Biomaterials 27 (2006) 986–995

Photo-iniferter-based thermoresponsive block copolymers composed

of poly(ethylene glycol) and poly(N-isopropylacrylamide) and

chondrocyte immobilization

Il Keun Kwon, Takehisa Matsuda

Division of Biomedical Engineering, Graduate School of Medicine, Kyushu University, 3-1-1 Maidashi, Higashi-ku, Fukuoka 812-8582, Japan

Received 21 April 2005; accepted 21 July2005

Available online 22 August 2005

Abstract

A series of thermoresponsive poly(N-isopropylacrylamide) (PNIPAM)–poly(ethylene glycol) (PEG) block copolymers with

various PNIPAM contents and copolymer architectures, such as linear, four-armed and eight-armed configurations, were prepared

by iniferter-based photopolymerization of dithiocarbamylated PEGs (DC-PEGs) under ultraviolet (UV)-light irradiation. The

increase in monomer/DC-PEG feed ratio resulted in an increase in both the molecular weight and PNIPAM content of copolymers.

The measurement of the optical transmittances of aqueous solutions of PNIPAM–PEG block copolymers determined the lower

critical solution temperatures (LCSTs) of block copolymers, which ranged from 31.3 to 34.0 1C. LCST decreased with increasing

block length of PNIPAM and with the formation of a branched architecture. Rabbit chondrocytes were immobilized and cultured in

a three-dimensional (3D) gel composed of PNIPAM–PEG block copolymer at 37 1C. Gels prepared from copolymers with higher

PNIPAM contents at higher concentrations appeared to exhibit a minimal decrease in both cell number and cell viabilityduring a 7-

dayculture. Cell viabilitydependencies on material and formulation parameters and the potential use of PNIPAM–PEG block

copolymers as an in situ formable scaffold for an engineered cartilage tissue were discussed.

r

2005 Elsevier Ltd. All rights reserved.

Keywords: Chondrocyte; Thermally responsive material

1. Introduction

Recentlydeveloped tissue-engineering-directed ther-

apeutic procedures enable the repair, regeneration or

replacement of injured, diseased, and lost tissues with

engineered tissues composed of cells, an artificial

extracellular matrix (ECM) and structural scaffold

One such targeted tissue is cartilage engineered tissue,

since articular cartilage has a limited capacityfor self-

repair once it has been damaged. Various tissue-

engineering approaches using autologous chondrocytes

with a preconstructed or injectable scaffold have been

studied

. The requirements of an injectable sub-

stance for this particular application include in situ self-

gelation without cell death and cell-adhesion and -

proliferation as well as a structural platform. Such a

cell-suspended, moldable solution can fill an inhomoge-

neous defect’s space to form an engineered cartilage

tissue in close contact with adjacent living tissue.

As biologicallyderived in situ gelable biomacromole-

cules, collagen and agarose, both of which are thermo-

responsive and gel at physiological temperature, have

been used for in situ injectable or ex vivo moldable cell-

incorporated engineered tissues

. Poly(N-isopropy-

lacrylamide) (PNIPAM) is a well-known temperature-

responsive polymer and demonstrates a phase transition

temperature or lower critical solution temperature

(LCST) in an aqueous solution at about 32 1C

ARTICLE IN PRESS

www.elsevier.com/locate/biomaterials

0142-9612/$ - see front matter r 2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biomaterials.2005.07.038

Corresponding author. Tel.: +81 92 642 6210;

fax: +81 92 642 6212.

E-mail address: matsuda@med.kyushu-u.ac.jp (T. Matsuda).

Below the LCST, PNIPAM is verysoluble in water.

However, as the temperature is increased above the

LCST, the polymer precipitates from the aqueous

solution due to hydrophobic associations. PNIPAM

and its copolymers have been widely utililized as

thermoresponsive drug deliveryvehicles

, three-

dimensional (3D) ECMs

, tissue-detachable-cul-

ture substrates

and wound-healing materials

In

our

previous

studies,

multiplyderivatized

PNIPAM-grafted biomacromolecules, such as gelatin

and hyaluronan

, were designed using

photochemistryof the dithiocarbamy

l (DC) group

attached to their macromolecules. PNIPAM-grafted

gelatin served as a cell adhesion platform for ancho-

rage-dependent cells and PNIPAM-grafted hyaluronan

as non-cell adhesive material, both of which function

well as thermoresponsive wound-healing substances.

The

DC

group,

called

the

iniferter

(initiator,

transfer and terminater), photolyzes to produce a

radical

pair

(alkyl

radical

and

DC

radical)

upon ultraviolet (UV)-light irradiation, which induce

spontaneous recombination to reform a dithiocarba-

mate group and an alkyl radical initiates radical

polymerization in the presence of a monomer. The

propagating chain end is routinelycoupled with the DC

group, enabling quasi-living radical polymerization

during photoirradiation.

In this study, poly(ethylene glycol)(PEG)s coupled

with DC groups at both chain ends were prepared as

PEG derivatized iniferters and subsequent photopoly-

merization of N-isopropylacrylamide (NIPAM) pro-

duced various PNIPAM–PEG block copolymers with

different PNIPAM block lengths and different copoly-

mer architectures. Irrespective of type of copolymers,

PEG block is a core segment and PNIPAM block is

terminal segment. The thermoresponsive characteristics

and cell-immobilization and cell-viabilitypotentials of

the PNIPAM–PEG block copolymer gels were exam-

ined. Based on the cell viabilityexperiments coupled

with the authors’ previous results, design criteria of

artificial extracellular miliue was discussed.

2. Materials and methods

2.1. General methods

1

H-NMR spectra were recorded in CDCl

3

using tetra-

methylsilane (0 ppm) as an internal standard with a JNM-

AL300 (JEOL, Tokyo, Japan). The number-average molecular

weight (Mn) of each polymer was determined by gel

permeation chromatography(GPC), which was carried out

on a high-performance liquid chromatograph (HPLC, Waters,

MA) equipped with a GF-510 column (Shodex, Osaka, Japan)

using PEG as a standard and dimethylformamide (DMF) as

an eluent at 40 1C. The light intensityat 250 nm was measured

with a photometer (UVR-25, Topcon, Tokyo, Japan).

2.2. Materials

Solvents, all of which were of special reagent grade, were

purchased from either Wako Pure Chemical Industries, Ltd.

(Osaka, Japan) or Tokyo Chemical Industry Ltd. (Tokyo.

Japan). NIPAM was used after recrystallization from a

benzene–hexane solution. Four-armed and eight-armed PEG

[mol. wt. of 2 10

3

and 1 10

4

, respectively, according to the

manufacturer’s information] were supplied byShearwater

Polymers, Inc. (Huntsville, AL). PEGs were purified by

precipitation from cold hexane and subsequentlydried under

vacuum prior to use. 4-(Chloromethyl)benzoyl chloride, N,N-

(dimethylamino)pyridine (DMAP), and sodium N,N-diethyl-

dithiocarbamate trihydrate were used as received without

further purification. Other solvents and reagents were purified

bydistillation. Dialysis membranes with molecular weight cut-

off values of 1.2 10

4

(Wako), 1.0 10

3

or 6–8 10

3

(Spectra/

Por., Spectrum Lab., CA) were used for purification depending

on the molecular weight of PEG or the copolymer.

2.3. Preparation of dithiocarbamyl PEG (DC-PEG)

To a dichloromethane solution (100 mL) of PEG (Mn ca.

3400, 10 g, ca. 2.9 mmol), an excess amount of 4-(chloro-

methyl)benzoyl chloride (11.1 g, 58.8 mmol) was added drop-

wise at 0 1C, and then DMAP (1.1 g, 8.8 mmol) was added.

After being stirred at room temperature for 24 h under a

nitrogen atmosphere, the reaction mixture was filtered,

precipitated in excess hexane/ether mixture, and dried under

reduced pressure. The residue was dissolved in methanol

(100 mL). After this solution was added dropwise to a

methanol solution (150 mL) of sodium N,N-diethyldithiocar-

bamate trihydrate (13.0 g, 58.0 mmol) at 0 1C, the mixture was

stirred at room temperature for 22 h. After filtration, the

filtrate was concentrated under reduced pressure. After

dissolving in an aqueous solution, the residue was purified

by dialysis against distilled water for 3 days, and subsequently

freeze-dried for 3 days to obtain DC-PEG [yield: 10.8 g (87%)].

1

H-NMR (CDCl

3

with Me

4

Si): d 1.28 (t, 12H, CH

3

), 3.65 (m,

309H, (CH

2

CH

2

O)

77.3

), 4.05 and 4.46 (mm, 4H each, CH

2

Me),

4.61 (s, 4H, CH

2

Ar), and 7.45 and 7.99 (dd, 4H each, C

6

H

4

).

2.4. Preparation of PNIPAM– PEG block copolymer

A methanol solution (500 mL) of NIPAM with DC-PEG

was placed in a glass apparatus. After bubbling drynitrogen

for 10 min, the solution was irradiated with a 400-W Hg lamp

(AH400RP; UV Company, Saitama, Japan) in a nitrogen

atmosphere (light intensity: 4 mW/cm

2

) with mild stirring. The

solvent was replaced with an aqueous solution under reduced

pressure, and subsequentlyfreeze-dried for 3 days.

2.5. Thermoresponsiveness of PNIPAM– PEG block copolymer

The thermoresponse phase transition of an aqueous

solution of the PNIPAM–PEG block copolymer (concentra-

tion: 0.2 mg/mL) was measured with a UV/VIS spectro-

photometer (DU 530, Beckman Instruments, Fullerton, CA)

bymonitoring the transmittance of a 600 nm light beam. The

samples were cooled at a rate of approximately0.5 1C/min

ARTICLE IN PRESS

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

987

from 45 to 25 1C. The temperature at the onset of increase in

transmittance, which was determined with an accuracyof

0.1 1C using a directlyimmersed thermosensor, was defined as

the LCST, which expresses the optical transmission of 90%.

2.6. Cell culture in PNIPAM-grafted gel

The PNIPAM–PEG block copolymer was dissolved in

Dulbecco’s modified Eagle’s medium (DMEM, Life Technol-

ogies Inc., Rockville, MD) supplemented with 10% fetal

bovine serum and (FBS, Life Technologies) and l-ascorbic acid

(50 mg/mL) to give a final concentration of 30% solids.

Chondrocytes, isolated from rabbit articular cartilage, were

suspended in the culture medium at room temperature (1 10

7

cells/mL). After collecting bycentrifugation (300g, 4 1C,

5 min), the suspension was mixed with the PNIPAM–PEG

block copolymer solution at 4 1C to a final cell concentration

of 5 10

6

cells/mL in 7.5%, 11%, and 15% copolymer

solutions, respectively. A 200 mL aliquot of the mixture

(approximately250 mm) was placed in a 48-well cell culture

cluster (Corning, Corning, NY), incubated for 30 min at 37 1C

for gelation and supplemented with fresh culture medium,

followed bya 7-dayculture at 37 1C (the medium was changed

everyday). The number of cells obtained bydissolving the gel

at room temperature (20 1C) was assessed using a hematocyt-

ometer.

2.7. Microscopic observations

The appearance of cells in the thermoresponsive gels was

observed bya phase-contrast microscope (TE300, Nikon,

Tokyo, Japan). In situ chondrocyte viability in the gel was

determined with a Live-Dead viability/cytotoxicity kit (Mole-

cular Probes, Eugene, OR), and chondrocytes were observed

using a confocal laser scanning microscope (CLSM, Radiance

2000, Bio-Rad Laboratories, Hercules, CA). The sample was

washed three times with PBS at 37 1C, and 500 mL of a 2 m

M

calcein AM and 4 m

M

ethidium homodimer-1 (EthD-1) mixture

was added and incubated at 37 1C for 40 min. Chondrocyte-

cultured PNIPAM–PEG block copolymer gels, which were

fixed with 1% glutaraldehyde–1.44% paraformaldehyde in

phosphate saline solution at 37 1C for 24 h, frozen in liquid

nitrogen, lyophilized and sputter-coated with platinum, were

observed byscanning electron microscopy(SEM, JSM-840A,

JEOL, Peabody, MA).

3. Results

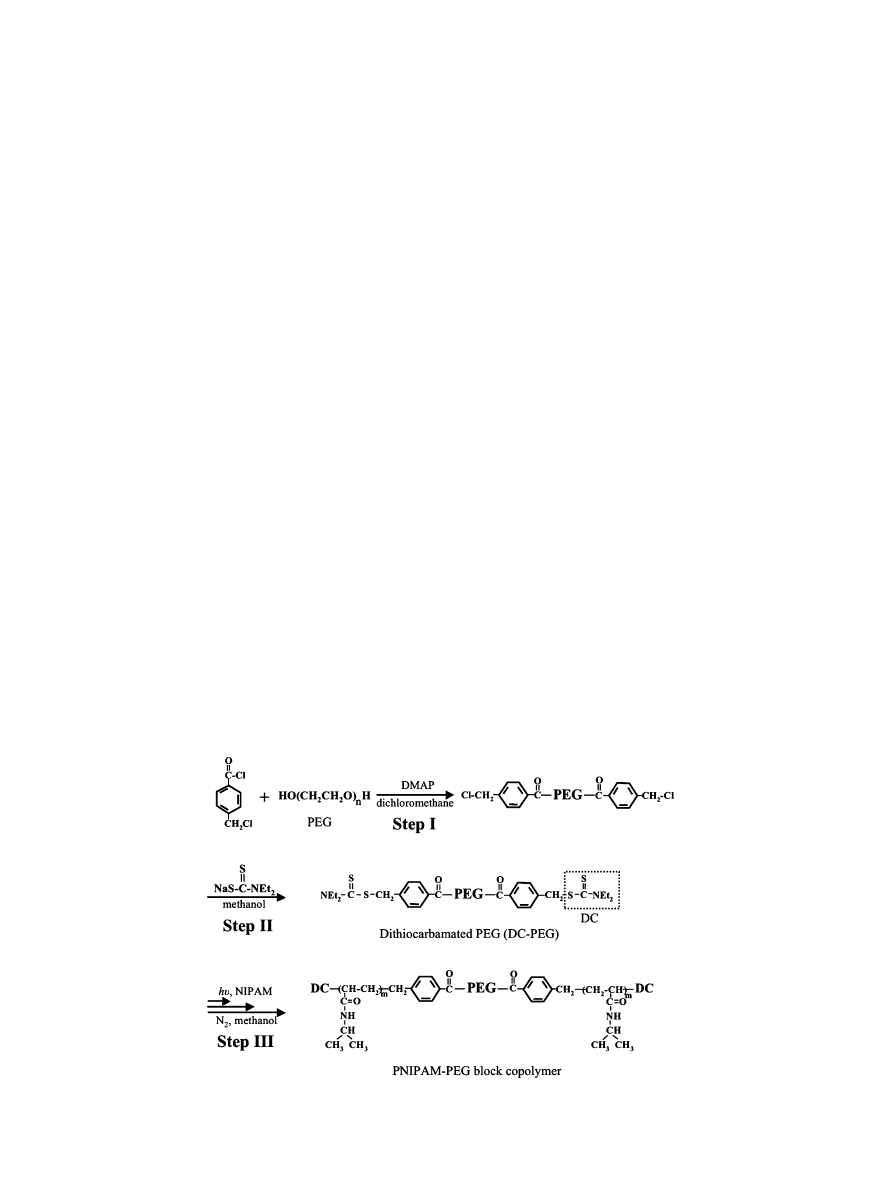

3.1. Synthesis of PNIPAM– PEG block copolymer

PNIPAM–PEG block copolymers were prepared

according to the methods shown in

. The

PEGs used were a linear PEG with the Mn of

3.4 10

3

g/mol (designated P3k), which was determined

byGPC; and two types of branched PEG, a four-armed

PEG (Mwt.; 2 10

3

g/mol) and an eight-armed PEG

(Mwt.; 1 10

4

g/mol). First, 4-(chloromethyl)benzoyl

PEG was synthesized in dichloromethane (Step I) and

subsequent dithiocarbamation in methanol, followed by

an extensive dialysis, produced a white powdery solid

(Step II).

shows the representative

1

H-NMR

spectrum of PEG (P3k) coupled with a DC group at

both ends. From the relative peak intensityratio of

methylene protons (d 3.65; corresponding to the PEG

unit

) to methyl protons (d 1.28) of the DC

group [

], almost complete dithiocarbamyla-

tion was achieved. In this particular case, the calculated

conversion was approximately115% (overestimated

value which exceeds 100% is probablydue to the

polydispersity of PEG). Irrespective of type of PEG,

almost complete end-group derivatization was achieved

ARTICLE IN PRESS

Scheme 1. Schematics of preparation routes of PNIPAM–PEG block copolymer.

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

988

to produce PEG dithiocarbamated at both ends (DC-

PEG).

Using DC-PEG, the NIPAM monomer was poly-

merized in methanol under UV light irradiation (Step

III). After extensive dialysis against distilled water at

room temperature and subsequent freeze-drying, both

GPC and

1

H-NMR spectral measurements were carried

out.

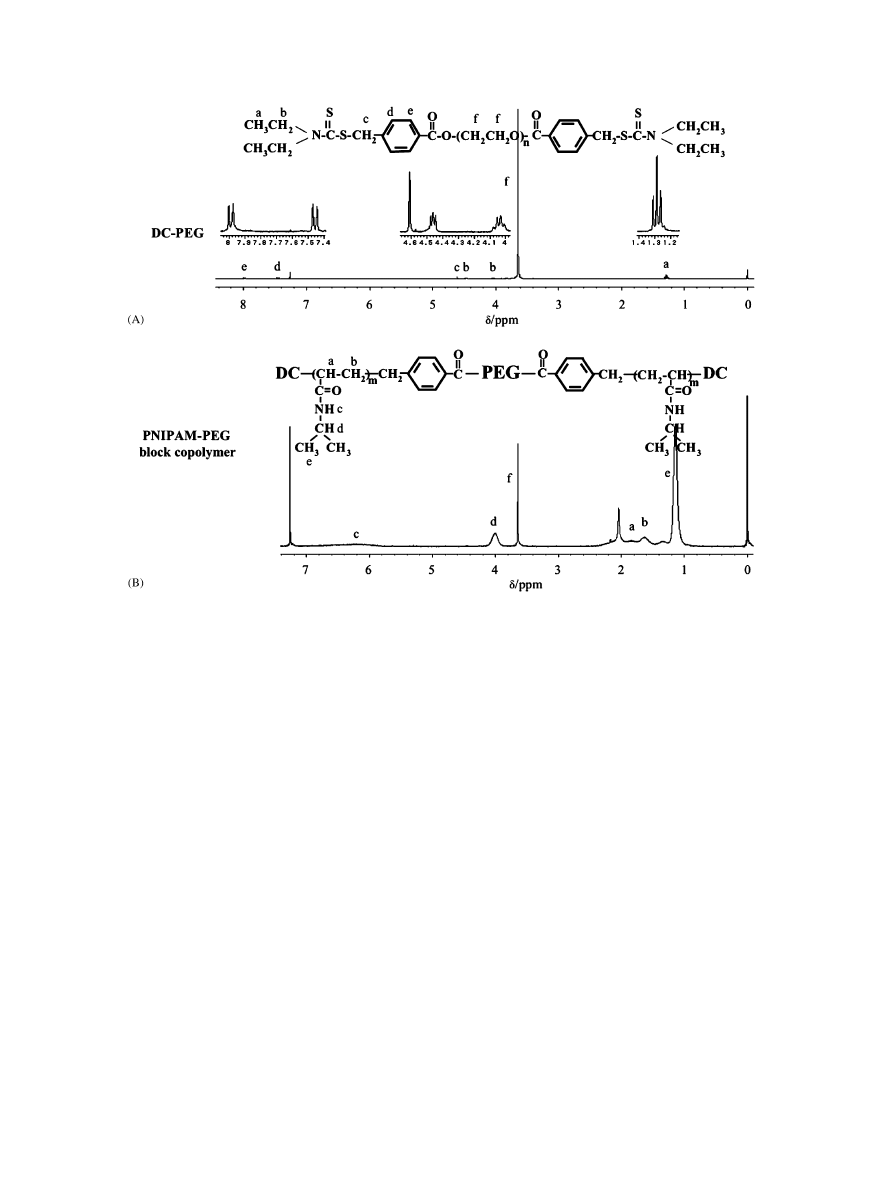

shows the change in the molecular weight of

products derived from DC-PEG derived from P3k as a

function of irradiation time and monomer concentration

under the fixed conditions described below. The

molecular weight increased proportionallyto both

irradiation time at a fixed monomer concentration

(1 mol/L) (

) and monomer concentration at a

fixed irradiation time (30 min) (

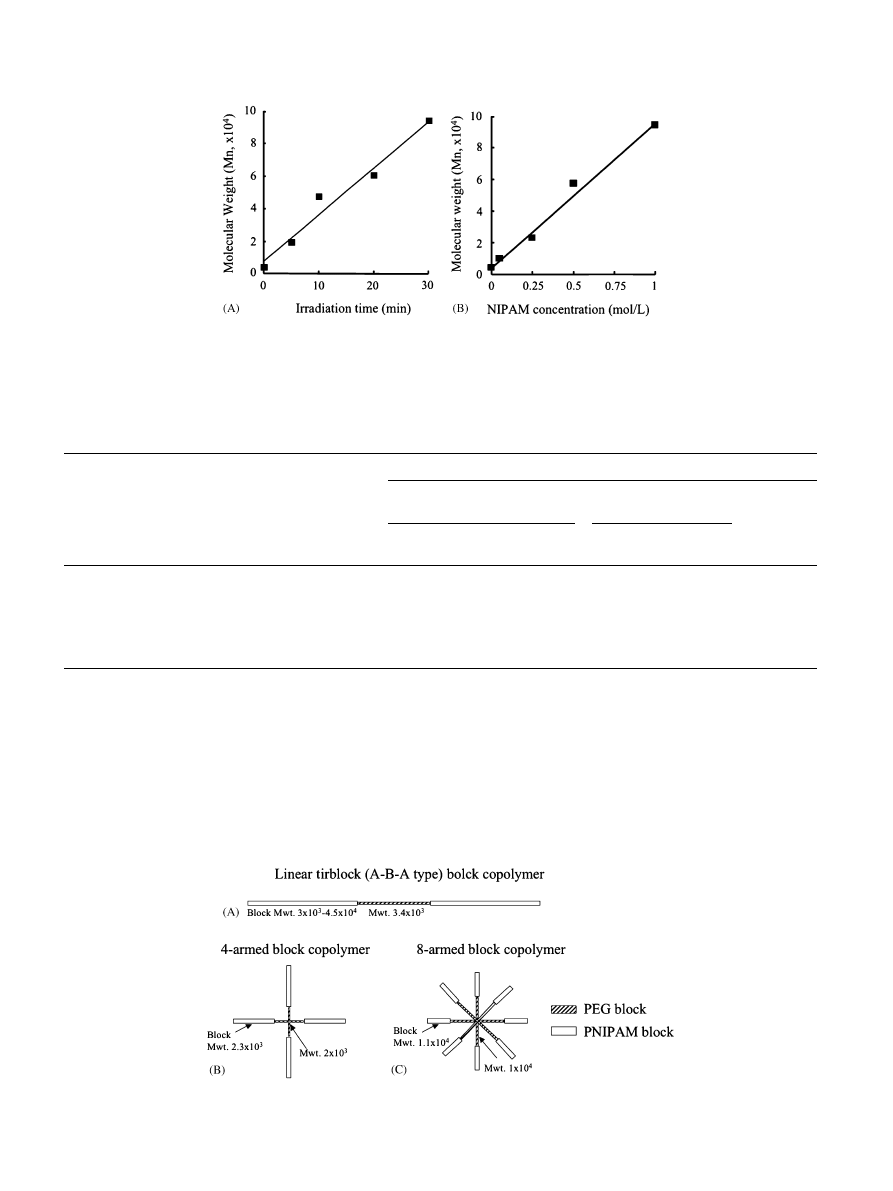

A series of PNIPAM–PEG block copolymers with

different PNIPAM block lengths were prepared at a

fixed irradiation time (30 min) but the different mono-

mer concentrations.

summarizes the reaction

conditions and copolymer compositions, which were

determined and calculated either by

1

H-NMR or GPC

measurement.

shows a representative

1

H-NMR

spectrum of the PNIPAM–PEG block copolymer (P3k/

90k in

). Copolymer composition was deter-

mined from relative intensityof the peak corresponding

to methyl protons (d 1.10) of the PNIPAM unit [

] to that of peak corresponding to the methylene

protons (d 3.65) of PEG unit [

]. The PNIPAM

content determined from GPC measurement was

calculated bysubtracting the molecular weight of DC-

PEG from the measured molecular weight of the

copolymer. The increase in monomer/DC-PEG ratio

resulted in an increase in both the molecular weight and

PNIPAM content in the copolymer (

). There is a

good correlation between the copolymer compositions

determined from

p

H-NMR and GPC measurements.

From the results, the PNIPAM–PEG block copolymers

were determined to be of the triblock type (A–B–A)

derived from linear DC-PEG, and of the star-block type

derived from multiple-armed DC-PEG, as schematically

shown in

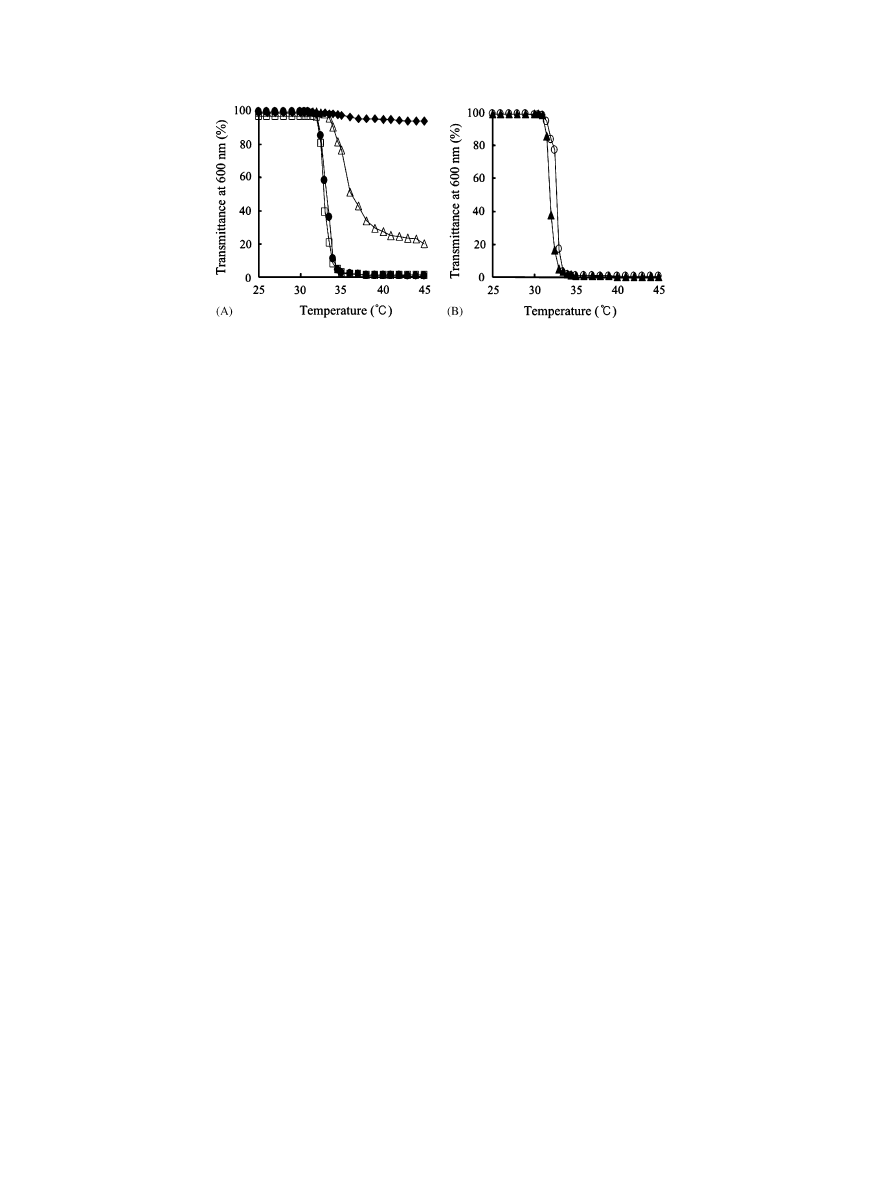

3.2. LCSTs of PNIPAM– PEG block copolymers

All the PNIPAM–PEG block copolymers were

soluble in water at room temperature, but sponta-

neouslyprecipitated at near physiological temperature

(37 1C). The optical transmittance changes of the

aqueous solutions of PNIPAM–PEG block copolymers,

determined using UV/VIS spectrophotometer at 600 nm,

are shown in

. The optical transmittances of the

aqueous solutions of PNIPAM–PEG block copolymers

ARTICLE IN PRESS

Fig. 1.

1

H-NMR spectra of (A) DC-PEG (iniferter) and (B) PNIPAM–PEG block copolymer solutions (CDCl

3

with Me

4

Si).

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

989

ARTICLE IN PRESS

Fig. 2. (A) Irradiation time and (B) NIPAM concentration dependencyon number- averaged molecular weight of the PNIPAM–PEG block

copolymers produced using DC-PEG (P3k) as an iniferter. Polymerization condition: [iniferter] ¼ 0.5 mmol/L; light intensity ¼ 4 mW/cm

2

;

[NIPAM] ¼ 1 mol/L for (A); irradiation time ¼ 30 min for (B).

Table 1

Preparation and characterof PNIPAM-grafted PEG block copolymers

Copolymer

code

a

Iniferter

b

Monomer to

initiator (molar

ratio)

PNIPAM–PEG block copolymer

c

Mn ( 10

4

)

Composition of PNIPAM/

PEG (wt ratio)

f

LCST

g

(1C)

NIPAM/PEG

Per molecule

d

Per PNIPAM

block

e

NMR

GPC

P3k/6k

DC-PEG3k

100

0.9

0.3

1

2

N.D.

h

P3k/18k

DC-PEG3k

500

2.2

0.9

5

5

34.0

P3k/52k

DC-PEG3k

1000

5.6

2.6

13

15

32.3

P3k90k

DC-PEG3k

2000

9.3

4.5

26

26

32.2

P4arm/92k

DC-4-armed PEG

2000

9.5

2.3

46

46

31.3

P8arm/88k

DC-8-armed PEG

2000

10.3

1.1

9

9

31.8

a

For example, P3k/6k denotes the copolymer with the composition of PEG (Mn; 3.4 10

3

g/mol) and PNIPAM (total mol. wt. in a molecule;

3 10

3

2 g/mol).

b

Prepared according to

c

Copolymerization conditions: UV light intensity: 4 mW/cm

2

, irradiation time: 30 min.

d

Number-averaged molecular weight (Mn) of PNIPAM–PEG block copolymer.

e

Number-averaged molecular weight of PNIPAM block [Mn of copolymerMn of initiator)/functionality(n ¼ 2, 4 or 8)].

f

Weight ratio of PNIPAM to PEG in copolymer determined by

1

H-NMR and GPC.

g

Determined at the optical transmission of 90% in aqueous solution measured byUV/VIS spectrophotometer.

h

N.D.: not determined.

Scheme 2. Schematic of linear and branched PNIPAM–PEG block copolymers.

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

990

with a relativelyhigh molecular weight of PNIPAM

block (P3k/52k and P3k/90k, see

), which are

transparent at room temperature, sharplydecreased to

zero upon increasing solution temperature; in contrast,

those of the copolymer solutions with a lower molecular

weight of the PNIPAM block graduallydecreased with

an increase in temperature and remained approximately

95% for P3k/6k and 25% for P3k/18k at over 40 1C

(

). For branched copolymers with different

architectures (DC-four-armed or -eight-armed PEG-

inifertered copolymers, the schematics of which archi-

tectures are shown in

), but with almost the

same Mn (approx. 1 10

5

g/mol), their optical trans-

mittance sharplydecreased with increasing temperature

(

). LCSTs of the linear copolymers, which were

determined at an optical transmission of 90% in an

aqueous solution, ranged from 32.2 to 34.0 1C, and

slightlyincreased with decreasing PNIPAM content at a

fixed initiator (

). Regarding the branched

PNIPAM–PEG block copolymers, their LCSTs were

slightlylower than those of linear copolymers.

3.3. Three-dimensional chondrocyte culture in

PNIPAM– PEG block copolymer gels

Rabbit

chondrocytes,

suspended

in

10%

FBS–DMEM solution containing PNIPAM–PEG block

copolymers at 4 1C and subsequentlymaintained at

37 1C, were immobilized in spontaneouslyformed

opaque gels and cultured for 7 days.

lists the

state of the gel and cell viabilityon day7 of culture in

cell-incorporated gels prepared using PNIPAM–PEG

block copolymers composed of linear PEG (Mn;

3.4 10

3

g/mol) and different molecular weights of

PNIPAM block (gel no. 1–9) at different copolymer

concentrations (7.5, 11.0 and 15.0 w/v%). An increase in

the Mn of PNIPAM (or compositional weight ratio of

PNIPAM/PEG) and an increase in the copolymer

concentration resulted in a mechanicallymore stable

gel formation. At a fixed concentration (11.0 w/v%), a

lower PNIPAM/PEG composition ratio (slightlyless

than 10 fold, see

) tended to produce a soft gel or

resulted in no gel formation, irrespective of the use of

linear or branched copolymers.

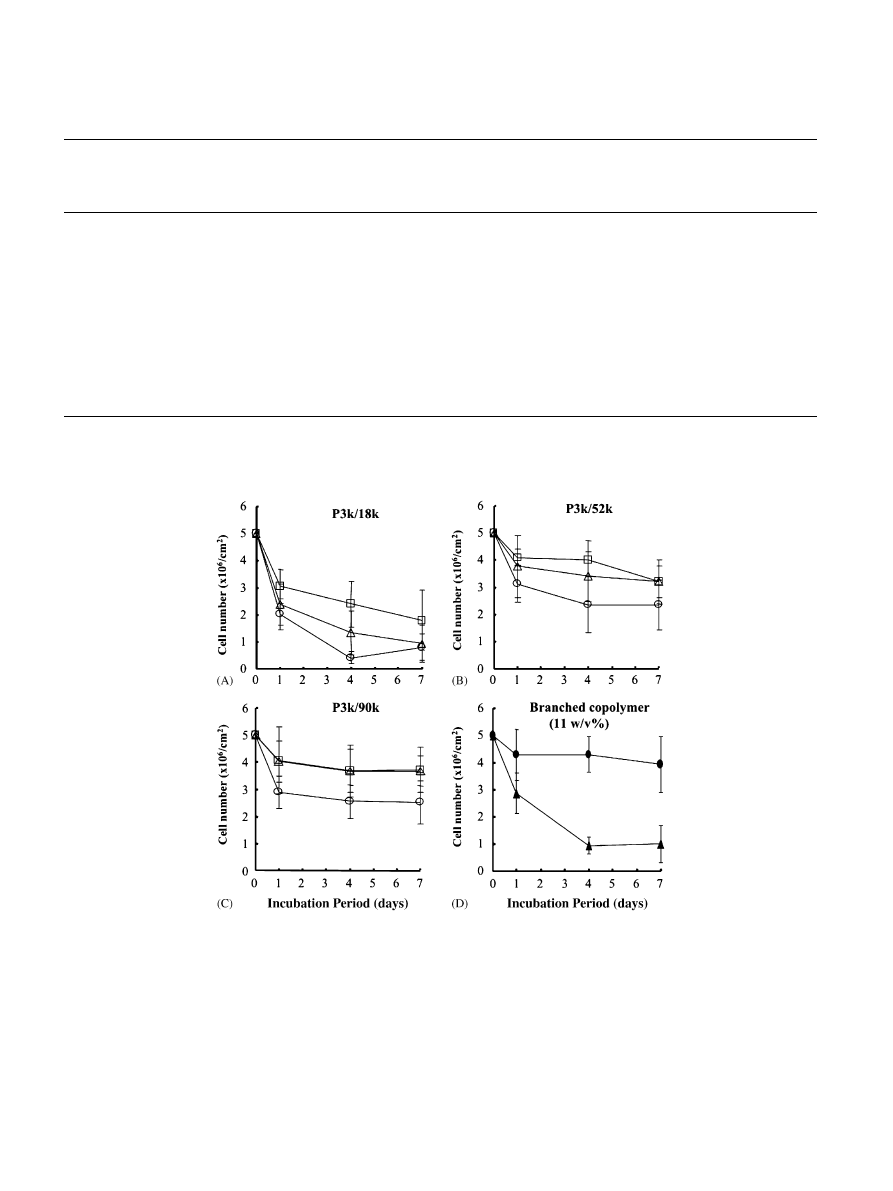

shows the time-dependent numbers of cells in

gels composed of different molecular architectures of

copolymers and different copolymer concentrations.

The general tendencyis that, at a fixed Mn of PEG

(3.4 10

3

g/mol), numbers of cells in gels composed of

copolymers with lower PNIPAM/PEG composition

ratio sharplydecreased with time (

). This

tendencywas stronger with decreasing copoly

mer

concentration (

)). The gels prepared from

copolymers with higher PNIPAM/PEG composition

ratio and at higher concentrations of PNIPAM–PEG

block copolymer appeared to exhibit a minimal decrease

in cell number during a 7-dayculture (

). The gel

prepared using branched copolymers with a higher

PNIPAM/PEG composition ratio (P4arm/92k) exhib-

ited a minimal reduction in the cell number during the

culture (

).

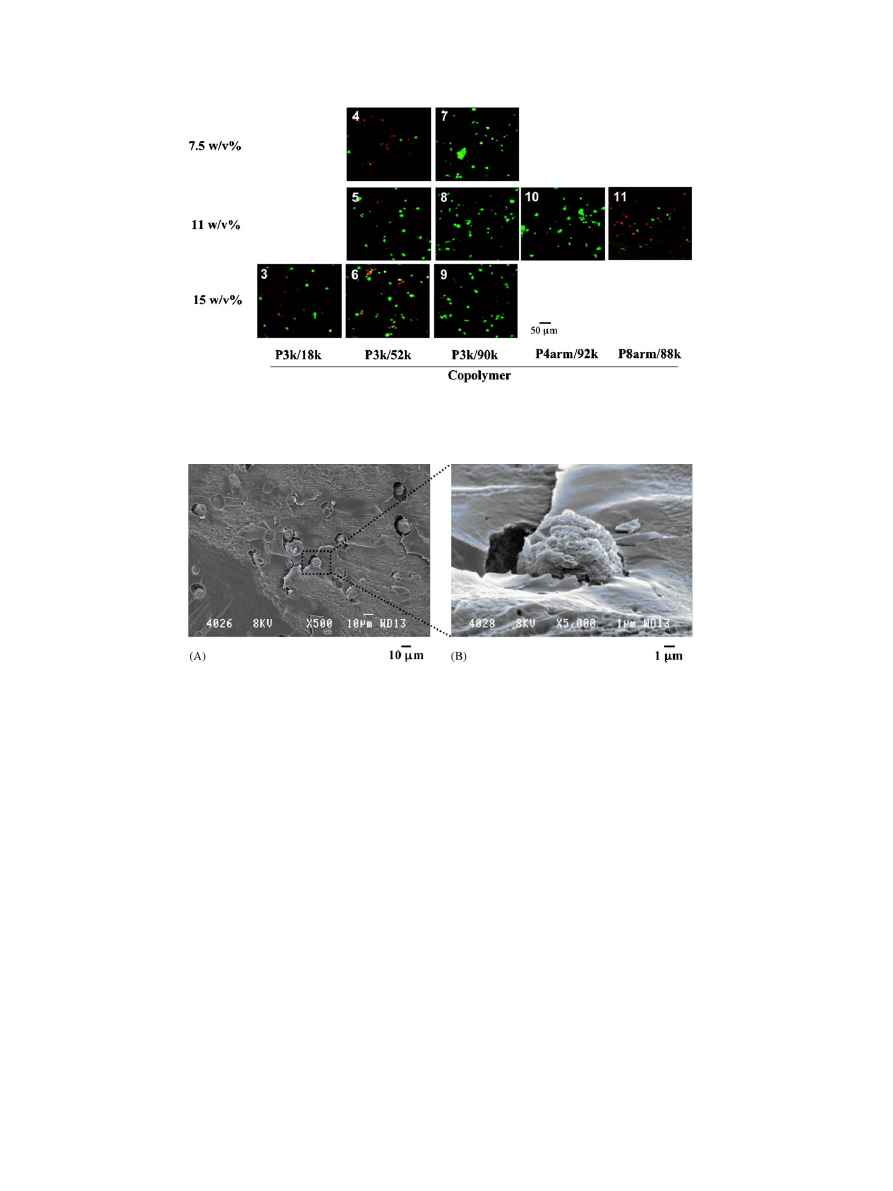

The live/dead cell assayclearlydifferentiated the cell

viabilitydependences on both copolymer composition

and copolymer concentration.

shows confocal

laser scanning micrographs of chondrocyte-inoculated

gels stained with live/dead fluorescence probes, showing

a qualitative tendencywith respect to cell viability

:

increases in the PNIPAM content in copolymers (or the

PNIPAM–PEG composition ratio) and the copolymer

concentration resulted in a high percentage of live cells

(stained green) and low percentage of dead cells (stained

red). This qualitative tendencywas stronglysupported

bythe quantitative data on cell viability(determined

from the fluorescence images) as tabulated in

shows the cross-sectional SEM images of a cell-

inoculated P4arm/92k-based gel after a 7-dayculture.

Well-dispersed and embedded round cells were observed

in the gel.

ARTICLE IN PRESS

Fig. 3. Temperature dependence of optical transmittance at 600 nm in aqueous solution for (A) linear PNIPAM–PEG block copolymers: P3k/6k

(~), P3k/18k (n), P3k/52k (K) and P3k/90k (&), and for (B) branched PNIPAM–PEG block copolymers, P4arm/92k (m) and P8arm/88k (

J

).

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

991

4. Discussion

A varietyof 3D porous solid scaffolds made of either

naturally occurring or synthetic polymers have been

used for cartilage repairing in tissue engineering

The main disadvantages of these ex vivo structured

scaffolds are inhomogeneous cell distribution in a

scaffold and the need for a surgical implantation

However, an injectable solution substance, that can

undergo in situ gelation under mild conditions to form

ARTICLE IN PRESS

Table 2

PNIPAM-grafted PEG hydrogels

Hydrogel code name

PNIPAM-grafted

PEG

a

Mn of PNIPAM

block ( l0

4

)

a

Concentration of

PNIPAM–PEG

block copolymer

solution (w/v%)

Occurrence of gel

formation

b

Cell viability(%)

c

1

7.5

—

2

P3k/18k

0.9

11.0

—

3

15.0

n

22.7

710.6

4

7.5

n

23.0

78.2

5

P3k/52k

2.3

11.0

J

55.3

710.2

6

15.0

J

57.3

75.0

7

7.5

J

64.7

711.0

8

P3k/90k

4.5

11.0

J

78.7

716.3

9

15.0

J

69.3

78.9

10

P4arm/92k

2.3

11.0

J

79.7

711.1

11

P8arm/88k

1.1

11.0

n

20.0

74.6

a

See footnote of

b

The appearance of the solution at 37 1C: , no gelation; n, soft gel;

J

, gel.

c

Mean-averaged cell viabilityat 7days-culture was calculated from CLSM images. Mean for n ¼ 4 SD.

Fig. 4. Time-dependent number of cells (chondrocytes) in inoculated gels with linear PNIPAM–PEG block copolymers of different PNIPAM

contents and different copolymer concentrations: 7.5 w/v% (

J

), 11 w/v% (n) and 15 w/v% (&) for copolymers with t different PNIPAM contents

(P3k/18k, P3k/52k and P3k/90k), and in branched copolymers, P4arm/92k (K) and P8arm/88k (m) at a fixed copolymer concentration (11 w/v%).

Mean for n ¼ 4 SD.

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

992

cell-inoculated and -residential gels, serves as a cell-

suspended, moldable scaffold. Simple injection of such a

mixed solution enables filling a defective tissue space,

thus forming a tissue-engineered cartilage in close

contact with adjacent living tissues.

Naturallyoccurring biomacromolecules, such as

collagen, agarose and alginate, which can be gelled by

thermoresponsive gelation (the former two biomacro-

molecules) or ionic complexation (the latter one), have

been used as cartilage tissue

. Synthetic counter-

parts of thermoresponsive gelable biomacromolecules

have been developed byutilizing thermoresponsive

PNIPAM as their major constituent in designed

molecules or poly(propylene glycol)–PEG triblock

copolymer with an appropriate copolymer composition

. Thermoresponsive copolymers composed of PNI-

PAM and PEG include triblock and star-block copoly-

mers, which are produced byredox-ty

pe ceric-ion-

induced radical polymerization initiated from hydroxyl

group of PEG at both ends, and graft copolymers in

which the PEG block is the main backbone and is

grafted with PNIPAM blocks

. These have

been mainlystudied from the viewpoints of struc-

ture–LCST relationship

, micelle formation and

rheological properties

. Another approach in-

volves the use of hybrid polymers composed of

biomacromolecules grafted with PNIPAM. For exam-

ple, our previous studies showed that PNIPAM-grafted

gelatin and PNIPAM-grafted hyaluronan, which are

prepared byphotochemicallydriven quasi-living graft

polymerization initiated from the dithiocarbamate

group derivatized on biomacromolecules, which pro-

ceeds reproduciblyunder well-defined poly

merization

condition, exhibit thermo-reversible phase transforma-

tion, resulting in temperature-dependent cell adhesion/

detachment on their coated surfaces and cell inoculation

in gel

In this study, as an extension of studies on dithio-

carbamate-based quasi-living radical photopolymeriza-

tion, thermoresponsive linear triblock and star-block

copolymers composed of PNIPAM and PEGs were

prepared according to the method shown in

ARTICLE IN PRESS

Fig. 5. Fluorescence images determining cell viability in gels with copolymers of different PNIPAM contents and copolymer concentrations after 7

days of culture: Living cells (stained green) and dead cells (stained red) were stained with calcein AM and ethidium homodimer 1, respectively.

Fig. 6. Cross-sectional SEM images of chondrocyte-inoculated P4arm/92k-based gel after 7 days of culture. Magnification (A) 500 and (B) 5000.

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

993

Linear and multiarmed PEGs were derivatized with a

dithiocarbamate group at near complete conversion

(

). The molecular weight of the PNIPAM block

increased proportionallywith photoirradiation time and

monomer concentration (

). All the triblock and

star-block copolymers have a PEG block at the central

segment and PNIPAM blocks at the terminal segments

(

). The PEG segment remains soluble in water

throughout the temperature range of interest. However,

the LCSTs of copolymers decreased with PNIPAM

content (or molecular weight) in copolymers. Regarding

multiarmed block copolymers, the LCSTs were very

slightlylower than that of the PNIPAM homopolymer

(32.0 1C).

The cell viabilityin PNIPAM–PEG block copolymer

gels (determined after 7-dayculture) depended on the

copolymer composition and architecture of the block

copolymers (

and

): the higher the

copolymer concentration and the PNIPAM content in

copolymer or the higher the PNIPAM/PEG ratio, the

higher the cell viability. That is, the block copolymers

with high PNIPAM/PEG ratios (P4arm/92K with a

ratio of 46 and P3K/90K with a ratio of 26) provided

cell viabilityof approximately80%, whereas those with

low PNIPAM/PEG ratios (P3K/18K with a ratio of 5

and P8arm/88K with a ratio of 9) provided a cell

viabilityof approximatelyonly20%. For the gels

composed of P3K/52K, the increase in the copolymer

concentration appeared to enhance cell viability.

In contrast to cell culture on 2D culture or in 3D

open-cell structured, solid microporous scaffold, cell

culture in 3D soft gel using a water-soluble synthetic gel

is quite a difficult task although biomacromolecular 3D

gels such as type I collagen gel provide much better

extracellular milieu than synthetic counterparts. This is

a missing or unsolved problem in artificial 3D ECM

designs. Although various factors determinimg the

survival of cells in soft gel can be discussed, clear-cut

mechanisms or plausible answers have not been

obtained yet. In our previous paper, the survival

strategyof cells inoculated in synthetic 3D gel culture

using thermoresponsive and cell-adhesive PMIPAM-

grafted gelatin was thoroughlydiscussed, and hypothe-

tical underlying mechanisms were presented. In this

article, the cell viabilitydependence on the molecular

design parameters of non-cell adhesive block copoly-

mers was presented. The genetral trends observed were

same as those found in PNIPAM-grafted gelatin.

Although some block copolymers significantly reduced

the cell viability, a majority of copolymers exhibited an

initial cell loss, but no further cell loss was observed at

prolonged period of culture.

Although there are few detailed studies defining the

structural interior-design criteria of cell-inoculated gels,

the following qualitative criteria have been discussed

. Cell viabilityin a gel can be stronglyinfluenced by

the mechanical strength and porosityof the gel: a higher

porosityfacilitates the supplyof oxygen and nutrients to

the interior of the gel, and an appropriate mechanical

strength of the gel is necessaryfor cell spread, which is

required for proliferation. That is, the gel should

mechanicallywithstand cell traction force to maintain

its shape and integrity, and trigger biological activity.

Large pores are a critical design criterion for 3D

scaffolds with a high cell viability. Such large pores

can be produced byinter- and intra-molecular associa-

tions of the PNIPAM block to form aggregates that are

interconnected, resulting in a large volume loss of the

PNIPAM block. This mayoccur for block copolymers

with a large PNIPAM/PEG ratio or high PNIPAM

content in a copolymer, which eventually induces a

marked accumulation of aggregated PNIPAM blocks,

resulting in the formation of mechanicallystable gels as

well as an enhanced passive transport of oxygen and

nutrients into the void space.

This hypothetical working principle is in good

agreement with the results of our previous study

in which distinct relationships between cell viability,

material and formulation parameters of PNIPAM-

grafted gelatin gels were identified: a higher PNIPAM

content in a copolymer and a higher copolymer

concentration resulted in a higher cell viabilityand

proliferation. This means that the higher total void

space and larger interconnected rigid pore favor for cell

viabilityand proliferability. This was deduced from the

analysis of focal plane images by reflection confocal

scanning laser microscopy. Although the detailed

physicochemical

and

mechano-biological

analyses

should be carried out before drawing concrete conclu-

sions, the state of aggregates of PNIPAM blocks and the

spatial distribution of interconnected voids must be

considered as keyissues for design criteria for 3D

scaffolds for vital engineered tissues.

Round cell shape of chondrocytes in gels dominated

as evidenced in CLSM (

) and SEM (

) images.

This coincides with the morphologyor cell shape in

native cartilage tissue in which chondrocytes are round,

demonstrating minimal or little interaction with the

adjacent ECM. Manystudies have demonstrated that

cell shape is a principal determinant of cell function

Therefore, PNIPAM–PEG block copolymers appear to

provide a suitable extracellular milieu for chondrocytes

in engineered cartilage tissue similarlyto natural

extracellular environment at least from the viewpoint

of cell shape.

The fate of the block copolymer in living cartilage

tissue is concerned in clinical setting. The block

copolymers prepared have one ester bond at both ends

of PEG segment, respectively. Therefore, when block

copolymer is being hydrolyzed, water-soluble PEG and

non-soluble

PNIPAM

microaggregates

should

be

formed. These are expected to be pinocytosed (for

ARTICLE IN PRESS

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

994

PEG) or phagocytosed (for PNIPAM aggregates) by

immuno-competent cells including neutrophils and

macrophages. Although slow degradation rate and low

population of immuno-competent cells are expected in

living cartilage tissue due to absence of vascular network

system within the tissue, it is envisaged that fragmented

microaggregates maybe scavenged with a prolonged

period of implantation. Further studyof cell function

and biodegradabilityis planned.

Acknowledgment

This studywas financiallysupported in part bya

Grant-in-Aid for Scientific Research (A2-15200038)

from the MEXT of Japan.

References

[1] Temenoff JS, Mikos AG. Review: tissue engineering for

regeneration of articular cartilage. Biomaterials 2000;21:431–40.

[2] Brittberg M, Lindahl A, Nilsson A, Ohlsson C, Isaksson O,

Peterson L. Treatment of deep cartilage defects in the knee with

autologous chondrocyte transplantation. N Engl J Med 1994;331:

889–95.

[3] Ishaug-RileySL, Okun LE, Prado G, Applegate MA, Ratcliffe A.

Human articular chondrocyte adhesion and proliferation on

synthetic biodegradable polymer films. Biomaterials 1999;20:

2245–56.

[4] Nehrer S, Breinan HA, Ramappa A, Shortkroff S, Young G,

Minas T, et al. Canine chondrocytes seeded in type I and type II

collagen implants investigated in vitro. J Biomed Mater Res

1997;38:95–107.

[5] Lee DA, Bader DL. Compressive strains at physiological

frequencies influence the metabolism of chondrocytes seeded in

agarose. J Orthop Res 1997;15:181–8.

[6] Hoffman AS. Hydrogels for biomedical applications. Adv Drug

Deliver Rev 2002;43:3–12.

[7] Neradovic D, Soga O, Van Nostrum CF, Hennink WE. The effect

of the processing and formulation parameters on the size of

nanoparticles based on block copolymer of poly(ethylene glycol)

and poly(N-isopropylacrylamide) with and without hydrolytically

sensitive group. Biomaterials 2004;25:2409–18.

[8] Kaneko Y, Nakamura S, Sakai K, Aoyaji T, Kikuchi A, Sakurai

Y, et al. Rapid deswelling response of poly(N-isopropylacryla-

mide) hydrogels by the formation of water release channels using

poly(ethylene oxide) graft chains. Macromolecules 1997;31:

6099–105.

[9] Matsuda T, Moghaddam MJ. Molecular design of artificial fibrin

glue. Mater Sci Eng 1993;C1:37–43.

[10] Morikawa N, Matsuda T. Thermoresponsive artificial extracel-

lular matrix: N-isopropylacrylamide-graft-copolymerized gelatin.

J Biomater Sci Polym Ed 2002;13:167–83.

[11] Ohya S, Matsuda T. Poly(N-isopropylacrylamide) (PNIPAM)-

grafted gelatin as thermoresponsive three-dimensional artificial

extracellular matrix: molecular and formulation parameters vs.

cell proliferation potential. J Biomater Sci Polymer Ed, in press.

[12] Ohya S, Kidoaki S, Matsuda T. Poly(N-isopropylacrylamide)

(PNIPAM)-graft

gelatin

hydrogel

surface:

interrelationship

between microscopic structure and mechanical propertyof surface

regions and cell adhesiveness. Biomaterials 2005;26:3105–11.

[13] Ohya S, Sonoda H, Nakayama Y, Matsuda T. The potential of

poly(N-isopropylamide)

(PNIPAM)-grafted

hyaluronan

and

PNIPAM-grafted gelatin in the control of post-surgical tissue

adhesions. Biomaterials 2005;26:655–9.

[14] Ibusuki S, Fujii Y, Iwamoto Y, Matsuda T. Tissue-engineered

cartilage using an injectable and in situ gelable thermoresponsive

gelatin: fabrication and in vitro performance. Tissue Eng

2003;9:371–84.

[15] Ibusuki S, Iwamoto Y, Matsuda T. System engineered cartilage

using Poly(N-isopropylacrylamide)-grafted gelatin as in situ

formable

scaffold:

in

vivo

performances.

Tissue

Eng

2003;9:1133–42.

[16] Matsuda T. Poly(N-isopropylacylamide)-grafted gelatin as a

thermoresponsive cell-adhesive, mold-releasable material for

shape-engineered

tissues.

J

Biomater

Sci

Polymer

Ed

2004;15:947–55.

[17] Tsukikawa S, Matsuoka H, Kurahashi Yuko, Konno Yasushi,

Satoh K, Satoh R, Isogai A, Kimura K, Watanabe Y, Nakano S,

Hayashi J, Kubota S. A new method to prepare multicellular

spheroids in cancer cell lines using a thermo-reversible gelation

polymer. Artif Organs 2003;27:598–604.

[18] Ohya S, Nakayama U, Matsuda T. Thermoresponsive artificial

extracellular matrix for tissue engineering: hyaluronic acid

bioconjugated with poly(N-isopropylacrylamide) grafts. Bioma-

cromolecules 2001;2(2):856–63.

[19] Wirth CJ, Rudert M. Techniques of cartilage growth enhance-

ment: a review of the literature. Arthroscopy1996;12:300–8.

[20] Buckwalter JA. Articular cartilage: injuries and potential for

healing. J Orthop Sports Phys Ther 1998;28:192–202.

[21] Bryant SJ, Anseth KS. The effects of scaffold thickness on the

tissue engineered cartilage in photocrosslinked poly(ethylene

oxide) hydrogels. Biomaterials 2001;20:619–26.

[22] Peter SJ, Miller MN, Yasko AW, Yaszemski MJ, Mikos AG.

Polymer concepts in tissue engineering. J Biomed Mater Res

1998;43:422–7.

[23] RowleyJA, Madlambayan G, MooneyDJ. Alginate hydrogels as

synthetic

extracellular

matrix

materials.

Biomaterials

1999;20:45–53.

[24] Yoshioka H, Mikami M, Mori Y, Tsuchida E. Preparation of

poly(N-isopropylacryamide)-b-poly(ethylene glycol) and calori-

metric analysis of its aqueous. J Macromol Sci Pure Appl Chem

1994;A31:109–12.

[25] Yoshioka H, Mikami M, Mori Y, Tsuchida E. A synthetic

hydrogel with thermoreversible gelation. I. Preparation and

rheological properties. 1994; A31: 113–20.

[26] Lin H-H, Cheng Y-L. In-situ thermoreversible gelation of block

and star copolymers of poly(ethylene glycol) and poly(N-

isopropylacrylamide) of varying architectures. Macromolecules

2001;34:3710–5.

ARTICLE IN PRESS

I.K. Kwon, T. Matsuda / Biomaterials 27 (2006) 986–995

995

Document Outline

- Photo-iniferter-based thermoresponsive block copolymers composed of poly(ethylene glycol) and poly(N-isopropylacrylamide) and chondrocyte immobilization

Wyszukiwarka

Podobne podstrony:

The incorporation of carboxylate groups into temperature responsive poly(N isopropylacrylamide) base

Poly(N isopropylacrylamide) coated

copolymers of ethylene oxide and glycidol with oligoglycidol

BSAVA Manual of Rabbit Surgery Dentistry and Imaging

Functional Origins of Religious Concepts Ontological and Strategic Selection in Evolved Minds

Guide to the properties and uses of detergents in biology and biochemistry

EurRad Ultrasound of thyroid, parathyroid glands and neck lymph nodes

Marijuana is one of the most discussed and controversial topics around the world

Preliminary Analysis of the Botany, Zoology, and Mineralogy of the Voynich Manuscript

Babi Yar Analysis of Yevtushenko's Writing Style and Meani

Improved Characterization of Nitromethane, Nitromethane Mixtures, and Shaped Charge Jet

Orzeczenia, dyrektywa 200438, DIRECTIVE 2004/58/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of

[Mises org]Mises,Ludwig von The Causes of The Economic Crisis And Other Essays Before And Aft

Comparative eco toxicity of nanoscale TiO2, SiO2, and ZnO

Biocatalytic preparation of natural flavours and fragrances POL

A Tale of Two Cities Summary and Themes of the Book

Combination of a Waste Incineration Plant and CombinedCyclePowerPlant 02bm 349 1993

Theory of Varied Consumer Choice?haviour and Its Implicati

więcej podobnych podstron