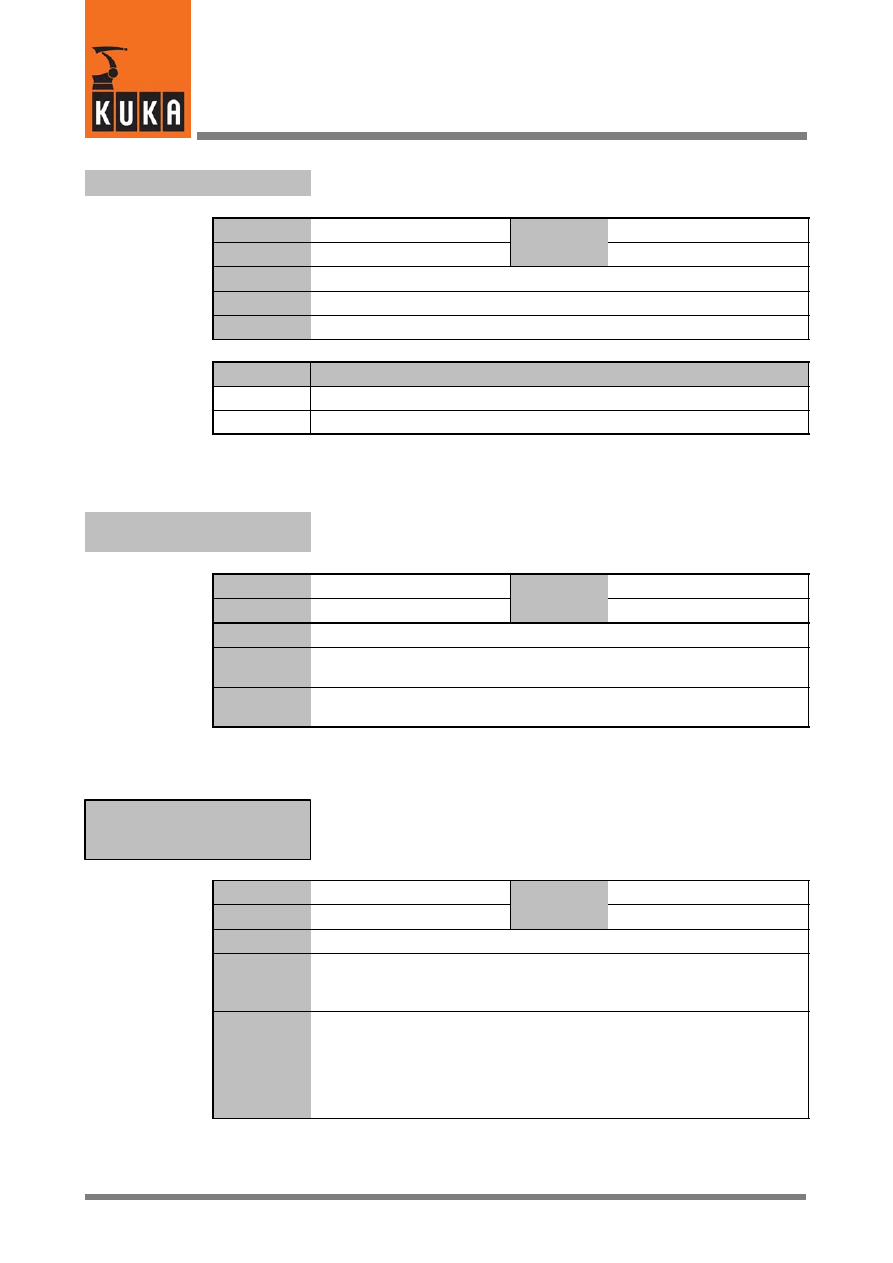

$ASYNC_MODE

Mode for asynchronous external axes

Data type

Integer

Value

min. 0

Unit

Value

max. 16

In file

Steu\Mada\$custom.dat

Original line

INT $ASYNC_MODE=’B0000’

;Mode für asynchrone Zusatzachsen

Comments

In the machine data of the controller, the bit mask $ASYNC_MODE can

be used to set various asynchronous motion execution modes.

It is not possible to change modes while the robot controller is running.

The modes can be combined in any way desired.

Certain modes must be set in order to use special applications.

In the standard setting (default mode) no $ASYNC_MODE bits are set.

Only bit 0 is used at this time:

Bit 0 = 0 (1st bit): default mode

Bit 0 = 1 (1st bit): mode 1

Bit 1 = (2nd bit): mode 2 block selection response

$ASYNC_OPT

Option flag for “Asynchronous axes are possible”

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

BOOL $ASYNC_OPT=FALSE

Comments

Options

Effect

TRUE

Asynchronous axes possible

FALSE

Asynchronous axes not possible

System Variables

18 of 170

SysVar 08.02.03 en

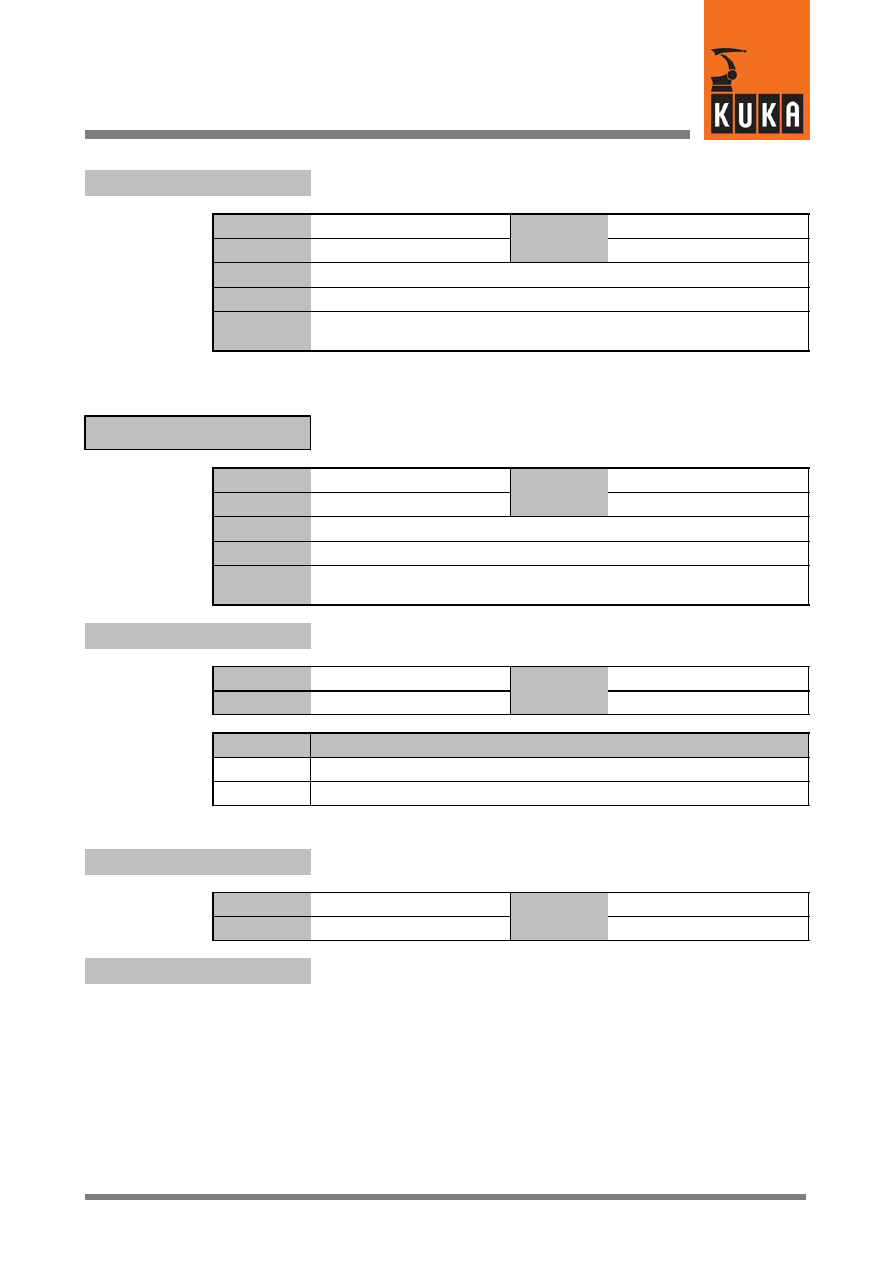

$ASYNC_STATE

Current asynchronous motion execution state

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL ASYNC_STATE $ASYNC_STATE

;Zustand der asynchronen Achsen

Comments

$ASYNC_STATE can be used to check the current asynchronous motion

execution state.

The value is read--only; no assignments are possible.

Asynchronous and “normal” robot motions can be synchronized using

this variable.

Options

Effect

#BUSY

Asynchronous motions active, stopped or temporarily stored.

#IDLE

No asynchronous motions active or stopped (queue is empty); last

motion terminated without an interrupt.

#CANCELLED No asynchronous motions active or stopped (queue is empty); last

motion was canceled.

#PEND

Asynchronous motion is planned, but is not currently being executed

$ASYNC_T1_FAST

Control of the velocity reduction factor in Test1 mode

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $ASYNC_T1_FAST=’B0000’

;Geschw.--Red. Deaktiviert ( T1 )

Comments

Options

Effect

0

Activated

1

Deactivated

2

A (Fortsetzung)

19 of 170

SysVar 08.02.03 en

$ASYS

Assignment of the jog keys

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL ASYS $ASYS

;Verfahrtastenbelegung (ROBOT = Roboter, EXTAX = Externe Achsen)

Comments

Options

Effect

#ROBOT

Robot axes A1 -- A6

#EXTAX

External axes E1 -- E6

#EXTAX2

External kinematic system

$AUT

Signal declaration “Automatic mode”

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $AUT $OUT[995]

;Betriebsart Automatik

Comments

$AUX_POWER

Signal declaration for external power supply

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $AUX_POWER $IN[1026]

;Externe Spannungsversorgung aktiv

Comments

If “$AUX_POWER” has the value “TRUE”, the external power supply is

active; if the value is “FALSE”, the external power supply is not active.

System Variables

20 of 170

SysVar 08.02.03 en

$AX_SIM_ON

Simulation of the closed speed control loop for the individual axes

on a desktop PC

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $AX_SIM_ON=’B111111’

;Achssimulation

Comments

Bit sequence:

LSB: Axis 1

MSB: Axis 12

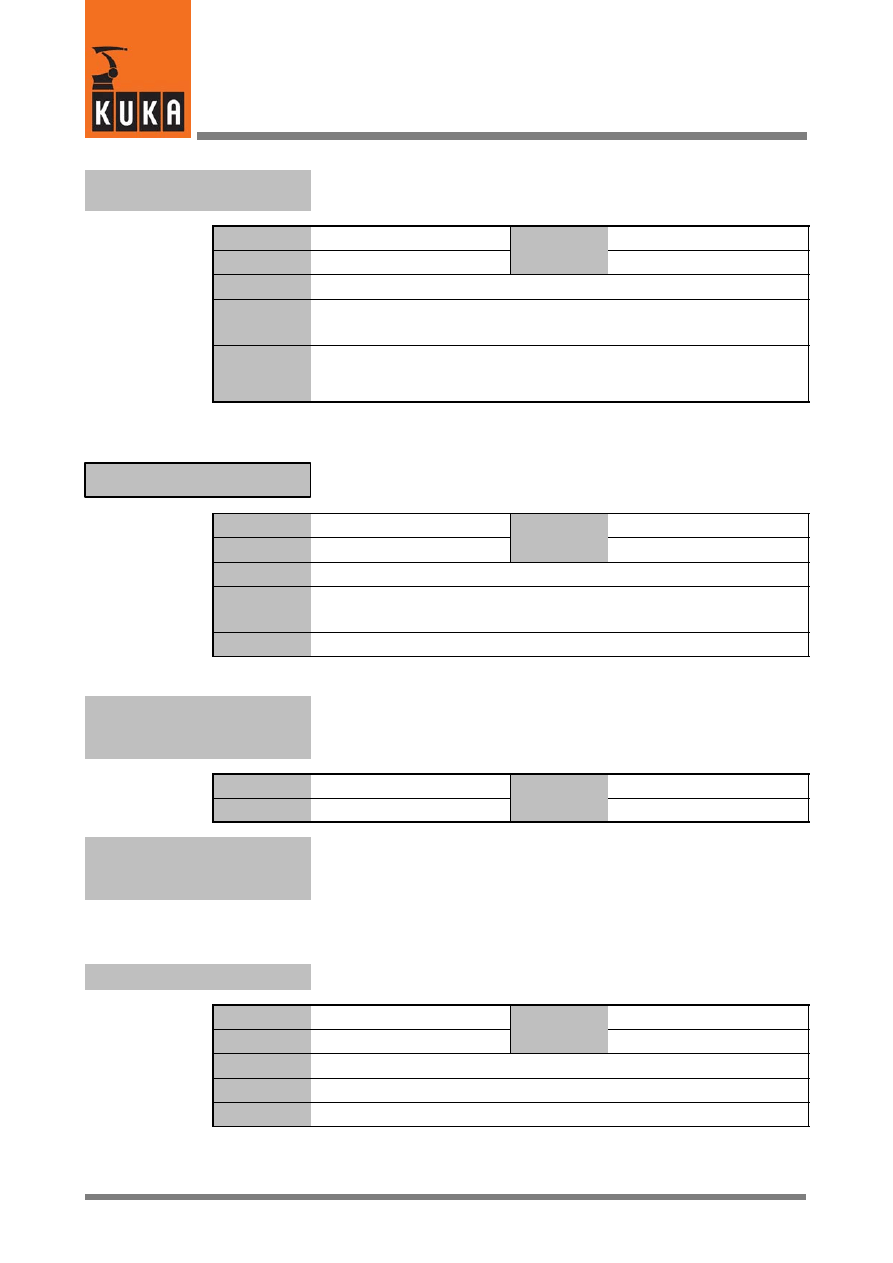

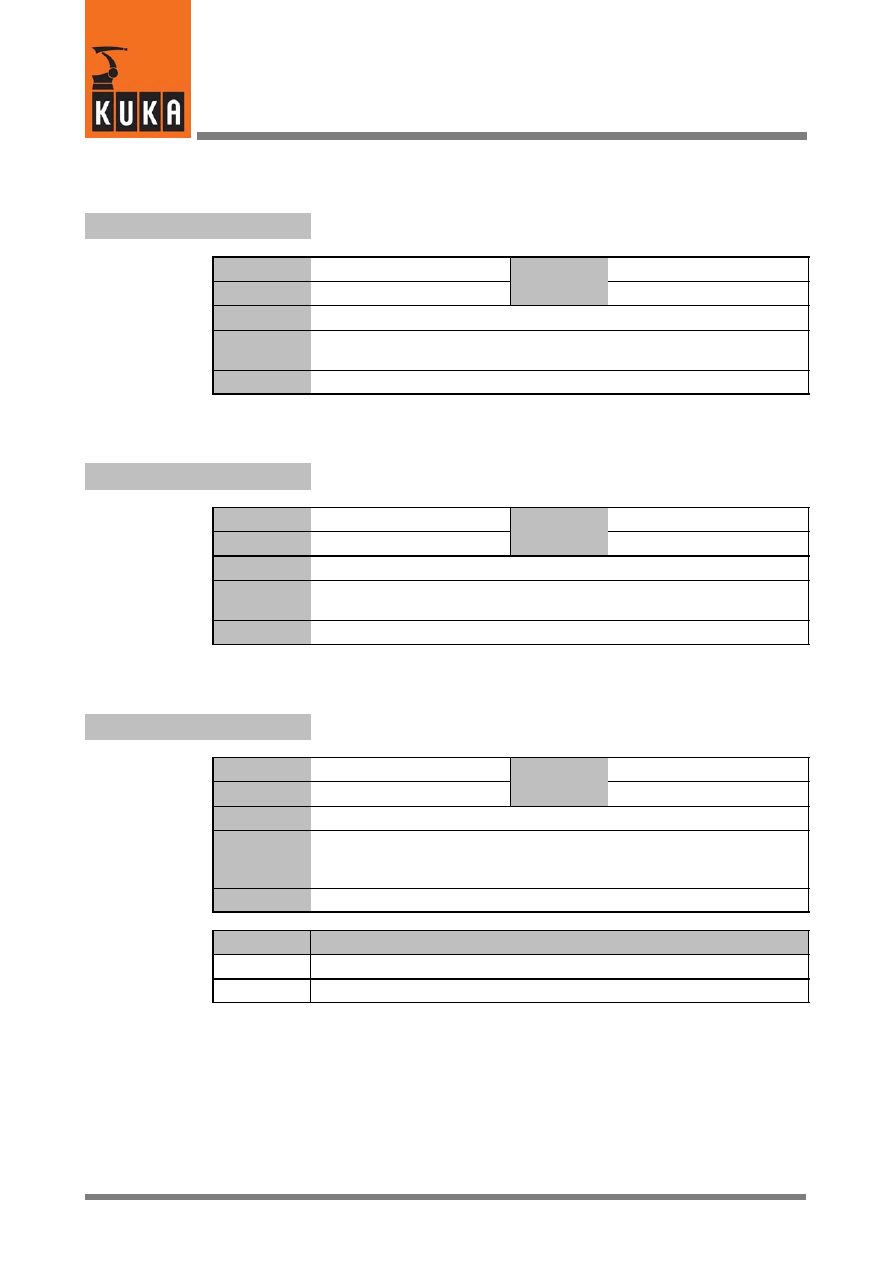

Current axis--specific robot position

$AXIS_ACT

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

------

Original line

E6AXIS $AXIS_ACT

;Aktuelle Roboterposition achsspezifisch [mm,Grad]

Comments

$AXIS_ACT.A1

...

$AXIS_ACT.A6

Current axis--specific robot position, axis 1 -- 6

Data type

Real

Value

min. 0

Unit

mm, °

Value

max.

$AXIS_ACT.E1

...

$AXIS_ACT.E6

Current axis--specific robot position, external axis 1 -- 6

$AXIS_ACTMOD

Display of axis angle modulo 180°

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

E6AXIS $AXIS_ACTMOD

Comments

2

A (Fortsetzung)

21 of 170

SysVar 08.02.03 en

Start position of the current motion block, axis--specific

$AXIS_BACK

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

------

Original line

E6AXIS $AXIS_BACK

;Anfangsposition des aktuellen Bewegungssatzes achsspezifisch

[mm,Grad]

Comments

$AXIS_BACK.A1

...

$AXIS_BACK.A6

Start position of the current motion block,

axis A1 -- A6

Data type

Real

Value

min. 0

Unit

mm, °

Value

max.

$AXIS_BACK.E1

...

$AXIS_BACK.E6

Start position of the current motion block,

external axis E1 -- E6

Display whether axis is referenced

$AXIS_CAL

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL AXIS_CAL $AXIS_CAL

Comments

Display of referenced axes

$AXIS_CAL.A1

...

$AXIS_CAL.A6

Display whether axis A1 ... A6 is referenced

Data type

Boolean

Value

min.

Unit

Value

max.

Options

Effect

TRUE

Axis is referenced

FALSE

Axis is not referenced

System Variables

22 of 170

SysVar 08.02.03 en

$AXIS_CAL.E1

...

$AXIS_CAL.E6

Display whether external axis E1 ... E6 is referenced

$AXIS_DIR[n]

Direction of rotation of axis[n]

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $AXIS_DIR[n]

Comments

[n] = [1] ... [6]:

axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

Options

Effect

1

Positive direction

--1

Negative direction

Target position of the current motion block, axis--specific

$AXIS_FOR

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

------

Original line

E6AXIS $AXIS_FOR

;Zielposition des aktuellen Bewegungssatzes achsspezifisch [mm,Grad]

Comments

$AXIS_FOR.A1

...

$AXIS_FOR.A6

Target position of the current motion block, axis A1 ... A6

Data type

Real

Value

min. 0

Unit

mm, °

Value

max.

$AXIS_FOR.E1

...

$AXIS_FOR.E6

Target position of the current motion block, external axis E1 ... E6

2

A (Fortsetzung)

23 of 170

SysVar 08.02.03 en

$AXIS_HOME[5]

Definition of the various home positions

Data type

Array

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

E6AXIS $AXIS_HOME[5]

Comments

Incremental actual values of the axes

$AXIS_INC

Data type

Structure

Value

min.

Unit

Increments

Value

max.

In file

------

Original line

DECL AXIS_INC $AXIS_INC

Comments

Indication of the axis position in increments.

$AXIS_INC.I1

...

$AXIS_INC.I6

Incremental actual value, axis A1 ... A6

Data type

Integer

Value

min. 0

Unit

Increments

Value

max.

$AXIS_INC.E1

...

$AXIS_INC.E6

Incremental actual value, external axis E1 ... E6

Robot position at the time of an interrupt

$AXIS_INT

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

------

Original line

E6AXIS $AXIS_INT

;Unterbrechungsposition achsspezifisch [mm,Grad]

Comments

System Variables

24 of 170

SysVar 08.02.03 en

$AXIS_INT.A1

...

$AXIS_INT.A6

Robot position at the time of an interrupt,

axis A1 ... A6

Data type

Real

Value

min. 0

Unit

mm, °

Value

max.

$AXIS_INT.E1

...

$AXIS_INT.E6

Robot position at the time of an interrupt,

external axis E1 ... E6

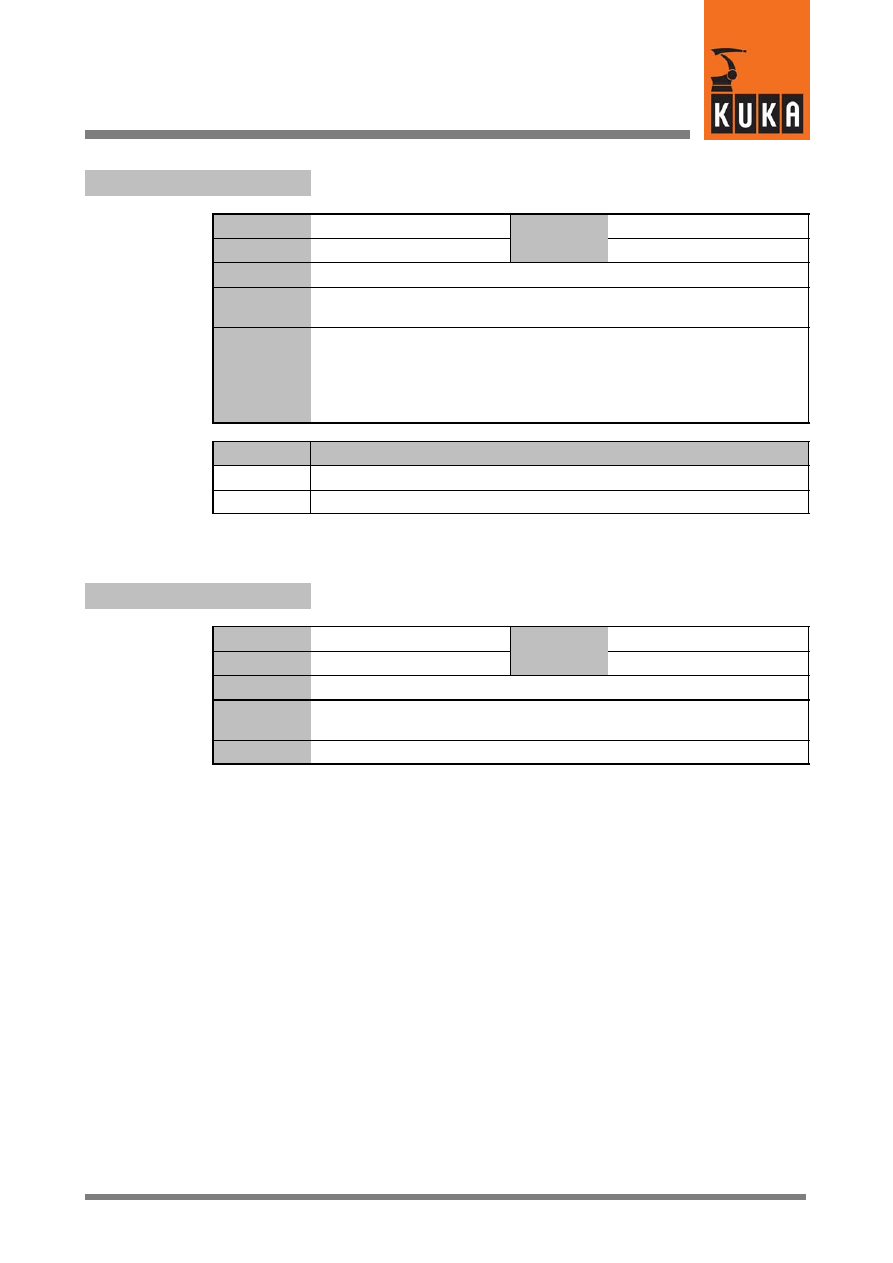

Display whether axis is mastered

$AXIS_JUS

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL AXIS_CAL $AXIS_JUS

;Anzeige justierter Achsen

Comments

$AXIS_JUS.A1

...

$AXIS_JUS.A6

Display whether axis A1 ... A6 is mastered

Data type

Boolean

Value

min.

Unit

Value

max.

Options

Effect

TRUE

Axis mastered

FALSE

Axis not mastered

$AXIS_JUS.E1

...

$AXIS_JUS.E6

Display whether external axis E1 ... E6 is mastered

$AXIS_RESO

Resolution of the position sensing system

Data type

Integer

Value

min.

Unit

Increments / revolution

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $AXIS_RESO[12]

;Auflösung des Meßsystems Achse(i) (i=1:A1, i=7:E1) [Inkr]

Comments

Number of pulses per revolution of the encoder

2

A (Fortsetzung)

25 of 170

SysVar 08.02.03 en

Axis positions when leaving the programmed path, axis--specific

$AXIS_RET

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

------

Original line

E6AXIS $AXIS_RET

;Rückpositionieren achsspezifisch [mm,Grad]

Comments

$AXIS_RET.A1

...

$AXIS_RET.A6

Position of axis A1 ... A6 when leaving the programmed path

Data type

Character

Value

min. 0

Unit

mm, °

Value

max.

$AXIS_RET.E1

...

$AXIS_RET.E6

Position of external axis E1 ... E6 when leaving the programmed path

$AXIS_SEQ[n]

Change in sequence of axis ... to axis ...

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $AXIS_SEQ[n]

Comments

[n] = [1] ... [6]: axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

System Variables

26 of 170

SysVar 08.02.03 en

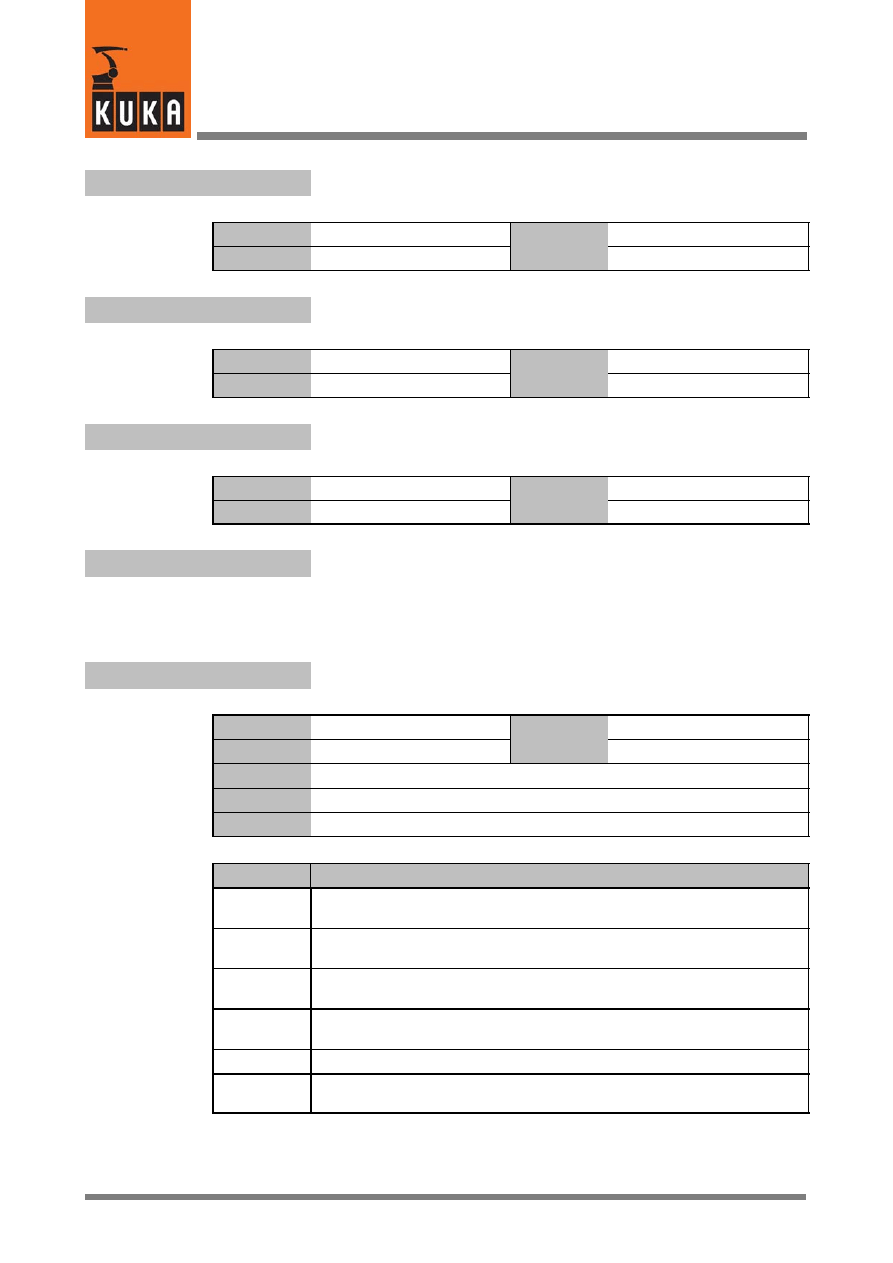

$AXIS_TYPE[n]

Axis identification

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $AXIS_TYPE[n]

Comments

[n] = [1] ... [6]: axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

Options

Effect

1

Linear

2

Spindle

3

Rotational

4

Finitely rotating

5

Infinitely rotating

$AXWORKSPACE[n]

Definition of axis--specific workspace monitoring

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL AXBOX$AXWORKSPACE[n]

Comments

[n] = [1] ... [8]

2

A (Fortsetzung)

27 of 170

SysVar 08.02.03 en

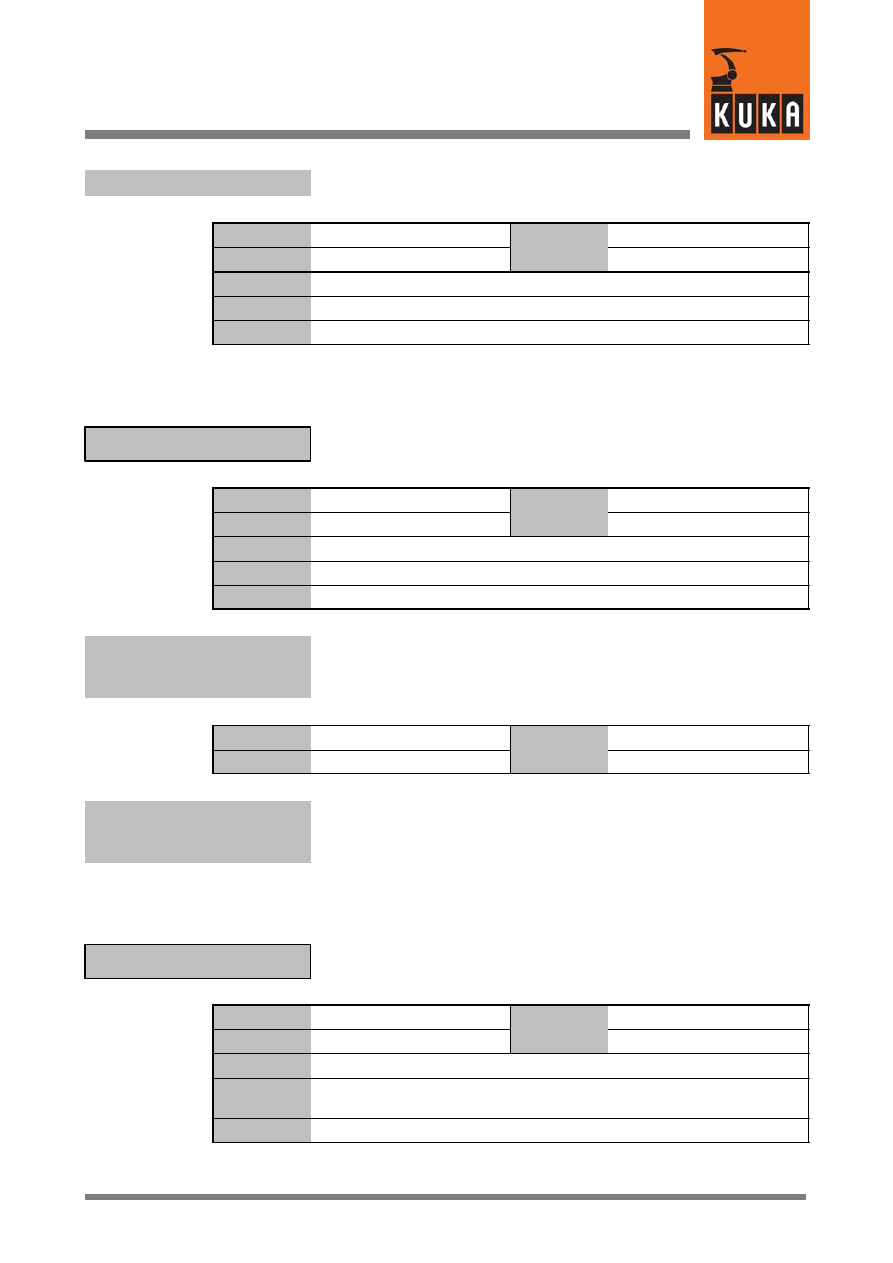

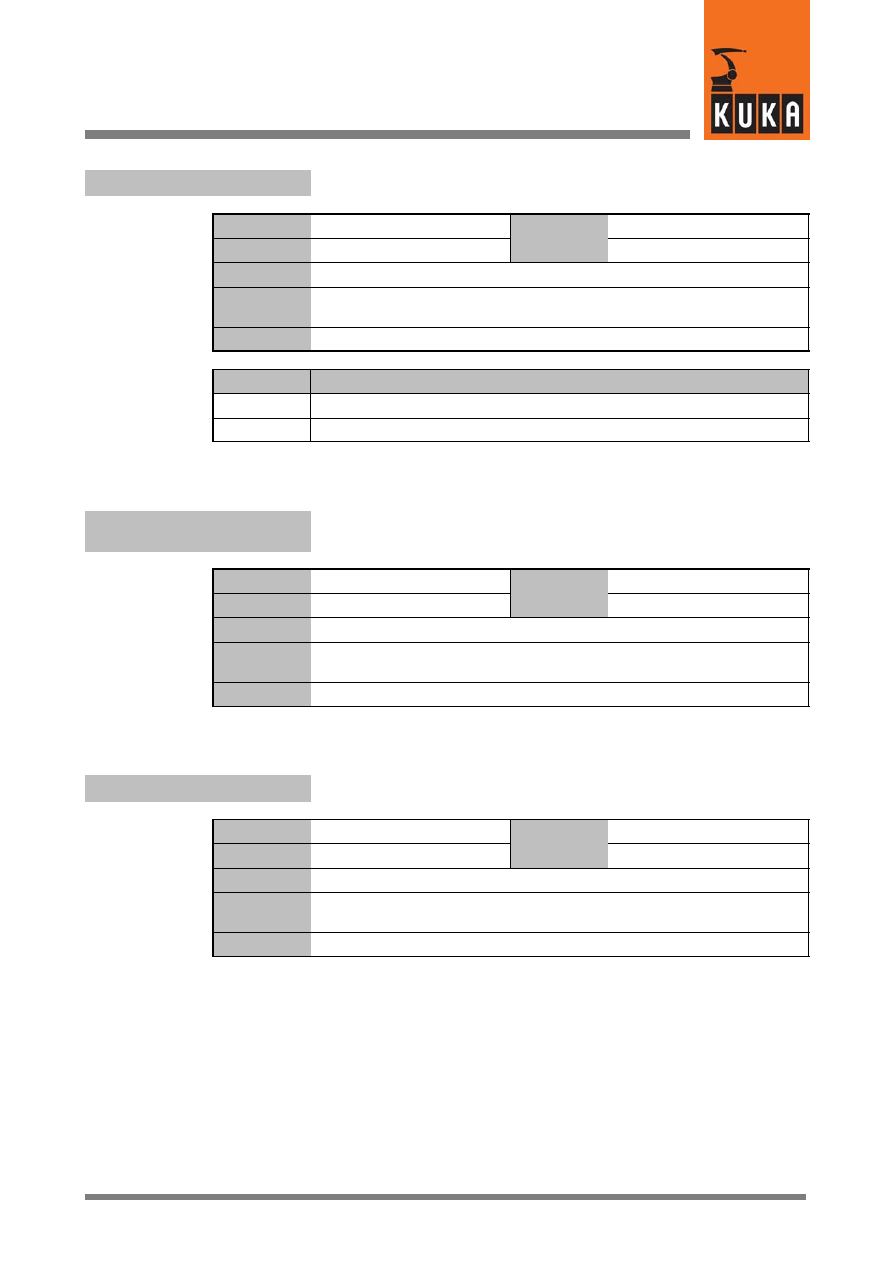

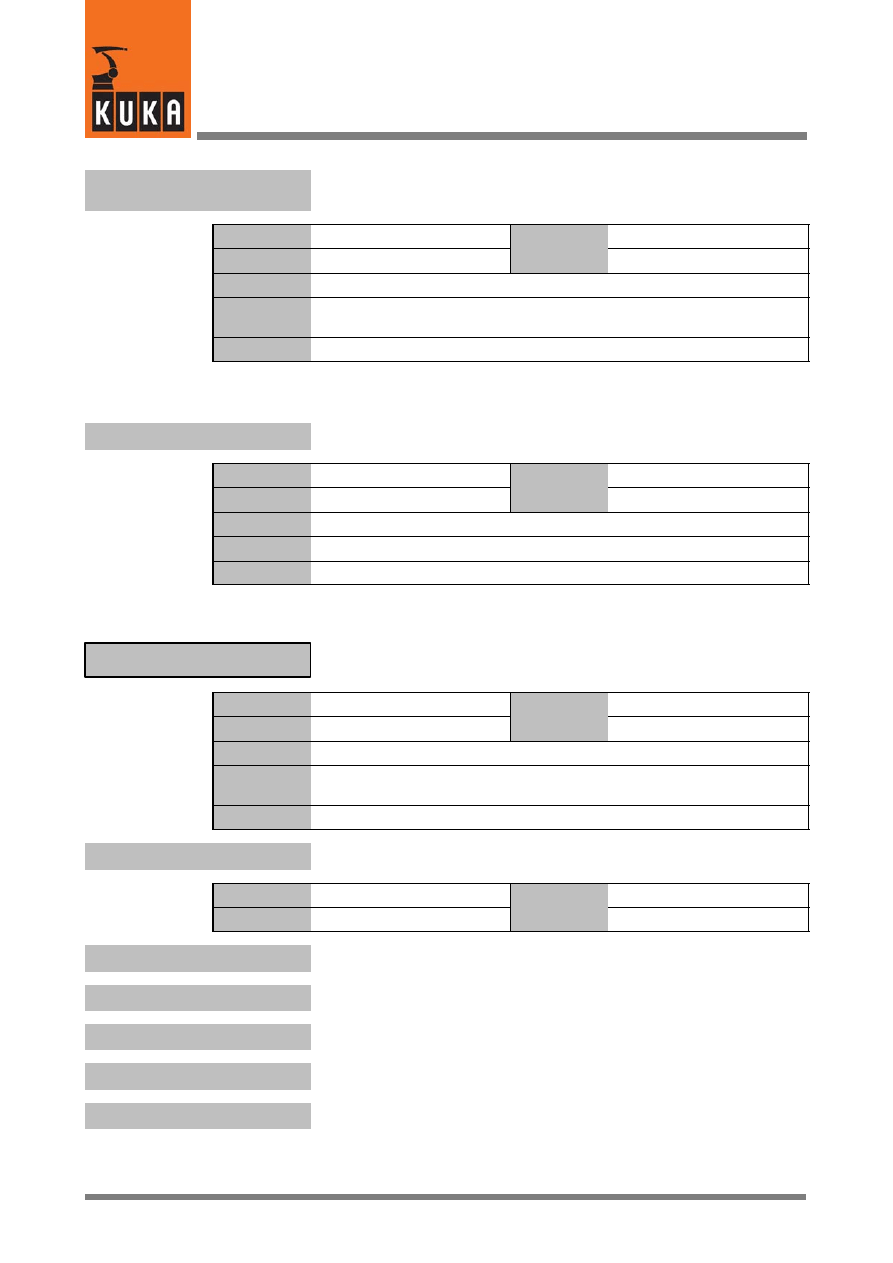

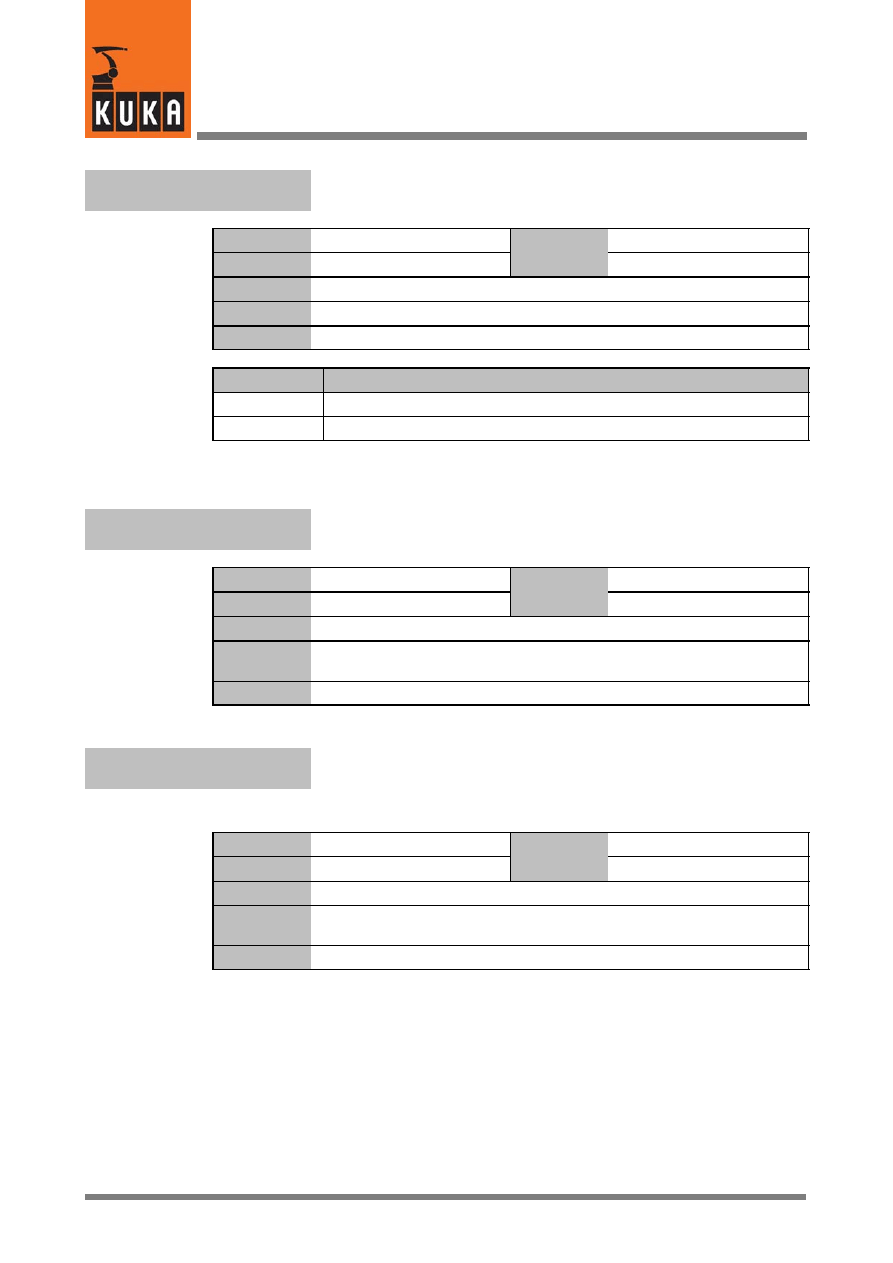

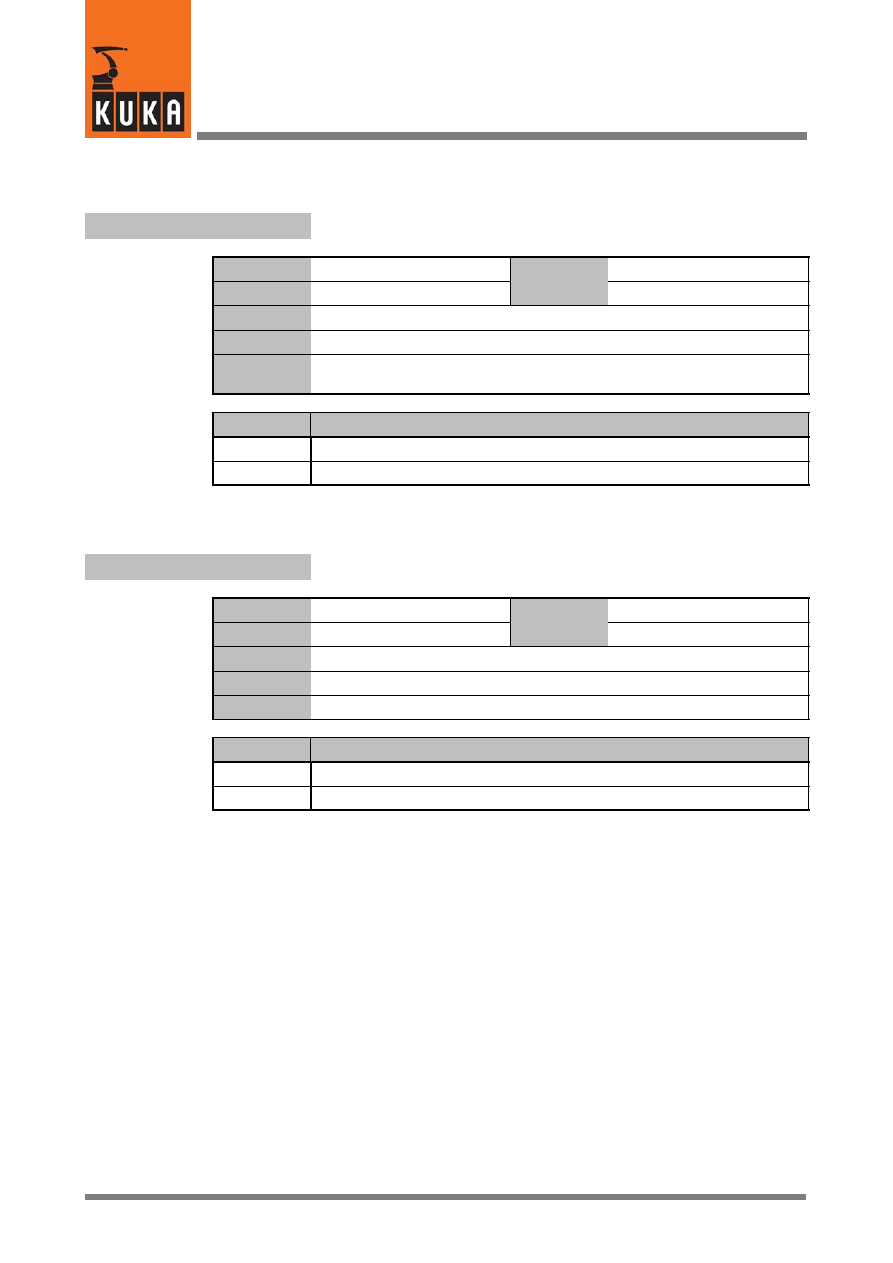

$AXWORKSPACE[n].MODE

Functional principle of the axis--specific workspace monitoring

function

Data type

Enum

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL AXBOX$AXWORKSPACE[n]

Comments

[n] = [1] ... [8]

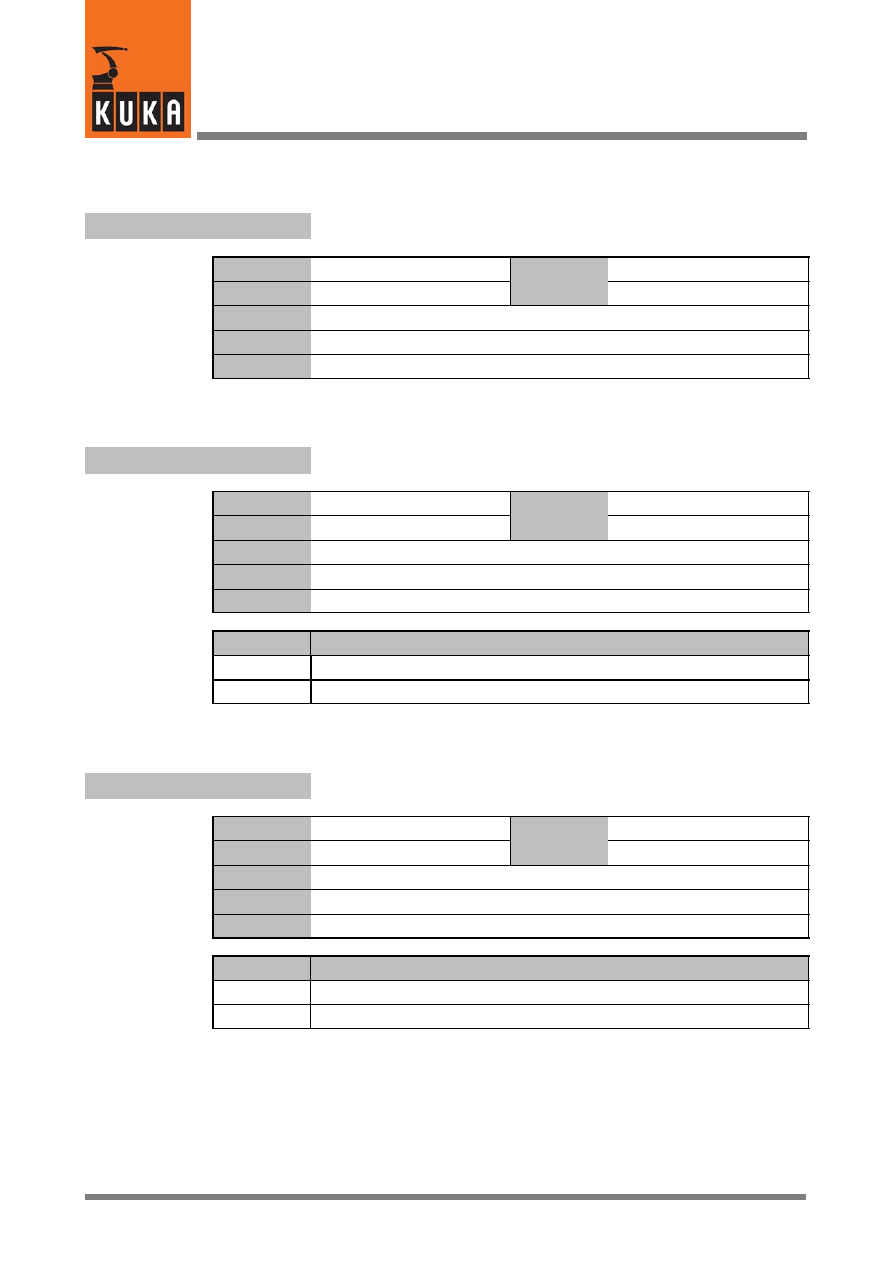

Options

Effect

#OFF

Work envelope monitoring deactivated

#INSIDE

The output is set if the TCP is located inside the work envelope

#OUTSIDE

The output is set if the TCP is located outside the work envelope

#INSIDE_STOP

The output is set and the robot stopped if the TCP is located inside

the work envelope

#OUTSIDE_STOP The output is set and the robot stopped if the TCP is located outside

the work envelope

$AXWORKSPACE[n].STATE

Violation of the axis--specific workspace

Data type

Boolean

Value

min.

Unit

Value

max.

Options

Effect

TRUE

The workspace has been violated

FALSE

The workspace has not been violated

$AXWORKSPACE_NAMEn[]

Name of the particular axis--specific workspace

Data type

Character

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

CHAR $AXWORKSPACE_NAMEn[24]

$AXWORKSPACE_NAMEn[]=”AXWORKSPACE_NAME n”

Comments

[n] = [1] ... [8]

System Variables

28 of 170

SysVar 08.02.03 en

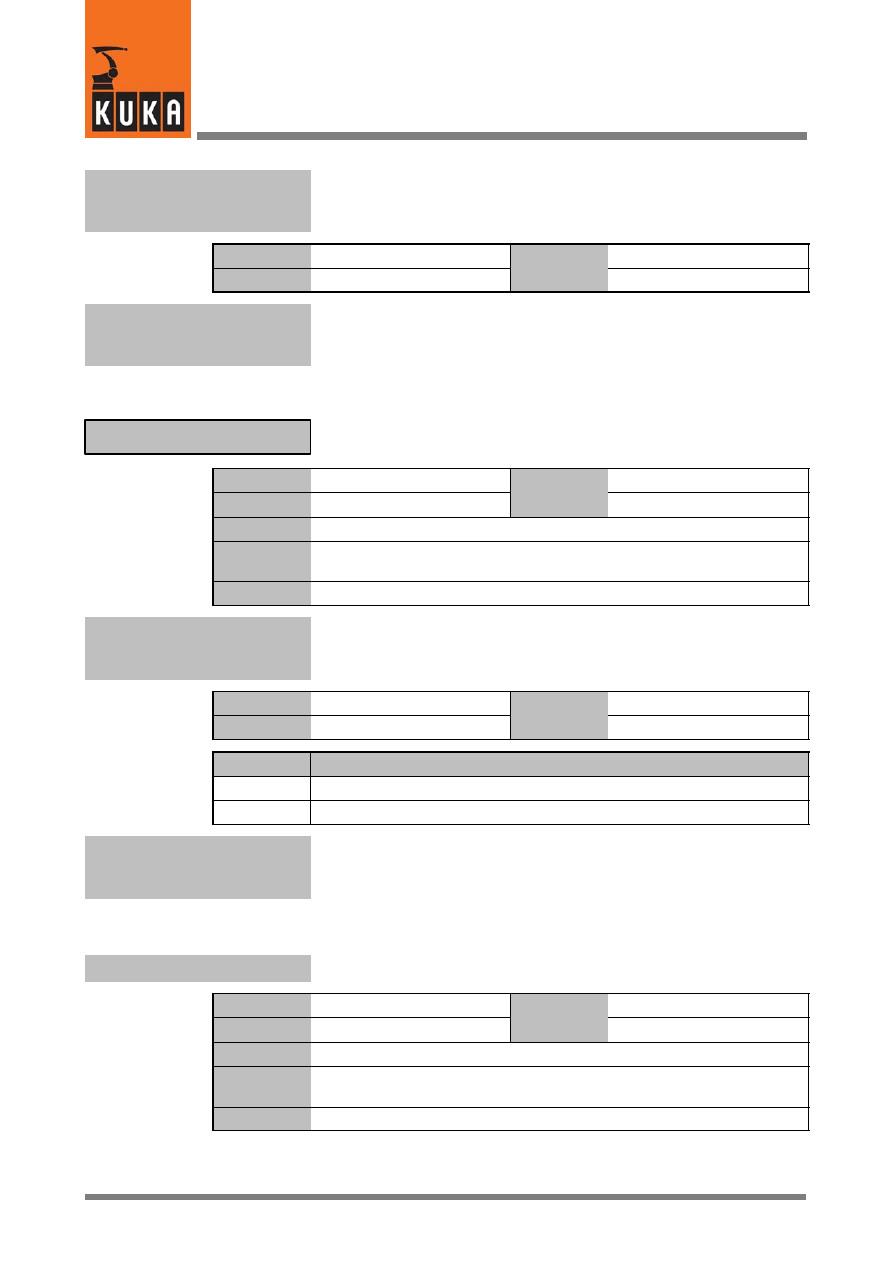

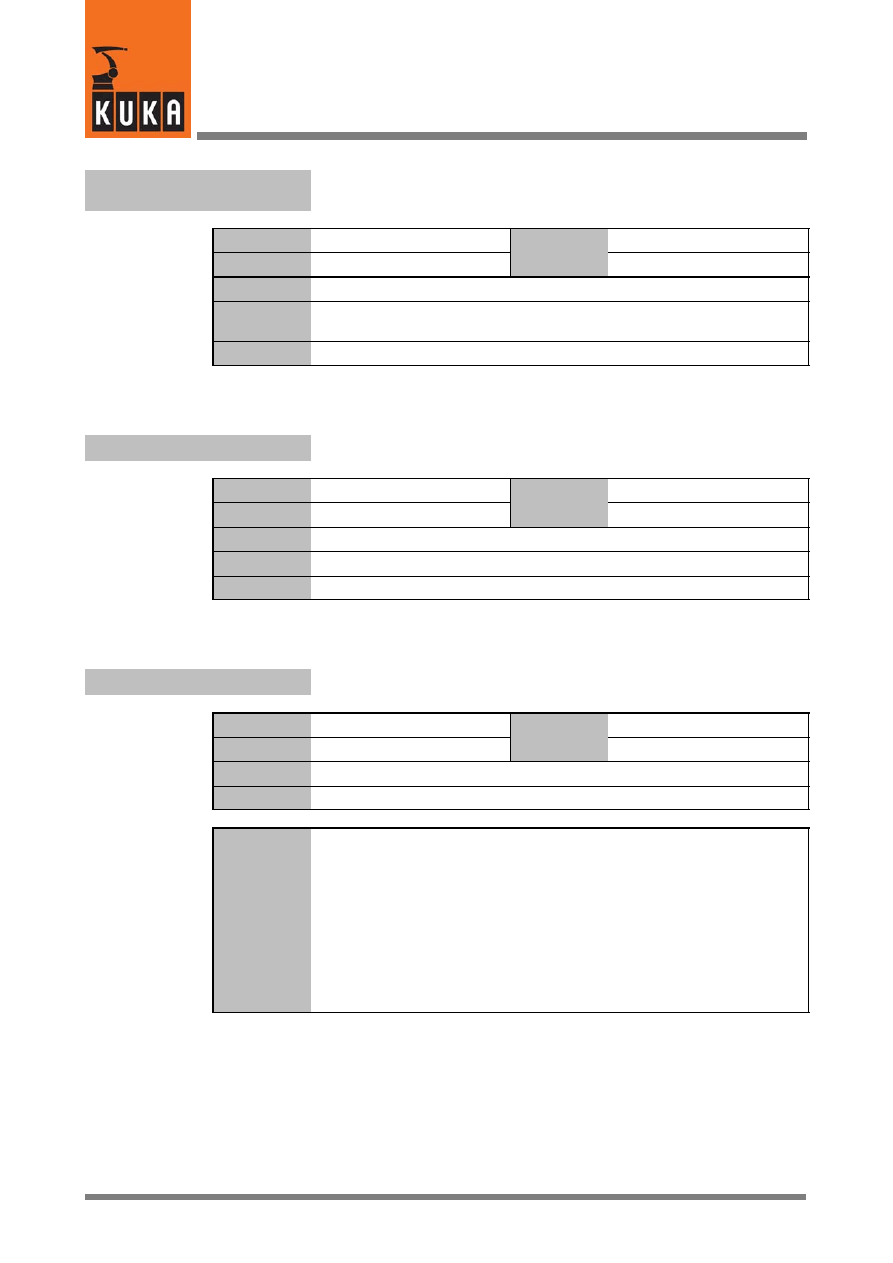

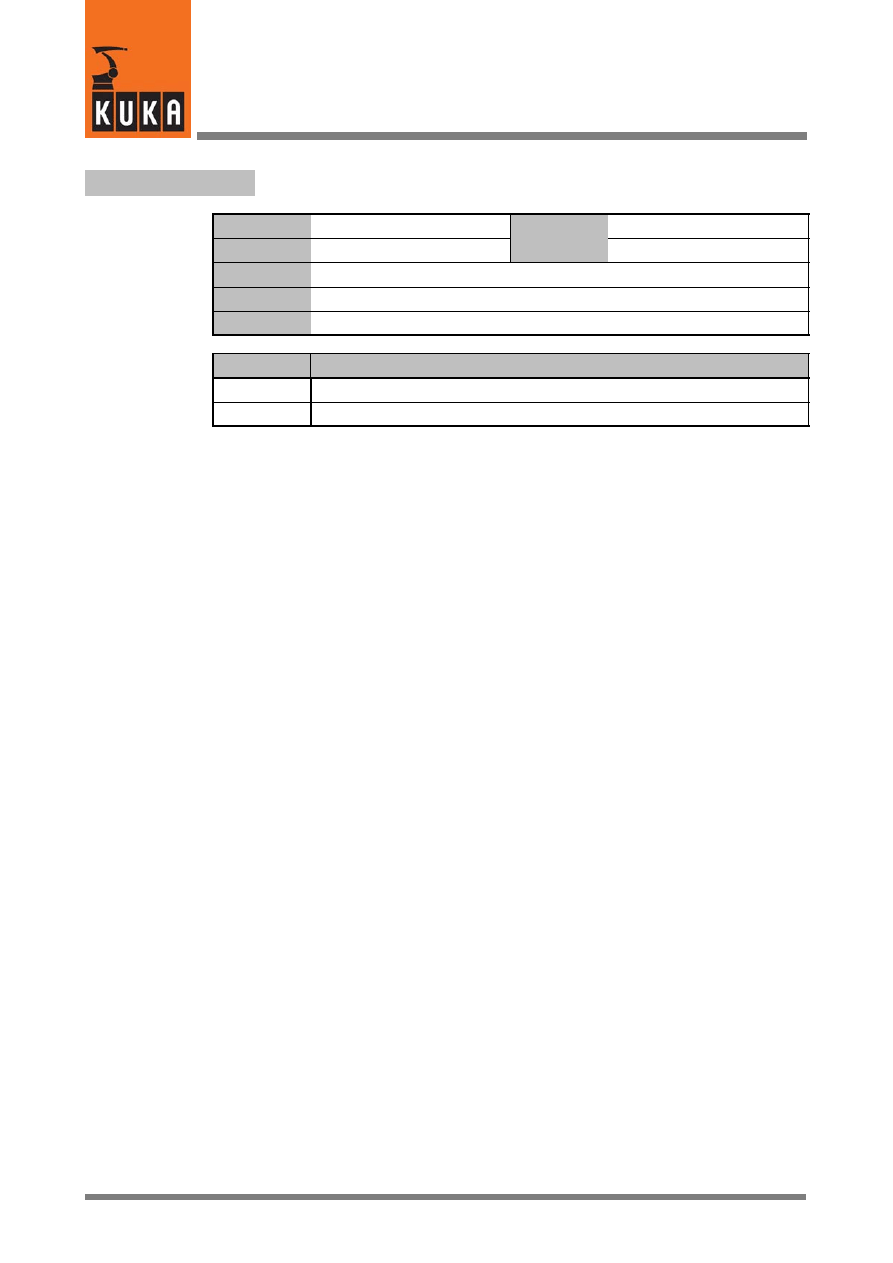

$AXWORKSTATE1

...

$AXWORKSTATE8

Signal declaration “Violation of workspace”

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $AXWORKSTATE1 $OUT[969]

.

.

SIGNAL $AXWORKSTATE8 $OUT[976]

; Ausgang der Achsarbeitsraumüberwachung .

Comments

Options

Effect

$OUT[n]

Output 1 ... 4096

FALSE

Outputs that are not required can be set to “FALSE”,

e.g. SIGNAL $AXWORKSTATE1 FALSE

3

B

29 of 170

SysVar 08.02.03 en

3

B

Offset and rotation of the base coordinate system in relation to the

world coordinate system in the advance run

$BASE

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$operate.dat

Original line

FRAME $BASE

;Basis im Weltkoordinatensystem Vorlauf

Comments

$BASE.A

Rotation of the base coordinate system about the Z axis in relation

to the world coordinate system in the advance run

Data type

Real

Value

min.

Unit

°

Value

max.

$BASE.B

Rotation of the base coordinate system about the Y axis in relation

to the world coordinate system in the advance run

$BASE.C

Rotation of the base coordinate system about the X axis in relation

to the world coordinate system in the advance run

$BASE.X

Offset of the base coordinate system in the X direction in relation

to the world coordinate system in the advance run

Data type

Real

Value

min.

Unit

mm

Value

max.

$BASE.Y

Offset of the base coordinate system in the Y direction in relation

to the world coordinate system in the advance run

$BASE.Z

Offset of the base coordinate system in the Z direction in relation

to the world coordinate system in the advance run

Offset and rotation of the base coordinate system in relation to the

world coordinate system in the main run

$BASE_C

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

FRAME $BASE_C

;Basis im Weltkoordinatensystem Hauptlauf

Comments

System Variables

30 of 170

SysVar 08.02.03 en

$BASE_C.A

Rotation of the base coordinate system about the Z axis in relation

to the world coordinate system in the main run

Data type

Real

Value

min.

Unit

°

Value

max.

$BASE_C.B

Rotation of the base coordinate system about the Y axis in relation

to the world coordinate system in the main run

$BASE_C.C

Rotation of the base coordinate system about the X axis in relation

to the world coordinate system in the main run

$BASE_C.X

Offset of the base coordinate system in the X direction in relation

to the world coordinate system in the main run

Data type

Real

Value

min.

Unit

mm

Value

max.

$BASE_C.Y

Offset of the base coordinate system in the Y direction in relation

to the world coordinate system in the main run

$BASE_C.Z

Offset of the base coordinate system in the Z direction in relation

to the world coordinate system in the main run

$BASE_KIN

External kinematic / axes in base

Data type

Character

Value

min.

Unit

Value

max.

In file

------

Original line

CHAR $BASE_KIN[29]

;Externe Kinematik / Achsen in Base

Comments

$BOUNCE_TIME

Bounce time for EMT signals

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BOUNCE_TIME

;Prellzeit für EMT--Taster [ms]

Comments

The signal is only accepted if it remains stable over the entire time

period defined in $BOUNCE_TIME.

3

B (Fortsetzung)

31 of 170

SysVar 08.02.03 en

$BRAKE_SIG

Bit array for axis brakes, A1 ... A6 and E1 ... E6

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $BRAKE_SIG

;Bit--Feld Bremsensignale

Comments

Options

Effect

0

Brake closed

1

Brake open

$BRK_DEL_COM

Time after which the axis brakes are closed on completion of posi-

tioning during jogging

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_DEL_COM

;Bremsverzögerungszeitkommando--Modus [ms]

Comments

$BRK_DEL_EX

Brake delay time for external axes

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_DEL_EX

;Bremsverzögerungszeit für Zusatzachsen

Comments

System Variables

32 of 170

SysVar 08.02.03 en

$BRK_DEL_PRO

Time after which the axis brakes are closed on completion of posi-

tioning in the program

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_DEL_PRO

;Bremsverzögerungszeit im Programm [ms]

Comments

$BRK_MAX_TM

Maximum deceleration time for path--maintaining Emergency Stop

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_MAX_TM

Comments

$BRK_MODE

Brake control mode

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_MODE=’B0101’

Comments

The bits are counted from right to left.

Bit 0:

Axes A 1 – A 6 close at command end (bit 0 = 1) /

do not close (bit 0 = 0)

Bit 1:

Axes A 1 – A 6 close individually

1)

(bit 1 = 1) /

together (bit 1 = 0)

Bit 2:

Axes A 1 – A 6 close during pauses in the motion (bit 2 = 1) /

do not close (bit 2 = 0)

Bit 3:

External axis brakes close during motion pauses

individually (bit 3 = 1) / together with axes A 1 – A 6 (bit 3 = 0)

1)

Special case

3

B (Fortsetzung)

33 of 170

SysVar 08.02.03 en

$BRK_OPENTM

Time delay of command value output after axis brakes have been

opened

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $BRK_OPENTM

;Bremsöffnungszeit [ms]

Comments

$BUS_PAR

L2 bus interface (KRC32)

Data type

Structure

Value

min.

Unit

Value

max.

In file

Steu\Mada\$custom.dat

Original line

DECL BUS $BUS_PAR={PROTO 1,PROC 5,RCO 5,BL 128,PT 0,TS

1,BAUD 187500,TSL --1,MIN_TDSR --1,MAX_TDSR --1,TTR --1,HSA

--1,G --1,DFLT_SAP --1}

Comments

System Variables

34 of 170

SysVar 08.02.03 en

4

C

$CABLE2_MON

Additional motor cable monitoring

Data type

Boolean

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

BOOL $CABLE2_MON=FALSE

Comments

Specifies whether the connection of the second motor cable should be

monitored (TRUE for special machines)

Options

Effect

TRUE

Monitoring activated

FALSE

Monitoring deactivated

$CAL_DIFF

Mastering difference for EMT mastering with check run

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $CAL_DIFF

;Justage--Differenz

Comments

Reference point offset between mathematical zero point and

encoder zero point

$CALP

Data type

Structure

Value

min. 0

Unit

Value

max.

In file

------

Original line

E6AXIS $CALP

;Referenzpunktverschiebung

Comments

4

C (Fortsetzung)

35 of 170

SysVar 08.02.03 en

$CALP.A1

...

$CALP.A6

Reference point offset between mathematical zero point and

encoder zero point, axis A1 ... A6

Data type

Real

Value

min. 0

Unit

°

Value

max.

$CALP.E1

...

$CALP.E6

Reference point offset between mathematical zero point and

encoder zero point, external axis E1 ... E6

$CIRC_TYPE

Orientation control with CIRC blocks in the advance run

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL CIRC_TYPE $CIRC_TYPE

;Bezugssystem für die Orientierungsinterpolation bei CIRC--Sätzen

(Vorlauf)

Comments

Options

Effect

#BASE

Space--related orientation control

#PATH

Path--related orientation control

$CIRC_TYPE_C

Orientation control with CIRC blocks in the main run

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL CIRC_TYPE $CIRC_TYPE_C

;Bezugssystem für die Orientierungsinterpolation bei CIRC--Sätzen

(Hauptlauf)

Comments

Options

Effect

#BASE

Space--related orientation control

#PATH

Path--related orientation control

System Variables

36 of 170

SysVar 08.02.03 en

$CMD

Display assignment number (handle) for command channel

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $CMD

Comments

$COM_NAME

Command which is to be processed after next start

Data type

Character

Value

min.

Unit

Value

max.

In file

------

Original line

CHAR $COM_NAME[486]

;Kommando, welches beim nächsten Start abgearbeitet wird

Comments

$COM_VAL_MI[n]

Limitation of command speed, axis[n]

Data type

Real

Value

min.

Unit

%

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $COM_VAL_MI[n]

Comments

[n] = [1] ... [6]:

axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

$CONF_MESS

Signal declaration “Reset acknowledgement messages”

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $CONF_MESS $IN[1026]

Comments

External confirmation

4

C (Fortsetzung)

37 of 170

SysVar 08.02.03 en

$COSYS

Coordinate system for jogging

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL COSYS $COSYS

Comments

Options

Effect

#AX

Motions are relative to the axis--specific coordinate system.

#CAR

Motions are relative to the Cartesian coordinate system.

$COUNT_I[n]

Freely usable integer variables

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $COUNT_I[n]

Comments

[n]=[1] ... [32]

Used as counters in the VW package

$COUP_COMP[N,D]

Axis coupling factors

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL FRA $COUP_COMP[6,6]

Comments

Axis coupling factor: N = numerator; D = denominator

System Variables

38 of 170

SysVar 08.02.03 en

$CP_VEL_TYPE

Reduction of the CP path velocity

Data type

Enum

Value

min.

Unit

Value

max.

In file

Steu\Mada\$custom.dat

Original line

DECL CP_VEL_TYPE $CP_VEL_TYPE=#CONSTANT

Comments

If the axis limit values are exceeded, the CP velocity is reduced.

Reduction is always active in Cartesian jogging.

Options

Effect

#Constant

No reduction

#VAR_T1

Reduction in jog mode SStep(T1)

#VAR_ALL

Reduction in all modes

$CPVELREDMELD

Generation of message if path velocity reduced

Data type

Real

Value

min.

Unit

Value

max.

In file

------

Original line

INT $CPVELREDMELD

Comments

The message contains the point name and the maximum reduction in the

specific motion command.

Options

Effect

0

Generation of message deactivated.

1

Generation of message in the event of block change in jog mode.

100

Generation of message in the event of block change in all modes.

$CURR_ACT

Actual current of axes 1 -- 12

Data type

Real

Value

min.

Unit

%

Value

max.

In file

------

Original line

REAL $CURR_ACT[12]

;Aktueller Motorstrom in %

Comments

Current value of current of axes 1 -- 12 in % of maximum servo drive

module current $CURR_MAX (--100% to +100%)

4

C (Fortsetzung)

39 of 170

SysVar 08.02.03 en

$CURR_CAL

Current calibration in the power module

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $CURR_CAL[12]

;Stromkalibrierung Powermodul (Stromwandler)

Comments

For KRC 1a and KRC 2, calibration =1

Options

Effect

1

High power

2

Medium / low power

4

Low power

$CURR_COM_EX

Current limitation for external axes in jog mode

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $CURR_COM_EX[6]

;Stromgrenze externer Achsen für Handverfahren

Comments

$CURR_LIM[n]

Current limitation, axis[n]

Data type

Integer

Value

min.

Unit

%

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $CURR_LIM[n]

Comments

[n] = [1] ... [6]: axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

$CURR_MAX

Maximum effective current on power module output

Data type

Real

Value

min.

Unit

A

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $CURR_MAX[12]

Comments

Effective current must be present

System Variables

40 of 170

SysVar 08.02.03 en

$CURR_MON[n]

Permissible rated current

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $CURR_MON[n]

;Zulässiger Nennstrom

Comments

Defines the limit for i

2

t monitoring for 55 °C

[n] = [1] ... [6]: axis A1 ... A6

[n] = [7] ... [12]: external axis E1 ... E6

$CURR_RED

Current limitation of axes 1 -- 12 in % of maximum current

Data type

Real

Value

min.

Unit

%

Value

max.

In file

------

Original line

REAL $CURR_RED[12,2]

Comments

1st digit:

axis

2nd digit:

1 = positive limit

2 = negative limit

$CYC_DEF1 ... 32

Input text for the corresponding cyclical flag

Data type

Character

Value

min.

Unit

Value

max.

In file

------

Original line

CHAR $CYC_DEF1[470]

...

CHAR $CYC_DEF32[470]

Comments

$CYCFLAG[n]

Cyclical flags

Data type

Boolean

Value

min.

Unit

Value

max.

In file

------

Original line

BOOL $CYCFLAG[32]

Comments

[n]=[1] ... [256]

There are 32 cyclical flags available; these flags are cyclically updated

independently of program execution. The default value is FALSE.

5

D

41 of 170

SysVar 08.02.03 en

5

D

$DATA_SERx

Number of serial receive messages read in the channel x buffer

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $DATA_SER1

;Zähler für Datenpakete die über: SER1 eintreffen

Comments

$DATA_INTEGRITY

A variable of type “Signal” is output either as groups of bits or one

bit at a time

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

BOOL $DATA_INTEGRITY=FALSE

;Signal--Datenkonsistenz Ein/Aus

Comments

If the signal variable is output as groups of bits, the signal must be defined

in one of the defined data objects “OUTB”, “OUTW” or “OUTDW”

Options

Effect

TRUE

Data are output as groups of bits

FALSE

Data are output one bit at a time

$DATAPATH

Name of the SRC file whose variables in the data list are to be

accessed using the variable modification function

Data type

Character

Value

min.

Unit

Value

max.

In file

------

Original line

CHAR $DATAPATH[16]

;Kommandocompiler--Suchpfad

Comments

System Variables

42 of 170

SysVar 08.02.03 en

$DATE

System time and system date

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL DATE $DATE

;Interne Systemzeit

Comments

$DECEL_MB

Deceleration time during maximum braking

Data type

Real

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $DECEL_MB[12]

Comments

Braking ramp for dynamic braking [ms].

In maximum braking, the current actual speed value is taken as the

command speed value and run down the ramp set in the machine datum

$DECEL_MB to zero.

$DEF_A4FIX

Fixing of axis 4 when palletizing

Data type

Boolean

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

BOOL $DEF_A4FIX=FALSE

;Achse 4 fixiert

Comments

Defines whether the robot has 5 or 6 axes.

When a program is loaded or reset, $PAL_MODE = $DEF_A4FIX is set,

i.e. palletizing mode is thus automatically activated for a 5--axis robot

and not for a normal 6--axis robot.

Options

Effect

TRUE

5--axis robot (axis 4 fixed)

FALSE

6--axis robot

5

D (Fortsetzung)

43 of 170

SysVar 08.02.03 en

$DEF_FLT_CP

Default filter for CP motion

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $DEF_FLT_CP

;Defaultfilter CP

Comments

$DEF_FLT_PTP

Default filter for PTP motion

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $DEF_FLT_PTP

;Defaultfilter PTP

Comments

Center of mass frame for the default load on the flange

in the flange coordinate system

$DEF_L_CM

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

FRAME $DEF_L_CM={x 230.0,y 0.0,z 210.0,a 0.0,b 0.0,c 0.0}

;Massenschwerpunkt--Frame

Comments

$DEF_L_CM.A

Rotation about the Z axis

Data type

Real

Value

min.

Unit

Value

max.

$DEF_L_CM.B

Rotation about the Y axis

$DEF_L_CM.C

Rotation about the X axis

$DEF_L_CM.X

Offset in the X direction

$DEF_L_CM.Y

Offset in the Y direction

$DEF_L_CM.Z

Offset in the Z direction

System Variables

44 of 170

SysVar 08.02.03 en

$DEF_L_J

Default moment of inertia of the load on the flange in the default

center of mass coordinate system of the load

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

DECL INERTIA $DEF_L_J={X 17,5,Y 17,5,Z 17,5}

;Eigentraegheitsmomente der Last

Comments

$DEF_L_M

Default mass of the load on the flange

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $DEF_L_M

Comments

Center of mass frame for the default mass of the supplementary

load on axis 3 in the flange coordinate system

$DEF_LA3_CM

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

FRAME $DEF_LA3_CM={x --505.0,y 0.0,z --1110.0,a 0.0,b 0.0,c 0.0}

;Massenschwerpunkt--Frame A3

Comments

$DEF_LA3_CM.A

Rotation about the Z axis

Data type

Real

Value

min.

Unit

Value

max.

$DEF_LA3_CM.B

Rotation about the Y axis

$DEF_LA3_CM.C

Rotation about the X axis

$DEF_LA3_CM.X

Offset in the X direction

$DEF_LA3_CM.Y

Offset in the Y direction

$DEF_LA3_CM.Z

Offset in the Z direction

5

D (Fortsetzung)

45 of 170

SysVar 08.02.03 en

$DEF_LA3_J

Default moment of inertia of the supplementary load on axis 3

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

DECL INERTIA $DEF_LA3_J={X 16,8,Y 16,8,Z 16,8}

Comments

$DEF_LA3_M

Default mass of the supplementary load on axis 3

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $DEF_LA3_M

Comments

$DEF_OV_JOG

Default value for override in jog mode

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $DEF_OV_JOG

Comments

$DEVICE

Operator control device status

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL DEVICE $DEVICE

;Bediengerätezustand (ACTIVE, BLOCK, PASSIVE, OFF)

Comments

Options

Effect

#ACTIVE

#BLOCK

#PASSIVE

#OFF

System Variables

46 of 170

SysVar 08.02.03 en

$DH_4

Denavit--Hartenberg parameters for the wrist

(frame between axes 4 and 5)

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL DHART $DH_4={DHART_A 0.0,DHART_D 0.0,DHART_ALPHA

90.0}

;A = Länge A, D = Länge D, ALPHA = Winkel ALPHA

Comments

Defines the frame between axes 4 and 5.

$DH_4.DHART_A

Denavit--Hartenberg parameters for the wrist – Length A

Data type

Real

Value

min.

Unit

mm

Value

max.

$DH_4.DHART_D

Denavit--Hartenberg parameters for the wrist – Length D

$DH_4.DHART_ALPHA

Denavit--Hartenberg parameters for the wrist – Angle alpha

Data type

Real

Value

min.

Unit

°

Value

max.

$DH_5

Denavit--Hartenberg parameters for the wrist

(frame between A5 and A6)

Data type

Structure

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL DHART $DH_5={DHART_A 0.0,DHART_D 0.0,DHART_ALPHA

--90.0}

;A = Laenge A, D = Laenge D, ALPHA = Winkel ALPHA

Comments

Defines the frame between axes 5 and 6.

$DH_5.DHART_A

Denavit--Hartenberg parameters for the wrist – Length A

Data type

Real

Value

min.

Unit

mm

Value

max.

$DH_5.DHART_D

Denavit--Hartenberg parameters for the wrist – Length D

$DH_5.DHART_ALPHA

Denavit--Hartenberg parameters for the wrist – Angle alpha

Data type

Real

Value

min.

Unit

°

Value

max.

5

D (Fortsetzung)

47 of 170

SysVar 08.02.03 en

$DIGIN1

...

$DIGIN6

Signal declaration defining the input to which the digital input

“$DIGIN1 ... 6” is assigned

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $DIGIN1 $IN[1026] TO $IN[1026]

...

SIGNAL $DIGIN6 $IN[1026] TO $IN[1026]

Comments

Assignment of digital inputs 1 to 6

$DIGIN1CODE

...

$DIGIN6CODE

Defines whether or not the value for “$DIGIN1 ... 6” is preceded by

a sign

Data type

Enum

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

DECL DIGINCODE $DIGIN1CODE=#UNSIGNED

...

DECL DIGINCODE $DIGIN6CODE=#UNSIGNED

Comments

Sign assignment for $DIGIN1 ... 6

Options

Effect

#SIGNED

With sign

#UNSIGNED Without sign

$DIR_CAL

Defines the referencing direction for each axis

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $DIR_CAL=’B000111111111’

;Referier--Richtung

Comments

Options

Effect

Bit (n)= 0

Reference point of axis n is approached in the positive direction

Bit (n)= 1

Reference point of axis n is approached in the negative direction

System Variables

48 of 170

SysVar 08.02.03 en

$DIRECTION

Direction of the start key –

program is executed either forwards or backwards

Data type

Enum

Value

min.

Unit

Value

max.

In file

------

Original line

DECL DIRECTION $DIRECTION

Comments

Options

Effect

#FORWARD

Forwards execution

#BACKWARD Backwards execution

$DIS_WRP1

Average distance of wrist point from singularity 1

(Alpha 1 singularity)

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $DIS_WRP1

;Mittlerer Abstand Handpunkt zur Singularitaet1

Comments

$DIS_WRP2

Average distance of wrist point from singularity 2

(Alpha 5 singularity)

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

REAL $DIS_WRP2

;Mittlerer Abstand Handpunkt zur Singularitaet2

Comments

5

D (Fortsetzung)

49 of 170

SysVar 08.02.03 en

$DISPLAY_REF

New form output when “$DISPLAY_VAR” is changed

Data type

Boolean

Value

min.

Unit

Value

max.

In file

------

Original line

BOOL $DISPLAY_REF

;Formularneuausgabe bei Aenderung von $DISPLAY_VAR

Comments

Name of observable variables

$DISPLAY_VAR.NAME[32]

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL DISPLAY_VAR $DISPLAY_VAR[32]

;Beobachtbare Variablen

Comments

$DISPLAY_VAR[1]...[32]

Observable variables

$DISPLAY_VAR.PATH[12]

Corresponding file list name

Data type

Character

Value

min.

Unit

Value

max.

$DISPLAY_VAR.TITLE[12]

Name to be displayed for the variable

$DIST_NEXT

Distance still to be covered to the next point

Data type

Real

Value

min.

Unit

Value

max.

In file

------

Original line

REAL $DIST_NEXT

Comments

System Variables

50 of 170

SysVar 08.02.03 en

$DISTANCE

Curve length, CP motion

Data type

Real

Value

min.

Unit

mm

Value

max.

In file

------

Original line

REAL $DISTANCE

;Bogenlaenge CP--Bewegung in [mm]

Comments

$DRIVE_CART

Option bit: PTP points with Cartesian coordinates

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

BOOL $DRIVE_CART=TRUE

;PTP mit kartesischen Koordinaten

Comments

Options

Effect

TRUE

PTP points can have Cartesian coordinates

FALSE

PTP points cannot have Cartesian coordinates

$DRIVE_CP

Option bit: Cartesian robot motion possible (LIN, CIRC)

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

BOOL $DRIVE_CP=TRUE

Comments

Options

Effect

TRUE

Cartesian robot motion possible

FALSE

Cartesian robot motion not possible

5

D (Fortsetzung)

51 of 170

SysVar 08.02.03 en

$DRIVES_OFF

Signal declaration “Drives OFF”

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

SIGNAL $DRIVES_OFF $IN[1025]

Comments

Drives OFF

$DRIVES_ON

Signal declaration “Drives ON”

Data type

Signal declaration

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

SIGNAL $DRIVES_ON $IN[1026]

Comments

Drives ON

$DSECHANNEL

Assignment of axes to channels of the digital servoelectronics

(DSE)

Data type

Integer

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $DSECHANNEL[12]

;Achszuordnung auf DSE

Comments

$DYN_DAT[350]

Model data of the robot for acceleration adaptation, higher motion

profile and kinetic energy

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $DYN_DAT[350]

Comments

Contains the model data of the robot, which are required for acceleration

adaptation, the higher motion profile and the calculation of kinetic energy

(moments of inertia, friction values, etc.)

System Variables

52 of 170

SysVar 08.02.03 en

6

E

53 of 170

SysVar 08.02.03 en

6

E

$EMSTOP_ADAP

Model--based Emergency Stop

Data type

Boolean

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

BOOL $EMSTOP_ADAP=FALSE

;NOT--AUS mit Dynamikmodell

Comments

The system variable “$ADAP_ACC” must not be set to “#NONE” (dynamic

model for the kinematic system must be present).

The path--maintaining EMERGENCY STOP motion for PTP and CP paths

is executed with maximum deceleration; this is determined by the motor and

gear torques calculated in the dynamic model.

External axes are still braked as before, thus affecting the robot axes.

Internally, both the new and the old functionality are calculated and

compared with one another. If this comparison indicates significantly higher

deceleration using the old method (e.g. due to completely incorrect model

or load data), braking is carried out using the old functionality.

Options

Effects

TRUE

Model--based Emergency Stop activated

FALSE

Model--based Emergency Stop not activated (old functionality)

$EMSTOP_GEARTORQ[n]

Maximum gear torque for Emergency Stop

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $EMSTOP_GEARTORQ[n]

;Max. Getriebemoment bei modellbasiertem NOT--AUS [Nm]

Comments

[n] = [1] ... [6]

$EMSTOP_MOTTORQ[n]

Maximum motor torque for Emergency Stop

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $EMSTOP_MOTTORQ[n]

;Max. Motormomente bei modellbasiertem NOT--AUS [Nm]

Comments

[n] = [1] ... [6]

System Variables

54 of 170

SysVar 08.02.03 en

Configuration of path--maintaining Emergency Stop for operating

modes T1, T2, AUT, EX

$EMSTOP_PATH

Data type

Structure

Value

min.

Unit

Value

max.

In file

Steu\Mada\$machine.dat

Original line

DECL EMSTOP_PATH $EMSTOP_PATH={T1 #ON,T2 #ON,AUT

#ON,EX #ON}

;Projektierung des bahntreuen NOT--AUS für T1, T2, AUT, EX

Comments

Options

Effects

#ON

Path--maintaining emergency stop for the corresponding operating mode is

on

#OFF

Path--maintaining emergency stop for the corresponding operating mode is

off

$EMSTOP_PATH.AUT

Configuration of path--maintaining Emergency Stop for operating

mode “AUT”

Data type

Enum

Value

min.

Unit

Value

max.

Options

Effects

#ON

Path--maintaining emergency stop for operating mode “AUT” is on

#OFF

Path--maintaining emergency stop for operating mode “AUT” is off

$EMSTOP_PATH.EX

Configuration of path--maintaining Emergency Stop for operating

mode “EX”

Options

Effects

#ON

Path--maintaining emergency stop for operating mode “EX” is on

#OFF

Path--maintaining emergency stop for operating mode “EX” is off

$EMSTOP_PATH.T1

Configuration of path--maintaining Emergency Stop for operating

mode “T1”

Options

Effects

#ON

Path--maintaining emergency stop for operating mode “T1” is on

#OFF

Path--maintaining emergency stop for operating mode “T1” is off

$EMSTOP_PATH.T2

Configuration of path--maintaining Emergency Stop for operating

mode “T2”

Options

Effects

#ON

Path--maintaining emergency stop for operating mode “T2” is on

#OFF

Path--maintaining emergency stop for operating mode “T2” is off

6

E (Fortsetzung)

55 of 170

SysVar 08.02.03 en

$EMSTOP_TIME

Time monitoring for path--maintaining Emergency Stop

Data type

Integer

Value

min.

Unit

ms

Value

max.

In file

R1\Mada\$machine.dat

Original line

INT $EMSTOP_TIME

;Zeitueberwachung für bahntreuen NOT--AUS [ms]

Comments

$EMSTOP_TORQRATE

Maximum changing of motor and gear torques

Data type

Real

Value

min.

Unit

Value

max.

In file

R1\Mada\$robcor.dat

Original line

REAL $EMSTOP_TORQRATE

;Max. Aenderung der Momente bei NOT--AUS mit Dynamikmodell

[Nm/ms]

Comments

For setting jolt limitation in the event of a model--based Emergency Stop

$EMT_MODE

Method for EMT mastering

Data type

Structure

Value

min.

Unit

Value

max.

In file

------

Original line

DECL EMT_MODE $EMT_MODE

Comments

Options

Effects

#FIRST_CAL

First mastering

#TOOL_TEACH Learn tool

#CHECK_CAL

Check

#RECALC_CAL Restore

System Variables

56 of 170

SysVar 08.02.03 en

$ENDLESS

Flag for infinitely rotating axes

Data type

Boolean

Value

min.

Unit

Value

max.

In file

Steu\Mada\$option.dat

Original line

BOOL $ENDLESS=TRUE

;Endlos drehende Achsen

Comments

Options

Effects

TRUE

Infinitely rotating axes possible

FALSE

Infinitely rotating axes not possible

$ENERGY_MON

Nominal energy monitoring (kinetic energy)

Data type

Boolean

Value

min.

Unit

Value

max.

In file

R1\Mada\$Robcor.dat

Original line

BOOL $ENERGY_MON=FALSE

;Ueberwachung kinetische Energie bei Crash

Comments

Options

Effects

TRUE

Energy monitoring activated

FALSE

Energy monitoring deactivated

$ERROFFMASK

Removal of individual error bits

Data type

Integer

Value

min.

Unit

Value

max.

In file

------

Original line

INT $ERROFFMASK[12]

;Abschaltung einzelner Fehlerbits

Comments

6

E (Fortsetzung)

57 of 170

SysVar 08.02.03 en

$ERSYSROOT

Offset and orientation of the robot when external axes are present,

with reference to the world coordinate system

Data type

Structure

Value

min.

Unit

mm, °

Value

max.

In file

R1\Mada\$machine.dat

Original line

FRAME $ERSYSROOT={x 0.0,y 0.0,z 0.0,a 0.0,b 0.0,c 0.0}

;Roboterfußpunktkinematik im Weltkoordinatensystem [mm,Grad]

Comments

Only valid when external axes are present. If “$ERSYSROOT” is valid,

then “$ROBROOT” will be ignored.

$ET1_AX

...

$ET6_AX

Assignment of external axes to external axis kinematic system

ET1 ... ET6

Data type

Enum

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

DECL ET_AX $ET1_AX={TR_A1 #NONE,TR_A2 #NONE,TR_A3

#NONE}

...

DECL ET_AX $ET6_AX={TR_A1 #NONE,TR_A2 #NONE,TR_A3

#NONE}

;Externe Achsen #NONE, #E1, #E2, #E3, #E4, #E5, #E6

Comments

List of external axes used in the 1st ... 6th external transformations

ET1 ... ET6.

Options

Effects

#NONE

#E1 -- #E6

$ET1_NAME

...

$ET6_NAME

Name of external axis kinematic system ET1 ... ET6

Data type

Character

Value

min.

Unit

Value

max.

In file

R1\Mada\$machine.dat

Original line

CHAR $ET1_NAME[20]

...

CHAR $ET6_NAME[20]

Comments

The name can have a maximum length of 20 characters.

System Variables

58 of 170

SysVar 08.02.03 en

$ET1_TA1KR

...

$ET6_TA1KR