Biomaterials 23 (2002) 3733–3740

Effect of metal alloy surface stresses on the viability of ROS-17/2.8

osteoblastic cells

Anita Kapanen

a,

*, Anatoli Danilov

a,c

, Petri Lehenkari

b

, Jorma Ryh

.anen

b

, Timo J

.ams.a

c

,

Juha Tuukkanen

a

a

Biocenter Oulu and Department of Anatomy and Cell Biology, University of Oulu, P.O. Box 5000 FIN-90014 Oulu, Finland

b

Department of Surgery, University of Oulu, P.O. Box 5000 FIN-90014 Oulu, Finland

c

Department of Medical Technology, University of Oulu, P.O. Box 5000 FIN-90014 Oulu, Finland

Received 2 July 2001; accepted 14 March 2002

Abstract

In this study we compared the effect of structural stresses and surface roughness on biocompatibility of NiTi- and Ti-alloy for

ROS-17/2.8 osteoblastic cells. We suggest here that cell viability and cell attachment are linear functions of internal (structural)

stress and subgrain size of the implant alloy. However, this is not the case with surface roughness. The two-phase state in these

materials is characterized by different mean values of structural stresses (s) in a-martensite and b-phase. We found a straight

correlation between cell viability and s

b

=s

a

ratio. Atomic force microscopy revealed that, even after equal surface polishing

treatments, roughness varied significantly between the different alloys. The effect of the surface structure of the alloy on the

osteoblastic ROS-17/2.8 cell survival rate was studied with combined calcein-ethidium-homodimer fluorescence labeling. The

possible effects on cell attachment to substrate were studied by staining the focal contacts with paxillin antibody. All the NiTi

surfaces were tolerated well and the cells attached most abundantly to the roughest NiTi surface but the smoothest Ti-alloy surface.

However, other parameters of the material state, such as the surface stresses created by hot rolling seem to be responsible for some

of the attachment and cell survival features observed in this study. r 2002 Elsevier Science Ltd. All rights reserved.

Keywords: NiTi; Titanium alloys; Surface stresses; AFM; ROS-17/2.8

1. Introduction

A material consisting of nearly equiatomic parts of

nickel and titanium (Nitinol) has superelasticity, ther-

mal shape memory and good damping properties, which

make it a promising surgical implant material, especially

in orthopedics [1–3]. Studies done with human fibro-

blasts and human osteoblasts show good in vitro

biocompatibility of NiTi [4,5].

There are several papers convincing that surface

roughness contributes to osteoblast attachment and

spreading. Rat calvaria-derived osteoblast attachment

increased as a function of surface roughness [6]. A study

on chemically pure Ti and Ti-alloy surfaces further

indicated increased attachment as a function of surface

roughness [7]. The recent study by Lohmann et al.

(2000) with three different cell lines showed that surface

roughness promotes osteogenic differentiation of less

mature cells. More mature cells exhibit a reduced

sensitivity to their substrate, but are still affected by

changes in surface roughness [8]. However, there are in

vitro studies that indicate attachment favoring smooth

surfaces [9–14]. Some in vivo studies done with dogs,

rabbits and pigs indicate that increasing surface rough-

ness is associated with enhanced bone formation at

implant surfaces [15–17]. But surface roughness, being a

characteristic of surface topography, could not describe

the whole spectrum of subtle differences in material

surface state caused by the differences in its structures

and phase composition. At the same time, it is well

known that the internal or structural stresses are very

sensitive characteristics of the state of the material. The

structural stresses reflect such structural parameters as

density and distribution of dislocations, twins and

stacking faults. The stresses react on phase composition

changes. In addition, the ratios of stresses in different

*Corresponding author. Tel.: +358-8-537-5188; fax: +358-8-537-

5172.

E-mail address:

anita.kapanen@oulu.fi (A. Kapanen).

0142-9612/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 14 2 - 9 6 12 ( 0 2 ) 0 0 10 7 - 2

phases inform about probable consequences of phase

transformations on corrosion and electrochemical prop-

erties. Among the important causes of internal stresses

we may mention mechanical, chemical, heat and

radiation treatments. Therefore, we find it relevant to

apply definition of structural stress to biocompatibility

investigations.

The aim of the present study was to assess the effect of

structural stresses in NiTi- and two-phase (a þ b) Ti-

alloys on the viability of ROS-17/2.8 osteoblastic cells in

comparison with the effect of surface roughness.

Different NiTi surfaces were compared with those of a

Ti-alloy with two different hot-rolling treatments. An

atomic force microscope (AFM) and X-ray structural

analysis was used to examine the surface characteristics.

2. Materials and methods

2.1. Test materials

The tested materials were binary NiTi shape memory

alloy (Ti–44 wt%, Ni–56 wt%, Unitec) and two phase

(a þ b) Ti-based alloy (Ti–90.5 wt%, Al–6 wt%, Mo–

2.2 wt%, Cr–1.3 wt%, Institute of Light Metals, Mos-

cow, Russia) vacuum-melted and hot-rolled. The choice

of materials was governed by their good perspectives for

biomedical application: NiTi because of its well-known

biomechanical and corrosion properties, Ti6Al2.2-

Mo1.3Cr alloy seems to be a competitor to wide-spread

Ti6Al4V-alloy because of toxic vanadium substitution

for less toxic elements as Mo and Cr. To initiate

different phase composition and thus different structural

stresses, two rolling temperatures for two groups of Ti-

alloy were used: 8501C (TiI) and 10501C (TiII). The

rolling temperature of NiTi was 9501C.

To initiate further surface stress grades, test disks of

5 mm in diameter and 3 mm in thickness were ground by

grinding stone N80 (group 80, n ¼ 6) followed by

carbon silicon paper of decreasing coarseness 240, 320,

400, 600 (group 600, n ¼ 6), 800, 1200 and finally

polished by rubber wheel (only NiTi-alloy samples) and

cloth with chromium oxide paste (group 1200, n ¼ 6).

The rubber wheel was used for NiTi samples to achieve

the high polished state, which could not be achieved

only by polishing with cloth because of the high wear-

proofness of NiTi. The test disks were then washed in an

ultrasonic vibrobath, degreased with 70% ethanol for

10 min and autoclaved at 1201C for 20 min before use.

2.2. Surface roughness measurement

AFM measurements were performed with Explorer

system (Thermomicroscopes, Sunnyvale, USA) and

SPMLabNT software ver. 5.01Explorer AFM (Ther-

momicroscopes, Sunnyvale, USA). The sizes of scanned

area were 100 100 mm

2

.

The following roughness parameters were measured:

R

a

is the average roughness is the arithmetic average

deviation from the mean line. R

p

the maximum peak is

the maximum height or the highest peak of the

roughness profile above the mean line. R

t

the maximum

peak to valley is the sum total of the maximum peak and

maximum valley measurements of roughness within the

length assessed. R

tm

is the more representative mean

value of the entire profile.

Three disks in each test group were analyzed on three

randomly chosen lines, and the means of the parameters

were calculated. Table 1displays the surface roughness

parameters of the different alloys.

2.3. X-ray structural analysis

X-ray structural analysis of phase composition,

internal stresses and subgrain sizes (in NiTi and TiI

samples) was performed on the X-ray diffractometer

DRON-3.0 (X-ray equipment Co ‘‘Burevestnik’’, Saint-

Petersburg, Russia) with filtered Cu K

a

-radiation. The

mean values of lattice strains (e) that were used for stress

calculation, and the mean size of subgrains were

determined in accordance with the procedure described

in [18]. The necessity to separate the effect of stresses

and subgrain sizes on diffraction line broadening was

the initial reason to analyze both of these structural

Table 1

Roughness parameters of the tested alloys

Alloy

R

a

(nm)

R

p

(nm)

R

t

(nm)

R

tm

(nm)

NiTi 80

362.2

7209.2

636.6

7152.6

1434.3

7501.1

448.4

754.8

NiTi 600

156.0

720.5

632.7

7195.2

633.2

7443.5

506.9

741.4

NiTi 1200

95.2

741.4

158.0

738.9

425.2

784.11

98.4

721.5

TiI 80

1479.5

738.9

3120.0

7583.4

6847.0

7301.9

2568.0

712.7

TiI 600

1428.5

7173.2

1850.0

71064.2

5823.0

7707.1

1198.0

7142.8

TiI 1200

304.8

731.4

846.0

7548.7

1353.0

71061.2

539.8

7161.7

TiII 80

732.1

749.12285.07304.13740.0772.1948.1

749.9

TiII 600

436.3

710.4

1098.0

7210.2

2244.0

7318.9

669.0

756.1

TiII 1200

339.2

739.9

579.8

785.8

1381.0

711.3

418.2

721.4

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3734

parameters. The structural stresses s were calculated

from formula s ¼ Ee; where Young

’

s modulus E was

7 10

4

MPa for NiTi, 10.3 10

4

MPa for b-phase and

11.3 10

4

MPa for a-martensite in titanium alloy. The

values of structural stresses and subgrain sizes in

martensitic phase of NiTi were not studied because of

the small amounts of martensite (weak diffraction lines).

The analysis of internal stresses in TiII group samples

was not performed in the present study.

2.4. Cell culture

Rat osteosarcoma cell line ROS-17/2.8 (a generous

gift from G.A. Rodan, Merck Research Laboratories,

West Point, PA, USA) cultures were carried out in

minimal essential medium (MEM, Gibco) supplemented

with 10% fetal calf serum (Bioclear), antibiotics (100 U

of penicillin/ml, 100 mg of streptomycin/ml) and l-

glutamine (2 mm) at +371C (5% CO

2

, 95% air). The

cultures were allowed to reach confluency before

subculturing onto metal alloy disks. The cells were

washed with 371C phosphate-buffered saline (PBS), and

adherent cells were detached by using trypsin-EDTA.

Five thousand cells were seeded per disk (n ¼ 6) and

allowed to attach for 3 h. The cells were allowed to grow

for 48 h before staining with a cytotoxicity test kit or

fixation with 4% paraformaldehyde (PFA).

Because cells grown on disks cannot be seen in normal

light microscopy, the cells were also cultured on glass

cover slips 10 mm in diameter to assess the time of

subculture confluency.

2.5. Cytotoxicity test

The cells on the disks were washed twice with a warm

PBS solution and stained with a LIVE/DEAD

s

Via-

bility/Cytotoxicity kit (Molecular Probes, Oregon,

USA). The optimal concentration of the ethidium

homodimer-1(EthD-1) dye was 0.1mm and that of the

calcein dye 1 mm. The samples were incubated for 15 min

at 371C and viewed under a fluorescence microscope.

Dead cells (stained red) and live cells (stained green)

counted from six randomly chosen areas (0.849 mm

2

) on

each disk were viewed. The cells were counted visually

under a fluorescence microscope (Nikon Eclipse E600,

Nikon, Japan) with a 10 objective, NA 0.25 (Nikon,

Japan), and the ratio of dead to live cells was computed.

Approximately 350 cells were seen in each area. The

number of dead cells per image was expressed as per

1000 cells.

2.6. Immunofluoresence microscopy of focal contacts

The PFA-fixed cells were permeabilized with 0.1%

Triton-X-100 in PBS for 10 min on ice. The cells were

stained

by

using

monoclonal

paxillin

antibody

(ZYMED Laboratories, Inc., San Francisco, CA,

USA) at 1:100 in PBS for 45 min on ice. Staining was

carried out with rhodamine-conjugated rabbit anti-

mouse immunoglobulin secondary antibodies (DAKO,

Glostrup, Denmark) for 30 min on ice. To visualize the

nuclei, the cells were incubated with the DNA-binding

fluorochrome Hoechst 33258 (1:1000) for 10 min at

room temperature. The focal contacts were studied

under a confocal microscope LSM 510 equipped with an

inverted microscope Axiovert 100M and 63 objective

(NA 1.2/water, Zeiss, Germany). From each sample

disk, 6 frames were scanned with 1024 1024 frame size

(pixel size 0.14 0.14 mm

2

). The number of focal

contacts was measured with a digital image analyzer

(MCID M4 v.3.0.re.1.1, Imaging Research Inc., Cana-

da).

The

measured

region

of

interest

was

146.2 146.2 mm

2

. The confocal microscope images

were segmented based on red color intensity. The

interactively defined paxillin-containing focal contacts

were automatically counted from the region of interest.

2.7. Statistical analysis

Mean values and standard deviations were computed.

Analysis of variance (ANOVA) and Student’s t-test

were utilized to assess the level of significance of the

differences between the experimental groups. Bonferro-

nis corrections were applied to the t-tests. All statistical

analyses were performed with commercial software

(Origin 5.0, Microcal Software, Inc., USA).

3. Results

3.1. X-ray structural analysis

The results of X-ray experiments showed that the

above treatments of tested alloys resulted in different

phase state of samples. The initial hot-rolled state of

NiTi sample was austenite. The grinding by stone N80

did not change the phase composition but gave rise to

diffraction line broadening that is typical for cold-

worked metals because of increase in structural stresses.

Further grinding and polishing were accompanied first

by remarkable decrease of structural stresses (group

600) and then by their negligible increase (group 1200).

Another structural parameter that was parallel stu-

died—mean size of subgrains—changed in opposite

manner: group 80 was characterized by the smallest

sizes, in group 600 samples subgrain sizes were the

biggest and in group 1200 this parameter again became

smaller (Table 2). Simultaneously, small amounts of

martensitic phase appeared in the samples of groups 600

and 1200.

The same behavior of structural stresses was observed

in the basic martensitic a-phase of titanium alloy. The

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3735

highest values of s

a

were in samples of group 80, in

group 600 they were the smallest and then rose again in

group 1200. As a result of the described behavior, the

ratio s

b

=s

a

had the minimum value in group 80,

maximum in group 600, and again decreased in group

1200. Nevertheless, the mean values of stresses in b-

phase (s

b

) steadily increased as well as the subgrain sizes

in both b-phase and a-martensite (Table 2). The

mechanical treatment of titanium alloy was not accom-

panied by changes in phase composition, and initial b-

phase content (10–12 vol%) were kept in the samples

within investigated groups.

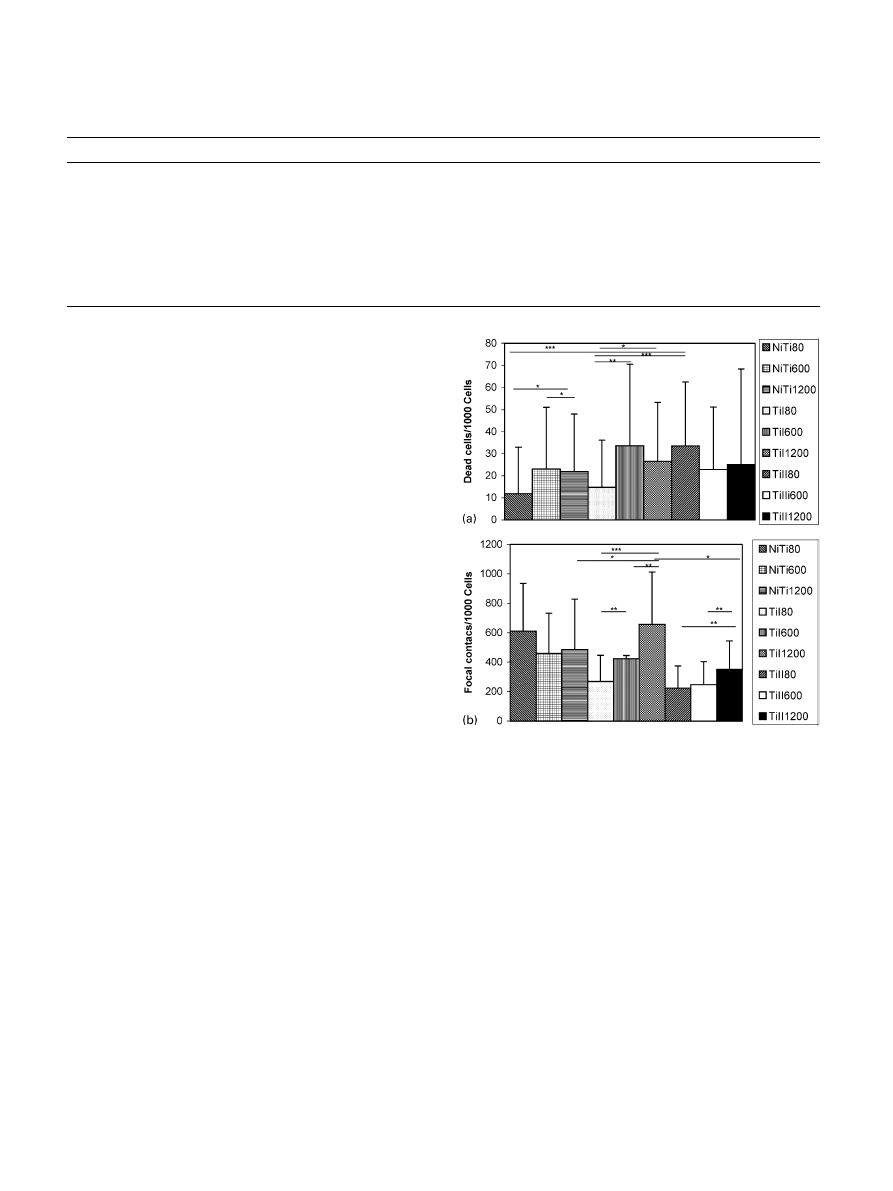

3.2. Cytotoxicity test

The cells cultured on sandpapered surfaces appeared

larger in a visual examination. On the roughest disks in

the TiII group, the cultures did not reach complete

confluency in 48 h, as did the cultures on NiTi. The

cytotoxicity test showed that the roughest NiTi and TiI

surfaces were significantly better in view of cell viability

than the other surfaces in the test groups. When we

compared the different alloys within the same roughness

group, it turned out that, in group 80, NiTi and TiI had

significantly fewer dead cells (12

721and 1

5

721,

respectively) than TiII (34

729), (pp0:001). The 600

and 1200 groups did not differ significantly. Within the

NiTi test group, the number of dead cells on the

roughest (80) surface (12

721) was significantly lower

compared to the 600 (23

728), (pp0:05) and 1200

(22

726), (pp0:05) surfaces. The results in the TiI group

were similar, with the 80 surface (15

721), showing a

significantly lower number of dead cells compared to the

600 (34

737), (pp0:01) and 1200 surfaces (27727),

(p

p0.05). The TiII group showed no significant

differences

between

the

three

roughness

groups

(34

729, 23729 and 25743, respectively) (Fig. 1A).

3.3. Attachment of cells

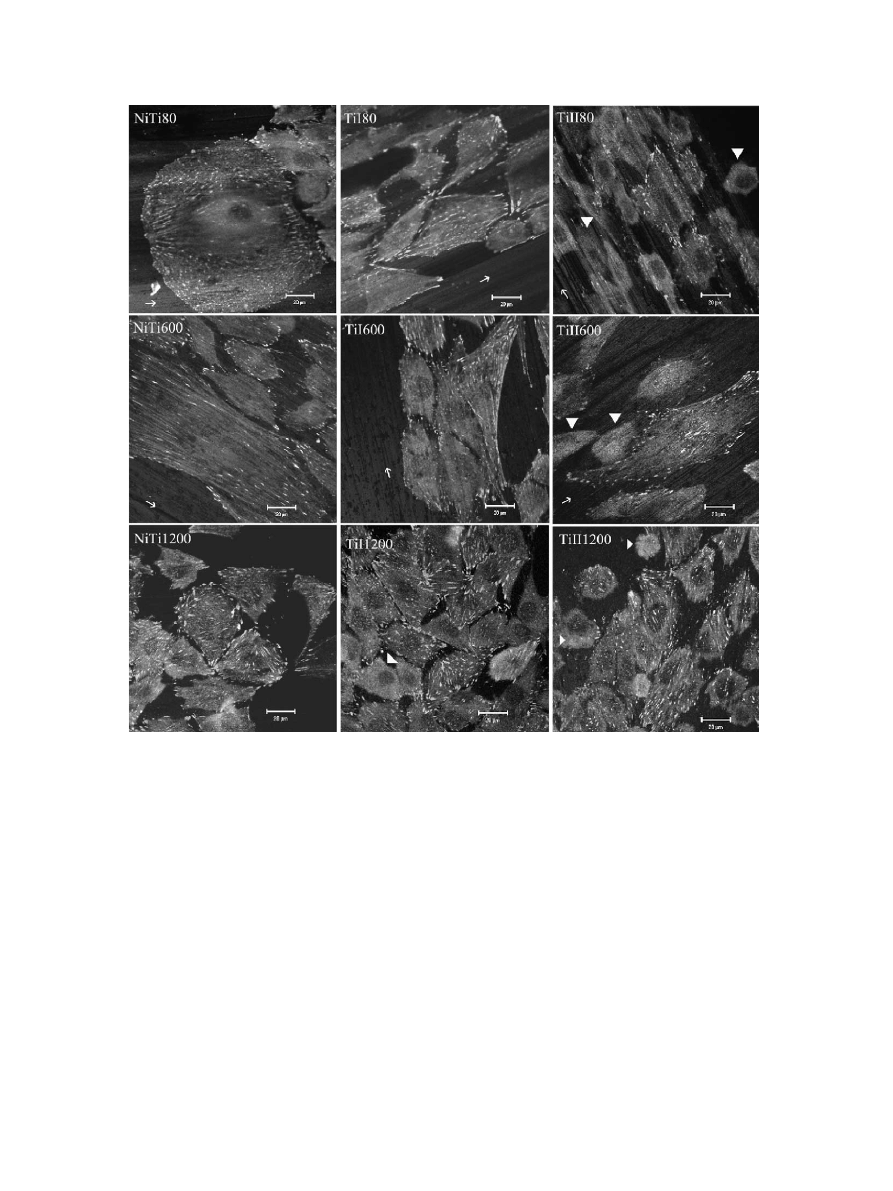

The focal adhesions of the cells grown on the test

materials seemed to locate parallel to the grinding

grooves (Fig. 2). This phenomenon was clearly seen on

the roughest surface, but was also observed on the other

surfaces.

We determined the number of focal adhesions based

on the paxillin staining of the cells. The results showed

that NiTi 80 strongly stimulated the formation of focal

adhesions formation. Only TiI 1200 was equally efficient

as NiTi 80 as a promoter of cell attachment. Overall, TiI

was a better matrix for osteoblast attachment than TiII.

The different surface roughness grades of NiTi did not

significantly differ in the number of focal adhesions

(611

7325, 4607272 and 4857343). In the TiI group,

the number of focal adhesions was significantly lower on

the roughest surface (269

7177) compared to the 600

(423

7222), (pp0:01) and 1200 (6587355), (pp0:001)

Table 2

The structural stresses and mean values of subgrain size in austenite of NiTi, b-phase and a-martensite of titanium alloy and Ti-alloys s

b

=s

a

ratio

Sample group NiTi

Structural stresses (MPa)

Subgrain size (nm)

80

259

71 9

35

600

143

79

88

1200

162

79

43

Sample groupTiI

b-phase

a-martensite

Structural stresses (MPa)

Subgrain size (nm)

Structural stresses (MPa)

Subgrain size (nm)

s

b

=s

a

80

164

76

28

1

24

77

62

1.32

600

228

71 3

39

45

73

100

5.07

1200

306

722

110

79

75

235

3.87

Fig. 1. (A) Results of the cytotoxicity test. NiTi—nickel titanium

alloy, TiI—titanium alloy with 8501C hot rolling, TiII—titanium alloy

with 10501C hot rolling. ¼ p

p0:05; ¼ pp0:01; ¼ pp0:001:

(B) Number of focal adhesions. ¼ p

p0:05; ¼ pp0:01; ¼

p

p0:001:

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3736

surfaces. The TiI 1200 group had a significantly

higher number of focal adhesions than the 600 group

(p

p0:01). The TiII 1200 surface had a significantly

higher number of focal adhesions (351

7194) than the

surfaces of the other two roughness grades (223

7151 in

group 80 and 248

7156 in group 600), (pp0:01)

(Fig. 1B).

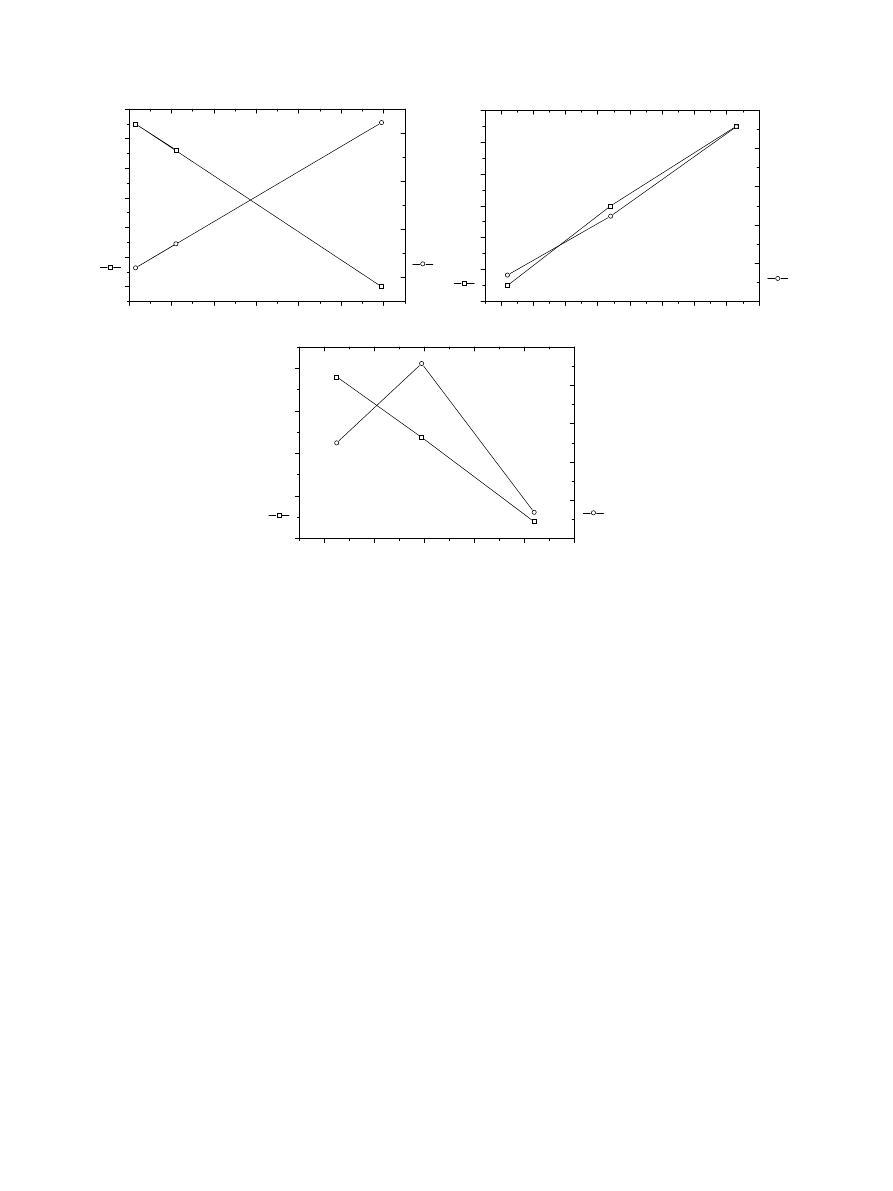

3.4. Effect of surface stress on biological parameters

The analysis of the results obtained from biological

tests and X-ray experiments demonstrate that mean

values of both biocompatibility parameters, cell survival

and cell attachment, seem to be linear functions of

internal stresses and subgrain sizes, respectively. In

the NiTi group, the increase in structural stress

increased the cell attachment but was in reverse

association to cell death rate (Fig. 3A). Interesting

finding was that in the b-phase of TiI alloy both the

cell attachment and the cell death rate increased with

increasing structural stress (Fig. 3B). In the a-martensite

phase of TiI alloy the effect of structural stress was

opposite (Fig. 3C).

4. Discussion

To detect common regularities of biocompatibility

relative to the surface of the implant, our study suggests

that it would be better to characterize surface stress than

roughness. A cyclic recovery effect (structural stress

decrease) during permanent deformation of pure metals

Fig. 2. Confocal microscope image of ROS-17/2.8 cultures on surfaces of different roughness. The small white arrows show the direction of the

grinding grooves, to which the focal contacts are parallel. The white arrowheads point out the diffusively stained cells without clear focal contacts.

Scale 20 mm.

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3737

has been long known [18] and is a result of dislocation

redistribution, which is testified by subgrain sizes

changes. Further investigations showed that the same

effect takes place as a result of strain-induced phase

reactions. Obviously, both of these mechanisms deter-

mine stress behavior in NiTi alloy, but only the

dislocation redistribution is responsible for stress

behavior in titanium alloy, though its details in b-phase

and martensite are different because of their different

crystal lattices.

The initial softness or hardness of the metal alloy

affects surface roughness. Therefore, in our study, the

roughness of the sandpaper used did not correlate with

the measured surface roughness parameters in Table 1.

Our results showed the roughest NiTi surface to be

favorable for osteoblastic cells. Both the low number of

dead cells and the high number of focal contacts showed

that a rough NiTi surface is well tolerated by ROS-17/

2.8 cells. Despite the fact that attachment number does

not give data about attachment strength, inverse

correlation between attachment site number and cell

death rate proves that cells do not tolerate different

surfaces on the same manner. Our finding of the effect of

NiTi surface roughness is contradictory to some earlier

studies done with other metal alloys, such as Ti6Al4V,

cobalt–chromium,

titanium

and

hydroxyapatite

[19,20,14]. However, our results on Ti-alloy are in line

with these studies. In both Ti-alloy groups, focal

contacts were less numerous on rough surfaces than

on smooth ones.

In addition, we found that focal contacts seemed to

align with the grinding grooves of the rough NiTi and

TiI surfaces. In cell culture studies, Anselme et al. (2000)

observed that the rougher the surface, the more

disorganized was the cell layer [19]. In our experiments,

no such correlation was seen.

We further found that there was a change in cell size

related to surface roughness. Larger cells were more

numerous on the roughest surface, especially on NiTi

disks. Large cells were also seen on the second roughest

surface (600). However, only few of them were noticed

on the smoothest surface (1200) and none on any of the

TiII alloy specimens. A study done with human

osteoblastic MG-63 cells showed that the cells cultured

on the roughest surfaces had more cuboidal morphology

and were more differentiated [12].

The regularities of biocompatibility parameters as

functions of structural stresses in NiTi-alloy reveal

that higher stresses promote better biocompatibility

parameters. This result is in contradiction with the

140

160

180

200

220

240

260

12

14

16

18

20

22

24

Structural stress, MPa

Dead cells

/1000 cells

450

500

550

600

NiTi

Focal adhesions

160

180

200

220

240

260

280

300

320

16

18

20

22

24

26

28

Structural stress, MPa

Dead cells

/1000 cells

200

300

400

500

600

700

Ti I(

β

)

Focal adhesions

40

60

80

100

120

140

15

20

25

30

35

Structural stress, MPa

Dead cells/1000 cells

200

300

400

500

600

700

Ti I(

α

)

Focal adhesions

(a)

(b)

(c)

Fig. 3. (A) Biocompatibility parameters as functions of structural stresses in NiTi. (B) Biocompatibility parameters as functions of structural stresses

of TiI-alloy b-phase. (C) Biocompatibility parameters as functions of structural stresses of TiI-alloy a-martensite.

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3738

well-known negative effect of stresses on the corrosion

properties of a material and the straight correlation

between these properties and biocompatibility [18].

Small number of experiments does not allow discussion

of

the

structural

reasons

of

this

phenomenon.

Results obtained for biocompatibility parameters in

titanium alloy b-phase point out the existence of

common

structural

causes

for

such

behavior

in

homogeneous materials with b-phase structure. How-

ever, it is possible that unusual NiTi-alloys proper-

ties provide different biochemical interaction with

cells.

If taken into account that biocompatibility para-

meters are the characteristics of whole sample and that

the basic phase in titanium alloys sample was a-

martensite, the obtained regularities of biocompatibility

parameters behavior in a þ b titanium alloy reflect the

same regularities for basic a-martensite. But the

behavior of cell viability as function of structural

stresses in titanium alloy b-phase remains unexplained.

To explain this experimental fact the effect of s

b

=s

a

ratio was analyzed. It is known that sharp difference of

structural stresses in two pieces of the same metal may

generate the pronounced values of electromotive force

(between two wires of the same metal one being in cold-

drawn state and other annealed, the emf is of the order

10

7

V/1C [18]). This effect may be reinforced by

chemical composition difference, which undoubtedly

exists between b-phase and a-martensite, otherwise b-

phase had to transform to martensite.

The present study showed a straight dependence of

amount of dead cells upon values of s

b

=s

a

ratio. This

may explains the observed dependence of focal adhesion

number on structural stresses in titanium alloy b-phase

and allows presuming that difference in electrochemical

properties of phases in heterogeneous materials and

phase quantity ratio are the main factors which

determine the cell viability. The results obtained in TiII

group samples (25–27 vol% of b-phase) confirmed the

above argumentation. Obviously, the same mechanism

acts in homogeneous materials, like NiTi. In those,

grains and subgrains play the role of different phases

with different concentration of stress. The apparent

dependence

of

biocompatibility

parameters

upon

the mean values of subgrain size in NiTi-alloy may

be

commented

in

terms

of

more

homogeneous

stress distribution in structures with smaller subgrain

sizes.

As shown in our previous work, nickel is toxic to

these cells [21]. It is important to notice that the rough

surface of a NiTi implant might release a high

concentration of Ni

2+

ions. However, this postulation

is not supported by our findings of the better attachment

and lower cytotoxicity of rough NiTi. The question

about the mechanisms that prevent nickel ion release,

even on a rough surface, remains to be solved.

5. Conclusion

Our results indicate low cytotoxicity of NiTi, even

after very rough surface treatment. NiTi disks were well

tolerated by osteoblastic ROS-17/2.8 cells. Because the

initial softness or hardness of metal alloys has an impact

on surface roughness, the characterization of surface

stresses could be a better method for assessing the

surface state of the implant after equal surface

manipulation. The results of the present study showed

that definition of structural stresses might be a sensitive

instrument in biocompatibility investigations.

Acknowledgements

This study was supported by Technology Develop-

ment Center of Finland (TEKES).

References

[1] Buehler WJ, Wang FEA. Summary of recent research on the

Nitinol alloys and their potential application in ocean engineer-

ing. Ocean Eng 1968;1:105–20.

[2] Castleman LS, Motzkin SM, Alicandri FP, Bonawit VL.

Biocompatibility of nitinol alloy as an implant material. J Biomed

Mater Res 1976;10(5):695–731.

[3] Baumgart F, Bensmann G, Haasters J. Memory alloys—new

material for implantation in orthopedic surgery. In: Uthof HK,

editor. Current concepts of internal fixation of fractures, vol. 1.

Berlin: Springer, 1980. p. 122–7.

[4] Putters JL, Kaulesar Sukul DM, de Zeeuw GR, Bijma A,

Besselink PA. Comparative cell culture effects of shape memory

metal (Nitinol), nickel and titanium: a biocompatibility estima-

tion. Eur Surg Res 1992;24(6):378–82.

[5] Ryh

.anen J, Niemi E, Serlo W, Niemel.a E, Sandvik P, Pernu H,

Salo T. Biocompatibility of nickel–titanium shape memory metal

and its corrosion behavior in human cell cultures. J Biomed Mater

Res 1997;35(4):451–7.

[6] Bowers KT, Keller JC, Randolph BA, Wick DG, Michaels CM.

Optimization of surface micromorphology for enhanced osteo-

blast responses in vitro. Int J Oral Maxillofac Implants

1992;7:302–10.

[7] Keller JC, Stanford CM, Wightman JP, Draughn RA, Zaharias

R. Characterizations of titanium implant surfaces. III. J Biomed

Mater Res 1994;28(8):939–46.

[8] Lohmann CH, Bonewald LF, Sisk M, Sylvia VL, Cochran DL,

Dean DD, Boyan BD, Schwartz Z. Maturation state determines

the response of osteogenic cells to surface roughness and 1,25-

dihydroxyvitamin D3. J Bone Miner Res 2000;15(6):1169–80.

[9] Malik MA, Puleo DO, Bizios R, Doremus RH. Osteoblasts on

hydroxyapatite, alumina and bone surface in vitro: morphology

during the first 2 h of attachment. Biomaterials 1992;13:123–8.

[10] Stanford CM, Keller JC, Solursh M. Bone cell expression on

titanium surfaces is altered by sterilization treatments. J Dent Res

1994;73(5):1061–71.

[11] Meyer U, Szulczewski DH, M

.oller K, Heide H, Jones DB.

Attachment kinetics and differentiation of osteoblasts on different

biomaterials. Cells Mater 1993;3:129–40.

[12] Martin JY, Schwartz Z, Hummert TW, Schraub DM, Simpson J,

Lankford Jr J, Dean DD, Cochran DL, Boyan BD. Effect of

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3739

titanium surface roughness on proliferation, differentiation, and

protein synthesis of human osteoblast-like cells (MG63). J

Biomed Mater Res 1995;29(3):389–401.

[13] Alliott-Licht B, Gregoire M, Orly I, Menanteau J. Cellular

activity of osteoblasts in the presence of hydroxyapatite: an in

vitro experiment. Biomaterials 1991;12:752–6.

[14] Desantis D, Guerriero C, Nocini PF, Ungerspock A, Richards G,

Gotte P, Armato U. Adult human bone cells from jaw bones

cultured on plasma-sprayed or polished surfaces of titanium or

hydroxyapatite discs. J Mater Sci 1996;7:21–8.

[15] Gotfredsen K, Nimb L, Hj

.orting-Hansen E, Jensen JS, Holm!en

A. Histomorphometric and removal torque analysis for TiO2-

blasted titanium implants. An experimental study on dogs. Clin

Oral Implants Res 1992;3:77–84.

[16] Wennerberg A, Albrektsson T, Lausmaa J. Torque and histo-

morphometric evaluation of c.p. titanium screws blasted with 25-

and 75-microns-sized particles of Al

2

O

3

. J Biomed Mater Res

1996;30(2):251–60.

[17] Buser D, Nydegger T, Hirt HP, Cochran DL, Nolte LP.

Removal torque values of titanium implants in the maxilla

of miniature pigs. Int J Oral Maxillofac Implants 1998;13(5):

611–9.

[18] Taylor A. X-ray metallography. New York, London: Wiley, 1961,

p. 993.

[19] Anselme K, Bigerelle M, Noel B, Dufresne E, Judas D, Iost A,

Hardouin P. Qualitative and quantitative study of human

osteoblast adhesion on materials with various surface roughness.

J Biomed Mater Res 2000;49(2):155–66.

[20] Naji A, Harmand MF. Study of the effect of the surface state on

the cytocompatibility of a Co–Cr alloy using human osteoblasts

and fibroblasts. J Biomed Mater Res 1990;24:861–71.

[21] Kapanen A, Ilvesaro J, Danilov A, Ryh

.anen J, Lehenkari P,

Tuukkanen J. Behaviour of Nitinol in osteoblast-like ROS-17 cell

cultures. Biomaterials 2002;23(3):645–50.

A. Kapanen et al. / Biomaterials 23 (2002) 3733–3740

3740

Document Outline

- Effect of metal alloy surface stresses on the viability of ROS-17/2.8 osteoblastic cells

Wyszukiwarka

Podobne podstrony:

Zieliński, Marek i inni Effects of Constant Magnetic Field on Electrodeposition of Co W Cu Alloy (2

Effect of long chain branching Nieznany

Effect of Kinesio taping on muscle strength in athletes

53 755 765 Effect of Microstructural Homogenity on Mechanical and Thermal Fatique

Effect of File Sharing on Record Sales March2004

31 411 423 Effect of EAF and ESR Technologies on the Yield of Alloying Elements

21 269 287 Effect of Niobium and Vanadium as an Alloying Elements in Tool Steels

(10)Bactericidal Effect of Silver Nanoparticles

Effect of?renaline on survival in out of hospital?rdiac arrest

Effects of the Great?pression on the U S and the World

4 effects of honed cylinder art Nieznany

Effects of the Atomic Bombs Dropped on Japan

Effect of aqueous extract

Effect of Active Muscle Forces Nieznany

Effects of Kinesio Tape to Reduce Hand Edema in Acute Stroke

1 Effect of Self Weight on a Cantilever Beam

effect of varying doses of caffeine on life span D melanogaster

Possible Effects of Strategy Instruction on L1 and L2 Reading

Pleiotropic Effects of Phytochemicals in AD

więcej podobnych podstron