Garage Workbench Plans

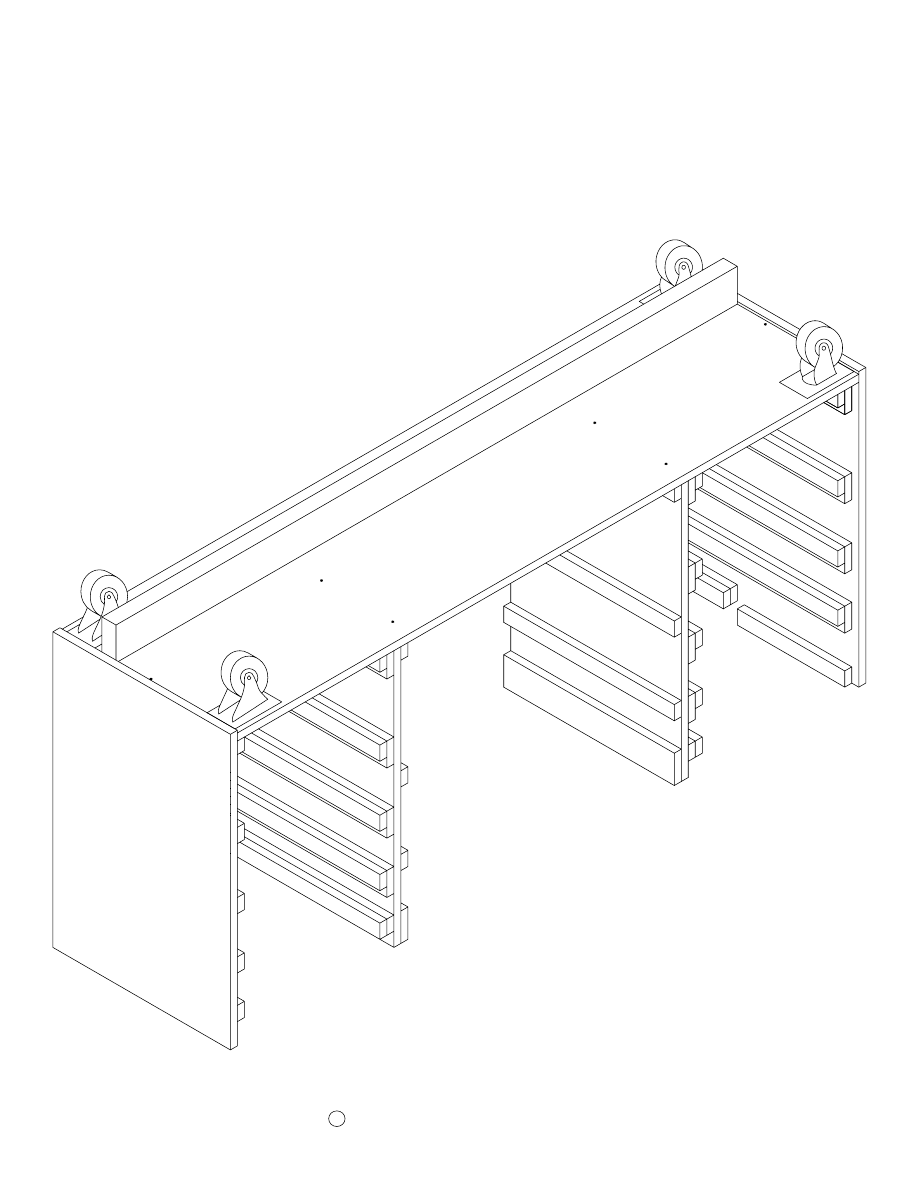

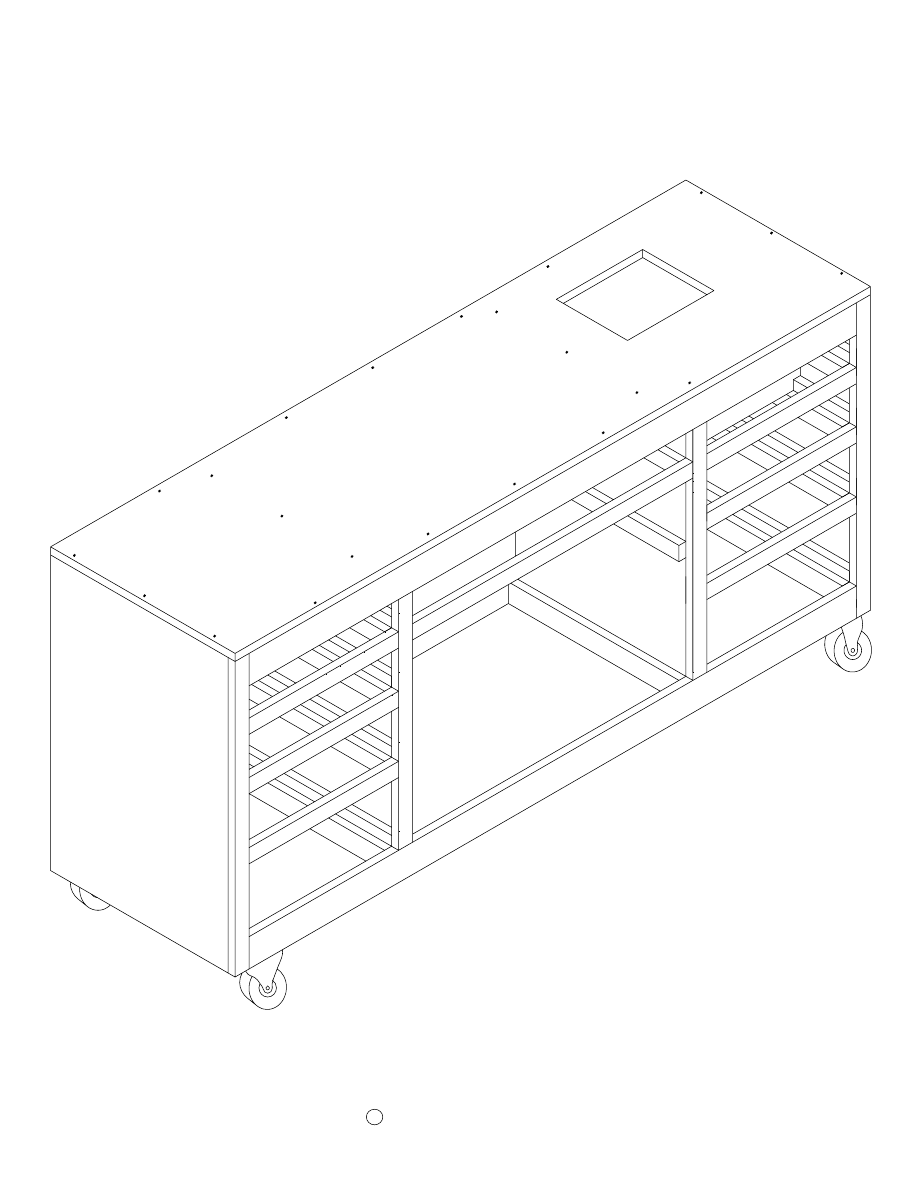

Every home woodworker knows the importance of making efficient use of the available space in his or

her shop. This workbench is designed to provide the maximum functionality using the minimum

amount of space possible. It provides a work surface of about six feet by two feet and is about 35” in

height. Just the right size to provide ample work space for most projects.

The features that make this workbench ideal for the home shop are the built in clamping system, the

built in router table, the nine drawers, the center cabinet space, and the mobility. The four inch casters

enable you to easily roll it into position when needed and roll it aside when it is not in use.

The top surface is made of two layers of 3/4” MDF. This provides an extremely flat work surface and

since it is also a router table, a flat work surface is a must. The T-track inlaid in the top and around the

edges makes the entire work surface a versatile clamping system that easily clamps very small or very

large work pieces.

Copyright © 2006 by Robert E. Reedy

All Rights Reserved

This document may not be reproduced in whole or in part without the express written consent of the author.

Table of Contents - 1

Dimensions Drawings

Materials List - 1 ......................................................................................................x

Materials List - 2 ......................................................................................................x

End and Center Panels ............................................................................................. 1

Base Dimensions & Layout ..................................................................................... 2

Back Dimensions & Layout .................................................................................... 3

Top Dimensions & Layout ...................................................................................... 4

Sub Top Dimensions & Layout .............................................................................. 5

Top Trim and T-Track ............................................................................................. 6

Drawer Slides, Stiffener, Misc. Small Parts ............................................................ 7

Drawer Fronts, Front Trim, and Doors ................................................................... 8

Drawer Boxes Dimensions ...................................................................................... 9

Router Bit Trays .................................................................................................... 10

Middle Shelf .......................................................................................................... 11

Table of Contents - 2

Assembly Instructions

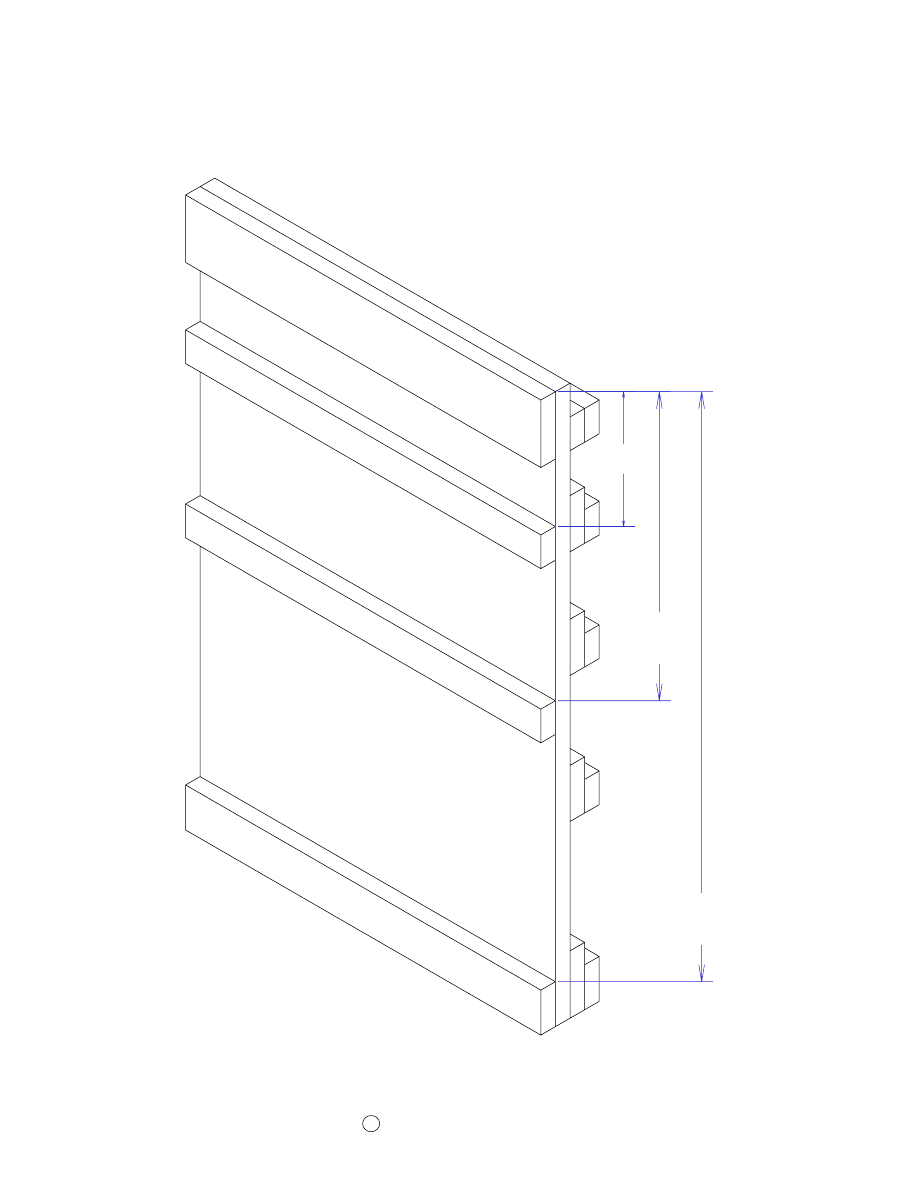

Drawer Slides - Left Section - Left Panel ............................................................. 12

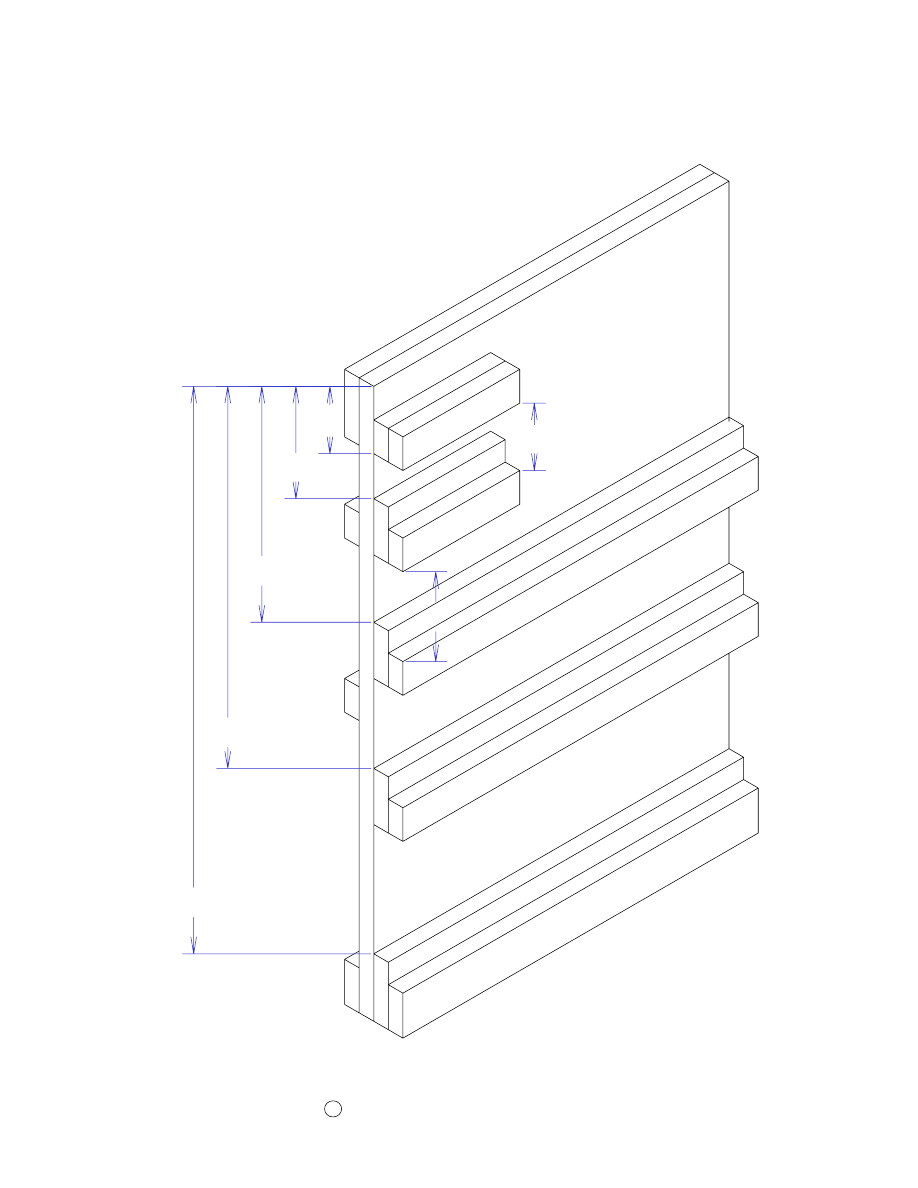

Drawer Slides - Left Section - Right Panel ........................................................... 13

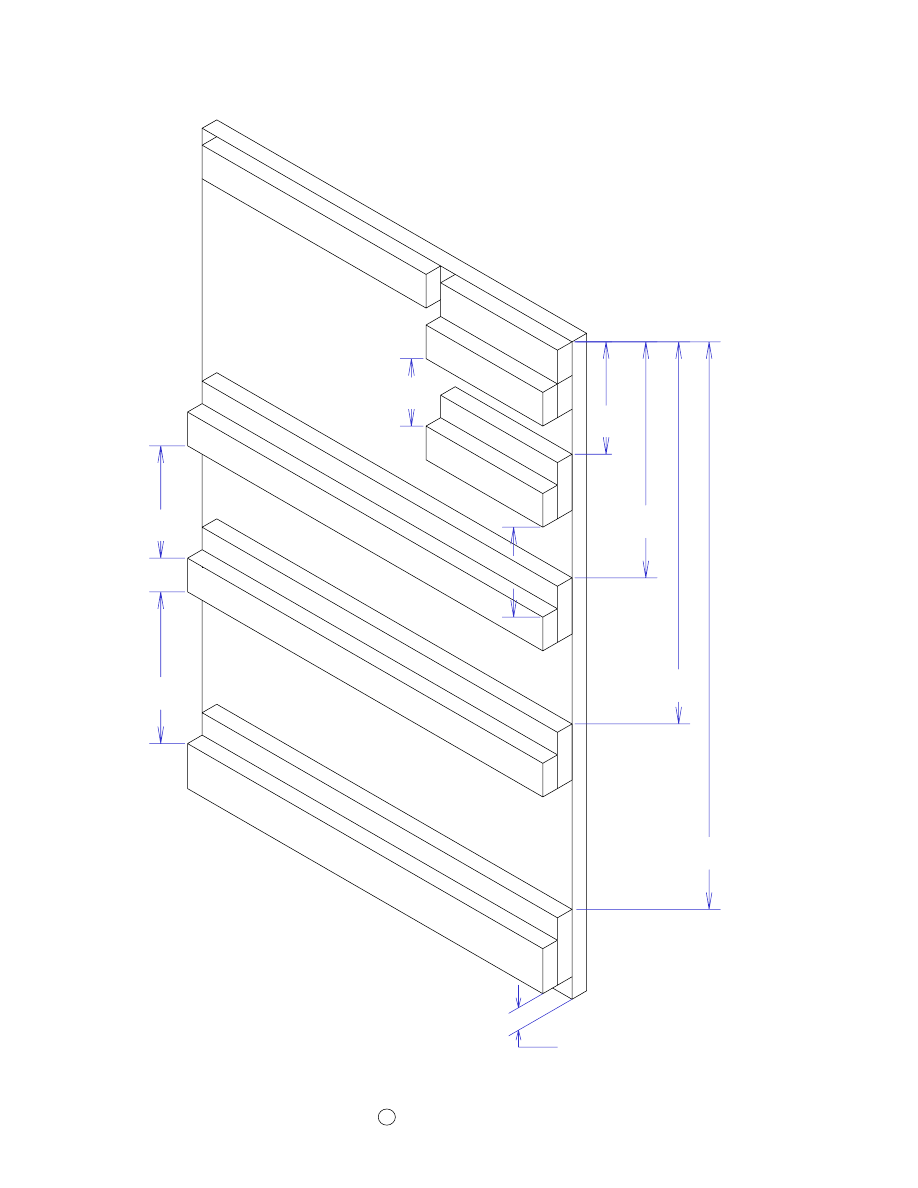

Drawer Slides - Center Section - Left Panel ......................................................... 14

Drawer Slides - Center Section -Right Panel ........................................................ 15

Drawer Slides - Right Section - Left Panel ........................................................... 16

Drawer Slides - Right Section - Right Panel ......................................................... 17

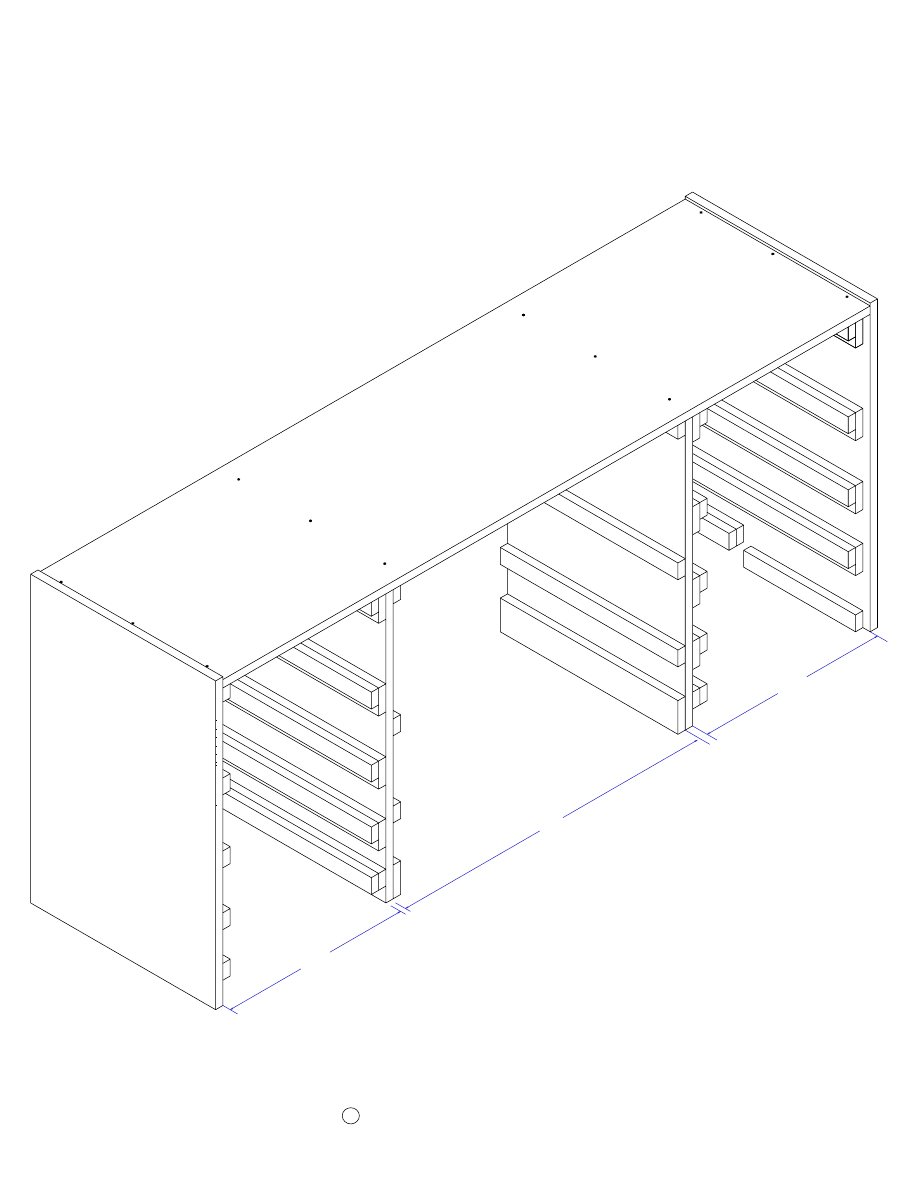

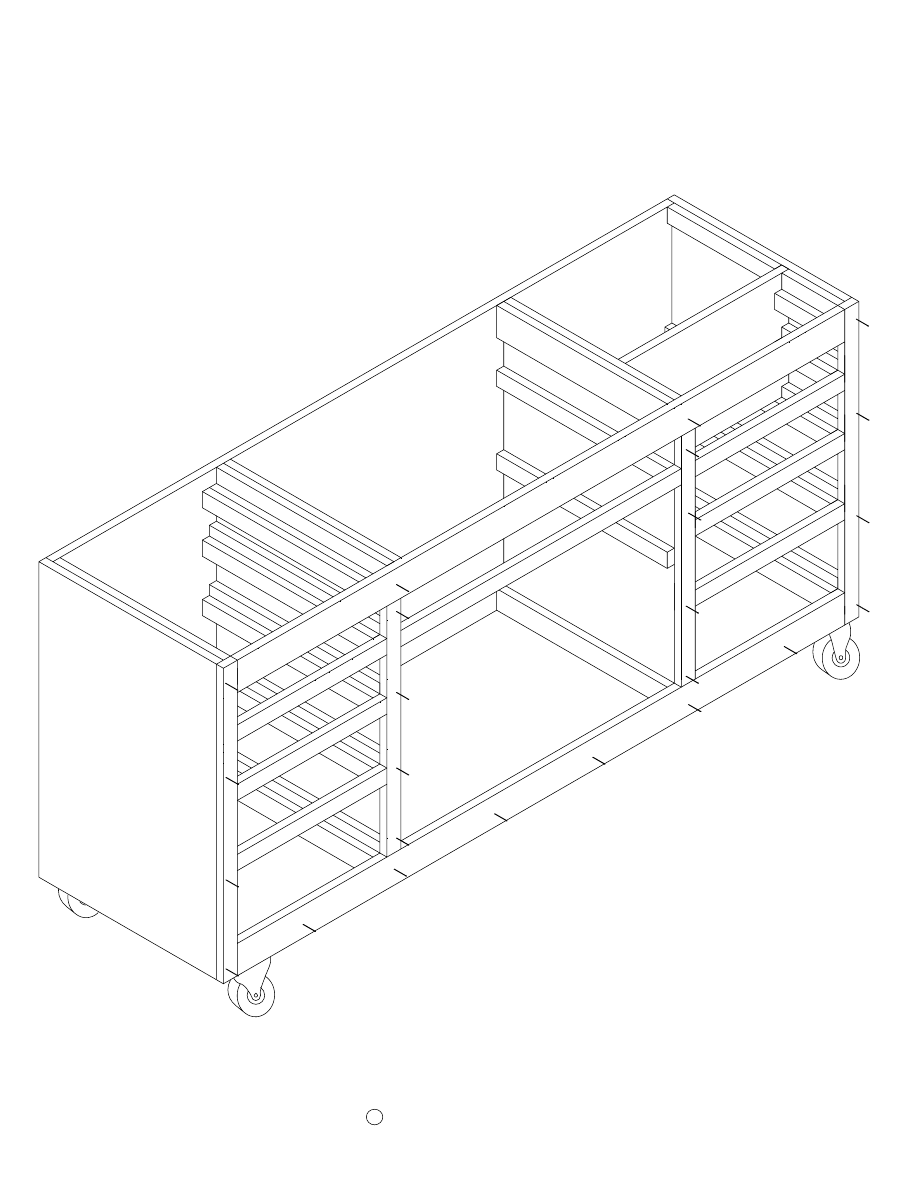

Base to Panels ........................................................................................................ 18

Stiffener - Casters .................................................................................................. 19

Attach the Back ..................................................................................................... 20

Router Box Bottom & Shelf .................................................................................. 21

Router Box Front ................................................................................................... 22

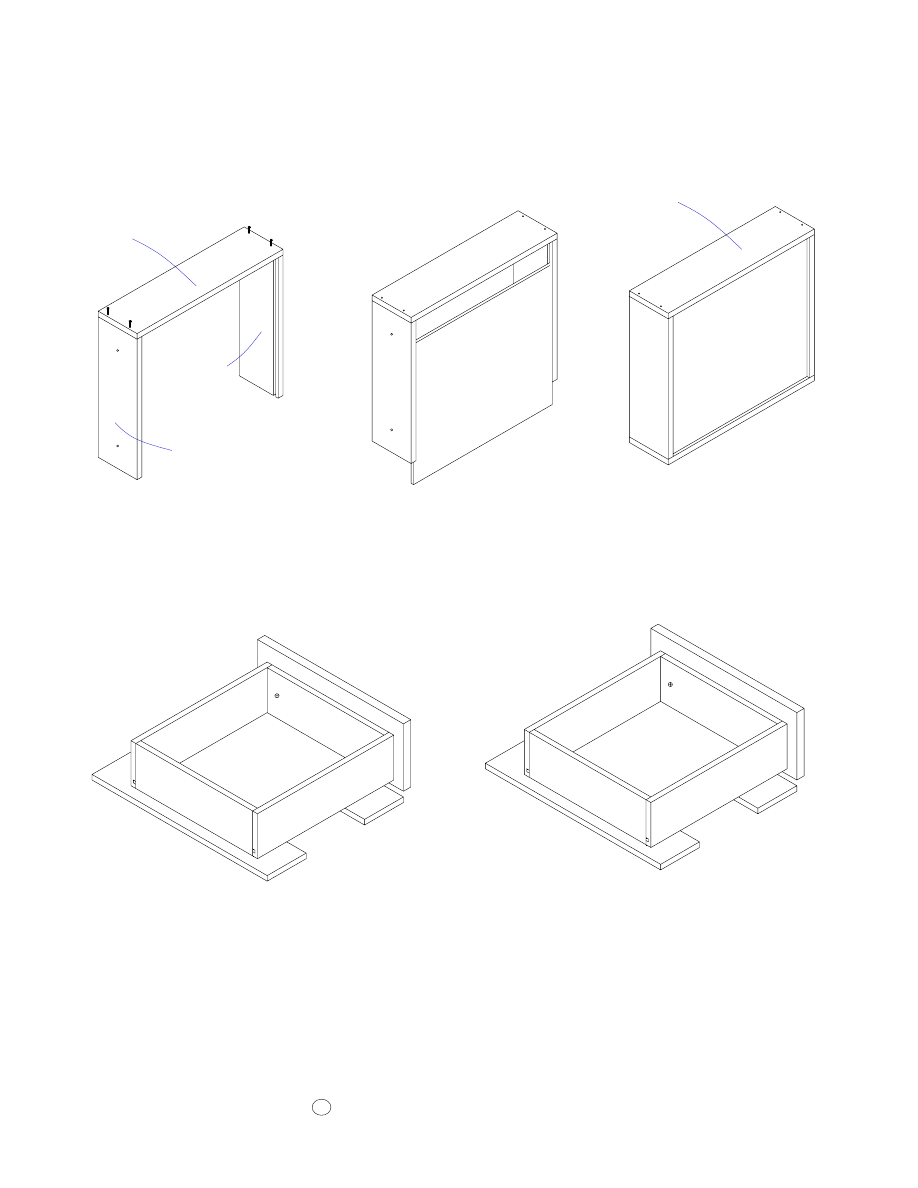

Assemble the Face Frame ...................................................................................... 23

Attach the Face Frame ........................................................................................... 24

Attach the Leveling Blocks to the Panels .............................................................. 25

Attach the Front & Rear Leveling Blocks ............................................................. 26

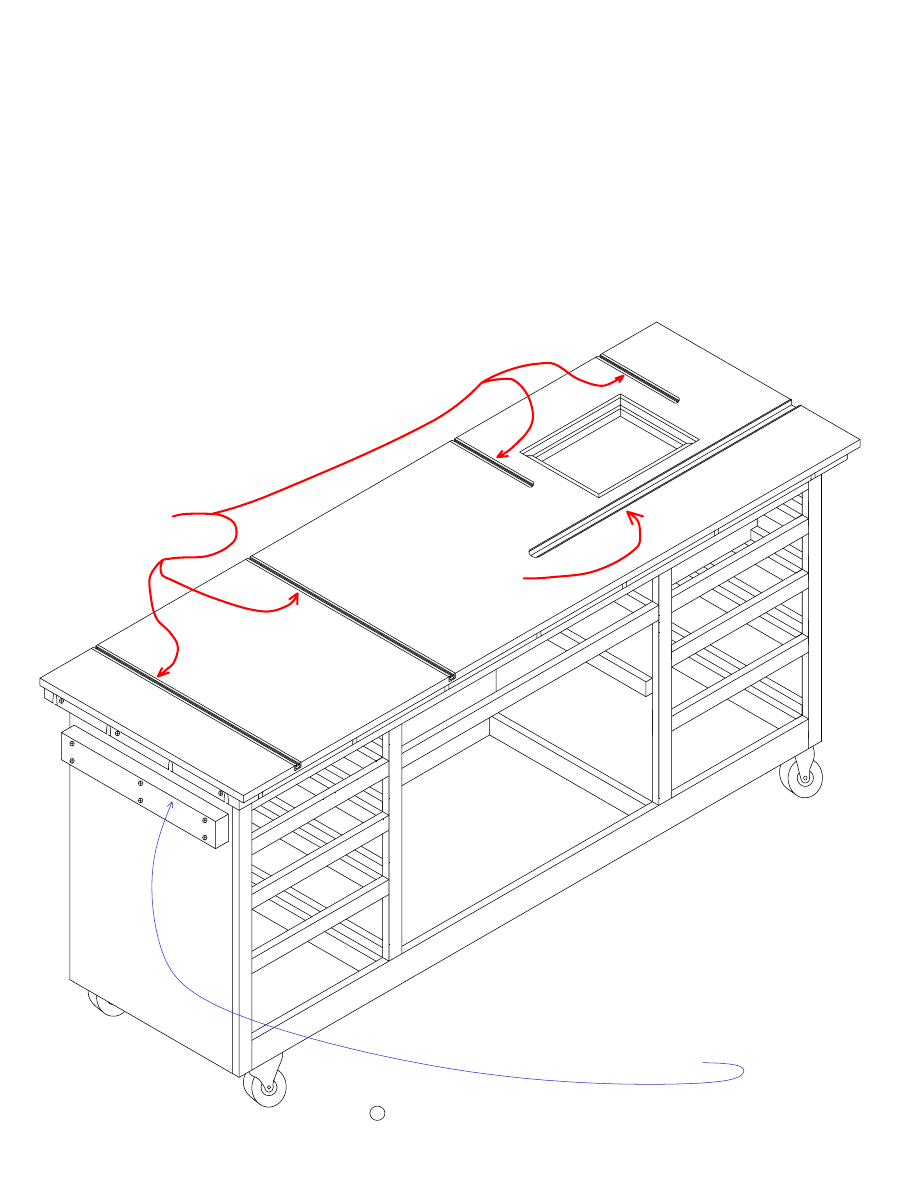

Attach the Sub Top ................................................................................................ 27

Attach the Inner Trim ............................................................................................ 28

Attach the Middle Trim ......................................................................................... 29

Attach the Top ....................................................................................................... 30

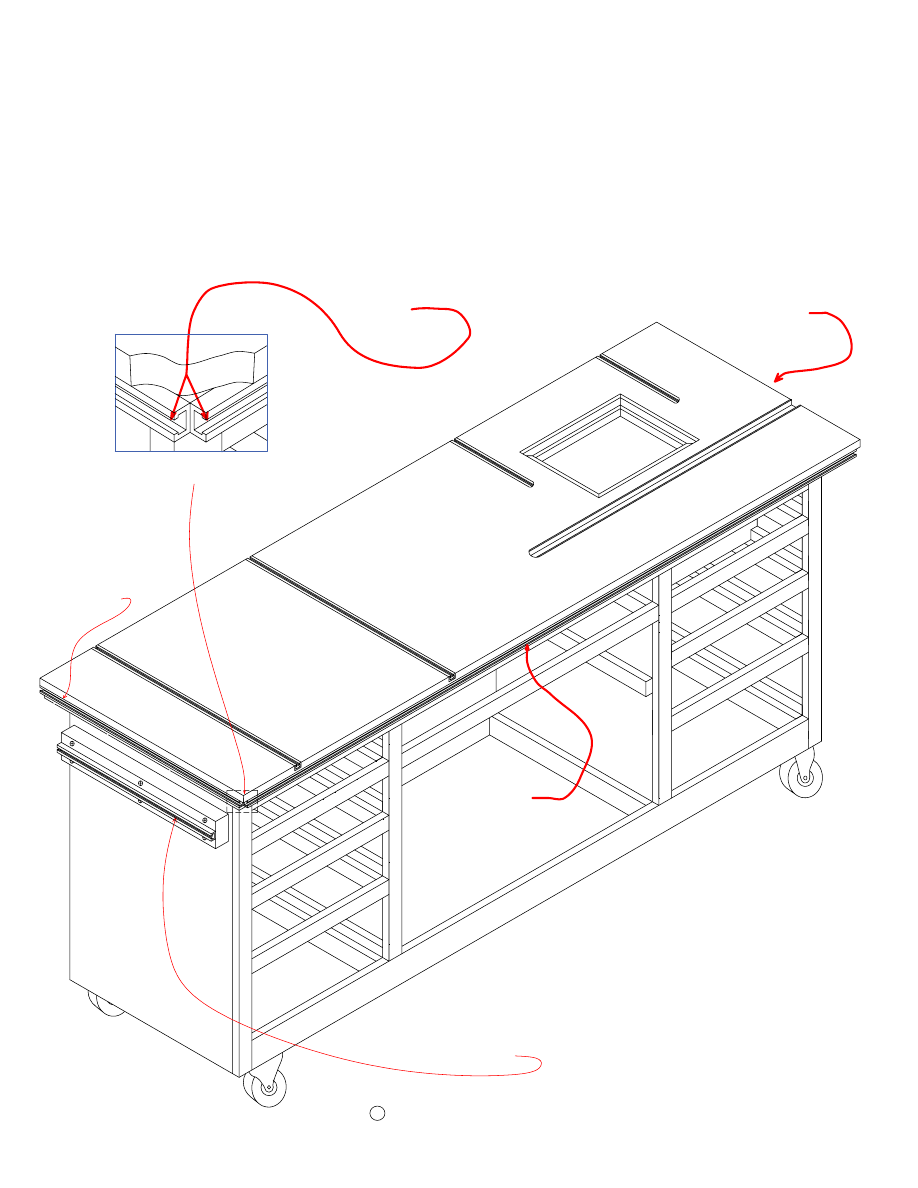

Attach the Track to the Top ................................................................................... 31

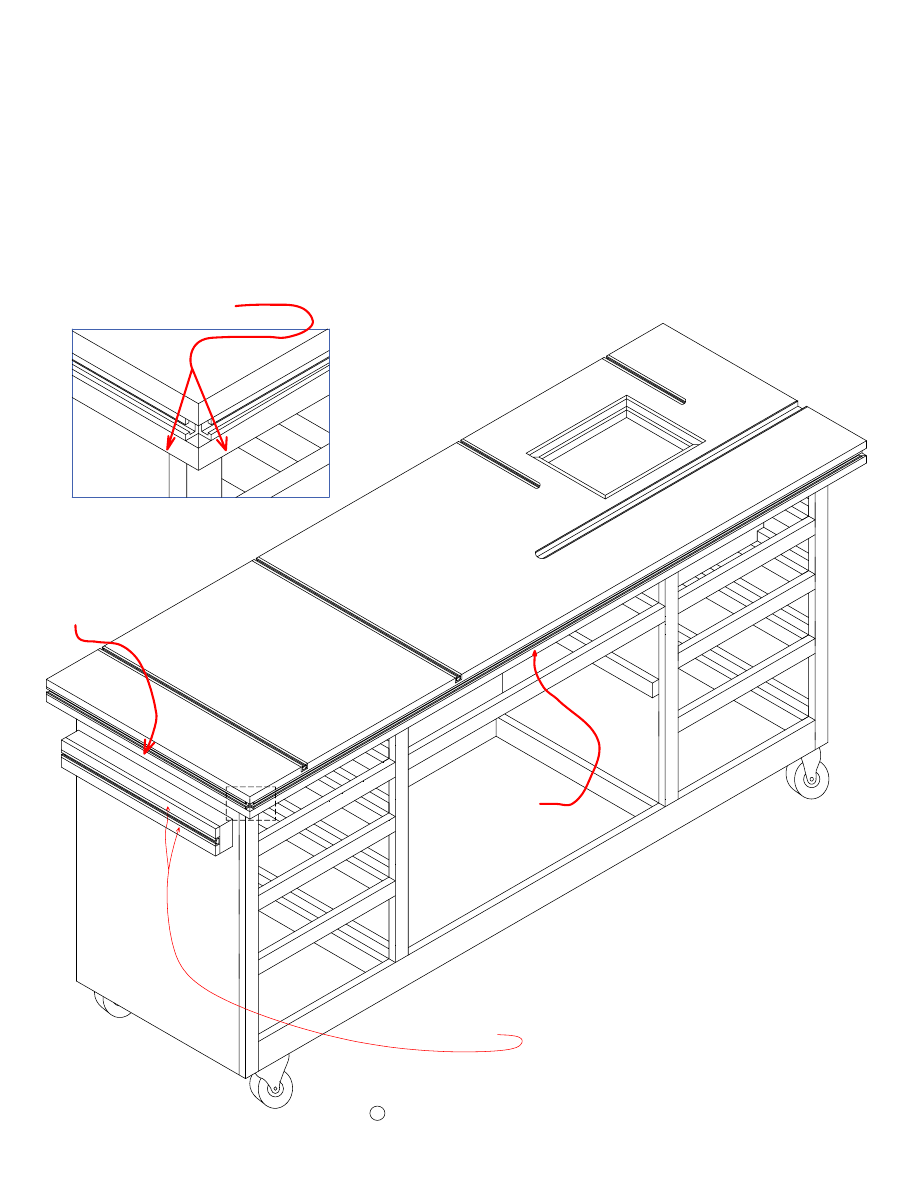

Attach the Track to the Front & Ends ................................................................... 32

Attach the Lower Trim .......................................................................................... 33

Assemble the Drawer Boxes & Fronts .................................................................. 34

Assemble the Router Trays ................................................................................... 35

Attach Cabinet Doors ............................................................................................ 36

Attach Middle Door trim ....................................................................................... 37

Clamping System Parts ......................................................................................... 38

Assemble the EZ Mount Stop ............................................................................... 39

Clamping System Usage Instructions .................................................................... 40

Clamping System Illustrations .............................................................................. 41

Snapshots ............................................................................................................... 42

Tools and Accessories You’ll Need

Note: Images and underlined text are active web links.

Low Cost Lift for Plunge Routers

is precision-engineered to within .002" tolerance

and CNC-machined from 1" solid aluminum to eliminate bend-

ing and sagging.

Built-in insert adjusters allow for snugging the lift in your table

for a perfect fit, while the built-in leveling system will not wear

into the table's recessed opening

Plate measures 9-1/4" x 11-3/4" x 3/8". Adjustments are made

with a drop-in speed handle that's elevated from the table.

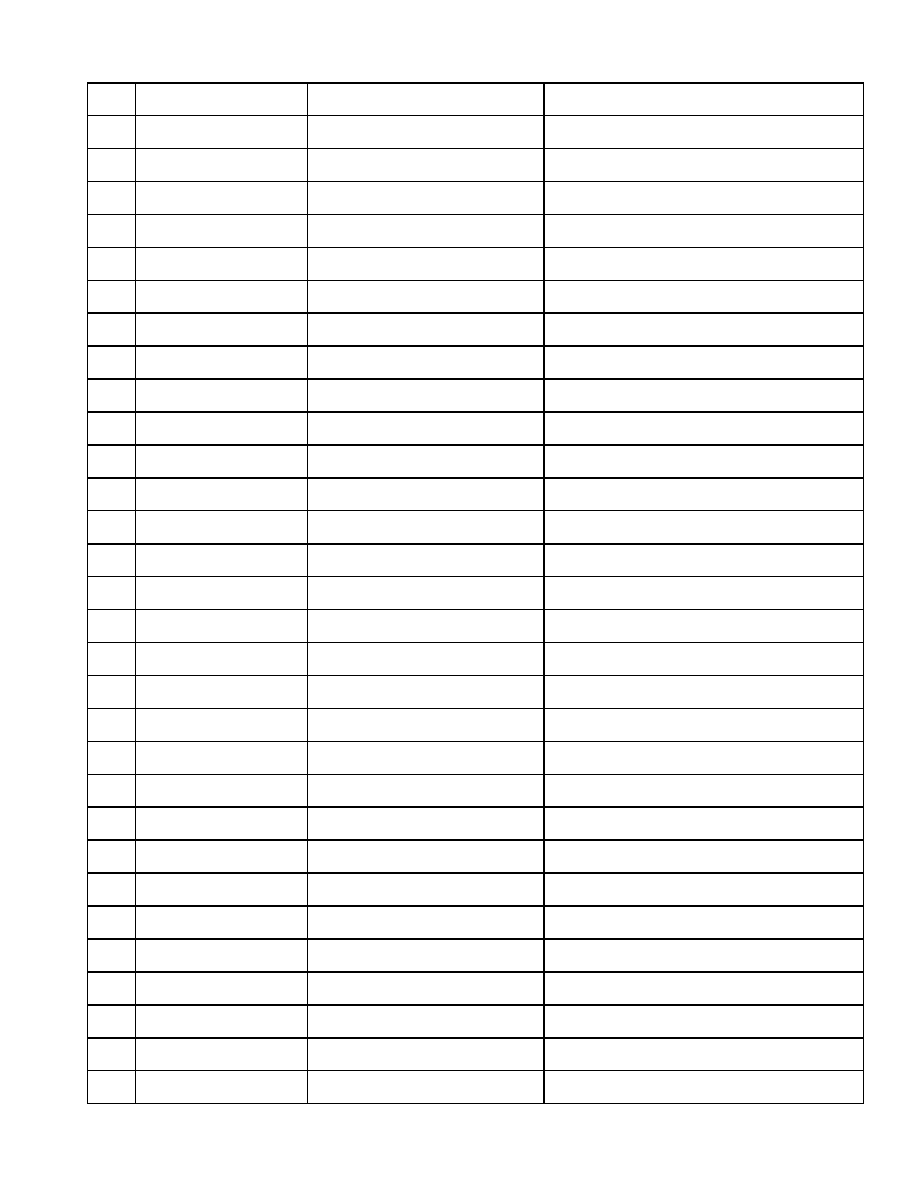

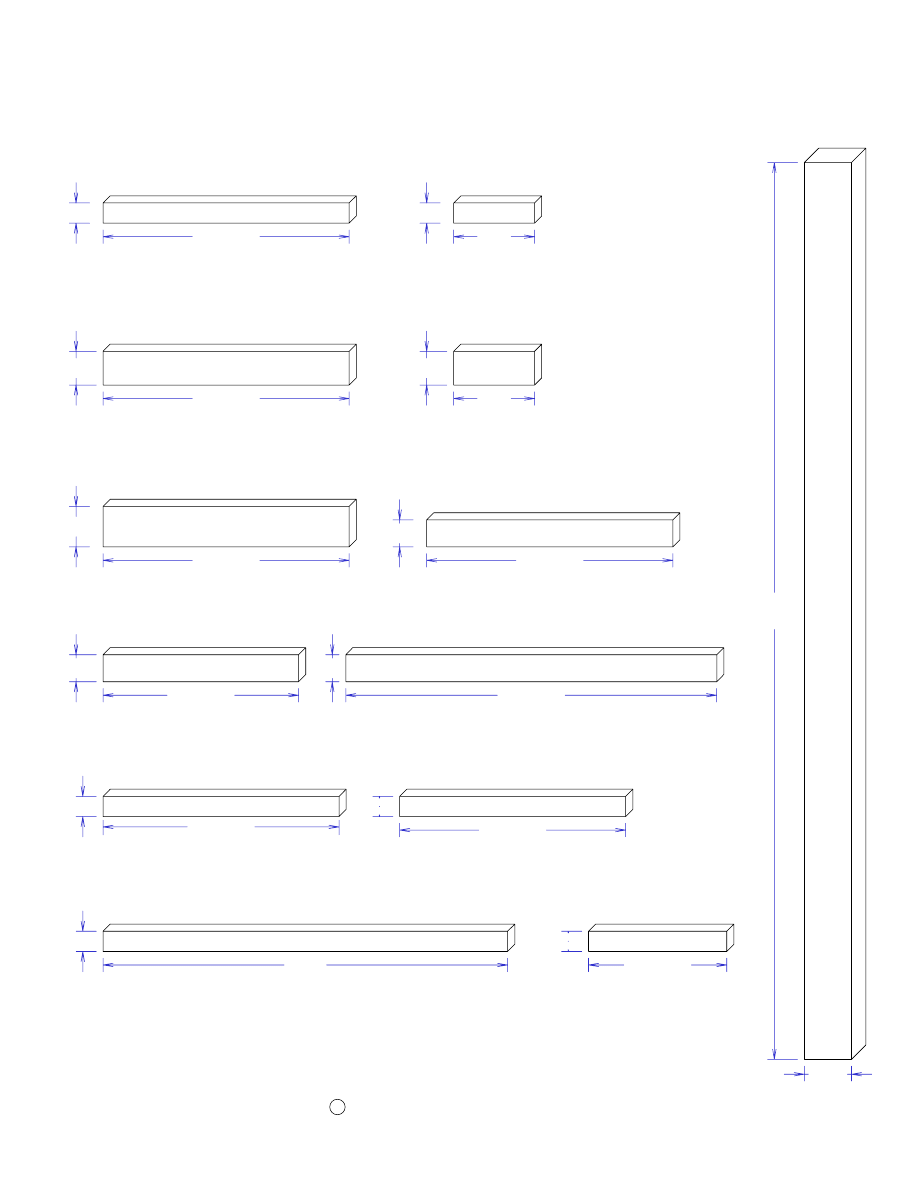

Materials List - 1

Qty

Size

Material

Item name

2

29 1/4” by 19”

3/4” Oak Plywood

End Panels

2

28 1/4” by 18 1/4”

3/4” Plywood

Middle Panels

1

66 1/2” by 19”

3/4” Plywood

Base

1

66 1/2” by 28 1/4”

3/4” Plywood

Back

1

72” by 24”

3/4” MDF Board

Top

1

68” by 19 3/4”

3/4” MDF Board

Sub Top

2

69 1/2” by 1 1/2”

3/4” Wood or Plywood

1st Front & Back Sub Top Trim

2

21 1/4” ” by 1 1/2”

3/4” Wood or Plywood

1st End Sub Top Trim

2

71” by 1 1/2”

3/4” Wood or Plywood

2nd Front & Back Sub Top Trim

2

22 3/4” by 1 1/2”

3/4” Wood or Plywood

2nd End Sub Top Trim

2

36”

1/2” by 3/4” T-Track

Front T-Track

5

24”

1/2” by 3/4” T-Track

End & Top T-Track

1

72” by 3/4” by 1/2”

1/2” Thick MDF or Wood

Front Lower T-Track Trim

2

24” by 3/4” by 1/2”

1/2” Thick MDF or Wood

End Lower T-Track Trim

17

18 1/4” by 1 1/2”

3/4” Wood

Drawer Supports

5

6” by 1 1/2”

3/4” Wood

Small Drawer Supports

10

18 1/4” by 2 1/2”

3/4” Wood

Drawer Side Guides

2

6” by 2 1/2”

3/4” Wood

Small Drawer Side Guides

4

18 1/4” by 3”

3/4” Wood

Lower Drawer Side Guides

6

18 1/4” by 2”

3/4” Wood

Lower Drawer Supports

2

14 1/2” by 2”

3/4” Wood

Lower Back Supports

1

27 1/2” by 2”

3/4” Wood

Center Lower Back Support

4

17 1/2” by 1 1/2”

3/4” Wood

17 1/2” Leveling Block

3

16 3/4” by 1 1/2”

3/4” Wood

16 3/4” Leveling Block

2

30” by 1 1/2”

3/4” Wood

30” Leveling Block

1

10 1/4” by 1 1/2”

3/4” Wood

10 1/4” Leveling Block

1

66 1/2”

2 by 4 (3 1/2” by 1 1/2”)

Stiffener

6

16” by 1 1/2”

3/4” thick wood or plywood

Drawer Trim

2

29 1/4” by 1 1/2”

3/4” thick wood or plywood

Vertical End Trim

1

30” by 1 1/2”

3/4” thick wood or plywood

Middel Trim

x

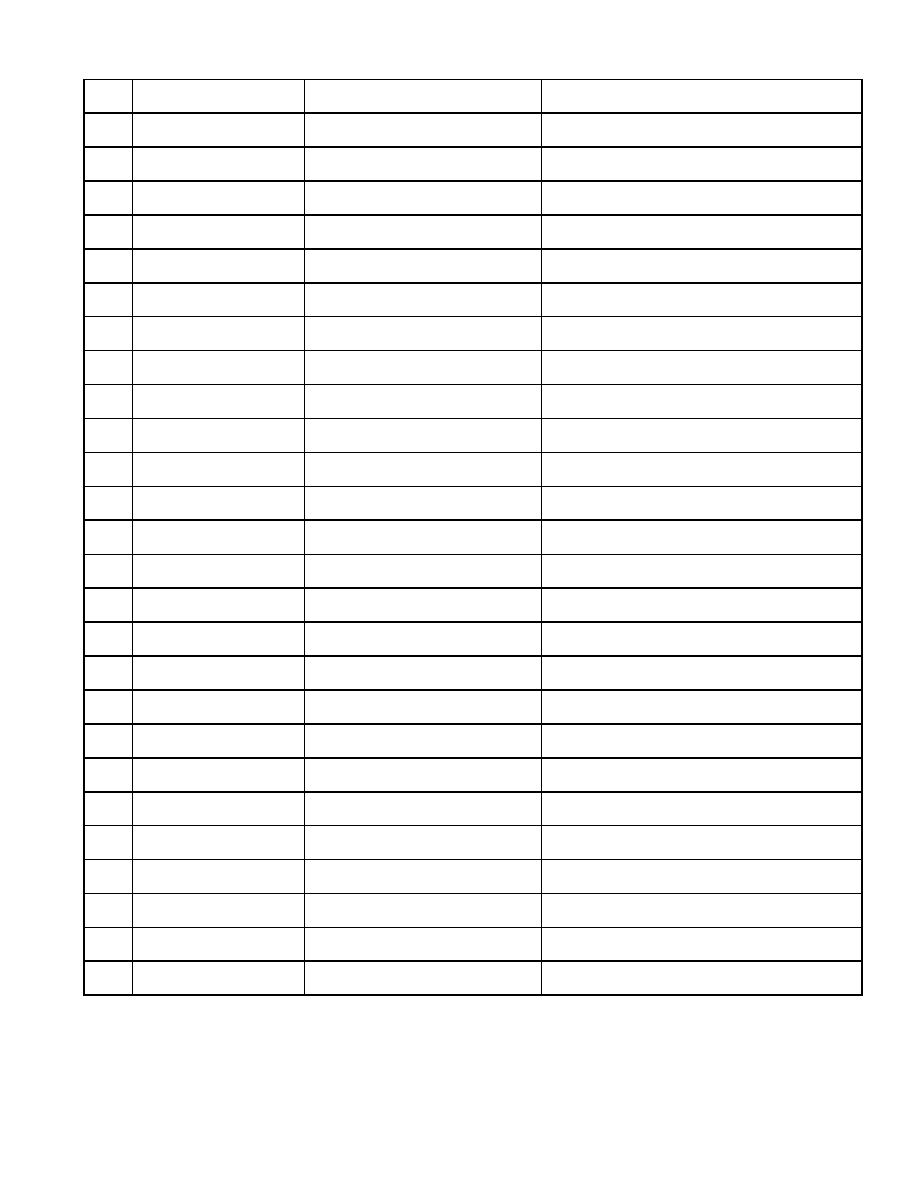

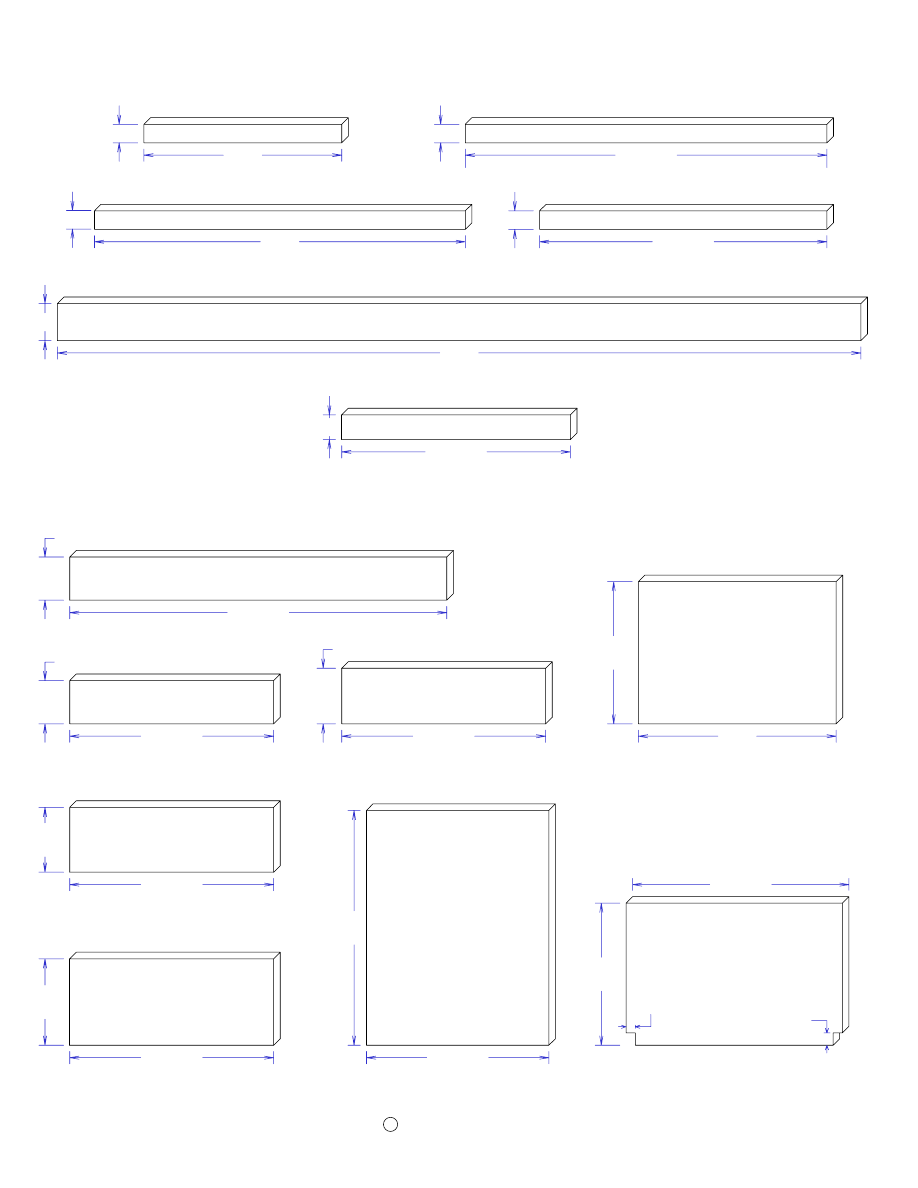

Materials List - 2

Qty

Size

Material

Item name

2

23 1/4” by 1 1/2”

3/4” thick wood or plywood

Vertical Divider Trim

2

65” by 3”

3/4” thick wood or plywood

Upper & Lower Trim

1

3 1/2” by 30 1/2”

3/4” thick wood or plywood

Center Drawer Front

2

3 1/2” by 16 1/2”

3/4” thick wood or plywood

Top Drawer Front

2

4 1/2” by 16 1/2”

3/4” thick wood or plywood

4 1/2” Drawer Front

2

5 1/4” by 16 1/2”

3/4” thick wood or plywood

5 1/4” Drawer Front

2

7” by 16 1/2”

3/4” thick wood or plywood

7” Drawer Front

2

19” by 14 3/4”

3/4” thick wood or plywood

Cabinet Doors

1

3/4” thick wood or plywood

Door Lip

1

17 1/2” by 11 1/2”

3/4” thick wood or plywood

Router Box Front

6

19” by 2 7/8”

3/4” thick wood or plywood

Top Drawer Sides

4

19” by 3 7/8”

3/4” thick wood or plywood

3 7/8” Drawer Sides

4

19” by 4 7/8”

3/4” thick wood or plywood

4 7/8” Drawer Sides

4

19” by 6 5/8”

3/4” thick wood or plywood

6 5/8” Drawer Sides

2

28 3/8” by 2 7/8”

3/4” thick wood or plywood

Center Drawer Ends

4

14 3/8” by 2 7/8”

3/4” thick wood or plywood

Top Drawer Ends

4

14 3/8” by 3 7/8”

3/4” thick wood or plywood

3 7/8” Drawer Ends

4

14 3/8” by 4 7/8”

3/4” thick wood or plywood

4 7/8” Drawer Ends

4

14 3/8” by 6 5/8”

3/4” thick wood or plywood

6 5/8” Drawer Ends

1

29 1/8” by 18 1/4”

1/4” Hardboard

Center Drawer Bottom

6

15 1/8”” by 18 1/4”

1/4” Hardboard

Drawer Bottom

2

6” by 2 7/8”

3/4” thick wood or plywood

Top Router Tray Sides

2

6” by 3 7/8”

3/4” thick wood or plywood

2nd Router Bit Trays

2

14 7/8” by 6”

1/2” thick material

Router Bit Trays

2

14 7/8” by 6”

1/4” thick material

Router Bit Bottoms

1

18 1/4” by 30”

3/4” plywood

Middle Shelf

xi

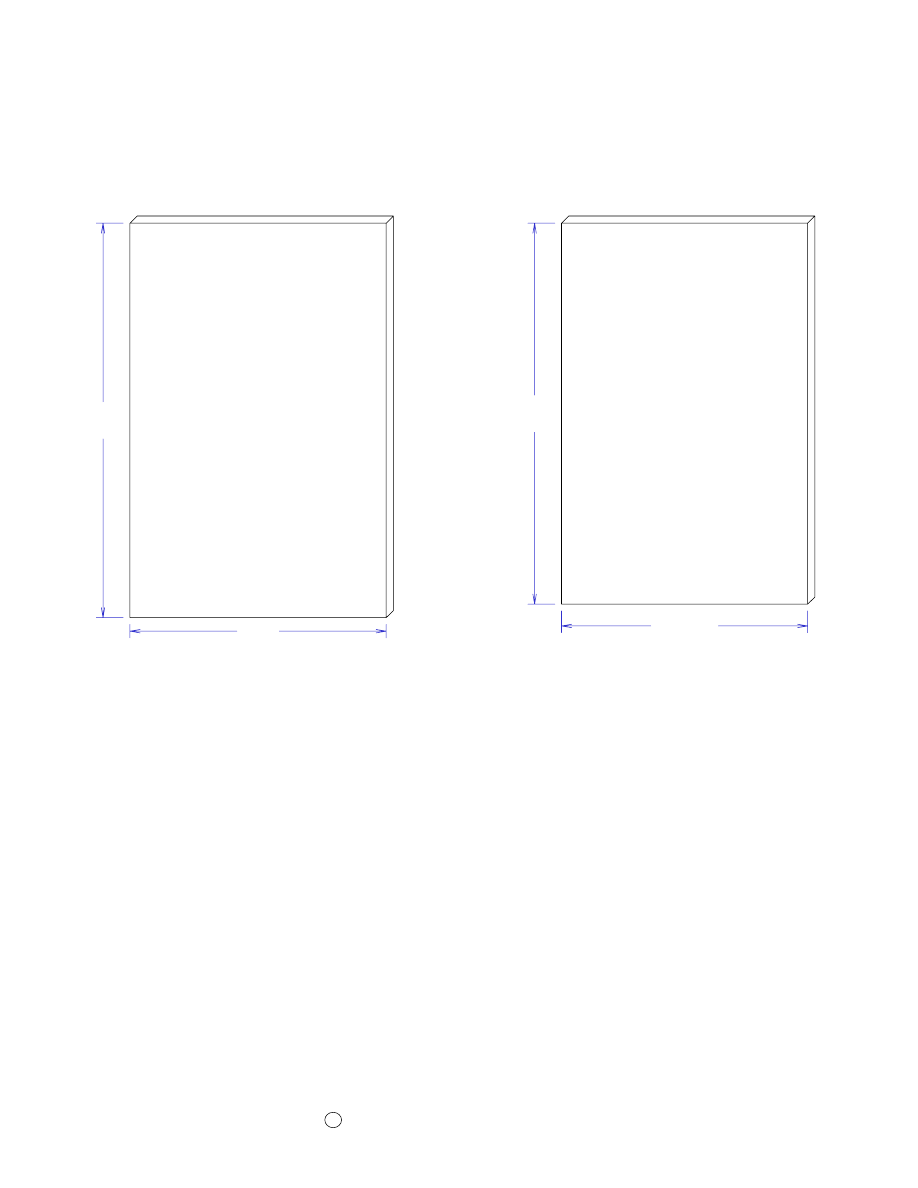

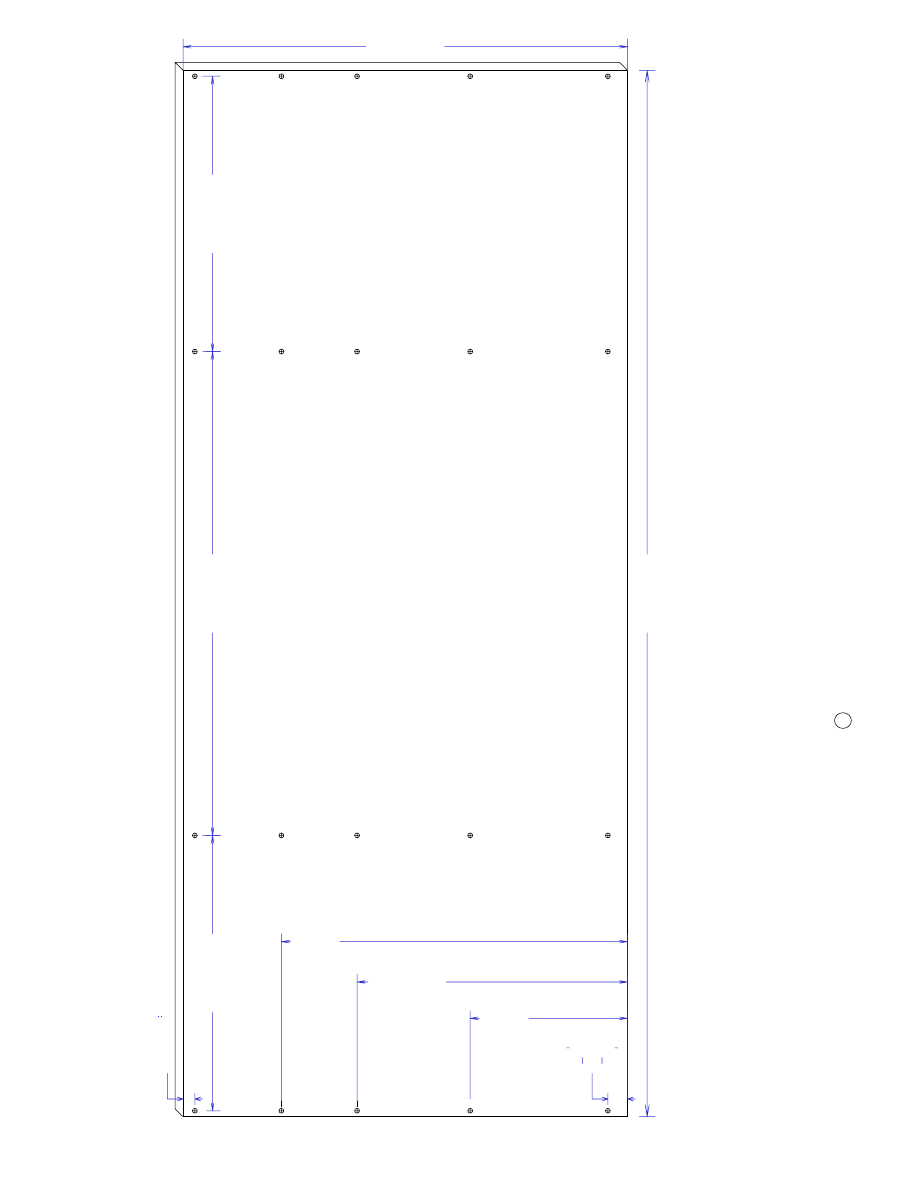

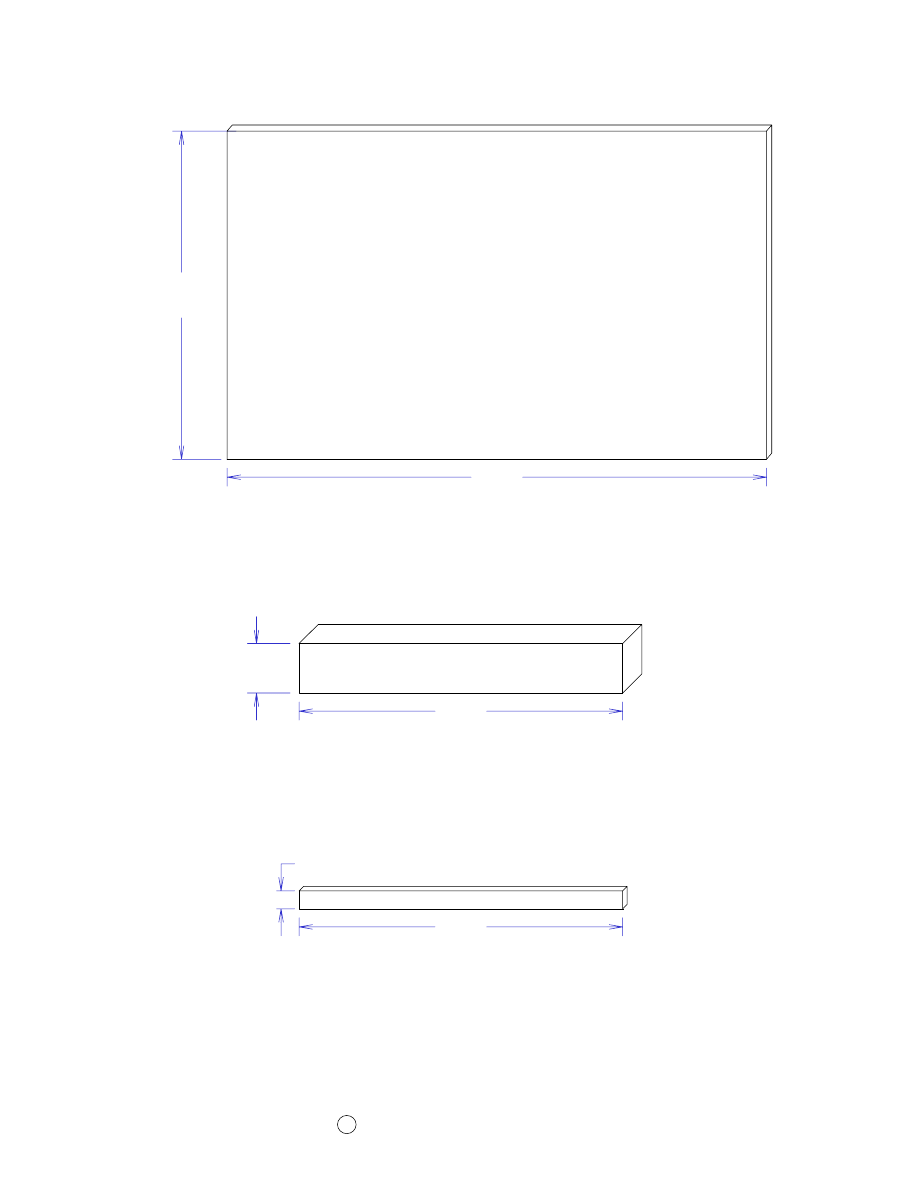

28 1/4"

18 1/4"

Middle Panels

(2 Required)

29 1/4"

19"

End Panel

(2 Required)

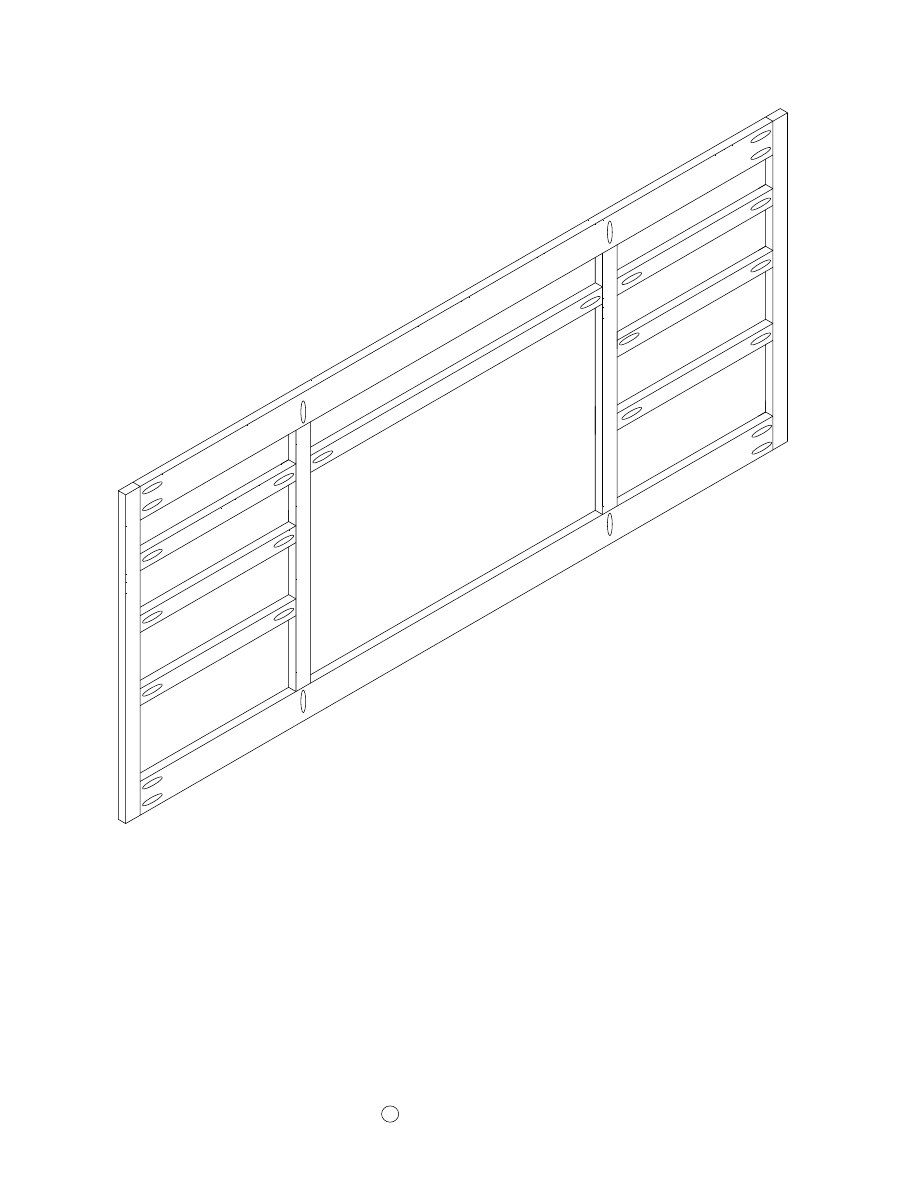

End and Center Panels

Page 1

The two end panels are 1" taller than the center panels. This is because the

center panels sit on the top surface of the base and the end panels extend 1/4"

below the bottom surface of the base..

The end panels are also 3/4" wider than the center panels. This is so they will

be flush with the ends of the back section.

C

2006 by Robert E. Reedy, Vandalia, Ohio

Copyright

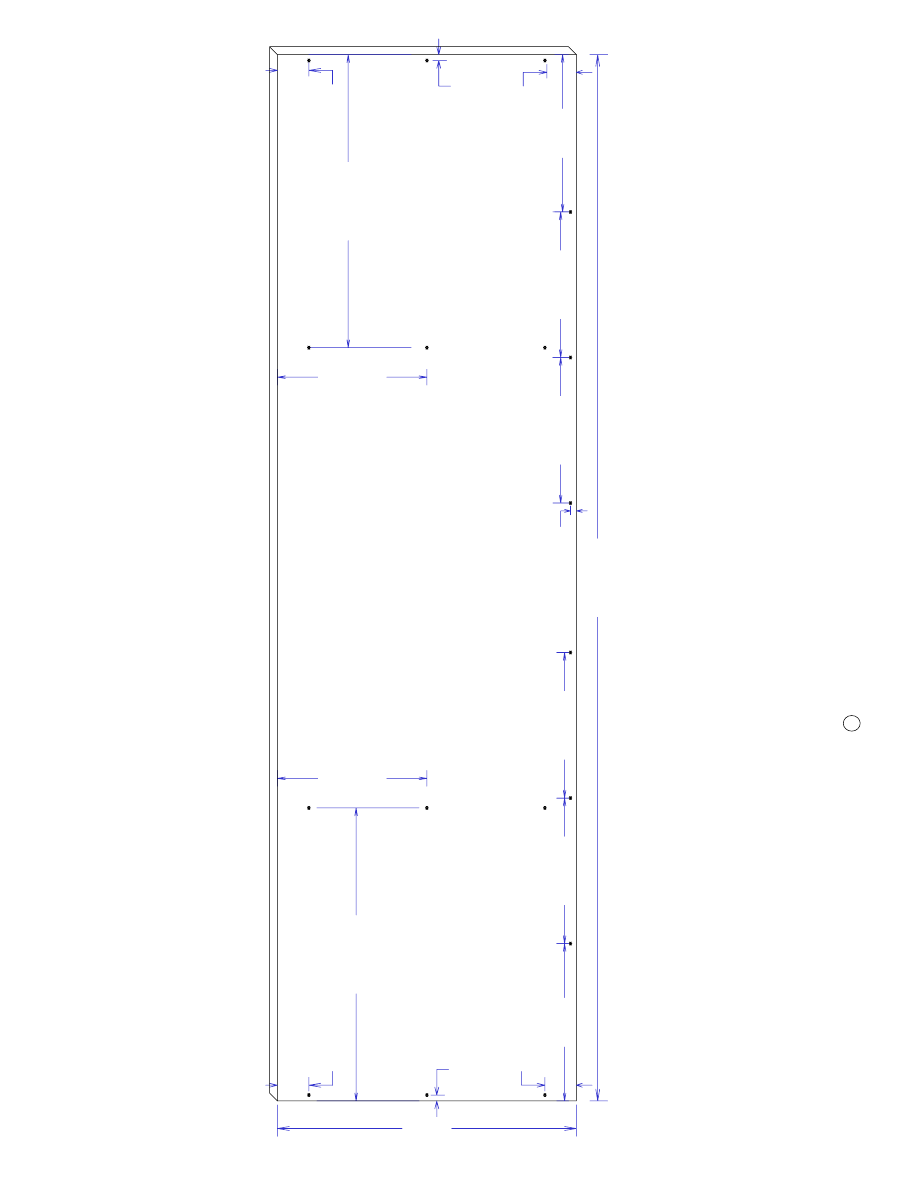

9 1/2"

9 1/2"

1

8

5

/8

"

19"

2

"

2

"

3

/8

"

2

"

3

/8

"

10"

9 1

/4

"

9 1/4

"

10"

9 1

/4

"

9 1/4"

3/8"

18

5/

8

"

2"

B

a

s

e

C

u

t

th

e

b

a

se

f

ro

m

3

/4

"

m

a

te

ri

a

l,

t

h

e

n

d

ri

ll

a

n

d

c

o

u

n

te

rs

in

k

h

o

le

s

fo

r

#

8

s

c

re

w

s

a

s

sh

o

w

n

i

n

th

e

d

ra

w

in

g

a

b

o

v

e

.

A

ll

t

h

e

s

c

re

w

s

a

ro

u

n

d

t

h

e

e

d

g

e

a

re

3

/8

"

fr

o

m

t

h

e

e

d

g

e

.

B

a

s

e

D

im

e

n

s

io

n

s

&

L

a

y

o

u

t

P

a

g

e

2

2

0

0

6

b

y

R

o

b

e

rt

E

.

R

e

e

d

y

,

V

a

n

d

a

lia

,

O

h

io

C

C

o

p

y

ri

g

h

t

66 1/2"

B

a

c

k

D

im

e

n

s

io

n

s

&

L

a

y

o

u

t

P

a

g

e

3

2

0

0

6

b

y

R

o

b

e

rt

E

.

R

e

e

d

y

,

V

a

n

d

a

lia

,

O

h

io

C

C

o

p

y

ri

g

h

t

B

a

c

k

1

7

1

/2

"

3

0

3

/4

"

1

7

1

/2

"

1 1/4"

3

/4

"

10"

17 1/8"

22"

28 1/4"

6

6

1

/2

"

C

u

t

th

e

b

ac

k

f

ro

m

3

/4

"

m

at

er

ia

l,

t

h

en

d

ri

ll

a

n

d

c

o

u

n

te

rs

in

k

h

o

le

s

fo

r

#

8

s

cr

ew

s

as

s

h

o

w

n

i

n

th

e

d

ra

w

in

g

a

b

o

v

e.

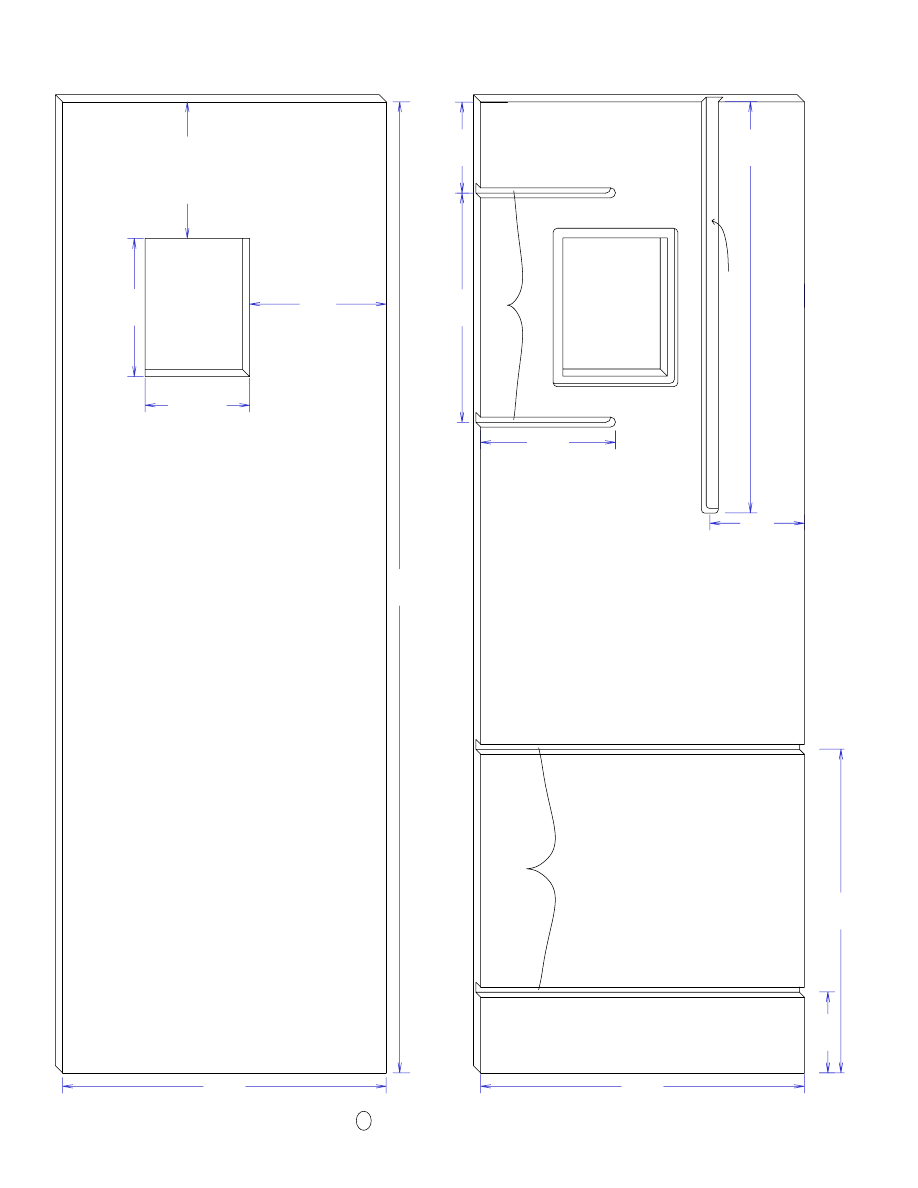

Top Dimensions and Layout

Page 4

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

T

h

is

d

ra

w

in

g

i

s

b

as

ed

o

n

a

9

1

/4

"

b

y

1

1

3

/4

"

ro

u

te

r

p

la

te

.

If

y

o

u

ar

e

u

si

n

g

a

d

if

fe

re

n

t

si

ze

p

la

te

,

y

o

u

w

il

l

n

ee

d

t

o

a

d

ju

st

t

h

e

si

ze

o

f

th

e

o

p

en

in

g

a

cc

o

rd

in

g

ly

.

T

h

e

ro

u

te

r

p

la

te

o

p

en

in

g

i

s

a

tw

o

s

te

p

p

ro

ce

ss

.

Y

o

u

m

u

st

c

u

t

an

i

n

n

er

o

p

en

in

g

t

h

at

l

ea

v

es

r

o

o

m

f

o

r

a

3

/4

"

w

id

e

li

p

a

ro

u

n

d

a

ll

f

o

u

r

ed

g

es

.

T

h

is

l

ip

i

s

w

h

at

t

h

e

ro

u

te

r

p

la

te

r

es

ts

u

p

o

n

.

F

ir

st

,

cu

t

th

e

in

n

er

o

p

en

in

g

c

o

m

p

le

te

ly

t

h

ro

u

g

h

t

h

e

to

p

.

If

y

o

u

'r

e

u

si

n

g

a

9

1

/4

"

b

y

1

1

3

/4

"

ro

u

te

r

p

la

te

,

th

is

i

n

n

er

o

p

en

in

g

s

h

o

u

ld

b

e

7

3

/4

"

b

y

1

0

1

/4

".

T

h

e

n

ex

t

st

ep

i

s

to

u

se

y

o

u

r

ro

u

te

r

to

c

re

at

e

th

e

li

p

a

ro

u

n

d

t

h

e

si

d

es

o

f

th

e

o

p

en

in

g

.

S

ee

t

h

e

d

et

ai

le

d

in

st

ru

ct

io

n

s

o

n

t

h

e

fo

ll

o

w

in

g

p

ag

e

fo

r

th

is

s

te

p

.

24"

72"

1

0

1

/8

"

1

0

1

/8

"

10 1/4"

7 3/4"

R

o

u

te

r

P

la

te

C

u

to

u

t

24"

7"

10"

6"

24"

F

e

n

c

e

T

-

T

ra

c

k

S

lo

t

T-Track & Miter Slot Cutout Dimensions

T

h

e

T

-T

ra

ck

a

n

d

m

it

er

g

au

g

e

sl

o

t

d

im

en

si

o

n

s

ar

e

b

as

ed

o

n

t

h

e

ce

n

te

r

o

f

th

e

sl

o

ts

.

H

o

w

ev

er

,

th

e

ex

ac

t

lo

ca

ti

o

n

o

f

th

es

e

it

em

s

is

st

ri

ct

ly

a

m

at

te

r

o

f

p

er

so

n

al

ch

o

ic

e.

30 1/2"

M

it

e

r

G

u

a

g

e

S

lo

t

If

y

o

u

w

il

l

b

e

u

si

n

g

a

re

ad

y

m

ad

e

ro

u

te

r

fe

n

ce

,

y

o

u

m

ay

n

ee

d

t

o

c

h

an

g

e

th

e

sp

ac

in

g

o

f

th

e

fe

n

ce

tr

ac

k

s

lo

ts

t

o

m

at

ch

y

o

u

r

fe

n

ce

.

T- Track Slot

T

-T

ra

ck

s

iz

es

v

ar

y

f

ro

m

b

ra

n

d

t

o

b

ra

n

d

.

T

h

e

m

o

st

c

o

m

m

o

n

s

iz

es

a

re

3

/4

"

w

id

e

b

y

1

/2

"

d

ee

p

o

r

3

/4

"

w

id

e

b

y

3

/8

"

d

ee

p

.

C

u

t

th

e

sl

o

ts

s

o

th

e

tr

ac

k

y

o

u

'r

e

u

si

n

g

i

s

fl

u

sh

w

it

h

t

h

e

to

p

su

rf

ac

e.

6 3/4"

17"

Sub Top Dimensions and Layout

Page 5

Drill and counter screwholes for #8 flathead screws in the locations shown below.

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

68"

19 3/4"

8"

R

o

u

te

r

B

o

x

C

u

to

u

t

18"

15 5/8"

N

o

te

:

T

h

is

d

ia

g

ra

m

i

s

b

a

s

e

d

o

n

a

9

1

/4

"

b

y

1

1

3

/4

"

ro

u

te

r

p

la

te

.

If

y

o

u

a

re

u

s

in

g

a

d

if

fe

re

n

t

s

iz

e

p

la

te

,

b

e

s

u

re

t

o

a

d

ju

s

t

th

e

o

p

e

n

in

g

s

iz

e

a

c

c

o

rd

in

g

ly

.

S

u

b

T

o

p

8 3/4"

10"

3

"

3

"

10"

3

"

3

"

3

"

3

"

1

1

/8

"

1

1

/8

"

1

1

/8

"

1

1

/8

"

S

u

b

T

o

p

S

c

re

w

H

o

le

L

a

y

o

u

t

S

c

re

w

H

o

le

L

a

y

o

u

t

R

o

u

te

r

B

o

x

C

u

to

u

t

19 3/8"

19 3/8"

14 5/8"

14 5/8"

9 1/2"

16"

26"

26"

16"

9 1/2"

2

0

0

6

b

y

R

o

b

e

rt

E

.

R

e

e

d

y

,

V

a

n

d

a

lia

,

O

h

io

C

C

o

p

y

ri

g

h

t

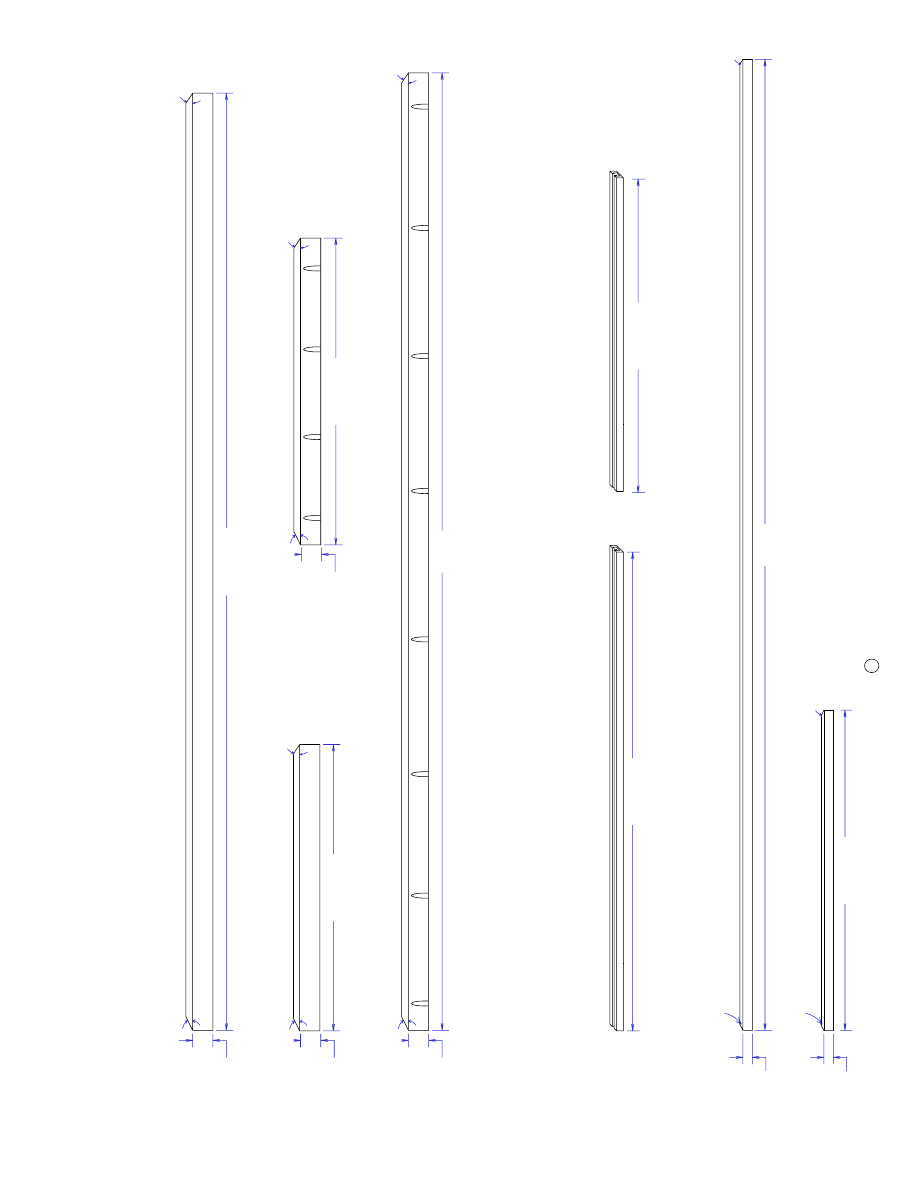

4

5

°

6

9

1

/2

"

4

5

°

1

s

t

F

ro

n

t

&

B

a

c

k

S

u

b

T

o

p

T

ri

m

(

2

R

e

q

u

ir

e

d

)

1 1/2"

T

h

e

S

u

b

T

o

p

t

ri

m

i

s

m

a

d

e

o

f

3

/4

"

th

ic

k

b

y

1

1

/2

"

h

ig

h

m

a

te

ri

a

l.

T

h

is

b

e

c

a

u

s

e

t

h

e

T

-T

ra

c

k

i

s

1

/2

"

b

y

3

/4

".

4

5

°

2

1

1

/4

"

4

5

°

1

s

t

E

n

d

S

u

b

T

o

p

T

ri

m

(

2

R

e

q

u

ir

e

d

)

1 1/2"

4

5

°

7

1

"

4

5

°

1 1/2"

2

n

d

F

ro

n

t

&

B

a

c

k

S

u

b

T

o

p

T

ri

m

(

2

R

e

q

u

ir

e

d

)

4

5

°

4

5

°

2

2

3

/4

"

1 1/2"

2

n

d

E

n

d

S

u

b

T

o

p

T

ri

m

(

2

R

e

q

u

ir

e

d

)

T

h

e

T

-T

ra

c

k

t

ri

m

i

s

m

a

d

e

o

f

1

/2

"

th

ic

k

b

y

3

/4

"

h

ig

h

m

a

te

ri

a

l.

T

h

is

b

e

c

a

u

s

e

t

h

e

T

-T

ra

c

k

i

s

1

/2

"

b

y

3

/4

".

3

/4

"

4

5

°

4

5

°

F

ro

n

t

T

-T

ra

c

k

T

ri

m

(

1

R

e

q

u

ir

e

d

)

7

2

"

3

/4

"

4

5

°

4

5

°

2

3

3

/4

"

E

n

d

T

-T

ra

c

k

T

ri

m

(

2

R

e

q

u

ir

e

d

)

3

5

1

/2

"

F

ro

n

t

T

-T

ra

c

k

(

2

R

e

q

u

ir

e

d

)

E

n

d

T

-T

ra

c

k

(

2

R

e

q

u

ir

e

d

)

23 1/4"

If

y

o

u

h

av

e

a

p

o

ck

et

h

o

le

j

ig

,

I

re

cc

o

m

m

en

d

d

ri

ll

in

g

p

o

ck

et

h

o

le

s

in

t

h

e

2

n

d

S

u

b

T

o

p

T

ri

m

p

ie

ce

s

as

s

h

o

w

n

.

T

h

es

e

p

o

ck

et

h

o

le

s

w

il

l

b

e

u

se

d

t

o

s

ec

u

re

t

h

e

T

o

p

t

o

t

h

e

S

u

b

T

o

p

.

T

h

e

ex

ac

t

lo

ca

ti

o

n

o

f

th

e

p

o

ck

et

h

o

le

s

is

n

o

t

cr

it

ic

al

.

T

h

e

im

p

o

rt

an

t

th

in

g

i

s

th

at

t

h

ey

d

o

n

o

t

li

n

e

u

p

w

it

h

t

h

e

sc

re

w

h

o

le

s

in

y

o

u

r

T

-T

ra

ck

.

If

y

o

u

d

o

n

o

t

h

av

e

a

p

o

ck

et

h

o

le

j

ig

,

th

e

T

o

p

c

an

b

e

se

cu

re

d

w

it

h

f

in

is

h

in

g

n

ai

ls

o

r

g

lu

e.

T

o

p

T

ri

m

&

T

-T

ra

c

k

P

a

g

e

6

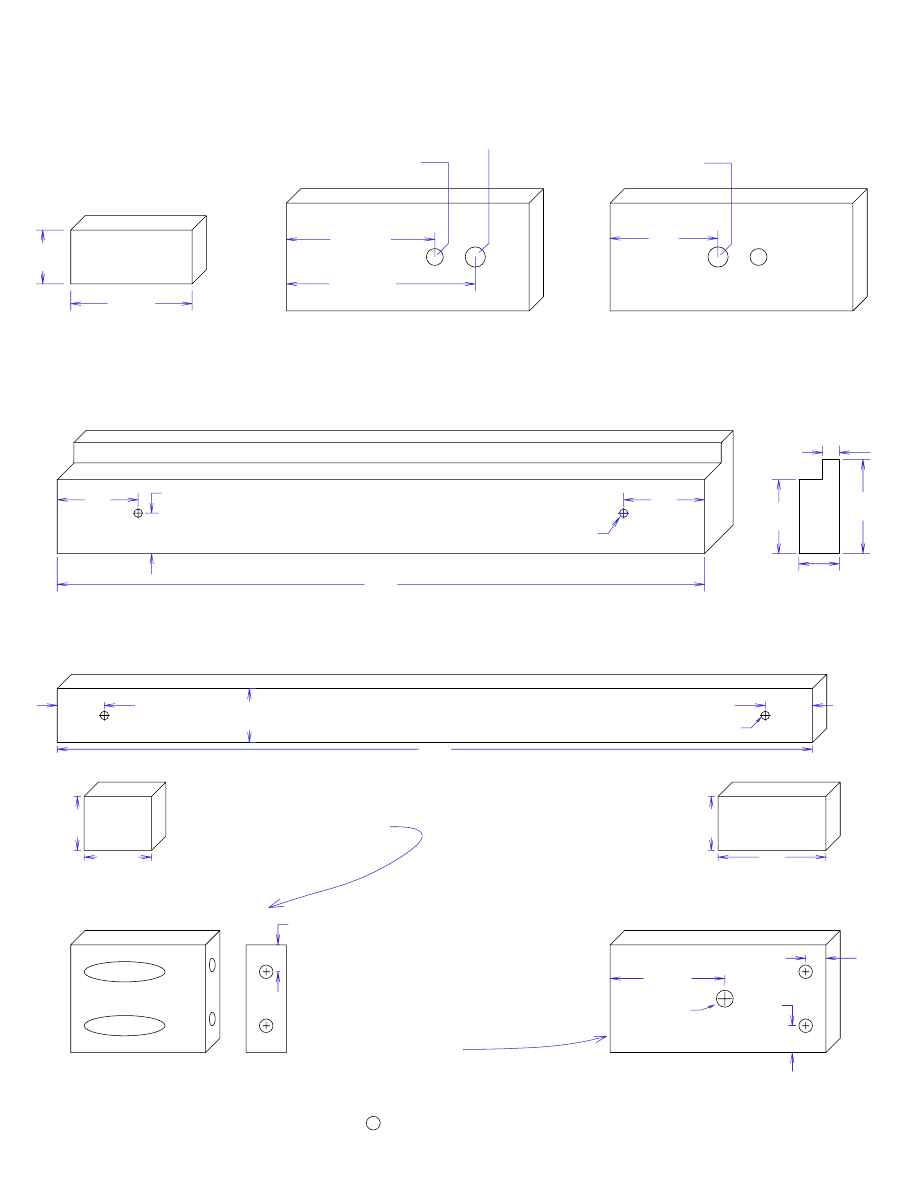

Center Lower Back Supports (1)

2"

27 1/2"

S

ti

ff

e

n

e

r

(M

a

k

e

t

h

e

s

ti

ff

e

n

e

r

fr

o

m

1

1

/2

"

th

ic

k

m

a

te

ri

a

l)

66 1/2"

3 1/2"

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

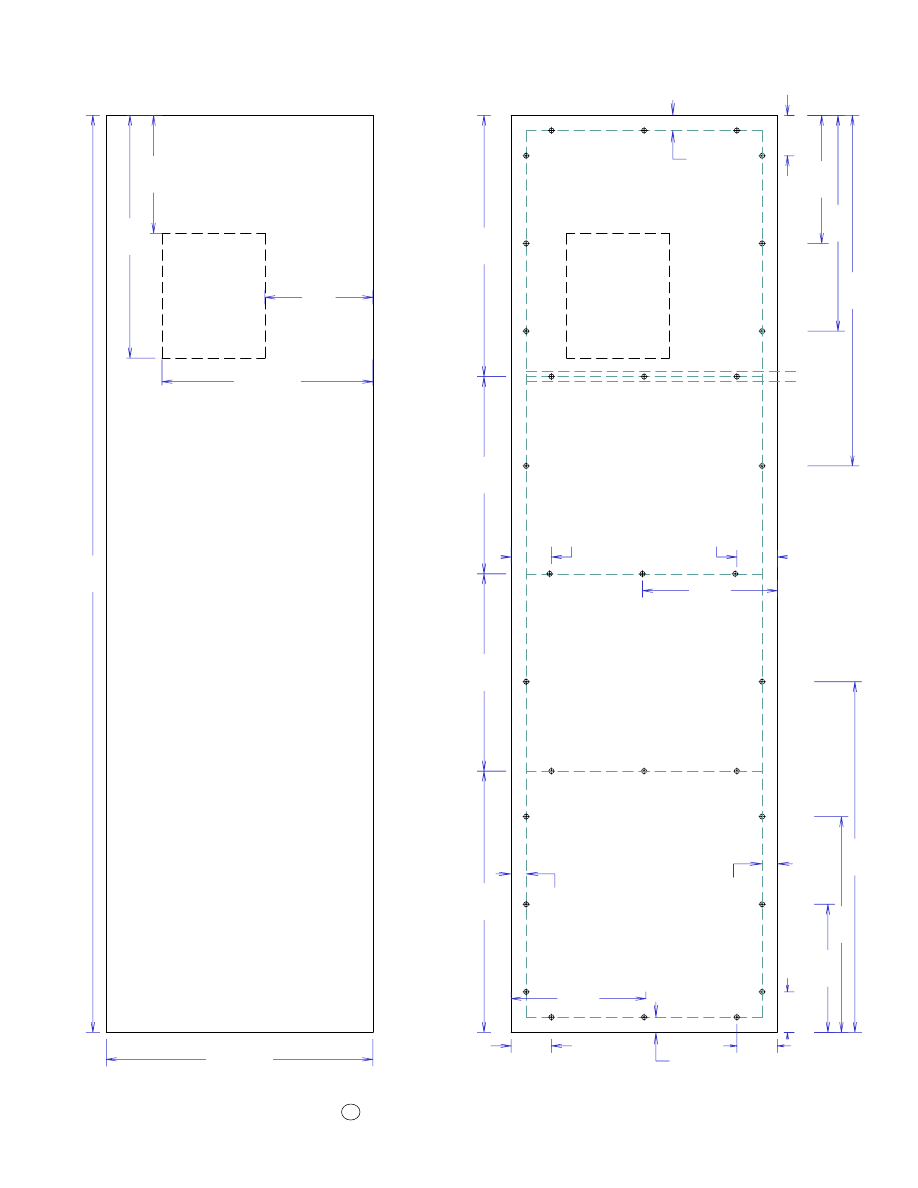

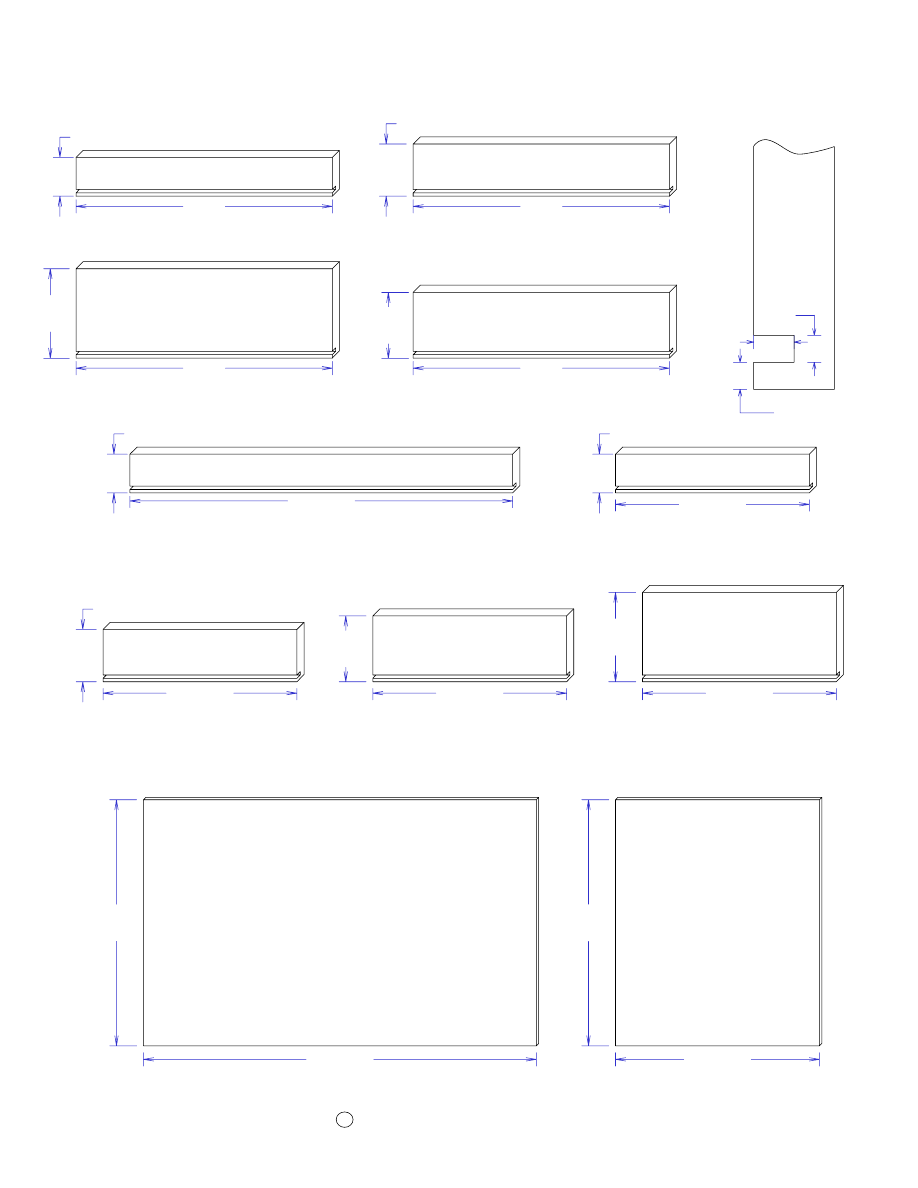

Drawer Slides / Stiffener / Misc Small Parts

18 1/4"

1 1/2"

Drawer Supports (17)

1 1/2"

6"

Small Drawer Supports (5)

2 1/2"

18 1/4"

Drawer Side Guides (10)

2 1/2"

6"

Small Drawer Side Guides (2)

18 1/4"

3"

Lower Drawer Side Guides (4)

2"

18 1/4"

Lower Drawer Supports (6)

Lower Back Supports (2)

2"

14 1/2"

1 1/2"

17 1/2"

17 1/2" Leveling Blocks (4)

16 3/4"

1 1/2"

16 3/4" Leveling Blocks (3)

30"

1 1/2"

30" Leveling Blocks (2)

1 1/2"

10 1/4" Leveling Block (1)

10 1/4"

Page 7

Drawer Fronts, Front Trim, and Doors

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

16 1/2"

7"

7" Drawer Fronts (2)

16 1/2"

5 1/4"

5 1/4" Drawer Fronts (2)

3 1/2"

Top Drawer Fronts (2)

16 1/2"

4 1/2" Drawer Fronts (2)

16 1/2"

4 1/2"

Cabinet Doors (2)

14 3/4"

19"

3 1/2"

30 1/2"

Center Drawer Front (1)

Router Box Bottom (1)

16"

11 1/2"

17 1/2"

11 1/2"

1"

3/4"

Router Box Front (1)

Drawer Fronts Dimensions

Router Box Dimensions

Page 8

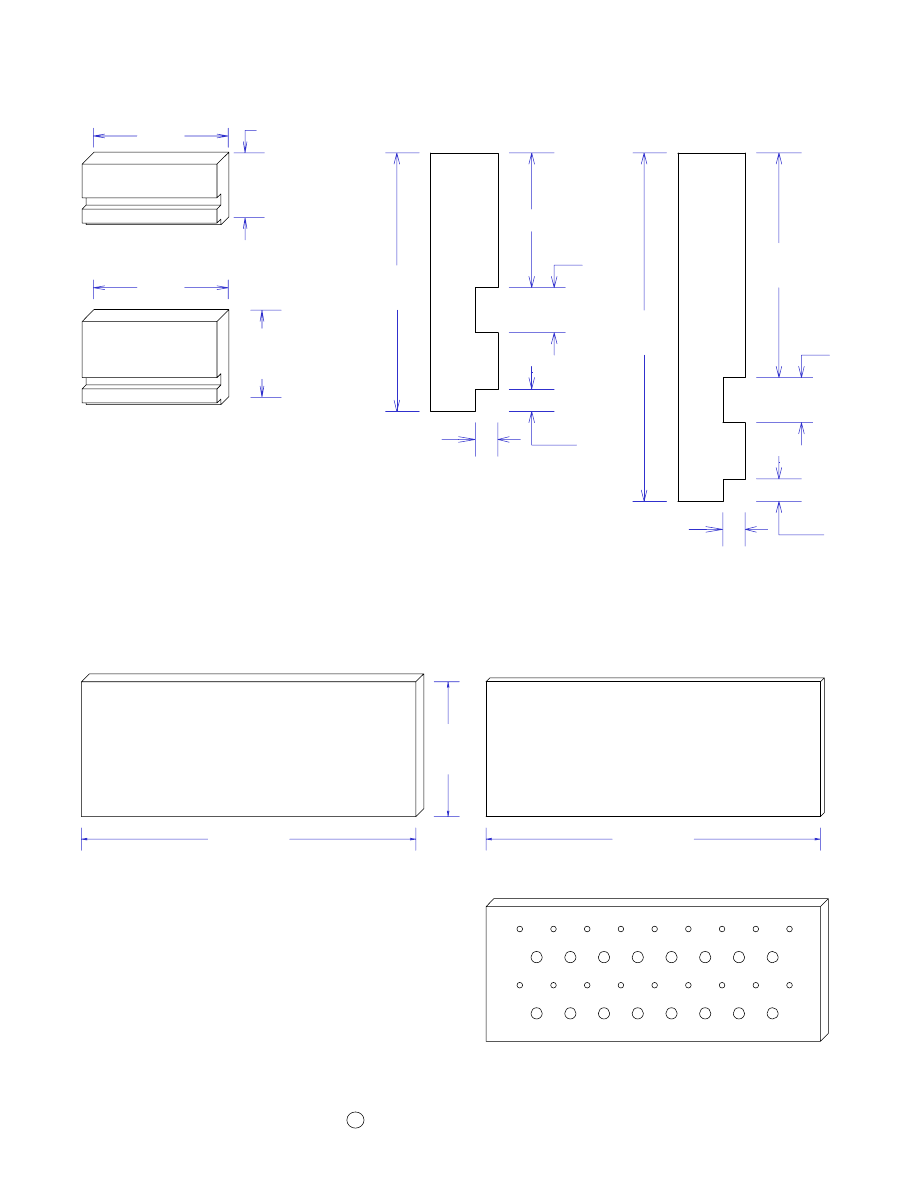

29 1/4"

1 1/2"

Vertical End Trim (2)

Drawer Trim (6)

1 1/2"

16"

Middle Trim (1)

1 1/2"

30"

23 1/4"

1 1/2"

Vertical Divider Trim (2)

Upper & Lower Trim (2)

65"

3"

18 1/2"

2"

Middle Door Trim (1)

2 7/8"

Center Drawer Ends (2)

28 3/8"

2 7/8"

14 3/8"

Top Drawer Ends (4)

14 3/8"

6 5/8"

6 5/8" Drawer Ends (4)

14 3/8"

3 7/8"

3 7/8" Drawer Ends (4)

14 3/8"

4 7/8"

4 7/8" Drawer Ends (4)

15 1/8"

Drawer Bottoms (6)

Center Drawer Bottom (1)

18 1/4"

29 1/8"

18 1/4"

Drawer Boxes Dimensions

Page 9

C

2006 by Robert E. Reedy, Vandalia, Ohio

Copyright

Top Drawer Sides (6)

2 7/8"

19"

19"

6 5/8"

6 5/8" Drawer Sides (4)

3 7/8" Drawer Sides (4)

19"

3 7/8"

19"

4 7/8" Drawer Sides (4)

4 7/8"

1/4"

3/8"

1/4"

D

e

ta

il

V

ie

w

-

D

ra

w

e

r

B

o

tt

o

m

C

u

to

u

t

6"

2 7/8"

Top Router Tray Sides (2)

6"

3 7/8"

2nd Router Tray Sides (2)

3 7/8"

1 1/2"

1/4"

1/4"

1/2"

T

o

p

R

o

u

te

r

T

ra

y

S

id

e

s

(

E

n

d

V

ie

w

)

1/4"

1/2"

2 1/2"

3 7/8"

1/4"

2

n

d

R

o

u

te

r

T

ra

y

S

id

e

s

(

E

n

d

V

ie

w

)

The tray sides are made from 3/4" material. The heights of

the sides are 2 7/8" and 3 7/8" respectively. This provides

1/8" of top clearance in the drawer openings.

Cut 1/2" wide by 1/4" deep slots for the router trays in the sides as

shown. Then cut a 1/4" rabbit on the bottom of each side as shown. The

1/4" rabbits are for the bottoms. The bottoms are necessary so the router

bits cannot protude past the bottom of the drawer opening.

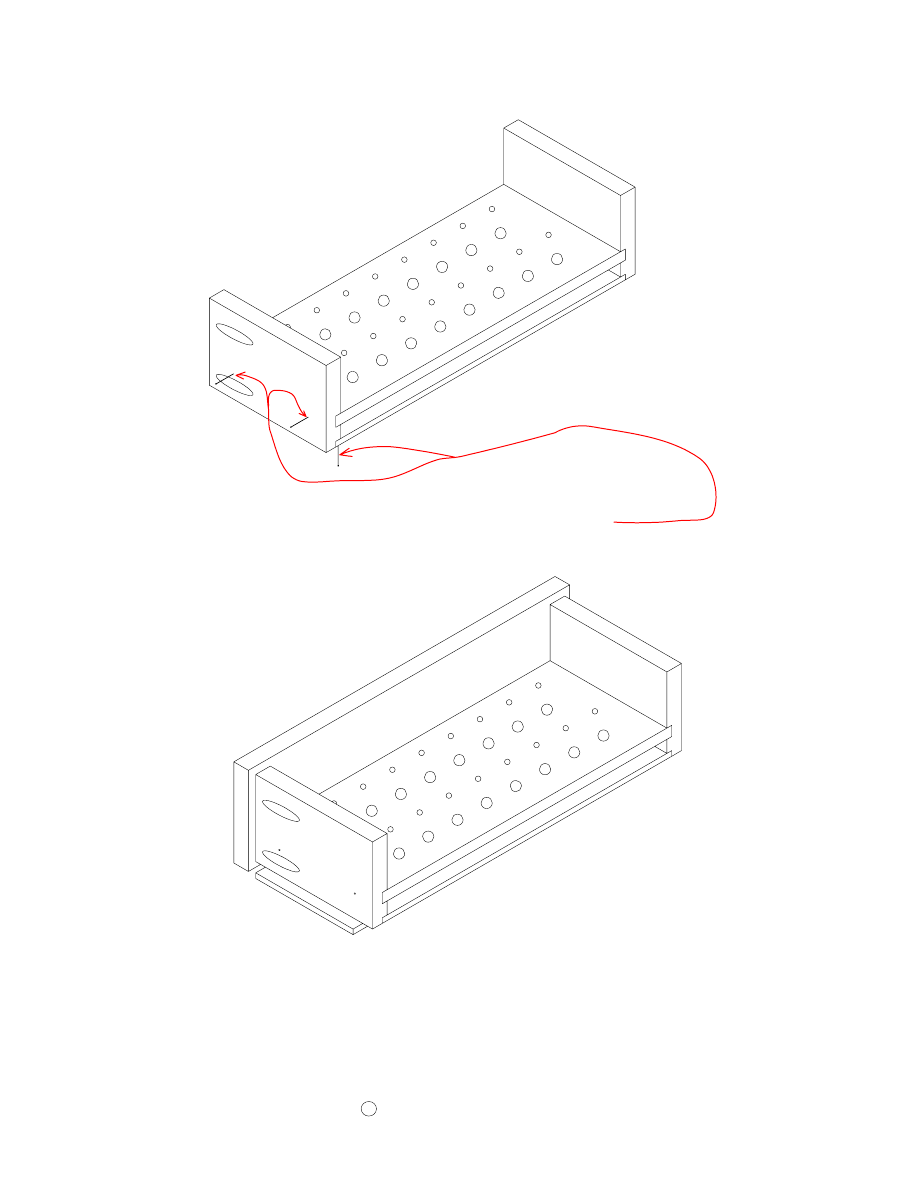

Router Bit Trays

Page 10

6"

14 7/8"

Cut two 6" by 14 7/8" router bits trays from

1/2" thick material and two bottoms from

1/4" thick material as shown above.

Drill several 1/4" and 1/2" holes for your

router bits in the 1/2" thick sections. The

exact location of the holes is strictly a matter

of preference. I put the holes about 1 1/2"

apart in the prototype.

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

14 7/8"

Router Bit Tray - Bottom (2)

1/4" thick material

Router Bit Tray (2)

1/2" thick material

Middle Shelves Dimensions

Page 11

18 1/4"

Middle Shelf

30"

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Lower Track Trim (2)

(Lower Track Trim is made of 1/2" thick material.)

18"

1"

18"

2 3/4"

Lower Track Support (2)

(Lower Track Support is made of 1 1/2" thick material.)

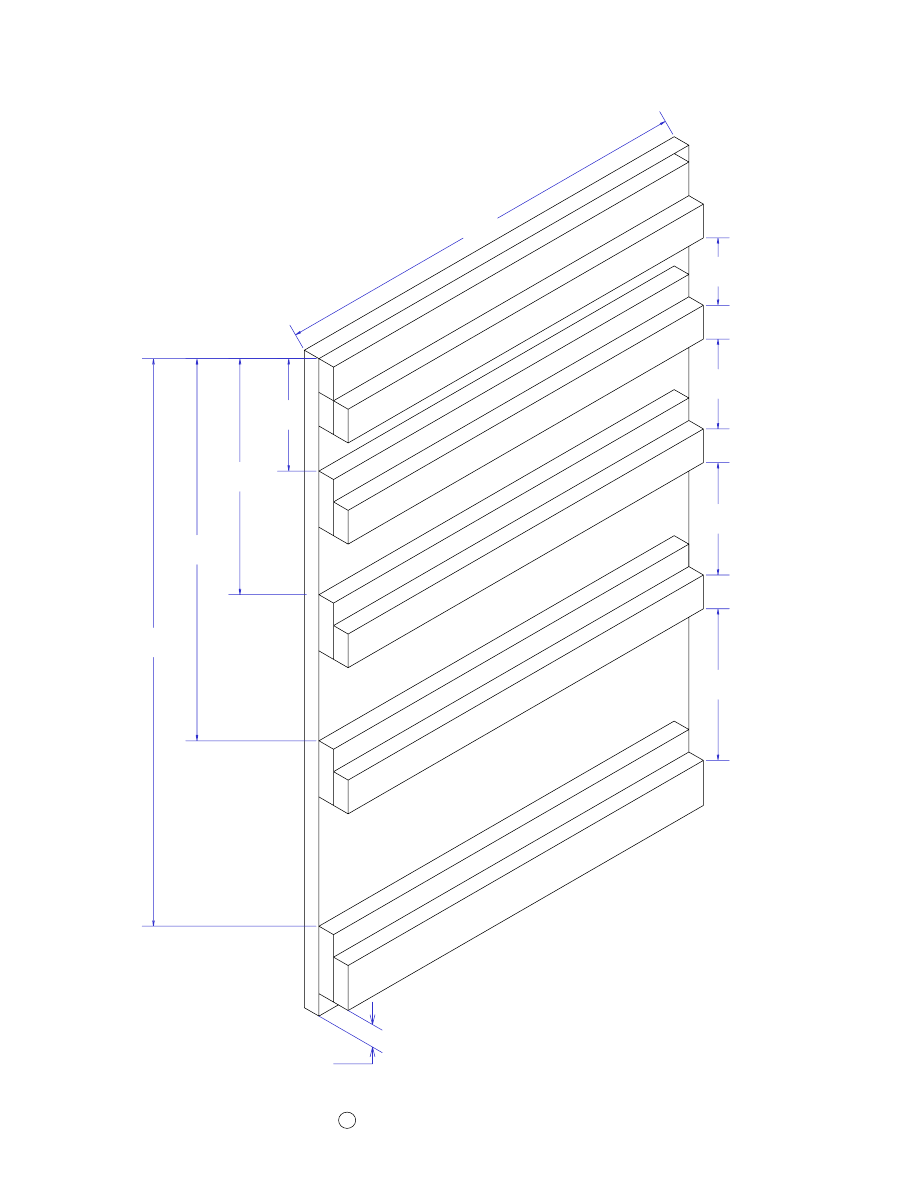

Attach Drawer Slides Left Section - Left Panel

Page 12

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

5"

17"

25 1/4"

19"

Le

ft E

nd

P

an

el

3"

4"

5"

6 3/4"

Dr

aw

er

Su

pp

ort

Dr

aw

er

Su

pp

ort

Lo

we

r D

raw

er

Su

pp

ort

Dr

aw

er

Su

pp

ort

Dr

aw

er

Sid

e G

uid

e

Dr

aw

er

Su

pp

ort

Le

ve

lin

g B

loc

k

1"

Lo

we

r D

raw

er

Sid

e G

uid

e

Dr

aw

er

Sid

e G

uid

e

Dr

aw

er

Sid

e G

uid

e

10 1/2"

Page 13

Attach Drawer Slides Left Section - Right Panel

5"

10 1/2"

17"

25 1/4"

3"

18 1/4"

Dra

wer

Su

ppo

rt

Dra

wer

Su

ppo

rt

Dra

wer

Su

ppo

rt

Low

er D

raw

er S

upp

ort

Dra

wer

Su

ppo

rt

Low

er D

raw

er S

ide

Gu

ide

Dra

wer

Sid

e G

uid

e

Dra

wer

Sid

e G

uid

e

Dra

wer

Sid

e G

uid

e

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Dr

aw

er

Su

pp

ort

Dr

aw

er

Su

pp

ort

Le

ve

lin

g B

loc

k

6"

13 3/4"

26 1/4"

Lo

we

r D

raw

er

Su

pp

ort

3"

6 1/4"

11"

Attach Drawer Slides Center Section - Left Panel

Page 14

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Left Inside Panel

Dra

wer

Su

ppo

rt

Dra

wer

Su

ppo

rt

Lev

elin

g B

lock

Low

er D

raw

er S

upp

ort

6"

13 3/4"

26 1/4"

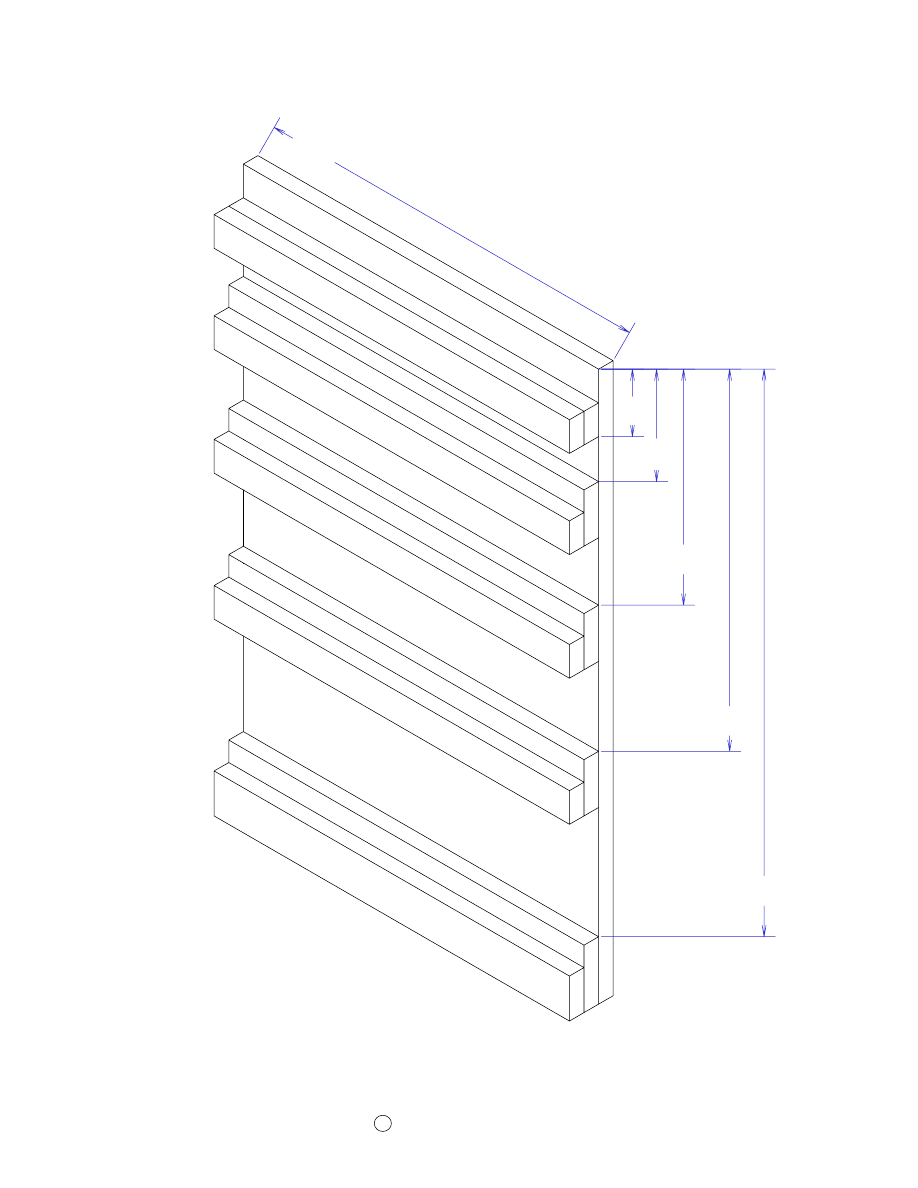

Attach Drawer Slides Center Section - Right Panel

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Right Inside Panel

Page 15

3"

3"

5"

10 1/2"

17"

25 1/4"

4"

Dr

aw

er

Sid

e G

uid

e

Dr

aw

er

Sid

e G

uid

e

Lo

we

r D

raw

er

Sid

e G

uid

e

Dr

aw

er

Su

pp

ort

Dr

aw

er

Su

pp

ort

Lo

we

r D

raw

er

Su

pp

ort

6"

Su

pp

ort

6"

Su

pp

ort

6"

Sid

e G

uid

e

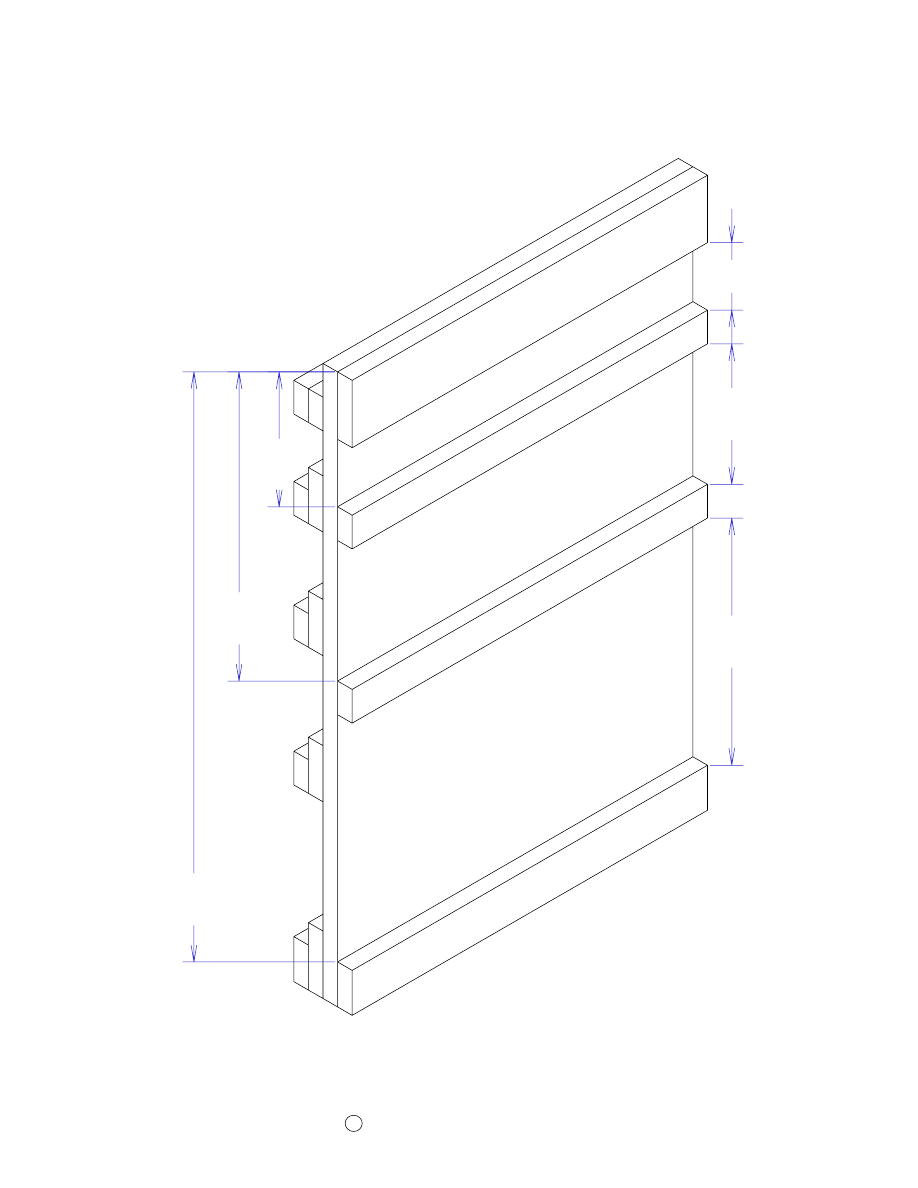

Attach Drawer Slides - Right Section - Left Panel

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Page 16

Right Section - Right Panel

3"

5"

10 1/2"

17"

25 1/4"

4"

5"

6 3/4"

Dra

wer

Sid

e G

uid

e

Dra

wer

Su

ppo

rt

Dra

wer

Sid

e G

uid

e

Dra

wer

Su

ppo

rt

Low

er D

raw

er S

ide

Gu

ide

Low

er D

raw

er S

upp

ort

6" S

upp

ort

6" S

ide

Gu

ide

6" S

upp

ort

6" L

eve

ler

1"

11 1

/2" L

eve

ler

Page 17

Attach Drawer Slides Right Section - Right Panel

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Panels to the Base

Page 18

17 1/2"

30"

17 1/2"

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

St

iffe

ne

r

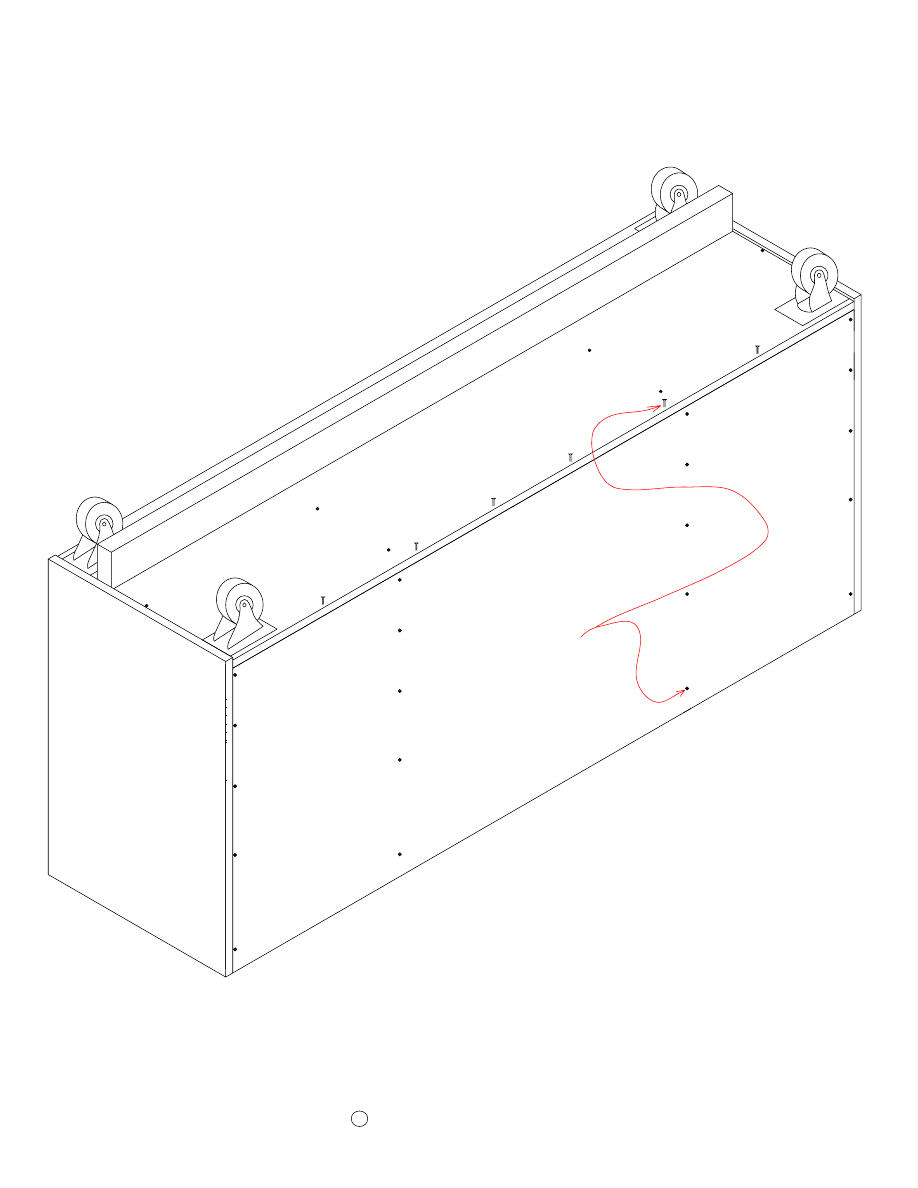

Attach the casters to the base as shown. Then position the stiffener as close

to the front as possible while still allowing clearance for the swival casters

to rotate. Mark the position of the stiffener, then drill about six holes for #8

wood screws through the base. Apply some glue and secure the stiffener to

the base with 2" #8 screws.

The screw heads will be inside cabinet below the drawers so it doesn't

matter if you use flathead or pan head screws..

Attach theStiffener & Casters to the Base

Page 19

At

tac

h t

he

ba

ck

to

th

e v

ert

ica

l p

an

els

an

d b

ase

w

ith

1

1/2

" #

8 f

lat

he

ad

sc

rew

s a

s s

ho

wn

.

Attach The Back

Page 20

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

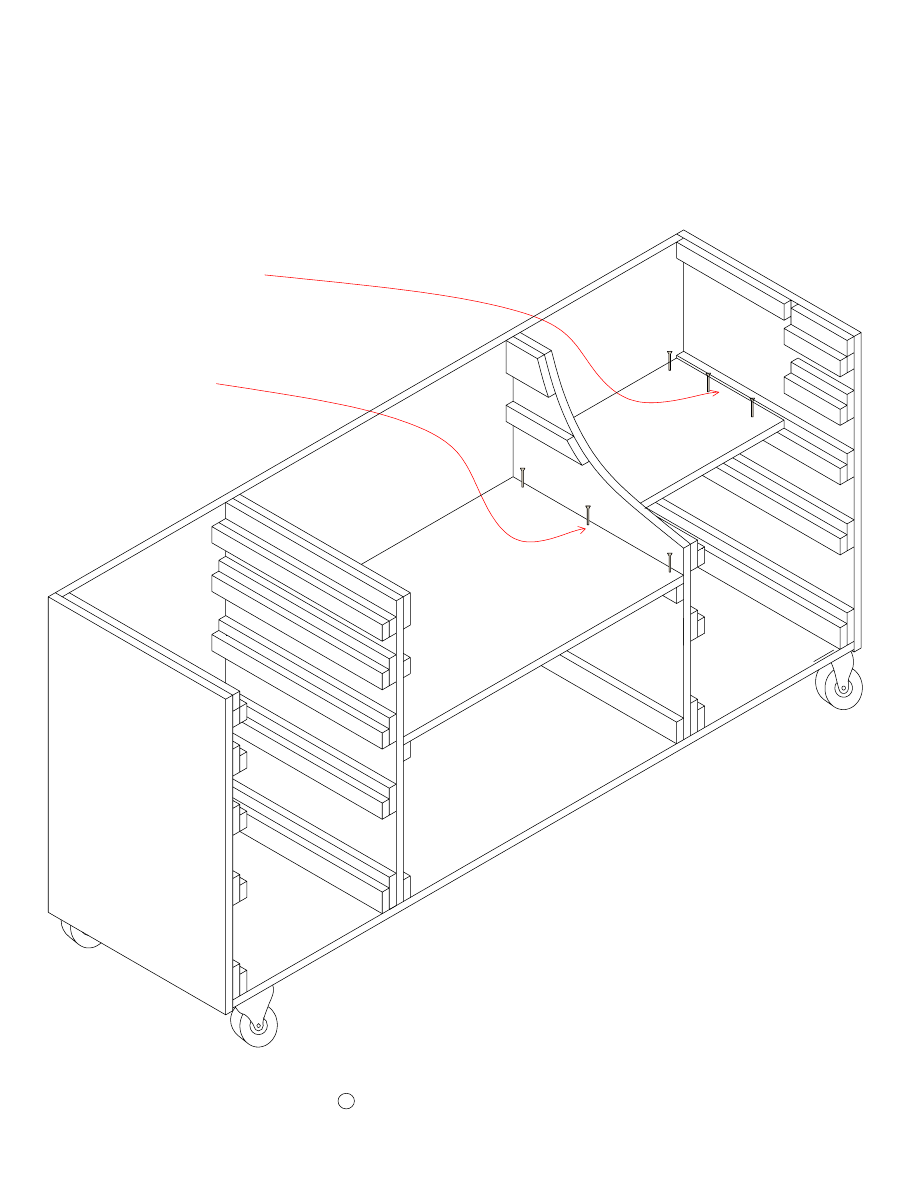

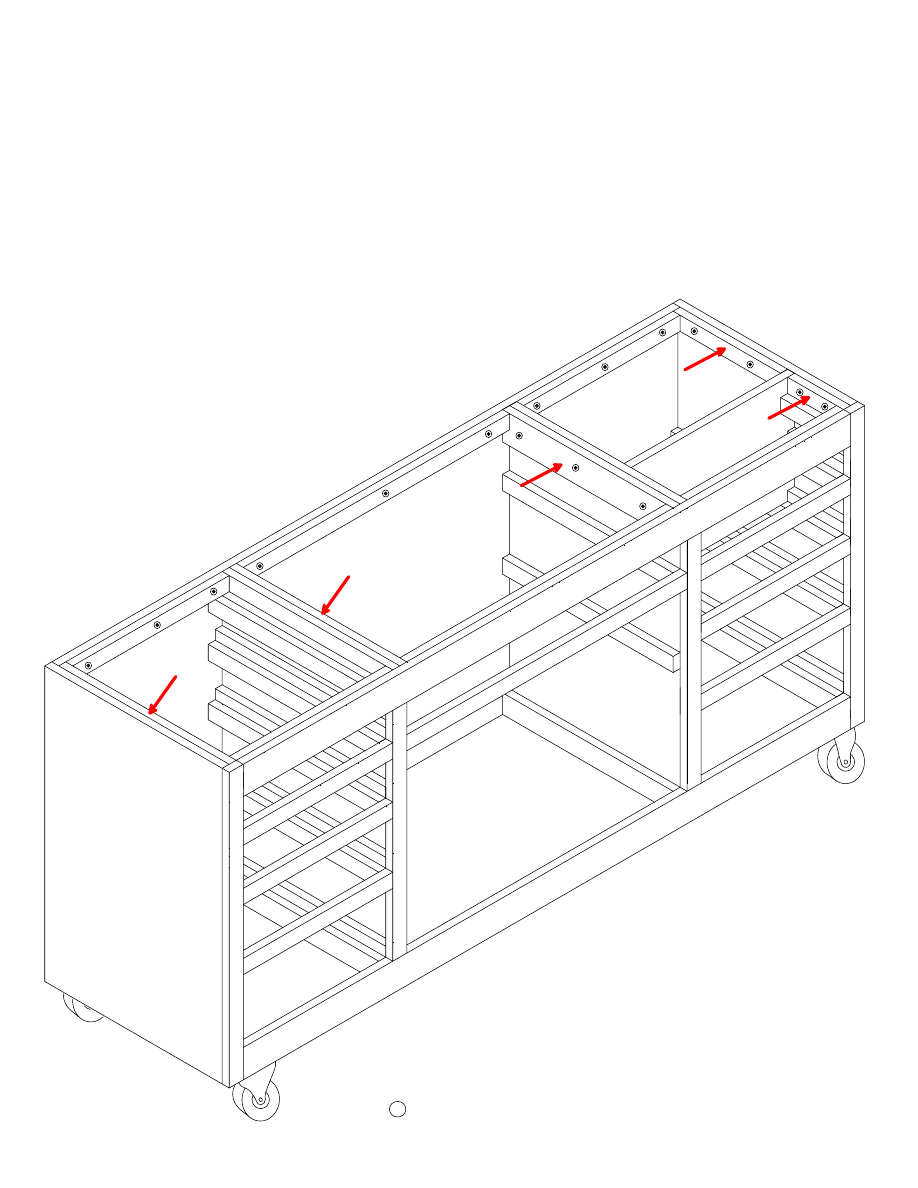

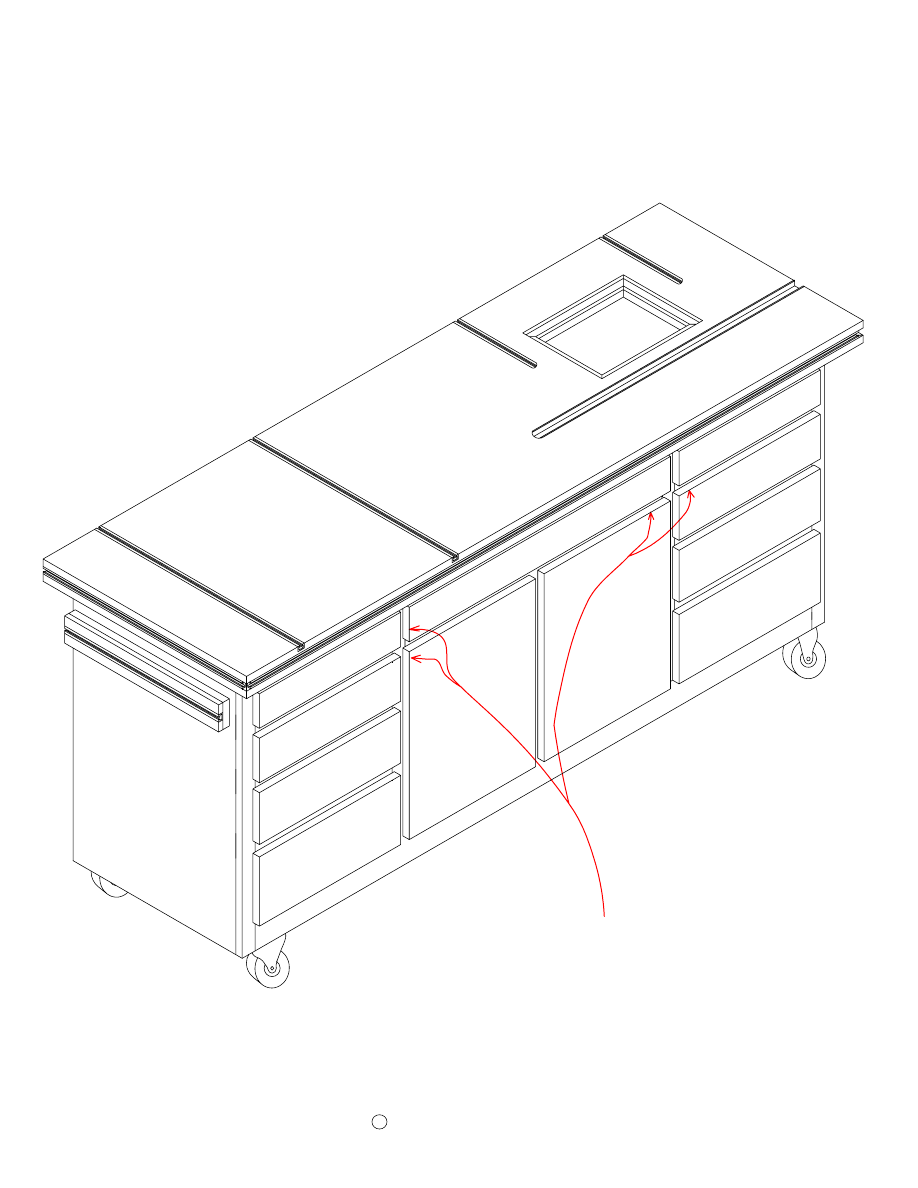

Attach the router box bottom to the

drawer slides.

Attach the middle shelf to the

supports.

Ro

ute

r B

ox

B

ot

tom

Mi

dd

le

Sh

elf

Attach the Router Box Bottom & Middle Shelf

Page 21

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

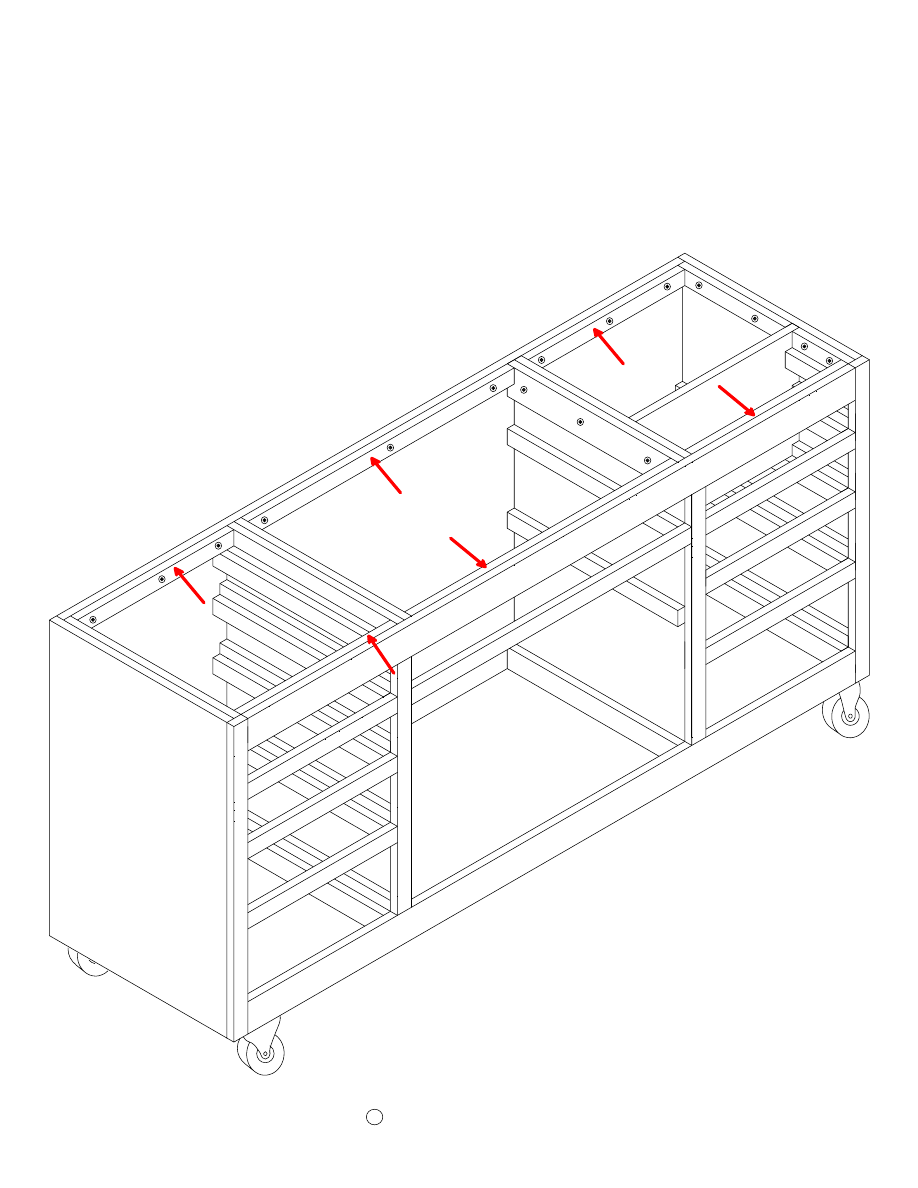

Attach the router box front to the

router box bottom and to the rear end

surface of the drawer slides.

Attach the Router Box Front

Page 22

Assemble the Face Frame

Page 23

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

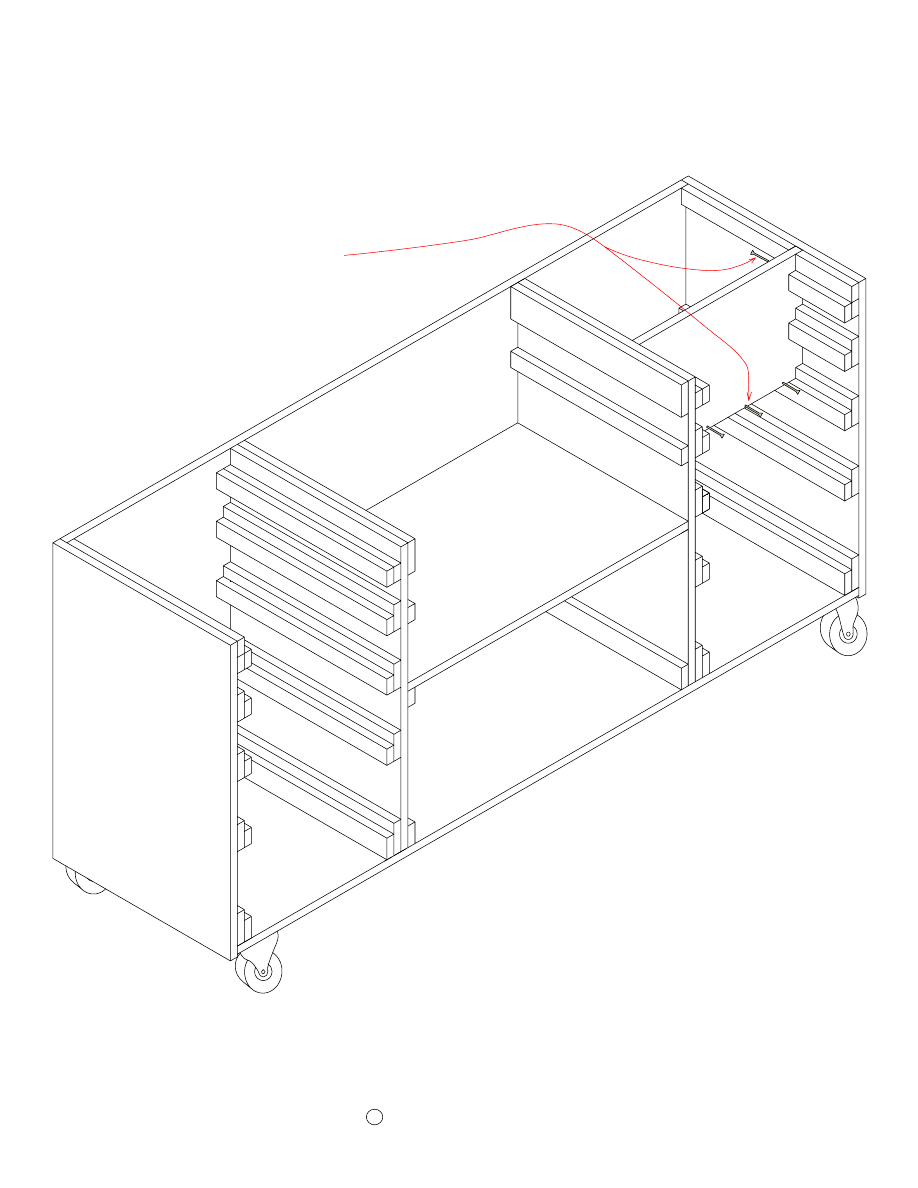

Assemble the front trim pieces (face frame) as shown. Be sure the horizontal

drawer separator pieces are properly spaced so they line up with the drawer

slides.

The top of each piece of horizontal drawer separator trim should be flush with

the top of a drawer slide.

Pocket holes are the easiest way to join trim or face frames as they are often

called. if you don't have a pocket hole jig, you can use dowel joints.

Don't forget! The pocket holes go on

the back side of the face frame.

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the FaceFrame to the Cabinet

Page 24

Attach the assembled face frame to

the cabinet with finishing nails.

Then, countersink and fill the nail

holes with wood putty.

When all the blocks are level, tighten the screws and

recheck that they did not move.

Now, you are ready to attach the leveling blocks. This is the way you ensure that the top is perfectly flat

when the workbench is completed. First, drill three 1/4" diameter holes completely through each leveling

block, (the two shortest ones only need two holes). The exact location of the holes is not critical. Drill a

hole about 2" from each end and one in the middle of each leveling block. To keep the glue from setting

before you're finished, it's best to attach the end and center panel leveling blocks first and ensure they are

level with each other before attaching the front and rear ones.

After all the blocks are in place, use a

straight edge to ensure the top surfaces of all

the leveling blocks are level with each other.

If you have a four foot level, that would

work great.

Apply some glue to the mating faces and attach the end and center panel

leveling blocks using 1 1/2" #8 pan head screws with flat washers as

shown. Do not tighten the screws yet as the blocks must be leveled first.

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

The important thing is that the top surfaces

of the leveling blocks be level with each

other. This will provide a flat surface to

mount the sub top to.

Attach the Leveling Blocks to the End and Center Panels

Page 25

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Front & Rear Leveling Blocks

Page 26

Apply glue to the mating surfaces and attach the front and rear leveling blocks as shown in the diagram.

Use your straight edge to ensure the tops are even with the tops of the end and center leveling blocks.

Then tighten the screws.

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

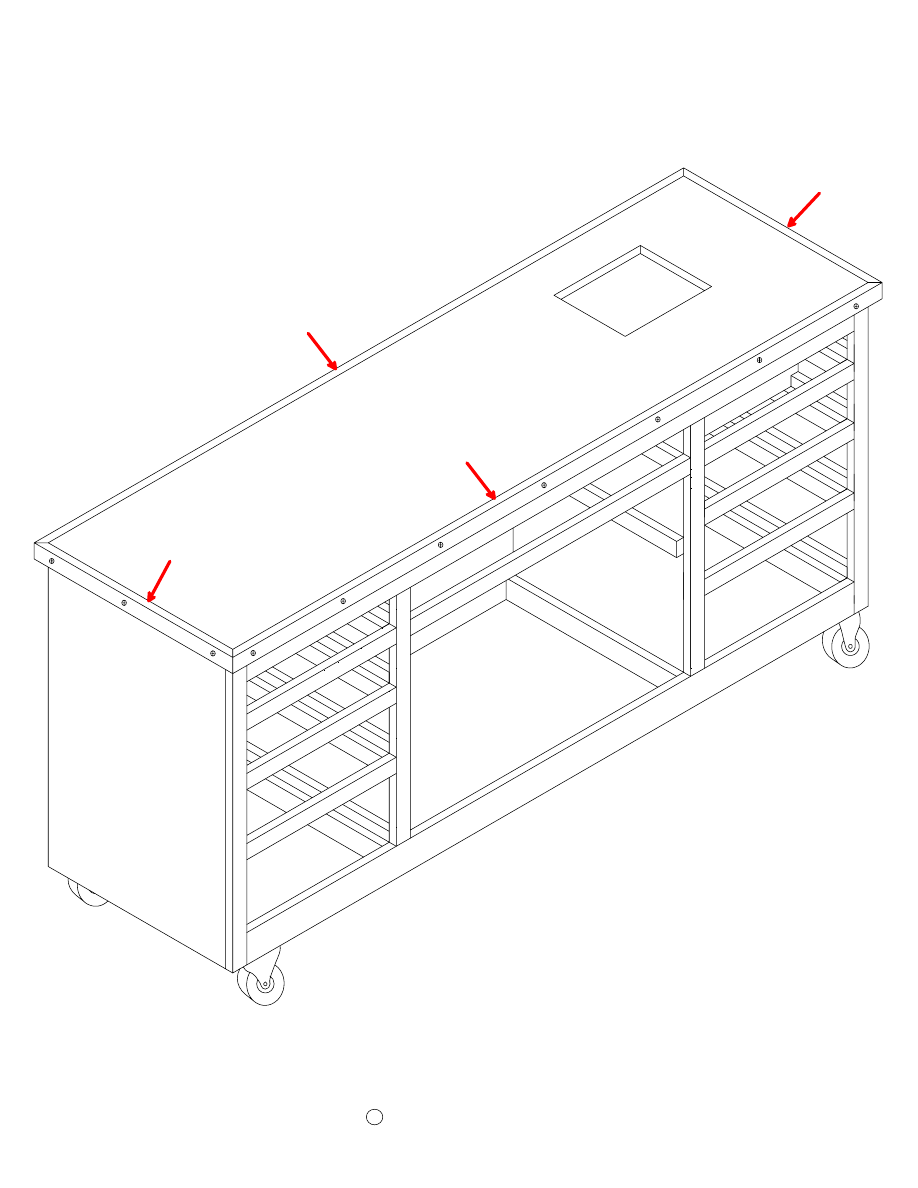

Attach the Sub Top with 1 1/2" #8

flathead screws. The Sub Top should

be flush to the edges of the cabinet

on all four sides.

Attach the Sub Top to the Cabinet

Page 27

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Inner Sub Top Trim to the Sub Top

with 1 1/2" #8 flathead screws. Be sure the top

of the trim is flush with the top surface of the

Sub Top.

Attach the Inner Sub Top Trim

Page 28

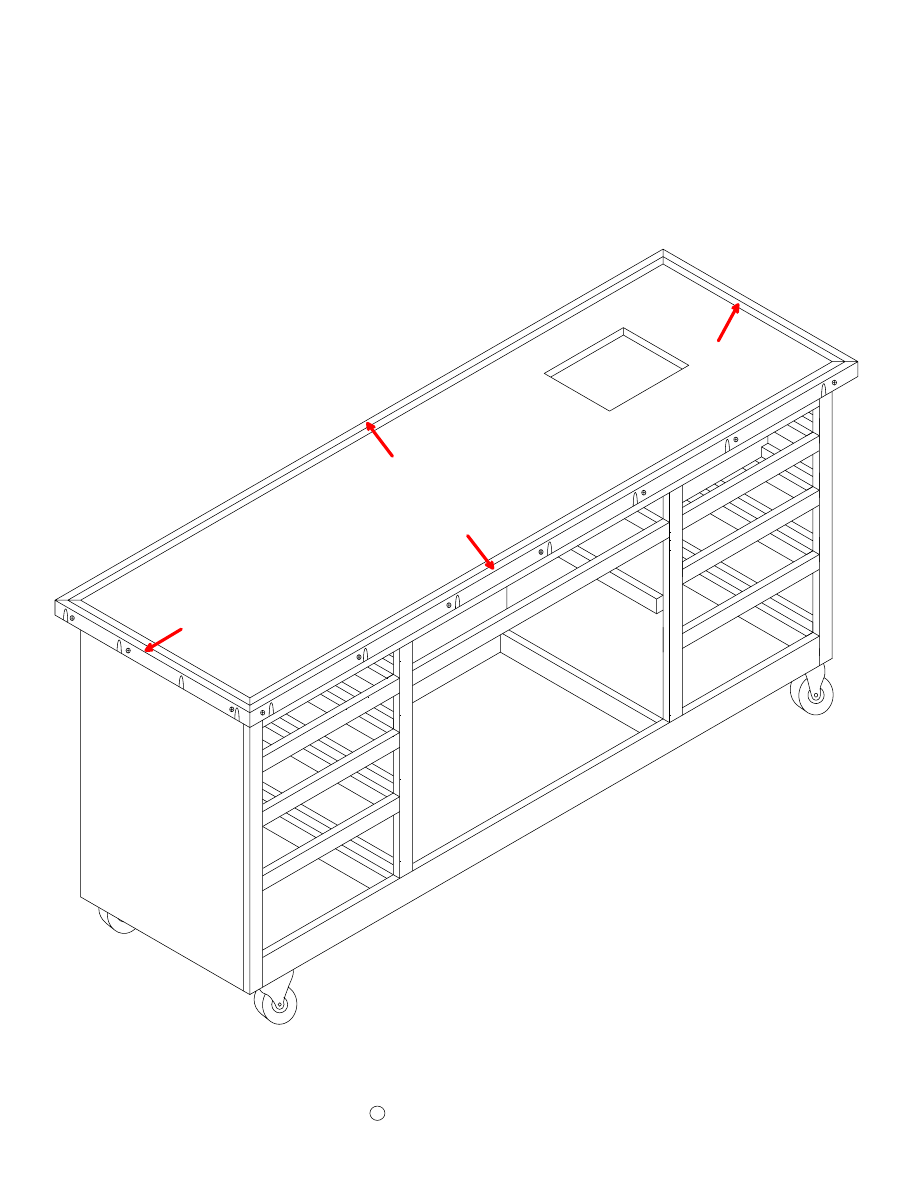

Attach the Middle Trim to the Inner Sub Top Trim

Page 29

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Middle Sub Top Trim to the Inner Sub Top

Trim with 1 1/2" #8 flathead screws. Be sure to space

these screws so they don't interfere with the screws in

the inner trim or the T-Track which will be attched to the

Middle Sub Top trim. The pocket holes will be used to

attach the edges of the top to the trim.

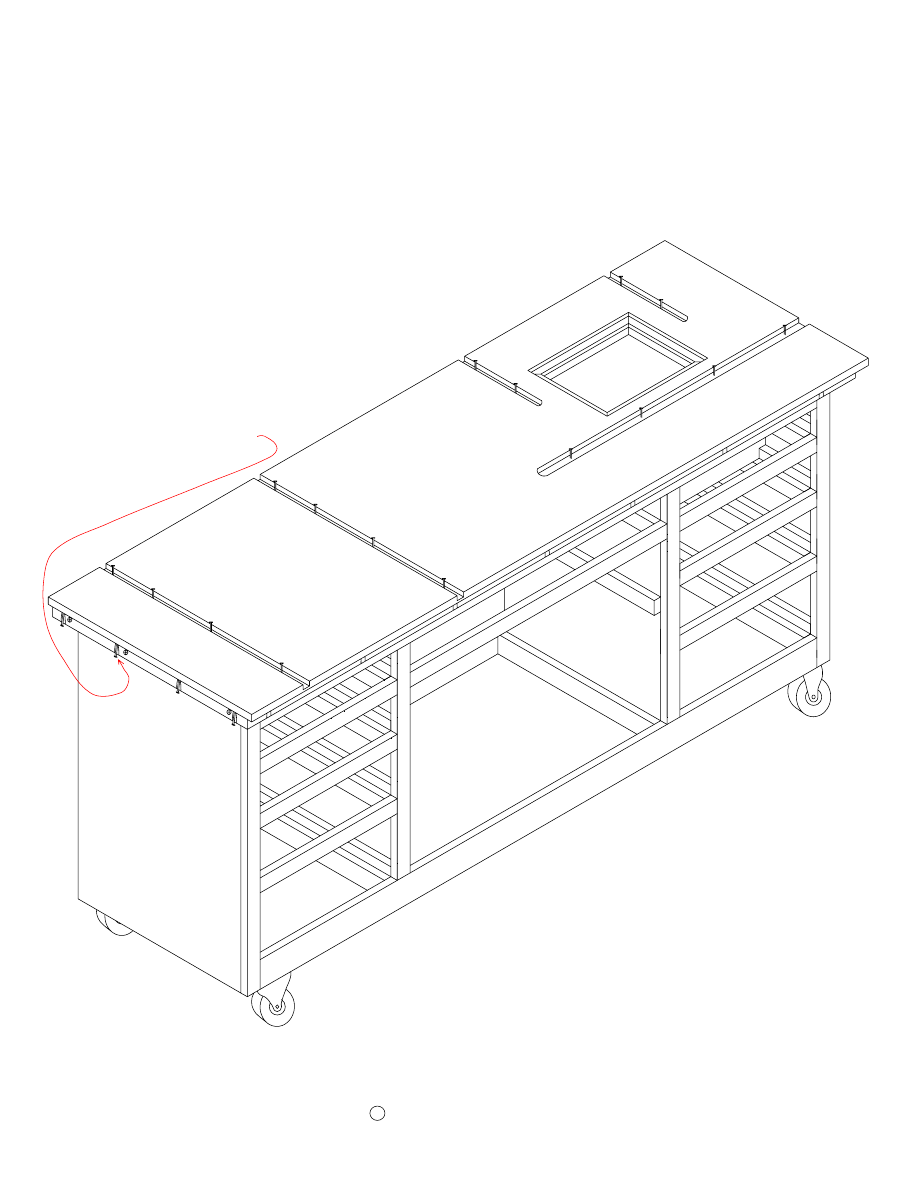

Attach the Top to the Sub Top

Page 30

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Pocket Hole Screws

Attach the Top to the Sub Top with 1" #8 flathead screws through the cutouts for the T-Track and Miter

guage track. Secure the edges of the top with pocket hole screws through the holes you drilled through

the Inner Sub Top Trim. If you don't have a pocket hole jig, you can glue the Top to the Sub Top.

However, gluing it will make it much more difficult to replace the top in the future if you need to.

Note: The dimensions given in these plans are

based using T-Track that is 3/4" wide and 1/2"

thick. If your T-Track is a different size, you will

need to modify the thickness of the inner trim

accordingly.

Attach the T-Track & Miter track to the Top

Page 31

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Lower Track Support to the left side

of the cabinet with six 2" #8 flathead screws.

Position this piece so it is 1" below the Sub Top

Trim and centered front to back.

Attach the T-Track to the top as shown with 1" #6 screws. Some manufacturers countersink the holes for

mounting the track and others do not. From my experience, I prefer flathead screws with countersunk

holes. This keeps the screw heads from interfering with the bolts sliding through the track. The track I

used for the prototype was designed for pan head screws, so I countersunk them on my drill press.

The miter guage track is not subject to much stress so you can glue it in the slot. If you use screws, be

sure the screw heads are below the surface so the miter guage does not hang up on them. I would not

reccommend polyurethane glues because they expand as they set up. The expanding glue would lift the

miter track up above the surface of the workbench top. A construction adhesive like liquid nails works

fine.

Top T-Track

Miter Guage Track

Attach the T-Track to the Edges of the Front and Ends

Page 32

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the edge T-Track on each end and along the front to the middle Sub Top Trim with 1" #6 screws.

Position this T-Track under the bottom surface of the Top as shown in the detail drawing.

T-Track joins at the corners like

this so you can slide the bolts in

and out.

End T-Track

Front T-Track

End T-Track

Detail

Attach the Lower T-Track to the Lower T-Track

Support. The T-Track should be centered top to

bottom.

Attach the Lower Front Trim to the Front and Ends

Page 33

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Detail

Attach the Lower Top Trim on each end and along the front to the middle Sub Top Trim with 1 1/2"

finishing nails.

If you cut the top a little larger than the dimensions called for, you can trim it with your router and a

flush trimming bit. Use the Lower Top Trim for the bit bearing to follow.

The Lower Top Trim joins at

the corners like this.

Lower Trim

Attach the Lower Track Trim with finishing

nails.

Lower Trim

Step 2

Step 3

Left Side

Step 1

Right Side

Front

Back

Step 5

Step 4

Support the drawer boxes with 1/4" thick strips of wood and attach the drawer fronts

with 1 1/8" screws as shown. This is necessary because the bottom of the front must

be 1/4" below the bottom of the box so it will overlap the rear cabinet trim when

installed.

Apply a little glue to the mating surfaces and assemble the drawer boxes.

Assemble the front, back, and right side with finishing nails as shown in Step 1.

Insert the bottom as shown in Step 2. Attach the left side as shown in Step 3.

Assemble the Drawers

Page 34

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Assemble the Router Bit Trays

Page 34

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

Attach the drawer fronts to the router tray fronts with pocket hole screws on each side as shown.

Don't forget to support the trays with 1/4" thick strips of wood while you attach the fronts. As with

the drawers, the bottom of the fronts must be 1/4" below the bottom of the trays so the fronts will

overlap the cabinet trim when installed.

Assemble the Router trays with finishing nails as shown above.

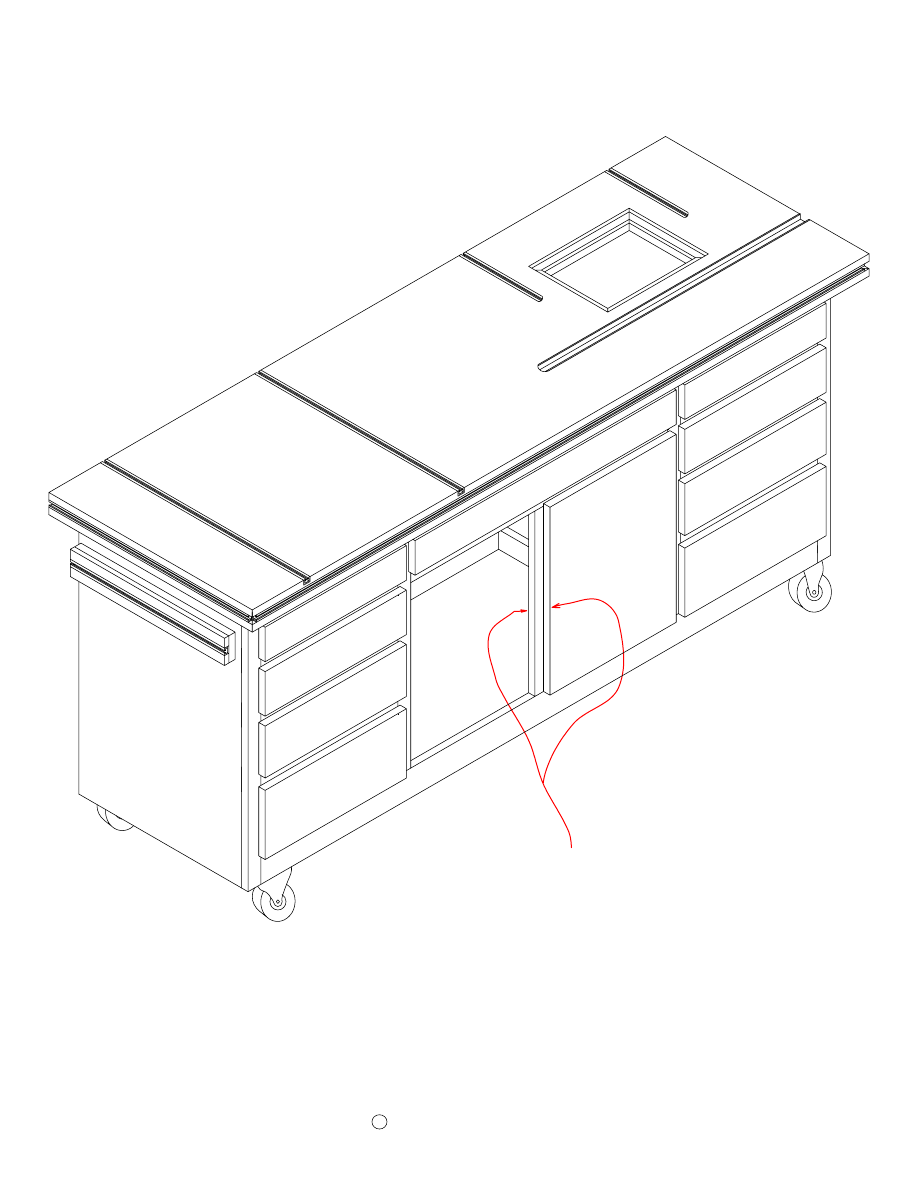

Attach the Cabinet Doors

Page 36

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the cabinet doors so the tops align with the tops of the

drawers and the sides align with the ends of the middle drawer as

shown above.

Attach the Middle Door trim

Page 37

Copyright

2006 by Robert E. Reedy, Vandalia, Ohio

C

Attach the Middle Door Lip to the back of either of the cabinet

doors so half of it is visible as shown. Attach it to the back of the

door with a couple of 1" wood screws. The left door is not

pictured in the drawing for clarity.

This piece serves as a door lip so there is no visible gap between

the doors.

Now, you're ready to attach the Drawer and Door handles and your work bench is finished.

Clamping System Parts

Page 38

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

"

2

3/8" Button Hole

Clamp Jaw Layout (Side 2)

"

2 3/4

5/16" Bolt Hole

3/8" Button Hole

"

3 1/2

Clamp Jaw Layout (Side 1)

2"

4 1/2"

Clamp Jaws (2)

5/8"

3 1/2"

1 1/2"

2 3/4"

E

n

d

V

ie

w

3"

3"

1 1/2"

Rear Stop

Dia - 5/16"

24"

Dia - 5/16"

1 3/4"

1 3/4"

2"

28"

EZ Clamp Stop

Post (2)

2"

2 1/2"

Drill two pocket holes in each Post as shown below. Next, drill two

1/4" diameter holes in the end of each Post as shown. (The 1/4" holes

should only be 1/2" deep.)

2"

4"

Jaws (2)

1/2"

Posts

Dia - 5/16"

1/2"

3/8"

Jaws

"

2 1/4

Drill a 5/16" bolt through each jaw as

shown. Next, drill two 5/16" holes for the

dowel pins in each Jaw as shown. (The

dowel pin holes are 5/16" diameter so the

Jaws can pivot over the pins. These holes

should be 1/2" deep.)

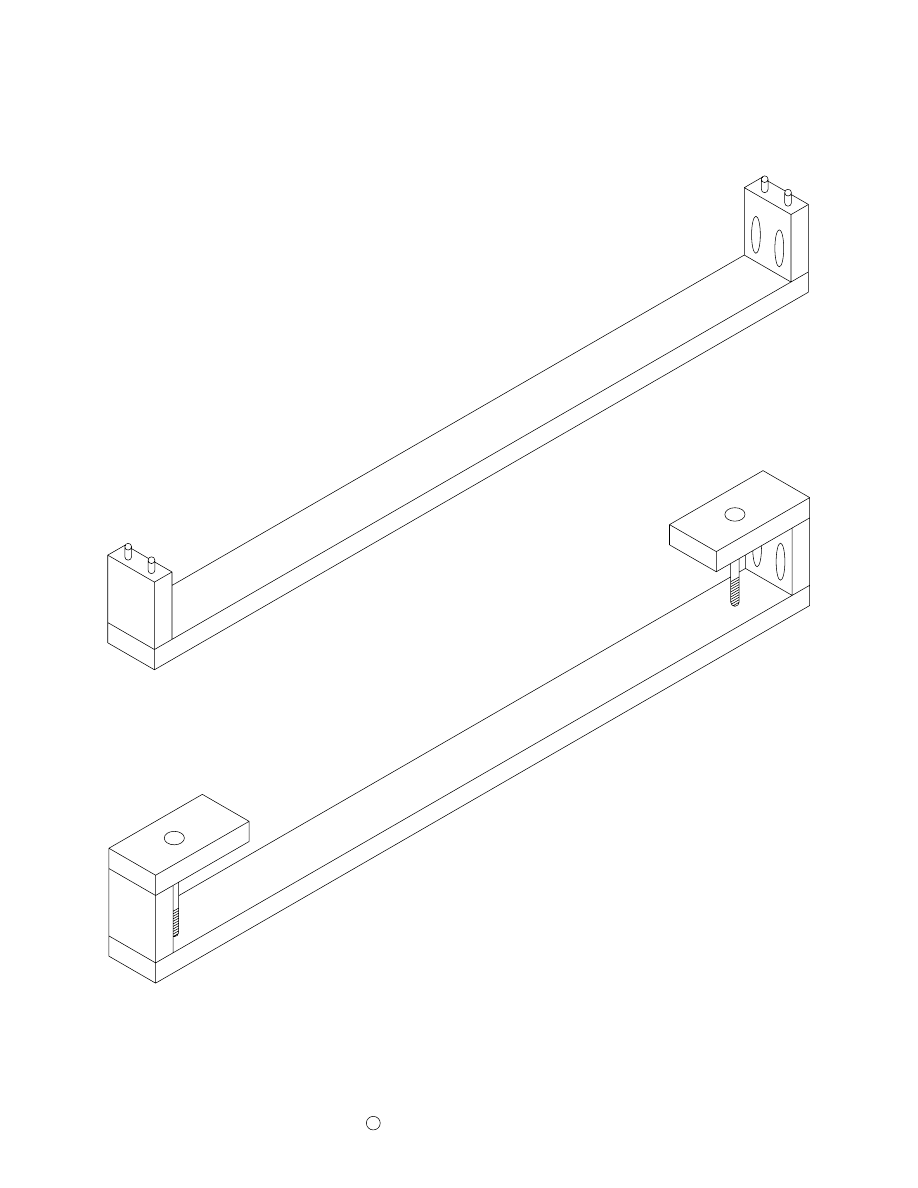

Assemble the EZ Mount Stop

Page 39

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

Attach the Posts to the ends of the Stop Bar with pocket hole screws as

shown below. Next, cut four 7/8" long dowel pins from 1/4" dowel

rod. Apply some glue and insert a 1/4" dowel pin into each hole in the

ends of the Posts. (The dowel pins should protude about 3/8" from the

ends of the Posts.)

Place the Jaws over the protuding dowel pins as shown above. (Do not

glue the dowel pins to the Jaws as the Jaws must be allowed to pivot

in order to work as clamps.) Insert a 5/16 carriage bolt through the

holes as shown. (The carriage bolt should be 5" long. Secure the

pieces with a flat washer and knob.

Clamping System Usage

Page 40

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

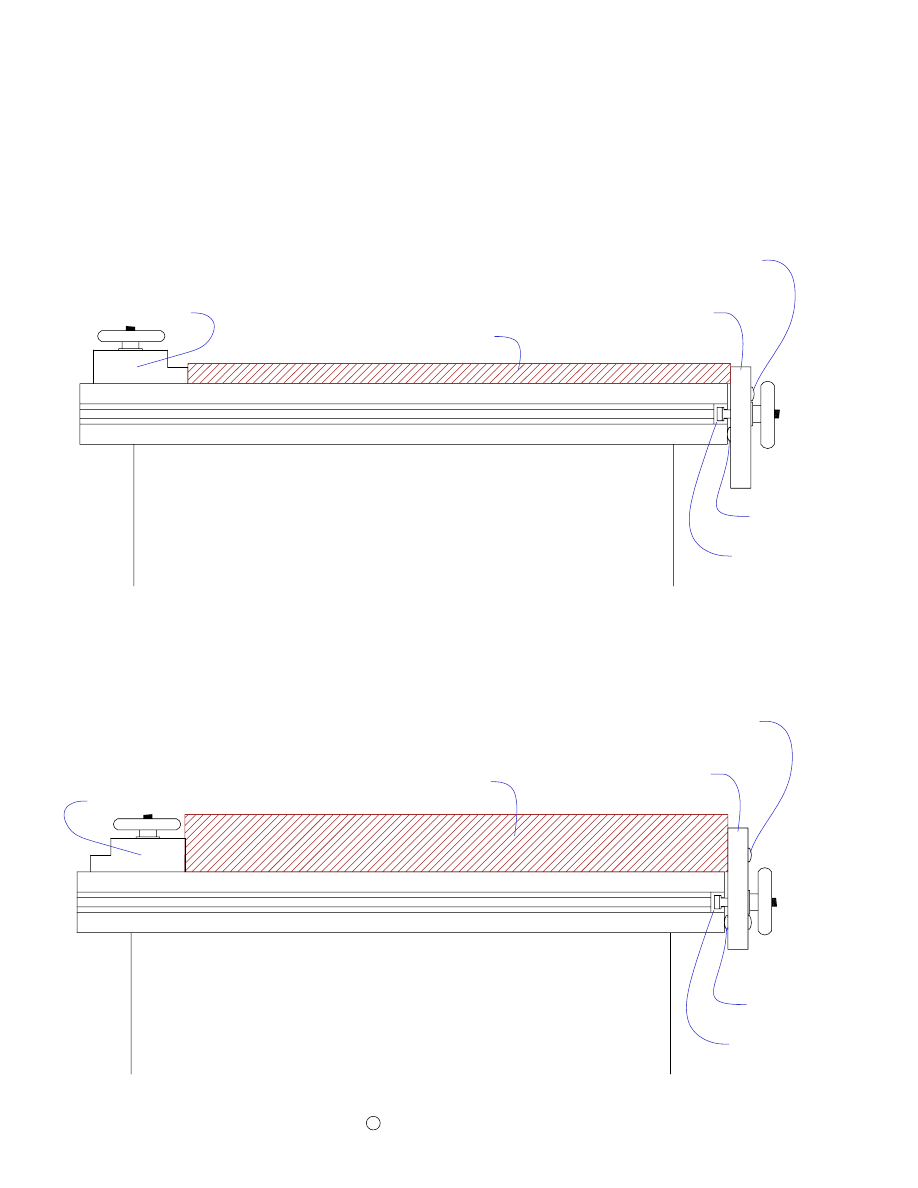

The T-Track clamping system provides a flexible way of clamping both large and small

work pieces. Most work pieces can be clamped using the two Clamp Jaws and the Rear

Stop. The Clamp Jaws are used with the T-Track that runs along the front edge of the

workbench. The Rear Stop is used with the T-Track that is embedded in the top surface of

the workbench.

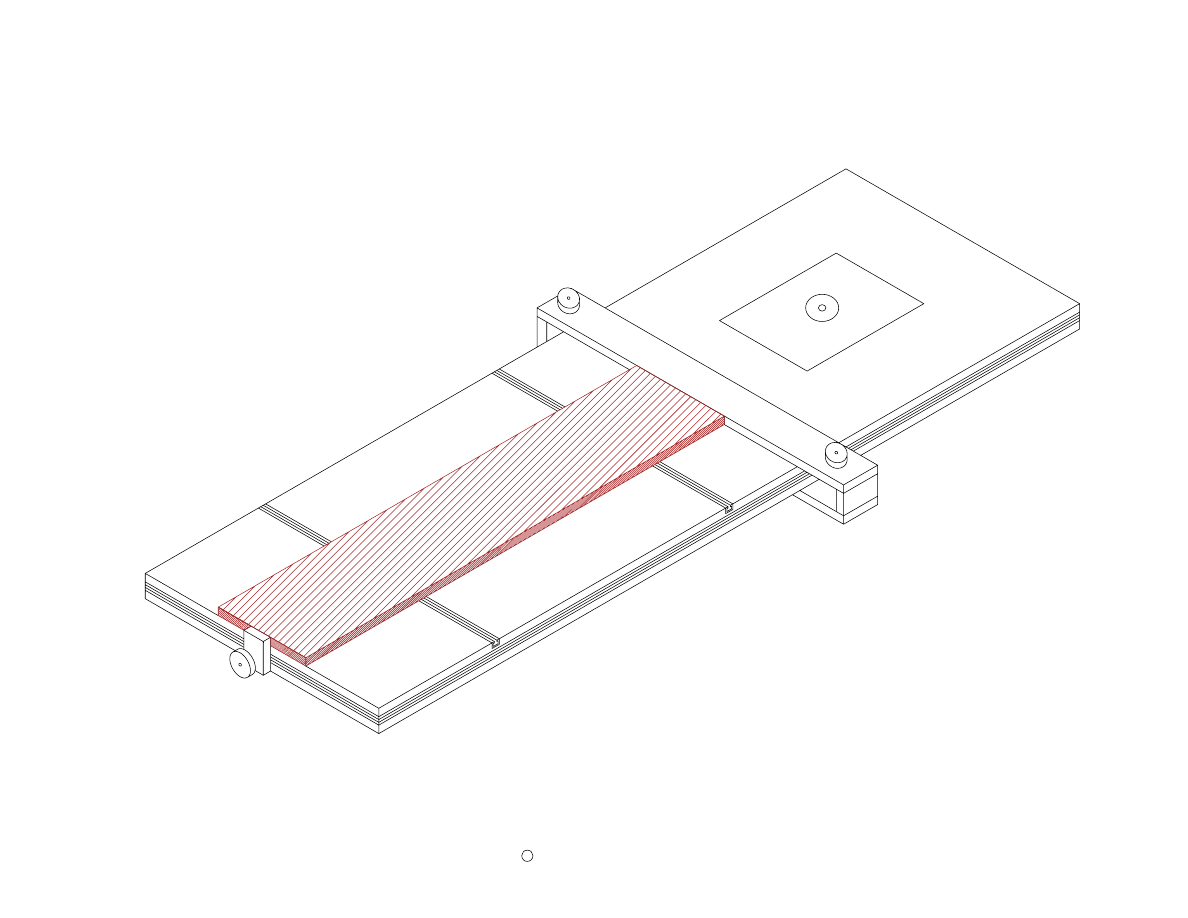

For longer workpieces, you can use the the Clamp Jaws with the T-Track on the ends of the

workbench. The EZ Mount Stop may be secured anywhere along the workbench top. The

simple clamps on each end of the EZ Mount Stop grip the edge of the workbench top as

well as C-Clamps. This feature enables you to use the workbench as a large bar clamp for

gluing up boards.

You can make the clamping system grip the work piece even tighter by gluing strips of 100

grit sandpaper along the edges that contact the workpiece. The sandpaper requires much

less force than the surface of bare wood.

The button arrangement on the Clamp Jaws allows you to filp the Clamp Jaws over for

thicker work pieces. The drawings on the next two pages illustrates how the clamps work.

To clamp a work piece, position the workpiece so the edge protudes slightly over the edge

of the workbench top as shown. Then, position the Rear Stop against the workpiece and

tighten it to T-Track using the knobs. Next, tighten the Clamp Jaws against the workpiece

with the knobs and your work piece will be clamped just like with a vice.

For thinner workpieces, position the Clamp Jaws and Rear Stop as shown. If your

workpiece is thinner than 3/4", you can place strips of wood under the work piece so it is

slightly higher than the top edges of the Clamp Jaws.

For thicker workpieces, flip the Clamp Jaws so the second button is against the Lower

T-Track Trim and reverse the Rear Stop so the thicker edge is against the workpiece.

Using the Clamps

Page 41

Copyright

C

2006 by Robert E. Reedy, Vandalia, Ohio

Rear Stop

T-Track

Second Button

Button

Clamp Jaw

Workpiece

For thicker workpieces, flip the Clamp Jaw so the second button is against the Lower T-Track Trim

and reverse the Rear Stop so the thicker edge is against the workpiece.

T-Track

Button

Second Button

Clamp Jaw

Workpiece

Rear Stop

For thinner workpieces, position the Clamp Jaws and Rear Stop as shown.

Clamping Long Workpieces

To clamp long work pieces, use the

Clamping Jaws and EZ Mount Stop as

shown.

Copyright c

by Robert E. Reedy, Vandalia, Ohio

Page 41

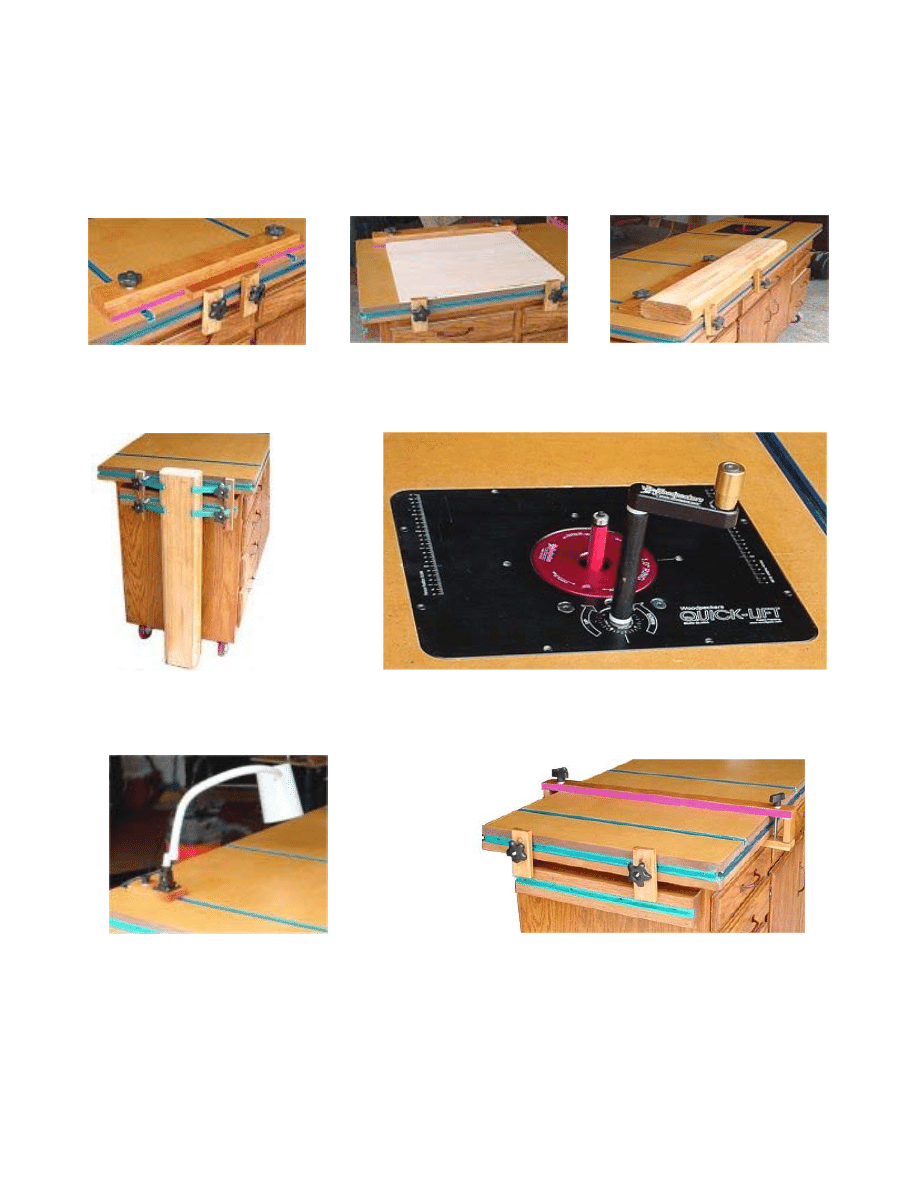

Snapshots

Clamping a small work piece

Clamping a large work piece

Clamping a thick work piece

Clamp a large work piece

Hold down clamps.

Close up view of the Woodpeckers Quick-Lift.

Clamping a work light.

Arranging the jaws for use with the EZ Mount Stop.

The purple edge is the 100 grit sandpaper used to

make the stop grip the work piece tighter.

Wyszukiwarka

Podobne podstrony:

Cwiczenie 6 WorkBench czwórniki pasywne

workbench

workbench

ANSYS Getting Started Tutorial Workbench

Do it Yourself Workbench id 137 Nieznany

Electronics Workbench 4 0 opis programu

WZÓR SPRAWOZDANIA ANSYS WORKBENCH=

Bauanleitung Instructions Workbee

(madera) Woodworking plans Workbench Popular Mechanics Hard Maple

(EBooks) DIY Woodwork Plans 10 Workbench Accessories

WorkBench workbench

Space Saver Workbench

Do it Yourself Workbench

Shop Notes WorkBench Top with Hold down Tracks

Developing your STM32VLDISCOVERY application using the IAR Embedded Workbench

WorkBench Monterey Potting Center

Woodwork Plans Workbench

Workbench1

więcej podobnych podstron