Biomaterials 27 (2006) 256–261

In vivo behavior of acrylic bone cement in total hip arthroplasty

Michael D. Ries

a

, Ernest Young

b

, Laila Al-Marashi

b

, Philip Goldstein

b

,

Alexander Hetherington

b

, Timothy Petrie

b

, Lisa Pruitt

c,

a

University of California, 500 Parnassus Avenue (MU-320-W), San Francisco, CA 94143, USA

b

University of California, 2121 Etcheverry Hall, Berkeley, CA 94720, USA

c

University of California, 5134 Etcheverry Hall, Berkeley, CA 94720-1740, USA

Received 14 April 2005; accepted 31 May 2005

Available online 21 July 2005

Abstract

Polymethylmethacrylate (PMMA) bone cement serves as the primary fixation material between bone and the prosthetic

component in cemented total hip arthroplasty. In vivo degradation of bone cement may lead to a decrease in mechanical properties

of PMMA and result in aseptic loosening. However, other factors such as porosity and location of the cement relative to the bone

implant interface may also contribute to mechanical behavior in vivo. This study investigated the mechanical properties of Simplex

s

cement retrieved from 43 patients undergoing revision total hip arthroplasty. The time in vivo was between 1 month and 27 years.

The variables studied included fracture toughness (K

IC

), porosity, molecular weight, time in vivo of the cement, and relative in vivo

location of the cement with respect to the implant and bone. K

IC

did not correlate with time in vivo of the samples or with molecular

weight. This suggests that time in vivo may not be the limiting factor in the mechanical integrity of the bone cement, A significant

and inverse relationship was found between porosity and K

IC

. This implies that porosity is the most important factor in the

mechanical behavior of bone cement during in vivo use.

r

2005 Elsevier Ltd. All rights reserved.

Keywords: Bone cement; In vivo degradation; Fracture toughness; Porosity

1. Introduction

PMMA augments load transfer between the prosthe-

sis and the bone by forming a mechanical bond between

the two components. When used as the fixation method

in total hip arthroplasty, 10 year survivorship rates in

patients aged 60 years or more have been reported as

greater than 90%

. Since cemented total hip

implants undergo cyclic loads of up to five times body

weight

, the bone cement is vulnerable to failure by

tensile stresses

. Consequently, bone cement fracture

may contribute to loss of mechanical integrity and

aseptic loosening of cemented total hip implants

A number of different factors and properties have

been shown to affect the mechanical properties of

PMMA-based bone cement. For example, PMMA has

relatively low fracture toughness, which has been

correlated with low impact and fatigue strength

One factor that could affect the fracture toughness is

porosity, although some investigators have suggested

otherwise

. Since pores have been identified in vitro as

stress-risers and crack-initiators

, higher degrees of

porosity may contribute to microcracking

Microcracking may also lead to PMMA-particle release,

which can induce local inflammation and osteolysis

Molecular weight and porosity may be affected by

different mixing and sterilization methods

Sterilization techniques such as gamma irradiation can

cause chain scission in PMMA, leading to a reduction in

molecular weight

. The molecular weight of the

ARTICLE IN PRESS

www.elsevier.com/locate/biomaterials

0142-9612/$ - see front matter r 2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biomaterials.2005.05.103

Corresponding author. Tel.: +1 510 642 2595;

fax: +1 510 643 5599.

E-mail address: lpruitt@me.berkeley.edu (L. Pruitt).

PMMA can further decrease over time during in vivo

use

. Since reduction in molecular weight can lead to

diminished fracture toughness, in vivo degradation of

PMMA may contribute to late mechanical failure of

total hip arthroplasty

. However, factors other than

length of time in vivo or molecular weight, such as

porosity, may also affect the mechanical performance of

PMMA.

This study investigated the effects of in vivo degrada-

tion on bone cement properties including fracture

toughness, porosity, and molecular weight. This analysis

utilized fracture toughness as a measure of the mechan-

ical integrity of the retrieved PMMA bone cement

The purpose of this study was to identify the most

important factors that affect the in vivo mechanical

behavior of PMMA.

2. Materials and methods

2.1. Sample preparation

Samples of Simplex

s

bone cement were retrieved from 43

patients who underwent revision total hip arthroplasty. The

size and amount of the retrievals varied among each patient.

The time in vivo before revision ranged from 1 month to 27

years. The age of the patients was between 50 and 92 years. All

samples were obtained from revision total hip arthroplasty in

aseptic conditions. Samples were rinsed in 0.85% saline

solution, and any residual organic tissue and constituents

were removed with a saline wash. Specimens were then allowed

to dry and afterwards stored in 10% neutral-buffered

formaldehyde (formalin) solution at 5 1C to preclude any

further environmental effects on the cement. For mechanical

testing preparation, all the samples were removed from

formalin, rinsed in deionized water twice, blotted with wipes,

and air-dried for 24 h.

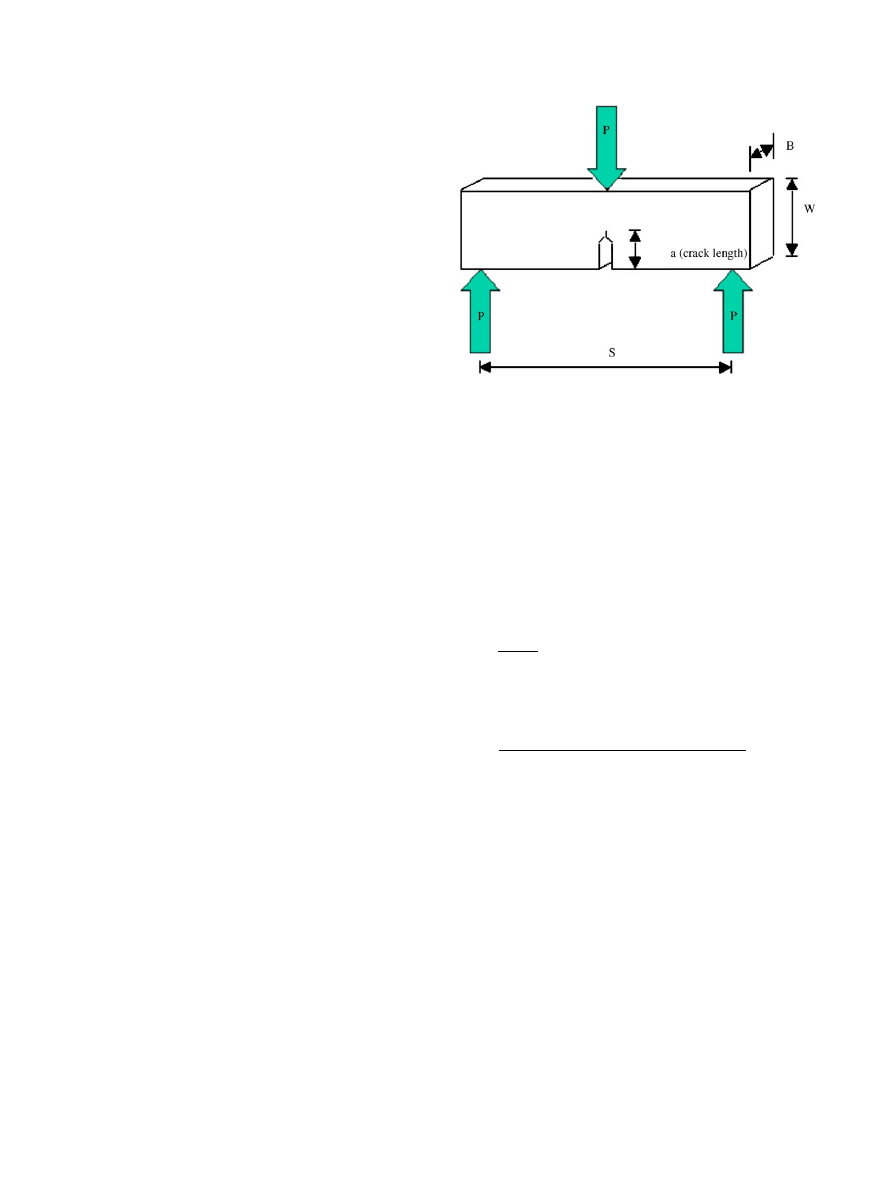

2.2. Fracture toughness testing

Fracture toughness, K

IC

, was determined for each specimen.

Retrieval samples were machined in accordance with ASTM

E399 standards for fracture toughness testing using a single

edge-notched bend (SENB) specimen, schematically illustrated

in

. Machining was performed with a diamond knife,

with beam shape and dimensions recommended by Lewis et al.

. The dimension of the specimens were as follows: span,

S ¼ 16 0:01 mm,

width

W ¼ 4:85 0:01 mm,

thickness

B ¼ 2:5 0:01 mm, initial crack length, a ¼ 1:45 0:01 mm.

Care was taken to ensure that specimens maintained an initial

crack to width ratio, a

init

¼

a

init

=W ¼ 0:3 0:01. Initial crack

length is known to affect fracture toughness values so only

specimens with an a

init

¼

0:3 0:01 were used in this study.

The location and orientation of each machined beam relative

to the original cement retrieval was recorded on a sample map

for location-dependent analyses. The SENB specimens were

pre-cracked using a standard guillotine method

. Plain

strain fracture toughness testing was performed using a three-

point bend test with a span S between the top two loading

points 3.3 times the width of the beam. All fracture toughness

testing was performed in accordance with ASTM E399

standards. Beams were loaded to failure under load control

in an Instron 8871 (Instron Corporation, Canton, MA) at a

loading rate of 0.25 N/s. The Instron program SAX V 7.0

(Instron Corporation) was used to record the maximum load

at failure for each beam. A total of 242 beams from 43 patients

were tested.

K

IC

values were calculated as a function of the maximum

load P and beam geometry as

K

IC

¼

PSf ðaÞ

BW

3=2

,

where S is the span distance between support pins, B is the

thickness of the specimen, W is the specimen width, a is the

crack length, a ¼ a=W , and f(a) is

f ðaÞ ¼

3a

1=2

ð

1:99 að1 aÞð2:15 3:93a þ 2:7a

2

ÞÞ

2 þ ð1 þ 2aÞð1 aÞ

3=2

.

Fracture beams were classified according to location with

respect to the adjacent bone and prosthesis in order to analyze

location dependency on in vivo mechanical degradation of

bone cement. During machining, maps were prepared that

recorded the location of each beam relative to the sample from

which they were machined. Images of the samples taken before

machining were compared to these location maps in order to

qualitatively determine the relative transverse location of each

beam across the thickness of the bone cement sample. Beams

were classified into three relative groups based on their pre-

machined position within each retrieved cement sample. These

classes were comprised of beams nearest to the cement/device

interface, the interior portion, and the cement/bone interface.

2.3. Porosity analysis

Fracture surfaces from the fracture toughness samples were

sonic-cleaned with ethanol and blow dried with cool air.

Cleaned surfaces were coated with a layer of gold and

photographs of fracture surfaces were acquired using a

ARTICLE IN PRESS

Fig. 1. Schematic illustration of single edge notch bend specimen used

for fracture toughness testing.

M.D. Ries et al. / Biomaterials 27 (2006) 256–261

257

scanning electron microscope (SEM). The photograph magni-

fication was normalized among all images captured to allow

comparable planar surface porosity values to be calculated.

Analysis of planar porosity was restricted only to the fracture

surfaces of imaged beams. The maximum pore size at the front

of initial crack was measured to see if it played a role in crack

inception. Photographs were scanned into a computer and

porosity quantified using the Scion Image Beta 4.0 (Scion

Corp, Frederick, MD) imaging program. Pores were qualita-

tively identified according to defined pore standards, such as

the number of pores, surface area, and the mean, standard

deviation, minimum, maximum, major, and minor pore

diameters. This data was used to calculate the total fracture

area, percent porosity, average area porosity, and maximum

and minimum pore areas. The correlation of percent planar

porosity to fracture toughness, location, and time in vivo was

examined.

2.4. Molecular weight analysis

Gel permeation chromatography (GPC) analysis was used

to determine the average molecular weight and molecular

weight distribution of the retrieved cements. Molecular weight

calibration was established based on polystyrene standards.

Samples were dissolved in tetrahydrofuran (THF) to a

concentration of 3 mg/mol at 30 1C, and then filtered in 2 mm

cup filters. Each sample was injected three times into two

American Polymer Standards Corporation GPC Gel linear

columns, 7.8 mm inner diameter 30 cm, packed with THF

with a pore size of 500 A˚. Injection size was 100 mL and the

flow rate was 1 mL/min at 30 1C. A Waters 150C system, which

uses a differential refractive index detector, was used to

monitor the changes in concentration of the sample. The

molecular weight distributions of the samples relative to

polystyrene were found in terms of the number-averaged

molecular weight M

n

, the weight-averaged molecular weight

M

w

, the z-averaged molecular weight M

z

, and the polydis-

persity index. Molecular weight was plotted versus K

IC

and in

vivo location of retrieved PMMA samples to determine if a

significant correlation existed.

2.5. Statistical analysis

Data from each of the tests were compared using one-way

analysis of variance (ANOVA) tests (Stata, College station,

TX) to determine the overall significance of data trends. For

this statistical system, p

o0:05 was considered significant.

3. Results

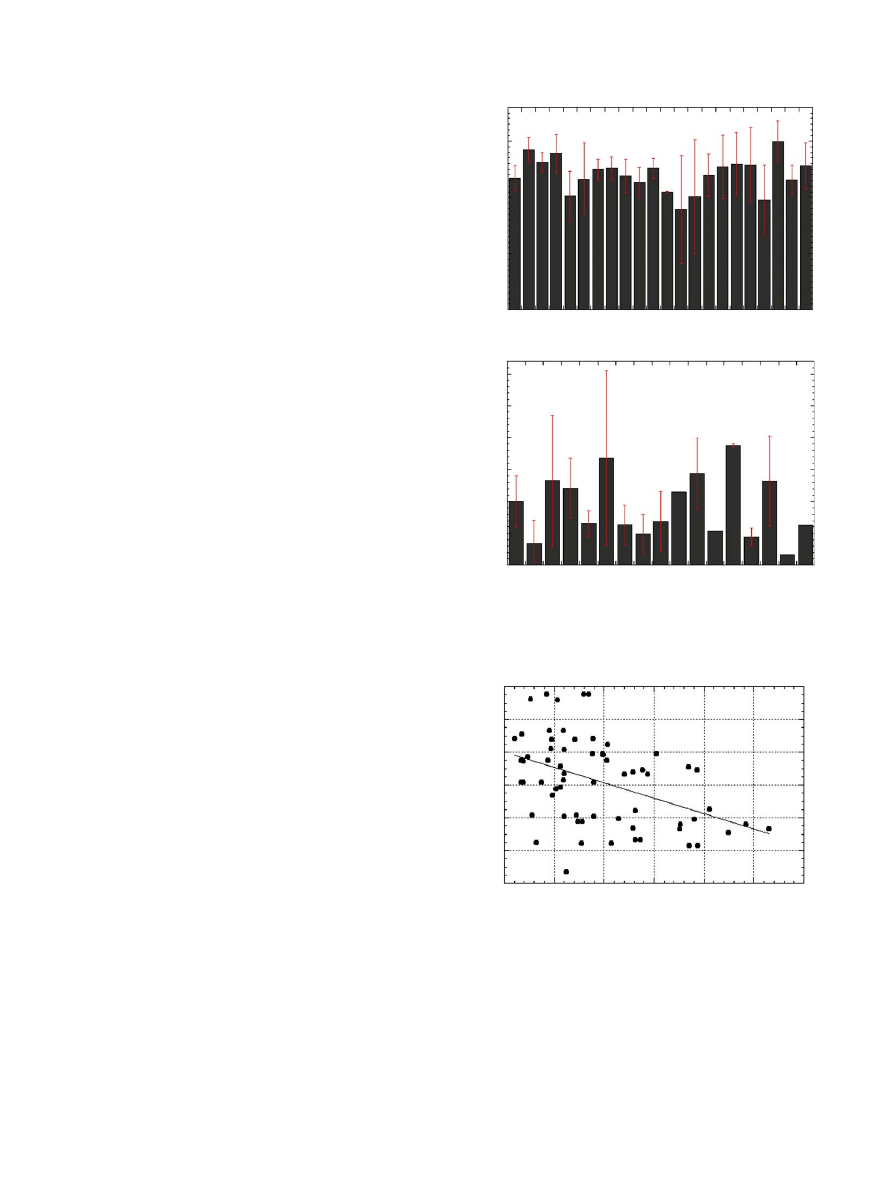

Fracture toughness is known to depend on steriliza-

tion method, bone cement chemistry, and mixing

method

. In this study, a statistical correlation

between fracture toughness and time in vivo was not

observed (

). In addition, porosity did not vary

significantly with time in vivo (

). However, when

fracture toughness and porosity were directly compared,

the higher porosity values corresponded with signifi-

cantly lower K

IC

values ðp

o0:05Þ (

). This indicates

that porosity and K

IC

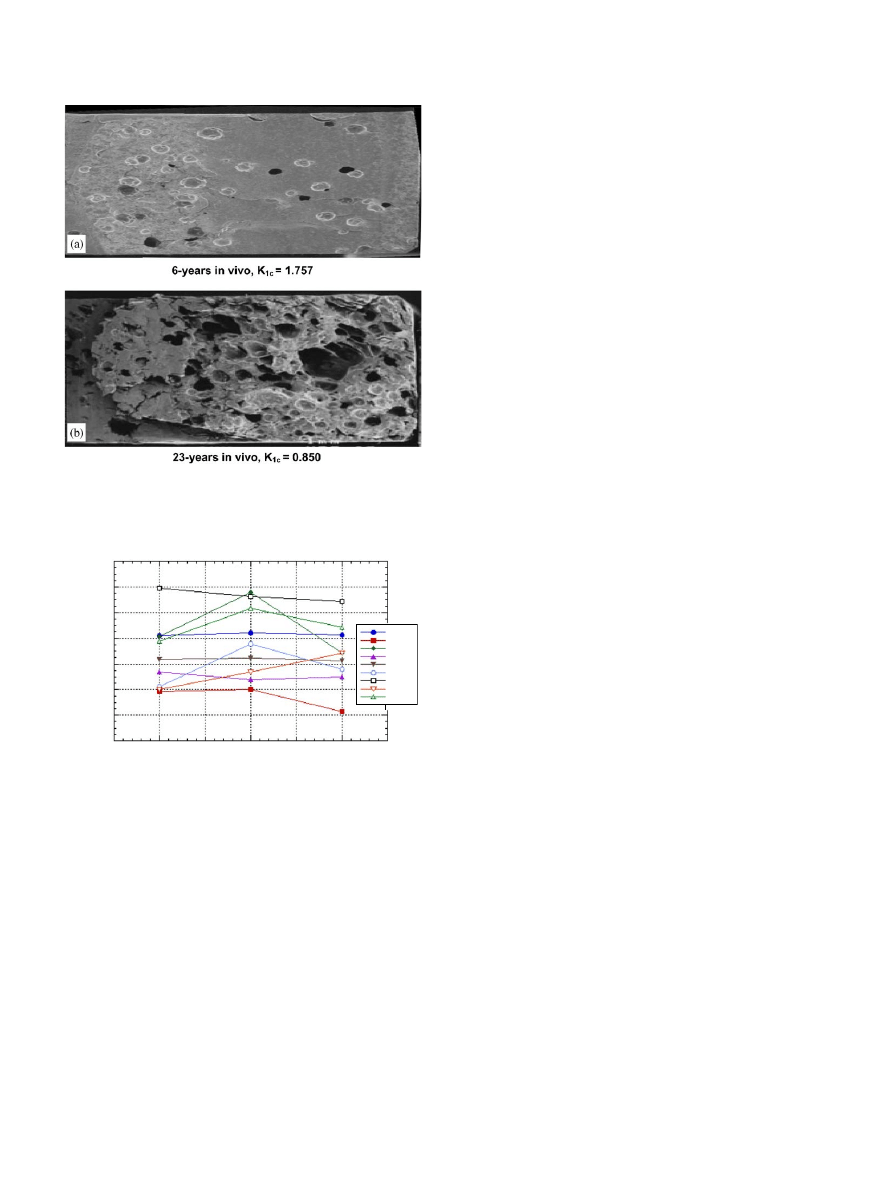

are inversely related. An example

of this correlation can be seen in representative SEM

photographs of fracture surfaces for samples retrieved

after 6 and 23 years in vivo (

). There was

no correlation of fracture toughness with pore size at

ARTICLE IN PRESS

0 1 3 4 5 6 7 9 10 11 12 13 14 15 17 18 19 20 22 23 25 27

Time In Vivo (Years)

0

1

4

5

6

9 10 11 12 15 17 18 20 22 23 25 27

Time In Vivo (Years)

Planar Porosity (%)

1.5

1

0.5

0

Fracture Toughness K

IC

(MPa m

0.5

)

30

25

20

15

10

5

0

(a)

(b)

Fig. 2. Plot showing (a) fracture toughness as a function of time in

vivo and (b) porosity as a function of time in vivo.

1.8

1.6

1.4

1.2

0.8

0.6

0

5

10

15

20

25

30

1

Planar Porosity (%)

Fracture Toughness K

IC

(MPa m

0.5

)

Fig. 3. Plot showing fracture toughness as a function of porosity.

M.D. Ries et al. / Biomaterials 27 (2006) 256–261

258

initial crack front. This finding is consistent with

previous studies

Sample location analysis results are presented in

. Sample K

IC

values were compared to relative

location across the transverse axis of the implant and no

significant trend was found ðp40:05Þ. Roughly half the

patients displayed larger K

IC

values in the interior of the

cement mantle and lower values at the interfaces.

Similarly, no significant relationship ðp40:05Þ between

relative cement beam location and porosity was

observed.

Moreover, molecular weight did not show a relation-

ship ðp40:05Þ with transverse location. In addition, a

significant correlation was not observed ðp40:05Þ

between molecular weight and K

IC

. Molecular weight

values for the samples tested ranged from 170,000 to

210,000 g/mol and K

IC

values ranged from 1.0 to

1.7 MPa

Om.

4. Discussion

Biological factors contribute to aseptic loosening of

total hip implants through a number of mechanisms.

Particulate debris can trigger a localized immune

response that leads to bone resorption

. UHMWPE

and PMMA particles cause macrophage activation and

subsequent secretion of proteolytic enzymes and cyto-

kines

. Degradation of PMMA bone cement may

also activate elements of the localized inflammatory

response and lead to a greater susceptibility of the

cement to fracture.

Hydrolysis of the bone cement may cause a reduction

in molecular weight of PMMA during in vivo use

. A

reduction in molecular weight can lead to a decrease in

mechanical properties. However, our results, utilizing

fracture toughness as the critical measurement of

resistance to failure, indicate that the in vivo time of

the bone cement does not have a significant correlation

with cement fracture toughness. Hence, the amount of

time that the bone cement spends in the implant

environment may not be the limiting factor in its in

vivo mechanical behavior. This result does not necessa-

rily imply that exposure to this degrading environment

does not have an effect. However, it does suggest that

other parameters may have a greater influence on the

resistance of the cement to this induced degradation.

For example, the cement mixing method used may

have a more significant impact on the long-term

integrity of the cement than biodegradation in vivo.

Vacuum mixing reduces the number and size of pores in

bone cement and improves fatigue resistance

. Pores

may act as stress-risers and crack-initiating sites that

reduce crack growth resistance. However, a correlation

between lower porosity and increased fracture toughness

in the literature has not been obvious. Topoleski et al.

hypothesized that pores may serve to blunt propa-

gating cracks, serving to enhance the fracture toughness

of a material. Rimnac et al.

postulated that existing

cracks and surface imperfections counteract any bene-

ficial stabilizing effects of pores since these existing flaws

are substantially larger than most internal pores in the

material. Vila et al.

suggested that the stress intensity

of the crack tip predominates over the stress concentra-

tion from porosity, in effect neglecting porosity effects

on fracture toughness.

Our results indicate that reduced porosity does

enhance the fracture toughness in implanted acrylic

bone cement. Factors affecting porosity include mixing

methods, intraoperative bleeding, bone preparation, and

cement implantation technique. An interesting finding in

ARTICLE IN PRESS

Fig. 4. Representative SEM photographs of fracture surfaces for

samples retrieved after (a) 6 years in vivo and (b) 23 years in vivo.

1 year

5 year

6 year

10 year

11 year

17 year

18 year

19 year

22 year

Cement/Device

Cement/Bone

Interior

2

1.8

1.6

1.4

1.2

0.8

0.6

1

Fracture Toughness K

IC

(MPa m

0.5

)

Fig. 5. Plot showing fracture toughness as a function of retrieval

location.

M.D. Ries et al. / Biomaterials 27 (2006) 256–261

259

this study is that although mixing methods have

drastically improved in the past 10 years with a trend

towards vacuum mixing, there was no clear reduction in

porosity with smaller aging times. This suggests that

that other factors such as surgical technique and

exothermal heating likely contribute to in vivo porosity.

A statistically significant inverse relationship between

porosity and fracture toughness was found in this

analysis. This finding correlates well with the findings

of Graham et al.

indication that reduced porosity

enhances fatigue resistance in PMMA bone cement.

In this study there was no relationship observed

between fracture toughness and molecular weight. The

findings revealed negligible variation in molecular

weight with a range of K

IC

values from 0.96 to

1.76 MPa

Om. Hence, no significant correlation was

inferred between MW and K

IC

of the retrieved bone

cement analyzed in this study. Hughes et al.

examined the effect of physiological aging on molecular

weight of PMMA and showed that molecular weight

degrades over time in a simulated oxidative and acidic

environment. Their results pointed at the existence of an

in vivo degradation mechanism in which the biological

environment becomes oxidative and pH is reduced

possibly due to particulate debris induced osteolysis.

However, studies by Kim et al.

deduced that many

mechanical properties, particularly fracture toughness

of PMMA, might be insensitive to MW values over

2 10

5

g/mol. Graham et al.

showed markedly

reduced changes in fracture toughness for PMMA

samples of MW over 1 10

5

g/mol. Our results appear

consistent with these studies. At equivalent MW levels

to those suggested, neither the porosity nor the fracture

toughness is significantly affected.

The findings in this study are also consistent with the

theory of ‘‘defect crazing’’

, which stipulates that

crazes are formed ahead of the crack tip, creating an

energy dissipation zone surrounding the crack

. This

zone contributes to ‘‘ligaments’’

of polymer chains

bridging these regions and the crack itself, enhancing the

load-bearing capacity of the cement microstructure.

Increasing the length of these ligaments by increasing

molecular weight will improve the resistance to fracture

of the cement

. However, once the polymer ligament

is able to bridge the crack, a further increase in MW

does little to enhance fracture and fatigue character-

istics. This may partially explain why fracture toughness

displayed no correlation with MW at such high MW

levels (2 10

5

g/mol). The retrieved PMMA bone

cements retained MW levels that were higher than the

threshold (1 10

5

g/mol)—hence, fracture properties

were not significantly affected with MW differences.

One aim of this study was to investigate the possibility

of a diffusion-limited degradation mechanism that may

act at the cement interface with the bone and with the

prosthesis

. In this proposed mechanism, hydro-

lytic biological fluids may seep into the interfaces

between both the cement/bone and cement/prosthesis

over time. These fluids may then diffuse into the bone

cement and degrade the cement. Therefore, it would be

expected that the areas of the bone cement at the

interfaces would display reduced fracture properties or

molecular weight compared to cement in the ‘‘interior’’

of the mantle farthest away from these two diffusive

interfaces. However, no correlation between location of

PMMA samples and intrinsic MW, porosity, or fracture

toughness ðp40:05Þ was found.

5. Conclusions

This study examines the effects of long-term implan-

tation of acrylic bone cement in femoral components of

total hip prostheses. The main result of this study is that

there exists an inverse relationship between fracture

toughness and pore size.

Acknowledgment

This work was supported by the Orthopedic Research

and Education Foundation.

References

[1] James ETR, Hunter GA, Cameron HU. Total hip revision

arthroplasty: does septis influence the results. Clin Orthop 1982;

170:88–94.

[2] Topoleski LD, Ducheyne P, Cuckler JM. A fractographic analysis

of in vivo poly (methyl methacrylate) bone cement failure

mechanisms. J Biomed Mater Res 1990;24:135–59.

[3] Nordin M, Frankel VH. Basic biomechanics of the musculoske-

letal system. 2nd ed. Philadelphia: Lea and Fibiger; 1989. p.

22–30.

[4] James SP, Jasty M, Davies J, Piehler H, Harris WH. A

fractographic investigation of PMMA bone cement focusing on

the relationship between porosity reduction and increased fatigue

life. J Biomed Mater Res 1992;26(5):651–62.

[5] Hertzberg RW, Manson JA. Fatigue of engineering plastics.

London: Academic Press; 1980. p. 74–121.

[6] Malchau H, Herberts P, Ahnfelt L. Prognosis of total hip

replacement in Sweden. Follow up of 92,675 operations

performed 1978–1990. Acta Orthop Scand 1993;64:497–506.

[7] Lewis G, Mladsi S. Relationship between fracture toughness and

impact strength of acrylic bone cement. Crit Rev Biomed Eng

2000;28(3–4):451–5.

[8] Vila MM, Ginebra MP, Gil FJ, Planell JA. Effect of porosity and

environment on the mechanical behavior of acrylic bone cement

modified with acrylonitrile-butadiene-styrene particles: I. Fracture

toughness. J Biomed Mater Res 1999;48(2):121–7.

[9] Topoleski LD, Ducheyne P, Cuckler JM. Microstructural path-

way of fracture in poly(methyl methacrylate) bone cement.

Biomaterials 1993;14(15):1165–72.

[10] Bhambri SK, Gilbertson LN. Micromechanisms of fatigue crack

initiation and propagation in bone cements. J Biomed Mater Res

1995;29:233–7.

ARTICLE IN PRESS

M.D. Ries et al. / Biomaterials 27 (2006) 256–261

260

[11] McCormack BAO, Prendergast PJ, Gallagher DJ. An experi-

mental study of damage accumulation in cemented hip prostheses.

Clin Biomech 1996;11(4):214–9.

[12] Murphy BP, Prendergast PJ. The relationship between stress,

porosity, and nonlinear damage accumulation in acrylic bone

cement. J Biomed Mater Res 2002;59(4):646–54.

[13] Horowitz SM, Doty SB, Lane JM, Burstein AH. Studies

of the mechanism by which the mechanical failure of poly-

methylmethacrylate leads to bone resorption. J Bone Jt Surg

1993;75A:803–13.

[14] Hughes KF, Ries MD, Pruitt LA. Structural degradation of

acrylic bone cements due to in vivo and simulated aging. J Biomed

Mater Res 2003;65A(2):126–35.

[15] Dunne NJ, Orr JF. Influence of mixing techniques on the

physical properties of bone cement. Biomaterials 2001;22(13):

1819–26.

[16] Graham J, Pruitt LA, Ries MD, Gundiah N. Fracture and fatigue

properties of acrylic bone cement: the effects of mixing method,

sterilization treatment, and molecular weight. J Arthroplasty 2000;

15(8):1028–35.

[17] Chapiro A. Radiation chemistry of polymeric systems. New York:

Wiley-Interscience; 1962.

[18] Harper EP, Braden M, Bonfield W, et al. Influence of sterilization

upon a range of properties of experimental bone cements. J Mater

Sci Mater Med 1997;8:849.

[19] Lewis G, Mladsi S. Effect of sterilization method on properties of

Palacos Racrylic bone cement. Biomaterials 1998;19(1-3):117–24.

[20] Hertzberg RW. Deformation and fracture mechanics of engineer-

ing materials. 2nd ed. New York: Wiley; 1983 [chapters 7–8].

[21] Lewis G. Properties of acrylic bone cement: State-of-the-art

review. J Biomed Mater Res (Appl Biomater) 1997;38:155–82.

[22] Lewis G. Apparent fracture toughness of acrylic bone cement:

effect of test specimen configuration and sterilization method.

Biomaterials 1999;20:69–78.

[23] Atkins AG, Mai YW. On the guillotining of materials. J Mater Sci

1979;14:2747–54.

[24] Jasty M, Smith E. Wear particles of total joint replacements and

their role in periprosthetic osteolysis. Curr Opin Rheumatol

1992;4(2):204–9.

[25] Jasty M, Jiranek W, Harris WH. Acrylic fragmentation in total

hip replacements and its biological consequences. Clin Orthop

1992;285:116–28.

[26] Miyaguchi M, Kobayashi A, Iwaki H, et al. Human monocyte

response to retrieved polymethylmethacrylate particles. J Biomed

Mater Res 2002;62(3):331–7.

[27] Shardlow DL, Stone MH, Ingham E, Fisher J. Cement particles

containing radio-pacifiers stimulate pro-osteolytic cytokine pro-

duction from a human monocytic cell line. J Bone Jt Surg Br

2003;85(6):900–5.

[28] Rimnac CM, Wright TM, Mcgill DL. The effect of centrifugation

on the fracture properties of acrylic bone cements. J Bone Jt Surg

Am 1986;66:281–7.

[29] Kim SL, Skibo M, Manson JA. Fatigue crack propagation in

poly(methyl methacrylate): effect of molecular weight and internal

plasticization. Polym Eng Sci 1977;17:194.

[30] Hertzberg RW. Deformation and fracture mechanics of engineer-

ing materials, 4th ed. New York: Wiley; 1996. p. 786–800.

[31] Bishop NE, Ferguson S, Tepic S. Porosity reduction in bone

cement at the cement-stem interface. J Bone Jt Surg Br 1996;

78(3):356–9.

[32] Hamilton HW, Cooper DF, Fels M. Shrinkage of centrifuged

cement. Orthop Rev 1988;17(1):48–54.

ARTICLE IN PRESS

M.D. Ries et al. / Biomaterials 27 (2006) 256–261

261

Document Outline

Wyszukiwarka

Podobne podstrony:

In vivo behaviour

In vivo MR spectroscopy in diagnosis and research of

Fluorescent proteins as a toolkit for in vivo imaging 2005 Trends in Biotechnology

2008 5 SEP Practical Applications and New Perspectives in Veterinary Behavior

Badania in vivo we współczesnej kosmetologii, Kosmetologia, inne

Metodyka?dań in vivo obieralny dr A Piastowska Ciesielska

Anty aging czy nawilżający co o skuteczności kwasu hialuronowego mówią testy in vivo

Testy umozliwiajace zbadanie uszkodzeń materiału genetycznego komórek ssaków in vivo i in vitro

An in vivo Proton MRS study in schizohrenia patients

In vivo MR spectroscopy in diagnosis and research of

In vivo dissolution

Antioxidant activity of tea polyphenols in vivo evidence from animal studies

In vivo absorption of aluminium containing vaccine adjuvants using 26Al

Emotion and Reason in Consumer Behavior Arjun Chaudhuri

Stages of change in dialectical behaviour therapy for BPD

The in vivo

The pathogenesis of Sh flexneri infection lessons from in vitro and in vivo studies

Wpływ preparatów hormonalnych na przemiany metaboliczne in vivo

In vitro behavior

więcej podobnych podstron