Small Knobs for Clamps

and Hold-Downs

Shop Notes

W

henever I find myself making the same part over

and over, I start looking around for a way to speed

up and simplify the process. This is particulary true

for small parts which are difficult and sometimes

even dangerous to shape using power tools.

Whenever I find myself making the same part over and

over, I start looking around for a way to speed up and

simplify the process. This is particulary true for small

parts which are difficult and sometimes even dangerous

to shape using power tools. I use a lot of small wooden

knobs with a t-nut for hold-downs and small clamps. My

first attempt at speeding up their manufacture involved

a pattern and hold-down mechanism that let me use a

router with a flush-routing bit to form the profile. It was

faster than marking them out one at a time and cutting

them on a bandsaw, but the router tended to chew up

the end grain. I've since figured out how to make them

eight to ten at a time with a tablesaw and stationary

sander.

The blanks are 4 inch long sections of hardwood 1X2.

Drill through the center of each using a bit appropriate

to the t-nut you'll be using. Since I'm using 3/8" bolts and

t-nuts, I drilled 29/64. Counter bore with a 1-1/8 forstner

bit just deep enough to sink the t-nut flush with the surface

of the knob. Do not insert the t-nuts yet.

Thread the blanks onto a 3/8" carriage bolt. Square them

up against a flat surface and secure with a washer and

nut. be sure to make the stack very tight.

For this size knob, I set the tablesaw to 25

°

and leave

5/8" clearance between the inside edge of the blade and

the fence. Check to be certain the blade clears the bolt,

nut, and washer before cutting. Two passes through the

blade remove opposite corners of the stack. Be careful

and feed slowly.

Rough sanding to shape is done with a belt sander or

stationary sander while the blanks are still together.

Round the ends and sides to eliminate sharp corners.

Final sanding and rounding all edges is done after the

parts have been separated. Apply a finish if you wish,

and insert a t-nut into the recess.

©2001 Dale Austin www-personal.umich.edu/~mrwizard

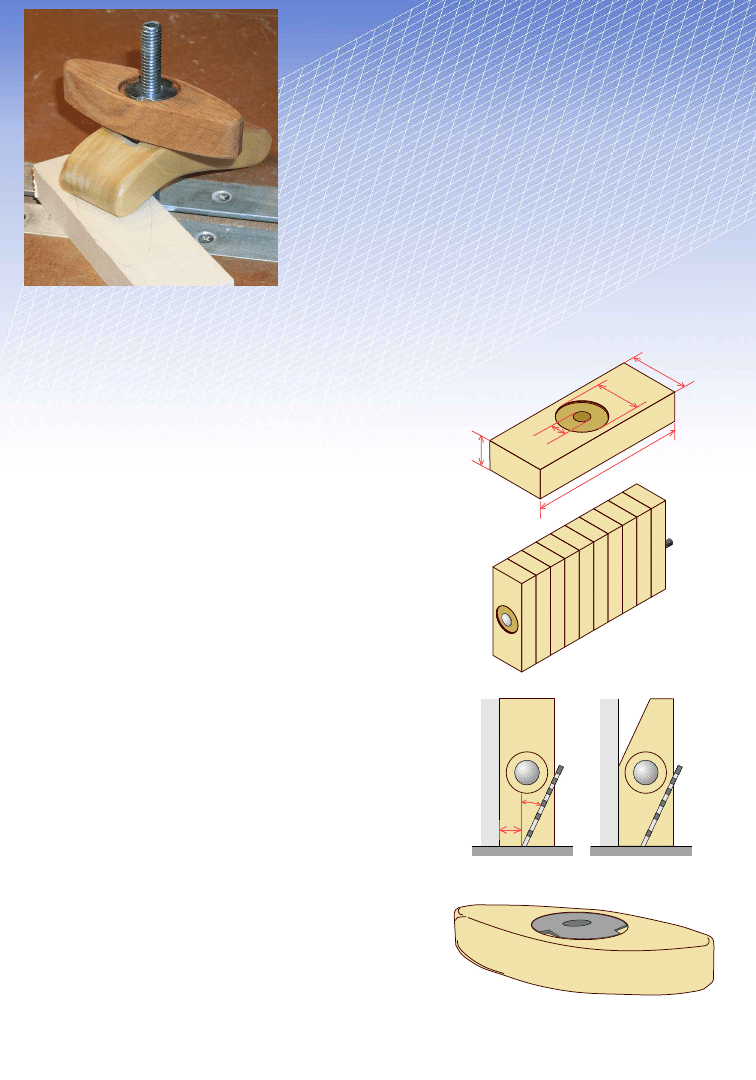

A single blank.

4"

1-1/2"

3/4"

1-1/8"

29/64"

First cut

Second Cut

Blanks threaded onto

a long carriage bolt.

A finished knob. Edges rounded and t-nut in place.

25

°

~ 5/8"

Wyszukiwarka

Podobne podstrony:

Shop Notes WorkBench Top with Hold down Tracks

Christina Aguilera Can t Hold Us Down

3 DOWN STREAM PROCESSING

Poker współczesny Texas Hold'em i inne odmiany pokera (2)

2006 Down phenotype PLoS2006

HAM Sample and Hold SDR 30Khz 70Mhz

Inny świat – hołd złożony człowiekowi i dokument degradacji człowieka, język polski

Pope Tells EU Nations to Tear Down Migrant Walls

72439 May the Lord Hold You

Hold- , Nowe

Income Down, Poverty Up (2009)

down, rehabilitacja

Hołd złożony wielkim Polakom w wierszach Norwida

Essentials of Sociology A Down to Earth Approach aZ06 HENS 7052 PC

HOŁD TOBIE

L 5522 Dress with lay down collar

M 5522 Dress with lay down collar

Instrukcja BHP strugarka 4 - stronna v, HOLD.

więcej podobnych podstron