System Identification and Self-Tuning Pole Placement

Control of the Two-Axes Pneumatic Artificial Muscle

Manipulator Optimized by Genetic Algorithm

Kyoung Kwan Ahn

Ho Pham Huy Anh

School of Mechanical and Automotive Engineering

Graduate School of Mechanical and Automotive Engineering

University of Ulsan

University of Ulsan

San 29, Muger 2dong, Nam-gu, Ulsan, 680-764, Korea

San 29, Muger 2dong, Nam-gu, Ulsan, 680-764, Korea

kkahn@ulsan.ac.kr

hphanh@hcmut.edu.vn

Abstract - In this paper, self-tuning pole placement control of

the 2-axes pneumatic artificial muscle (PAM) manipulator is

proposed as an appropriate strategy which can automatically

accommodate wide changes in operating conditions, such as

payload and time varying parameters of the 2-axes PAM

manipulator. This novel proposed control scheme is initially

applied to the independent control of the PAM manipulator joint

angle position. Proposed pole placement controller utilizes a low

order linear approximation of the PAM manipulator ARX model,

whose parameters are estimated online from past input and

output values by RLS system identification algorithm.

Furthermore, parametric values of ARX model are optimized by

a modified genetic algorithm (MGA). This superb combination

between MGA and self-tuning pole placement controller is

developed for tracking the joint angle position of the prototype 2-

axes PAM manipulator. Simulation and experiment results

demonstrate the excellent performance of the proposed control

scheme. These results can be applied to model, identify and

control other highly nonlinear systems as well.

Index Terms - modified genetic algorithm (MGA), online ARX

model identification, 2-axes pneumatic artificial muscle (PAM)

manipulator, modified self-tuning pole placement control.

I. I

NTRODUCTION

Control of pneumatic artificial muscle (PAM) actuators is

an ongoing area of research due to some challenging

difficulties [1, 2]. Nowadays, research into the control and the

physical and modeling properties of PAM has been

undertaken at the INSA (Toulouse, France) [2], the Bio-

Robotics Lab at the University of Washington, Seattle, [3],

Human Sensory Feedback (HSF) Laboratory at Wright

Patterson Air Force Base [4](Reynolds, Repperger, Phillips

and Bandry 2003), and Fluid Power Machine Intelligence

Laboratory (FPMI Lab) at Ulsan University [5][6] among

others.

This paper addresses the modeling, identification and

control of a two-joint planar PAM manipulator actuated by

two groups of antagonistic PAM pair. Due to their highly

nonlinear and time-varying parameter nature, PAM

manipulator control presents a challenging nonlinear control

problem that has been approached via many methodologies.

Related literature has appeared some of ways for modeling

and control the PAM actuator. In [7], a direct continuous-time

adaptive control technique is applied to control joint angle in a

single-joint arm. The simulation considers PAM individually

in both bicep and tricep positions. In [8], a gain scheduling

controller is designed for a single PAM hanging vertically in

the lab actuating a mass. Both force as well as position control

are considered. Chan and Lilly (2003)[9] suggested a fuzzy

model reference learning controller designed for a single PAM

hanging vertically actuating a mass in the lab. Tracking results

are obtained, and these are shown to agree well with simulated

results. In [10], a fuzzy P+ID controller is designed for the

same previous system. The novel feature is a new method of

identifying fuzzy systems from experimental data using

evolutionary techniques. The experimental results are shown

to be superior to those in [9], i.e., tracking error is less while

using less control effort. All these results prove that up to

now, it is still lack of a simple and quite efficient model for

the PAM manipulator which will be utilized efficiently in

adaptive & self-tuning control such highly nonlinear PAM

manipulator.

The contributions of this paper include ARX model-based

modeling and identification of the 2-axes PAM manipulator

composed two antagonistic groups of PAM actuators;

optimizing PAM manipulator ARX model’s parameters using

a novel proposed modified genetic algorithm (MGA);

formulating a simple but highly efficient ARX model so that it

is suitable for online parameter modified self-tuning pole

placement control the highly nonlinear 2-axes PAM

manipulator. This novel proposed control strategy is initially

applied and obtains from simulation and experiment

outperforming results in comparison with other control

algorithms.

This paper is arranged as follows. Section 2 introduces

modified genetic algorithm (MGA) used in PAM manipulator

modeling and identification. Section 3 presents the

configuration of the 2-axes PAM manipulator with hardware

used in process of modeling, identification and control.

Section 4 presents and analyses the results of MGA-based

PAM manipulator modeling and identification process.

Section 5 introduces the modified pole placement control

algorithm based on online ARX model to control the 2-axes

PAM manipulator. Section 6 presents simulation and

experiment results of the joint angle position control of the

modified pole placement controller. Section 7 contains

discussion and conclusion.

1-4244-0828-8/07/$20.00 © 2007 IEEE.

2604

Proceedings of the 2007 IEEE

International Conference on Mechatronics and Automation

August 5 - 8, 2007, Harbin, China

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

II. M

ODIFIED

G

ENETIC

A

LGORITHM

(MGA)

FOR

O

PTIMIZING

T

HE

2-A

XES

PAM M

ANIPULATOR

ARX M

ODEL

P

ARAMETERS

.

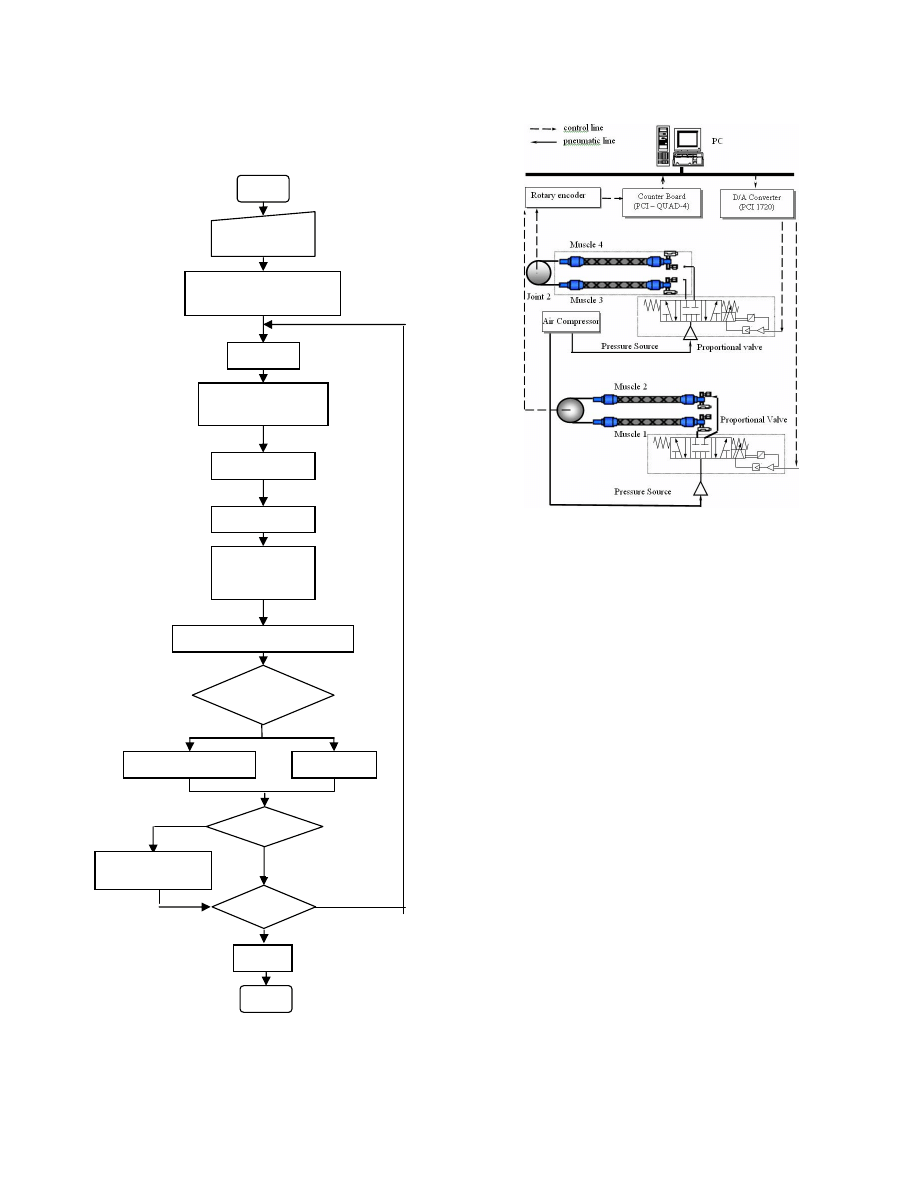

The steps of MGA-based model identification procedure

are summarized as in Fig. 1:

Fig.1 Flow chart of MGA-based optimal Identification Process

III. C

ONFIGURATION OF

T

HE

2-A

XES

PAM M

ANIPULATOR

S

YSTEM

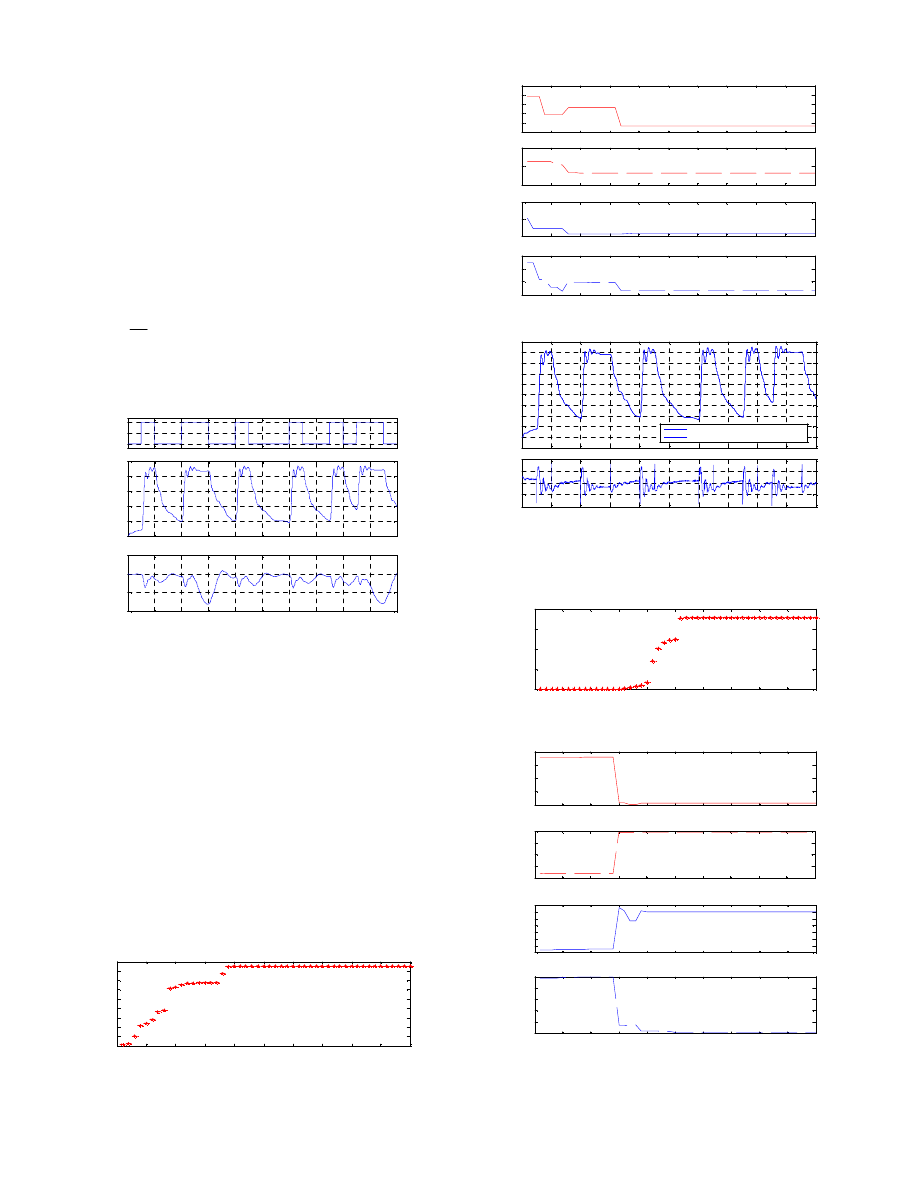

Fig. 2 Schematic diagram of the experimental apparatus

.

Fig. 2 presents the configuration of the hardware set-up

installed from Fig.2 as to model and to identify the 2

nd

order

ARX model of the both of joints of the 2-axes PAM

manipulator by obtaining PRBS training and validating data

from the 2 joints of the 2-axes PAM manipulator. This set-up

is also used to control the 2-axes PAM manipulator based on

adaptive pole placement controller as well.

The hardware includes an IBM compatible PC (Pentium

1.7 GHz) which sends the voltage signals to control the two

proportional valves (FESTO, MPYE-5-1/8HF-710B), through

a D/A board (ADVANTECH, PCI 1720 card). The rotating

torque is generated by the pneumatic pressure difference

supplied from air-compressor between the antagonistic

artificial muscles. Consequently, the both of joints of the 2-

axes PAM manipulator will be rotated to follow the desired

joint angle reference. The joint angles,

θ

1

[deg] and

θ

2

[deg],

are detected by two rotary encoders (METRONIX, H40-8-

3600ZO) and fed back to the computer through a 32-bit

counter board (COMPUTING MEASUREMENT, PCI

QUAD-4 card). The pneumatic line is conducted under the

pressure of 5[bar] and the software control algorithm of the

closed-loop system is coded in C-mex program language run

in Real-Time Windows Target of MATLAB-SIMULINK

environment.

IV. R

ESULTS OF

MGA-B

ASED

I

DENTIFICATION OF

T

HE

2-

AXES

PAM M

ANIPULATOR

.

Considering an ARX model with noisy input which can

be described as

)

(

)

(

)

(

)

(

)

(

)

(

1

1

1

t

e

q

C

T

t

u

q

B

t

y

q

A

−

−

−

+

−

=

(1)

End

Decod

e

no

yes

m=L

t

Extinction strategy

k = 0

no

yes

k=L

e

yes

no

k=k+1, m=m+1

k=0, m=0

1

max

max

−

=

i

i

F

F

Take place the worst

Reproduction

Crossover

Mutation

Fitness Scaling

Elitist strategy

Decode and evaluate

Fitness value

i = i + 1

Randomly generate N set

of Initial population

Set initial value

(i=0, k=0, m=0)

Start

2605

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

with

2

2

1

1

1

1

)

(

−

−

−

+

+

=

q

a

q

a

q

A

1

2

1

1

)

(

−

−

+

=

q

b

b

q

B

2

3

1

2

1

1

)

(

−

−

−

+

+

=

q

c

q

c

c

q

C

with e(t) is the white noise sequence with zero mean and unit

variance.

The purpose here is to apply MGA for optimally

identifying a

1

, a

2

, b

1

and b

2

parameters in present of the noise.

The excitation input u(t) to be used is chosen as pseudo

random binary sequence (PRBS). Fig. 3 presents the PRBS

input applied to each joint of the real 2-axes PAM manipulator

and the corresponding output.

The fitness function calculated in this case is given as

¦

−

=

1

2

)]]

(

[

1

[

k

e

M

F

(2)

with e(k) represents the error between the actual PAM

manipulator joint angle output and PAM manipulator ARX

model response.

0

2

4

6

8

10

12

14

16

18

20

4.5

5

5.5

PR

B

S

i

n

put

-

[

v

]

2-AXES PAM MANIPULATOR

(OPEN-LOOP PRBS TEST1)

0

2

4

6

8

10

12

14

16

18

20

0

20

40

60

80

100

T

het

a2 -

[

deg

ree]

0

2

4

6

8

10

12

14

16

18

20

-40

-20

0

20

t - [sec]

T

het

a1 -

[

degr

ee]

Fig. 3 Input PRBS and output response of the 2-axes PAM manipulator

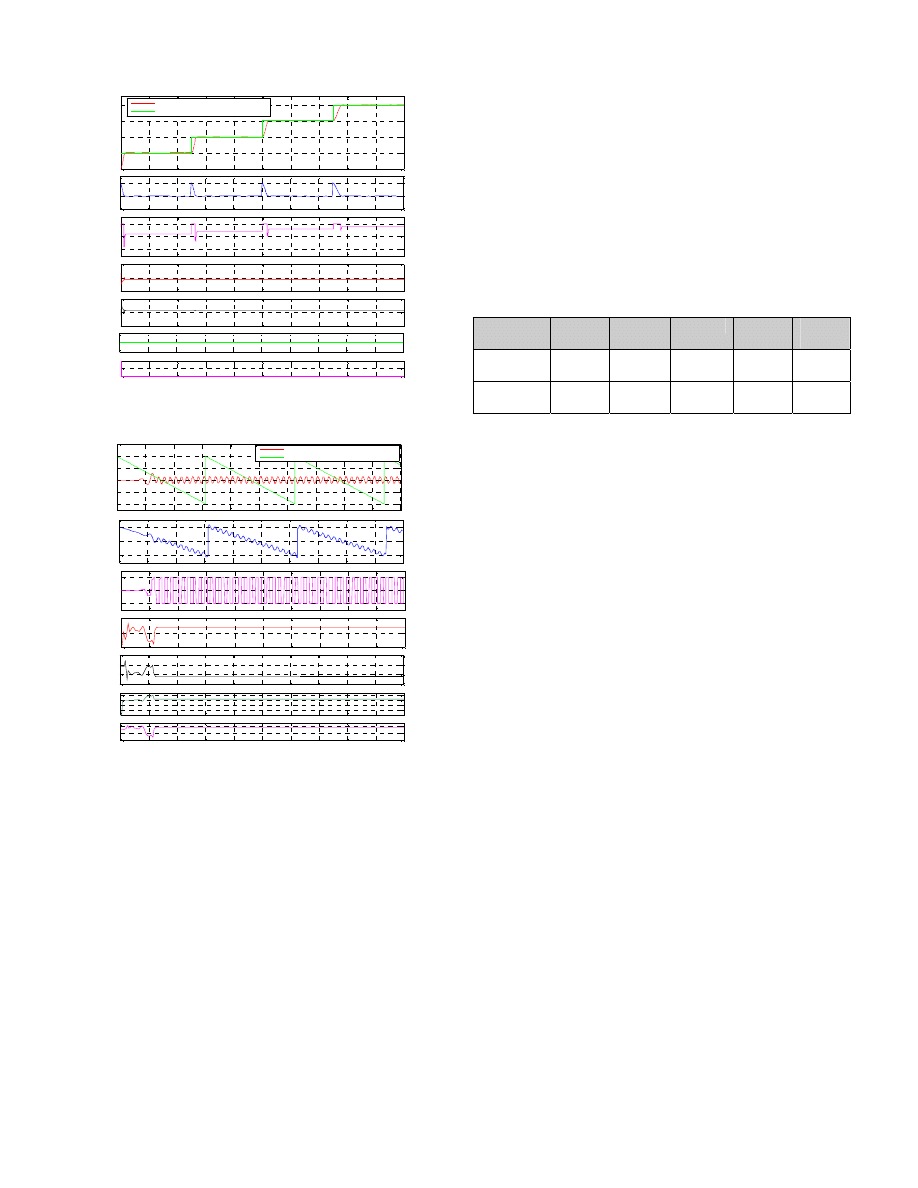

Both fitness values of each Link ARX model converge

rapidly toward the global optimum, as shown in Fig.4a and

Fig.6a. The convergence plot of the estimated parameters by

the MGA is shown in Fig.4b and Fig.6b for 1

st

Link ARX

model’s a

1

, a

2

, b

1

and b

2

and 2

nd

Link ARX model’s

respectively. From these figures, it can note that, even with the

present of noise, the identification parameter value converges

rapidly from a random set of parameters with best obtained

fitness value. The optimized identified parameters of both

Two Link ARX model of the 2-axes PAM manipulator

obtained from MGA at the end of 100

th

generation are

tabulated in Table 1.

Fig.5 and Fig.7 present the output of the MGA-based

identified ARX models against the actual PAM output

response.

ARX-model Link 2 - Max Fitness = 42

[a

1

= -1.9023; a

2

= 0.90625; b

1

= -0.97435; b

2

=1.0156]

.

0

5

10

15

20

25

30

35

40

45

50

0

5

10

15

20

25

30

35

40

45

generat ion

fi

tn

e

s

s

v

a

lu

e

Fig.4a Convergence trace of fitness value (MGA method) – Link2

.

0

5

10

15

20

25

30

35

40

45

50

-1.903

-1.902

-1.901

-1.9

-1.899

-1.898

generat ion

e

s

ti

m

a

te

a

1

0

5

10

15

20

25

30

35

40

45

50

0.9

0.91

0.92

generat ion

e

st

im

a

te

a

2

0

5

10

15

20

25

30

35

40

45

50

-1

-0.8

-0.6

generation

es

ti

m

at

e

b1

0

5

10

15

20

25

30

35

40

45

50

1

1.05

1.1

1.15

generat ion

e

s

ti

m

a

te

b

2

Fig.4b Convergence of the identified parameters (MGA method) – Link2

0

2

4

6

8

10

12

14

16

18

20

-10

0

10

20

30

40

50

60

70

80

90

yy a

nd y

h2 -

[

degr

ee]

2 AXES PAM MANIPULATOR

(COMPARISON OP ENLOOP P RBS TEST - LINK2)

0

2

4

6

8

10

12

14

16

18

20

-1

-0. 5

0

0. 5

1

t - [ sec]

e

rr

2

=

y

y

-y

h2 [

degr

e

e]

2-axes PAM manipulator response

ARX model (a1 a2 b1 b2) response

Fig.5 Output of MGA-based ARX model against actual PAM manipulator

response - (Link2)

ARX-model Link 1 - Max Fitness = 35.97

[a

1

=-1.9374; a

2

=0.9386; b

1

= 1.5; b

2

=-1.4873]

0

5

10

15

20

25

30

35

40

45

50

0

10

20

30

40

generation

fi

tn

e

s

s

v

a

lu

e

Fig.6a Convergence trace of fitness value (MGA method) – Link1

.

0

5

10

15

20

25

30

35

40

45

50

-2

-1. 5

-1

-0. 5

0

generation

e

st

im

a

te

a

1

0

5

10

15

20

25

30

35

40

45

50

-1

-0.5

0

0.5

1

generation

e

st

im

a

te

a

2

0

5

10

15

20

25

30

35

40

45

50

-1. 5

-1

-0. 5

0

0.5

1

1.5

2

generation

e

s

ti

m

a

te

b

1

0

5

10

15

20

25

30

35

40

45

50

-1. 5

-1

-0. 5

0

0.5

1

generation

e

s

ti

m

a

te

b

2

Fig.6b Convergence of the identified parameters (MGA method) – Link1

2606

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

0

2

4

6

8

10

12

14

16

18

20

-35

-30

-25

-20

-15

-10

-5

0

5

yy

a

n

d y

h

1 -

[

d

e

gr

ee

]

2 AXES PAM MANIPULATOR

(COMPARISON OPENLOOP PRBS TEST - LINK1)

0

2

4

6

8

10

12

14

16

18

20

-2

-1

0

1

2

t - [sec]

e

rr1

=

yy

-yh

1

[

d

eg

re

e

]

2-axes PAM manipulator response

ARX model (a1 a2 b1 b2) response

Fig.7 Output of MGA-based ARX model against actual PAM manipulator

response (Link1)

V. A

DAPTIVE

S

ELF

-T

UNING

C

ONTROLLER

B

ASED ON

M

ODIFIED

P

OLE

P

LACEMENT

M

ETHOD

A self-tuning pole placement controller design will ensure

the desired control loop dynamic behavior by choosing the

available characteristic polynomial.

The block diagram of modified Pole placement controller

used in this paper is shown in Fig.8, where

)

(

)

(

)

(

)

(

)

(

1

1

−

−

=

=

z

A

z

B

z

U

z

Y

z

G

P

(3)

is the discrete transfer function of the controlled 2-axes PAM

manipulator with polynomials

2

2

1

1

1

1

)

(

−

−

−

+

+

=

z

a

z

a

z

A

2

2

1

1

1

)

(

−

−

−

+

=

z

b

z

b

z

B

(4)

Pole placement controller equation takes the form

)

(

1

)].

(

).

(

'

)

(

.

[

)

(

1

1

−

−

−

=

z

P

z

Y

z

Q

z

E

z

U

β

(5)

with polynomial P(z

-1

) has the form as

)

.

1

)(

1

(

)

(

1

1

1

−

−

−

+

−

=

z

z

z

P

γ

(6)

and polynomial Q(z

-1

) takes the form

)

.

'

'

)(

1

(

)

(

'

1

2

0

1

1

−

−

−

−

−

=

z

q

q

z

z

Q

(7)

Fig. 8 Block diagram of modified adaptive pole placement controller

.

Substitution (6) and (7) into (5) yields the following

relation for the controller output:

)

(

.

)

2

(

.

)

1

(

).

1

(

)]

2

(

'

)

1

(

).

'

'

(

)

(

).

'

[(

)

(

2

2

0

0

k

k

u

k

u

k

y

q

k

y

q

q

k

y

q

k

u

ω

β

γ

γ

β

+

−

+

−

−

−

−

+

−

+

−

+

−

=

(8)

For the transfer function of the closed loop in Fig.8, it is

obtained the relation:

]

)

(

'

).[

(

)

(

).

(

)

(

.

)

(

)

(

)

(

1

1

1

1

1

β

β

+

+

=

=

−

−

−

−

−

z

Q

z

B

z

P

z

A

z

B

z

W

z

Y

z

G

w

(9)

So the characteristic polynomial takes the form

)

(

]

)

(

'

).[

(

)

(

).

(

1

1

1

1

1

−

−

−

−

−

=

+

+

z

D

z

Q

z

B

z

P

z

A

β

(10)

In the case of a controlled 2-axes PAM manipulator

polynomial in the form of (3), equation (10) will define a

system of 4 linear algebraic equations with 4 unknown

controller parameters

γ

β

,

,

'

,

'

2

0

q

q

:

»

»

»

»

¼

º

«

«

«

«

¬

ª

=

»

»

»

»

¼

º

«

«

«

«

¬

ª

»

»

»

»

¼

º

«

«

«

«

¬

ª

−

−

−

−

−

−

4

3

2

1

2

0

2

2

2

1

1

2

2

1

2

1

1

2

1

1

'

'

0

0

0

1

1

0

x

x

x

x

q

q

a

b

a

a

b

b

b

a

b

b

b

b

b

b

γ

β

(11)

The 1

st

matrix in the left side of (11) depends only on the

parameters of the controlled PAM manipulator ARX model.

The next vector contains the unknown parameters (q

’

0

, q

’

2

,

ȕ

and

Ȗ) of the controller, being the solution of the system (11),

and the vector on the right side depends on the number of

poles of D(z

-1

) and their position in the z complex plane.

Then parameters of adaptive pole placement controller

now are obtained by inserting appropriately modified relation

of D(z

-1

) as

)]

(

)].[

(

.[

)

(

)

(

2

ω

α

ω

α

α

j

z

j

z

z

z

D

−

−

+

−

−

=

(12)

This characteristic polynomial has a pair of complex

conjugated poles

jw

z

±

=

α

2

,

1

placed inside the unit circle at

interval

1

0

<

≤

α

and double real poles

α

=

4

,

3

z

.

The parameter

Į can be used to change the speed of the

control response and the size of the changes in the controller

output. It is also possible to modify parameter

Ȧ to select a

desired overshoot.

Put (12) into (10), where the vector components on the

right side of (11) are determined by

x

1

=c+1- a

1

; x

2

=d + a

1

- a

2

; x

3

= - f - a

2

; x

4

= g

(13)

with

α

4

−

=

c

;

2

2

.

6

ω

α

+

=

d

;

)

2

(

2

2

2

ω

α

α

+

−

=

f

;

)

(

2

2

2

ω

α

α

+

=

g

(14)

By solving equation system (11), it is obtained the

equations for calculating the pole placement controller

parameters as follows:

2

1

4

3

2

1

1

5

1

7

6

2

1

4

3

2

0

'

'

b

b

x

x

x

x

r

r

r

r

r

q

r

r

r

r

q

+

+

−

+

=

=

+

=

+

+

−

=

β

γ

(15)

with

)]

(

)

(

[

)

(

)

(

)]

(

)[

(

)]

(

[

]

)

(

[

4

1

2

2

4

2

2

4

1

1

2

7

4

2

4

1

3

2

2

1

6

1

3

2

2

2

2

3

2

1

4

2

1

1

5

4

3

2

4

1

2

1

4

4

3

2

1

1

2

1

2

3

1

2

4

3

2

1

2

1

2

x

x

a

b

x

x

a

x

a

b

b

r

x

a

x

a

x

a

b

r

x

b

x

b

x

b

b

x

b

b

r

x

x

b

x

b

b

b

r

x

x

x

b

x

b

b

a

r

x

b

x

x

x

b

b

a

r

+

−

−

+

=

−

+

=

−

+

+

=

−

+

+

=

+

−

−

=

−

+

−

=

(16)

VI. S

IMULATION AND

E

XPERIMENT

R

ESULTS

.

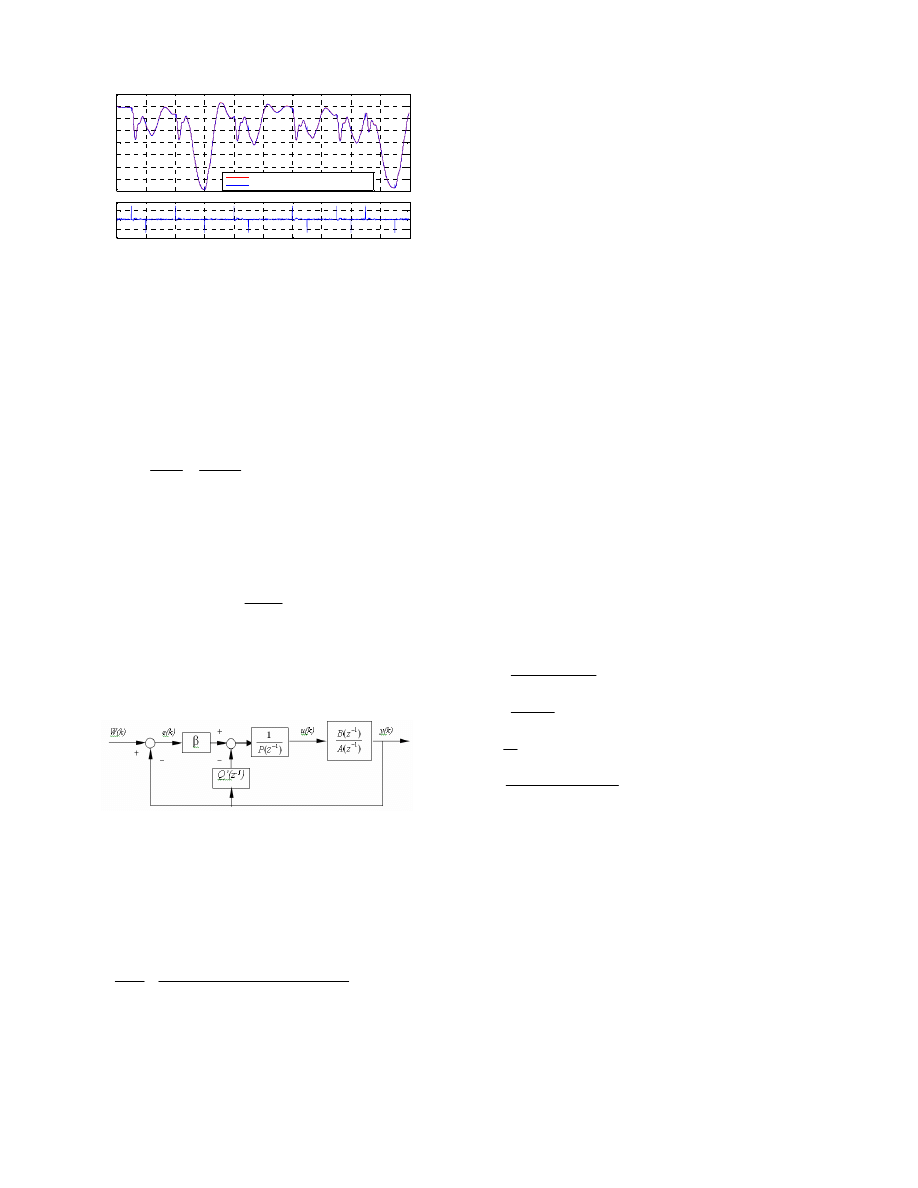

Simulation and experimentation will be carried on the 2-

axes PAM manipulator shown in Fig.2. SIMULINK diagram

run in MATLAB for simulating the proposed modified pole

placement control algorithm is presented in Fig. 9 in which the

2607

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

transfer function of each Link of the 2-axes PAM manipulator

is converted from the corresponding ARX model respectively.

u_in(k )

y (k )

w(k )

u(k )

ID params

adapti ve pp2b_1

parameters

To Workspace1

Si ne Wave2

Saturati on1

Reference signal 2

Output1

0.2

5s +10s+1

2

Noi se fi ltration1

ID parameters1

Band-Lim ited

White Noi se1

154.2s+131.1

s +6.337s+12.39

2

2-axes PAM mani pul ator

Link1

a) The first link

.

u_in(k)

y (k)

w(k)

u(k)

ID params

adaptive pp2b_2

parameters

T o Workspace

Sine Wave2

Saturation

Reference signal2

Output

0.2

5s +10s+1

2

Noi se filtration

ID parameters

Band-Lim ited

White Noise

-104.6s+433.2

s +9.846s+41.49

2

2-axes PAM m ani pul ator

Link2

b) The second link

.

Fig.9 The SIMULINK diagram of the 2-axes PAM manipulator joint angle

position control using modified pole placement controller:

The modified pole placement control scheme is shown in

Fig.10 which is in the category of indirect adaptive control.

Referring to Fig.10,

ș

i

is the joint displacement of link i, u

i

is

the corresponding control voltage. To implement modified

pole placement controller strategy, it is required to determine

ARX model the 2-axes PAM manipulator in the form of

2

2

1

1

2

2

1

1

1

1

.

.

1

.

.

)

(

)

(

−

−

−

−

−

−

+

+

+

=

z

a

z

a

z

b

z

b

z

u

z

i

i

θ

(17)

with a

1

, a

2

, b

1

, b

2

parameters of each link’s ARX model of the

2-axes PAM manipulator will be determined from PRBS

input-output testing and be optimized with offline Modified

Genetic Algorithm (MGA).

Fig. 10 Pole placement position control of the 2-axes PAM manipulator

Equation (17) represents a second order system with the

output in discrete time form:

)

2

(

)

1

(

)

2

(

)

1

(

)

(

2

1

2

1

−

+

−

+

−

−

−

−

=

k

u

b

k

u

b

k

a

k

a

k

i

i

i

i

i

i

i

θ

θ

θ

(18)

In order to update the best values for the coefficients of

A(z

-i

) and B(z

-i

), in the sense of minimum square errors, the

RLS is used to perform the online estimation based on the

input-output data pairs ([u

k

,

ș

k

] pairs). The experiment control

voltage is within the range of [4.5v – 5.5v]. The sampling time

T

0

was chosen to be 0.01 [s].

The design parameters of pole placement controller

include pole assignment values

Į, Ȧ and forgetting factor Ȝ.

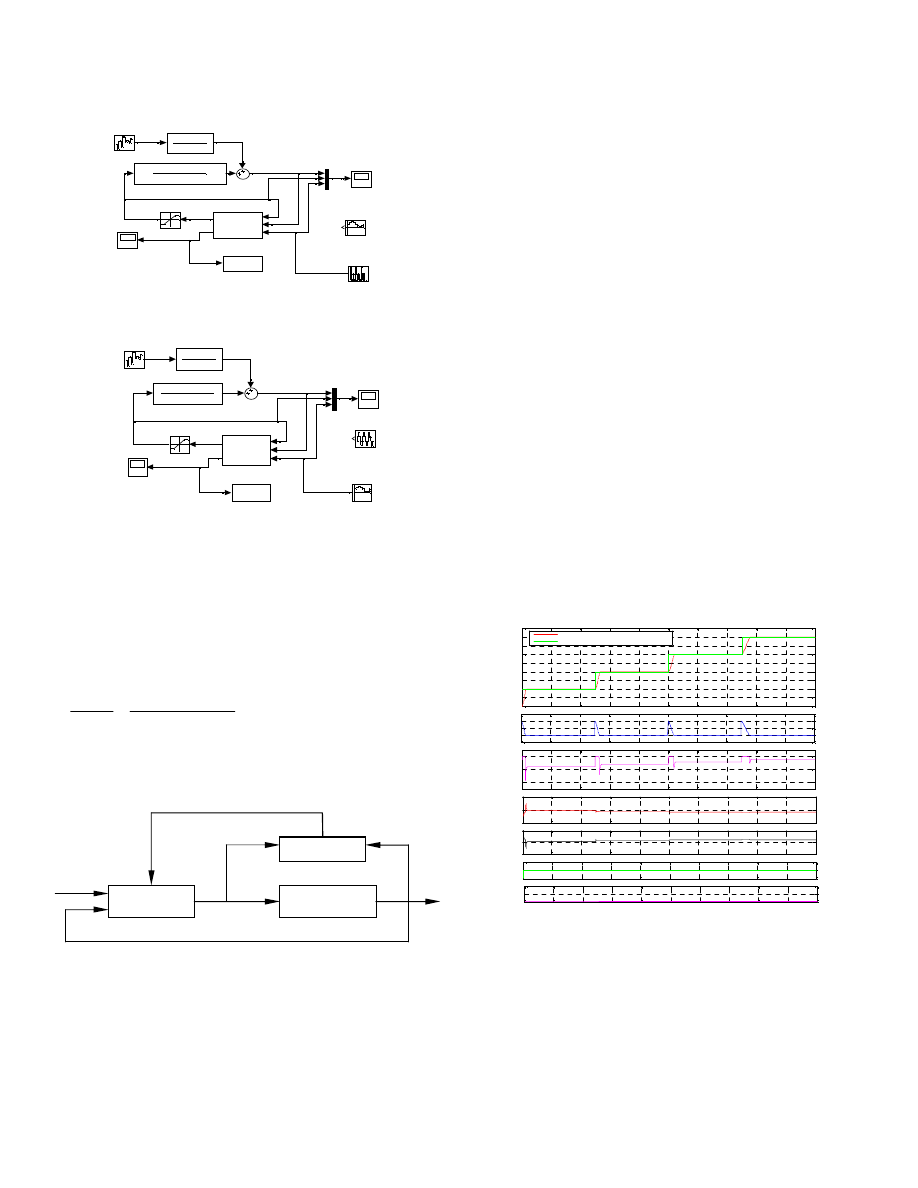

Figure 11 to Figure 13 show the joint displacement and

the control input results. The response of 2-axes PAM

manipulator position control using Modified Pole Placement

controller was fast, overshoot free and offset free despite the

different scales of set-points. Furthermore, these figurative

results demonstrate the performance of the on-line RLS

estimator. The online ARX model parameter values always

converge and roughly remained constant. It is clear that the

estimation was consistent with the initial values obtained from

the offline MGA-based optimization. Before the online ARX

mode1 was correctly established, the response was oscillatory,

which also clearly proved how the on-line estimation helped

the control performance.

Tests were also carried out to study the effects that the

design parameters might have on the pole placement controller

performance. Using (19) as the standard parameter setting, the

tests were carried out in such a way that only one parameter's

value was changed at a time.

In following results, the pole placement controller used in

position control the 2-axes PAM manipulator has the standard

characteristic parameters as follows:

* Forgetting Factor

Ȝ of RLS algorithm = 0.99.

* T

sample

of discrete pole placement control = 0.01 [s]. (19)

* Pole assignment values

Į + j*w = 0.5 +j*0.1.

0

2

4

6

8

10

12

14

16

18

20

0

5

10

15

20

25

30

35

40

45

Jo

in

t A

n

g

le

-

Y

/Y

d

-[

d

e

gr

e

e

]

2-ax es PAM Manipulator - Modified Pole Placement Cont roller

(Forgett ing Fac tor Lambda = 0.999 - Link2)

0

2

4

6

8

10

12

14

16

18

20

-5

0

5

10

15

E

rr

o

r -

[d

eg

re

e

]

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

U

-c

o

n

tr

o

l -

[

v

]

0

2

4

6

8

10

12

14

16

18

20

-2

-1. 9

-1. 8

a1

0

2

4

6

8

10

12

14

16

18

20

0. 8

0. 9

1

a

2

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

b

1

0

2

4

6

8

10

12

14

16

18

20

0

0. 5

1

time - [ second]

b2

Joint Angle Y - [ degree]

Desired Reference Yd - [ degree]

Fig. 11 The 2-axes PAM manipulator Modified Pole Placement Controller

(Online Parameter Self-Tuning– Forgetting Factor

Ȝ = 0.99)

Figure 11 and 12 represent the various results of the 2-

axes PAM manipulator joint angle ramp trajectory tracking

using modified pole placement control algorithm with

forgetting factor

Ȝ chosen equal 0.99 (Fig. 11) and 0.75 (Fig.

12) respectively. These results determine that the best chosen

value of forgetting factor

Ȝ is about 0.99.

RLS

Id

ifi

i

Pole

placement

2-axes PAM

Manipulator

Process parameter

ș

di

u

i

ș

i

2608

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

0

2

4

6

8

10

12

14

16

18

20

0

10

20

30

40

Jo

in

t A

n

gl

e -

Y

&

Y

d

-

[degr

ee]

2-ax es PAM Manipulator - Modified Pole Plac ement Controller

(Forgetting Factor Lambda = 0.75 - Link2)

0

2

4

6

8

10

12

14

16

18

20

-10

0

10

E

rr

o

r -

[

degr

e

e]

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

U

-c

o

nt

ro

l -

[

v

]

0

2

4

6

8

10

12

14

16

18

20

-2

-1.9

-1.8

a1

0

2

4

6

8

10

12

14

16

18

20

0.8

0.9

1

a

2

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

b1

0

2

4

6

8

10

12

14

16

18

20

0

0.5

1

time - [s ec ond]

b2

Joint Angle Y - [degree]

Des ired Reference Yd - [degree]

Fig. 12 The 2-axes PAM Manipulator Modified Pole Placement Controller

(Online Parameter Self-Tuning– Forgetting Factor

Ȝ = 0.75)

0

2

4

6

8

10

12

14

16

18

20

-20

-10

0

10

20

30

J

o

in

t A

n

gl

e

- Y

&

Y

d

-

[d

egr

e

e

]

2-axes PAM Manipulator - Modified Pole Plac ement Controller

(pole ass ignment value: alpha + j*omega = 1 +j*1 - Link 1) - Unstable

0

2

4

6

8

10

12

14

16

18

20

-20

0

20

E

rr

o

r -

[d

e

g

re

e

]

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

U

-c

o

n

tr

o

l -

[v

]

0

2

4

6

8

10

12

14

16

18

20

-2

-1.5

-1

a1

0

2

4

6

8

10

12

14

16

18

20

0

0.5

1

1.5

a2

0

2

4

6

8

10

12

14

16

18

20

-1

0

1

2

3

b1

0

2

4

6

8

10

12

14

16

18

20

-2

0

2

time - [second]

b2

Joint Angle Y - [degree]

Des ired Referenc e Yd - [degree]

Fig. 13 The 2-axes PAM Manipulator Modified Pole Placement Controller

(Online Parameter Self-Tuning– Pole Assignment Value:

Į + j*w = 1 + j*1 ).

Figure 13 shows the attractive results of the 2-axes PAM

manipulator joint angle saw-tooth trajectory tracking using

modified pole placement control algorithm with different pole

assignment values. This figure demonstrates the unstable and

oscillatory result in case chosen pole assignment values

Į +

j*w = 1 +j*1.

All these results prove the superb capacity of proposed

pole placement control algorithm not only in satisfying robust

control requirement but also in modifying specific control

system features (overshoot value, settling time, steady state

error, etc.).

VII. C

ONCLUSIONS

This paper provides a novel and effective method, MGA-

based system identification method, for identifying and

controlling a highly nonlinear 2-axes PAM manipulator.

Through simulation and experimental investigation, the

proposed MGA-based identification algorithm achieves

excellent performance. Although the ARX model obtained is

quite simple, it can be used to describe the dynamics of the

system very well. The proposed control algorithm is applied to

control joint angle position of the 2-axes PAM manipulator.

Simulation and experiment results prove that the novel

proposed Pole Placement controller possesses less settling

time, zero overshoot, small rise time as well as quite accurate

joint angle trajectory tracking

.

These results can be applied to

model, identify and control other highly nonlinear systems as

well.

TABLE 1: MGA-BASED PAM MANIPULATOR ARX MODEL PARAMETERS

Parameter

a

1

a

2

b

1

b

2

Fitness

value

1

st

Link

ARX model

-1.9374

0.9386

1.5

-1.4873

35.97

2

nd

Link

ARX model

-1.9023

0.90625

-0.97435

1.0156

42.98

A

CKNOWLEDGMENT

This research is supported by BK21, Korea.

R

EFERENCES

[1] D. Repperger, and C. Phillips,“Developing intelligent control from a

biological perspective to examine paradigms for activation utilizing

pneumatic muscle actuators," in Proceedings of the 15th IEEE

International Symposium on Intelligent Control, Rio Patras, Greece, 2000,

pp. 205-210.

[2] B.Tondu, and P. Lopez, “Modeling and control of McKibben artificial

muscle robot actuators," IEEE Control Systems Magazine, vol. 20, no. 2,

2000, pp.15-38.

[3] C. Chou, and B.Hannaford, “Dynamic characteristics of McKibben

pneumatic artificial muscles,” in Proceedings IEEE Robotics Automation

Conf., pp. 281–286, 1994.

[4] D. Reynolds, D. Repperger, C. Phillips, and G. Bandry, “Dynamic

characteristics of pneumatic muscle,” Journal of Ann. Biomed. Eng., pp.

310–317, 2003.

[5] K.K. Ahn, and T.D.C. Thanh,

“

Intelligent phase plane switching control

of pneumatic artificial muscle (PAM) manipulators with magneto-

rheological brake”, March 2006, Mechatronics, Vol. 16, Issue 2, pp.85-

95, 2006.

[6] K.K.Ahn, and H.P.H. Anh, “System modeling and identification of the

two-link pneumatic artificial muscle (PAM) manipulator optimized with

genetic algorithm,” in Proceedings 2006 IEEE-ICASE Int. Conf., Busan,

Korea, pp. 356–361, 2006.

[7] J. Lilly, “Adaptive tracking for pneumatic muscle actuators in bicep and

tricep configurations,” IEEE Trans. Neural Syst. Rehab. Eng., pp. 56-63,

2005.

[8] P. Carbonell, Z. Jiang, and D.Repperger, “A fuzzy back-stepping

controller for a pneumatic muscle actuator system,” Proceedings IEEE

Int. Symp. Intelligent Control, Mexico City, Mexico, pp. 353–358, 2001.

[9] S. Chan, J. Lilly, D. Repperger, and J. Berlin, “Fuzzy PD+I learning

control for a pneumatic muscle,” Proceedings 2003 IEEE Int. Conf. Fuzzy

Systems, St. Louis, MO, pp. 278–283, 2003.

[10] X. Chang, and J. Lilly, “Tracking control of a pneumatic muscle by an

evolutionary fuzzy controller,” Journal of Intell. Automat. Soft Comput.,

vol. 9, no. 3, pp. 227–244, 2003.

[11] V. Bobal,“Auto-tuning of digital PID controllers using Recursive

Identification,” Report ESR9409, Ruhr University, Germany, 1994.

[12] V. Bobal, and M. Kubalcik, “Auto-tuning of digital PID controllers using

Recursive Identification”, in Proceedings of the 5

th

IFAC Symposium on

Adaptive Systems in Control and Signal Processing (Budapest), pp. 384-

389, 1995.

2609

Authorized licensed use limited to: Biblioteka Glowna i OINT. Downloaded on May 20, 2009 at 05:48 from IEEE Xplore. Restrictions apply.

Wyszukiwarka

Podobne podstrony:

0415165733 Routledge Personal Identity and Self Consciousness May 1998

Energy Body Manupulation Development and Self Healing Systems Robert Bruce

The gender caste system identity, privacy and heteronormativity

Gerrilyn Smith,?e Cox, Jacqui Saradjian Women and Self harm

SYSTEM OBRONNY RP, Liceum, PO,PP

Identifcation and Simultaneous Determination of Twelve Active

Practical Optical System Layout And Use of Stock Lenses

A systematic review and meta analysis of the effect of an ankle foot orthosis on gait biomechanics a

Luhmann's Progeny Systems Theory and Literary Studies in the Post Wall Era

Embedded Systems Building and Programming Embedded Devices

Am I Who I Say I Am Social Identities and Identification

O'Reilly Programming Embedded Systems in C and C

Measuring power system harmincs and interharmonics by envelope spectrum analysis

Synchronous Generator And Frequency Converter In Wind Turbine Applications System Design And Efficie

Identity and the Young English Language Learner (E M Day)

leadership and self deception

Systems Theory and the System of Theory

wearing ideology state schooling and self presentation in japan

więcej podobnych podstron