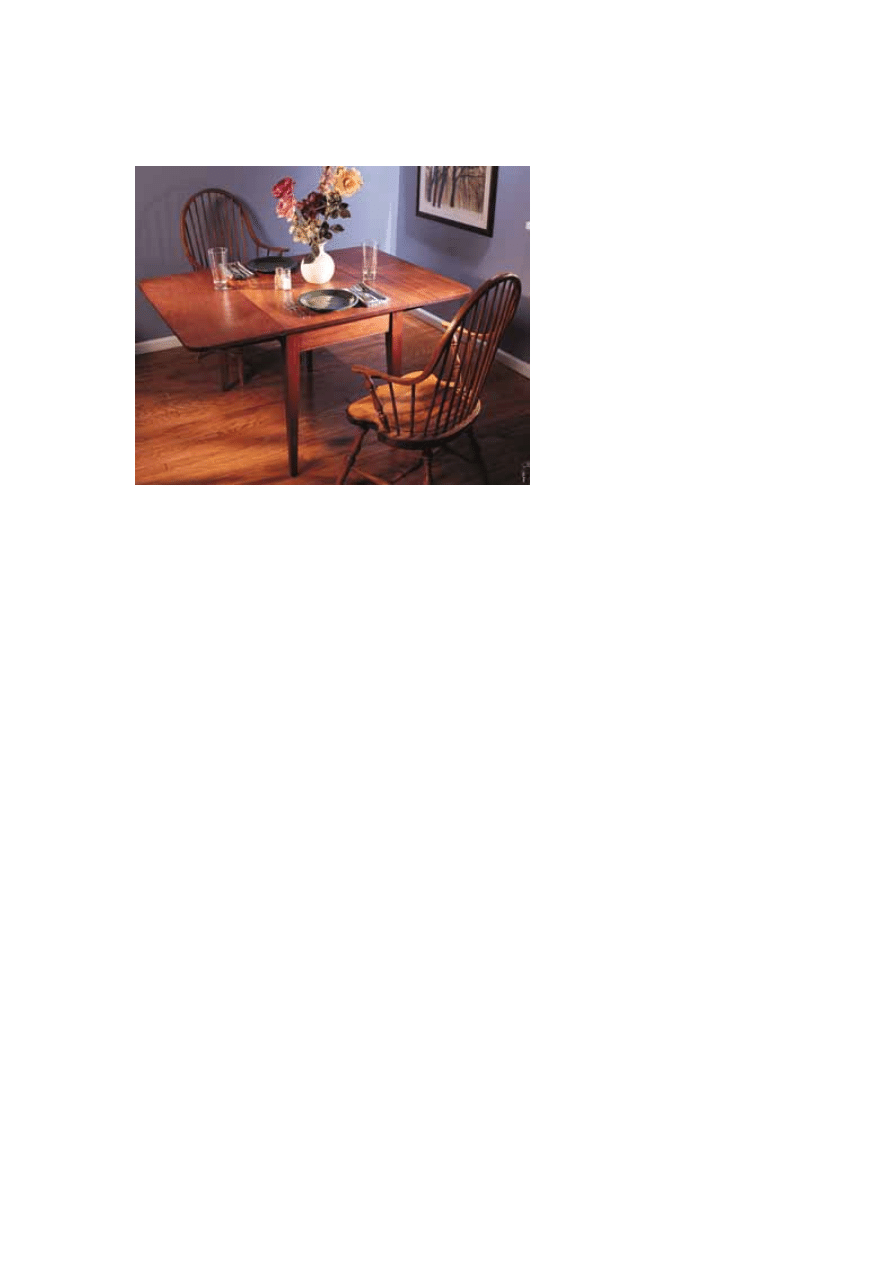

Drop-Leaf Table

This table may look complex, but it requires mostly simple joinery.

In our living room, we keep a mahogany table that I vaguely knew one of my ancestors had

built. After I began my internship at this magazine, I became more interested in that table. I

asked my paternal grandmother about the table, and she told me that my great-great-

grandfather, Carl Edward Wulff, built it at his furniture shop in downtown Cincinnati about 1870.

She even had a photograph of his shop dated 1878. In the picture you can see the simple sign

that says “Furniture.” With this proof, I knew that woodworking was definitely in my blood.

Having the family tradition in mind, I set about building a slightly simplified facsimile. In fact, the

joinery in this project is so simple that almost any beginner can do it.

Start with the Basics

After cutting all your rough stock to length, surface your wood down to ¾" thick (except for the

legs). The original 19th-century table’s top was only one board. You can still find mahogany in

these widths, but I couldn’t. To obtain the appropriate width, I had to glue up two boards for both

the leaves and the tabletop. I used three biscuits at each joint to keep the boards aligned during

glue-up. Also, if you can’t get 2¼"-thick stock for the legs, ask for turning blanks at the lumber

store instead; you might just get lucky.

Mortises, Tenons and Tapers

The first step is to make mortise-and-tenon joints where the aprons join the legs. I made the

tenons using a dado stack on the table saw. Cut the shoulders as shown in the photo on the

next page. Make the tenons 3/8" thick, 1" long and 3¼" wide. After cutting your tenons, cut a

groove in the aprons for the tabletop fasteners, which will attach the top to the table’s base.

Make this slot by cutting a kerf in the aprons that’s 7/16" down from the top edge. For a nice

detail, I routed a bead on the bottom edge of the aprons.

The mortises on all the legs are made 1-7/16" from the inside for the short aprons and 7/16"

from the inside for the long aprons as shown in the diagram below. Cut your mortises on the

legs; I used a mortiser, but you can use a chisel or Forstner bit.

The original table had turned legs, but in order to simplify things, I tapered the legs. Tapering

jigs for the table saw can be tricky, so I used a band saw to cut the tapers about 1/16" shy of my

line and then cleaned up the cut on the jointer. The taper should start 1" below where the

aprons end and result in a leg that tapers to one-half the original thickness. Remember: taper

only the sides that have mortises.

Install the Hinges

After tapering, sand the legs and aprons. Start with 100-grit sandpaper, move up to 150-grit,

then finish with 220-grit. Next, glue up the legs and aprons and clamp. After gluing up the base,

turn your attention to the top.

Install the hinges that connect the tabletop to the leaves. Use two on each side, and place them

7¼" inches from the end to allow room for the leaf supports. Lay out the location of the hinges

by first placing a 1/16" spacer (I used pieces of plastic laminate) between the leaf and tabletop.

Clamp the pieces together, put the hinges down and trace them with a pencil. Use a router with

a straight bit to hog out most of the area. Then use a chisel to define the corners. Install the

hinges and make sure they work properly.

A 4" radius on the outside corners of the leaves on the original table was a nice touch. In order

to recreate this, I traced the curve from the original and made a template using a piece of

plywood. Cut the shape to size on a band saw and then use the template with a router and

straight bit to finish the radius.

Make the Leaf Supports

To keep the leaves upright, assemble two supports for each side. These are basically two

pieces of wood finger-jointed together to form a “knuckle” joint hinge. The ½" knuckle joints are

made on a table saw using a finger-jointing jig. Round the edges of the “fingers” with a rasp or

sandpaper so the joint pivots. Then drill a ¼" hole through the fingers and tap a ¼" dowel in

place. Instant wooden hinges. One note: you’ll have to cut a notch in the two supports so they’ll

clear the hinge barrels on the top. Mark the location of the notch when you dry-assemble the

table. The angle cuts on the supports form a triangular hole against the apron. Cut a triangular

piece of mahogany to fill this space, being careful not to let the filler rub against the supports.

For simplicity, you may use brass hinges instead of knuckle joints.

Sanding and Finishing

Remove the hinges from the tabletop and sand the table. Because the top will be the most

visible surface, I chose to go up to 220 grit. The bottom requires only 150 grit. In order to

simplify finishing, I waited to attach the supports until after finishing. This requires masking off

the area where the support will be glued. For the finish, I applied a dark mahogany stain made

by United Gilsonite Laboratories (P.O. Box 70, Scranton, Penn. 18501; 800-272-3235;

www.ugl.com). The color is called “118 Dark Mahogany,” order number 11811, LR1294. Both

the phone number and the website can refer you to a retailer in your area. After letting the stain

cure, I applied four coats of clear lacquer.

Final Construction Details

After the lacquer has dried, attach the supports and the triangle with glue and nails through the

inside of the aprons. Place the top on the base and make sure the supports keep the leaves

level. Now attach the top. Because of the expansion and contraction of wood, you will need to

attach the aprons to the tabletop using tabletop fasteners. These fasteners are available from

Rockler and are listed in the Schedule of Materials. The tabletop fasteners are installed by

simply screwing the fasteners into place. Because the wood will move more in width than in

length over time, be sure to leave more space on the long apron sides for the fasteners.

Overall, I was extremely pleased with the results of my project. I think my great-great-

grandfather would be proud to know that I’ve continued the family tradition.

Wyszukiwarka

Podobne podstrony:

Drop Leaf Table

Drop Leaf Table

Shaker Single Drop leaf Table

Table Leaf Table

Drop Table

oak dining table

Assessment of cytotoxicity exerted by leaf extracts

Coffee Table 1

table style2, ♥Dokumenty

table cellspacin5, ❀KODY RAMEK I INNE, Ramki

table border (2)

Foresight Resolution Table

Leaf and Apple Calendar Numbers

Chess Table

więcej podobnych podstron